Abstract

In ultrasonic machining (USM), higher amplitude is required for higher material removal rate (MRR). The objective of this research is to develop a new horn design for high displacement amplitude for getting maximum MRR within a working condition. The profile of the horn has been optimized and designed. In this analysis, optimization procedure and finite-element method have been used for the design of horn of USM. In this, the variation of stress components along the length of the horn has been studied. In the middle, maximum stress is found due to a change in cross-section but it is within the endurance limit of the horn material. The cubic Bezier horn as compared with traditional horn is up to 19% more amplified. Finally, an optimized cubic Bezier profile for the horn has been designed, which has maximum displacement amplitude for higher MRR and safe working stresses for the horn material.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

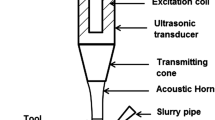

In the field of manufacturing, more and more challenges are faced by the technologist and engineers with the development of technology [1,2,3]. Lot of new engineering materials have been developed, in recent years. These materials have many potential engineering applications. However, because of the high machining cost, application has been limited. A cost-effective advance machining process is required for these materials. Ultrasonic machining (USM) is one of the advanced machining processes. Figure 1 shows the set-up of an ultrasonic machine. The ability of cutting of USM depends initially on the design ability of horn (also known as tool holder or concentrator) [4,5,6,7,8].

In the modal analysis, Seah et al [9] have suggested three methods of simulation for obtaining the frequencies. These results are correlated with experimentally measured frequency. They investigated the design of efficient concentrators for the conventional USM process by employing finite-element analysis (FEA). Because of low stresses generated in the conical horn, they suggested that the chances of failure by the fatigue loading are negligible. If radius of the curvature of the corner is small, because of the stress concentration they also suggested that the stepped horn encounter is dangerous. This stress concentration leads to overheating and formation of cracks. For high amplification application of horns, one should not use the stepped horn. For any significant change in the frequency obtained, they also found that the addition of neither tool nor the hollow tube is important along a longitudinal axis of the horn. Amin et al [10] have suggested a design of concentrators for the conventional USM process by employing the FEA. They have also studied the amplification and the stresses on the horn domain. For obtaining the maximum magnification factor, optimization procedure is followed. After the safe working stresses for getting a higher material removal rate (MRR), the concentrator material study has been elaborated. They also show that the concentrator profile should be cylindrical in shape at the lower (tool) end and conical shape at the upper (transducer) end. Yadava and Deoghare [11] have analysed by employing the finite-element method (FEM) and the design of concentrators (horns) for the rotary ultrasonic machine within working condition of the conventional ultrasonic machine. They also show that for the same boundary conditions and material properties the amplification factor is more for the rotary ultrasonic machine as compared with the conventional ultrasonic machine. They also show that the stresses obtained for the other conditions are more than the stress obtained for the resonance. Rosca et al [12] suggested the design of ultrasonic horn, which is useful in manufacturing process for USM. On the workpiece, high-amplitude waves are injected. To establish the frequency at which optimal wave transmission occurs, the dimensions of both the ultrasound transducer and tool are important. In this paper, the optimal design of horn has been obtained. These parameters vary in an integrated set-up as required. Thoe et al [13] suggest that the machining rate is maximum for the optimum static load and dependent on tool configuration (e.g. shape and area of cross-section), mean grit size and amplitude. The rotary ultrasonic machine performance over conventional ultrasonic machine may be explained by the combined effects of rolling contact between the embedded grains on the workpiece/tool, sliding contact between free abrasive grains/workpiece and indentation of workpiece surface. To maximize the MRR and for a resonant USM system, the tool and horn design play an important role. Wang et al [14] have suggested the new horn design for high amplification at the lower end of horn. A design procedure using multi-objective optimization algorithm and FEM has been utilized for optimizing the displacement amplitude of the horn. Comparison of experimentally measured working frequency between the fabricated and designed horn validates the results. Jagadish and Ray [15] have suggested the stepped rectangular horn by the FEM. In this study, the horn material is taken as a titanium alloy. For finding the amplitude of vibration, stress components and natural frequency over the horn domain, the FEA has been used.

From this literature review, to get low value of stresses, maximum amplitude of vibration and the resonance condition, some shaping of horn design has been done. During the process, it is observed that designing of concentrator for ultrasonic machine has been done for the exponential, cylindrical and stepped shapes. This work has been done theoretically and experimentally using a conventional ultrasonic machine for finding the MRR. The literature review shows that for the conventional ultrasonic machine design of horn of various Bezier profiles, optimization has not been done by employing the FEM. In this paper, the main aim is to design the horn with optimized Bezier profile for the conventional USM within the working condition. In this paper, FEM-based analysis has been done to find the stress components, resonance frequency and axial amplitude over the domain for the USM using optimized Bezier profile. All results are validated with the results available in the literature.

2 Horn design

The design of horn with Bezier profile for high amplification is based on optimization procedure. The control points of cubic Bezier curve profile are optimized by parameters to meet the requirement of higher displacement amplitude. The curve of cubic Bezier horn is determined by four-point Bezier polygene L0–L3 as shown in figure 2. As described by Zeid [16], the last and first points, L3 and L0, respectively, define the polygon for cubic Bezier profile curve. At the end and the beginning of the curve, the tangent vector has the same direction as the last and first polygons span, respectively. The cubic Bezier parametric curve is given by Eq. (1) [16]:

where u is a parameter and PLi is position vector of point Li.

Points L1 and L2 are optimized for cubic Bezier to move in the design space enclosed by the dashed rectangle in figure 2. Positions of cubic Bezier points L0 and L3 are fixed, respectively, by the specified front and back horn radius R1 and R2. The horn is assumed to be axisymmetric. An optimality procedure is developed and the flowchart is shown in figure 3. The non-dominated sorting genetic algorithm (NDSGA) [17] is applied for solving constraints. In each generation of genetic algorithm (GA) [18] the following are performed:

where f0 is the first axial modal frequency of the population of each generation of the horn. M is the amplification defined by the ratio of axial displacement at lower end to upper end of the horn. To solve the two objective optimization problems the fast non-dominated sorting approach [17] is used. In the sorting procedure, the concept of Pareto dominance [19] is utilized to evaluate fitness or assigning selection probability to the solution. Table 1 shows the merits and demerits of several commonly used horn profiles.

3 Analysis

3.1 FEA

Analysis has been done using the ANSYS software, which is flexible and the most powerful tool available for the FEM-based analysis. It is known very well that the FEM analysis is a suitable method for the amplitude, equivalent stress and resonance frequency of the USM horn of any dimensions. In the FEM, the major use of modelling a general structural simulation includes the geometry, meshing, boundary conditions, element type, real constants and material properties [20,21,22]. The analysis may begin, after these factors have been given. These factors are used for modal and harmonic analysis. The USM horn is manufactured from steel AISI (4063) with the material properties presented in table 2.

3.2 Modal analysis

Modal analysis allows the design to vibrate at a specified frequency or at resonance. For other dynamic analyses, it helps in calculation of solutions because structure vibration characteristics determine different types of dynamic load and responses. Always perform a modal analysis first. Modal analysis is a linear analysis [23, 24]. In the modal analysis, several number of modes are available. Several numbers of modes are shown in figure 4 at different resonance frequencies.

3.3 Harmonic analysis

Harmonic analysis is the technique to find a steady-state response of the cubic Bezier horn to harmonic load of known frequency, where input sinusoidal loads are the forces. To solve the sinusoidal equation of motion, however, in this case, full method is used for the present ultrasonic Bezier horn.

3.4 Mesh generation

According to the basic principle of the FEM theory, if the mesh element size is reduced, the accuracy of result will improve. If the size of the mesh element is very small, the model will approach the optimum solution.

3.5 Boundary condition

Steel AISI (4063) is selected as the USM horn material. The properties of the material are available in table 2. Boundary condition is applied at the end of the transducer. The output of the piezoelectric transducer has been applied as the input (15-µm amplitude) at the large end of cubic Bezier horn [23,24,25,26,27].

4 Results and discussion

In this work, for calculation of the stress components, displacement and natural frequency, ANSYS is used. For meshing the horn domain, ANSYS APDL is used as a pre-processor. The output of ANSYS software is the co-ordinates of the nodes and connectivity of the elements, and these data have been used as the input. For presenting the results in the graphical form, MS ORIGIN software is used. The results are validated with those of Amin et al [10]. Later, the stresses, displacement and natural frequency are calculated for the cubic Bezier horn.

4.1 Model validation

The present FEM model has been validated by comparing the result of Amin et al [10] for displacement and stresses by taking all conditions to be the same as given in Ref. [10]. The domain is axisymmetric about Z-axis as shown in figure 5. The initial displacement of 15 µm has been given on top end DC. The problem has been solved using FEM by considering all the given boundary conditions. The axial displacement along the axis is calculated and compared with the result given in Ref. [10] as shown in figure 6. The nature of variation of the curve is similar to that in Ref. [10]. The average error in this comparison is 2.4% for the cubic Bezier horn. The magnification factor and stress obtained from present FEM model of cubic Bezier horn and corresponding value by literature [10] are very close. The corresponding error is 5.5%, which shows the accuracy of present FEM model.

4.2 Effect of stresses along the horn axis

The magnification factor is maximum for the cubic Bezier horn and the corresponding value is 7.34. Figure 7 shows the minimum circumferential stress for the cubic Bezier horn. The variation of the circumferential stress is similar to that of Amin et al [10]. Figure 8 shows the variation of the axial stress; the value of axial stress is minimum for the optimized cubic Bezier horn, the stress is within the allowable endurance limit and the horn is safe. Also, the maximum axial stress variation along the axial length of the horn is larger in comparison with circumferential stress variation. Figure 9 shows radial stress variation along axial length of the horn and the stress variation is lower in comparison with axial stress variation. Figure 9 shows that the radial stress is minimum for the cubic Bezier horn and maximum for the literature result and also the result is validated by Amin et al [10]. Optimized cubic Bezier horn is safe within the horn domain. Figure 10 shows shear stress variation along axial length of horn. Value of shear stress is minimum for the cubic Bezier horn and the horn is safe. Due to the low value of shear stress, there is no distortion within the horn and also in figure 10 the variation of the shear stress is similar to that of Amin et al [10]. Figure 11 shows equivalent stress variation along the length of horn and literature stress variation is maximum as compared with the present cubic Bezier horn. The maximum value of equivalent stress is for the cubic Bezier horn; its value is 155.31 MPa and it is much lower than the allowable endurance limit. The stress generated over the domain of the horn is within the allowable endurance limit of the material, so the designed cubic Bezier horn is safe.

4.3 Experimental verification

Experimental verification has been done by figure 12. For comparison, the input parameter has been taken to be the same as that of Wang et al [14]. It is found that the present Bezier horn has 55.5% more amplitude as compared with Wang et al [14]. Figure 12 shows a trend of the present result similar to that given in the literature [14] and the magnification factor has been found to be more in the present Bezier horn. Through the experimental investigation, researchers have found that for high amplification the MRR is high as given in Rozenberg et al [1]. In the present work, amplification has been found to be more so the MRR would be high for the Bezier horn profile. Table 3 shows the ease/complexity in manufacture aspects of several commonly used horns profile.

5 Conclusions

In this present work, the optimized design of cubic Bezier profile horn for USM by the FEM have been considered. The stress components, natural frequency and magnification factor induced within the domain of optimized cubic Bezier profile horn have been calculated.

-

1.

FEM and multiobjective optimization algorithm are developed to optimizing the displacement amplification of the cubic Bezier profile horn.

-

2.

Value of the natural frequency of cubic Bezier horn is 23.6 kHz. For the same boundary conditions and material properties, the amplitude is more for the optimized cubic Bezier horn as compared with the result from literature.

-

3.

The maximum equivalent stress for optimized cubic Bezier horn is 155.71 MPa at the middle of horn towards lower end.

-

4.

The maximum equivalent stress is lower than the allowable endurance strength (520 MPa). Optimized cubic Bezier shape of the horn has not failed by yielding or by fatigue.

-

5.

At the lower end of the horn, stresses generated are almost zero because it is free to move. The induced shear stress is almost zero, so there is no distortion taking place within the horn and also stresses are linear in radial direction.

-

6.

It is concluded that the present Bezier horn has obtained 55.5% more amplitude as compared with experimental horn in literature.

References

Rozenberg L D, Kazantsev V F, Makarov L O and Yakhimovich D F 1964 Ultrasonic cutting. New York: Consultants Bureau

Roy S and Jagadish 2017 Design of a circular hollow ultrasonic horn for USM using finite element analysis. Int. J. Adv. Manuf. Technol. 93: 319–328

Jain V K 2002 Advanced machining processes. New Delhi (India): Allied

Ghosh A and Mallik A K 1985 Manufacturing science. New Delhi (India): EWP Pvt. Ltd.

Pandey C P and Shah H S 2003 Modern machining processes. New Delhi (India): TMH

Mishra P K 1997 Nonconventional machining. New Delhi (India): Narosa Book Distributors Pvt. Ltd.

Choi Y J, Park K H, Hong Y H, Kim K T, Lee S W and Choi H Z 2013 Effect of ultrasonic vibration in grinding; horn design and experiment. Int. J. Precis. Eng. Manuf. 14: 1873–1879

Jung W, Ra J and Park K 2012 Design optimization of ultrasonic horn for micro-pattern replication. Int. J. Precis. Eng. Manuf. 13: 2195–2201

Seah K H W, Wong Y S and Lee L C 1993 Design of tool holders for ultrasonic machining using FEM. J. Mater. Process. Technol. 37: 801–816

Amin S G, Ahmed M H M and Youssef H A 1995 Computer-aided design of acoustic horns for ultrasonic machining using finite-element analysis. J. Mater. Process. Technol. 55: 254–260

Yadava V and Deoghare A 2008 Design of horn for rotary ultrasonic machining using the finite element method. Int. J. Adv. Manuf. Technol. 39: 9–20

Rosca I C, Pop M I and Cretu N 2015 Experimental and numerical study on an ultrasonic horn with shape designed with an optimization algorithm. Appl. Acoust. 95: 60–69

Thoe T B, Aspinwall D K and Wise M L H 1998 Review on ultrasonic machining. Int. J. Mach. Tool. Manuf. 38: 239–255

Wang D A, Chuang W Y, Hsu K and Pham H T 2011 Design of a Bézier-profile horn for high displacement amplification. Ultrasonics 51: 148–156

Jagadish and Ray A 2018 Design and performance analysis of ultrasonic horn with a longitudinally changing rectangular cross section for USM using finite element analysis. J. Braz. Soc. Mech. Sci. Eng. 40: 1–11

Zeid I 1998 CAD/CAM theory and practice. New Delhi (India): Tata McGraw-Hill Edition

Deb K, Pratap A, Agarwal S and Meyarrivan T 2002 A fast and elitist multiobjective genetic algorithm NSGA-II. IEEE Trans. Evol. Comput. 6:182-197

Anand K and Elangovan S 2019 Modelling and multi-objective optimization of ultrasonic inserting parameters through fuzzy logic and genetic algorithm. J. Braz. Soc. Mech. Sci. Eng. 41: 1–20

Goldberg D E 1989 Genetic algorithms in search, optimization and machine learning. MA: Addison Wesley Publishing Company

Reddy J N 2005 An introduction to finite element method. New Delhi (India): Tata McGraw-Hill Edition

Kwon Y W and Bang H 2000 The finite element method using MATLAB. USA: CRC Press

Belegundu A D and Chandrupatla R T 2008 Introduction to finite elements in engineering. India: PHI

He T, Ye X Q and Zhao Y 2015 Optimization design for ultrasonic horn with large amplitude based on genetic algorithm. J. Vibroeng. 17: 1157–1168

Naseri R, Koohkan K, Ebrahimi M, Djavanroodi F and Ahmadian H 2017 Horn design for ultrasonic vibration-aided equal channel angular pressing. Int. J. Adv. Manuf. Technol. 90: 1727–1734

Timoshenko P S, Weaver W and Young D H 1990 Vibration problems in engineering. Singapore: Wiley

Timoshenko S P and Goodier J N 1970 Theory of elasticity. Singapore: International edition

Kumar V and Singh H 2018 Machining optimization in rotary ultrasonic drilling of BK-7 through response surface methodology using desirability approach. J. Braz. Soc. Mech. Sci. Eng. 40: 1–14

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rai, P.K., Yadava, V. & Patel, R.K. Design optimization of cubic Bezier horn for ultrasonic machining. Sādhanā 45, 85 (2020). https://doi.org/10.1007/s12046-020-1321-8

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12046-020-1321-8