Abstract

Paper industry being a mature mega-scale industry is focusing on process oriented technical modifications to reduce dependency on wood fibers and resource utilization. In this research study, conventional chlorine dioxide (D0) bleaching method was modified to hot chlorine dioxide (DHT) with an aim of reducing the effluent load with special concern to chlorolignin compounds. These compounds were measured by gas chromatograph equipped with ECD detector. The chlorophenols, chlorocatechols, chloroguaiacols, chlorovanillins, chlorosyringols and bromophenols were reduced by 9%, 50%, 34%, 47%, 17% and 31%, respectively under DHT based sequence at same dose of chemicals. The general environmental parameters i.e. COD, BOD, TS, colour, lignin and AOX also got reduced in DHT based sequence. The modification of D0 to DHT was found to be effective as effluent quality was enhanced without compromising the optical and strength properties of cellulosic paper even at low dose of chlorine dioxide.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The concerns for environmental unbalancing and consumer’s demands for product quality coerce the pulp and paper industry to find fibrous substitutes for woody raw materials and the environment friendly techniques to convert these raw materials into furnished products. The unharnessed lignocellulosic biomass in agricultural fields and agricultural byproducts including cereal straws, hemp, bagasse, reed grass, jute, kenaf and bamboo have high potential to compete with forest based woody materials. The pulp and paper mills are exploring the benefits of these agro wastes in papermaking to endorse industry production (Kaur et al. 2017a). Rice straw is a profuse and easily accessible raw material in Asian countries that consists of cellulose, hemicelluloses, lignin, silica and ash content and produced in almost equal quantities to grain during paddy cultivation (Kaur et al. 2018a). The conversion of this agricultural residue into pulp and paper may help the farmers to manage it without onsite burning i.e. the major issue of air pollution, respiratory problems and road accidents (Zhang et al. 2017a, b). The soda anthraquinone (AQ) pulping process is widely used for efficient conversion of non woods into fibrous pulp without much cellulose degradation (Hart and Rudie 2014). Jahan et al. (2012) reported that alkaline and hot water extraction of rice straw prior to Soda-AQ pulping improved the pulp yields and quality significantly. Jahan et al. (2015) suggested the delignification of rice straw with organic acids as formic acid: acetic acid: water to remove lignin and short chain fibers without affecting the α-cellulose and silica within the pulp. Approximately 90% of delignification occurred during cooking of raw materials and rest is achieved in bleaching using different oxidizing agents. Among the whole pulp mill processes, the largest amount of wastewater loaded with high BOD, COD, colour, total solids and toxic chlorolignin components is produced during pulp bleaching process (Singh and Dutt 2014). The poor quality bleaching effluent even after treatment possesses the characteristics unfavourable for aquatic life and beyond the prescribed limits of pollution control boards. The major groups of chlorolignin compounds found in pulp mill effluent by their family are chlorophenols (CP), chlorocatechols (CC), chloroguaiacols (CG), chlorosyringols (CS), chlorosyringaldehydes (CSA), chlorovanillins (CV), chlorinated resin and fatty acids (cRFA) etc. (Kaur et al. 2017b). Zhang et al. (2018) also reported that the conventional D0 stage bleaching effluent of sugarcane bagasse pulp consisted of huge amount of chloro-organic compounds. These chlorophenolic compounds possess toxic characteristics and are well known for inducing carcinogenicity and mutations. These compounds can penetrate to the skin and may cause malfunctioning of organs resulting in paralytic attacks, lungs and heart disorders (Kaur et al. 2017a). To become competitive and to make a way in the National and International market, paper industry has to adapt the inventive and intermittent technology change with due consideration to the environmental issues (Sankaralingam 2014). To minimize the generation and effects of toxic effluents, it becomes important to recognize the precise constituents that threaten the human health and environmental quality. Technology advancement in bleaching process must be executed in a manner that environmental and human health can be sheltered with economic expansion of the industry.

The Elemental chlorine free (ECF) and Total chlorine free (TCF) are the two bleaching processes that focus on elimination of toxic components from the bleaching effluents. Studies revealed that TCF bleaching of hardwoods resulted into weaker fiber strength, lower brightness potential, lower yield, higher energy requirements and high capital cost that have eroded its further use as a successor to ECF (Jour et al. 2013). In the USA, ECF process is regarded as being the Best Available Technology and in Europe, the Commission has decided that there is no significant difference between TCF and ECF (CPI 2013).

ECF bleaching is the most adapted process by the national and international paper industry as chlorine dioxide (ClO2) is specific for lignin removal than other oxidizing agents. ClO2 provides the good quality pulp of high brightness without carbohydrates degradation (Bouiri and Amrani 2011). The oxidation potential of ClO2 is five times more than the molecular chlorine thus consumed in low concentration during bleaching results into less discharge of toxic chemicals into wastewater (Kaur et al. 2018a). Effluents of ECF bleaching are less polluted in terms of biological and chemical oxygen demands, colour and adsorbable organic halides (AOX) that included the chlorophenols, bromophenols and resin fatty acids (Gomes et al. 2007). ClO2 oxidizes the phenolic and non-phenolic structures of lignin into muconic acids and quinines, attacks aliphatic double bonds that reduces colour and neutralizes the radicals generated during the bleaching reactions (Tavast et al. 2011). Delignification rate determines the chemical consumption during bleaching but presence of hexenuronic acid (HexA) representing the false lignin (generated during pulping) may enhance the dose of these chemicals (Ventorim et al. 2008). HexA are oxidized in acidic conditions and exploit the major fraction of bleaching chemical applied. Zhang et al. (2019) found that HexA not only reacts with chlorine dioxide but also with its intermediates, such as hypochloric acid and chlorine thus influence the bleaching rate and formation of organohalides.

Modification in ClO2 bleaching at high temperature and low pH (DHT) at first stage offers several advantages in contrast to conventional D0 bleaching. The hydrolysis of HexA occurs rapidly at high temperature and low pH and can be removed easily from the pulp (Jiang et al. 2006). This lowers the consumption of chemicals during bleaching leading to less generation of chlorolignin compounds. Lachenal and Chirat (1998) reported that hot chlorine dioxide involves the reaction at low pH representing acid and dioxide treatment in single stage using acid involved for maintaining pH so there is no need to give any extra acid stage. Low chlorine dioxide requirement with same targeted brightness as in conventional D0 bleaching reduced the yellowing tendency of bleached pulp, provided higher brightness ceiling and reduced the pollution load in wastewater also (Ragnar and Backa 2004). Different bleaching stages have specific conditions of time, temperature and pH. If these conditions will be modified, it may show negative impact on the pulp characteristics. For DHT, the time—2 h is specific as also studied in most of the research papers available on DHT (Zhang et al. 2018; Gomes et al. 2007; Milanez and Colodette 2005). A study by Ventorim (2005) revealed that in DHT treatment with increase in time and temperature, partial acid hydrolysis of HexA occurred resulting into decrease in generation of chlorinated organic halides which is not a possible reaction in D0. The studies revealed that hot chlorine dioxide stage is able to dissociate the phenolic lignin and HexA and limit the generation of organiochlorides (Zhang et al. 2017a, b, 2018). Many of the research literatures studied were found to be oriented towards the use of DHT at initial stage of bleaching for kraft hardwood and bagasse pulp (Zhang et al. 2019; Tavast et al. 2011; Davies et al. 2009; Ventorim et al. 2008; Ragnar and Backa 2004) but scarce literature was available for the agricultural residues specially the cereal straws. Available literature focuses on brightness reversion, higher delignification, removal of HexA and reduction in AOX generation but the detailed impact of using DHT on major chlorolignin groups is not presented yet.

Present study emphasized on use of rice straw in papermaking as an approach for agro waste utilization with industry benefits. With aim of reducing the pollution load in wastewater elemental chlorine free bleaching was performed. The D0 stage was modified to DHT and its impact on final paper properties as well as the effluent quality was studied. Reduction in different chlorolignin compounds (CP, CC, CG, CS, and CV) was studied. The research was oriented towards the agro waste management and wastewater pollution load elimination during paper production. Results were expressed in terms of paper properties achieved and wastewater load reduction due to DHT stage.

Materials and methods

Rice straw processing

The raw material used for study was procured from a village of Haryana, India. It was analyzed for its chemical composition and found that it contained 33% cellulose, 37% hemicelluloses and 13% lignin. The cellulose within rice straw was measured using the method of Updegroff, 1969. The hemicelluloses were determined using TAPPI test method T 223 cm-01. The acid insoluble lignin was quantified using T 222 om-85. The material was cooked in autoclave batch digester (batch size-150 g oven dry weight basis) at 155 °C for 20 min. An alkali dose of 12%, 0.05% of anthraquinone and water were added on over dry weight basis of rice straw. The bath ratio of 1:4 was maintained for each batch. After cooking, the black liquor was removed then pulp was washed and screened. The pulp produced was of 15 kappa number with 37.3% ISO brightness and 14.2 cP viscosity. Rice straw soda-AQ pulp possessed good physical characteristics like tensile index 42.2 Nm/g, tear index 2.12 mNm2/g and burst index 2.46 kN/g and was found suitable for papermaking.

Bleaching of rice straw pulp

With objectives of achieving 83% ISO brightness and low wastewater load, the unbleached soda-AQ rice straw pulp was bleached using ECF bleaching. A control set (DEOPD bleaching) with conventional D0 process (temperature-55 °C, pH-3.0 and time-45 min) with chlorine demand of 3.75% was executed where D denoted the ClO2 and EOP represented oxygen reinforced alkali extraction using hydrogen peroxide. Four more sets of same bleaching sequence were demonstrated with modification of D0 stage to DHT (temperature-85 °C, pH-2.0 and time-120 min), one at the same dose as in control set and other three were at 10%, 15% and 25% lower chemical dose at initial stage than control. Chlorine dioxide water was procured from a nearby paper mill. To find the chlorine demand, kappa factor 0.25 was selected based on optimization performed in earlier study (Kaur et al. 2018a, b). The chorine demand of rice straw pulp was calculated using formula given below:

The extraction stage was conducted at temp-75 °C, pH-11 and 10% consistency for 120 min for all the bleaching sets. The final bleaching with chlorine dioxide at 10% consistency was performed for 180 min at 80 °C and pH 3.5. The pulp was well mixed with the chemicals by kneading during bleaching and placed in the water bath for D0, DHT and D stages and in air heated digester for EOP stage. On completion of bleaching process, pulp was filtered and filtrate was collected as effluent. Pulp was washed with filtered water to remove all the residuals of bleaching chemicals and used for analyzing its optical and strength properties.

Analysis of bleached pulp properties

The moisture content of the unbleached and bleached pulps was analyzed using method IS 1060 (Part I)-1966 (Revised 2009). To find the residual lignin in unbleached pulp, kappa number was calculated using TAPPI test method T 236 om 99 and the micro kappa number of bleached pulp after EOP stage was analyzed with method TAPPI UM-246. Viscosity of all the bleached pulp sets was measured by using TAPPI test method T 230 om-99 using Cannon viscometer (9721-B62, USA make) that directed the idea for degradation of carbohydrates during pulping and bleaching. To find the physical strength of the paper hand sheets of 60 g/m2 were prepared on a sheet former (make-Universal) as per the TAPPI method, T 205 sp-97. The tear index of handsheets was measured by L&W tearing tester, SE 009 using method, T 414 om-88 in which the force needed to tear the multiple piles of the paper through a specified distance was noticed. The L&W bursting strength tester, code 181 was used to measure the burst index using method, T 403 om-91 where, the test specimens of handsheets were held between annular clamps and subjected to an increasing pressure by a rubber diaphragm. The diaphragm was expanded by hydraulic pressure at a controlled rate, until the test specimen bursted. The tensile index of handsheets was analyzed using L&W tensile strength tester, code 060 (TAPPI T 494 om-01). The method, ISO-5267 was followed to analyze the Schopper-Riegler number. The optical properties of pulp like brightness, whiteness and yellowness were also measured using instrument. Elrepho brightness tester of L&W, code 070/071.

Effluent characterization

General characteristics

The effluent collected after each stage was characterized for different environmental parameters using methodology of IS and APHA standards. The composite effluents were prepared after mixing each stage effluent in its volumetric proportion for all the sequences studied. The methods included in IS: 3025 were adopted to find the BOD (Part 38 and 44), COD (Part 58), pH (Part 11), TS (Part 15), TDS (Part 16) and TSS (Part 17). Lignin content and colour within the effluent were analyzed spectrophotometerically (U.V. spectrophotometer, Varian Cary 100 Bio) following the APHA test methods 5550 and 2120 C, respectively. The AOX amount was measured using an AOX analyzer (Thermo Scientific, ECS-1200) and following the method ISO 9562.

Analysis of chlorophenolic compounds

The composite effluent samples of different bleaching sets were analyzed for chlorophenolic compounds using gas chromatograph equipped with electron capturing detector (Varian 450 GC). 500 mL of each sample was extracted and derivatized according to a method given by Lindström and Nordin (1976). The samples were acidified (2.0 pH) using 4 N H2SO4. The samples were taken in separating funnels and 200 mL of solvent mixture of diethyl ether and acetone (HPLC grade) in ratio 90:10 was added to each separating funnel. The samples were extracted for 48 h in the solvent mixture with intermittent shaking. The emulsion formed during extraction was broken using heat gun and all the ethereal solution of different samples was transferred to new separating funnels. The extracts were washed with 2.5 mL of 0.5 M sodium bicarbonate to make the layer acid free. Sodium hydroxide (0.5 M) was added to the separating funnel and the content was shaken for 5 min. The aqueous NaOH layer with extracted chlolophenolic compounds was washed with fresh diethyl ether and taken in PTFE lined screw capped glass tube. To maintain the pH the 0.5 mL of 0.5 M buffer solution of disodium hydrogen phosphate was added. To covert the chlorophenols into their acetyl derivatives 0.5 mL of acetic anhydride (AR grade) was added. The content was shaken for 5 min and at last extracted in 4 mL of HPLC grade n-hexane. The reference compounds including 34 isomers of various chlorophenolic compounds supplied by Sigma Aldrich, USA, were also derivatized by the same process as used for samples. The retention time and area for each chlorophenolic component was calculated by running the standards and their presence was detected in sample by matching their retention time (± 0.5 min) with those of pure standards. The GC conditions for analysis are given below:

Column type | Factor four Capillary column (VF-1 ms) |

Column dimensions | 30 m × 0.25 mm I.D. with 0.25 µm thickness |

Detector type | ECD |

Sample size (µl) | 1 |

Detector temperature (°C) | 290 |

Injector | 270 |

Column temperature (°C) | Initial 100 for 3 min |

100–180 @ 4 °C/min | |

180 for 10 min | |

180–270 @ 15 °C/min | |

270 for 2 min | |

Column pneumatics | 1 mL min |

Make up nitrogen flow | 28 mL min |

Split ratio | 1:20 |

Extraction efficiency

For calculating the extraction efficiency of each chlorophenolic compound, standard solutions were extracted and derivatized by the same process as used for samples and their peak area was identified using GC. The quantity of chlorophenols in the extracts was estimated on the basis of peak area by using formula:

Results and discussion

Effect of DHT on kappa number

The residual ClO2 in conventional D0 set was found to be 69 ppm and in DHT treatment at same dose it was reported as 51 ppm. On reducing the dose to 10% and 15% the residual ClO2 was decreased to 34 ppm and 21 ppm, respectively. The residual ClO2 was found to be nil at 20% lower dose of ClO2. At higher time and temperature in DHT, the most of the ClO2 was consumed during bleaching and its effect was also reflected during kappa number measurement after EOP stage. The residual peroxide and ClO2 in EOP and D stage were higher in DHTEOPD sequence than D0EOPD sequence having same dose of ClO2 at initial stage depicting the high dose of bleaching agents in these two stages. Petit-Breuilh et al. (2004) found that DHT bleaching is more efficient than D0 and support chlorine dioxide dose reduction during bleaching. The kappa number of D0EOP stage in control set was found to be 2.8 but decreased to 1.9 in the pulp after DHTEOP stage with same ClO2 dose as that of control. Zhang et al. (2018) found that more lignin was dissolved after increasing reaction temperature which led to lower lignin content in comparison to the control. For the pulp sets with 10% and 15% of ClO2, the kappa number was reported as 2.1 and 2.5, respectively. But on decreasing the chemical dose by 20% less ClO2, the kappa number was found to be 3.4. It represented that better delignification occurred in DHT treatments even at lower (10 and 15%) dose of ClO2 at initial stage. Zhang et al. (2019) found that in DHT stage, improved kappa number and brightness reversion for bleached bagasse pulp was achieved. The results of reduction in kappa number were also found to be in good agreement with the findings of Zhou et al. (2008) and Kumar et al. (2007).

Effect of DHT on optical properties

The digital photographs of the handsheets bleached by different sequences are given in Fig. 1. Modification of D0 into DHT stage showed marked influence on optical properties of paper. Jahan et al. (2015) reported the brightness of 80% ISO on bleaching rice straw organosolv pulp with DEPD sequence consuming 25 kg ClO2 per ton of pulp. The brightness of pulp in D0EOPD sequence was found to be 82.9% ISO where as in DHTEOPD sequence having same dose of ClO2 at initial stage as in control, the brightness was found to be 83.6% ISO. The result was in line with the earlier study of Zhang et al. (2018) on DHT treatment of bagasse pulp where the brightness increased by 1.86% ISO in comparison to normal ClO2 treatment. The studies by Rosenau et al. (2017) and Zwirchmayr et al. (2017) have found that HexA-derived chromophores have a prominent impact on brightness development of chemical pulps during bleaching. For the sequence in which the ClO2 was reduced by 10% at initial stage, 83.2% ISO brightness was observed. In DHTEOPD sequence with 15% low dose of ClO2 at initial stage the comparable brightness to the control set was observed. On further reducing the ClO2 dose by 20%, 82.1% ISO brightness was achieved for rice straw pulp. It indicated that DHT at initial stage was effective in terms of achieving the optical properties even at low dose of ClO2, better delignification occurs resulting into higher or comparable brightness to the control set of the rice straw pulp. Pie et al. (2016) revealed that HexA formed during pulping reacts with intermediate products of chlorine dioxide bleaching and affects the bleachability and generation of adsorbabale organic halides. A study by Ragnar and Backa (2004) also reported that even on reducing the dose of ClO2 by 20–30%, the comparable brightness can be achieved in DHT treatment in comparison to conventional D0 process. The whiteness of pulp was found to be 75.4% in DHTEOPD sequence having same dose of ClO2 as in control.

The whiteness of pulp in DHTEOPD sequence having 10%, 15% and 20% low dose of ClO2 at initial stage than control was found to be 74.6%, 74.1% and 74%, respectively and was better than whiteness (72.8%) obtained for D0EOPD sequence. Kumar et al. (2007) in their study on DHT bleaching of hardwood and bamboo pulps observed the better brightness and whiteness than the conventional D0 process. DHT had a significant role in the destruction of the conjugated carbonyl resulting into increased whiteness (Zhang et al. 2018). The yellowness of the different pulp sets was also reduced in DHT based sequences except when lowering chlorine dioxide dose by 20%. Davies et al. (2009) reported that in DHT not only the optical properties were improved but also the brightness stability of the paper was enhanced. A study by Zhang et al. (2017a, b) revealed that DHT is found to be highly effective in dissociating the bonds between HexA and hemicellulose and also possess higher delignification selectivity. The data depicting the effect of DHT on optical properties of paper is given in Table 1.

Effect of DHT on strength properties

The modification of D0 stage of bleaching in DHT did not show any potential impact on tear, tensile and burst indices of handsheets prepared from rice straw soda-AQ pulp. The tensile index of the pulp was increased from 46.9 Nm/g in D0EOPD sequence to 47.5 Nm/g in DHTEOPD sequence. The tensile index was further increased slightly on reducing the ClO2 dose at initial stage by 10%, 15%, 20%. The same trend of increase was also observed for burst index that increased by 12% in DHTEOPD sequence in comparison to D0EOPD sequence both having same dose of chemicals. On reducing the ClO2 dose at initial stage by 10%, 15% and 20%, increase of 11%, 13% and 15%, respectively in burst index was observed. DHT stage imposed negative impact on tear index as it was decreased by 5% in DHTEOPD sequence in comparison to D0EOPD sequence. The tear index was found to be better in DHTEOPD sequence having less dioxide dose at initial stage than DHTEOPD sequence with 3.75% ClO2 dose. The study on fiber morphology of bagasse pulp after DHT treatment showed the lower fiber length values than control set (Zhang et al. 2018). Eiras and Maria (2002) in their study revealed that hot chlorine dioxide bleaching at optimized dose and other conditions can improve the pulp properties with saving the cost by ~ 7%. A slight decrease in viscosity was also observed in DHT based sequence. This may be attributed to the high time period and temperature during bleaching that attacks the cellulosic fibers and converts them to short chain fibers. The chemical reactions that occurred during HexA degradation at a higher temperature were more sensitive than at the temperature between 60 and 70 °C (Zhang et al. 2019), The final viscosity of DHTEOPD sequence was found to be comparable (8.4 cP) to the conventional D0EOPD sequence (9.0 cP). Ragnar and Backa (2004) reported that the loss of viscosity was due to the presence of small amount of elemental chlorine in ClO2 produced in the mills. The final viscosity of the set having 10% lower dose of ClO2 at initial stage in DHT was found to be 8.6 cP but on further decreasing the ClO2 dose by 15% and 20%, comparable viscosity to D0EOPD sequence was achieved. In DHT based sequence residual lignin and HexA content decreases in the pulp, so, the hypochlorous acid attacks and oxidizes the carbohydrates resulting into drop in pulp viscosity. This loss is mainly due to excessive degradation of carbohydrates under thermal and acidic environment as also observed by Karim et al. (2011). The results of viscosity in DHT based sequences were reported in close proximity to the studies of Zhou et al. (2008) and Lachenal and Chirat (1998). Zhang et al. (2018) studied that during DHT stage the breakdown of β-glycosidic and C–H bonds occurs that may be the potential reason for drop in viscosity. The data regarding the effect of DHT on paper properties has been shown in Table 2.

Effect of DHT on general effluent characteristics

The significant impact on wastewater pollution load was observed on modifying the D0 stage to DHT as also shown in Table 3. On comparing the single stage effluent, it was found that EOP stage effluent was the most polluted of D0EOPD sequence. The COD values (kg/t) for EOP stage were found to be 21.7 for D0EOPD sequence and 19.5 for DHTEOPD sequence. Mounteer et al. (2007) reported that EOP effluents of bleaching sequences are primarily loaded with approx. 13.6 kg/t of COD and 3.8 kg/t of BOD. The COD was further reduced in DHT based sequences on reducing the ClO2 dose. The COD for D0 stage was reported as 10.6 kg/t and reduced to 8.4 kg/t in DHT having same dose of ClO2 as in D0. The values for COD at 10%, 15% and 20% less dose of chlorine dioxide in DHT stage were found to be 7.1 kg/t, 6.2 kg/t and 5.5 kg/t, respectively. The BOD of DHT stage in all the sequences was found slightly less in comparison to D0 stage. During bleaching treatments chromophoric, highly oxidized, polymeric lignin or chlorolignin derivatives are formed that impart dark colour to the effluent.

The colour of DHT, EOP and D stage effluents in DHT based sequences was found to be less in comparison to different stages in conventional D0EOPD sequence. The effect of modification of D0 to DHT and reducing the chlorine dose at initial stage on each stage effluent quality is shown in Fig. 2.

As compared to control set at same dose of ClO2 in initial stage in DHTEOPD sequence, the % reduction in COD was found to be 20%. On reducing the ClO2 dose by 10%, 15% and 20%, the % reduction in COD achieved was 25%, 33% and 44%, respectively. The meager effect of DHT observed on BOD that was reduced from 13.6 kg/t in control to 11.9 kg/t in DHTEOPD sequence with 20% less ClO2 at initial stage. A reduction of 19%, 33%, 36% and 41% was observed in colour in DHTEOPD sequence (with same, 10%, 15% and 20% less doses of ClO2), respectively. The significant reduction in lignin content was also observed.

Majority of AOX comes from the first chlorine dioxide stage (Lehtimaa et al. 2010). Study by Yao et al. (2017) revealed that the compounds identified in bleaching effluents are the degradation products of lignin. During ClO2 bleaching, free chlorine is generated from ClO2 that reacts with residual lignin and HexA in the pulp and generates AOX (Nie et al. 2015). The amount of adsorbable halides was reduced drastically in effluents of DHT based sequences. Research investigation (Zhang et al. 2018; Nie et al. 2015, 2016; Yao et al. 2017) on removing the factors responsible for AOX formation have been conducted including DHT treatment so that the norms of Central Pollution Control Boards can be fulfilled. Malhotra et al. (2013) found that DHT stage inhibited the chlorination of lignin and weakened the other ways for the generation of AOX by oxychloride resulting into lesser pollution load in bleaching effluents. Even adding the same dose of chemicals in DHTEOPD sequence as of conventional bleaching 13% reduction in AOX was observed at high temperature and extended time, the most of chlorine dioxide was consumed during bleaching leading to more delignification with less pollution load. The result was found to be in strong agreement with the results of Gomes et al. (2007). On reducing the amount of ClO2 by 10%, 15% and 20% in DHTEOPD sequence, reduction of 25%, 33% and 41%, respectively was observed in AOX. Different studies revealed that on decreasing the dosage of chlorine dioxide at initial stage, the AOX content may decrease by 50% without compromising the brightness of the pulp (Zhang et al. 2018; Zhu et al. 2016; Ventorim 2005). Zhang et al. (2019) reported that DHT breaks the bonds of lignin-HexA-Xylan complexes which increase the degradation of HexA and thereby decreasing the consumption of chlorine dioxide in DHT stage.

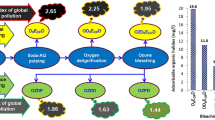

Effect of DHT on generation of chlorolignin compounds

The composite effluent of each sequence was characterized for the type and amount of chlorolignin compounds present in it. The effluents were found to be rich in 26 chlorolignin compounds of family chlorophenols, chlorocatechols, chloroguaiacols, chlorosyringols, chlorosyringaldehyde and bromophenols. Table 4 represents the type and amount of chlorolignin compounds generated during pulp bleaching. AOX content in effluent mainly comprises the chlorophenols and guaiacols and chlorobenzenes (Yao et al. 2017; Malhotra et al. 2013). The total amount of these compounds was found to be 448 mg/t in conventional D0EOPD sequence. On modifying the D0EOPD sequence to DHTEOPD sequence with same bleaching chemicals dose, the amount of chlorolignin compounds was reduced to 361 mg/t. On reducing the chlorine dioxide dose by 10, 15, 20% at initial stage, the amount of these compounds reduced to 278 mg/t, 238 mg/t and 194 mg/t, respectively with comparable paper properties. Zhang et al. (2018) during their study on bagasse pulp bleaching found that the DHT stage is an effective method of reducing the AOX content in the ECF bleaching sequence. In DHT treatment with increase in reaction time and temperature partial acid hydrolysis of HexA occurred resulting into decrease in generation of chlorinated organic halides (Ventorim 2005). Reduction in chlorine dose in DHT is more efficient than D0 in terms of reducing the AOX (Zhang et al., 2018).

The major chlorolignin compounds in bleaching effluent of D0EOPD sequence were chalorocatechols followed by chlorovanillins and chlorophenols. Malhotra et al. (2013) also observed that chloroguaiacols and chlorophenols are the major contributor to total chlorophenolic compounds in DED bleaching. The literature regarding the detailed impacts of DHT on chlorolignin compounds generation during rice straw pulp bleaching till date was inadequate to discuss the results of present study. The amount of chlorophenols in D0EOPD sequence was estimated to be 100.3 mg/t and was not much affected by DHTEOPD sequence at same bleaching chemicals dose as of D0EOPD sequence. The reduction achievement in chlorophenolic compounds was less than reported by Zhang et al. (2018) on DHT bleaching of bagasse fibres. Kaur et al. (2017b) in their study on using chlorine dioxide achieved the 92% reduction in chlorophenolic compounds than chlorine based bleaching. This reduction may further be improved by modifying the conventional ECF bleaching to hot chlorine dioxide bleaching even at lower dose of bleaching chemicals. On reducing the dose of chlorine dioxide by 10%, 25.8% reduction in these compounds was achieved. On further lowering the dose by 15% and 20%, the % reduction was improved by 37.7% and 57% respectively. Prasetyo et al. (2015) in his study reported that 72% reduction in chlorophenolic compounds was achieved after enzymatic bleaching. The chlorocatechols that was found in the highest amount in D0EOPD sequence were reduced potentially on modifying the conventional D0 process to DHT. At same dose of chlorine dioxide in DHTEOPD sequence as in D0EOPD sequence, the amount of chlorocatechols was reduced down to 35%. This reduction was further increased (45%, 52% and 60%) with further decrease (10%, 15% and 20%) in chemical dose of chlorine dioxide at initial stage. Kumar et al. (2012) found the significant reduction in chlorocatechols in DEOPD sequence but the present study emphasized on further improvement of DEOPD sequence to DHTEOPD sequence for reducing the pollution load of bleaching effluents. The process modification during bleaching may enhance the quality of wastewater that may prove to be helpful for improving the efficiency of end of pipe wastewater treatment plants (Kaur et al. 2017a). Chloroguaiacols and chlorocatechols are compounds formed in higher concentration during bleaching and remain bounded to chlorolignins (Van den Berg et al. 2006). The most affected group by DHT was chloroguaiacols that are highly known for their aquatic toxicity. On reducing the chlorine dioxide dose by 20%, 75% reduction in chloroguaiacols was achieved. Many of the chloroguaiacols like 4,6- dichloroguaiacol, tetrachloroguaiacol and 4,5,6-trichloroguaiacol were reduced sarcastically on lowering the bleaching chemical dose. On modifying the D0 process to DHT without chlorine dioxide dose reduction, reduction of 31%, 36% and 39% was observed in 4,5,6-trichloroguaiacol, tetrachloroguaiacol and 4,6-dichloroguaiacol, respectively. When the temperature was increased, the rate of bleaching increased as well as the consumption of chlorine dioxide leading to low formation of chlorilignin components (Alajoutsijärvi 2015). The compound, 3,5-dichloroguaiacol that generated in minute quantities in D0EOPD sequence was not found in DHT based sequence. The compound 5-chloroguaiacol was not much affected by the DHT process. The amount of chlorolignin components present in bleaching effluents by their family has been presented in Fig. 3.

Chlorovanillins were also reduced significantly (47%) in DHTEOPD sequence in comparison to D0EOPD sequence at same bleaching chemical dose. The % reduction in chlorovanillins on reducing chlorine dioxide dose by 10% at DHT stage was found to be 56% and increased to 59% at 15% less chlorine dioxide dose. Approx 64% of reduction in chlorovanillins was observed on reducing 20% of chlorine dioxide dose at DHT stage. The 5,4-dichlorovanillin was the most affected by the modification of D0 process to DHT whereas 3,4,5-trichlorovanillin was the least affected by process change. The amount of 5-chlorovanillin was 3.1 mg/t in D0EOPD sequence and not generated in DHT based sequence. The total amount of chlorosyringols including chlorosyringaldehyde in D0EOPD sequence was 36.8 g/t. A reduction of 17% in these compounds was notified in DHTEOPD sequence without reducing the bleaching chemical dose that enhanced by 34%, 46% and 52% on reducing the chlorine dioxide dose by 10%, 15%, and 20% in DHTEOPD sequence, respectively. The 3,5-dichlorosyringol was not produced in DHT based sequences but meager impact was observed on 3-chlorosyringol. The amount of 2,6-dichlorosyringaldehyde was reduced potentially on modifying the D0 process to DHT and a reduction of 24% was achieved in DHTEOPD sequence having same dose of chlorine dioxide as in D0EOPD sequence. Kaur et al. (2017b) found potential decrease in 2,6-dichlorosyringaldehyde on incorporating oxygen bleaching stage prior to ECF.

Only 2 components of bromophenols (2,6-dibromophenol and 2,4,6-tribromophenol) were studied and both were significantly contributing to the chlorolignin compounds in bleaching effluents. The amount of bromophenols in D0EOPD sequence was 41 mg/t and was reduced to 37.5 mg/t in DHTEOPD sequence with same chlorine dioxide dose at initial stage. A slight decrease in generation of these compounds was found on decreasing the dose of chlorine dioxide in DHTEOPD sequence. The modification of D0 process to DHT has marked effect on generation of chlorolignin compounds in bleaching effluents and the effect was potentially enhanced on decreasing the dose of bleaching chemicals at initial stage in DHT based sequence.

Conclusions

The modification of conventional ClO2 bleaching to high temperature and low pH chlorine dioxide bleaching called DHT stage was found to be highly effective in terms of reducing the chemical dose and pollution load of wastewater with improved or comparable pulp and paper properties. The experiments were demonstrated with DHT (temperature-85 °C, pH-2.0 and time-120 min), one at the same dose as in control set and other three were at 10%, 15% and 25% lower chemical dose at initial stage than control. The optical properties of pulp in DHTEOPD sequence having same dose of bleaching chemicals and at 10% lower dose of chlorine dioxide at initial stage were better than the conventional process. On reducing the dose by 15%, the brightness of the pulp was comparable (82.8%ISO) to that obtained by D0EOPD sequence. On reducing the chlorine dioxide dose by 10%, 15% and 20%, the % COD was cut down by 25%, 33% and 44%. The significant reduction in chlorolignin compounds like 9% in CP, 50% in CC, 34% in CG, 47% in CV, 17% in CS and 31% in BP was observed in DHTEOPD sequence in comparison to D0EOPD sequence, both having same dose of chemicals which enhanced manifold on decreasing the chlorine dioxide dose. The DHT bleaching with 20% less chlorine dioxide was found to be optimal as huge reduction in BOD, COD, colour and lignin is achieved without much compromising the pulp and paper properties.

References

Alajoutsijärvi T (2015) Replacing sulfuric acid in pulp bleaching with internally formed organic acids. Master’s thesis for the degree of Master of Science in Technology submitted for inspection, Espoo, 7 January, 2014

Bouiri B, Amrani M (2011) Elemental chlorine-free delignification of kraft pulp produced from halfa (Stipa tenacissima). Fibres Text Eastern Europe 19:142–147

Confederation of Paper Indusrty (2013) Fact sheet: environmental aspect of ECF and TCF chemical wood pulp bleaching. www.paper.org.uk. March 2013. Accessed on 07 June 2016

Davies D, Dietz T, Suess HU (2009) A comparison of options to improve brightness stability of chemical pulp. Pulp Paper Can 110:25–31

Eiras BM, Maria K (2002) Optimisation of the high temperature chlorine dioxide bleaching stage for eucalyptus kraft pulp. Visosa Federal University, Brazil

Gomes CM, Colodette JL, Delantonio NRN, Mounteer AH, Silva CM (2007) Effect of hot acid hydrolysis and hot chlorine dioxide stage on bleaching effluent biodegradability. Water Sci Technol 55:39–46

Hart PW, Rudie AW (2014) Anthraquinone—a review of the rise and fall of a pulping catalyst. Rev Process Inf Refereed (Peer Rev) 13:23

Jahan MS, Shamsuzzaman M, Rahman MM, Moeiz SI, Ni Y (2012) Effect of pre-extraction on soda-anthraquinone (AQ) pulping of rice straw. Ind Crops Prod 37(1):164–169

Jahan MS, Rahman MM, Sutradhar S, Quaiyyum MA (2015) Fractionation of rice straw for producing dissolving pulp in biorefinery concept. Nord Pulp Pap Res J 30(4):562–567

Jiang Z-H, Bouchard J, Berry R (2006) Evidence for the formation of lignin hexenuronic acid-xylan complexes during modified kraft pulping processes. Holzforschung 60:137–142

Jour P, Halldén K, Wackerberg E (2013) Environmental systems analysis of alternative bleaching sequences with focus on carbon footprint. In: Proceedings of the ABTCP, the 46th ABTCP international pulp and paper congress, October, 8–10

Karim MR, Islam MN, Malinen RO (2011) Response of Eucalyptus camaldulensis and Acacia mangium kraft pulp in different ECF bleaching options. Wood Sci Technol 45:473–485

Kaur D, Bhardwaj NK, Lohchab RK (2017a) Improvement in rice straw pulp bleaching effluent quality by incorporating oxygen delignification stage prior to elemental chlorine-free bleaching. Environ Sci Pollut Res 24(30):23488–23497

Kaur D, Bhardwaj NK, Lohchab RK (2017b) Prospects of rice straw as a raw material for paper making. Waste Manag 60:127–139

Kaur D, Bhardwaj NK, Lohchab RK (2018a) A study on pulping of rice straw and impact of incorporation of chlorine dioxide during bleaching on pulp properties and effluents characteristics. J Clean Prod 170:174–182

Kaur D, Bhardwaj NK, Lohchab RK (2018b) Reduction in chlorophenolic compounds during bleaching of rice straw pulp by replacing elemental chlorine with chlorine dioxide. Int J Environ Sci Technol 15:1113–1122

Kumar S, Mishra SP, Mishra OP, Bajpai P, Tripathi S, Bajpai PK, Varadhan R (2007) Hot chlorine dioxide versus conventional d stage in ECF. Ippta J 19:87–91

Kumar P, Kumar S, Bhardwaj NK, Choudhary AK (2012) Optimization of process parameters for the photocatlytic treatment of paper mill waste water. Environ Eng Manag J 10:595–601

Lachenal D, Chirat C (1998) High temperature chlorine dioxide delignification: a breakthrough in ECF bleaching of hardwood kraft pulp. 1998. In: Tappi pulping conference proceedings. October, 25–29

Lehtimaa T, Tarvo V, Kuitunen S, Jääskeläinen AS, Vuorinen T (2010) The effect of process variables in chlorine dioxide prebleaching of birch kraft pulp. Part 2. AOX and OX formation. J Wood Chem Technol 30:19–30

Lindström K, Nordin J (1976) Gas chromatography-mass spectrometry of chlorophenols in spent bleach liquors. J. Chromatography 128(1):13–26

Malhotra R, Prakash D, Shukla SK, Kim T, Kumar S, Rao NJ (2013) Comparative study of toxic chlorophenolic compounds generated in various bleaching sequences of wheat straw pulp. Clean Technol Environ Policy 15:999–1011

Milanez A, Colodette JL (2005) Optimal conditions for bleaching eucalyptus kraft pulp with three stage sequence. IPBC´05 Stockholm, June 14–16

Mounteer AH, Pereira RO, Morais AA, Silveira DSA (2007) Effect of recent bleaching technology development on organic matter balance in Eucalypt kraft pulp bleaching effluents. In: Third international colloquium on Eucalyptus Pulp. Federal University of Vicosa, Belo Horizonte, Brazil

Nie S, Wang S, Qin C, Yao S, Ebonka JF, Song X, Li K (2015) Removal of hexenuronic acid by xylanase to reduceadsorbable organic halides formation in chlorine dioxidebleaching of bagasse pulp. Biores Technol 196:413–417

Nie S, Yao S, Wang S, Qin C (2016) Absorbable organic halide (AOX) reduction in elemental chlorine-free (ECF) bleaching of bagasse pulp from the addition of sodium sulphide. BioResources 11:713–723

Pei Y, Wang S, Qin C, Su J, Nie S, Song X (2016) Optimization of laccase-aided chlorine dioxide bleaching of bagasse pulp. BioResources 11:696–712

Petit-Breuilh X, Melo R, Zaror C (2004) Environmental implications of hexeneuronic acid removal from Eucalipyus globules kraft pulp using peroxymonosulphuric acid. Chem Soc 49:355

Prasetyo EN, Rodríguez RD, Lukesch BS, Murkovic M, Katsoyannos E, Sygmund R, Ludwig CR, Nyanhongo GS, Guebitz GM (2015) Laccase–cellobiose dehydrogenase-catalyzed detoxification of phenolic-rich olive processing residues. Int J Environ Sci Technol 12:1343–1352

Ragnar M, Backa S (2004) Hot chlorine dioxide bleaching—a modified approach. Nord Pulp Pap Res J 19:417–419

Rosenau T, Potthast A, Zwirchmayr NS, Hosoya T, Hettegger H, Bacher M et al (2017) Chromophores from hexeneuronic acids (HexA): synthesis of model compounds and primary degradation intermediates. Cellulose 24:3703–3723

Sankaralingam P (2014) Alkaline chlorine dioxide bleaching of cloned eucalyptus wood 2012 and its environmental impact. IOSR J Eng 4:49–58

Singh S, Dutt D (2014) Mitigation of adsorbable organic halides in combined effluents of wheat straw soda-AQ pulp bleached with cellulase-poor crude xylanases of Coprinellus disseminatus in elemental chlorine free bleaching. Cellul Chem Technol 48:127–135

Tavast D, Brännvall E, Lindström ME, Henriksson G (2011) Selectiveness and efficiency of combined peracetic acid and chlorine dioxide bleaching stage for kraft pulp in removing hexeuronic acid. Cellul Chem Technol 45:89

Van den Berg M, Birnbaum LS, Denison M, De Vito M, Farland W, Feeley M, Rose M (2006) The 2005 World Health Organization reevaluation of human and mammalian toxic equivalency factors for dioxins and dioxin-like compounds. Toxicol Sci 93:223–241

Ventorim G (2005) The fate of chlorine species during high temperature chlorine dioxide bleaching. Nord Pulp Pap Res J 20:7–11

Ventorim G, Colodette JL, De Fatima Gomes A, Da Silva LHM (2008) Reaction rates of lignin and hexenuronic acids with chlorine dioxide, ozone, and sulfuric acid. Wood Fiber Sci 40:190–201

Yao S, Nie S, Zhu H, Wang S, Song X, Qin C (2017) Extraction of hemicellulose by hot water to reduce adsorbable organic halogen formation in chlorine dioxide bleaching of bagasse pulp. Ind Crops Prod 96:178–185

Zhang H, Hu J, Qi Y, Li C, Chen J, Wang X, Zhang L (2017a) Emission characterization, environmental impact, and control measure of PM 2.5 emitted from agricultural crop residue burning in China. J Clean Prod 149:629–635

Zhang H, Nie S, Qin C, Bowers R, Zhang K, Xia N, Wang S (2017b) Optimization of oxidative degradation of HexA during chlorine dioxide delignification of bagasse pulp. BioResources 12:8970–8985

Zhang H, Nie S, Qin C, Zhang K, Wang S (2018) Effect of hot chlorine dioxide delignification on AOX in bagasse pulp wastewater. Cellulose 25:2037–2049

Zhang H, Nie S, Qin C, Wang S (2019) Removal of hexenuronic acid to reduce AOX formation in hot chlorine dioxide bleaching of bagasse pulp. Ind Crops Prod 128:338–345

Zhou Z, Jaaskelainen AS, Vuorinen T (2008) Oxidation of cellulose and carboxylic acids by hypochlorous acid: kinetics and mechanisms. Pulp Paper Sci 34:212–218

Zhu H, Yao S, Jiang L, Wang S, Qin C (2016) Kinetics of adsorbable organic halogen formation during the first chlorine dioxide bleaching stage of eucalyptus kraft pulp. BioResources 11:8820–8830

Zwirchmayr NS, Hosoya T, Hettegger H, Bacher M, Krainz K, Dietz T et al (2017) Chromophores from hexeneuronic acids: chemical behavior under peroxide bleaching conditions. Cellulose 24:3689–3702

Acknowledgments

The authors acknowledge the Ministry of Minority Affairs (India) and University Grants Commission (India) (Grant No. F-17.1/2013-14/MANF/2013-14/SIK/HAR/22981) for providing the financial support under Maulana Azad National Fellowship for Minority Students to first author. The first author is highly thankful to Director, Avantha Centre for Industrial Research and Development for allowing to carry out research work and also to the Department of Environmental Science and Engg, Guru Jambeshwar University of Science and Technology, Hisar (India).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kaur, D., Bhardwaj, N.K. & Lohchab, R.K. Impact of modifying conventional chlorine dioxide stage to hot chlorine dioxide during rice straw pulp bleaching on pulp, paper and effluent characteristics. Cellulose 26, 7469–7482 (2019). https://doi.org/10.1007/s10570-019-02616-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-019-02616-5