Abstract

The characterization of bacteria with hydrolytic potential significantly contributes to the industries. Six cellulose-degrading bacteria were isolated from mixture soil samples collected at Kingfisher Lake and the University of Manitoba campus by Congo red method using carboxymethyl cellulose agar medium and identified as Paenarthrobacter sp. MKAL1, Hymenobacter sp. MKAL2, Mycobacterium sp. MKAL3, Stenotrophomonas sp. MKAL4, Chryseobacterium sp. MKAL5, and Bacillus sp. MKAL6. Their cellulase production was optimized by controlling different environmental and nutritional factors such as pH, temperature, incubation period, substrate concentration, nitrogen, and carbon sources using the dinitrosalicylic acid and response surface methods. Except for Paenarthrobacter sp. MKAL1, all strains are motile. Only Bacillus sp. MKAL6 was non-salt-tolerant and showed gelatinase activity. Sucrose enhanced higher cellulase activity of 78.87 ± 4.71 to 190.30 ± 6.42 U/mL in these strains at their optimum pH (5–6) and temperature (35–40 °C). The molecular weights of these cellulases were about 25 kDa. These bacterial strains could be promising biocatalysts for converting cellulose into glucose for industrial purposes.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

In the past, humans used cellulosic materials as fertilizers, fodder, and firewood. Nowadays, it has become a cost-effective raw material and its industrial applications have become more complex. These applications have created a vast platform based on cellulose research in multidisciplinary projects. Cellulose hydrolysis is one of the approaches catalyzed by cellulases. Cellulose is a linear polymer made up of D-glucopyranose units linked by β-(1–4) glycosidic linkage and constitutes practically inexhaustible carbon and renewable energy resource [1]. Cellulose offers the best prospects for reducing the production costs of many products due to its abundance and potentially lower price than other substrates, despite the complexity of the transformation processes [2]. It constitutes a significant challenge in research, particularly in the field of bioproducts, biofuels, and chemicals. Cellulose (crystalline and amorphous) forms with hemicellulose and lignin, a water-insoluble compact network structure that limits its degradation [3]. Therefore, pretreatment (physical, chemical, and biological) is required to facilitate fermentable sugar release. Biological pretreatment (enzymes and cellulolytic microorganisms) remains the best approach to address this issue because it is eco-friendly [4].

Cellulase is a whole enzyme system composed of endoglucanase and exoglucanases including cellobiohydrolases and β-glucosidase [5], which breaks down β-1,4-linkages in cellulose polymer to release glucose units. Many investigators have reported that aerobic and anaerobic bacteria [6,7,8,9], fungi, and actinomycetes [6, 10, 11] are good cellulase enzyme producers. These microbes secrete free or cell surface-bound cellulases and exhibit an efficient enzyme decomposition. Among different types of microbes, bacteria are the most efficient cellulose degraders because they grow fast and have high cellulase synergistic activity [12]. Cellulases are very successful in the industrial exploitation of the degradation of lignocellulosic biomass. Cellulases have a wide range of applications in several sectors such as chemicals, food and feed, pulp and paper, textiles, beverages, automobiles, electronics, and, most importantly, energy [13, 14].

Recent data shows that the market demand for cellulase is 29.71% in animal feed, 26.37% in food and beverages, and 13.77% in the textile industry [15]. Also, cellulase applications are drastically rising annually. They will reach 2300 million USD by the end of 2025, with a 5.5% of annual growth rate for the 2018–2025 period according to the Global Cellulase (CAS 9012–54-8) market growth 2021–2026 report [16]. However, few cellulases perform well on an industrial scale, and their production cost remains very high. Therefore, it is essential to search for new cellulases with interesting properties from an industrial point of view. In recent years, much work has been devoted to selecting cellulolytic microorganisms, genetic mutations for obtaining hyperproductive strains, and the culture conditions of the microorganisms involved [17]. Their cellulase yields depend on a combination of various factors such as pH, temperature, inoculum size, cellulose type, aeration, incubation time, and inducers [18]. In the present study, we have characterized six cellulose-degrading bacteria isolated from the soil samples collected at Kingfisher Lake (Thunder Bay, Canada) and the University of Manitoba campus (Winnipeg, Canada). The culture conditions for these bacterial strains were optimized to achieve maximum cellulase production.

Materials and Methods

Culture Media

Different culture media were used for bacterial growth and cellulase production. These culture media include (a) Reasoner’s 2A (R2A) agar, (b) Luria–Bertani (LB) broth, (c) carboxymethyl cellulose (CMC) agar, and (d) CMC broth. Their compositions were as follows:

-

a)

R2A agar: 0.5 g yeast extract, 0.5 g peptone, 0.5 g starch, 0.5 g MgSO4, 0.5 g casein hydrolysate, 0.5 g glucose, 0.3 g K2HPO4, 15 g agar, and distilled water up to 1 L

-

b)

LB broth: 10 g peptone, 5 g yeast extract, 5 g NaCl, and distilled water up to 1 L

-

c)

CMC agar: 5 g CMC, 1 g NaNO3, 1 g K2HPO4, 1 g KCl, 0.5 g MgSO4, 0.5 g yeast extract, 15 g agar, and distilled water up to 1 L

-

d)

CMC broth: 5 g CMC, 1 g NaNO3, 1 g K2HPO4, 1 g KCl, 0.5 g MgSO4, 0.5 g yeast extract, and distilled water up to 1 L

Screening of Cellulose-Degrading Bacteria

The soil samples were collected from Kingfisher Lake and the University of Manitoba campus. The topsoil was dug by a sterile spatula, kept in a clean zip lock bag, and transported to the laboratory. The samples were mixed for bacterial isolation by dilution method [19]. The samples (0.5 g) were suspended in distilled water (50 mL) by vortexing for 2 min. A 10 × dilution series was made and each dilution (5 μL) was plated onto R2A agar. All plates were incubated for 72 h at 28 °C. Based on their morphological features (size, shape, and color), forty-one bacterial colonies were selected. These colonies were streaked out in R2A agar Petri dishes. After incubation at 30 °C for 48 h, these colonies were screened for their ability to produce cellulase using Congo red method [20]. For this purpose, the isolates (bacterial colonies, negative and positive controls) were grown in LB broth (10 mL) for 24-h shaking at 30 °C. Bacillus sp. IM7 and Escherichia coli JM109 from Dr. Qin’s lab were used as positive and negative controls respectively. All broth cultures (5 μL) were singly dropped onto CMC agar plates and then incubated at 30 °C for 48 h. After incubation, plates were stained with aqueous Congo red solution (0.1% w/v) as an indicator to visualize the cellulase activity. The appearance of a clear halo around the isolate confirms cellulase activity by the isolate. Halo diameters were measured using a ruler for a semi-qualitative comparison of cellulase activity among isolates. Plates were photographed, and six cellulose-degrading bacterial isolates (CDBs) were selected and stored for subsequent uses (Fig. 1). These bacteria were identified as Paenarthrobacter sp. MKAL1, Hymenobacter sp. MKAL2, Mycobacterium sp. MKAL3, Stenotrophomonas sp. MKAL4, Chryseobacterium sp. MKAL5, and Bacillus sp. MKAL6 with the NCBI accession numbers ON442553, ON442554, ON442555, ON442556, ON442557, and ON442558 respectively [21].

Characterization of Cellulose-Degrading Bacteria

Morphological and Biochemical Characterization

CDBs were differentiated based on mobility, cell wall composition (Gram stain), vegetative cells and endospores (endospore stain), carbon source utilization, and enzymatic activities by standard methods such as catalase production, gas production, starch hydrolysis, gelatin hydrolysis, DNA hydrolysis, urease test, bile esculin test, oxidase test, nitrate reduction, salt tolerance, and sugar fermentation [22].

Quantification of Cellulase Activity

Quantitative cellulase activities of CDBs were determined by measuring the release of reducing sugars from CMC using the 3,5-dinitrosalicylic acid (DNS) method [5]. CDBs were grown in 5 mL of LB broth (24 h, 30 °C, and 200 rpm). Five hundred microliters of each cultured isolate was centrifuged at 12,000 × g for 5 min and the cells were suspended in 0.05 M citrate buffer (pH 6). These bacterial samples were inoculated separately into a 250-mL Erlenmeyer flask containing CMC broth (50 mL, 1% CMC) prepared with citrate buffer (0.05 M, pH 6). Then, the flasks were incubated at 35 °C and 200 rpm for 5 days. Cellulase assay was performed using the cell-free culture supernatant as an extracellular crude enzyme. Each crude enzyme was obtained by centrifugation of 500 µL of culture at 12,000 × g for 5 min. The reaction mixture containing crude enzyme (10 μL), 0.05 M citrate buffer pH 6 (20 μL), and 1% CMC (20 μL) was transferred into a 1-mL microcentrifuge tube and incubated in the water bath at 50 °C for 15 min. The DNS solution (60 μL) was added to the reaction mixture and the tube was heated for 5 min to stop the reaction. The release of reducing sugars in reaction mixture was estimated using glucose (1.1–2 mg/mL) as a standard for the calibration curve (y = 0.6419x − 0.1021; r2 = 0.9975). Every 24 h for 120 h, reaction mixture and bacterial growth were respectively measured at 540 and 600 nm by using a microplate reader spectrophotometer (BioTek, USA). The bacterial growth was expressed in terms of biomass, whereas the cellulase activity was measured in U/mL (one unit of cellulase enzyme corresponds to the release of 1 μM of reducing sugar equivalent per minute from CMC) [23].

Optimization of Cellulase Production

Cellulase production was optimized by varying some parameters such as incubation time, pH, temperature, CMC concentration, salts, surfactants, carbon, and nitrogen sources. CDBs were grown in LB broth (24 h, 30 °C, and 200 rpm). The culture medium was inoculated and incubated for 5 days and the cellulase amount produced was determined from supernatant using DNS method [5].

Effect of Temperature and Incubation Period on Cellulase Production

The CMC broth (50 mL) containing overnight cultured bacterial strain (500 µL) was incubated in a shaking incubator (200 rpm) at 30, 35, 40, 45, and 50 °C for 5 days. The effect of temperature and incubation time on enzyme production was quantified by collecting culture solution (500 µL) every day.

Effect of pH on Cellulase Production

The CMC broth (50 mL) containing overnight cultured bacterial strain (500 µL) was incubated in a shaking incubator (200 rpm) in the pH ranges from 4 to 9. The effect of pH on enzyme production was investigated at the optimum temperature of each bacterial isolate.

Effect of CMC Concentration on Cellulase Production

Bacterial strain was inoculated in the culture medium with CMC (0.5–2.5% w/v) at optimum pH and temperature and shaking at 200 rpm for 120 h.

Effect of Carbon Sources on Cellulase Production

The effect of carbon sources on enzyme production was performed by replacing CMC with other carbon sources such as pure cellulose, cellulose acetate, poly(ethylene terephthalate) (PET), D-sucrose, D-glucose, D-fructose, D-sorbitol, D-mannitol, and D-xylose. Bacterial strain was inoculated with a carbon source (0.5–2.5% w/v) in the production medium at the optimum temperature and pH and shaking at 200 rpm for 120 h.

Effect of Nitrogen Sources on Cellulase Production

Effect of various nitrogen sources such as yeast extract, malt extract, tryptone, casein hydrolysate, peptone, urea, ammonium chloride (NH4Cl), ammonium sulfate ((NH4)2SO4), and ammonium nitrate (NH4NO3) was examined. Bacterial strain was inoculated with a nitrogen source (0.05–2% w/v) in the culture medium at the optimum temperature and pH and shaking at 200 rpm for 120 h.

Effect of Salts on Cellulase Production

The influence of salt supplementation was investigated by adding various salts such as potassium chloride, sodium chloride, calcium chloride, aluminum chloride, magnesium chloride, manganese chloride, cobalt chloride, nickel chloride, zinc chloride, chromium (III) chloride, lead chloride, and barium chloride. Bacterial strain was inoculated with salt (0.5–5 mM) in the production medium at the optimum temperature and pH and shaking at 200 rpm for 120 h.

Effect of Surfactants and EDTA on Cellulase Production

Effect of surfactant supplementation was performed by adding different surfactants such as tween 20, sodium dodecyl sulfate (SDS), triton X-100 (0.1–2.5% w/v), and a chelating agent, ethylenediaminetetraacetic acid (EDTA, 0.5–2.5 mM). The bacterial strain was inoculated with surfactant in the culture medium at the optimum temperature and pH and shaking at 200 rpm for 120 h.

Optimization of Cellulase Production Using Response Surface Methodology (RSM)

Response surface methodology (RSM) was used to optimize the fermentation conditions to produce cellulase. The experiment was performed by Box–Behnken design (BBD) using the SYSTAT 12 software (SYSTAT Software Inc., San Jose, USA). The temperature (X1), initial pH (X2), and fermentation period (X3) were determined as independent variables based on the results of the preliminary single-factor experiments. Cellulase activity was used as a response value. The ranges and levels of these independent variables are presented in Table 2. BBD was used to generate the second-order response surface. The F test at the 0.05 significance level, coefficient of determination (R2), and the lack of fit were used to measure the goodness of fit of the second-order polynomial model. The fitted contour plots were obtained with the response surface methods-contour/surface program in SYSTAT 12 software.

SDS–Polyacrylamide Gel Electrophoresis and Zymogram

The cellulase molecular weights were determined by sodium dodecyl sulfate–polyacrylamide gel electrophoresis (SDS-PAGE) analysis. The crude enzymes from CDBs (20 µL) were mixed with loading buffer (5 µL) and boiled (100 °C) before electrophoresis. Enzyme samples and protein ladder were run in 15% acrylamide gel. A constant supply of 120 V was maintained throughout the experiment. After gel running, the gel was divided into two parts. One part was stained overnight in Coomassie Brilliant Blue R-250, and then de-stained with a de-stain solution. Protein bands present in the gel were compared with the protein ladder (BioRad, Canada) to estimate their molecular weights. Another part of the gel was soaked in Triton X-100 (1% v/v) for 30 min to remove SDS and allow activity. Then, the gel was submerged in Congo red solution (0.1% w/v) for 30 min and de-stained with NaCl solution (1 M) until the halos appeared. The reaction was stopped by dipping the gel in acetic acid solution (4% v/v).

Results

Morphological and Biochemical Characterization

Among forty-one bacterial isolates, only six were selected based on the appearance of a clear halo around confirming cellulase production by these bacteria. Morphological and biochemical characteristics of CDBs are presented in Table 1. Different shapes were observed among these strains. MKAL1 and MKAL3 are circular-shaped while MKAL2, MKAL4, MKAL5, and MKAL6 are rod-shaped. Strains MKAL2, MKAL4, and MKAL5 are negative Gram bacteria. MKAL1, MKAL3, and MKAL6 are positive Gram bacteria. MKAL1 and MKAL4 are pale colored, while MKAL2, MKAL3, MKAL5, and MKAL6 are red, white, yellow, and creamy colored respectively. All strains are non-endospore-forming bacteria. Except for MKAL1, all tested strains are motile. All strains did not produce indole, hydrogen sulfide, gas, phenylalanine deaminase, citrate permease, lysine decarboxylase, and lysine deaminase. Except for MKAL3, all strains produced catalase and α-amylase and hydrolyzed malonate, DNA, and esculin. Only MKAL6 was non-salt-tolerant and showed a gelatinase activity. All strains degraded most sugars tested.

Effect of Temperature and Incubation Period on Cellulase Production

The effect of different temperatures was evaluated on the enzymatic activity and growth rate of isolates. Bacterial isolates were separately cultured in 250-mL conical flasks containing CMC broth (50 mL) for 5 days at 30, 35, 40, 45, and 50 °C. The results are presented in Fig. 2. All strains did not produce cellulase at 50 °C and no cell growth was observed at this temperature. MKAL3 showed cellulase activity only at 35 °C. Strains MKAL1, MKAL4, MKAL5, and MKAL6 exhibited maximum activity at 35 °C while the optimum temperature of MKAL2 for cellulase production occurred at 40 °C. The cell growth of isolates increased until the optimum temperatures and then declined. All strains exerted optimum cellulase production after 96 h of incubation (Fig. 3).

Effect of pH on Cellulase Production

The effect of pH on cellulase production and bacterial growth was studied by adjusting the pH of the culture medium between 4 and 9. No cellulase activity and cell growth of strains were observed at pH 4 (Fig. 4). Only MKAL2 and MKAL6 produced cellulase at pH 5. MKAL3 exhibited cellulase activity only at pH 6. The optimum pH of MKAL6 for cellulase production was 5, while MKAL1, MKAL2, MKAL3, MKAL4, and MKAL5 showed maximum activity at pH 6.

Effect of CMC Concentration on Cellulase Production

The effects of CMC concentration on cell growth and cellulase production are presented in Fig. 5. No cellulase production was observed at 0.5% CMC. However, isolates showed cellulase activity at a range of CMC concentrations from 1 to 2.5% except for MKAL3 which exerted cellulase activity only at 1% CMC (9.66 ± 0.75 U/mL). MKAL1 (13.22 ± 0.53 U/mL) and MKAL5 (11.51 ± 0.95 U/mL) showed optimum cellulase production at 1.5% CMC, while MKAL2 (16.50 ± 1.36 U/mL), MKAL4 (10.93 ± 0.83 U/mL), and MKAL6 (18.06 ± 1.30 U/mL) exhibited maximum activity at 2% CMC.

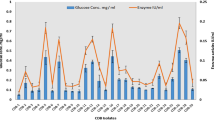

Effect of Carbon Sources on Cellulase Production

The effect of carbon sources on enzyme production was determined by replacing CMC in the culture medium with various carbon sources (0–2.5%). All tested carbon sources boosted cellulase production at different concentrations except for pure cellulose, cellulose acetate, and PET (Fig. 6, Table S1). Some carbohydrates enhanced cellulase production by strains compared to CMC (9.66 ± 0.75 to 18.06 ± 1.30 U/mL). MKAL1 exhibited maximum activity at 1% sucrose (158.27 ± 10.48 U/mL), 1.5% fructose (21.16 ± 8.08 U/mL), 1.5% xylose (25.56 ± 9.51 U/mL), 2% sorbitol (33.34 ± 10.98 U/mL), and 2% mannitol (44.22 ± 7.13 U/mL). MKAL2 showed higher activity at 1.5% sorbitol (34.01 ± 4.01 U/mL), 2% sucrose (78.87 ± 4.71 U/mL), 2% mannitol (40.20 ± 4.72 U/mL), and 2% xylose (26.57 ± 5.47 U/mL). MKAL3 exhibited maximum activity at 1.5% sucrose (100.82 ± 8.93 U/mL), 1.5% glucose (15.40 ± 4.62 U/mL), 1.5% mannitol (39.72 ± 6.66 U/mL), and 2% sorbitol (44.01 ± 7.06 U/mL). MKAL4 showed higher activity at 2% of sucrose (190.30 ± 6.42 U/mL), fructose (39.44 ± 5.96 U/mL), sorbitol (56.96 ± 4.75 U/mL), and mannitol (27.25 ± 4.27 U/mL). Higher cellulase production by MKAL5 was found only at 1.5% sucrose (134.76 ± 9.11 U/mL). Maximum cellulase activity by MKAL6 occurred at 1.5% sucrose (186.54 ± 7.23 U/mL), 1.5% sorbitol (27.48 ± 8.58 U/mL), 1.5% mannitol (44.99 ± 5.99 U/mL), 2% glucose (34.90 ± 5.65 U/mL), 2% fructose (23.33 ± 4.28 U/mL), and 2% xylose (48.52 ± 6.89 U/mL). However, sucrose was the best cellulase production inducer by these bacterial strains.

Effect of carbon sources on cellulase production by strains MKAL1, MKAL2, MKAL3, MKAL4, MKAL5, and MKAL6. Carbon sources enhanced cellulase production at different concentrations: MKAL1 (1% sucrose, 1.5% CMC, 1.5% glucose, 1.5% fructose, 1.5% xylose, 2% sorbitol, and 2% mannitol), MKAL2 (1.5% sorbitol, 2% CMC, 2% sucrose, 2% glucose, 2% fructose, 2% mannitol, and 2% xylose), MKAL3 (1% CMC; 1.5% sucrose, 1.5% glucose, 1.5% mannitol, 2% fructose, 2% sorbitol, and 2% xylose), MKAL4 (2% of all tested carbon sources), MKAL5 (1% xylose, 1.5% CMC, sucrose, 1.5% fructose, 2% glucose, and 2% mannitol), and MKAL6 (1.5% sucrose, 1.5% sorbitol, 1.5% mannitol, 2% CMC, 2% glucose, 2% fructose, and 2% xylose). CMC, carboxymethyl cellulose

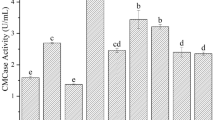

Effect of Nitrogen Sources on Cellulase Production

The cellulase production was highly affected by various nitrogen sources. The effect of each nitrogen source (0.05–2% w/v) on enzyme production by strains was investigated at their optimum pH (5 and 6) and temperature (35 and 40 °C). Except for MKAL6, all tested bacterial isolates cannot degrade CMC without a nitrogen source in the culture medium. No cellulase production and cell growth by MKAL1, MKAL2, MKAL3, and MKAL4 were observed with urea. Also, ammonium nitrate inhibited cellulase production by MKAL6, while ammonium chloride and ammonium sulfate inhibited cellulase activity of MKAL2. Organic nitrogen sources promoted higher cellulase production than inorganic nitrogen sources (Fig. 7, Table S2). The results showed higher cellulase production when yeast extract (MKAL2 and MKAL6), casein hydrolysate (MKAL1, MKAL4, and MKAL5), and tryptone (MKAL3) were used. MKAL2 (20.50 ± 1.35 U/mL) and MKAL6 (26.60 ± 3.36 U/mL) exerted maximum activity at 0.5 and 1.5% yeast extract respectively. Maximum cellulase production by MKAL1 (19.62 ± 2.55 U/mL), MKAL5 (17.75 ± 1.49 U/mL), and MKAL4 (21.80 ± 1.14 U/mL) occurred at 1 and 1.5% casein hydrolysate respectively. The highest cellulase activity in MKAL3 (14.00 ± 0.91 U/mL) was observed when 1.5% tryptone was used.

Effect of nitrogen sources on cellulase production by strains MKAL1, MKAL2, MKAL3, MKAL4, MKAL5, and MKAL6. Nitrogen sources enhanced cellulase production at different concentrations: MKAL1 (1% of all tested nitrogen sources except for urea), MKAL2 (0.5% yeast extract, 0.5% malt extract, 0.5% NH4NO3, 1.5% casein hydrolysate, 1.5% peptone, and 1.5% tryptone), MKAL3 (0.5% malt extract, 1% NH4Cl, 1% NH4NO3, 1.5% yeast extract, 1.5% casein hydrolysate, 1.5% peptone, 1.5% tryptone, and 1.5% (NH4)2SO4), MKAL4 (0.5% malt extract, 0.5% NH4Cl, 0.5% NH4NO3, 1% (NH4)2SO4, 1.5% yeast extract, 1.5% casein hydrolysate, 1.5% peptone, and 1.5% tryptone), MKAL5 (0.5% NH4Cl, 0.5% NH4NO3, 0.5% urea, 1% yeast extract, 1% malt extract, 1% casein hydrolysate, 1.5% peptone, 1.5% tryptone, and 1.5% (NH4)2SO4), and MKAL6 (0.5% NH4Cl, 0.5% (NH4)2SO4, 0.5% urea; 1% malt extract, 1.5% yeast extract, 1.5% casein hydrolysate, 1.5% peptone, and 1.5% tryptone)

Effect of Salts on Cellulase Production

The effect of salts (0.5–5 mM) on enzyme production by strains was performed at their optimum pH (5 and 6) and temperature (35 and 40 °C). Except for MKAL3, all bacterial strains stimulated cellulase production in a non-salt supplemented culture medium (Fig. 8, Table S3). Some salts enhanced cellulase production by strains compared to control (0.09 ± 0.00 to 10.92 ± 2.45 U/mL). MKAL4 (24.38 ± 2.60 U/mL), MKAL6 (28.71 ± 1.22 U/mL), and MKAL2 (23.23 ± 1.90 U/mL) exhibited maximum activity at 1 and 2.5 mM CoCl2 respectively. The optimum enzyme production by MKAL1 (21.15 ± 3.29 U/mL) and MKAL3 (16.39 ± 1.41 U/mL) occurred at 2.5 mM KCl, while the maximum production by MKAL5 (20.05 ± 2.29 U/mL) was at 2.5 mM MgCl2.

Effect of salts on cellulase production by strains MKAL1, MKAL2, MKAL3, MKAL4, MKAL5, and MKAL6. Salts enhanced cellulase production at different concentrations: MKAL1 (1 mM CoCl2, 1 mM ZnCl2, 1 mM PbCl2, 2.5 mM KCl, and 2.5 mM CrCl3), MKAL2 (1 mM NaCl, 1 mM CaCl2, 1 mM CrCl3, 1 mM PbCl2, 2.5 mM KCl, 2.5 mM AlCl3, 2.5 mM MgCl2, 2.5 mM CoCl2, and 2.5 mM NiCl2), MKAL3 (1 mM NaCl, 1 mM CaCl2, 1 mM AlCl3, 1 mM MgCl2, 1 mM CoCl2, 1 mM CrCl3, 1 mM PbCl2, 1 mM BaCl2, 2.5 mM KCl, 2.5 mM NiCl2, and 2.5 mM ZnCl2), MKAL4 (1 mM KCl, 1 mM CaCl2, 1 mM AlCl3, 1 mM MgCl2, 1 mM CoCl2, 2.5 mM NaCl, and 2.5 mM NiCl2), MKAL5 (1 mM CaCl2, 1 mM CrCl3, 2.5 mM KCl, 2.5 mM MgCl2, and 2.5 mM CoCl2), and MKAL6 (1 mM NaCl, 1 mM CaCl2, 1 mM AlCl3, 1 mM MgCl2, 1 mM CoCl2, 2.5 mM KCl, and 2.5 mM NiCl2)

Effect of Surfactants and EDTA on Cellulase Production

No cellulase production was observed with triton X-100, SDS, and EDTA. The presence of tween 20 in the culture medium enhanced cellulase production by MKAL6 (33.99 ± 0.58 to 35.91 ± 1.03 U/mL), MKAL2 (27.87 ± 3.10 to 31.72 ± 4.40 U/mL), and MKAL4 (28.93 ± 3.64 to 32.00 ± 2.86 U/mL) compared to control (23.23 ± 1.90 to 28.71 ± 1.22 U/mL) (Fig. 9). This cellulase production gradually increased with an increase in tween 20 concentration and reached a maximum production at 1% (w/v) concentration in the medium. This trend was also observed in bacterial growth.

Optimization of Fermentation

The Box–Behnken design was used to optimize the fermentation conditions (Table 2). Results are presented in Table S4. Cellulase was the response variable, while temperature (X1), pH (X2), and fermentation time (X3) were independent variables. Quadratic equations showing the linear relationship between response and independent variables were as follows:

The analysis of variance revealed that p values of regression and lack of fit were 0.000–0.009 (p < 0.05) and 0.074–0.778 (p > 0.05) respectively for strains MKAL1, MKAL2, MKAL4, and MKAL5 (Table S4). This indicates that the built quadratic equation is relatively credible for the evaluation of glucose isomerase activity of these bacterial strains. However, the p value of the lack of fit was 0.001 (p < 0.05) respectively for MKAL3 and MKAL6. This suggests that the relationship between parameters is not significant, or the response surface quadratic model does not fit well for the assessment of enzyme activity of those two bacteria. Contour plots were produced based on the fitted model to estimate response surface shape. All contour plots appeared as ellipses, suggesting interactions between temperature, pH, and fermentation time. These variables affect cellulase activity and optimum conditions for maximum enzyme production yield were in the design range (Fig. S1). The optimal responses, 13.474, 18.982, 11.052, and 11.502 U/mL with a 95% confidence interval, were obtained by canonical analysis for MKAL1, MKAL2, MKAL4, and MKAL5 respectively. The coded factor values for the stationary point were as follows:

-

(1)

MKAL1: \(0.133 \left({X}_{1}\right), 0.158 \left({X}_{2}\right), 0.081 \left({X}_{3}\right)\), with corresponding experimental conditions: temperature 35.67 °C, pH 6.16, and fermentation time 97.94 h

-

(2)

MKAL2: \(-0.181 \left({X}_{1}\right), -0.248 \left({X}_{2}\right), 0.029 \left({X}_{3}\right)\), with corresponding experimental conditions: temperature 39.10 °C, pH 5.75, and fermentation time 96.70 h

-

(3)

MKAL4: \(0.126 \left({X}_{1}\right), 0.168 \left({X}_{2}\right), 0.033 \left({X}_{3}\right)\), with corresponding experimental conditions: temperature 35.63 °C, pH 6.17, and fermentation time 96.79 h

-

(4)

MKAL5: \(0.197 \left({X}_{1}\right), 0.175 \left({X}_{2}\right), 0.082 \left({X}_{3}\right)\), with corresponding experimental conditions: temperature 35.99 °C, pH 6.18, and fermentation time 97.97 h

The fitness of the model was checked by performing triplicate experiments under predicted optimum fermentation conditions. Experimental values were 13.303 ± 1.57, 18.817 ± 2.08, 10.89 ± 0.78, and 11.381 ± 1.12 U/mL for MKAL1, MKAL2, MKAL4, and MKAL5, respectively. This demonstrates reliable goodness of fit to predict cellulase production yield during the fermentation process with these bacterial strains.

Molecular Weight Determination and Zymogram

Protein bands of cellulases were observed in 15% acrylamide gel. Multiple bands were observed in the gel. However, the bands with hydrolytic zone correspond to 25 kDa (Fig. 10) confirming the presence of cellulase.

Discussion

Cellulases are demanding industrial enzymes and play a major role in the bioconversion of cellulosic biomass into fermentable sugars which are further exploited for many applications [24]. Cellulose-degrading bacteria are widely spread in nature, soils, and agricultural environments.

We identified six cellulose-degrading bacteria from soil samples belonging to genera Bacillus, Hymenobacter, Chryseobacterium, Paenarthrobacter, Mycobacterium, and Stenotrophomonas. Many investigators reported cellulase activity of the members of these bacteria isolated from various sources [25,26,27,28,29]. Their cellulase production was influenced by growth parameters such as temperature, incubation period, pH, carbon and nitrogen sources, metal ions, surfactants, and incubation time.

Each microorganism needs optimum temperature for enzyme production stabilization. MKAL1, MKAL3 MKAL4, MKAL5, and MKAL6 exhibited maximum activity at 35 °C, while the optimum temperature of MKAL2 for cellulase production occurred at 40 °C. Bacillus subtilis subsp. subtilis JJBS300 [30], Bacillus velezensis [31], and Bacillus subtilis strain MU S1 [32] were reported to produce higher cellulase yield at 35 °C. Some other bacteria such as Bacillus pacificus, Pseudomonas mucidolens [33], Bacillus pseudomycoides [34], and Streptomyces thermocoprophilus strain TC13W [35] showed higher cellulase activity at 40 °C. No cellulase production by strains was observed at 30 and 50 °C. Enzyme inactivation at these temperatures would be due to weak intermolecular interactions on the enzyme structure stability, decreasing enzyme catalytic abilities. At lower temperatures, substrate transport across the cell is suppressed, while at a higher temperature, the enzyme is unfolded and inactivated (thermal denaturation) [36]. However, some researchers revealed cellulase production by Paenibacillus sp. IM7, Bacillus sp., Bacillus wiedmannii, and Chryseobacterium sp. at 30 and 50 °C [37,38,39,40,41]. Optimal cellulase production was achieved at an incubation period of 96 h. Beyond, enzyme activity decreased. This occurred due to nutrient depletion in the fermentation medium, inhibition by end-products, or by-product production. Nutrient depletion causes bacterial stress leading to enzyme secretion inactivation and cell death [42]. Micrococcus sp. SAMRC-UFH3 [43], Bacillus amyloliquefaciens AK9 [44], and Bacillus albus [45] were reported to produce maximum cellulase after 96 h of incubation.

Medium pH is an essential factor for enzyme production and enzyme stability. All isolates tested showed cellulase production at optimum pH ranging from 5 to 6. Similar optimum pH of 5 to 6 was reported in Chryseobacterium sp. [37], Stenotrophomonas maltophilia [46], and Bacillus albus [45]. However, MKAL1, MKAL2, MKAL4, and MKAL6 also exerted cellulase production in the broader pH ranges from 6 to 8. These results were also recorded for different bacterial cellulases [34, 36, 39, 40, 47,48,49]. We observed a decrease in enzyme activity that may be due to ionization group change at the enzyme active site or conformational change of the enzyme slowing or preventing the enzyme–substrate complex formation [36].

CMC is widely used to produce microbial cellulase because it is a soluble cellulose derivative with a high degree of polymerization. Its concentration in the culture influences enzyme production [50]. All tested strains exhibited cellulase activity at concentrations ranging from 1 to 2.5%. MKAL6 exhibited cellulase activity of 6.27 ± 0.79 U/mL at 1% CMC. Malik and Javed [51] reported cellulase activity of 2.4 U/mL in Bacillus subtilis CD001 at 1% CMC. Sugars act as inducers or repressors for enzyme production. Sucrose enhanced higher production, which suggested the negligible requirement of this sugar for appropriate enzyme induction. Hussain et al. [52] showed that Bacillus amyloliquefaciens SA5, Bacillus subtilis BTN7A, Bacillus megaterium BMS4, and Anoxybacillus flavithermus BTN7B exhibited maximum cellulase production when sucrose was used as sole carbon in the culture medium. Pure cellulose, cellulose acetate, and PET did not stimulate enzyme production because of their structural complexity and insolubility.

The fermentation medium not supplemented by nitrogen sources did not promote cellulase production by isolates. Thus, nitrogen sources are essential for cellulase production. Yeast extract, casein hydrolysate, and tryptone boosted higher cellulase activity. Other investigators recorded similar results [34, 53]. Organic nitrogen sources have stimulated higher production than inorganic nitrogen sources because their metabolism contributes to culture medium acidification, affecting cellulase production. However, other studies revealed that inorganic nitrogen sources such as urea and ammonium chloride promoted maximum cellulase production by Bacillus licheniformis 2D55 [54] and Aneurinibacillus aneurinilyticus BKT-9 [55].

Metal ions play a vital role in enzyme catalysis by binding directly or indirectly to the enzyme active site [56]. CoCl2, KCl, and MgCl2 promoted higher cellulase production. Other reports showed these salts enhanced higher cellulase activity in Bacillus tequilensis S28 [57], Bacillus cereus [58], and Bacillus amyloliquefaciens [59].

The presence of tween 20 in the culture medium boosted cellulase production in MKAL2, MKAL4, and MKAL6 at 0.1 and 1%. This cellulase production declined at higher concentrations. Bhagia et al. [60] revealed that even nonionic surfactants at high concentrations such as tween 20 could negatively affect enzymatic hydrolysis.

Hydrolytic bands of cellulases indicated cellulolytic activity in zymogram corresponding to ~ 25 kDa. Cellulase bands in the range of 24.4–185 kDa have been estimated from SDS-PAGE [61,62,63,64]. A similar molecular weight of 25 kDa has been reported in Bacillus licheniformis SVD1 [65], Bacillus subtilis MA139 [66], Penicillium verruculosum [67], and Novosphingobium sp. Cm1 [68].

Conclusions

This study aimed to characterize cellulose-degrading bacteria and optimize their cellulase production. Six CDBs were isolated from soil samples showing that soil is a vast cellulolytic bacteria untapped reservoir and identified as Paenarthrobacter sp. MKAL1, Hymenobacter sp. MKAL2, Mycobacterium sp. MKAL3, Stenotrophomonas sp. MKAL4, Chryseobacterium sp. MKAL5, and Bacillus sp. MKAL6. The higher cellulase production in these strains occurred at the culture conditions of 35–40 °C, pH 5–6, 1–2% CMC, and 96 h of incubation. The presence of yeast extract, casein hydrolysate, tryptone, sucrose, potassium chloride, cobalt chloride, magnesium chloride, and tween 20 boosted their cellulase production. Response surface quadratic model was reliable to predict cellulase production during the fermentation process with strains MKAL1, MKAL2, MKAL4, and MKAL5. The purification of these cellulases for hydrolysis and saccharification of lignocellulosic biomasses are being studied.

Data Availability

All data generated or analyzed during this study are included in this article.

References

Danalache, F., Mata, P., Alves, VD., Moldão-Martins, M. (2018). Chapter 10: Enzyme-assisted extraction of fruit juices (In Rajauria G. Tiwari BK., ed.), Academic Press, pp. 183–200.

Silalertruksa, T., & Gheewala, S. H. (2020). Competitive use of sugarcane for food, fuel, and biochemical through the environmental and economic factors. The International Journal of Life Cycle Assessment, 25, 1343–1355.

Faria, SP., de Melo, GR., Cintra, LC., Ramos, LP., Amorim Jesuino, RS., Ulhoa, CJ., de Faria, FP. (2020). Production of cellulases and xylanases by Humicolagrisea var. thermoidea and application in sugarcane bagasse arabinoxylan hydrolysis. Industrial Crops and Products, 158, 112968.

Sankaran, R., Parra Cruz, R. A., Pakalapati, H., Show, P. L., Ling, T. C., Chen, W. H., & Tao, Y. (2020). Recent advances in the pretreatment of microalgal and lignocellulosic biomass: A comprehensive review. Bioresource Technology, 298, 122476.

Paudel, P. Y., & Qin, W. (2015). Characterization of novel cellulase-producing bacteria isolated from rotting wood samples. Applied Biochemistry and Biotechnology, 177, 1186–1198.

Kumar, VA., Kurup, RSC., Snishamol, C., Prabhu, GN. (2019). Role of cellulases in food, feed, and beverage industries (In Parameswaran B., Varjani S., & Raveendran S., ed.), Green Bioprocesses: Enzymes in Industrial Food Processing, Springer Singapore, pp. 323–343.

Sampathkumar, K., Kumar, V., Sivamani, S., Sivakumar, N. (2019). An insight into fungal cellulases and their industrial applications (In Srivastava M., Srivastava N., Ramteke P.W., & Mishra P.K., ed.), Approaches to Enhance Industrial Production of Fungal Cellulases, Springer International Publishing, pp. 19–35.

Soni, SK., Sharma, A., Soni, R. (2018). Cellulases: Role in lignocellulosic biomass utilization (In Lübeck M., ed.), Cellulases, Humana Press, New York, pp. 3–23.

Singhania, RR., Adsul, M., Pandey, A., Patel, AK. (2017). Cellulases (In Pandey A., Negi S., Soccol C. R., ed.), Current developments in biotechnology and bioengineering-Production, isolation and purification of industrial products, Elsevier, pp. 73–101.

Ramesh, A., Devi, PH., Chattopadhyay, S., Kavitha, M. (2020). Commercial applications of microbial enzymes (In Arora N.K., Mishra J., & Mishra V., ed.), Microbial enzymes: Roles and applications in industries, Springer Nature, pp. 137–184.

Shida, Y., Furukawa, T., & Ogasawara, W. (2016). Deciphering the molecular mechanisms behind cellulase production in Trichoderma reesei, the hyper-cellulolytic filamentous fungus. Bioscience, Biotechnology, and Biochemistry, 80, 1712–1729.

Bilal, M., & Iqbal, H. M. (2020). State-of-the-art strategies and applied perspectives of enzyme biocatalysis in food sector—current status and future trends. Critical Reviews in Food Science and Nutrition, 60, 2052–2066.

De Souza, T. S. P., & Kawaguti, H. Y. (2021). Cellulases, Hemicellulases, and Pectinases: Applications in the Food and Beverage Industry. Food and Bioprocess Technology, 14, 1446–1477.

Cipolatti, EP., Cerqueira, PMCC., Henriques, RO., da Silva Pinto, JCC., de Castro, AM., Freire, DMG., Manoel, EA. (2019). Enzymes in green chemistry: The state of the art in chemical transformations (In Singh R.S., Singhania RR., Pandey A. Larroche C., ed.), Advances in Enzyme Technology. Elsevier, pp. 137–151.

Guerrand, D. (2018). Economics of food and feed enzymes: Status and prospectives (In Nunes C. & Kumar V., ed.), Enzymes in Human and Animal Nutrition. Elsevier, pp. 487–514.

Global Cellulase (CAS 9012–54–8) Market Growth 2021–2026 2021. Available from: https://www.360researchreports.com/global-cellulase-cas-9012-54-8-sales-market-16610450. Accessed October 30, 2020.

Marques, N. P., de Cassia Pereira, J., Gomes, E., da Silva, R., Araújo, A. R., Ferreira, H., Rodrigues, A., Dussan, K. J., & Bocchini, D. A. (2018). Cellulases and xylanases production by endophytic fungi by solid state fermentation using lignocellulosic substrates and enzymatic saccharification of pretreated sugarcane bagasse. Industrial Crops and Products, 122, 66–75.

Islam, F., & Roy, N. (2018). Screening, purification and characterization of cellulase from cellulose producing bacteria in molasses. BMC Research Notes, 11, 445–451.

Maki, M. L., Broere, M., Leung, K. T., & Qin, W. (2011). Characterization of some efficient cellulase producing bacteria isolated from paper mill sludges and organic fertilizers. International Journal of Biochemistry and Molecular Biology, 2, 146–154.

Cangelosi, G. A., Palermo, C. O., Laurent, J. P., Hamlin, A. M., & Brabant, W. H. (1999). Colony morphotypes on Congo red agar segregate along species and drug susceptibility lines in the Mycobacterium avium-intracellulare complex. Microbiology, 145, 1317–1324.

Mokale, KAL., Chio, C., Khatiwada, JR., Shrestha, S., Chen, X., Li, H., Zhu, Y., Jiang, Z-H., Xu, C. (C.), Qin, W. (2022). Characterization of glucose isomerase-producing bacteria and optimization of fermentation conditions for producing glucose isomerase using biomass. Green Chemical Engineering. https://doi.org/10.1016/j.gce.2022.05.003

Cowan, ST. Steel, KJ. (2003). Manual for the identification of medical bacteria (G.I. Barrow and R.K.A., ed.), Cambridge University Press, pp. 188–238

Rahman MS., Fernando S., Ross B., Wu J., Qin W. (2018). Endoglucanase (EG) activity assays (In: Lübeck M., ed.), Cellulases, Methods in Molecular Biology, Humana Press, New York.

Scarcella, ASd. A., Pasin, T. M., de Oliveira, T. B., de Lucas, R. C., Ferreira-Nozawa, M. S., Freitas, E. N., & Polizeli, Md. LTd. M. (2021). Saccharification of different sugarcane bagasse varieties by enzymatic cocktails produced by Mycothermusthermophilus and Trichodermareesei RP698 cultures in agro-industrial residues. Energy, 226, 120360.

Van Wyk, N., Navarro, D., Blaise, M., Berrin, J. G., Henrissat, B., Drancourt, M., & Kremer, L. (2017). Characterization of a mycobacterial cellulase and its impact on biofilm- and drug-induced cellulose production. Glycobiology, 27, 392–399.

Ye, M., Sun, L., Yang, R., Wang, Z., & Qi, K. Z. (2017). The optimization of fermentation conditions for producing cellulase of Bacillus amyloliquefaciens and its application to goose feed. Royal Society Open Science, 4, 171012.

Molina, G. C. E., de la Rosa, G., Gonzalez, C. J., Sánchez, Y., Castillo-Michel, H., Valdez-Vazquez, I., Balcazar, E., & Salmerón, I. (2018). Optimization of culture conditions for production of cellulase by Stenotrophomonas maltophilia. BioResources, 13, 8358–8372.

Tan, H., Miao, R., Liu, T., Yang, L., Yang, Y., Chen, C., Lei, J., Li, Y., He, J., Sun, Q., Peng, W., Gan, B., & Huang, Z. (2018). A bifunctional cellulase-xylanase of a new Chryseobacterium strain isolated from the dung of a straw-fed cattle. Microbial biotechnology, 11, 381–398.

Dai, J., Dong, A., Xiong, G., Liu, Y., Hossain, M. S., Liu, S., Gao, N., Li, S., Wang, J., & Qiu, D. (2020). Production of highly active extracellular amylase and cellulase from Bacillus subtilis ZIM3 and a recombinant strain with a potential application in tobacco fermentation. Frontiers in Microbiology, 11, 1539.

Kumar, Anu, Kumar, S., Kumar, A., Kumar, V., & Singh, B. (2021). Optimization of cellulase production by Bacillus subtilis subsp. subtilis JJBS300 and biocatalytic potential in saccharification of alkaline-pretreated rice straw. Preparative Biochemistry & Biotechnology, 51, 697–704.

Li, F., Xie, Y., Gao, X., Shan, M., Sun, C., Niu, Y. D., & Shan, A. (2020). Screening of cellulose degradation bacteria from min pigs and optimization of its cellulase production. Electronic Journal of Biotechnology, 48, 29–35.

Sreena, C. P., & Sebastian, D. (2018). Augmented cellulase production by Bacillus subtilis strain MU S1 using different statistical experimental designs. Journal of Genetic Engineering and Biotechnology, 16, 9–16.

Krishnaswamy, V. G., Sridharan, R., Kumar, P. S., & Fathima, M. J. (2022). Cellulase enzyme catalyst producing bacterial strains from vermico post and its application in low-density polyethylene degradation. Chemosphere, 288, 132552.

Pramanik, S. K., Mahmud, S., Paul, G. K., Jabin, T., Naher, K., Uddin, M. S., Zaman, S., & Saleh, M. A. (2020). Fermentation optimization of cellulase production from sugarcane bagasse by Bacillus pseudomycoides and molecular modeling study of cellulase. Current Research in Microbial Sciences, 2, 100013.

Sinjaroonsak, S., Chaiyaso, T., & Kittikun, H. A. (2019). Optimization of cellulase and xylanase productions by Streptomyces thermocoprophilus strain TC13W using oil palm empty fruit bunch and tuna condensate as substrates. Applied Biochemistry and Biotechnology, 189, 76–86.

Ibrahim, A. M., Hamouda, R. A., El-Naggar, N. E. A., & Al-Shakankery, F. M. (2021). Bioprocess development for enhanced endoglucanase production by newly isolated bacteria, purification, characterization and in-vitro efficacy as anti-biofilm of Pseudomonas aeruginosa. Scientific Reports, 11, 9754.

Nkohla, A., Okaiyeto, K., Nwodo, U. U., Mabinya, L. V., & Okoh, A. I. (2017). Endoglucanase and xylanase production by Chryseobacterium species isolated from decaying biomass. Polish Journal of Environmental Studies, 26, 2651–2660.

Almuharef, I., Rahman, M. S. Q., & W. (2020). High production of cellulase by a newly isolated strain Paenibacillus sp. IM7. Waste and Biomass Valorization, 11, 6085–6094.

Steiner, E., & Margesin, R. (2020). Production and partial characterization of a crude cold-active cellulase (CMCase) from Bacillus mycoides AR20-61 isolated from an Alpine forest site. Annals of Microbiology, 70, 67.

Bhagat, S. A., & Kokitkar, S. S. (2021). Isolation and identification of bacteria with cellulose-degrading potential from soil and optimization of cellulase production. Journal of Applied Biology and Biotechnology, 9, 154–161.

Indumathi, T., Jayaraj, R., Kumar, P. S., Sonali, J. M. I., Krishnaswamy, V. G., Ghfar, A. A., & Govindaraju, S. (2022). Biological approach in deinking of waste paper using bacterial cellulase as an effective enzyme catalyst. Chemosphere, 287, 132088.

Ariffin, H. N., Abdullah, M. S., Umi Kalsom, Y., & Shirai Hassan, M. A. (2006). Production and characterisation of cellulase by Bacillus pumilus EB3. International Journal of Engineering & Technology, 3, 47–53.

Mmango-Kaseke, Z., Okaiyeto, K., Nwodo, U. U., Mabinya, L. V., & Okoh, A. I. (2016). Optimization of cellulase and xylanase production by Micrococcus species under submerged fermentation. Sustainability, 8, 1168.

Irfan, M., Tayyab, A., Hasan, F., Khan, S., Badshah, M., & Shah, A. A. (2017). Production and characterization of organic solvent-tolerant cellulase from bacillus amyloliquefaciens AK9 isolated from hot spring. Applied Biochemistry and Biotechnology, 182, 1390–1402.

Abada, E. A., Elbaz, R. M., Sonbol, H., & korany, SM. (2021). Optimization of cellulase production from Bacillus albus (MN755587) and its involvement in bioethanol production. Polish Journal of Environmental Studies, 30, 2459–2466.

Molina Guerrero, C. E., de la Rosa, G., Gonzalez Castañeda, J., Sánchez, Y., Castillo-Michel, H., Valdez-Vazquez, I., Balcazar, E., & Salmerón, I. (2018). Optimization of culture conditions for production of cellulase by Stenotrophomonas maltophilia. BioResources, 13, 8358–8372.

Potprommanee, L., Wang, X. Q., Han, Y. J., Nyobe, D., Peng, Y. P., Huang, Q., Liu, J. Y., Liao, Y. L., & Chang, K. L. (2017). Characterization of a thermophilic cellulase from Geobacillus sp. HTA426, an efficient cellulose producer on alkali pretreated of lignocellulosic biomass. PloS one, 12, e0175004.

Herrera, L. M., Braña, V., Franco, F. L., & Castro-Sowinski, S. (2019). Characterization of the cellulase-secretome produced by the Antarctic bacterium Flavobacterium sp. AUG42. Microbiological Research, 223–225, 13–21.

Thapa, S., Mishra, J., Arora, N., Mishra, P., Li, H., & O′Hair, J., Bhatti, S., Zhou, S. (2020). Microbial cellulolytic enzymes: Diversity and biotechnology with reference to lignocellulosic biomass degradation. Reviews in Environmental Science and Bio/Technology, 19, 621–648.

da Silva, R. N., Melo, LFd. A., & Luna Finkler, C. L. (2021). Optimization of the cultivation conditions of Bacillus Licheniformis BCLLNF-01 for cellulase production. Biotechnology Reports, 29, e00599.

Malik, W. A., & Javed, S. (2021). Biochemical characterization of cellulase from Bacillus subtilis strain and its effect on digestibility and structural modifications of lignocellulose rich biomass. Frontiers in bioengineering and biotechnology, 9, 800265.

Hussain, A. A., Abdel-Salam, M. S., Abo-Ghalia, H. H., Hegazy, W. K., & Hafez, S. S. (2017). Optimization and molecular identification of novel cellulose degrading bacteria isolated from Egyptian environment. Journal of Genetic Engineering and Biotechnology, 15, 77–85.

Sharma, H. K., Xu, C. C., & Qin, W. (2020). Co-culturing of novel bacillus species isolated from municipal sludge and gut of red wiggler worm for improving CMCase activity. Waste and Biomass Valorization, 11, 2047–2058.

Kazeem, M. O., Shah, U. K. M., Baharuddin, A. S., & Rahman, N. A. (2016). Enhanced cellulase production by a novel thermophilic Bacillus licheniformis 2D55: Characterization and application in lignocellulosic saccharification. BioResources, 11, 5404–5423.

Ahmad, T., Sharma, A., Gupta, G., Mansoor, S., Jan, S., Kaur, B., Paray, B. A., & Ahmad, A. (2020). Response surface optimization of cellulase production from Aneurinibacillus aneurinilyticus BKT-9: An isolate of urban Himalayan freshwater. Saudi Journal of Biological Sciences, 27, 2333–2343.

Paulraj Gundupalli, M., Sahithi, S. T. A., Cheng, Y. S., Tantayotai, P., & Sriariyanun, M. (2021). Differential effects of inorganic salts on cellulase kinetics in enzymatic saccharification of cellulose and lignocellulosic biomass. Bioprocess and Biosystems Engineering, 44, 2331–2344.

Sharma, A., Tewari, R., & Soni, S. (2015). Application of statistical approach for optimizing CMCase production by Bacillus tequilensis S28 strain via submerged fermentation using wheat bran as carbon source. World Academy of Science, Engineering and Technology International Journal of Biotechnology and Bioengineering, 9, 76–86.

Tabssum, F., Irfan, M., Shakir, H. A., & Qazi, J. I. (2018). RSM based optimization of nutritional conditions for cellulase mediated saccharification by Bacillus cereus. Journal of biological engineering, 12, 7.

Pham, V. H. T., Kim, J., Shim, J., Chang, S., & Chung, W. (2022). Coconut mesocarp-based lignocellulosic waste as a substrate for cellulase production from high promising multienzyme-producing Bacillus amyloliquefaciens FW2 without pretreatments. Microorganisms, 10, 327.

Bhagia, S., Wyman, C. E., & Kumar, R. (2019). Impacts of cellulase deactivation at the moving air-liquid interface on cellulose conversions at low enzyme loadings. Biotechnology for Biofuels and Bioproducts, 12, 96.

Sriariyanun, M., Tantayotai, P., Yasurin, P., Pornwongthong, P., & Cheenkachorn, K. (2016). Production, purification and characterization of an ionic liquid tolerant cellulase from Bacillus sp. isolated from rice paddy field soil. Electronic Journal of Biotechnology, 19, 23–28.

Barbosa, K. L., Malta, V. R. D. S., Machado, S. S., Leal Junior, G. A., da Silva, A. P. V., da Almeida, R. M. R. G., & Luz, J. M. R. (2020). Bacterial cellulase from the intestinal tract of the sugarcane borer. International Journal of Biological Macromolecules, 161, 441–448.

Mafa, M. S., Pletschke, B. I. M., & S. (2021). Defining the frontiers of synergism between cellulolytic enzymes for improved hydrolysis of lignocellulosic feedstocks. Catalysts, 11, 1343.

Shankar, T., Sankaralingam, S., Balachandran, C., Chinnathambi, A., Nasif, O., Alharbi, S. A., Park, S., & Baskar, K. (2021). Purifcation and characterization of carboxymethylcellulase from Bacillus pumilus EWBCM1 isolated from earthworm gut (Eudrilus eugeniae). Journal of King Saud University - Science, 33, 1–8.

Van Dyk, J. S., Sakka, M., Sakka, K., & Pletschke, B. I. (2009). The cellulolytic and hemi-cellulolytic system of Bacillus licheniformis SVD1 and the evidence for production of a large multi-enzyme complex. Enzyme and Microbial Technology, 45, 372–378.

Qiao, J., Dong, B., Li, Y., Zhang, B., & Cao, Y. (2009). Cloning of a beta-1,3–1,4-glucanase gene from Bacillus subtilis MA139 and its functional expression in Escherichia coli. Applied Biochemistry and Biotechnology, 152, 334–342.

Morozova, V. V., Gusakov, A. V., Andrianov, R. M., Pravilnikov, A. G., Osipov, D. O., & Sinitsyn, A. P. (2010). Cellulases of Penicillium verruculosum. Biotechnology Journal, 5, 871–880.

Goswami, K., Deka Boruah, H. P., & Saikia, R. (2022). Purification and characterization of cellulase produced by Novosphingobium sp. Cm1 and its waste hydrolysis efficiency and bio-stoning potential. Journal of Applied Microbiology, 132, 3618–3628.

Acknowledgements

The authors are grateful to the Natural Science and Engineering Research Council of Canada (NSERC) via the Discovery Program.

Funding

This project was supported by the Natural Science and Engineering Research Council of Canada (NSERC) Discovery Grant (RGPIN- 2017- 05366) to WQ.

Author information

Authors and Affiliations

Contributions

Conceptualization, WQ, CX, ZHJ, and ALMK; methodology, ALMK and CC; validation, WQ, CX, ZHJ, and ALMK; formal analysis, ALMK and JRK; investigation, ALMK; resources, WQ, CX, ZHJ, and ALMK; data curation, ALMK; software, ALMK; writing—original draft, ALMK; writing—review and editing, ALMK, SS, XC, SH, HL, WQ, CX, and ZHJ; supervision, WQ, CX, and ZHJ; project administration, WQ. All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Ethics Approval

Not applicable.

Consent to Participate

The authors agreed to participate in this work.

Consent for Publication

The authors agreed to publish this work.

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Mokale Kognou, A.L., Chio, C., Khatiwada, J.R. et al. Characterization of Cellulose-Degrading Bacteria Isolated from Soil and the Optimization of Their Culture Conditions for Cellulase Production. Appl Biochem Biotechnol 194, 5060–5082 (2022). https://doi.org/10.1007/s12010-022-04002-7

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-022-04002-7