Abstract

Acrylamide, a suspected human carcinogen, is a Maillard reaction product that forms when carbohydrate-rich foods are cooked at high temperatures. Processed potato products, including French fries and potato chips, make a substantial contribution to total dietary acrylamide. Health safety concerns raised by acrylamide in food increased financial risks to the potato industry and encouraged industry to take a proactive approach toward acrylamide mitigation. The USDA National Institutes of Food and Agriculture Specialty Crop Research Initiative (SCRI) on acrylamide reduction in potato was a cooperative endeavor in which industry partners worked at a systems level with university and government researchers to develop acrylamide mitigation strategies. Short-term goals focused on identifying advanced breeding clones and recently released varieties that have lower acrylamide-forming potential than standard potato varieties. Research was also directed at developing more efficient potato breeding methods, including marker-assisted breeding, genome wide selection, and improved phenotyping methods. Data from the National Fry Processing Trial (NFPT) and SCRI agronomic trial have shown that dramatic reductions in acrylamide are achievable through the use of new varieties that maintain low concentrations of tuber reducing sugars. Chipping potato trials coordinated by Potatoes USA and data from breeding populations suggest that maintaining low tuber reducing sugars through extended storage and lowering tuber asparagine content are options for decreasing acrylamide content in potato chips. To have an impact, new varieties must have exceptional agronomic performance and must produce finished products that meet requirements for consumer attributes including color, texture and taste. Data consistently show that this is more easily achievable in chipping potatoes than in fry processing potatoes.

Resumen

La acrilamida, un posible cancerígeno humano, es un producto de la reacción de Maillard que se forma cuando alimentos ricos en carbohidratos se cocinan a altas temperaturas. Los productos procesados de papa, incluyendo las papas a la francesa y las hojuelas, hacen una contribución substancial para la acrilamida total en la dieta. Las preocupaciones en la seguridad de la salud, surgidas por la acrilamida en los alimentos, aumentó los riesgos financieros a la industria de la papa y estimuló a la industria a tomar una estrategia proactiva hacia la mitigación de la acrilamida. La Iniciativa de Investigación en Cultivos de Especialidad de los Institutos Nacionales de Alimentos y Agricultura del Departamento de Agricultura de los Estados Unidos (SCRI, por sus siglas en inglés) sobre la reducción de la acrilamida en papa, fue un esfuerzo de cooperación en el cual los socios de la industria trabajaron a nivel de sistemas con investigadores de universidades y del gobierno, para desarrollar estrategias de mitigación de la acrilamida. Las metas de corto plazo se enfocaron en la identificación de clones avanzados de mejoramiento y de variedades liberadas recientemente, que tienen un potencial más bajo de formación de acrilamida que las variedades comunes de papa. También se dirigió la investigación al desarrollo de métodos de mejoramiento genético más eficiente en papa, incluyendo el mejoramiento asistido con marcadores, amplia selección de genomios, y métodos mejorados para la descripción fenotípica. Datos del Ensayo Nacional en Procesamiento de Freído (NFPT) y el ensayo agronómico del SCRI, han mostrado que reducciones dramáticas en acrilamida son alcanzables a través del uso de nuevas variedades que mantienen bajas concentraciones de azúcares reductores en el tubérculo. Ensayos de freído en papa coordinados por Potatoes USA y datos de poblaciones de mejoramiento sugieren que manteniendo bajos los azúcares reductores de tubérculo mediante almacenamiento extendido y bajando el contenido de asparagina de tubérculo, son opciones para disminuir el contenido de acrilamida en las papas fritas. Para tener un impacto, las nuevas variedades deben tener comportamiento agronómico excepcional, y deben producir productos terminados que reúnan los requerimientos respecto a los atributos para el consumidor, incluyendo el color, textura y sabor. Los datos demuestran consistentemente que es más fácilmente alcanzable en papas fritas que en las de procesamiento.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Background

Acrylamide in processed potato products was identified as the US Potato industry’s highest research priority in the fall of 2010. In response to this need, 23 scientists working at 10 institutions across the US proposed that the USDA National Institutes of Food and Agriculture fund research on acrylamide mitigation with the twin goals of identifying potato varieties with low acrylamide-forming potential and developing potato breeding methods that would more efficiently bring new potatoes with low acrylamide-forming potential to market. In large part because of unprecedented support from multiple segments of the industry, that proposal, “Improved breeding and variety evaluation methods to reduce acrylamide content and increase quality in processed potato products”, was funded by the SCRI program in 2011.

Why acrylamide? Why was the potato industry concerned about acrylamide in processed potato products? The short answer is that acrylamide introduced unknown, potentially large risks to the potato industry. Acrylamide was a relatively new problem in 2010. Its presence in a wide range of cooked foods was first reported less than a decade earlier (Mottram et al. 2002; Stadler et al. 2002; Tareke et al. 2002; reviewed in Bethke and Bussan 2013). Because acrylamide was a known human neurotoxin (Garland and Patterson 1967) and carcinogen in rodents (Dearfield et al. 1988; Rice 2005), health concerns were raised immediately (Dybing and Sanner 2003; Vainio 2003). It was quickly discovered that the amount of dietary acrylamide ingested by humans was well below the amount needed for neurotoxicity. However, concerns about carcinogenesis persisted (Vainio 2003). On the one hand, data from multiple research studies showed clearly that acrylamide in food or drinking water caused a range of cancers in rodents (Rice 2005). On the other hand, very few epidemiological studies had examined the effects of dietary acrylamide on humans. The data from early reports on acrylamide and human cancers were less consistent than the rodent data, with a small increase in cancer risk identified in some research studies, and no evidence for increased cancer risk in others (Mucci et al. 2003; Pelucchi et al. 2003; Mucci et al. 2004; Mucci 2005; Pelucchi et al. 2006; Hogervorst et al. 2007; EFSA 2008; Hogervorst et al. 2008; Parzefall 2008; Larsson et al. 2009; Wilson et al. 2009; Burley et al. 2010; Hogervorst et al. 2010; Wilson et al. 2010; Pelucchi et al. 2011). The International Agency for Research on Cancer had classified acrylamide as “probably carcinogenic to humans” in 1999 (IARC 1999). The United Nations Joint FAO/WHO Expert Committee on Food Additives also concluded that dietary exposure levels to acrylamide may indicate a human health concern (FAO/WHO 2005; FAO/WHO 2010).

The data on potential health effects of acrylamide may not have been clear, but data identifying the primary sources of dietary acrylamide were in place by mid-decade (FDA 2006a; FDA 2006b). In the US, 38% of dietary acrylamide came from processed potato products; 16% from French fries prepared in restaurants, 12% from oven-baked French fries, and 10% from potato chips (Table 1; DiNovi 2006). Thus, potato products, more than any other food, would be linked to detrimental heath outcomes related to acrylamide consumption if continuing research showed that such outcomes existed.

Acrylamide can be viewed as a food contaminant, but it does not have the characteristics of many food contaminants. Unlike a microbial contaminant, it does not result from lack of sanitation. It is not an acquired chemical impurity like lead, mercury or a pesticide residue. Rather, it is a compound that is formed during the cooking process, and is a by product of the same set of chemical reactions that generate the desirable flavors and golden brown color of fried and roasted potatoes (Fig. 1; Halford et al. 2012; Pedreschi et al. 2014). Those reactions are collectively referred to as the Maillard reaction and they produce a wide range of products during high temperature cooking when reducing sugars react with amino groups, primarily those in free amino acids. When the amino acid is asparagine, a byproduct of the cooking process is trace amounts of acrylamide (Becalski et al. 2004; Weisshaar 2004; Pedreschi et al. 2014). Potato products such as French fries and potato chips contain relatively high amounts of acrylamide because asparagine is an abundant free amino acid in potato tubers, and tuber concentrations of reducing sugars may be relatively high as well (Vinci et al. 2012).

In addition to uncertainty about potential health effects, there was also uncertainty about potential regulatory responses to acrylamide in food. In the US, legal concerns were most prominent in California, because acrylamide was included in the Proposition 65 list of chemicals known to the State of California to cause cancer or reproductive toxicity (OEHHA 2016). The Attorney General of the State of California sued potato chip and French fry manufactures as well as quick service restaurants over the presence of acrylamide in foods. That lawsuit was settled by 2008 (Arrendodo and Weil 2008), but legal concerns remained. Finally, there were concerns about how acrylamide in potato products might influence consumer perceptions about those products. The low carb diet craze had demonstrated unequivocally that a negative image of potato could decrease consumer demand for potato products (Bentley 2004; Huber and Bond 2011). Acrylamide and its associated heath concerns were viewed as potential contributors to negative perceptions about potato products (Huber and Bond 2011).

Acrylamide mitigation measures were evaluated extensively by the potato industry (reviewed in FoodDrinkEurope 2011; Vinci et al. 2012; Bethke and Bussan 2013; Pedreschi et al. 2014; Israilides and Theodoros 2015; FDA 2016). Modifications to processing methods were found to be difficult to implement without changing the product or degrading product quality (FDA 2016). These modifications included increasing the cut size, decreasing cooking temperature, frying under vacuum, extended blanching, and changing soaking or blanching solutions by lowering the pH, and adding cations, non-asparagine amino acids, the enzyme aspariginase, or lactobacillus. Food preparation labels were modified to include guidance on cooking products to a light golden-brown color, which results in less acrylamide formation than longer cooking to a darker color. The industry’s preferred long-term approach, however, was to make changes to raw product quality so that acrylamide reductions could be achieved without altering processing methodology. The merit of this approach was recognized in FDA’s Guidance to Industry (FDA 2016) which states “Development and commercialization of new varieties is a lengthy process, but may ultimately provide the most effective solution for acrylamide reduction”.

The SCRI Acrylamide Project

The SCRI acrylamide project was designed to be a cooperative effort between the US potato industry and researchers in academia and government. Research teams in many cases included potato growers, processors, end users, and representatives of regional potato organizations. Multiple activities depended on evaluating advanced breeding lines developed by public potato breeding programs located across the US.

Four research focus areas were established with the guidance of leadership in the US potato industry. The first was to identify potato varieties that produced products with low acrylamide content and outstanding quality. The second was to develop quantitative targets for sugars and asparagine content in raw tubers of chip and fry processing potatoes. The third was to develop improved methods of potato breeding. The fourth and final goal was to assess the potential economic benefits and risks of using new varieties with low-acrylamide forming potential. A guiding principle for much of this research was that potato varieties with low acrylamide-forming potential must be exceptional in every way if they are to achieve a high rate of market penetration and have an appreciable impact on dietary acrylamide consumption. Some of the research conducted in these four areas is highlighted below.

National Fry Processing Trial

The National Fry Processing trial was a cooperative effort in which potato growers, processors, end users and researchers advanced recently released varieties and advanced breeding clones for consumer attribute testing based on agronomic and acrylamide data. Originally conducted in 2011 with trial sites in Washington, Oregon and Idaho, the NFPT was expanded as part of the SCRI acrylamide project in 2012 to include additional sites in Wisconsin and Maine. Agronomists and food processing experts at frozen process companies, breeders of fry processing clones, and project participants chose approximately 60 advanced breeding lines and recent varieties for evaluation each year. Clones were planted in non-replicated trials at each site, and performance characteristics were compared with industry standard varieties Russet Burbank and Ranger Russet. Genotypes were evaluated using criteria agreed upon by representatives of the frozen process industry and growers during the early phase of the project (Table 2).

Data from the NFPT demonstrated clearly that tuber reducing sugar content was an excellent predictor of acrylamide content in finished French fries (Wang et al. 2016). Across a wide range of tuber glucose contents, from less than 0.1 to over 2 mg per gram fresh weight, acrylamide was linearly related to tuber glucose content (Fig. 2). This relationship had a coefficient of determination (R2) that ranged from 0.64 to 0.77 for tubers approximately 1, 4 and 8 months after harvest. In all cases, the best-fit regression line for acrylamide content as a function of tuber glucose content did not intersect the Y-axis at zero acrylamide. Although most genotypes produced products with less acrylamide than standard varieties Russet Burbank and Ranger Russet, only a few maintained low reducing sugars and low acrylamide though 8 months of storage (Fig. 2b). It is from these few that a replacement for Russet Burbank, the industry standard for frozen processing after long duration storage, might be selected.

Acrylamide content of French fries prepared from NFPT entries and standard varieties Russet Burbank and Ranger Russet after 1 (a) or 8 (b) months of storage at 9 °C. Data from (Wang et al. 2016)

Identifying opportunities for acrylamide reduction through adoption of genotypes with low acrylamide-forming potential was an important goal of the NFPT, but industry partners participating in the project made it clear that for a new variety to be successful, agronomic traits and consumer acceptance traits also had to be as good or better than industry benchmarks. Overall, advanced clones entered into the NFPT compared favorably with industry standards Russet Burbank and Ranger Russet with regard to agronomic performance (Wang et al. 2016). Marketable yield for the majority of clones was as high or higher than Russet Burbank, and many genotypes had marketable yields greater than Ranger Russet as well. Tuber specific gravity was often in the desirable range although, as expected, there were differences between test sites. The distribution of tuber sizes was frequently outside of the desirable range (Wang et al. 2016). This finding was not surprising given that agronomic management was not optimized for each genotype. All varieties were planted with the same seed piece spacing, given the same amount of nutrients, and harvested at the same time.

Under the conditions used for the NFPT trials, most entries produced fries with lower acrylamide contents than standard varieties and several had attractive agronomic performance as well. Few entries, however, produced commercially acceptable French fries. In general, fry color was good and most entries had a low percentage of sugar end defects, but fry texture and taste were often unacceptable. In many cases, finished fries rapidly lost their crispness or were limp when removed from the fryer. Internal texture, which should have the consistency of a slightly dry baked potato, was frequently overly moist, or excessively dry.

NFPT trial samples of Russet Burbank, which for decades has been the standard variety for French fry production in the US, consistently produced unacceptable French fries with poor appearance, texture and taste. This finding highlighted a limitation of variety screening trials like the NFPT. Fry quality can only be assessed accurately after a clone has been grown, stored and processed under optimal conditions. Variety trials, like the NFPT, are not optimized and often underestimate the capacity of a clone to produce acceptable French fries. In the case of Russet Burbank, a variety that is difficult to grow well, the difference between the potential to produce a quality product and the product produced from material grown in the trial was extremely large.

The NFPT demonstrated that multi-site trials are an effective way to rapidly identify high priority clones for more detailed evaluation. Data from all five sites were found to be useful for ranking clones using multiple criteria (Wang et al. 2016). This enabled a higher level of selection efficiency than that achievable with evaluations from a more restricted number of sites. Genotypes that demonstrated outstanding merit in the NFPT were advanced to the SCRI agronomic trial for more in-depth evaluation.

SCRI Agronomic Trial

The SCRI agronomic trial evaluated advanced selections from the NFPT in greater depth. Genotypes were grown in three or four replicated plots during field years 2013, 2014 and 2015 at sites in ID, WA, OR, MN, WI and ME. The larger number of hills planted at each site was required to generate a sufficient volume of harvested material for evaluation, and allowed for more robust statistical comparisons. Key additional evaluations included determination of individual tuber specific gravity distribution and evaluation of tuber sugars and fry quality during postharvest storage at multiple locations. Limited consumer attribute tests were also conducted. Trait stability across environments can be objectively quantified using these data.

Replication within a site and across trial locations rapidly provided agronomic data that could be used to compare the relative performance of each genotype. For example, Easton, tested as AF3001–6 and released as a variety in 2014, was the highest yielding clone at 5 of 6 sites in the 2014 SCRI acrylamide agronomic trial. In that same year, AF4296–3 was the second or third highest yielding clone of the ten planted at 5 of the 6 sites. In the storage trials, as in the NFPT trial, A02507-2LB demonstrated an ability to maintain light fry color during long-term storage. Fries from A02507-2LB grown at four locations (WA,OR, ID, WI) had the lightest or second lightest fry color after 8 mo storage for field year 2013. A02507-2LB was released as the variety Payette Russet in 2015.

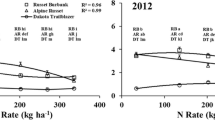

Specific gravity, an indirect measure of tuber dry matter content, is an important processing quality parameter (Wang et al. 2017). Clones with little variation in specific gravity between tubers and within tubers are more likely to succeed as fry processing clones than varieties that produce tubers with greater variation in specific gravity (Sayre et al. 1975). Specific gravity distribution of individual tubers was measured for each clone at each site in the SCRI agronomic trial. It is notable that Russet Burbank consistently had a narrow distribution of specific gravity over all six sites. An example of this is illustrated in Fig. 3 for Russet Burbank grown at Hancock WI in 2015. Payette Russet and Dakota Russet (ND8229–3) also had narrow distributions of specific gravity at many locations, suggesting that they have potential for successful fry processing. Other clones had a wider distribution of specific gravity that would make it difficult to produce a product without some fries being over or under processed (Wang et al. 2017). Data on specific gravity distribution were not collected routinely by US breeding programs or university agronomists prior to the SCRI acrylamide project. Representatives of the fry processing industry emphasized that specific gravity distribution is a key trait, and it is now being measured as part of the ongoing, industry-funded NFPT.

Par-fried samples from SCRI agronomic trial entries were produced at the USDA Sugarbeet and Potato Worksite in East Grand Forks, MN. These were used to produce finished fries by the trial coordinator and evaluated for key consumer attribute traits. The goal of this effort was to determine if some consumer attribute traits related to finished fry quality could be scored reliably by breeding programs as part of a variety trial evaluation. Fries were scored for color variation, sugar end defects, limp units, and internal texture using methods suggested by industry. Preliminary estimates of trait heritability indicate that limp units and color variation can be scored reliably and thus could be used as selection criteria in a breeding program.

Seed Production for Larger Scale Processing Trials

A substantial challenge for the frozen process industry is generating enough raw product volume to conduct evaluations of new varieties in a commercial, frozen-process plant. The minimum volume needed for a commercial trial is in the range of 25–50 t. In an attempt to bring new clones with low acrylamide-forming potential to market rapidly, the SCRI acrylamide program, in consultation with the program Advisory Committee, produced disease-free plantlets of AF4296–3, Dakota Russet, AC96052-1RU and Payette Russet. Plantlets were sent to seed growers for mini-tuber production in 2013 and seed tuber production in 2014. First field year seed were used for the SCRI Agronomic trials and agronomic trials conducted by industry partners. Approximately 4500 kg (100 cwt) of year one seed of Dakota Russet was distributed for commercial trialing in 2015, along with additional seed generated independently by the licensee of that variety. Remaining Payette Russet seed was replanted in 2015 and 11,800 kg (260 cwt) of seed was made available for commercial-scale evaluations by frozen process partners in spring 2016. Seed of AF4296–3 produced from mini-tubers distributed by the SCRI acrylamide project in spring 2014 were also planted for a commercial trial in 2016.

Acrylamide Mitigation Efforts for Chipping Potatoes

The SCRI acrylamide project evaluated chip samples produced in commercial chip plants as part of the chipping potato variety development program coordinated by the Potatoes USA Chip Committee. The key finding revealed by those evaluations was that new chipping potato varieties provide modest opportunities for acrylamide mitigation. This observation is in stark contrast to the findings for fry processing potatoes. This difference between chipping potatoes and fry processing potatoes may be due, in large part, to the difference in reducing sugar contents in tubers from the two market classes. Reducing sugar concentrations in chipping potatoes are often one tenth of those observed in fry processing material, and further reductions in reducing sugars in chipping potatoes may not be achievable. It is worth noting that potato chips and French fries have comparable amounts of acrylamide per gram of product, even when potato chips are made from potatoes having much lower reducing sugar contents. The reason for this is that acrylamide is produced effectively near the surface of both products, but not in the moist center of a French fry, which accounts for a substantial percentage of product weight.

The largest opportunities for near-term reductions in potato chip acrylamide content as a result of improved germplasm may come from providing raw product with greater consistency throughout the year. The advantages of this strategy are illustrated clearly in Fig. 4. This figure presents data on acrylamide content of potato chips collected by the European Snacks Association from 2002 to 2011 (Powers et al. 2013). Potato chip acrylamide content was found to be, on average, lowest for chip samples acquired near the time of harvest, and acrylamide content was higher for chip samples acquired during the late storage period. Thus, chipping potato varieties that maintain low sugars though extended storage times are likely to contribute to acrylamide mitigation efforts. In this regard the goals of the acrylamide project and the Potatoes USA chipping potato trials are in alignment as they seek to identify clones that maintain low reducing sugar contents and excellent product attributes through long-term storage. The potential for long-term, bulk storage of several promising new chipping potato clones was assessed as part of these coordinated programs. One of the first to be evaluated was Lamoka, which demonstrated an ability to maintain low tuber sugar contents and acceptable chip color from September through June, approximately two months longer than industry standard variety Snowden. Adoption of Lamoka by growers and processors has been strong. Wanteta, a sibling of Lamoka with slightly lower specific gravity, was evaluated more recently and also maintained low tuber sugars through late May–June when held in bulk storage.

Seasonality in potato chip acrylamide content from 2002 to 2011. Data were supplied by the European Snack Association and represent 40,455 observations from chips produced in 20 countries. Data points are means ± standard error. Reprinted from Powers et al. (2013)

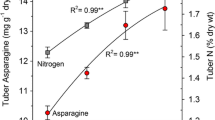

Asparagine is one of the reactants in the formation of acrylamide, and reduction of asparagine in potato tubers using biotechnology reduced the acrylamide content in processed products (Rommens et al. 2008; Chawla et al. 2012; Zhu et al. 2015). This trait was engineered into commercial potato lines using biotechnology and some of these lines were approved for commercial sale in 2014 (Waltz 2015). Asparagine in tubers of these lines was in the range of 2–3 mg per gram dry weight. The potato diversity panel used for the USDA SolCAP project was assayed for tuber asparagine content as part of the SCRI acrylamide project. Asparagine in tubers ranged from 2.5–27 mg per gram dry weight (Fig. 5). Tuber asparagine content for most entries in the diversity panel far exceeded the asparagine content in potato tubers engineered to have low acrylamide as a result of low asparagine. These data indicated that dedicated breeding efforts would be needed to bring tuber asparagine content of conventionally bred potatoes into the range required for acrylamide mitigation, yet the success of this approach was uncertain since potato had never been bred for low tuber asparagine.

Research was initiated at Michigan State University to determine the feasibility of breeding for low asparagine content in chipping potato tubers. Two recently released chipping potato varieties, Kalkaska and Tundra, were crossed and tubers of progeny screened for asparagine content. Although the parents had similar amounts of asparagine in tubers, between 6.5 and 7.5 mg asparagine per gram dry weight, progeny had a much wider range of asparagine content, from 2 to 14 mg per gram dry weight in the first field season. Further research activities in this area are ongoing, but the range of asparagine values observed in progeny suggests that there is sufficient genetic diversity for the trait within elite chipping potato lines for the approach to succeed.

Potato Breeding and Phenotyping Methods

A goal of the SCRI acrylamide project was to develop tools that would accelerate the rate that germplasm with low acrylamide-forming potential is identified and utilized. One aspect of this goal was to identify molecular markers linked to high value traits that breeding programs could use to screen progeny or choose parents. Several bi-parental mapping populations were phenotyped in the field over multiple years. These populations had been genotyped previously with the SolCAP SNP array (Stich et al. 2013). Phenotype and genotype data were used for QTL analysis. Selected individuals from a cross of Premier Russet by Rio Grande Russet were scored for traits related to fry processing quality, low tuber asparagine, and agronomic traits. Progeny from the Kalkaska by Tundra cross were scored for tuber asparagine and chip processing traits. Progeny from a Wauseon by Lenape cross were scored for in field growth characteristics, chip processing traits including chip defects, and resistance to cold-induced sweetening. QTL for many traits have been identified and formal reports on these activities are expected soon.

Although QTL analysis of bi-parental families has been used widely to identify genetic markers linked to specific traits, there are significant challenges associated with using this approach for potato breeding. Perhaps the biggest challenge is the expense, effort and field space need to maintain populations with 100–250 individual potato clones. An alternative approach is to use data from less structured populations, such as those entered into variety evaluation trials. This can be done using genome-wide association studies (GWAS), but computational tools for GWAS were not available for tetraploid potato. Such tools were developed as part of the SCRI acrylamide project. The ability of these computational tools to detect QTL associated with specific traits was demonstrated initially using the SolCAP diversity panel (Rosyara et al. 2016). These tools are being used currently to analyze data from the NFPT and National Chip Processing Trial (NCPT) to look for QTL related to high value traits in elite potato chip and fry processing germplasm.

QTL identified by various approaches can be combined into a genetic trait map that will guide future potato breeding activities. Such a map will allow for informed selection of parental combinations based on the presence and absence of key markers in their genomes. Unlinked markers that are associated with the same trait may encode components in a metabolic pathway. Uncovering the biochemical entities underlying QTL will add to our understanding of potato physiology and genetics, and may suggest opportunities for favorable trait modification. In the end, it will be important to uncover the underlying genetic cause of each QTL. This discovery process, and potentially the utilization of the result, will be aided by highly targeted genetic modification using genome editing and plant transformation.

Stable transformation of elite potato varieties is one way to reduce acrylamide in processed products. In one part of the SCRI acrylamide project, transgenic lines of Russet Burbank with low expression of the vacuolar invertase gene were compared to Russet Burbank standards with respect to the incidence and severity of sugar end defects and the acrylamide content in fried products (Zhu et al. 2014). Invertase silencing using RNAi prevented the formation of sugar end defects, and decreased the acrylamide content of fried strips from an average of approximately 600 μg per kg fresh weight to less than 100 μg per kg fresh weight (Table 3). Similar reductions were observed in transgenic lines of Russet Burbank in which both asparagine synthetase genes and the vacuolar invertase gene were silenced (Zhu et al. 2015). A key finding from this work on fry processing varieties was that silencing of the invertase gene alone reduced acrylamide by about the same amount as silencing the invertase gene and the asparagine synthetase genes.

A separate line of investigation looked at the effect that invertase gene silencing had on the expression of other genes that encode enzymes central to carbohydrate metabolism in potatoes. Transgenic and standard lines of three chipping potato varieties and one fresh market variety were slowly cooled to 3 °C and gene expression during and after cooling quantified by quantitative reverse transcriptase PCR. In these studies, there were no indications that altered tuber sucrose or glucose contents affected gene expression of multiple enzymes involved in sucrose or starch synthesis and breakdown (Wiberley-Bradford et al. 2014; Wiberley-Bradford et al. 2016).

Economic Analysis

The SCRI acrylamide project did not produce transgenic lines for commercial release, however, potatoes produced using biotechnology with the potential to reduce acrylamide in finished products were moving though the deregulation process during the grant period. Research conducted as part of the SCRI acrylamide project determined how much consumers would be willing to pay for low acrylamide products. For this research, consumers were recruited from three regions of the country to participate in experimental auctions (Lacy and Huffman 2016). Willingness to pay for potatoes with low-acrylamide forming potential was found to be strongly influenced by information statements made available to the auction participants. Participants were willing to pay significantly more for biotech potato products with low acrylamide-forming potential after they were given a positive information statement on using biotechnology to reduce potential health concerns related to acrylamide consumption (Lacy and Huffman 2016).

Summary

The SCRI acrylamide project contributed to a wide range of research activities, all of which were focused on enabling the potato industry to respond better to concerns about dietary acrylamide. In addition to these direct befits, there were other indirect benefits, some of which will pay dividends over many years. The SCRI acrylamide project was a framework for extensive, ongoing dialog within the research community and industry at many levels. Project participants worked across regional and corporate barriers to make progress collectively. New relationships developed during the process, and new lines of communication were opened that may have recurrent value in future years. The SCRI acrylamide project also contributed substantially to the training of graduate students and postdoctoral researchers, some of who are likely to make further contributions to US agriculture. Undergraduate students benefited through direct participation in field and laboratory research. Finally, the SCRI acrylamide project demonstrated the value of mounting a coordinated, multifaceted attack on a pressing need of the potato industry. Through the SCRI acrylamide project and other related activities, the potato research community and the potato industry have made impressive progress on mitigation of acrylamide in processed potato products.

References

Arrendodo, A., and E. Weil. 2008. Atty. Gen. Brown Settles Potato Chip Lawsuit With Heinz, Frito-Lay & Kettle Foods. State of California, Department of Justice, Office of the Attorney General. http://oag.ca.gov/news/press-releases/atty-gen-brown-settles-potato-chip-lawsuit-heinz-frito-lay-kettle-foods. Acessed 6/27/16.

Becalski, A., B.P.-Y. Lau, D. Lewis, S.W. Seaman, S. Hayward, M. Sahagian, M. Ramesh, and Y. Leclerc. 2004. Acrylamide in french fries: Influence of free amino acids and sugars. Journal of Agricultural and Food Chemistry 52: 3801–3806.

Bentley, A. 2004. The other Atkins revolution: Atkins and the shifting culture of dieting. Gastronomica 4: 34–45.

Bethke, P.C., and A.J. Bussan. 2013. Acrylamide in processed potato products. American Journal of Potato Research 90: 403–424.

Burley, V.J., D.C. Greenwood, S.J. Hepworth, L.K. Fraser, T.M. de Kok, S.G. van Breda, S.A. Kyrtopoulos, M. Botsivali, J. Kleinjans, P.A. McKinney, and J.E. Cade. 2010. Dietary acrylamide intake and risk of breast cancer in the UK women's cohort. British Journal of Cancer 103: 1749–1754.

Chawla, R., R. Shakya, and C.M. Rommens. 2012. Tuber-specific silencing of asparagine synthetase-1 reduces the acrylamide-forming potential of potatoes grown in the field without affecting tuber shape and yield. Plant Biotechnology Journal 10: 913–924.

Dearfield, K.L., C.O. Abernathy, M.S. Ottley, J.H. Brantner, and P.F. Hayes. 1988. Acrylamide: Its metabolism, developmental and reproductive effects, genotoxicity, and carcinogenicity. Mutation Research 195: 45–77.

DiNovi, M. 2006. The 2006 Exposure Assessment for Acrylamide. FDA. http://www.fda.gov/downloads/Food/FoodborneIllnessContaminants/UCM197239.pdf. Accessed 6/27/16.

Dybing, E., and T. Sanner. 2003. Risk assessment of acrylamide in foods. Toxicological Sciences 75: 7–15.

EFSA. 2008. Acrylamide carcinogenicity. New evidence in relation to dietary exposure. European Food Safety Authority Scientific Colloquium No. 11 - May 2008.

FAO/WHO. 2005. Statement of the scientific panel on contaminants in the food chain to a summary report on acrylamide in food of the 64th meeting of the Joint FAO/WHO Expert Committee on Food Additives. European Food Safety Authority. http://www.efsa.europa.eu/sites/default/files/scientific_output/files/main_documents/619.pdf. Accessed 6/27/16.

FAO/WHO. 2010. Joint FAO/WHO Expert Committee on Food Additives seventy-second meeting. JECFA/72/SC. JECFA. http://www.who.int/foodsafety/chem/summary72_rev.pdf. Accessed 6/27/16.

FDA. 2006a. Survey data on acrylamide in food: Individual food products. US Food and Drug Administration. http://www.fda.gov/Food/FoodborneIllnessContaminants/ChemicalContaminants/ucm053549.htm. Accessed 6/27/16.

FDA. 2006b. Survey Data on Acrylamide in Food: Total Diet Study Results. fda.gov . US Food and Drug Administration. http://www.fda.gov/Food/FoodborneIllnessContaminants/ChemicalContaminants/ucm053566.htm. Accessed 6/27/16.

FDA. 2016. Guidance for Industry: Acrylamide in foods. http://www.fda.gov/Food/GuidanceRegulation/GuidanceDocumentsRegulatoryInformation/ucm374524.htm. Accessed 6/27/16.

FoodDrinkEurope. 2011. Food Drink Europe Acrylamide Toolbox 2011. Food Drink Europe. http://www.fooddrinkeurope.eu/uploads/publications_documents/Toolboxfinal260911.pdf. Accessed 6/27/16.

Garland, T.O., and M.W. Patterson. 1967. Six cases of acrylamide poisoning. British Medical Journal 4: 134–138.

Halford, N.G., T.Y. Curtis, N. Muttucumaru, J. Postles, J.S. Elmore, and D.S. Mottram. 2012. The acrylamide problem: A plant and agronomic science issue. Journal of Experimental Botany 63: 2841–2851.

Hogervorst, J.G., L.J. Schouten, E.J. Konings, R.A. Goldbohm, and P.A. van den Brandt. 2007. A prospective study of dietary acrylamide intake and the risk of endometrial ovarian, and breast cancer. Cancer Epidemiology, Biomarkers & Prevention 16: 2304–2313.

Hogervorst, J.G., L.J. Schouten, E.J. Konings, R.A. Goldbohm, and P.A. van den Brandt. 2008. Dietary acrylamide intake and the risk of renal cell, bladder, and prostate cancer. American Journal of Clinical Nutrition 87: 1428–1438.

Hogervorst, J.G., B.-J. Baars, L.J. Schouten, E.J.M. Konings, R.A. Goldbohm, and P.A. van den Brandt. 2010. The carcinogenicity of dietary acrylamide intake: A comparative discussion of epidemiological and experimental animal research. Critical Reviews in Toxicology 40: 485–512.

Huber, C., and J.K. Bond. 2011. Challenges to stimulating fresh potato consumption : a summary of market research. Agricultural Marketing Report. 11: 1–6. Colorado State University, Dept. of Agricultural and Resource Economics : Extension.

IARC. 1999. Acrylamide. IRAC monographs. 60: 389–433. IARC Monographs on the Evaluation of Carcinogenic Risks to Humans. http://monographs.iarc.fr/ENG/Monographs/vol60/volume60.pdf. Accessed 6/27/16.

Israilides, C., and V. Theodoros. 2015. Strategies to reduce the formation of acrylamide in potato chips: A market and consumer’s prospective. Current Research in Nutrition and Food Science Journal 3: 20–25.

Lacy, K., and W.E. Huffman. 2016. Consumer demand for potato products and willingness-to-pay for low-acrylamide, sulfite-free fresh potatoes and dices: Evidence from lab auctions. Journal of Agricultural and Resource Economics 41: 116–137.

Larsson, S.C., A. Akesson, and A. Wolk. 2009. Long-term dietary acrylamide intake and risk of epithelial ovarian cancer in a prospective cohort of Swedish women. Cancer Epidemiology, Biomarkers & Prevention 18: 994–997.

Mottram, D.S., B.L. Wedzicha, and A.T. Dodson. 2002. Acrylamide is formed in the Maillard reaction. Nature 419: 448–449.

Mucci, L.A. 2005. Acrylamide intake and breast cancer risk in Swedish women. JAMA: The Journal of the American Medical Association. 293: 1326–1327.

Mucci, L.A., P.W. Dickman, G. Steineck, H.O. Adami, and K. Augustsson. 2003. Dietary acrylamide and cancer of the large bowel, kidney, and bladder: Absence of an association in a population-based study in Sweden. British Journal of Cancer 88: 84–89.

Mucci, L.A, P. Lindblad, G. Steineck, and H.-O. Adami. 2004. Dietary acrylamide and risk of renal cell cancer. International Journal of Cancer. Journal International du Cancer 109: 774–776.

OEHHA. 2016. Acrylamide. California Office of Environmental Health Hazard Assessment. http://oehha.ca.gov/proposition-65/chemicals/acrylamide. Accessed 6/27/16.

Parzefall, W. 2008. Minireview on the toxicity of dietary acrylamide. Food and Chemical Toxicology 46: 1360–1364.

Pedreschi, F., M.S. Mariotti, and K. Granby. 2014. Current issues in dietary acrylamide: Formation, mitigation and risk assessment. Journal of the Science of Food and Agriculture 94: 9–20.

Pelucchi, C., S. Franceschi, F. Levi, D. Trichopoulos, C. Bosetti, E. Negri, and C. La Vecchia. 2003. Fried potatoes and human cancer. International Journal of Cancer. Journal International du Cancer 105: 558–560.

Pelucchi, C., C. Galeone, F. Levi, E. Negri, S. Franceschi, R. Talamini, C. Bosetti, A. Giacosa, and C. La Vecchia. 2006. Dietary acrylamide and human cancer. International Journal of Cancer. Journal International du Cancer 118: 467–471.

Pelucchi, C., C. La Vecchia, C. Bosetti, P. Boyle, and P. Boffetta. 2011. Exposure to acrylamide and human cancer-a review and meta-analysis of epidemiologic studies. Annals of Oncology 22: 1487–1499.

Powers, S.J., D.S. Mottram, A. Curtis, and N.G. Halford. 2013. Acrylamide concentrations in potato crisps in Europe from 2002 to 2011. Food Additives and Contaminants Part A. 30: 1493–1500.

Rice, J.M. 2005. The carcinogenicity of acrylamide. Mutation Research 580: 3–20.

Rommens, C.M., H. Yan, K. Swords, C. Richael, and J. Ye. 2008. Low-acrylamide French fries and potato chips. Plant Biotechnology Journal 6: 843–853.

Rosyara, U.R., W.S. De Jong, D.S. Douches, and J.B. Endelman. 2016. Software for genome-wide association studies in autopolyploids and its application to potato. The Plant Genome. Journal 9. https://doi.org/10.3835/plantgenome2015.08.0073.

Sayre, R.N., M. Nonaka, and M.L. Weaver. 1975. French fry quality related to specific gravity and solids content variation among potato strips within the same tuber. American Potato Journal 52: 73–82.

Stadler, R.H., I. Blank, N. Varga, F. Robert, J. Hau, P.A. Guy, M.C. Robert, and S. Riediker. 2002. Acrylamide from Maillard reaction products. Nature 419: 449–450.

Stich, B., C. Urbany, P. Hoffmann, and C. Gebhardt. 2013. Population structure and linkage disequilibrium in diploid and tetraploid potato revealed by genome-wide high-density genotyping using the SolCAP SNP array. Plant Breeding 132: 718–724.

Tareke, E., P. Rydberg, P. Karlsson, S. Eriksson, and M. Tornqvist. 2002. Analysis of acrylamide, a carcinogen formed in heated foodstuffs. Journal of Agricultural and Food Chemistry 50: 4998–5006.

Vainio, H. 2003. Acrylamide in heat-processed foods - a carcinogen looking for human cancer? European Journal of Epidemiology 18: 1105–1106.

Vinci, R.M., F. Mestdagh, and B. de Meulenaer. 2012. Acrylamide formation in fried potato products - present and future, a critical review on mitigation strategies. Food Chemistry 133: 1138–1154.

Waltz, E. 2015. USDA approves next-generation GM potato. Nature Biotechnology 33: 12–13.

Wang, Y., P.C. Bethke, A.J. Bussan, M.T. Glynn, D.G. Holm, F.M. Navarro, R.G. Novy, J.P. Palta, M.J. Pavek, G.A. Porter, V.R. Sathuvalli, A.L. Thompson, P.J. Voglewede, J.L. Whitworth, D.I. Parish, and J.B. Endelman. 2016. Acrylamide-forming potential and agronomic properties of elite US potato germplasm from the National fry Processing Trial. Crop Science 56: 30–39.

Wang, Y., L.B. Snodgrass, P.C. Bethke, A.J. Bussan, D.G. Holm, R.G. Novy, M.J. Pavek, G.A. Porter, C.J. Rosen, V. Sathuvalli, A.L. Thompson, M.T. Thornton, and J.B. Endelman. 2017. Reliability of measurement and genotype x environment interaction for potato specific gravity. Crop Science 57: 1966–1972.

Weisshaar, R. 2004. Acrylamide in heated potato products - analytics and formation routes. European Journal of Lipid Science and Technology 106: 786–792.

Wiberley-Bradford, A.E., J.S. Busse, J. Jiang, and P.C. Bethke. 2014. Sugar metabolism, chip color, invertase activity, and gene expression during long-term cold storage of potato (Solanum tuberosum) tubers from wild-type and vacuolar invertase silencing lines of Katahdin. BMC Research Notes 7: 801.

Wiberley-Bradford, A.E., J.S. Busse, and P.C. Bethke. 2016. Temperature-dependent regulation of sugar metabolism in wild-type and low-invertase transgenic chipping potatoes during and after cooling for low-temperature storage. Postharvest Biology and Technology 115: 60–71.

Wilson, K.M., L.A. Mucci, E. Cho, D.J. Hunter, W.Y. Chen, and W.C. Willett. 2009. Dietary acrylamide intake and risk of premenopausal breast cancer. American Journal of Epidemiology 169: 954–961.

Wilson, K.M., L.A. Mucci, B.A. Rosner, and W.C. Willett. 2010. A prospective study on dietary acrylamide intake and the risk for breast, endometrial, and ovarian cancers. Cancer Epidemiology, Biomarkers & Prevention 19: 2503–2515.

Zhu, X., C. Richael, P. Chamberlain, J.S. Busse, A.J. Bussan, J. Jiang, and P.C. Bethke. 2014. Vacuolar invertase gene silencing in potato (Solanum tuberosum L.) improves processing quality by decreasing the frequency of sugar-end defects. PLoS One 9: e93381.

Zhu, X., H. Gong, Q. He, Z. Zeng, J.S. Busse, W. Jin, P.C. Bethke, and J. Jiang. 2015. Silencing of vacuolar invertase and asparagine synthetase genes and its impact on acrylamide formation of fried potato products. Plant Biotechnology Journal 14: 709–718.

Acknowledgements

Financial support for the SCRI acrylamide project was provided by USDA-NIFA-SCRI Grant No. 2011-51181-30629 (Improved Breeding and Variety Evaluation Methods to Reduce Acrylamide Content and Increase Quality in Processed Potato Products). Special thanks are offered to John Keeling of the National Potato Council and Tim O’Connor (formerly with the US Potato Board) for guidance and encouragement as the project was being developed. Members of the SCRI acrylamide Advisory Committee, agronomists and food processing experts from companies that manufacture potato chips and French fries, representatives of potato growers from across the US, and experts from quick service restaurants contributed to this project through their participation in multiple meetings and conference calls. Their commitment of time, expert advice and constructive feedback was extremely important to this project and is gratefully acknowledged. Special thanks are given to the potato breeders who contributed advanced selections to the NFPT, NCPT, SCRI agronomic trial and other research trials that were key components of the SCRI acrylamide project. We would also like to thank David Parish and Paul Voglewede at AIS Consulting for their assistance in organizing and reporting variety evaluation efforts. Finally, we express our appreciation to Marty Glynn and Darrin Haagenson and the staff at the USDA Sugarbeet and Potato worksite in East Grand forks MN for their essential contribution to the NFPT.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Dedication

We dedicate this manuscript to Marty Glynn on the occasion of his retirement from USDA after 44 years of tireless service to the US potato industry.

Rights and permissions

About this article

Cite this article

Bethke, P.C. Progress and Successes of the Specialty Crop Research Initiative on Acrylamide Reduction in Processed Potato Products. Am. J. Potato Res. 95, 328–337 (2018). https://doi.org/10.1007/s12230-018-9660-2

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12230-018-9660-2