Abstract

The objective of this study was to check the potential of crude xylano-pectinolytic enzymes in bleaching of rice straw pulp, in order to reduce the toxic waste load for managing the environmental pollution. The xylano-pectinolytic enzymatic bleaching step for delignification was found to be most effective at pulp consistency 1:10 g/ml, xylanase:pectinase dose of 9:4 IU/ml, pH 8.5 and treatment time 180 min at temperature of 55 °C, and resulted in lowering of kappa number of the rice straw pulp by 15.29%. In subsequent bleaching stages, this enzymatic pre-bleaching treatment also resulted in 30% reduction of active chlorine dioxide dose without any loss of optical properties. Significant improvement in various physical properties of the enzymes treated pulp, tear index (15.43%), breaking length (11.11%), double fold number (25.92%), burst index (9.88%) and viscosity (13.63%), and Gurley porosity (39.86%) was also noticed. This approach resulted in reduction of BOD and COD values by 21.07% and 26.57%, respectively. This is the first study on the use of crude xylano-pectinolytic enzymes for bio-bleaching of rice straw pulp.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

In most Asian countries including India, rice (Oryzae sativa) is the main staple food and rice crop produces an enormous amount of straw (Singh et al. 2016). India is the second largest rice producer country across the world (Dey et al. 2020). Among the total production, almost two-thirds of rice straw is being burnt in the fields, before sowing next crop (Trivedi et al. 2017). It contains nearly 30–35% hemicellulose, 12–16% lignin, 9–14% silica, 28–36% cellulose and pectin (Singh et al. 2014). Soda pulping processes have been used to convert rice straw into fibrous material pulp (Navaee-Ardeh et al. 2003; Huang et al. 2007; Rodríguez et al. 2008; Kaur et al. 2017b). Soda-anthraquinone method is being widely used for agro-waste pulp production (Kaur et al. 2018). The brown pulp is further bleached using various bleaching chemicals in order to get bright and white pulp (Pathak et al. 2016). The bleaching stage generates maximum quantity of toxic effluents, among the different production stages of paper (Catalkaya and Kargi 2007). Effluents have furans, dioxin, chlorophenols and organic halides (Satyanarayana et al. 2012). These absorbable organic halides and chlorinated organic compounds are hazardous for living systems (Beg et al. 2000; Ali and Sreekrishnan 2001; Techapun et al. 2003). Kumar et al. (2005) also reported that these compounds also have detrimental effects on animals including human reproductive, developmental and haematological organs. These paper industries’ effluents are also the cause of dreadful health problems including paralytic attacks, carcinogenicity and lungs and skin malfunctioning (Singh and Chandra 2019). Thus, in the paper industry, bleaching effluents have high BOD and COD values (Pokhrel and Viraraghavan 2004) and require the costly effluent treatment (Zhang et al. 2012).

In recent years, pulp and paper industries have started adopting environmentally safe processes for production in order to decrease the discharge of highly toxic effluents. Bio-bleaching is one of the alternative processes to decrease the demand of chemicals, hence lowers toxicity in the effluents. Enzymatic bleaching untightens the compact structure of cell wall of raw material and releases reducing sugars and other chromophores, which leads to increases in porosity and further improves the diffusion of chemicals, ultimately making the process eco-friendly (Walia et al. 2017). Crude xylano-pectinolytic enzymes have been successfully used for bleaching of mixed hardwood kraft pulp (Kaur et al. 2010) and plywood industrial waste pulp (Agrawal et al. 2016; Sharma et al. 2017). The goal of the present study is to evaluate the effect of xylano-pectinolytic enzymes in rice straw pulp bleaching, in order to reduce bleaching chemical dose and wastewater load, and simultaneously improve the paper quality. Few reports are available in the literature for bleaching of rice straw using xylanase enzyme only. This is the first report on the bio-bleaching of rice straw pulp using xylanase and pectinase enzymes.

Materials and methods

Microorganism and chemicals

The microbial strain Bacillus pumilus AJK with MTCC Accession No. 10414 was used for producing both enzymes (xylanase and pectinase) in the same production medium. The substrates (i.e. birchwood xylan and pectin) used for the measurement of enzyme activity were purchased from Sigma. Chemicals used for pulping and bleaching were provided by Avantha Center for Industrial Research and Development, Paper Mill Campus, Yamuna Nagar, Haryana, India. Other chemicals used in this study were purchased from HiMedia. Unbleached rice straw pulp used for this study was generated manually by conventional method at Paper Mill Campus, Yamuna Nagar, Haryana, India.

Enzyme production

The crude enzymes were produced extracellularly by submerged fermentation (Kaur et al. 2017a). Erlenmeyer flasks (250 ml) containing 50 ml of basal medium (0.5% peptone, 10 mM MgSO4; pH 7.0), citrus peel and wheat bran (2% each) were sterilized. Inoculation was done with 2% of 21-h-old inoculum. After inoculation, flasks were incubated at 37 °C for 60 h under shaking conditions at 150 rpm. Crude enzymes were obtained as clear supernatant after centrifugation (at 10,000 rpm) for 15 min and enzyme preparation was stored at 4 °C (both enzymes were 100% stable at 4 °C) until further use. The batch of enzymes used for the study contained 200 IU of alkaline xylanase and 88 IU of alkaline pectinase per milliliter of supernatant.

Enzyme assay conditions

The estimation of the activity of both xylanase and pectinase enzymes was done, as reported by Kaur et al. (2011). The reducing sugars liberated from substrates, polymethylgalacturonic acid (1%, prepared in 0.1 M glycine-NaOH buffer, pH 9.0) and birchwood xylan (2%, prepared in 0.1 M glycine-NaOH buffer, pH 8.5), for assaying pectinase and xylanase activity, respectively, were measured by using 3,5-dinitrosalicylic acid method (Miller 1959). The activity of both enzymes was calculated from the amount of xylose and galacturonic acid liberated after enzyme-substrate reaction for xylanase and pectinase enzymes, respectively, and expressed in terms of IU.

Chemical pulping

For the production of rice straw pulp, soda-anthraquinone pulping method was used (Kaur et al. 2018). For chemical pulping of straw samples (150 g oven-dried), 14% active alkali content and 0.05% anthraquinone were used. The pulp was cooked for 20 min at 160 °C. To achieve the cooking temperature, a 90-min ramp time was given. During pulping, rice straw to liquor ratio was kept at 1:4 (g/ml). Pulp was washed, screened and used for determining the kappa number using TAPPI T236 om-99 2004 method. Finally, the pulp was stored in sealed bags until further use.

Evaluation of enzymatic bleaching conditions

Rice straw pulp samples (oven-dried) were treated with crude xylano-pectinolytic enzymes prior to chemical bleaching to assess the best conditions for bio-bleaching. For efficient removal of impurities, parameters like pH, pulp consistency, treatment time, enzyme dose and temperature for enzymatic bleaching were checked. The enzymatic treatment of rice straw pulp samples was given in transparent plastic bags. Pulp consistency range was taken from 5 to 15%, pH values from 7.5 to 10 and xylanase enzyme dose from 4 to 20 IU, along with dosages of pectinase from 1.77 to 8.88 IU per gram rice straw pulp (oven-dried) were also taken for testing purposes. In the same way, the temperature from 45 to 65 °C and retention time from 60 to 240 min were also checked, in order to get the most effective conditions of enzymatic bleaching. After enzymatic treatment, pulp samples were washed thrice using tap water and dried at 37 °C. Similar conditions (without adding enzymes) were used for the preparation of control pulp samples. Each experiment was repeated five times, and in each repeat, samples in triplicates were taken.

To evaluate the final most effective conditions of bio-bleaching, pulp-free filtrate samples were collected after squeezing the rice straw pulp samples. Reducing sugar content was estimated by Miller’s method (Miller 1959) and release of lignin, hydrophobic compounds and phenolic compounds in filtrate samples was checked by measuring absorbance at λ 280 nm (Nissen et al. 1992; Khandeparkar and Bhosle 2007), at λ 465 nm (Patel et al. 1993) and at λ 237 nm (Gupta et al. 2000; Khandeparkar and Bhosle 2007) respectively. The effect of bio-bleaching was also analysed by determining the kappa number and optical properties like brightness, whiteness and yellowness of each pulp sample of each treatment.

Chemical bleaching of bio-bleached and control rice straw pulps

After pulping, chemical bleaching of both (control and bio-bleached) pulp samples was done using bleaching sequence, i.e. DoEPD1D2. D0, D1 and D2 stages denote for chlorine dioxide treatment and EP denotes the use of NaOH and hydrogen peroxide at standardized pH and temperature conditions. The dose of ClO2 was calculated using equation given by Hise (1996). Washing of both samples was done for determining the pulp optical properties and kappa number.

Microscopic analysis

Microscopic pictures of control pulp (without enzymatic treatment), bio-bleached pulp, 100% chemically bleached pulp and bio-bleached pulp with 30% reduced dose of bleaching chemical were clicked (× 400 magnification) in order to assess the potential of enzymatic treatment during bleaching, using a microscope (Olympus Megacam, Japan).

Handsheet formation and testing of bleached pulp samples

Handsheets of both control (100% chemically bleached) and bio-bleached (using 70% ClO2 dose) pulp samples were formed using the method TAPPI T205 sp-02 2002. In this study, 60 g/m2 (GSM) handsheets were used to study pulp properties. Analysis of viscosity and pulp freeness was done using Schopper-Riegler number (°SR) test method, TAPPI T230 om-99 1976, and SCAN-C 19:65 1999, respectively. Handsheets were used in order to analyse the double fold (TAPPI T511 om-02 2002), tear factor (TAPPI T414 om-04 2004), burst factor (TAPPI T403 om-10 2010), breaking length (TAPPI T494 om-01 2001) and Gurley porosity (TAPPI T460 om-02 2002).

After each stage, handsheets were made using nearly 3 g of oven-dried pulp, in order to check the optical properties (TAPPI T217 wd-77 2004) of rice straw pulp samples.

Effluent characterization

After completion of each step of bleaching, bleaching liquors of control as well as bio-bleached plus 70% chemically bleached were collected in triplicates. In order to check the effect of bio-bleaching, in reducing the toxicity of the bleaching effluents, composite samples were prepared by mixing the effluent collected from various stages of bleaching sequence, in equal volumetric proportions. The total dissolved solids (TDS) (IS: 3025 Part 16, 1983), pH (IS: 3025 Part 11, 1983), colour (APHA 2017a, b), total suspended solids (TSS) (IS: 3025 Part 17, 1983) and lignin (APHA 2017a, b) were also measured in both composite effluent samples. Furthermore, BOD was also analysed using the method IS: 3025 Part 38 and 44, 1983. In both effluent samples, COD was calculated by using the method of open reflux (IS: 3025 Part 58, 1983). The comparison between control and bio-bleached effluent samples was performed in order to calculate the percent reduction in wastewater parameters.

Results and discussion

In this study, crude xylanase and pectinase enzymes obtained from Bacillus pumilus AJK have been used as bio-bleaching agents. The best bio-bleaching conditions were selected and used for pre-treatment of rice straw pulp before chemical bleaching step, in order to evaluate the bio-bleaching effect on pulp properties, effluent characteristics and chlorine dioxide consumption. The results obtained are discussed under the following heads:

Assessment of bio-bleaching conditions

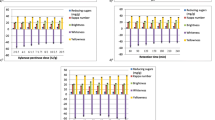

The different parameters were analysed in order to get the final best bio-bleaching conditions. Material to liquid ratio of 1 g:10 ml was found to be best for bio-bleaching of rice straw pulp samples (Fig. 1a). The bleaching efficiency of crude xylanase and pectinase enzymes was maximum at pH 8.5 (Fig. 1b). Choudhury et al. (2006) also reported that pre-bleaching of rice straw pulp using crude xylanase (obtained from Bacillus brevis BISR-062) was found to be best at pH 8.5. Bio-bleaching results showed that 9 IU of xylanase and 4 IU of pectinase dose per gram pulp sample were sufficient for effective treatment (Fig. 1d). Higher dose of enzymes beyond these values did not further improve the efficiency of bio-bleaching. The pre-bleaching treatment of rice straw pulp using crude xylanase enzyme preparation was found to be most effective at enzyme dose of 10 IU/g pulp (Ziaie-Shirkolaee et al. 2008). The xylanase dosages of 20 IU (Kumar et al. 2017), 10 IU (Gautam et al. 2018) and 12.5 IU (Nagar and Gupta 2020) were best for effective bleaching of various wood pulp samples. For effective crude xylano-pectinolytic enzymatic treatment of pulp, retention time 3 h and temperature 55 °C were found to be the best (Fig. 1c, e). Immanuel et al. (2017) also reported a 180-min treatment time for xylanase enzymatic bleaching of rice straw pulp.

The control and bio-bleached rice straw pulp samples released nearly 1.30 ± 0.10 and 8.06 ± 0.09 mg reducing sugars per gram of straw pulp (oven-dried) under the best pre-bleaching conditions, respectively. The reducing sugar level in straw pulp-free filtrates was increased from 132 to 140 mg/ml after bleaching using xylanase, produced from Streptomyces albus, and increased from 149 to 170 mg/ml after treatment with xylanase, obtained from Streptomyces chromofuscus (Rifaat et al. 2006). Immanuel et al. (2017) also reported that higher reducing sugar content from rice straw pulp was released, using 100 IU of xylanase dose at temperature of 40 °C, pH 7.0 and treatment time of 180 min. Measurement of optical density of pulp-free filtrate samples also indicates the release of chromophores during enzymatic treatment and absorbance of filtrate samples for hydrophobic compounds was 0.90 at λ465 nm, lignin was 0.75 at λ 280 nm and phenolic compounds was 0.75 at λ 237 nm after 2× dilution (Fig. 2). Immanuel et al. (2017) have also reported the absorbance values for phenolic compounds nearly 0.12 (at λ237 nm) after enzymatic bleaching of rice straw pulp. Hence, the enzymatic bleaching enhanced the absorbance of pulp-free filtrates at various wavelengths due to the hydrolysis of impurities. The release of chromophores and reducing sugars from the raw material is an interconnected phenomenon (Gautam et al. 2018).

Kappa number is also one of the most important factors for analysing the effectiveness of enzymes. The kappa number was decreased from 13.6 ± 0.25 to 11.52 ± 0.24 in bio-bleached pulp samples as compared to control pulp samples, thus showing 15.29% reduction in kappa number after bio-bleaching. The enzymatic treatment dissociates lignin-carbohydrate complexes from pulp fibers that results in the release of reducing sugars and other chromophores, phenolic and hydrophobic compounds, which further cause reduction in kappa number and ultimately improvement in optical properties. The kappa number in rice straw pulp decreased from 15.2 to 13.2 and 12.5 to 10.5 after pre-bleaching with xylanase, obtained from Streptomyces albus and Streptomyces chromofuscus, respectively (Rifaat et al. 2006). The crude xylanase treatment of rice straw pulp also caused 8.8% (Choudhury et al. 2006), 13% (Ziaie-Shirkolaee et al. 2008) and nearly 15% (Immanuel et al. 2017) decrease in the kappa number. The decline in the kappa number values is by 14.51% (Gautam et al. 2018).

The increase in brightness (4.13%) and whiteness (2.85%) and decrease in yellowness (2.06%) were observed in bio-bleached pulp samples (Table 1). Xylano-pectinolytic enzyme (obtained from Bacillus firmus SDB9)-treated mixed hardwood pulp showed 2.7% increase in brightness values (Bhagat et al. 2016). Similarly, an increase in brightness value is by 2.9% (Gautam et al. 2018) and 2.8% ISO (Nagar and Gupta 2020) in xylanase-assisted bleaching of hardwood pulp. Ziaie-Shirkolaee et al. (2008) also reported improvement in brightness by 2.1% after pre-treatment of rice straw pulp with the commercial xylanase.

Efficiency of xylanase-pectinase enzymatic bleaching of rice straw pulp has also been supported by comparing the microscopic images of both control (without enzymes treated) and bio-bleached straw pulp samples (Fig. 3a, b). The bio-bleached pulp surface is relatively clean, showing the removal of impurities.

Evaluation of bio-bleaching effect on reduction of chlorine dioxide dose

After comparison of control (100% bleaching chemical) and bio-bleached plus 100% chemically bleached pulps, it was observed that brightness and whiteness values were higher, and yellowness and kappa number values were lower in bio-bleached plus 100% chemical bleaching samples. The xylanase and pectinase enzymatic pre-treatment of rice straw pulp also resulted in 30% reduction in chlorine dioxide consumption at each D0 and D1 stages of bleaching, and the optical property values like brightness, yellowness and whiteness of the pulp were nearly similar to that obtained by 100% conventional chemical bleaching of control pulp samples (Table 1). This reduction in the chlorine dioxide dose makes the process not only eco-friendly but also refine the paper quality. This is due to the hydrolysis of non-cellulosic material by enzymes during bio-bleaching, which facilitates effective delignification by bleaching chemicals at low concentration. Xylanase and pectinase enzymatic bleaching of plywood veneer soda-anthraquinone and mixed hardwood kraft pulp samples also showed reduction in Cl2 and ClO2 dose by 25% and 23.8% (Agrawal et al. 2016) and chlorine di-oxide dose by 15%, respectively (Bhagat et al. 2016). The reduction in bleaching chemical dose was also reported nearly 25% (Ziaie-Shirkolaee et al. 2008), 12.5% (Walia et al. 2015) and 19.01% (Nagar and Gupta 2020) after the xylanase-assisted bleaching of rice straw, wheat straw and hardwood pulp samples, respectively.

Microscopic images of 100% chemically bleached and bio-bleached plus 70% chemically bleached pulp samples are also similar, which also confirms the effectiveness of enzymes (Fig. 3c, d).

Effectiveness of bio-bleaching on the optical properties

The bio-bleached pulp samples (bleached with 100% chlorine dioxide dose) were compared with 100% chemically bleached pulp samples; bio-bleached pulp samples showed higher brightness (7.80%) along with less ClO2 consumption at D0 stage of bleaching (Table 3). In EP stage of bleaching, increase in brightness and whiteness values by 11.93% and 28.54%, respectively, and reduction in yellowness value by 48.38% were observed in the case of bio-bleached pulp samples over control pulp samples. Similarly, enzymatically bleached pulp samples showed higher brightness and whiteness values along with reduction in yellowness after D1 and D2 stages of bleaching (Table 3). The significant increase in the brightness (3.56%), whiteness (8.39%) along with reduction in yellowness (28.4%) was observed at D1 stage. In bio-bleached samples, optical properties at D1 stage were better than the optical properties of control samples at D2 stage. The optical properties of enzymatically bleached pulp samples with 70% ClO2 dose were found to be same with the control pulp samples. Rifaat et al. (2006) have reported improvement in the brightness from 47.2 to 49.1% ISO and 50.2 to 54.2% ISO after bleaching treatment of rice straw pulp with xylanase from Streptomyces albus and Streptomyces chromofuscus, respectively. In another study, the bleaching of rice straw pulp using xylanase improved the brightness by 5.5% ISO and 5% ISO at pH 7.0 and 8.5, respectively, after the completion of second stage of chemical bleaching (Choudhury et al. 2006).

Evaluation of bio-bleaching effect on the strength properties

The bio-bleached pulp samples with 70% chlorine dioxide dose had higher double fold (25.92%), burst index (9.88%), viscosity (13.63%), tear index (15.43%), Gurley porosity (39.86%) and breaking length (11.11%), as compared to 100% chlorine dioxide–treated control samples (Table 2). These results showed that xylanase-pectinase enzymatic treatment of rice straw prior to chemical bleaching reduces bleaching chemical requirement and also resulted in better physical properties of pulp. The pre-treatment of rice straw pulp with xylanase enzyme also showed an improvement in tensile index from 43.1 to 42.6 and tear index from 4.9 to 5.7 (Choudhury et al. 2006). Similarly, gain in breaking length (9.71%), tear factor (13.33%) and burst factor (9.12%) was observed in bio-bleached hardwood kraft pulp samples (Nagar and Gupta 2020). Gautam et al. (2018) reported that xylanase-assisted bleaching of Eulaliopsis binata pulp samples improved pulp viscosity by 3.90% over control pulp samples. This work concluded that xylano-pectinolytic enzymes improved the delignification process and seems to be an effective way for protecting the environment, along with making the paper with superior quality.

Effect of bio-bleaching on effluent characteristics

Analysis of effluent was done after making composite mixture, by adding the effluent collected from each stage of bleaching in equal volume. The total effluent generated after bleaching was 36 m3 per ton of pulp. After comparing the control pulp effluent characteristics with bio-bleached pulp effluent (also 70% chemically bleached), it was observed that effluents of bio-bleached pulp with 30% reduced bleaching chemical dose were less polluted in terms of different parameters like COD, BOD, colour, lignin TDS and TSS. BOD was reduced from 24.2 to 19.1 kg/ton of pulp and showed significant reduction (21.07%) in bio-bleached pulp samples. Similarly, effluent COD value for control pulp was found to be 66.11 kg/ton of pulp, which reduced to 48.54 kg/ton of pulp and showed significant reduction (26.57%) in the case of bio-bleached pulp samples. Reduction of ClO2 amount also showed reduction in TDS (5.97%), TSS (7.04%), lignin content (16.34%) and colour (9.52%) values in bio-bleached effluent (Table 3). The bio-bleaching of wheat straw soda-AQ pulp using Coprinellus disseminatus SH-1 and SH-2 xylanase enzyme showed decline in COD values by 18.04% and 20.6%, respectively (Singh et al. 2011), while xylano-pectinolytic enzyme-assisted bleaching of plywood veneer pulp also reduced the COD and BOD values by 18.03% and 16.67%, respectively, over control samples (Agrawal et al. 2016). Experimental summary of bio-bleaching process for rice straw pulp has been given in Fig. 4.

Conclusion

This study concluded that bleaching of rice straw pulp with xylanase-pectinase enzymes produced pulp of superior quality. This bio-bleaching approach has the potential to decrease the bleaching chemical demand, toxic effluent load and ultimately chemical pollution. Hence, it also appears to be suitable in the management of environmental pollution by utilizing agro-waste, which is burnt by the farmers and causing serious health-related problems. Production cost of enzymes is the main limiting factor for industries, in order to adopt this eco-friendly approach. Future research should be concentrated in this area, so that industries could shift to eco-friendly enzyme-based processes.

Data availability

Not applicable.

References

Agrawal S, Yadav RD, Mahajan R (2016) Synergistic effect of xylano-pectinolytic enzymes produced by a bacterial isolate in bleaching of plywood industrial waste. J Clean Prod 118:229–233

Ali M, Sreekrishnan TR (2001) Aquatic toxicity from pulp and paper mill effluents: a review. Adv Environ Res 5(2):175–196

APHA (2017a) In: Clesceri LS, Greenberg AE, Eaton AD (eds) Method 2120: Standard methods for the examination of colour of water and wastewater, 21st edn. American Public Health Association United Book Press, Inc, Baltimore

APHA (2017b) In: Clesceri LS, Greenberg AE, Eaton AD (eds) Method 5550: Standard methods for the examination of tannin and lignin from water and wastewater, 21st edn. American Public Health Association United Book Press, Inc, Baltimore

Beg QK, Bhushan B, Kapoor M, Hoondal GS (2000) Enhanced production of a thermostable xylanase from Streptomyces sp. QG-11-3 and its application in biobleaching of eucalyptus kraft pulp. Enzym Microb Technol 27(7):459–466

Bhagat DD, Dudhagara PR, Desai PV (2016) Statistical approach for pectinase production by Bacillus firmus SDB9 and evaluation of pectino-xylanolytic enzymes for pretreatment of kraft pulp. J Microbiol Biotechnol Food Sci 2019:396–406

Catalkaya EC, Kargi F (2007) Color, TOC and AOX removals from pulp mill effluent by advanced oxidation processes: a comparative study. J Hazard Mater 139(2):244–253

Choudhury B, Aggarwal P, Gothwal RK, Mantri R, Mohan MK, Ghosh P (2006) Biobleaching of nonwoody pulps using xylanase of Bacillus brevis BISR-062. Appl Microbiol Biotechnol 128(2):159–169

Dey A, Dinesh, Rashmi (2020) Rice and wheat production in India: an overtime study on growth and instability. J Pharmacog Phytochem 9(2):158–161

Gautam A, Kumar A, Bharti AK, Dutt D (2018) Rice straw fermentation by Schizophyllum commune ARC-11 to produce high level of xylanase for its application in pre-bleaching. J Genet Eng Biotechnol 16(2):693–701

Gupta S, Bhushan B, Hoondal GS (2000) Isolation, purification and characterization of xylanase from Staphylococcus sp. SG-13 and its application in biobleaching of kraft pulp. J Appl Microbiol 88:325–334

Hise R (1996) Chlorination. In: Dence CW, Reeve DW (eds) Pulp bleaching principles and practice. Tappi Press Atlanta, Georgia, pp 241–259

Huang G, Shi JX, Langrish TA (2007) NH4OH–KOH pulping mechanisms and kinetics of rice straw. Bioresour Technol 98(6):1218–1223

Immanuel G, Sanjivkumar M, Dhanabalrameshbabu (2017) Biobleaching property of β-1,4-xylanase from a novel mangrove associated actinobacterium Streptomyces olivaceus (MSU3) using pretreated rice straw pulp. IJASEAT 5(2):54–59

IS:3025 (1983) Methods of sampling and test (physical and chemical) for water and waste water

Kaur A, Mahajan R, Singh A, Garg G, Sharma J (2010) Application of cellulase-free xylano-pectinolytic enzymes from the same bacterial isolate in biobleaching of kraft pulp. Bioresour Technol 101(23):9150–9155

Kaur A, Mahajan R, Singh A, Garg G, Sharma J (2011) A novel and cost effective methodology for qualitative screening of alkalo-thermophilic cellulase free xylano-pectinolytic microorganisms using agricultural wastes. World J Microbiol Biotechnol 27(2):459–463

Kaur A, Singh A, Dua A, Mahajan R (2017a) Cost-effective and concurrent production of industrially valuable xylano-pectinolytic enzymes by a bacterial isolate Bacillus pumilus AJK. Prep Biochem Biotechnol 47(1):8–18

Kaur D, Bhardwaj NK, Lohchab RK (2017b) Prospects of rice straw as a raw material for paper making. Waste Manag 60:127–139

Kaur D, Bhardwaj NK, Lohchab RK (2018) A study on pulping of rice straw and impact of incorporation of chlorine dioxide during bleaching on pulp properties and effluents characteristics. J Clean Prod 170:174–182

Khandeparkar R, Bhosle NB (2007) Application of thermoalkalophilic xylanase from Arthrobacter sp. MTCC 5214 in biobleaching of kraft pulp. Bioresour Technol 98:897–903

Kumar A, Kumar S, Kumar S (2005) Biodegradation kinetics of phenol and catechol using Pseudomonas putida MTCC1194. Biochem Eng J 22:151–159

Kumar S, Haq I, Prakash J, Singh SK, Mishra S, Raj A (2017) Purification, characterization and thermostability improvement of xylanase from Bacillus amyloliquefaciens and its application in pre-bleaching of kraft pulp. 3 Biotech 7(1):20

Miller GL (1959) Use of dinitrosalicylic acid reagent for determination of reducing sugars. Anal Chem 31(1):426–428

Nagar S, Gupta VK (2020) Hyper production and eco-friendly bleaching of kraft pulp by xylanase from Bacillus pumilus SV-205 using agro waste material. Waste Biomass Valor. https://doi.org/10.1007/s12649-020-01258-0

Navaee-Ardeh S, Mohammadi-rovshandeh J, Khodadadi AA, Pourjoozi M (2003) Pulp and paper characterization of rice straw produced from aqueous ethanol pulping. Cellul Chem Technol 37(5-6):405–413

Nissen AM, Anker L, Munk N and Lange K (1992) Xylanase for the pulp and paper industry. In: Xylan and Xylanses (Visser J, Beldman G, Kustersvan Someren MA, Voragen AGJ eds.) Biotechnol Prog 7325–7337

Patel RN, Grabski AC, Jeffries TW (1993) Chromophore release from kraft pulp by purified Streptomyces roseiscleroticus xylanases. Appl Microbiol Biotechnol 39:405–412

Pathak P, Kaur P, Bhardwaj NK (2016) Microbial enzymes for pulp and paper industry: an interdisciplinary approach. United states: CRC Press, Taylor and Francis Group, Microbiol Biotechnol 163–240

Pokhrel D, Viraraghavan T (2004) Treatment of pulp and paper mill wastewater-a review. Sci Total Environ 333(1-3):37–58

Rifaat HM, Nagieb ZA, Ahmed YM (2006) Production of xylanases by Streptomyces species and their bleaching effect on rice straw pulp. Appl Ecol Environ Res 4(1):151–160

Rodríguez A, Moral A, Serrano L, Labidi J, Jiménez L (2008) Rice straw pulp obtained by using various methods. Bioresour Technol 99(8):2881–2886

Satyanarayana T, Johri BN, Prakash A (2012) In: Johri BN, Prakash A (eds) Microorganisms in environmental management: microbes and environment. Springer Sci Bus Media, Berlin

SCAN-C 19:65 (1999) Pulps determination of drainability-part 1 (Schopper-Riegler method). TAPPI Press, Atlanta

Sharma D, Agrawal S, Yadav RD, Mahajan R (2017) Improved efficacy of ultrafiltered xylanase–pectinase concoction in biobleaching of plywood waste soda pulp. 3 Biotech 7(1):2

Singh AK, Chandra R (2019) Pollutants released from the pulp paper industry: aquatic toxicity and their health hazards. Aquat Toxicol 211:202–216

Singh S, Dutt D, Tyagi CH, Upadhyaya JS (2011) Bio-conventional bleaching of wheat straw soda–AQ pulp with crude xylanases from SH-1 NTCC-1163 and SH-2 NTCC-1164 strains of Coprinellus disseminatus to mitigate AOX generation. New Biotechnol 28(1):47–57

Singh R, Tiwari S, Srivastava M, Shukla A (2014) Microwave assisted alkali pretreatment of rice straw for enhancing enzymatic digestibility. J Energy 2014:483813

Singh R, Srivastava M, Shukla A (2016) Environmental sustainability of bioethanol production from rice straw in India: a review. Renew Sust Energ Rev 54:202–216

TAPPI T205 sp-02 (2002) Forming handsheets for physical tests of pulp. TAPPI Press, Atlanta

TAPPI T217 wd-77 (2004) Brightness of pulp. TAPPI Press, Atlanta

TAPPI T230 om-99 (1976) Viscosity of pulp (capillary viscometer method). TAPPI Press, Atlanta

TAPPI T236 om-99 (2004) Kappa number of pulp. TAPPI Press, Atlanta

TAPPI T403 om-10 (2010) Burst strength of paper. TAPPI Press, Atlanta

TAPPI T414 om-04 (2004) Internal tearing resistance of paper (Elmendorf-type method). TAPPI Press, Atlanta

TAPPI T460 om-02 (2002) Air resistance of paper (Gurley method). TAPPI Press, Atlanta

TAPPI T494 om-01 (2001) Tensile breaking properties of paper and paperboard. TAPPI Press, Atlanta

TAPPI T511 om-02 (2002) Folding endurance of paper (MIT Tester). TAPPI Press, Atlanta

Techapun C, Poosaran N, Watanabe M, Sasaki K (2003) Thermostable and alkaline-tolerant microbial cellulase-free xylanases produced from agricultural wastes and the properties required for use in pulp bleaching bioprocesses: a review. Process Biochem 38(9):1327–1340

Trivedi A, Verma AR, Kaur S, Jha B, Vijay V, Chandra R, Vijay VK, Subbarao PM, Tiwari R, Hariprasad P, Prasad R (2017) Sustainable bio-energy production models for eradicating open field burning of paddy straw in Punjab, India. Energy 127:310–317

Walia A, Mehta P, Guleria S, Shirkot CK (2015) Modification in the properties of paper by using cellulase-free xylanase in biobleaching of wheat straw pulp produced from alkalophilic Cellulosimicrobium cellulans CKMX1. Can J Microbiol 61(9):671–681

Walia A, Guleria S, Mehta P, Chauhan A, Parkash J (2017) Microbial xylanases and their industrial application in pulp and paper biobleaching: a review. 3 Biotech 7(1):11

Zhang C, Chen J, Wen Z (2012) Alternative policy assessment for water pollution control in China’s pulp and paper industry. Resour Conserv Recycl 66:15–26

Ziaie-Shirkolaee Y, Talebizadeh A, Soltanali S (2008) Comparative study on application of T. lanuginosus SSBP xylanase and commercial xylanase on biobleaching of non wood pulps. Bioresour Technol 99(16):7433–7437

Acknowledgements

The authors are thankful to the Director, Avantha Center for Industrial Research and Development, Yamuna Nagar, for allowing us to carry out this research.

Funding

The financial support was provided by the Department of Biotechnology (DBT), Ministry of Science & Technology, Government of India (Grant Number: BT/PR 20438/BCE/8/1220/2016 for 3 years). The first author is thankful to Kurukshetra University, Kurukshetra, for providing the financial support in the form of University Research Scholarship (URS).

Author information

Authors and Affiliations

Contributions

RM (corresponding Author) gave the idea of concept, planning and designing of various experiments done for this manuscript. Experimental work was done by the first author of this manuscript under the corresponding author’s supervision. RN (first author) done all experimental work mentioned in this manuscript, both at research laboratory and paper industry level. NKB supervised the research work done by the first author, at paper industry level. All authors read and approved the final manuscript

Corresponding author

Ethics declarations

Ethical approval and consent to participate

Not applicable.

Consent to publication

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Responsible Editor: Ta Yeong Wu

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Nagpal, R., Bhardwaj, N.K. & Mahajan, R. Potential of crude xylano-pectinolytic enzymes in bleaching of rice straw pulp for improving paper quality and reducing toxic effluent load generation. Environ Sci Pollut Res 28, 18284–18293 (2021). https://doi.org/10.1007/s11356-021-13204-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-021-13204-1