Abstract

The aim of this study was to evaluate the potential of xylanase-pectinase enzymes in bleaching of wheat straw pulp, just to cut down the toxic wastes, in order to manage the environmental pollution. The appropriate parameters of bleaching were evaluated, and best conditions were xylanase and pectinase dose of 5.0 and 1.66 IU/g of pulp, respectively, along with material to liquid ratio of 1:7.5 (g/ml), temperature 55 °C, treatment time 3 h, Tween-80 1%, and pH 8.5. The release of reducing sugar and other non-cellulosic impurities, phenolic-hydrophobic-lignin was maximum at best bleaching conditions. Prebleaching of wheat straw pulp using these enzymes showed 14.75% decline in kappa number. Enzymatic bleaching plus 100% chemical bleaching also led to 27.90% reduction in yellowness. Using this methodology, the consumption of active chlorine was reduced up to 25%, along with an increase in burst index (7.98%), tear index (3.42%), breaking length (5.30%), viscosity (11.22%), gurley porosity (12.50%), and double-fold number (23.08%), which exhibits a remarkable enhancement in all the properties of pulp treated with enzymes. Microscopic images also confirm the effectiveness of enzymatic treatment in bleaching of wheat straw pulp. BOD and COD values of effluent also decreased by 20.74 and 17.87%, respectively. This research focussing on producing better grade paper using an eco-friendly approach would certainly benefit the paper and pulp industry. This is the first report, depicting bleaching capability of xylanase-pectinase enzymes for soda-anthraquinone pulp of wheat straw.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Due to increasing demand and utilization of paper, paper and pulp industries are trying to use alternate raw fibrous materials for production. The increased reduction in forest area elicits the great attentiveness towards the use of agricultural wastes. These agro-wastes are the major renewable sources that can be used to generate important industrial products like paper and fuels [1]. In last decade, the various waste products of agriculture have gained great interest due to their ample production throughout the year, economic to buy, and presence of different types of polysaccharides. Various agricultural and agro-allied industries such as pulp and paper, textile, breweries, and timber also produce large amount of hemicellulosic byproducts, which accumulates in the environment as waste if not converted into valuable products and causes severe environmental pollution-related hazards [2]. From the paper and pulp industry point of view, agro-wastes are the plausible substitute of raw material, and among these agro-wastes, wheat straw, a non-wood fibre, is the most abundant, due to wide cultivation of wheat [3]. Wheat straw (Triticum sativum) is the waste product obtained from the processing of wheat crop and present in large amount. Traditionally, the major fraction of these post-harvest residues is burnt off, which exerts deleterious effects on the atmosphere and also adversely affect the human health, so it is better to utilize them for generating useful products. In the world, the annual production of wheat is around 529 million tonnes and it is the second most abundant feedstock. Wheat straw is produced globally in huge amount, within minimum period of growth cycle and its utilization for production of paper is the best eco-friendly as well as cost-effective strategy. India has the advantage of having varied agroecological conditions, which is favourable to meet the food and nutrition requirements of large Indian population through production. India is the second major producer of wheat crop around the world under cultivation area of 30 million ha (14% of global area) with 99.70 million tonnes of wheat production (13.64% of world production), i.e. average productivity of 3371 kg/ha [4]. Wheat straw can be utilized for making different types of paper like linerboard, corrugated medium, writing, and printing papers [5]. Wheat straw is composed of 8–15% lignin, 35–45% cellulose, and 20–30% hemicelluloses and non-cellulosic components, which provide structural support, and all these components are associated with covalent and non-covalent interactions [6].

The formation of pulp, whitening of pulp, and final finishing to paper are the main steps involved for the manufacturing of paper. Soda-anthraquinone (AQ) method is being widely used for agro-waste pulp production [7], as it improves the delignification. The brown pulp is further bleached with various bleaching chemicals, in order to get bright and white pulp [8]. Paper industries commonly employ the usage of bleaching chemicals, i.e. CEH stages, chlorination (C), alkaline extraction (E), and hypochlorite (H), to enhance the whiteness of pulps [9]. In conventional chemical methods, various types of detrimental chlorinated compounds are formed during bleaching stage and these are continuously increasing, along with harmful effect on the biological systems [10]. The main organochlorine side products are dioxins, which cause serious damage to our environment, also increases the COD value of water and eventually accountable for high priced treatment of waste water [11]. Therefore, in order to handle the pressure imposed by various Environmental Regulatory Agencies, and also to avoid these environmental damaging effects, paper industries should adopt environment friendly methods. These methods along with enzyme technology are now becoming more popular in developing countries. Enzymes also offer a simple eco-friendly approach by reducing the use of toxic chemicals, and also enhance optical and physicochemical characteristics of paper [12,13,14]. Enzymes, xylanase [15, 16], and pectinase [17, 18] have given positive outcomes for the paper and pulp bleaching industries. The xylanase has the ability to enhance the bleaching effect and also decrease the consumption of toxic chemicals [19]. However, there are only few references available in the literature for the bio-bleaching of wheat straw pulp. The prime objectives of using xylanase and pectinase enzymes are to assess their bleaching capabilities for wheat straw pulp and reduction in the usage of chemicals during bleaching and also to check the optical as well as physical properties of final pulp, along with effluent characteristics, after enzymatic treatment.

Materials and Methods

Materials

Simultaneous production of xylanase and pectinase enzymes was done using Bacillus pumilus AJK (MTCC 10,414). The agro-waste, wheat straw, was procured from local fields of Kurukshetra, India. Wheat straw was cleaned using tap water and dried. High purity-grade pectin and xylan were purchased from Sigma-Aldrich. All other chemicals utilized in this study were obtained from HiMedia.

Production of Xylanase-Pectinase Enzymes and Their Activity Determination

The xylano-pectinolytic enzymes were produced using submerged fermentation method [20] and their activity was estimated by calculating the amount of reducing sugars released from xylan-pectin, respectively. The quantity of reducing sugar (xylose and galacturonic acid equivalent) was assessed using 3,5-dinitrosalicylic acid reagent [21]. Estimation of enzyme activity was done using protocols of Kaur et al. [22].

Evaluation of Various Bio-bleaching Conditions for Wheat Straw Soda-AQ Pulp

The bio-bleaching conditions were checked using dry wheat straw soda-AQ pulp and were treated with xylanase-pectinase in Erlenmeyer flasks. Experiments were conducted at different material to liquid ratios from 1:2.5 to 1:15, with xylanase-pectinase enzyme dosage ranging from 2.0 to 20.0 and 0.66 to 6.66 IU/g oven-dried pulp of wheat straw, at different pH ranges from 7.5 to 10.0. Retention time and temperature were checked with retention time range of 60 to 240 min and temperature range from 45 to 65 °C, respectively. Bio-bleaching efficiency was assessed through the estimation of reducing sugars released in pulp-free filtrates [21] and simultaneously by taking the optical density readings at λ 465 nm for hydrophobic compounds [23], at λ 280 and 400 nm for lignin and at λ 237 nm for phenolic compounds, respectively [24]. Bleaching ability of xylanase-pectinase was additionally enhanced by using different concentrations (0.1–2.0%) of Tween-80. In case of control experiments, enzymes were denatured by boiling and these experiments were run side by side to ensure the authenticity of experiments. Each experiment was repeated six times and, in each repeat, each sample in triplicate was tested.

Chemical Bleaching

Wheat straw pulp and bio-bleached pulp were chemically bleached using DoEPD1D2 sequence, where Do, D1, and D2 stages denote for ClO2 and EP designates for NaOH and H2O2 stage. DO step was carried out at 55 °C temperature and pH 2.5 for 45 min. For EP step, pulp was mixed with 1.7% alkali at pH 12 and treated at 75 °C for 120 min. D1 and D2 steps were carried out at 75 °C and pH 3.5 for 180 min. At the varied kappa factors, the ClO2 dose was used, after calculating according to the equation of Hise [25]. The pulp obtained after treatment with enzymes was also bleached with varying percent of ClO2, from 100 to 70% in order to check the reduction in the amount of chemicals and equivalent level of brightness (as observed in the case of control samples, without enzymatic treatment). Pulp filtrate samples were also evaluated after each step of bleaching, to check the amount of ClO2 present in the filtrate or utilized. Each experiment was repeated six times and, in each repeat, each sample in triplicate was tested.

Handsheet Formation and Testing

Handsheets were prepared by applying standard TAPPI methods. T205 sp-02 [26] was used to make the handsheets for control and enzyme-treated pulps. Pulp handsheets of bleached pulp (with 10% consistency) were made, by beating the pulp at 2600 revolutions (in beating-PFI mill), to examine the optical as well as physical parameters of pulp. For measuring the various optical properties like yellowness, whiteness, and brightness, method T217 wd-77 was used [27], and for physical properties such as burst index, breaking length, tear index, viscosity, double-fold number, pulp freeness, and Gurley porosity, methods T403 om-10 [28], T494 om-01 [29], T414 om-04 [30], T 230 om-99 [31], T 511 om-02 [32], (SCAN-C 19:65) [33], and T 460 om-02 [34] were used. Each experiment was repeated six times and, in each repeat, each sample in triplicate was tested.

Effluent Characterization

After completion of each step of bleaching, bleaching liquors of control as well as bio-bleached plus 75% chemically bleached were collected. In order to evaluate the effect of bio-bleaching, composite samples were prepared using effluents of all bleaching stages, which were assorted in equivalent volumetric ratio. The total suspended solids (TSS), pH, total dissolved solids (TDS), and lignin were estimated in control and bio-bleached (also 75% chemically bleached) effluent samples by using IS:3025 (part 17), IS:3025 (part11), and IS:3025 (part16) and the 22nd edition APHA 5550, respectively. BOD and COD (open reflux method) were analyzed using method IS:3025 (parts 38 and 44) and IS:3025 (part 58), respectively. Colour of effluent samples was analyzed, according to the protocol mentioned in the 22nd edition of APHA 2120 C. The comparison between control and bio-bleached effluent samples was done in order to calculate the effect of bio-bleaching. Each experiment was repeated six times and, in each repeat, each sample in triplicates was tested.

Microscopic Analysis of Bio-bleached Wheat Straw Pulp Samples

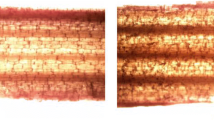

Wheat straw pulp samples, i.e. pulp after treatment with enzymes, pulp after 100% chemical bleaching, and pulp after bio-bleaching plus 75% chemical bleaching treatment, were analyzed by using a microscope at 400 × magnification.

Results and Discussion

Crude xylanase and pectinase enzymes obtained from Bacillus pumilus AJK have been used for bio-bleaching purpose. Effect of bio-bleaching on the reduction of chemical bleaching dose, on optical and strength properties of paper, and on effluent characteristics has been discussed under the following headings.

Evaluation of Best Enzymatic Bleaching Conditions

For the evaluation of appropriate bio-bleaching conditions, parameters which affect the enzyme activity were checked. Bio-bleaching conditions were evaluated by assessing the maximum release of reducing sugar from the filtrates obtained after treating the pulp samples with enzymes [21], maximum decrease in kappa number, along with enhancement in pulp’s optical properties and simultaneous measurement of optical density of pulp-free filtrate samples collected after squeezing the wheat straw pulp samples, for release of lignin, phenolics, and hydrophobic compounds, by measuring absorbance at 280–400 nm, 237 nm, and 465 nm, respectively. Maximum bio-bleaching with xylano-pectinolytic enzymes was achieved with pulp consistency of 1:7.5 (material to liquid ratio, g/ml) and pH 8.5 (Fig. 1a and 1b). Xylanase-pectinase enzyme dose of 5 and 1.66 IU/g of pulp, respectively, was sufficient for attaining maximum bio-bleaching of soda-AQ pulp (Fig. 1c). Additional increase in enzyme dose did not enhance the efficiency of bio-bleaching. Treatment time of 180 min (Fig. 1d) and temperature of 55 °C (Fig. 1e) were found to be suitable for bio-bleaching. Similarly, Tween-80 at a concentration of 1% (v/v) was sufficient for the highest release of sugars from wheat straw (Fig. 1f). The pretreatment of pulp with xylanase-pectinase enzymes under best evaluated conditions have liberated 3.97 ± 0.05 mg/g of reducing sugars. After the treatment of pulp fibres with enzymes, improvement in the optical density readings of filtrates at different wavelengths, resulted from the degradation of xylan and pectin, along with increase in the release of lignin, phenolic, and hydrophobic compounds, was noticed (Fig. 1).

(a) These experiments were performed at temperature –55° C, pH-8.5, enzymes dose IU/g (X:P)- 20:6 and retention time-3h. (b) These experiments were performed at enzymes dose IU/g (X:P)– 20:6, retention time–3h, temperature– 55° C and pulp consistency (material: liquid) –1:7.5. (c) These experiments were performed at pH-8.5, retention time-3h, temperature- 55° C and pulp consistency (material: liquid) – 1:7.5. (d) These experiments were performed at pH-8.5, enzymes dose IU/g (X:P)– 5.00:1.66, temperature– 55° C and pulp consistency (material: liquid) – 1:7.5. (e) These experiments were performed at pH-8.5, enzymes dose IU/g (X:P)– 5.00:1.66, retention time- 3h and pulp consistency (material: liquid) – 1:7.5. (f) These experiments were performed at pH-8.5, enzymes dose IU/g (X:P)– 5.00:1.66, retention time– 3h, temperature- 55° C and pulp consistency (material: liquid)– 1:7.5. Absorbance for all the above experiments was taken directly at 280, 400 nm and 465 nm and after 5x dilution at 237 nm

Xylanase enzyme dose of 20 [35], 10 [36], 4 [37], and 5 IU/g pulp [38] were obtained as the most effective dose for the bleaching treatment of wheat straw pulp. Bio-bleaching of the kraft pulp (10% consistency) was obtained maximally with pectinase enzyme dose of 5 IU/g of pulp at temperature 60 °C, pH 9.5, and treatment time 150 min [18]. Garg et al. [36] and Comlekcioglu et al. [37] have mentioned temperature 60 and 50 °C, pH 9.0, and 6.0 and time period of 2 and 3 h, respectively, for bleaching of wheat straw. Kaur et al. [22] and Agrawal et al. [39] have reported the xylanase dose of 4.5 and 6 IU/g of pulp and pectinase dose of 0.9 and 2.4 IU/g of pulp, treatment time 180 and 120 min, temperature 55 °C, and pH 8.5, respectively, for the effective bio-bleaching of mixed hardwood pulp and plywood pulp, respectively. Xylanase enzyme (dose 10 IU/g pulp) from Bacillus pumilus SV-85S, at temperature of 55 °C, pH 9.0, and treatment time of 120 min, was found to be appropriate for the bleaching of mixed woody kraft pulp [40]. Raj et al. [13] have reported xylanase dose of 20 IU/g, pH 9.0, temperature 60 °C, pulp consistency 10%, and treatment time 2 h, respectively, for the bleaching of eucalyptus kraft pulp. Xylanase enzyme dose of 30 IU/g, pH 7.0, temperature 70 °C, pulp consistency 10%, and treatment time 2 h was found to be effective for the bleaching of pine and eucalyptus kraft pulps [41]. Sharma et al. [42] have used 15 IU of xylanase and 2 IU of pectinase along with other enzymes for the bio-bleaching of agro (wheat straw, bagasse, and bamboo) pulp at pH 9.5 and temperature 65 °C with treatment time of 90 min.

Bio-bleaching with crude xylanase and pectinase enzymes showed 14.75% decline in kappa number. Under the best bleaching conditions, xylanase enzyme diminished the kappa number up to 11.32% [35] and 7.14% [36] for wheat straw pulp. The use of xylanase enzyme has reduced the kappa number by 1.6 points for the mixed woody kraft pulp [40]. Kappa number was reduced by 2.96 units [37] and 7.69% [38] for the bio-bleaching of wheat straw. Kappa number was mitigated up to 8.50% for the bleaching of bamboo pulp [43]. Ozer et al. [41] have reported 9.76 and 28.52% decline in kappa number for pine and eucalyptus kraft pulps, respectively. Kappa number was mitigated up to 19% after bio-bleaching of eucalyptus kraft pulp [13]. Sharma et al. [42] have reported 4.54% mitigation in kappa for the bio-bleaching of agro (wheat straw, bagasse, and bamboo) pulp.

Effect of Enzymatic Bleaching on ClO2Consumption

Xylanase-pectinase enzymes used for the bleaching of soda-AQ pulp have reduced chlorine consumption up to 25%, and similar optical properties attained, as obtained by 100% chemical bleaching (Table 1). The 25% reduction in chlorine utilization is due to the degradation of xylan-pectin polymer of the pulp fibre by concurrent action of xylanase and pectinase enzymes, which further increase the access of bleaching chemicals in the lignin layer of the pulp [22]. Garg et al. [36] have reported 20% decrease in chlorine consumption after bio-bleaching of wheat straw pulp. Similarly, 29.16% reduction in chlorine consumption was also reported after bio-bleaching treatment of woody kraft pulp [40]. Walia et al. [38] have mentioned 12.5% reduction in chlorine consumption after bio-bleaching of wheat straw pulp.

Effect of Enzymatic Bleaching on Optical Properties of Paper

After bio-bleaching with enzymes, chemical bleaching was done in order to visualize the effect of bio-bleaching. Brightness was increased up to 12.40% using 100% chemicals plus enzymes in comparison with 100% chemicals only, after the Do stage. After the addition of alkali and H2O2, kappa number and yellowness were decreased up to 11.76 and 20.12%, along with 12.99 and 11.32% increase in brightness and whiteness, respectively, using 100% chemicals plus enzymes, in comparison with 100% chemicals only. At the end of D-1 stage, the brightness and whiteness values were increased up to 3.13 and 8.83% together with a decrease of 44.48% in yellowness, respectively, using 100% chemicals plus enzymes in comparison with 100% chemicals only. After the completion of final stage of bleaching, i.e. D-2 stage, brightness and whiteness values were increased up to 2.31 and 1.97% along with 27.91% reduction in yellowness, respectively, using 100% chemicals plus enzymes in comparison with 100% chemicals only. Optical pulp properties like brightness, whiteness, and yellowness in both samples, i.e. the enzyme-treated pulp (with 75% chemicals plus enzyme) and the control pulp (with 100% chemicals), were found to be the same, which clearly demonstrated the influence of these enzymes during bleaching (Table 1).

Garg et al. [36] have reported 4.75 and 22.31% increase in brightness and whiteness, respectively, after bio-bleaching of wheat straw pulp. After bio-bleaching of wheat straw pulp using xylanase enzyme, brightness was increased up to 0.9% [37]. Nagar et al. [40] have described 2.7-point gain in brightness for woody kraft pulp, using xylanase enzyme. Walia et al. [38] mentioned 1.1 and 2.2% increase in brightness of wheat straw kraft pulp, using xylanase enzyme dose of 2 and 5 U/g pulp, respectively. Bleaching of bamboo pulp using xylanase enzyme from P. meleagrinum increased the pulp brightness up to 68–69% [43]. Bio-bleaching of pine and eucalyptus pulp using xylanase XyzGeo71 from Geobacillus sp. have resulted in 4.68 and 15.04% increase in brightness, respectively [41]. Sharma et al. [42] have reported 2.24% gain in brightness after bio-bleaching of agro (wheat straw, bagasse, and bamboo) pulp.

Effect of Enzymatic Bleaching on Physical Properties of Paper

Different types of physical parameters like breaking length, burst index, tear index, double-fold number, and Gurley porosity were enhanced after bleaching with these enzymes, which further upgraded the paper quality. An increase of 7.98, 3.42, 5.30, 23.08, 11.22, and 12.50% in burst index, tear index, breaking length, double-fold number, viscosity, and Gurley porosity was observed (Table 2). The increase in all physical properties of pulp displayed the role of enzymatic bleaching, which assist the progress of pulp fibrillation and restoration of bonding in fibres [44].

Li et al. [35] have reported 11.9 and 58.2% increase in tensile index and burst index, respectively, for the bio-bleaching of wheat straw pulp using cellulase-free thermostable xylanase enzymes. An increase of 9, 4.6, 4.4, 12.5, 4, and 11.8% in burst factor, tear factor, breaking length, double-fold number, Gurley porosity, and viscosity, respectively, was observed after bio-bleaching of mixed hardwood plus bamboo pulp [22]. Garg et al. [36] have reported 5.91, 13.15, 6.15, 6.96, 5.32, and 4.70% enhancement in burst factor, tear factor, double-fold number, breaking length, Gurley porosity, and viscosity, respectively, after bio-bleaching of wheat straw pulp. Xylanase treatment has enhanced the breaking length (8.69%), burst factor (7.34%), and tear factor (10.38%), in the case of mixed woody kraft pulp [40]. An increase of 1.61 and 1.07% in breaking length was observed after bio-bleaching of wheat straw kraft pulp using xylanase dose of 2 and 5 U/g pulp, respectively [38]. Agrawal et al. [39] have mentioned 4.2, 8.5, 13.4, and 10.8% gain in viscosity, breaking length, burst factor, and tear factor, respectively, for plywood veneer soda-AQ pulp. Sharma et al. [42] have reported 8.2, 5.1, and 20.96% rise in tear factor, burst factor, and tensile strength, respectively, for the bio-bleaching of agro (wheat straw, bagasse, and bamboo) pulp.

Microscopic Analysis of Bio-bleached Wheat Straw Pulp Samples

The effectiveness of xylanase-pectinase enzymes in bleaching has also been confirmed by microscopic analysis of enzymatically treated wheat straw pulp samples, as the bio-bleached samples were relatively clean in comparison to non-treated samples (Fig. 2B). This is due to the enzymatic degradation of xylan and pectin from the wheat straw pulp. The surface of non-bio-bleached pulp samples showed high content of deposits as compared to enzymatically treated samples (Fig. 2A). Wheat straw pulp fibres after 100% chemical bleaching (Fig. 2C) and after bio-bleaching plus 75% chemical bleaching treatment appeared almost similar microscopically, in terms of removal of deposits (Fig. 2D).

Characteristics of Effluents Generated After Bio-bleaching of Wheat Straw Pulp Samples

Paper industries produce bulk of toxic effluents that cause severe environmental pollution problems. These industries are constantly making efforts, so as to scale back the effluent load by producing paper in an eco-friendly way and also to satisfy the government standards, while improving profitability at the same time. After comparing the 100% chemically bleached pulp effluent load with bio-bleached plus 75% chemically bleached pulp effluent, it was observed that bio-bleached effluent (treated with 25% reduced bleaching chemical dose) was less polluted in terms of different parameters like BOD, COD, colour, lignin, TDS, and TSS. Effluents released after bio-bleaching of soda-AQ pulp using crude enzymes, with 25% less chlorination, caused 20.74 and 17.87% decrease in BOD and COD values. Colour, lignin content, TDS, and TSS values also decreased in the bio-bleached effluent by 4.27, 3.16, 2.48, and 10.00%, respectively (Table 2). Agrawal et al. [39] have reported 16.67 and 18.03% reduction in BOD and COD values of effluent after bio-bleaching of plywood veneer soda-AQ pulp.

This work concluded that xylano-pectinolytic enzymes improved the delignification process, without affecting any physical properties of pulp; decreased chemical demand, and seemed to be an effective solution for saving the environment, along with the manufacturing of superior quality paper.

A glimpse of producing superior quality paper from agro-waste wheat straw using crude cellulase-free xylanase-pectinase enzymes plus 75% bleaching has been depicted in Fig. 3.

Conclusion

Due to increased pressure on paper and pulp industry by various Environmental Regulatory Agencies, there is a necessity to develop economical, greener, safer, and effortlessly accessible technology, in order to decrease the use of conventional toxic bleaching chemicals. In this study, alkalo-thermotolerant cellulase-free xylano-pectinolytic enzymes have been used to achieve the abovementioned objective and bio-bleaching of wheat straw soda-AQ pulp with these enzymes has mitigated the chlorine dioxide consumption up to 25%, along with the epochal improvement in physical properties of pulp and effluent quality. Conclusively, bacterial alkalo-thermotolerant xylano-pectinolytic enzymes have remarkable ability in reducing kappa number and improving the optical properties of wheat straw soda-AQ pulp. Moreover, the use of agro-waste wheat straw for the production of paper is of commercial significance and production of these enzymes by a bacterial isolate also promotes the acquisition of enzyme-based technologies in pulp bleaching by paper mills for reducing pollution level.

Data availability

Not applicable.

Abbreviations

- BOD:

-

Biochemical oxygen demand

- COD:

-

Chemical oxygen demand

- SAQ:

-

Soda-anthraquinone

- CEH:

-

C—chlorination, E—alkaline extraction, H—hypochlorite

- TAPPI:

-

Technical Association of the Pulp and Paper Industry

- TSS:

-

Total suspended solids

- TDS:

-

Total dissolved solids

References

Singh, S., Dutt, D., & Tyagi, C. H. (2011). Environmentally friendly totally chlorine free bleaching of wheat straw pulp using novel cellulase-poor xylanases of wild strains of Coprinellus disseminates. BioResources, 6(4), 3876–3882.

Soni, M., Mathur, C., Soni, A., Solanki, M. K., Kashyap and B. K., Kamboj, D. V. (2020). Xylanase in waste management and its industrial applications. In: Kashyap B. K., Solanki M. K., Kamboj D. V., Pandey A. K. (eds.) Waste to energy: Prospects and applications. Springer, Singapore. 393–414. https://doi.org/10.1007/978-981-33-4347-4_16

Marin, N., Puitel, A. C., Chesca, A., & Gavrilescu, D. (2017). Response surface modeling of wheat straw pulping using sodium carbonate and sodium hydroxide mixtures. Cellulose Chem. Technol., 51(7–8), 745–753.

Ramadas, S., Kumar, T. M. K. and Singh, G. P. (2019). Wheat production in India: Trends and prospects, recent advances in grain crops research, farooq shah, zafar khan, amjad iqbal, metin turan and murat olgun, intechopen. 1–16. https://www.intechopen.com/books/recent-advances-in-grain-crops-research/wheat-production-in-india-trends-and-prospects

Fang, G. and Shen, K. (2018). Wheat straw pulping for paper and paperboard production. 1–19. https://doi.org/10.5772/intechopen.77274

Tufail, T., Saeed, F., Imran, M., Arshad, U. M., Anjum, F. M., Afzaal, M., Ain, H. B. U., Shahbaz, M., Gondal, T. A., & Hussain, S. (2018). Biochemical characterization of wheat straw cell wall with special reference to bioactive profile. International Journal of Food Properties, 21(1), 1303–1310.

Kaur, D., Bhardwaj, N. K., & Lohchab, R. K. (2018). A study on pulping of rice straw and impact of incorporation of chlorine dioxide during bleaching on pulp properties and effluents characteristics. Journal of Cleaner Production, 170, 174–182.

Kaur, D., Bhardwaj, N. K., & Lohchab, R. K. (2016). Prospects of rice straw as a raw material for paper making. Waste Management, 60, 127–139.

Zhao, D. Q., Chen, K. F., Mo, L. H., Li, J., Xu, J., Yang, R. D., & Yang, F. (2010). Chlorine dioxide bleaching reinforced by alkaline extraction and corresponding ECF bleaching sequences for wheat straw pulp. J. South China Univ. Technol., 38, 45–50.

Gangwar, A. K., Prakash, N. T., & Prakash, R. (2014). Applicability of microbial xylanase in paper pulp bleaching: A review. BioResources, 9(2), 3733–3754.

Zhang, X., Renaud, S., & Paice, M. (2008). Cellulase deinking of fresh and aged recycled newsprint/magazines (ONP/OMG). Enyzme and Microbial Technology, 43(2), 103–108.

Nathan, V. K., Rani, M. E., Rathinasamy, G., & Dhirviam, K. N. (2017). Low molecular weight xylanase from trichoderma viride vkf3 for bio-bleaching of newspaper pulp. BioResources, 12(3), 5264–5278.

Raj, A., Kumar, S., Singh, S. K., & Prakash, J. (2018). Production and purification of xylanase from alkaliphilic Bacillus licheniformis and its pretreatment of eucalyptus kraft pulp. Biocatalysis and Agricultural Biotechnology, 15, 199–209.

Kaur, D., Bhardwaj, N. K., & Lohchab, R. K. (2019). Impact of modifying conventional chlorine dioxide stage to hot chlorine dioxide during rice straw pulp bleaching on pulp, paper and effluent characteristics. Cellulose, 26(1), 7469–7482.

Silva, L. A. O., Terrasan, C. R. F., & Carmona, E. C. (2015). Purification and characterization of xylanases from Trichoderma inhamatum. Electronic Journal of Biotechnology, 18, 307–313.

Adesina, F. C., Onilude, A. A., Oluboyede, O. A., Olajide, A., Bamkefa, B., & Abiola-Olagunju, A. (2017). Production and application of xylanase by Fusarium Sp. using wood shavings as substrate. EC Microbiogy, 6(1), 4–13.

Viikari, L., Tenkanen, M. and Suurnakki, A. (2001). Biotechnology in the pulp and paper industry. 523–546.

Ahlawat, S., Battan, B., Dhiman, S. S., Sharma, J., & Mandhan, R. P. (2007). Production of thermostable pectinase and xylanase for their potential application in bleaching of kraft pulp. Journal of Industrial Microbiology and Biotechnology, 34, 763–770.

Zhao, Y., Meng, K., Luo, H., Huang, H., Yuan, T., Yang, P., & Yao, B. (2013). Molecular and biochemical characterization of a new alkaline active multidomain xylanase from alkaline wastewater sludge. World Journal of Microbiology & Biotechnology, 29(2), 327–334.

Kaur, A., Singh, A., Dua, A., & Mahajan, R. (2017). Cost-effective and concurrent production of industrially valuable xylano-pectinolytic enzymes by a bacterial isolate Bacillus pumilus AJK. Preparative Biochemistry & Biotechnology, 47(1), 8–18.

Miller, G. L. (1959). Use of dinitrosalicylic acid reagent for determination of reducing sugar. Analytical Chemistry, 31(3), 426–428.

Kaur, A., Mahajan, R., Singh, A., Garg, G., & Sharma, J. (2010). Application of cellulase-free xylano-pectinolytic enzymes from the same bacterial isolate in biobleaching of kraft pulp. Bioresource Technology, 101(23), 9150–9155.

Patel, R. N., Grabski, A. C., & Jeffries, T. W. (1993). Chromophore release from kraft pulp by purified Streptomyces roseiscleroticus xylanases. Applied Microbiology and Biotechnology, 39, 405–412.

Khandeparkar, R., & Bhosle, N. B. (2007). Application of thermoalkalophilic xylanase from Arthrobacter sp. MTCC 5214 in biobleaching of kraft pulp. Bioresource Technology, 98(4), 897–903.

Hise, R. (1996). Chlorination. In C. W. Dence & D. W. Reeve (Eds.), Pulp bleaching–Principles and practice (pp. 241–259). Tappi Press Atlanta.

TAPPI T205 sp-02. (2002). Forming handsheets for physical tests of pulp. TAPPI Press.

TAPPI T217 wd-77. (2004). Brightness of pulp. TAPPI Press.

TAPPI T403 om-10. (2010). Burst strength of paper. TAPPI Press.

TAPPI T494 om-01. (2001). Tensile breaking properties of paper and paperboard. TAPPI Press.

TAPPI T414 om-04. (2004). Internal tearing resistance of paper (Elmendorf-type method). TAPPI Press.

TAPPI T230 om-99. (1976). Viscosity of pulp (capillary viscometer method). TAPPI Press.

TAPPI T511 om-02. (2002). Folding endurance of paper (MIT tester). TAPPI Press.

SCAN-C 19:65 (1999). Pulps determination of drainability-part 1 (Schopper-Riegler method)

TAPPI T460 om-02. (2002). Air resistance of paper. TAPPI Press.

Li, X., She, Y., Sun, B., Song, H., Zhu, Y., Lv, Y., & Song, H. (2010). Purification and characterization of a cellulase-free, thermostable xylanase from Streptomyces rameus L2001 and its biobleaching effect on wheat straw pulp. Biochemical Engineering Journal, 52, 71–78.

Garg, G., Dhiman, S. S., Mahajan, R., Kaur, A., & Sharma, J. (2011). Bleach-boosting effect of crude xylanase from Bacillus Stearothermophilus SDX on wheat straw pulp. New Biotechnology, 28(1), 1–7.

Comlekcioglu, U., Tutus, A., Cicekler, M., Gunes, M., & Aygan, A. (2014). Application of recombinant xylanase from Orpinomyces sp. in elemental chlorine-free bleaching of kraft pulps. Romanian Biotechnological Letters, 19(1), 1–10.

Walia, A., Mehta, P., Guleria, S. and Shirkot, C. K. (2015). Modification in the properties of paper by using cellulase-free xylanase in biobleaching of wheat straw pulp produced from alkalophilic Cellulosimicrobium cellulans CKMX1. Canadian Journal of Microbiology, 1–25

Agrawal, S., Yadav, R. D., & Mahajan, R. (2016). Synergistic effect of xylano-pectinolytic enzymes produced by a bacterial isolate in bleaching of plywood industrial waste. Journal of Cleaner Production, 118, 229–233.

Nagar, S., Jain, R. K., Thakur, V. V., & Gupta, V. K. (2013). Biobleaching application of cellulase poor and alkali stable xylanase from Bacillus pumilus SV-85S. 3 Biotech, 3, 277–285.

Ozer, A., Canakci, S., Gocmen, G., Denij, I., Kirci, H., Okan, O. T., & Belduz, A. O. (2018). Distinctive delignification with consecutive application of geobacillus sp. 71 xylanase and Rhodococcus jostii rha1 lignin peroxidase. Maderas. Ciencia y tecnología, 20(3), 505–518.

Sharma, A., Balda, S., Gupta, N., Capalash, N., & Sharma, P. (2020). Enzyme cocktail: An opportunity for greener agro-pulp biobleaching in paper industry. Journal of Cleaner Production., 271(1), 122573.

Boruah, P., Dowarah, P., Hazarika, R., Yadav, A., Barkakati, P., & Goswami, T. (2016). Xylanase from Penicillium meleagrinum var. viridiflavum-A potential source for bamboo pulp bleaching. Journal of Cleaner Production, 116, 259–267.

Torres, C. E., Negro, C., Fuente, E., & Blanco, A. (2012). Enzymatic approaches in paper industry for pulp refining and biofilm control. Applied Microbiology and Biotechnology, 96, 327–344.

Acknowledgements

The corresponding author would like to thank Avantha Centre for Industrial Research and Development (ACIRD), Yamuna Nagar, for providing their laboratory facilities.

Funding

The financial support provided by Department of Biotechnology (DBT), Ministry of Science & Technology, Government of India (Grant Number: BT/PR 20438/BCE/8/1220/2016 for 3 years).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Ethics Approval and Consent to Participate

Not applicable.

Consent for Publication

Not applicable.

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sharma, D., Nagpal, R., Agrawal, S. et al. Eco-friendly Bleaching of Agrowaste Wheat Straw Using Crude Alkalo-Thermotolerant Cellulase-Free Xylano-Pectinolytic Enzymes. Appl Biochem Biotechnol 194, 620–634 (2022). https://doi.org/10.1007/s12010-021-03641-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-021-03641-6