Abstract

Canola seeds are one of the most important sources of edible vegetable oils globally. Crude canola oil is industrially extracted from canola seeds by expeller-pressing of heat-preconditioned flaked seeds. The residual oil in the pressed “canola cake” is recovered by solvent extraction using hexane. However, hexane extraction may pose adverse safety and environmental impacts compared to safer and environmentally friendly alternatives that have been studied recently. This manuscript provides a review of the conventional canola oil extraction process and the state of the art on novel alternatives currently explored to improve oil yield and quality. The latter includes supercritical extraction, aqueous enzyme extraction, microwave, and ultrasound processing. The last two technologies can be implemented either as novel processes or as processing interventions into traditional processes. The levels of technology readiness and the challenges for industrial uptake of each technology are also discussed.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The canola oilseed is a Canadian rapeseed belonging to the Brassica family, whose name is a trademark that comes from the contraction of “Canada” and “ola” for oil low acid. For hundreds of years, it has been one of the most important sources of edible oil [15]. During the last five decades, considerable research has been undertaken to enhance the industrial productivity and quality of canola oil in order to increase oxidative and thermal stability, resulting in a longer shelf life [2].

Rapeseed culture was introduced in western Canada during World War II. At that time, the oil was principally used as a lubricant, since it was deemed inedible, due to its high glucosinolate content and the toxic effects of high erucic acid content [7]. High amount of erucic acid and glucosinolate in edible oils were also found to increase blood cholesterol [7]. Two types of rapeseeds were grown: B. napus, also called Argentine canola, and Polish seeds (B. campestris). The former produced oils suitable for lubricants, due to its iodine value in the range of 103 to 105, whereas Polish seeds were not suitable as a lubricant due to its higher iodine value which was close to 115 [9, 10]. The iodine value is proportional to the degree of unsaturation (double bonds). Hence, higher iodine values correspond to oils rich in polyunsaturated fatty acids whereas oils with low iodine value have a lower degree of unsaturation. Generally, it is considered that oils that are rich in saturated fats may raise blood cholesterol and increase the risk of heart disease, while unsaturated fatty acids have been reported to exhibit health benefits [9, 10]. A breeding program introduced after World War II allowed for the development of rapeseed varieties with improved agronomy, such as uniformity, lodging, oil content increase and lower iodine value [19]. Canola oil contains a low fraction of saturated fat (7%), a moderate content of the omega-3 polyunsaturated fatty acids, alpha linolenic acid (9–11%) and phytosterols (about 0.9% by weight) [9, 10].

Canola is the second largest oil crop in the world, following soybean, with a total production of 100 million metric tons in 2017. Canola oil exports have more than doubled in the last decade and global demand is forecasted to rise by 40% in 2025. The European Union is the largest producer of rapeseeds followed by Canada and China [20]. Canola is not only a major source of edible oil, mainly used in the production of margarine stock, salad oil and vegetable oil [9, 10] but it is also an important source of biodiesel. The consumption of canola oil for biodiesel production has grown sharply. For instance, in the European Union, the use of canola oil for biodiesel increased from 30 to 57% in the last decade [20]. Canola is a summer crop in Canada where it is seeded in May and harvested between August and October. In EU and China, it is considered a winter crop, seeded in August and harvested in the following year. In Australia, canola is also a winter crop. It is seeded in February and March and harvested in November and December [54]. Table 1 presents the major compositions of canola seeds in various part of the world [54].

Traditional industrial processing uses expellers, on conditioned flaked seeds, to extract the oil mechanically leaving a cake with an oil content ranging between 15 and 20%. Then, the oil remaining in the cake is recovered by solvent extraction. Hexane is used to extract almost all the pressed cake oil [9, 10] but the use of hexane has health and environmental concerns. Human exposure to hexane can cause dizziness, nausea, and headache. Hexane can also leak into the atmosphere. Due to its flammability, scrupulous attention to safe handling techniques is required [35]. To address these concerns, extensive research has been undertaken to find alternative environmental friendly solvents to replace hexane and enhance oil yield and quality. The aim of this review paper is to provide an overview of the conventional and novel technologies for canola oil processing, focusing on seed conditioning, mechanical pressing, and solvent extraction. Refining stages are mentioned but detailed explanations are out of the scope of this review. Novel technologies such as microwave and ultrasound, which are considered environmental friendly processes, can enhance oil yield and quality when employed as intervention treatments.

Methods for Crude Canola Oil Production

Conventional Canola Oil Extraction Method

The most commonly used extraction process to produce high oil yield from canola seeds involves both mechanical pressing and solvent extraction as shown in Fig. 1. Daun [68] has detailed the conventional extraction of canola oil. A series of steps occur prior to and in preparation for expeller pressing. These include seed cleaning, preconditioning, flaking, and cooking. Firstly, seeds are feed to a destoner to separate stones, ashes and any other contaminants. A preconditioning stage is employed to adjust the temperature to 50–70 °C and moisture content to less than 8% in order to prevent seed shattering during flaking [42, 68]. Preconditioning is performed in a steam jacketed vessel with steam at approximately 150 to 180 °C with injection of live steam to keep the seed from drying and within the desired moisture content. The softened seeds are fed through flaking rollers with a clearance ranging from 0.25 to 0.4 mm [62]. Flaking physically ruptures the seed coat and flattens the seed, thereby increasing the surface area and rupturing the lipid containing olesome organelles. The optimum thickness of the flake and preconditioning conditions are important variables which can be optimized to increase oil yield during pressing.

The flaked seeds are thermally conditioned by moving them through a sequence of 2 or 3 steam heated drums known as the cooker. The cooking step also helps to thermally break the oil containing oleosomes. The temperature increase reduces oil viscosity and promotes the coalescence of oil droplets, accelerating the diffusion rate of oil toward the external surface of the cake. Cooking also reduces the flake moisture, positively enhancing subsequent pressing efficiency, oil yield, and quality. The flakes are cooked at a temperature from 80 to 100 °C for 30 to 35 min. In some cases, cooking temperature is increased to 120 °C to remove some of the sulfur compounds that produce unwanted odor in the oil. However, high temperature may have negative effects on the canola meal protein that is used as animal feed [68]. Pathak et al. [39] reported that high cooking temperature caused a degradation of tocopherols. Cooking of flakes at 140 °C for 5 min caused a loss of tocopherol content of 41% and 36% for α- and γ-tocopherol, respectively, while cooking at 100 °C for 7 min reduced α- and γ-tocopherol by 36% and 34%, respectively [39]. In addition, high temperature may cause the development of off-colors and flavors [39], the reduction of lysine content and meal protein digestibility as well as the formation of antinutritional glucosinolate hydrolysis products [6].

The main extraction step is pressing. The cooked flakes are expeller-pressed to extract the oil by mechanically squeezing out the oil resulting in 70 to 80% yield (w/w, oil in flake). [15]. Expeller-pressing produces oil of higher quality than the oil extracted from the pressed meal using hexane [62].

The second step is solvent extraction. This is needed to extract almost all of the residual oil that remains in the pressed cake that contains between 15 and 20% oil (w/w). In preparation for solvent extraction, the canola cake is broken into smaller pieces with an extruder to facilitate the diffusion of hexane into the cake and reduce the amount of hexane needed for extraction. This is important not only for economic but also for environmental benefits because it minimizes the emission of hexane into the atmosphere. A typical canola oil processing plant will lose 1 L of hexane for each ton of canola seeds extracted. The solvent used in plants is not pure hexane but a mixture of hexane, 2-methyl pentane, and 3-methylpentane with actual n-hexane content lower than 25%. The use of solvent is an efficient and cost-effective extraction method; only around 0.5% of oil remains in the hexane after extraction which can be easily redistilled and recycled due to its low boiling point of 63–67 °C [15]. The content of hexane remaining in the oil is less than 100 ppm after toasting or desolventization. After solvent extraction, the conversion of seed to oil is 94% (w/w), whereas the residual meal contains less than 1% of oil [62].

After solvent extraction, the oil is refined to remove harmful components making it appropriate for human consumption. This is achieved in three stages: degumming, bleaching and deodorization. Degumming is a chemical refining process that removes phospholipids, which are classified as hydratable or non-hydratable. Hydratable-phospholipids can be removed by washing the oil with water but non-hydratable-phospholipids need the addition of phosphoric or citric acid [2]. In water degumming, the oil is heated up to 75 °C, mixed with water by 5% volume of water, and then the mixture is centrifuged for 30 min to precipitate gums, reducing the oil content of phospholipids to about 200 ppm [25]. In acid degumming, citric acid (30% conc.) is added representing 2% of total oil volume. The acid forms complex compounds with potassium, calcium, and phosphorus that precipitate and that can be separated via centrifugation. Usually, citric acid is used not only for decomposition of metal salts but as a chelating agent to keep the metals as water-soluble complexes [76]. Total degumming as shown in Fig. 3 is the most efficient and popular method to remove phospholipids and it consists of three steps: addition of phosphoric acid (0.05–0.1%), water addition and then neutralization with sodium hydroxide (8 to 12% conc.) to neutralize the pH and to form complex compounds that precipitate and that can be separated via centrifugation. Total degumming produces oil with less than 20 ppm of phospholipids [64, 76]. It also can reduce free fatty acids (FFA), mucilaginous gum, phospholipids, color, pigments, dyes, and fine meal particles. The sodium hydroxide and free fatty acids react forming water-soluble soaps, which can be easily removed via centrifugation. In some cases, a total degumming process do not required further purification [76].

Bleaching is a chemical absorption process where oil is filtrated usually through a natural clay filter (bleaching earth) but may also include activated charcoal that removes contaminants and unattractive color compounds, including chlorophyll, oxidation compounds, and iron. This step is performed under vacuum for about 5 to 30 min at 100–110 °C. The color and suspended contaminants are absorbed by the clay particles and/or activate carbon (charcoal). After bleaching, the canola oil meets color standard requirements [68].

The final step in the refining of canola oil is deodorization where unacceptable odor compounds are removed; this step is carried out at high temperature (> 200 °C) with steam at high vacuum. Modern deodorizing equipment utilizes packed columns that provide a very high efficiency in stripping the free fatty acids and other volatiles from the oil [68]. The Environmental Protection Agency (EPA) has identified n-hexane among the most serious chemical hazards because of the likelihood of explosion if solvent leakage occurs [11]. Hence, alternative solvents or non-solvent methods of extraction have been explored (see below).

Supercritical Fluid Extraction of Canola Oil

Supercritical solvent extraction with gases such as carbon dioxide (CO2) or propane have been studied as alternatives to hexane extraction of canola pressed cake [52]. Supercritical fluid extraction separates oil from the cake by using gases in supercritical form at temperatures and pressures above critical values [21, 62]. Supercritical fluids exhibit both the solvating characteristics of a hydrocarbon liquid and the permeability and low density of a gas. Carbon dioxide is the most popularly used solvent in supercritical form because of its relative low critical temperature and pressure of 30 °C and 7 MPa respectively. In addition, it is non-toxic, non-corrosive, non-flammable, inert, and cheap. Moreover, following the extraction process, the solvent can be easily decompressed and CO2 can be removed or recondensed for reuse. Therefore, the oil and extracted meal can be obtained without requiring any further solvent removal treatment [11, 52]. The diagram in Fig. 2 shows a proposed supercritical extraction process for the extraction of canola oil. Table 2 summarizes the research found in the literature regarding the supercritical extraction of canola oil. Pilot and industrial scale supercritical CO2 extractors manufactured by DEPAMU are available from 50 to 1500 L capacity. Supercritical CO2 extraction has been used for the extraction of microalgal, antioxidant pigment at industrial scale but to our knowledge, supercritical fluid extraction (SFE) has not been bused yet for the industrial extraction of vegetable oils. Figure 3 shows a picture of a SFE unit manufactured by DEPAMU.

Koubaa et al. [27] investigated the impact of seed dehulling on both oil yield and quality after cold pressing followed by supercritical carbon dioxide extraction from the pressed cake. The influence of key extraction process parameters such as pressure, temperature, and CO2 flow rate were studied. The authors reported optimal process parameters of 35 MPa for extraction pressure, 8.5 kg/h for CO2 flow rate, and temperatures between 40 and 60 °C to achieved a maximum oil yield of 74.5%. This process extracted the oil very effectively while keeping the same quality compared to the oil extracted with hexane without dehulling. The oil yield was significantly higher than yield of 28.27% obtained by Cvjetko et al. [14] who optimized the supercritical carbon dioxide extraction parameters to 29.7 MPa, 52.14 °C, and 3.36 h.

Oxidative stability is a key factor to enhance oil shelf life. Oil oxidative stability can be increased by increasing the amount of antioxidant components such as tocopherols, canolol, and phytosterols. Przybylski et al. [43] studied the effect of using supercritical carbon dioxide as solvent on the canola oil oxidative stability as compared to hexane solvent. The authors observed that CO2 contributed positively on the oxidative stability due to an increase in the amount of antioxidant components. For instance, the content of phytosterol increased by 51% compared to the hexane extracted oil.

Pederssetti et al. [41] conducted a comparative study between the canola seed oil extraction using two supercritical gases, carbon dioxide and propane. The extraction process was performed at a pressure range from 20 to 25 MPa and at a temperature range from 40 °C to 60. The flow rate of propane and carbon dioxide was kept constant at 0.8 cm3/min and 3 cm3/min, respectively. The authors reported that both pressure and temperature at which the supercritical carbon dioxide extraction process was carried out were the main parameters affecting the extraction yield, whereas the supercritical propane extraction oil yield was significantly affected only by temperature. The authors indicated that propane extraction needed less time and a lower pressure than supercritical carbon dioxide. However, both solvents produced extracted oils with similar fatty acid compositions compared to that obtained by hexane extraction. This agreed with Boutin and Badens [8] who also investigated the effect of various operational parameters using supercritical carbon dioxide such pressure, temperature, flow rate and extraction time on the yield of canola oil. Their results indicated that pressure had a considerable influence on the oil yield, while temperature exhibited only a small effect. The authors reported optimum flow rates and processing times versus pressure to achieve the highest oil yield without affecting the content of phospholipids. In a similar study, Uquiche et al. [63] analyzed the influence of supercritical carbon dioxide process variables on the yield and composition of cold pressed canola cake residual oil. The authors reported that an increase in pressure resulted in an increase in oil yield while an increase in temperature had little effect. The oxidative stability of oil extracted from canola cake by supercritical carbon dioxide was found to be higher than the oil extracted by hexane. This is attributed to the fact that supercritical CO2 extracted more antioxidant components such as tocopherols, phytosterols, and/or polyphenols into the oil than the hexane extraction.

Dunford and Temelli [17] carried out supercritical carbon dioxide extraction on canola flakes at temperatures in the range of 35 to 75 °C and pressures from 20 to 62 MPa. The authors reported that for preheated seeds and then cooked canola flakes the oil yield increased with increasing temperature and pressure, except at 20 MPa where the oil yield decreased with increasing temperature. However, Dong, M. and T. H. Walker [16] reported that maximum oil yield from supercritical carbon dioxide extraction of flaked canola seeds is obtained at 20 MPa and 35 °C.

Canola Oil Aqueous Enzyme-Assisted Extraction

Aqueous enzyme-assisted extraction (AEE) is an environmentally friendly alternative technology for the extraction of edible oil from seeds. Oil extracted using this method is considered superior in quality and is also safe for human consumption as it does not use toxic solvents such as hexane. Since enzymes can hydrolyze and solubilize proteins [26, 38] their use facilitates the extraction of oil from oleosomes, concomitantly with the extraction of other components such as antioxidants, while minimizing the formation of deleterious free fatty acids and phospholipid gums. AEE also increased substantially the oil quality in terms of flavor and odor [57, 71]. From an environmental perspective, aqueous enzyme-assisted extraction is considered safer and more environmentally friendly than solvent extraction process which is energy intensive and uses solvents that pose environmental and health issues [71].

Canola seeds are complex structures that consist of three major components: (1) the embryo which is composed of cotyledons, hypocotyl, and radicle; (2) the endosperm, which provides nourishment for the developing embryo; and (3) the seed coat, which surrounds the embryo and the endosperm serving as a mechanical protective barrier [7]. A. Rosenthal et al. [49] described the mechanism by which enzymes assist in the release the oil from seeds during AEE. Enzymes such as pectinases, cellulases, and hemicellulases break the structure of the cotyledon of grounded or flaked seeds, making the seeds structure permeable and hence facilitates the release of oil from the cotyledons cell wall.

Factors Affecting the Efficiency of Aqueous Enzyme-Assisted Extraction

Seed Particle Size

Generally, lower particle size provides higher oil yield as a result of a higher surface area and shorter path length for enzymes to break down the cotyledon cell wall [38, 57]. However, seeds with high oil content may have weaker wall structure, causing the seeds to collapse and lose their micro-porosity properties when the oil is extracted with solvents. This reduced porosity can result in a non-uniform percolation of enzymes that reduce the extraction efficiency [7, 73, 74]. As a result, an optimum particle size is needed to maximize the extraction efficiency.

Moisture Content

The moisture content can assist the diffusion of enzymes facilitating the breakdown of the cotyledon cell wall [26, 32]. On the other hand, oil bearing materials with low moisture content can form a thick suspension which is a barrier to the penetration of enzymes into the cell walls [50]. However, excessive moisture can dilute the enzyme concentration and activity and hence reduce the extraction efficiency. Therefore, it is important to optimize the moisture content in order to enhance the oil yield [12, 29].

Enzyme/Substrate Ratio

A sufficiently high enzyme concentration is required for an effective enzyme-substrate interaction [71]. Very high enzyme concentration may influence negatively the oil flavors [26] possibly due to the extraction of undesirable components. Jiang and Zhang reported that the extraction yield increased with the enzyme concentration up to a certain value; a further increase above that value resulted in a yield decrease, possibly due to substrate saturation [26, 73, 74].

pH of Extraction Medium

The optimum pH usually corresponds to the pH of the enzyme maximum activity. In earlier studies, the pH was set in the range of the isoelectric pH of proteins where the solubility is minimal [12, 50]. However, Passos et al. [38] reported that for a mixture of enzymes, high activity can be obtained at pH values outside of the isoelectric range.

Incubation Temperature

The optimum temperature range for enzymatic hydrolysis is between 40 and 55 °C. Passos et al. [38] and B, Aliakbarian [1] employed AEE temperatures which fall within this range. Gros et al. [22] also used a temperature of 34 °C in the extraction of linseed oil; however, oil yield reduced significantly at this temperature compared to higher temperatures. Sharma et al. [56] indicated that the highest oil yield of peanut oil was at 40 °C, while a significant reduction was observed at 37 °C.

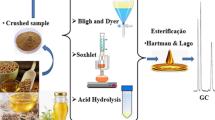

Figure 4 shows the aqueous enzyme-assisted extraction (AEE) process. Hot water is added to the seeds to facilitate grinding and then sodium hydroxide is added to adjust the pH before adding enzymes for incubation. De-emulsification is achieved by heating the emulsion to a temperature ranging from 60 to 90 °C followed by cooling to room temperature. The mixture is then centrifuged to separate the oil from the aqueous phase containing the enzyme [26, 29]. Table 3 summarizes the different types of enzymes employed to extract canola oil.

Latif et al. [28] investigated the influence of three different aqueous enzymes: protex, pectinase, multifect, and without enzyme, on the extraction of canola oil and compared it with solvent extraction in terms of oil yield and quality. The experiments were carried out by adding various enzymes to ground seeds. The authors adjusted treatment conditions to a heating temperature of 45 °C and an incubation time of 2 h, with constant shaking at 120 rpm. Multifect CX 13L provided the highest oil yield (26%), which is considerably lower than the 43% yield achieved with solvent extraction. However, the concentration of tocopherols which resulted from aqueous enzymatic extraction (200 mg/kg) was comparable to the solvent extraction (239 mg/kg). In a related study, Zhang et al. [73, 74] used various types of enzymes with different ratios to extract canola oil. The experiments were performed at a pH of 9 with an incubation time of 3 h at 60 °C. A yield of 89% was obtained in an emulsified form when a mixture of pectinase and cellulase were used at a ratio of 2:1(w/w). This yield is greater than the maximum oil yield of 84% obtained with pectinase alone. This result was in agreement with that reported by S. Zhang., et al. [73, 74] who used a combination of various enzymes with different ratios to maximize the canola oil yield, (Table 3). The authors used dehulled and ground seeds incubated at 60 °C at pH 9. The highest oil yield (92%) was obtained with a mixture of cellulase, pectinase, and β-glucanase at a ratio of 4:1:1(w/w/w). As reported, oil yield can be enhanced when the best combination of enzymes is used and their ratios are optimized. Despite its advantages, aqueous enzymatic extraction is not employed by the canola industry because of its long processing time, expensive cost of drying after AEE treatment and the need for de-emulsification [12].

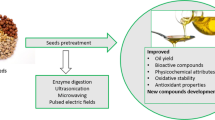

Microwave-Assisted Canola Oil Extraction

In conventional solvent extraction, the rate of oil extraction depends on the oil solubility in the solvent and its rate of mass transfer through the solid material [58]. Mechanical pressing physically ruptures the cells in flaked seeds to help release the oil during pressing. Numerous processes have been developed to enhance the oil yield such as size reduction, de-hulling, and hydrolysis. Microwave irradiation is an advanced method that has attracted attention over the last two decades [44, 58,59,60]. Microwaves are electromagnetic radiations at a frequency range of 300 MHz to 300 GHz. Microwaves penetrate the oil containing material converting electromagnetic energy into heat following two mechanisms: ionic conduction and dipole rotation. The ionic conduction can generate heat as a result of collision between molecules due to the resistance of the medium to ion migration. When the electrical field changes polarity, the flow of ions change direction while polar molecules rotate following the electrical field direction, this is called dipole rotation. The agitation of molecules generates energy and hence raises the temperature of the material or biomass. The absorbed heat depends on the permittivity of the seed at a particular frequency [59, 60]. The effectiveness of microwave processing depends on the heating rate which is partially dependent on the dielectric properties of the biomass, and the subsequent intracellular pressure build-up, which ruptures the oilseeds cell walls facilitating the release of oils. The rate of heating due to microwave irradiation also depends on frequency, power level, and initial product temperature, in addition to the dielectric properties of processed materials [58]. Microwave processing has been extensively studied and found to enhance the yield of various seed oils.

During oil production, particularly during pre-conditioning and cooking of seed and flaked seeds, the interaction between triacylglycerol (TAG) and native enzymes, under the effect of moisture and heat, can lead to the reduction of oil yield and quality as a result of hydrolysis and the production of unwanted phospholipids in the extracted oil, which then need to be removed by degumming. Therefore, the denaturing and deactivation of native enzymes can significantly improve the oil yield and quality and reduce the need for degumming. Veldsink, J. et al. [65] studied the effect of enzyme activity vs temperature (see Fig. 5). The authors reported that during preconditioning, oil seeds heat from T0 to T2, the activity of enzymes increases gradually with time and reached its maximum activity at T1. To minimize the enzymatic action, pre-conditioning of oil seeds from T0 to T2 should be as quick as possible. Therefore, methods which can achieve accelerated heating can quickly deactivate enzymes and minimize their deleterious effects on oil yield and quality. Another theory that explains the enhancement of oil yield by MW pre-treatment was proposed by Zárate et al. [72] and Oberndorfer et al. [36] who reported that MW pre-treatment reduces the oil viscosity therefore improving the oil fluidity, facilitating the oil release out from the seeds after cell wall rupture.

Enzyme activity with temperature curve as proposed by J. W. Veldsink [65]

The major advantages of microwave pre-treatment of seeds are short process time and reduced solvent usage compared to conventional extraction due to increased oil extraction in the pressing step. It has also been demonstrated that MW assisted pre-treatment of seed prior to extraction resulted in a higher content of desirable components such as tocopherols, phytosterols, and phenolic compounds in the final oil product [5].

There are several heating mechanisms of seeds each one affecting the oil quality differently. Veldsink et al. [65] investigated the effect of three alternatives for seed conditioning: steam heating, infrared irradiation, and microwave irradiation, on the oil quality of canola oil. The MW experiments were carried out using a microwave oven at 225 °C, 6 kW, and 2450 MHz; a short radiator infrared oven at 240 °C; and steam at 3 bar and 130 °C. The results demonstrated that microwave heating provided better oxidative stability at higher frying temperature in comparison to other heating techniques (steam and infrared) and increased the content of free fatty acids. A drawback of infrared heating is that the seeds can be quickly burnt to produce a heavy undesirable odor.

Azadmard et al. [4] studied the MW pre-treatment on minor components of canola oil. The authors reported that the tocopherol content in the extracted oil rose significantly compared to those when using conventional steam preheating. This result was attributed to greater disruption of seed walls which facilitated a higher extraction of minor components in the final oil product. In a related study, Sanchez et al. [51] studied the effect of microwave seed preconditioning on the yield and quality of canola oil extracted with hexane. The moisture level of the seeds was adjusted to 5.7 ± 0.2% (of dry weight). The extraction process was carried out in a batch system agitated with a magnetic stirrer at 200 rpm. The authors studied the effect of processing times from 5 min to 1 h and temperature ranging from 25 to 60 °C. It was reported that oil yield increased by 41% with microwave pretreament compared with an untreated sample. No major changes of oil quality were detected after microwave processing. In fact, microwave treated samples showed an increase in the concentration of β-tocopherol by 3%, ϭ-tocopherol by 30%, and canolol by 517% compared with samples cooked by steam. Similar results were obtained by Yang et al. [70] who reported that the canolol content in an oil extracted sample that was MW irradiated for 7 min at 160 °C was sixfold greater than the canolol content in the oil extracted from an untreated sample. In addition, phenolic compounds such as sinapine, and sinapic acid reached a maximum content in an oil extracted sample after 3 min of MW pre-treatment as compared to untreated samples.

Oxidative or thermal stability are important criteria for the commercialization of food grade canola oil. The presence of antioxidant components such as tocopherols, and polyphenols in canola oil prolongs the oil shelf life and therefore are seen as desirable components. Yang et al. [69] investigated the effect of microwave pre-treatment on the content of antioxidant components in canola oil using seeds with different initial moisture levels (9–15%). The content of antioxidant components increased when reducing the initial moisture content, and increasing the MW pre-treatment time. The content of phytosterols and polyphenols reached 950 mg/100 g oil and 97 mg/100 g oil respectively, after 7 min of MW seed pre-treatment. After 4 min of MW pre-treatment, the content of tocopherols was 52 mg/100 g oil when the moisture range was 9 to 11%. In terms of oil yield, MW pre-treatment during 7 min enhanced the oil yield lowering the oil content in the residual cake by 11% compared to the untreated samples. Similarly, [45, 46] investigated the effect of MW treatment at three processing times (3, 6, and 9 min) on the physicochemical properties of high-oleic canola seeds prepared from de-hulled seeds. The author’s results demonstrated that MW treatment of de-hulled seeds improved the color, flavor, and nutritional value of the oil. After 9 min of MW treatment, the content of canolol increased 155 fold, the total tocopherol concentration was 71.19 mg/100 g-oil, and the antioxidant capacity was nearly 4 times higher, as compared to the control samples. The same outcome was obtained by [45, 46] for MW pre-treatment with de-hulled seeds. The authors stated that MW injunction on de-hulled seeds increased phytosterols, carotenoids, and phenolic compounds.

Due to the increased global demand of canola oil, it is required to understand the degradation rate of antioxidant components in order to extend the oil shelf life [18, 61]. Rekas et al. [45, 46] investigated the influence of MW pre-treatment compared to conventional steam heating on the degradation of phenolic compounds during 1 year of storage at temperature of 20 °C. After 10 min MW seed pre-treatment, the canolol content was 63 fold higher than that obtained after steam preheating and hexane solvent extraction. The degradation rate of phenolic compounds in the control sample was higher than that in the oil extracted after MW per-treatment. In similar study, the effect of MW cooking on canola seeds in terms of storability and oil quality has been investigated [40]. For this purpose, canola seeds were MW cooked at temperature levels of 80, 90, and 100 °C. After treatment, the seeds were stored for 6 months at 30 °C and under a relative humidity hovering from 50 to 70%. The authors reported lower acid values and slightly higher peroxide values of MW-treated seeds, compared to control ones, before storage. After 6 months of storage, reduced water content and slower metabolic activity were observed for MW-treated seeds. The results demonstrated that no significant variations in oil quality are noticed between the MW-treated samples and the untreated ones. The outcome of that study was that MW pre-treatment of canola seeds, improved the quality during storage, even under extreme environmental conditions. These findings are in line with [47, 48] who investigated the storage stability of tocochromanols and carotenoids in canola oil after MW treatment times ranging from 2 to 10 min, for 1 year storage at 20 °C. The author’s reported that the total tocochromanols was 76.64 mg/100 g, after 9 min MW treatment, while a maximum carotenoid concentration of 861.28 μg/100 g was obtained following 6 min of MW treatment. The authors concluded that the oil obtained from MW pre-treated seeds lost from 9 to 15% of its antioxidant capacity lower than control ones, after 1 year of storage. Similarly, [47, 48] mentioned that MW pre-treated seeds slowed down the degradation rate of carotenoids (14.678 μg/100 g/month), while the control sample rate of degradation was 18.168 μg/100 g/month. The half-life (t1/2) of canolol content in the oil obtained was nearly twofold higher than control ones (6.2 months), for seeds exposed 2–8 min to MW pre-treatment. However, the degradation rate of tocochromanols, carotenoids, and phenolic compounds varied significantly, depending on the seeds MW pre-treatment time. The study concluded that MW pre-treated seeds slowed down the degradation rate of the oil antioxidant capacity, in comparison to control samples.

Zhou et al. [75] studied the effect of MW pre-treatment on the taste and flavor sensory properties of canola oil, obtained from dehulled and non-dehulled seeds. The study demonstrated that treating non-dehulled canola seeds with microwave for 3 min at a power of 800 W improved the taste and flavor characteristics of the extracted oil compared with dehulled seeds and non-dehulled samples without MW pre-treatment. The results of this study showed that MW pre-treatment provided a pleasant odor and a better taste which enhanced the sensory attributes of canola oil.

Aqueous Ultrasonic-Assisted Extraction of Canola and Other Seed Oils

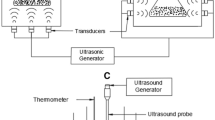

Megasonic separation is a technique that uses high-frequency ultrasonic standing waves, of frequencies from 0.4 to 2 MHz, to separate particles and droplets suspended in fluids. The acoustic field exerts Bjerknes radiation forces that move particles and droplets toward either pressure nodal or antinodal planes, depending on the density and compressibility of particles or droplets with respect to those of the fluid. Once particles or droplets are displaced to the nodes or antinodes, they may agglomerate or coalesce into larger entities allowing for a faster precipitation or flotation due to the effect of gravity (buoyancy force) [24, 30]. Ultrasonic cavitation, which is undesirable for an effective ultrasound separation process, may occur if the applied ultrasonic intensity is high. The deleterious consequences of cavitation are a result of intense shearing forces. The formation of radical species can also occur due to the splitting of water molecules during the violent collapse of acoustic bubbles, and shock waves [30]. There are several key parameters that control the effectiveness of ultrasound treatments for separation such as frequency, ultrasound power, and extraction time. The application of ultrasound treatments can enhance oil yield and reduce extraction time without negatively affecting oil quality [13, 31]. Fang et al. [67] investigated the effectiveness of ultrasound-assisted extraction of oil from canola seeds obtaining a maximum oil yield of 47% by employing a liquid to solid ratio of 1:2, an extraction time of 60 min, and ultrasound power of 400 W. This study showed that ultrasound treatment resulted in a rapid canola oil extraction that was five times faster than conventional solvent extraction. Another study evaluated the effect of megasonic on the oil extraction from canola seeds using supercritical CO2 (SC-CO2) as an extraction solvent [23]. The effect of US-assisted SC-CO2 extraction operating parameters (i.e. crushed seeds particle size, SC-CO2 flow rate, extraction vessel aspect ratio, and ultrasound power) on the extraction efficiency was investigated. The authors reported that increasing the particle size of samples reduced the extraction rate, which was maximum at a CO2 flow rate of 6.2 L/min. A decrease in the aspect ratio of the extraction vessel enhanced the extraction rate and extraction yield. Moreover, application of US-assisted SC-CO2 extraction slightly increased the extraction yield when the CO2 flow rate was below 6 mL/min.

Linseed (flax) is an important industrial oilseed crop, because of its high oil content (> 40%) [37]. Cold pressing or pre-pressing followed by solvent extraction are the common processes used for oil extraction from flax seeds. Some non-conventional emerging technologies have been implemented to enhance the flax seeds oil extraction yield and quality. One of those technologies is megasonic or ultrasound-assisted extraction [66]. The authors studied the effect of megasonic on the oil yield under different operating parameters such as ultrasonic power, extraction time, extraction temperature, and solvent (n-hexane) to solid ratio. The results showed that oil yield increased from 66.7 to 84.9% (18.2%increases) when the megasonic power was enhanced from 20 to 50 W. The optimum conditions were ultrasonic power of 50 W, extraction temperature of 30 °C, extraction time of 30 min and liquid to solid ratio: of 6:1 (v/w). In similar study, Metherel et al. [34] studied the effect of ultrasound treatment to enhanced lipid extraction from flaxseed. The oil from ground flaxseed was extracted using different solvents mixtures: chloroform: methanol (2:1, v/v), hexane: isopropanol (3:2, v/v) and diethyl ether: petroleum ether (1:1, v/v). Oil yield increased proportionally to treatment time and power when sonicating at 20 kHz. Sharma et al. [53, 55] evaluated the effect of ultrasonic pre-treatment in the oil extraction from Jatropha curcas L., almond and apricot seeds in conjunction with aqueous enzymatic extraction. The authors indicated that a 5 min ultrasonic pre-treatment, followed by aqueous enzyme treatment with protease, increased the oil yield of Jatropha curcas L by 74% compared to traditional extraction. In the case of almond and apricot seeds, aqueous ultrasound treatment decreased the processing time and enhanced the oil yield. For almonds, a 2-min ultrasonic pre-treatment at 70 W increased the oil yield from 75 to 95% and reduced the processing time from 18 to 6 h. For apricot seeds, ultrasound slightly increased the oil production from 75 to 77% and reduced the processing time by a third. In a similar study, Long et al. [33] experimented with a combined enzymatic and ultrasonic-assisted extraction of flaxseeds using cellulase, pectinase, and hemi-cellulase. The authors reported that oil recovery increased by 1.5% using ultrasound compared to enzymatic-assisted extraction alone. Due to the scarcity of studies on the effect of ultrasound on canola oil extraction further research is needed.

Final Remarks

In spite of the progress during the last five decades resulting in an increase of oxidative and thermal stability of canola oil, conventional processing using highly flammable solvents such as hexane poses environmental and health risks as well as reduces the oil quality since several desirable oil components such as phytosterols and antioxidants such as tochopherols, and phenolic compounds are either not affectively extracted and/or are partially lost during refining. Supercritical fluid extraction uses non-toxic food grade carbon dioxide and offers an environmentally friendly way which is gentle and safe, for the efficient extraction of high-quality oil at the lab scale. However, pilot scale studies are required to determine whether canola oil yield will increase at larger scale production.

To make aqueous enzyme-assisted extraction processes economically viable, further research is required to choose suitable enzymes that enhance the oil yield and protein recovery. In addition, oil de-emulsification show cost challenges that need to be overcame together with the expensive nature of suitable enzymes at commercial scales.

Microwave-assisted oil extraction can be very efficient for canola oil preconditioning because it can reduce the amount of solvent, enhance oil yield, and reduce processing time. Compared to the untreated samples, most of the studies concluded that MW pre-treatment achieved similar or higher oil quality, with an enhanced content of desirable nutraceuticals such as phytosterols, tocopherols, canolol, and phenolic compounds, which increases the oxidative stability of the oil and extends its shelf life. However, further research is needed for industrial scale trials to carry out a cost benefit analysis.

Aqueous ultrasound extraction is also a promising technology which could provide improvements in canola oil extraction processes, particularly in reducing solvent usage, and enriching oils in high-added value compounds, but further lab scale research is needed to assess the economic feasibility of combining this technology with current industrial solvent extraction technologies to see whether benefits are gained to uptake this technology at industrial scale.

References

Aliakbarian B, De Faveri D, Converti A, Perego P (2008) Optimisation of olive oil extraction by means of enzyme processing aids using response surface methodology. Biochem Eng J 42(1):34–40

Aukema H, Campbell L (2011) Oil nutrition and utilization. In: Canola. Elsevier, pp 245–280

Ayton J (2014) Variability of quality traits in canola seed, oil and meal: a review. New South Wales Department of Primary Industries. New South Wales, Australia

Azadmard-Damirchi S, Habibi-Nodeh F, Hesari J, Nemati M, Achachlouei BF (2010) Effect of pretreatment with microwaves on oxidative stability and nutraceuticals content of oil from rapeseed. Food Chem 121(4):1211–1215

Azadmard-Damirchi S, Alirezalu K, Achachlouei BF (2011) Microwave pretreatment of seeds to extract high quality vegetable oil. World Acad Sci Eng Technol 57:72–75

Beckie HJ, Harker KN, Legere A, Morrison MJ, Seguin-Swartz G, Falk KC (2011) GM canola: the Canadian experience. Farm Policy J 8(1):43–49

Bewley J, Black M (1994) Seeds: physiology of development and germination. Plenum Press, New York Google Scholar

Boutin O, Badens E (2009) Extraction from oleaginous seeds using supercritical CO 2: experimental design and products quality. J Food Eng 92(4):396–402

Burdge GC, Calder PC (2005a) Conversion of $\alpha $-linolenic acid to longer-chain polyunsaturated fatty acids in human adults. Reprod Nutr Dev 45(5):581–597

Burdge GC, Calder PC (2005b) α-Linolenic acid metabolism in adult humans: the effects of gender and age on conversion to longer-chain polyunsaturated fatty acids. Eur J Lipid Sci Technol 107(6):426–439

Campbell K, Glatz C, Johnson L, Jung S, De Moura J, Kapchie V, Murphy P (2011) Advances in aqueous extraction processing of soybeans. J Am Oil Chem Soc 88(4):449–465

Chabrand RM, Glatz CE (2009) Destabilization of the emulsion formed during the enzyme-assisted aqueous extraction of oil from soybean flour. Enzym Microb Technol 45(1):28–35

Chemat F, Khan MK (2011) Applications of ultrasound in food technology: processing, preservation and extraction. Ultrason Sonochem 18(4):813–835

Cvjetko M, Jokić S, Lepojević Ž, Vidović S, Marić B, Radojčić Redovniković I (2012) Optimization of the supercritical CO2 extraction of oil from rapeseed using response surface methodology. Food Technol Biotechnol 50(2):208–215

Daun JK, Eskin N, Hickling D (2011) Canola: chemistry, production, processing, and utilization, AOCS Press

Dong M, Walker TH (2008) Characterization of high-pressure carbon dioxide explosion to enhance oil extraction from canola. J Supercrit Fluids 44(2):193–200

Dunford NT, Temelli F (1997) Extraction conditions and moisture content of canola flakes as related to lipid composition of supercritical CO2 extracts. J Food Sci 62(1):155–159

Farhoosh R, Einafshar S, Sharayei P (2009) The effect of commercial refining steps on the rancidity measures of soybean and canola oils. Food Chem 115(3):933–938

Fried EJ (2006) The Oxford Encyclopedia of Food and Drink in America. Public Health Rep 121(2):203–204

Friedrich JP (1982) Petroleum-free extraction of oil from soybeans with supercritical CO2. J Am Oil Chem Soc 59(7):288–292 v.1959 no.1987

Friedrich J, List G, Heakin A (1982) Petroleum-free extraction of oil from soybeans with supercritical CO2. J Am Oil Chem Soc 59(7):288–292

Gros C, Lanoisellé J-L, Vorobiev E (2003) Towards an alternative extraction process for linseed oil. Chem Eng Res Des 81(9):1059–1065

Hwang A-R, Lim G-B, Ryu J-H (2010) Ultrasound-assisted extraction of canola oil using supercritical fluid process. KSBB J 25(5):437–442

Kotwaliwale N et al (2014) X-ray imaging methods for internal quality evaluation of agricultural produce. J Food Sci Technol 51(1):1–15

Kővári K (2004) Recent developments, new trends in seed crushing and oil refining. Ol Corps Gras, Lipides 11(6):381–387

Jiang L, Hua D, Wang Z, Xu S (2010) Aqueous enzymatic extraction of peanut oil and protein hydrolysates. Food Bioprod Process 88(2):233–238

Koubaa M, Mhemdi H, Vorobiev E (2016) Influence of canola seed dehulling on the oil recovery by cold pressing and supercritical CO 2 extraction. J Food Eng 182:18–25

Latif S, Diosady LL, Anwar F (2008) Enzyme-assisted aqueous extraction of oil and protein from canola (Brassica napus L.) seeds. Eur J Lipid Sci Technol 110(10):887–892

Latif S, Anwar F, Hussain AI, Shahid M (2011) Aqueous enzymatic process for oil and protein extraction from Moringa oleifera seed. Eur J Lipid Sci Technol 113(8):1012–1018

Leong T, Knoerzer K, Trujillo FJ, Johansson L, Manasseh R, Barbosa-Cánovas GV, Juliano P (2015) Megasonic separation of food droplets and particles: design considerations. Food Eng Rev 7(3):298–320

Li H, Pordesimo L, Weiss J (2004) High intensity ultrasound-assisted extraction of oil from soybeans. Food Res Int 37(7):731–738

Li Y, Jiang L, Sui X, Wang S (2011) Optimization of the aqueous enzymatic extraction of pine kernel oil by response surface methodology. Procedia Eng 15:4641–4652

Long J-j, Fu Y-j, Zu Y-g, Li J, Wang W, Gu C-b, Luo M (2011) Ultrasound-assisted extraction of flaxseed oil using immobilized enzymes. Bioresour Technol 102(21):9991–9996

Metherel AH, Taha AY, Izadi H, Stark KD (2009) The application of ultrasound energy to increase lipid extraction throughput of solid matrix samples (flaxseed). Prostaglandins Leukot Essent Fat Acids 81(5):417–423

Motohashi N, Kamata K, Meyer R (1993) Chromatographic techniques used to determine benz [c] acridines in environmental samples. J Chromatogr A 643:1–2): 1-10

Oberndorfer C, Pawelzik E, Lücke W (2000) Prospects for the application of dielectric heating processes in the pre-treatment of oilseeds. Eur J Lipid Sci Technol 102(7):487–493

Oomah BD (2001) Flaxseed as a functional food source. J Sci Food Agric 81(9):889–894

Passos CP, Yilmaz S, Silva CM, Coimbra MA (2009) Enhancement of grape seed oil extraction using a cell wall degrading enzyme cocktail. Food Chem 115(1):48–53

Pathak P, Agrawal Y, Singh B (1991) Effect of elevated drying temperature on rapeseed oil quality. J Am Oil Chem Soc 68(8):580–582

Pawelzik E, Irfan I, Luecke W (1998) Microwave treatment of rape to ensure seed quality during storage. Proceedings of the 7th international working conference on stored-product protection, Sichuan Publishing House of Science and Technology, Chengdu, China (Beijing, China)

Pederssetti MM, Palú F, Da Silva EA, Rohling JH, Cardozo-Filho L, Dariva C (2011) Extraction of canola seed (Brassica napus) oil using compressed propane and supercritical carbon dioxide. J Food Eng 102(2):189–196

Prior EM, Vadke VS, Sosulski FW (1991) Effect of heat treatments on canola press oils. I. Non-triglyceride components. J Am Oil Chem Soc 68(6):401–406

Przybylski R, Lee Y-C, Kim I-H (1998) Oxidative stability of canola oils extracted with supercritical carbon dioxide. LWT 31(7):687–693

Regier M, Schubert (2005) Introducing microwave processing of food: principles and technologies. The microwave processing of foods. CRC, Woodhead Publishing Limited, England, p 3–20

Rękas A, Ścibisz I, Siger A, Wroniak M (2017a) The effect of microwave pretreatment of seeds on the stability and degradation kinetics of phenolic compounds in rapeseed oil during long-term storage. Food Chem 222:43–52

Rękas A, Siger A, Wroniak M, Ścibisz I, Derewiaka D, Anders A (2017b) Dehulling and microwave pretreatment effects on the physicochemical composition and antioxidant capacity of virgin rapeseed oil. J Food Sci Technol 54(3):627–638

Rękas A, Siger A, Wroniak M (2018a) The effect of microwave pre-treatment of rapeseed on the degradation kinetics of lipophilic bioactive compounds of the oil during storage. Grasas Aceites 69(1):233

Rękas A, Siger A, Wroniak M, Ścibisz I (2018b) Phytochemicals and antioxidant activity degradation kinetics during long-term storage of rapeseed oil pressed from microwave-treated seeds. Eur J Lipid Sci Technol 120(2):1700283

Rosenthal A, Pyle D, Niranjan K (1996) Aqueous and enzymatic processes for edible oil extraction. Enzym Microb Technol 19(6):402–420

Rosenthal A, Pyle DL, Niranjan K, Gilmour S, Trinca L (2001) Combined effect of operational variables and enzyme activity on aqueous enzymatic extraction of oil and protein from soybean. Enzym Microb Technol 28(6):499–509

Sánchez R, Mateo C, Fernández M, Nolasco S (2017) Bidimensional modeling applied to oil extraction kinetics of microwave-pretreated canola seeds. J Food Eng 192:28–35

Sarmento CMP, Ferreira SRS, Hense H (2006) Supercritical fluid extraction (SFE) of rice bran oil to obtain fractions enriched with tocopherols and tocotrienols. Braz J Chem Eng 23(2):243–249

Shah S, Sharma A, Gupta M (2005) Extraction of oil from Jatropha curcas L. seed kernels by combination of ultrasonication and aqueous enzymatic oil extraction. Bioresour Technol 96(1):121–123

Shahidi F (1990) Canola and rapeseed: production, chemistry, nutrition, and processing technology. Springer Science & Business Media

Sharma A, Gupta M (2006) Ultrasonic pre-irradiation effect upon aqueous enzymatic oil extraction from almond and apricot seeds. Ultrason Sonochem 13(6):529–534

Sharma A, Khare S, Gupta M (2002) Enzyme-assisted aqueous extraction of peanut oil. J Am Oil Chem Soc 79(3):215–218

Soto C, Chamy R, Zuniga M (2007) Enzymatic hydrolysis and pressing conditions effect on borage oil extraction by cold pressing. Food Chem 102(3):834–840

Spigno G, De Faveri D (2009) Microwave-assisted extraction of tea phenols: a phenomenological study. J Food Eng 93(2):210–217

Terigar B, Balasubramanian S, Boldor D, Xu Z, Lima M, Sabliov C (2010a) Continuous microwave-assisted isoflavone extraction system: design and performance evaluation. Bioresour Technol 101(7):2466–2471

Terigar BG, Balasubramanian S, Boldor D (2010b) An analysis of the microwave dielectric properties of solvent-oil feedstock mixtures at 300–3000MHz. Bioresour Technol 101(16):6510–6516

Terigar B, Balasubramanian S, Sabliov C, Lima M, Boldor D (2011) Soybean and rice bran oil extraction in a continuous microwave system: from laboratory-to pilot-scale. J Food Eng 104(2):208–217

Unger EH (1990) Commercial processing of canola and rapeseed: crushing and oil extraction. In Canola and Rapeseed, Springer, p 235–249

Uquiche E, Romero V, Ortiz J, Del Valle J (2012) Extraction of oil and minor lipids from cold-press rapeseed cake with supercritical CO2. Braz J Chem Eng 29(3):585–598

Vaisali C, Charanyaa S, Belur PD, Regupathi I (2015) Refining of edible oils: a critical appraisal of current and potential technologies. J Food Sci Technol 50(1):13–23

Veldsink JW, Muuse BG, Meijer MM, Cuperus FP, van de Sande RL, van Putte KP (1999) Heat pretreatment of oilseeds: effect on oil quality. Eur J Lipid Sci Technol 101(7):244–248

Wanasundara P, Shahidi F (1998) Process-induced changes in edible oils. Process-induced chemical changes in food. Springer, p 135–160

Wei F, Gao G-Z, Wang X-F, Dong X-Y, Li P-P, Hua W, Wang X, Wu X-M, Chen H (2008) Quantitative determination of oil content in small quantity of oilseed rape by ultrasound-assisted extraction combined with gas chromatography. Ultrason Sonochem 15(6):938–942

Wrigley CW, Corke H, Seetharaman K, Faubion J (2015) Encyclopedia of Food Grains. Academic Press

Yang M, Huang F, Liu C, Zheng C, Zhou Q, Wang H (2013) Influence of microwave treatment of rapeseed on minor components content and oxidative stability of oil. Food Bioprocess Technol 6(11):3206–3216

Yang M, Zheng C, Zhou Q, Liu C, Li W, Huang F (2014) Influence of microwaves treatment of rapeseed on phenolic compounds and canolol content. J Agric Food Chem 62(8):1956–1963

Yusoff MM, Gordon MH, Niranjan K (2015) Aqueous enzyme assisted oil extraction from oilseeds and emulsion de-emulsifying methods: a review. Trends Food Sci Technol 41(1):60–82

Zárate V, Perez EE, Crapiste GH, Nolasco SM, Fernández MB (2015) Oil extraction kinetics of hydrothermally pretreated canola seeds. Can J Chem Eng 93(5):842–848

Zhang SB, Wang Z, Xu SY (2007a) Downstream processes for aqueous enzymatic extraction of rapeseed oil and protein hydrolysates. J Am Oil Chem Soc 84(7):693–700

Zhang SB, Wang Z, Xu SY (2007b) Optimization of the aqueous enzymatic extraction of rapeseed oil and protein hydrolysates. J Am Oil Chem Soc 84(1):97–105

Zhou Q, Yang M, Huang F, Zheng C, Deng Q (2013) Effect of pretreatment with dehulling and microwaving on the flavor characteristics of cold-pressed rapeseed oil by GC-MS-PCA and electronic nose discrimination. J Food Sci 78(7):C961–C970

Zufarov O, Schmidt S, Sekretár S (2008) Degumming of rapeseed and sunflower oils. Acta Chimica Slovaca 1(1):321–328

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gaber, M.A.F.M., Tujillo, F.J., Mansour, M.P. et al. Improving Oil Extraction from Canola Seeds by Conventional and Advanced Methods. Food Eng Rev 10, 198–210 (2018). https://doi.org/10.1007/s12393-018-9182-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12393-018-9182-1