Abstract

High-fructose corn syrup (HFCS) is an agro-source product and has been the most commonly used substitute for sugar as sweetener in food industry due to its low price and high solution property. In this study, the F55 HFCS, rich in fructose and glucose, was first tested for biomass and docosahexaenoic acid productions as a mixed carbon source by a newly isolated Aurantiochytrium sp.YLH70. After the compositions of the HFCS media were optimized, the results showed that the HFCS with additions of metal ion and vitamin at low concentrations was suitable for biomass and docosahexaenoic acid productions and the metal ion and sea salt had the most significant effects on biomass production. During the 5-l fed-batch fermentation, total HFCS containing 180 g l−1 reducing sugar was consumed and yields of biomass, lipid, and DHA could reach 78.5, 51, and 20.1 g l−1, respectively, at 114 h. Meanwhile, the daily productivity and the reducing sugar conversion yield for docosahexaenoic acid were up to 4.23 g l−1day−1 and 0.11 g g−1. The fatty acid profile of Aurantiochytrium sp.YLH70 showed that 46.4 % of total fatty acid was docosahexaenoic acid, suggesting that Aurantiochytrium sp.YLH70 was a promising DHA producer.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

High-fructose corn syrup (HFCS), a corn-made product that mainly contains fructose and glucose, has been the traditional and most commonly used substitute for sugar as sweetener in food and beverage industry due to its low price and sweetness comparable with the sucrose [1, 2]. Moreover, since HFCS contains large amount of fermentable sugar, nice flavor, and high solution properties, it was used in microbial fermentations for productions of yoghurt [3] and proteinase [4]. However, utilization of the HFCS for microbial lipids rich in docosahexaenoic acid (DHA) has not been investigated.

DHA is a member of ω-3 polyunsaturated fatty acids (PUFAs) and has been recently reported to have beneficial effects on preventing cardiovascular diseases, cancer, schizophrenia, and Alzheimer’s disease. DHA also plays a significant role in infant nervous development and is an essential nutrient for cultured animals in feed industry [5]. Aurantiochytrium sp. is a heterotrophic marine thraustochytrids microorganism which can grow on various carbon sources. It has been attracted much attentions for its high growth rate and capabilities to produce a large amount of DHA when grown on glucose and fructose [6]. However, compared with the fish oil DHA, microbial DHA has high production cost [7]. For decreasing production cost of microbial DHA, higher space-time productivities must be obtained by culture optimization, high-cell-density cultivation, and utilization of economic materials [8, 9]. The growth rate, biomass, and DHA content were considered as key factors for the space-time productivity [10]. Many inexpensive materials, such as cane molasses [11], waste glycerol [12], sweet sorghum juice [13], and shochu distillery wastewater [14], have been used for DHA productions by thraustochytrids. However, utilization of the HFCS for DHA production by Aurantiochytrium sp. has never been investigated.

The response surface methodology (RSM) was considered to be a more effective mathematical and statistical technique for optimizing conditions. By providing statistical model and experiment, RSM reveals interactions among the relative factors and calculates the optimal condition [15]. For example, after optimizations of glucose, yeast extract, NaCl, pH, and incubation time by RSM, the DHA production by Schizochytrium sp. S31 reached 516 mg l−1 [16]. The amount of eicosapentaenoic acid (EPA) for the marine bacteria 717 increased from 9 to 45 mg g−1 biomass after RSM performances, showing the significant effects of temperature, pH, and dissolved oxygen on the EPA production [17].

In this study, we report our findings on the utilization of HFCS by a newly isolated Aurantiochytrium sp. YLH70 for biomass and DHA productions. The strain isolation, identification, medium optimization, and fermentation performance are also presented here.

Materials and Methods

Materials

The F55 high-fructose corn syrup (HFCS) was purchased from the Deanfu Sugar Ltd. (Xiaogan, Hubei, China), and its main compositions are shown in Table 1. The glucose, fructose, xylose, maltose, sucrose, glycerol, starch, lactose, olive oil, and corn steep liquor were obtained from the Aladdin Industrial Inc. (Shanghai, China). The yeast extract and peptone were obtained from the OXOID Scientific Inc. (England). The bean cake powder was obtained from the Guanqian Industrial Inc. (Tianjin, China). The nonadecanoic acid methyl ester and the docosahexaenoic acid methyl ester standards were purchased from Sigma-Aldrich (St. Louis, USA). The BF3-methanol was purchased from ANPEL Laboratory Technologies Inc. (Shanghai, China).

Samplings and Isolations of Aurantiochytrium Strains

Leaves from Kandelia plants were collected from the mangrove ecosystem in Yueqing Bay, Zhejiang province, China. Strains of Aurantiochytrium-like microorganisms were obtained from the samples using the pollen baiting technology reported by Gupta et al. [18]. The purified Aurantiochytrium-like colonies were preserved in glycerol tubes and at −80 °C for further study.

Strain and Cultivations

Strain YLH 70 was cultivated on the GPY medium (60 g l−1 glucose, 20 g l−1 yeast extract, 20 g l−1 sea salt) in flasks at 28 °C and 180 rpm in a horizontal rotator. For optimizations, as described as below, the GPY medium was a base medium and one factor in the medium was changed while the others were fixed.

Measurement of Biomass

The biomass was measured as the dry cell weight (DCW). Fifty milliliters of cell cultures were centrifuged at 10,000 rpm and 4 °C for 10 min, and the cell pellets were then washed twice with distilled water. The washed cell pellets were then lyophilized to constant weight at 40 °C for 48 h and weighted.

Measurement of Reducing Sugar

Reducing sugar in the fermented media or HFCS was measured by the Nelson-Somogyi method, and the amount of reducing sugar was calculated [19]. Glucose and fructose were separated and analyzed by Waters Alliance 2414 HPLC system with Waters Refractive Index Detector. Hypersil NH2 column (4.6 mm * 250 mm, Yilite Ltd., China) was used with an acetonitrile/water (80:20) mobile phase for isocratic elution. The flow rate was 1.4 ml/min and injection volume was 10 μl. The column temperature was kept at 30 °C. Glucose and fructose, which were used as standard for quantitative analysis, were obtained from Sigma-Aldrich (St. Louis, USA).

Lipid Extraction and Analysis of Fatty Acid Composition

The lipid extraction and analysis of fatty acid composition was performed based on the method reported by Gao et al. with moderate modifications [20]. The lyophilized cell was pestled into fine powder with mortar under liquid nitrogen. The cell powder was extracted into 100 ml chloroform/methanol (2:1, v/v) at room temperature. The lipid extract was dried by evaporation and weighed. For fatty acid analysis, 0.1 g of cell powder was mixed with 5 ml of 0.4 M methanolic KOH and incubated at 60 °C for 1 h, followed by an esterification procedure in 5 ml of BF3-methanol (14 %, w/w) reagent at 60 °C for another 1 h. The fatty acid methyl esters (FAMEs) was extracted with 5 ml of hexane and analyzed by Agilent 6890N GC using an HP-INNOWAX column (30 m * 0.25 mm, 0.25 μm film thickness, Agilent Technologies) with the He as carrier gas. The temperature-controlling procedure was as follows: from 100 to 240 °C at 15 °C min−1 and maintained at 240 °C for another 10 min; the temperature of the injection port and flame ionization port was 250 °C. The nonadecanoic acid methyl ester was used as the internal standard.

Molecular Identification of the Strain YLH70 by 18S rDNA Sequencing

The genomic DNA of the strain YLH70 was extracted by a universal genomic DNA extraction kit (Takara, Japan) according to the kit protocol. The 18S rDNA was amplified with genomic DNA as a template using the forward primer 16S1N (5′-TCCTGCCAGTAGTCATATGC-3′) and the reverse primer 16S2N (5′-TGATCCTCYGCAGGTTCAC-3′) [21]. The 50-μl polymerase chain reaction (PCR) system contained 5 μl ×10 PCR buffer, 10 mM dNTP, 10 μM each primer, 1.25 U Taq DNA polymerase (Takara, Japan), and 1 μg genomic DNA. The PCR program was run for 5 min at 94 °C, followed by 35 cycles each consisted of 30 s at 94 °C, 30 s at 50 °C, and 2 min at 72 °C. The final extension consisted of 5 min at 72 °C. The PCR product was purified from gel electrophoresis using the Axygen DNA extraction kit (Axygen, Hangzhou, China) and cloned into the pMD-18T (Takara, Japan). The final vectors were sent to the Sangon Biotech Ltd. (Shanghai, China) for DNA sequencings.

The resulting 18S rDNA sequences were aligned to the nucleotide sequences in the database of the National Center for Biotechnology Information (NCBI) using Basic Local Alignment Search Tool (BLAST) for identification of the isolated strain. The 18S rDNA sequences of related microorganisms were downloaded and analyzed by MEGA software (Version 4.0) to construct a neighbor-jointing (NJ) tree with bootstrap 1000 replicates.

Optimizations of Media Compositions for DCW, Lipid, and DHA Productions

“One-at-a-time” method was used to select suitable carbon and nitrogen sources of the GPY medium for DCW, lipid, and DHA productions by Aurantiochytrium sp. YLH70. Optimizations were performed at 50-ml flash level. Strain was cultivated at 28 °C and 180 rpm for 5 days. Ten carbon sources, including glucose, fructose, xylose, maltose, sucrose, glycerol, starch, lactose, olive oil, and HFCS, and four nitrogen sources, including yeast extract, peptone, corn steep liquor, and bean cake powder, were tested, while the other factors of media were fixed as the initial condition. The effects of different concentrations of HFCS (40, 60, 80, 100, 120, 140 ml l−1) and yeast extract (5, 10, 15, 20, 30 g l−1) on the DCW, lipid, and DHA productions were also studied.

As shown in Table 2, a central composite design (CCD) for five variables, which represent compositions of the medium at five coded levels (+2, +1, 0, −1, −2) was used for experimental design and analysis by response surface methodology (RSM). Among these compositions, the HFCS, yeast extract, sea salt, metal ion, and vitamin were tested for their significances and the optimal levels for production of DCW by Aurantiochytrium sp. YLH70. The CCD and analysis of variance (ANOVA) were performed with the Design Expert software package (Version 7.0, State-Ease Inc., Minneapolis, MN, USA).

Bioreactor Cultivations

A RALF 5 l bioreactor (Bioengineering, Swiss) was used to perform the fed-batch bioreactor cultivation using the medium for Aurantiochytrium sp. YLH70 DCW production optimized by CCD. The preculture was prepared in a 500-ml flask and then transferred into the 5 l bioreactor containing 4 l medium. One milliliter of antifoam chemical (1 g l−1, Sigma) was used to suppress foaming. The fermentation was set at 25 °C with aeration and agitation rate kept at 1 vvm and 400 rpm, respectively. During the fermentation, when the concentration of reducing sugar in medium dropped to 10 g l−1, the sterilized HFCS was supplied for increasing up to 60 g l−1 reducing sugar in medium. Fifty milliliters of sample was taken at 6-h intervals over the entire cultivation (120 h) for DCW, reducing sugar, lipid, and fatty acid composition analyses.

Results and Discussion

Isolation and Identification of Strain YLH70

About 100 purified strains of Aurantiochytrium-like microorganisms were isolated from the fallen leaf samples. The DCW and DHA contents of these strains ranged from 7.66 to 14.5 and 0.18 g l−1 to 1.98 g l−1, respectively. Based on the DCW and DHA yields, the strain YLH70 was selected for further study. Using microscope inspection (data not shown) and molecular phylogeny reconstruction, the strain YLH70 was confirmed to be an Aurantiochytrium strain. In the neighbor-jointing (NJ) tree of 18S rDNA (Fig. 1), the strain YLH70 was located in the well-supported monophyletic group with the strains of Aurantiochytrium sp. BL11, KRS101, and TF23. Moreover, as shown in Table 3, the fatty acid profile of the YLH70 strain is simple, with palmitic acid (C16:0, 33.4 % TFA), eicosapentaenoic acid (C22:5, 9.71 % TFA), and DHA (C22:6, 46.3 % TFA) as main fatty acids, which was used as a tool for thraustochytriaceae strain identification and very similar to those for other Aurantiochytrium sp. Strains [22]. Thus, the strain YLH70 was designated as Aurantiochytrium sp. YLH70.

Optimizations of Media Components

Various carbon sources were used as substrates to investigate the DCW and DHA yields of Aurantiochytrium sp. YLH70 (Fig. 2a). Among the single carbon sources, fructose was the optimal carbon source with 15 g l−1 DCW, 7.77 g l−1 lipid, and 2.5 g l−1 DHA followed by glucose with 14.5 g l−1 DCW, 7.55 g l−1 lipid, and 1.98 g l−1 DHA. These results were similar to those for Schizochytrium limacinum SR21 [6]. Liang et al. reported that mixed carbon source, such as sweet sorghum juice (mainly composed of glucose, fructose, and sucrose), resulted in higher DHA yield than that from single glucose at the same concentration of sugar [13]. Thus, the mixed carbon source, F55 HFCS, was also tested for DCW, lipid, and DHA productions by Aurantiochytrium sp. YLH70. The composition of the F55 HFCS is shown in Table 1, showing an up to 800 g l−1 of reducing sugar with fructose and glucose as main sugars. As shown in Fig. 2a, HFCS was a superior carbon source to fructose and glucose for DHA production, which was similar to the result from Liang et al. [13]. The explanation for these results may be as follows: (1) some trace substrates in HFCS at some concentration could stimulate cell growth and DHA production and (2) less amount of glucose in HFCS than pure glucose could decrease the inhibition effect of glucose on the cell growth and DHA production. HFCS, a material which originated from plant starch, is cheaper than fructose and sucrose and has almost the same price as that of glucose. As shown in Fig. 2b, the optimal concentration of HFCS for DCW, lipid, and DHA yields was 100 ml l−1, showing that Aurantiochytrium sp. YLH70 could endure up to 96 g l−1 reducing sugar (120 ml l−1 HFCS) in media, which was as same as S. limacinum SR21 [6] and even higher than Schizochytrium mangrovei PQ6 [23] and Aurantiochytrium sp. KRS101 [24]. A further increase in concentration of carbon source inhibited cell growth and DHA production, while had little effect on lipid production. As shown in Fig. 3a, yeast extract was the optimal nitrogen source for DCW and DHA yields by Aurantiochytrium sp. YLH70, followed by peptone, corn steep liquor, and bean cake powder. Moreover, the optimal DCW, lipid, and DHA valves of 21.3, 14.6, and 6.86 g l−1 were obtained at 20 g l−1 yeast extract (Fig. 3b). The carbon/nitrogen ratio in medium plays a significant role in lipid and DHA productions, and high C/N ratio was effective for accumulations of lipid and DHA. Under nitrogen depletion condition, residual carbon source in medium flow to the lipid synthesis by producing acetoacetyl coenzyme A, which was the structural unit for lipid and DHA synthesis [25]. As shown in Fig. 2b and Fig. 3b, it was deduced that when C/N ratio in medium was 5 (100 g l−1 reducing sugar and 20 g l−1 yeast extract), the optimal lipid and DHA yields were obtained, with the same tendency as in S. mangrovei PQ6 [23] and Aurantiochytrium sp. SD116 [20]. Meanwhile, the C/N ratio had almost the same effect on the lipid and DHA accumulations, showing the lipid and DHA synthesis are related biological processes.

Effects of various carbon sources (a) and high fructose corn syrup (HFCS) concentrations (b) on dry cell weight (DCW), docosahexaenoic acid (DHA) yields, and lipid productions for Aurantiochytrium sp. YLH70. All data are means of three replicates; vertical bars represent error bars with the value equal to the standard error of the mean. DCW, close bar; DHA yield, open bar; lipid production, slash bar

Effects of various nitrogen sources (a) and yeast extract concentrations (b) on DCW, DHA yields, and lipid productions for Aurantiochytrium sp. YLH70. All data are means of three replicates; vertical bars represent error bars with the value equal to the standard error of the mean. DCW, close bar; DHA yield, open bar; lipid production, slash bar

In addition to the macronutrients (carbon and nitrogen sources), micronutrients (vitamin and trace element) and sea salt are both required for growth and DHA productions by Aurantiochytrium sp. [26, 27]. Thus, the HFCS, yeast extract, sea salt, two kinds of vitamins (thiamine and biotin) and four kinds of metal ions (FeSO4·7H2O, CuSO4·5H2O, ZnSO4·7H2O, MnSO4·H2O) were optimized using central composite design (CCD) and the interactive effects of these factors were also analyzed. A summary of variables and their variations was listed in Table 2. The regression model of the CCD results was fit to a second-order polynomial:

where Y, A, B, C, D, and E are the DCW, HFCS, yeast extract, sea salt, metal ion, and vitamin, respectively. The plot described by model Y is shown in Fig. 4, showing that the maximum DCW value of 35.8 g l−1 was obtained when the optimal concentrations for A, B, C, D, and E were 100 ml l−1, 20 g l−1, 20 g l−1, 1.0, and 1.0, respectively, and the model predicted the optimal DCW value of 35.5 g l−1. As shown in Table 4, the fit of the model Y was evaluated by the coefficient of determination, R 2, which was 0.966, indicating that the model could explain 96.6 % of the variability. The model F value of 40.6 implies the model is significant. There is only a 0.01 % chance that a “model F value” this large could occur due to noise. P value less than 0.0001 and sum of squares more than 100 indicate model terms are significant; thus, Table 4 shows that the metal ion (D) and the squares of sea salt and metal ion (C 2 and D 2) had significant effects on the DCW. Through Plackett-Burman design, Chi et al. also found that trace metals significantly affected growth and DHA yield of Aurantiochytrium limacinum SR21 [28]. It is well known that trace metals, especially manganese, iron, cobalt, nickel, copper, zinc, and molybdenum are essential micronutrients for growths of various species of thraustochytrids [27]. Therefore, metal ions were usually used in fermentations of Aurantiochytrium [29, 30]. Aurantiochytrium sp. YLH70 was able to endure a range of 10 to 30 g l−1 sea salt, and the optimal one for DCW production was 20 g l−1 sea salt. It had been reported that A. limacinum SR21 showed a salinity tolerance of 0–200 % that of seawater, the optimum being 50–100 % [6]. Thraustochytrids from mangrove environments, where salinity fluctuates highly, may show wider salinity tolerance. “Adeq Precision” measures the signal-to-noise ratio. A ratio greater than 4 is desirable. The value of 25 indicates an adequate signal. To verify the model results, cultivations of Aurantiochytrium sp. YLH70 under the optimal condition at flash level were performed in triplicate. The average value in experiments was 36.1 g l−1 of DCW with 20.5 g l−1 lipid and 9.03 g l−1 DHA, very close to the maximum DCW of model prediction (35.5 g l−1). There is an improvement of DCW and DHA yields by 149 and 356 %, respectively, relative to those in the initial condition.

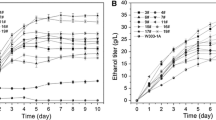

Fermentation Experiments for Aurantiochytrium sp. YLH70

Under the optimum culture condition, the time course of DCW, residual reducing sugar concentration, lipid, and DHA yields by Aurantiochytrium sp. YLH70 in fed-batch fermentation were shown in Fig. 5. During the 120-h fermentation, an approximate total 180 g l−1 reducing sugar was consumed. The maximum DCW could reach 78.5 g l−1 at 114 h, with 51 g l−1 lipids and 20.1 g l−1 DHA. The daily DCW and DHA productivities of Aurantiochytrium sp. YLH70 could reach up to 16.5 and 4.23 g l−1day−1, respectively. The most notable characteristics of Aurantiochytrium sp. YLH70 is its high growth rate. The daily biomass and DHA productivities under large-scale fermentation were even higher than those at flash level, which would be of great benefit for industrial purpose. The same characteristic was also found in a thraustochytrid-like microorganism 12B [9].

References

Prithviraj, L., & Schmitz, A. (2013). Sugar and high fructose corn syrup consumption shifts: change in tastes or relative prices? International Sugar Journal, 115, 556–559.

Singh, I., Langyan, S., & Yadava, P. (2014). Sweet corn and corn-based sweeteners. Sugar Tech, 16, 144–149.

Popa, D., & Ustunol, Z. (2011). Influence of sucrose, high fructose corn syrup and honey from different floral sources on growth and acid production by lactic acid bacteria and bifidobacteria. International Journal of Dairy Technology, 64, 247–253.

Aleksieva, P., Pancheva, V., & Djambazov, I. (1996). Large scale production of acid proteinases by Humicola lutea 120–5. Biotechnology & Biotechnological Equipment, 10, 51–55.

Ward, O. P., & Singh, A. (2005). Omega-3/6 fatty acids: alternative sources of production. Process Biochemistry, 40, 3627–3652.

Yokochi, T., Honda, D., Higashihara, T., & Nakahara, T. (1998). Optimization of docosahexaenoic acid production by Schizochytrium limacinum SR21. Applied Microbiology and Biotechnology, 49, 72–76.

Santangelo, G., Bongiorni, L., & Pignataro, L. (2007). Microbial oils: production, processing and markets for specialty long-chain omega-3 polyunsaturated fatty acids (pp. 43–72). Bridgwater:The Oily Press.

Ganuza, E., Anderson, A. J., & Ratledge, C. (2008). High-cell-density cultivation of Schizochytrium sp in an ammonium/pH-auxostat fed-batch system. Biotechnology Letters, 30, 1559–1564.

Perveen, Z., Ando, H., Ueno, A., Ito, Y., Yamamoto, Y., Yamada, Y., Takagi, T., Kaneko, T., Kogame, K., & Okuyama, H. (2006). Isolation and characterization of a novel thraustochytrid-like microorganism that efficiently produces docosahexaenoic acid. Biotechnology Letters, 28, 197–202.

Sijtsma, L., & De Swaaf, M. E. (2004). Biotechnological production and applications of the omega-3 polyunsaturated fatty acid docosahexaenoic acid. Applied Microbiology and Biotechnology, 64, 146–153.

Ren, L. J., Li, J., Hu, Y. W., Ji, X. J., & Huang, H. (2013). Utilization of cane molasses for docosahexaenoic acid production by Schizochytrium sp CCTCC M209059. Korean Journal of Chemical Engineering, 30, 787–789.

Hong, D. D., Mai, D. T. N., Thom, L. T., Ha, N. C., Lam, B. D., Tam, L. T., Anh, H. T. L., & Thu, N. T. H. (2013). Biodiesel production from Vietnam heterotrophic marine microalga Schizochytrium mangrovei PQ6. Journal of Bioscience and Bioengineering, 116, 180–185.

Liang, Y. N., Sarkany, N., Cui, Y., Yesuf, J., Trushenski, J., & Blackburn, J. W. (2010). Use of sweet sorghum juice for lipid production by Schizochytrium limacinum SR21. Bioresource Technology, 101, 3623–3627.

Yamasaki, T., Aki, T., Shinozaki, M., Taguchi, M., Kawamoto, S., & Ono, K. (2006). Utilization of shochu distillery wastewater for production of polyunsaturated fatty acids and xanthophylls using thraustochytrid. Journal of Bioscience and Bioengineering, 102, 323–327.

Weuster-Botz, D. (2000). Experimental design for fermentation media development: statistical design or global random search? Journal of Bioscience and Bioengineering, 90, 473–483.

Wu, S. T., & Lin, L. P. (2003). Application of response surface methodology to optimize docosahexaenoic acid production by Schizochytrium sp S31. Journal of Food Biochemistry, 27, 127–139.

Abd Elrazak, A., Ward, A. C., & Glassey, J. (2013). Response surface methodology for optimising the culture conditions for eicosapentaenoic acid production by marine bacteria. Journal of Industrial Microbiology & Biotechnology, 40, 477–487.

Gupta, A., Wilkens, S., Adcock, J. L., Puri, M., & Barrow, C. J. (2013). Pollen baiting facilitates the isolation of marine thraustochytrids with potential in omega-3 and biodiesel production. Journal of Industrial Microbiology & Biotechnology, 40, 1231–1240.

Spiro, R. G. (1966) Analysis of sugars found in glycoproteins. ed.

Gao, M., Song, X. J., Feng, Y. G., Li, W. L., & Cui, Q. (2013). Isolation and characterization of Aurantiochytrium species: high docosahexaenoic acid (DHA) production by the newly isolated microalga, Aurantiochytrium sp SD116. Journal of Oleo Science, 62, 143–151.

Grzebyk, D., & Sako, Y. (1998). Phylogenetic analysis of nine species of Prorocentrum (Dinophyceae) inferred from 18S ribosomal DNA sequences, morphological comparisons, and description of Prorocentrum panamensis, sp. Nov. Journal of Phycology, 34, 1055–1068.

Chang, K. J. L., Dunstan, G. A., Abell, G. C. J., Clementson, L. A., Blackburn, S. I., Nichols, P. D., & Koutoulis, A. (2012). Biodiscovery of new Australian thraustochytrids for production of biodiesel and long-chain omega-3 oils. Applied Microbiology and Biotechnology, 93, 2215–2231.

Hong, D. D., Hoang, T. L. A., & Ngo, T. H. T. (2011). Study on biological characteristics of heterotrophic marine microalga-Schizochytrium mangrovei PQ6 isolated from Phu Quoc Island, Kien Giang province, Vietnam. Journal of Phycology, 47, 944–954.

Hong, W. K., Rairakhwada, D., Seo, P. S., Park, S. Y., Hur, B. K., Kim, C. H., & Seo, J. W. (2011). Production of lipids containing high levels of docosahexaenoic acid by a newly isolated microalga, Aurantiochytrium sp KRS101. Applied Biochemistry and Biotechnology, 164, 1468–1480.

Ratledge, C. (2004). Fatty acid biosynthesis in microorganisms being used for single cell oil production. Biochimie, 86, 807–815.

Goldstein, S., & Belsky, M. (1963). B12 and B1 auxotrophy of lower marine phycomycetes. Archiv für Mikrobiologie, 47, 161–163.

Nagano, N., Taoka, Y., Honda, D., & Hayashi, M. (2013). Effect of trace elements on growth of marine eukaryotes, tharaustochytrids. Journal of Bioscience and Bioengineering, 116, 337–339.

Chi, Z., Pyle, D., Wen, Z., Frear, C., & Chen, S. (2007). A laboratory study of producing docosahexaenoic acid from biodiesel-waste glycerol by microalgal fermentation. Process Biochemistry, 42, 1537–1545.

Ganuza, E., & Izquierdo, M. S. (2007). Lipid accumulation in Schizochytrium G13/2S produced in continuous culture. Applied Microbiology and Biotechnology, 76, 985–990.

Jakobsen, A. N., Aasen, I. M., Josefsen, K. D., & Strom, A. R. (2008). Accumulation of docosahexaenoic acid-rich lipid in thraustochytrid Aurantiochytrium sp strain T66: effects of N and P starvation and O(2) limitation. Applied Microbiology and Biotechnology, 80, 297–306.

Acknowledgments

This research was financially supported by Zhejiang Provincial Natural Science Foundation of China (no. LQ13C010002), Natural Science Foundation of Zhejiang University of Technology (no. 2013XZ007), and Research Foundation of Zhejiang Education Department (no. Y201225077).

Compliance with Ethical Standards

ᅟ

Conflict of Interest

This study was funded by Zhejiang Provincial Natural Science Foundation of China (no. LQ13C010002), Natural Science Foundation of Zhejiang University of Technology (no. 2013XZ007), and Research Foundation of Zhejiang Education Department (no. Y201225077). The authors declare that they have no conflict of interest.

Research Involving Human Participants and/or Animals

This article does not contain any studies with human participants or animals performed by any of the authors.

Informed Consent

Informed consent was obtained from all individual participants included in the study.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yu, XJ., Yu, ZQ., Liu, YL. et al. Utilization of High-Fructose Corn Syrup for Biomass Production Containing High Levels of Docosahexaenoic Acid by a Newly Isolated Aurantiochytrium sp. YLH70. Appl Biochem Biotechnol 177, 1229–1240 (2015). https://doi.org/10.1007/s12010-015-1809-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-015-1809-6