Abstract

Thraustochytrids, in particular Schizochytrium spp., are used for the production of the valuable polyunsaturated fatty acid, docosahexaenoic acid (DHA; 22:6 n-3). Growth of Schizochytrium sp. G13/2S in a defined medium was initially made in shake-flask cultures to determine the optimum concentrations of glucose (100–200 g l−1) and ammonia (∼300 mg l−1) that could be used by this microorganism. In subsequent fermenter cultures, a pH-auxostat method was used to maintain NH3 from 200–300 mg l−1. During the first 49 h of fermentation, 150 g glucose l−1 produced 63 g cell dry wt l−1. Although growth was not limited by the supply of nitrogen, total fatty acids were at 25% cell dry wt which is more than half the final lipid content of commercially-grown Schizochytrium biomass which uses N-limited medium in the final stages for maximum lipid accumulation. This strategy is therefore useful for the cultivation of Schizochytrium to a high cell density up to the point when lipid accumulation can be triggered by N exhaustion.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Polyunsaturated fatty acids (PUFA), particularly the very long chain ones of eicosapentaenoic acid (22:5, n − 3) and docosahexaenoic acid (DHA; 22:6, n − 3), are widely recognised as important nutritional components that may help prevent various cardiac disorders. The latter fatty acid, together with arachidonic acid (ARA: 20:4, n − 6), is also incorporated into infant formulae in many countries of the world because of their promotion of visual acuity and neural development (Sinclair et al. 2005). Both DHA and ARA are produced exclusively for this purpose from microorganisms: Crypthecodinium cohnii and Mortierella alpina, respectively (Wynn and Ratledge 2007). DHA is also produced for the adult oil supplement market using a Schizochytrium sp. (Barclay et al. 2005). The whole biomass of this organism may also be useful for the development of aquafeeds for farmed fish, which require a source of DHA for the development of fish fry (Izquierdo 2005; Ganuza et al. 2008).

In order to achieve lipid accumulation in microorganisms, the culture medium is formulated so that the supply of nitrogen becomes exhausted part way through the culture after which cell proliferation ceases but the carbon feedstock (usually glucose) continues to be assimilated (Ratledge and Wynn 2002). However in large-scale cultivations, which can involve a series of fermenters of increasing volume up to 150–220 m3 (see, for example, Wynn and Ratledge 2007), the cells are cultivated in a balanced medium so that the maximum biomass can be produced at each stage. It is therefore not until the cells are inoculated into the final fermenter will the culture be allowed to become N-limited and lipid accumulation then commence (Ganuza and Izquierdo 2007). Even here it is not until the final stages of the run that this will occur. For reasons of commercial confidentiality, very little information is available about the details of the large-scale production of single cell oils.

Schizochytrium spp. are heterotrophic marine thraustochytrids that produce about 35%–40% of their total fatty acids (TFA) as DHA (Yokochi et al. 1998; Barclay et al. 2005). However, this source of DHA is limited by the high production costs in comparison to the current fish oil prices (Wynn and Ratledge 2007). In order to decrease the costs of microbial DHA production, higher volumetric productivities must be pursued by culture optimization and the use of inexpensive medium components. Growth rate, cell density and DHA content of the biomass are essential parameters contributing to optimum DHA productivity (Sijtsma and de Swaaf 2004). High cell-densities are usually attained using fed-batch systems as this technique avoids high initial concentrations of a substrate that might be growth-inhibitory for the organism. Within fed-batch systems, the pH-auxostat was first applied to the automatic feeding of an acidic or basic nutrient in response to changes in the medium pH (Martin and Hempfling 1976). Under a pH-auxostat system, the activity of the microorganism itself regulates the nutrient supply by causing a shift in the pH of the medium which, in turn, causes the addition of more nutrient (as the pH titrant) into the medium. Such a system then permits the fastest possible growth rate. This technique was successfully used for microbial DHA production using acetic acid as feeding nutrient for Crypthecodinium cohnii (Ratledge et al. 2001; de Swaaf et al. 2003). At the moment, Schizochytrium spp. are grown in fed-batch cultures using glucose as carbon source and NH + 4 as nitrogen source (Barclay et al. 2003; Yaguchi et al. 1997). The aim of this present work was to evaluate the capacity of the pH-auxostat system to optimize growth under non-limiting conditions as a first step for the commercial production of a DHA-rich biomass. It has also enabled us to make observations on the amounts of lipid produced during balanced growth which have not been reported before.

Materials and methods

Organism and culture conditions

Schizochytrium sp. G13/2S, derived by nutritional selection from strain G13 (Mr Graham Bremer, University of Portsmouth, UK), was initially cultured in flasks (250 ml) containing 50 ml complex medium [(g l−1): glucose (40), proteose peptone (8), yeast extract (5) sea salts (Sigma) (25) and MOPS (21)]. Further shake-flask cultures were carried out in a defined medium containing (g l−1): glucose (80), diammonium tartrate (1.65), NaCl (12.5), MgSO4 · 7H2O (2.5), KH2PO4 (0.5), KCl (0.5), CaCl2 (0.1) and MOPS (21) unless stated otherwise. This medium also contained trace element solution (5 ml l−1) and vitamin solution (1 ml l−1) that were added after sterilization. The trace element solution contained (g l−1): EDTA di-sodium salt (6), FeCl3 6H2O (0.29), H2BO3 (6.84), MnCl2 · 4H2O (0.86), ZnCl2 (0.06), CoCl2 · 6H2O (0.026), NiSO4 · 6H2O (0.052), CuSO4 · 5H2O (0.002), Na2MoO4 · 2H2O (0.005). The vitamin solution was filter-sterilised (0.2 μm) and contained (mg l−1): thiamine (100), biotin (0.5) and cyanocobalamin (0.5). The medium used in the fermenter contained (g l−1): glucose (150), (NH4)2SO4 (1.65), NaCl (12.5), MgSO4 · 7H2O (2.5), KH2PO4 (2.5), KCl (0.5), CaCl2 (0.1) as well as trace element solution (10 ml l−1) and vitamin solution (1 ml l−1). Before autoclaving (121°C, 15–30 min, with glucose and MgSO4 · 7H2O in a separate container) the pH of the medium was adjusted to 7 with 2 M KOH.

Shake-flask cultures (180 rpm, grown for 24 h), containing either complex or defined medium, were also used as the respective inocula (10% v/v) for the shake-flask experiments and fermenter cultures. All cultures were grown at 27°C with an initial pH of 7. Schizochytrium sp. G13/2S was finally cultivated in a 1 l working capacity bioreactor (Braun) in which the pH was controlled by the automatic addition of NH4OH (10% w/v). Dissolved O2 was maintained over 30% by manually increasing the stirring speed (Rushton blade impellers) from 300 to a maximum of 700 rpm. The aeration rate was always 0.5 vol. air (vol. medium)−1 min−1, previously filtered through a 0.2 μm filter. Addition of antifoam was not necessary during the fermentation.

Determination of cell dry weight (CDW)

Culture samples (20 ml) were centrifuged (3,000g, 5 min, 10°C) and biomass was washed twice in demineralised water. The pellet fraction was freeze-dried and dry biomass then weighed.

Lipid analysis

Fatty acid methyl esters (FAME) were prepared according to the method described by Rodríguez-Ruiz et al. (1998) with nonadecanoic acid as internal standard. FAMEs were separated by GC with He as a carrier gas using BPX70 25 m × 0.22 mm i.d. column (SGE). The column was raised from 160°C to 225°C at 5°C min−1 and then maintained at 225°C for further 5 min. Both the injection port and flame-ionisation detector were at 250°C. Fatty acids were identified by comparison to external standards.

Glucose and ammonia determinations

Glucose concentrations were analysed using a glucose oxidase method (Boehringer, Mannheim, Germany) and ammonia by an indophenol-based method.

Results

Optimum ammonium concentration

Schizochytrium sp. G13/2S was grown in shake-flask cultures on a defined medium with glucose and diammonium tartrate as the principal carbon and nitrogen sources where its performance was equal to that obtained using complex medium (data not shown). It could grow without impediment with diammonium tartrate up to 13.2 g l−1 (2.4 g NH4 l−1) even though the final pH of the medium was <4 (see Table 1). The drop in pH was not preventable even when the medium was strongly buffered with 0.25 M MOPS. [Diammonium tartrate was used in preference to (NH4)2SO4 in order to prevent an even greater fall in pH.] The low pH, however, did not appear to be detrimental to growth.

Optimum glucose concentration

The maximum glucose concentration that sustained optimal growth was between 100 g l−1 and 200 g l−1 (see Fig. 1). In these experiments, sodium glutamate was used as N source as this prevented a decrease in pH which then remained at ∼6.8–6.9 during growth. (It would have, however, been inappropriate to use this as a nitrogen source in the previous experiments as it clearly is not a direct source of ammonium ions.)

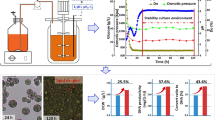

NH4–pH-auxostat fermentation

Having determined the highest concentrations of glucose and ammonia (150 g l−1 and 2.4 g l−1, respectively) to which Schizochytrium sp. G13/2S was tolerant, a pH-auxostat fermentation was initiated in which NH4OH was added to control the pH at 7. During a typical fermentation run—see Fig. 2—some 135 ml 9.5% (w/v) NH4 OH (=6.2 g NH3) were added over 49 h providing a biomass yield of approx. 10 g CDW g−1 NH3. The ammonia concentration within the fermenter was maintained between 300 mg l−1 and 400 mg l−1 by this strategy (Fig. 2b). Thus, Schizochytrium sp. G13/2S could be grown under non-nitrogen limiting conditions to a high biomass density (∼60 g l−1) in 2 days.

The pH-auxostat cultivation of Schizochytrium sp. G13/2S in a 5 l stirred fermenter with 3.5 l medium using 10% (w/v) NH4OH for pH control and well as acting as source of nitrogen to the cells. The initial medium contained 150 g glucose l−1. It was inoculated at 10% (v/v). Data given are typical values of several fermentations carried under the same conditions. (a) Biomass production (Δ), residual glucose (■) and addition of 10% (w/v) NH4OH (○); (b) Residual NH +4 in medium (○) and total fatty acids as %(w/w) cell dry wt (•); (c) total fatty acid production (•) and DHA production (□); D: Dissolved O2 tension in medium (▴) related to the stirring speed (◊)

Glucose, initially at 150 g l−1, was readily utilized during the fermentation (see Fig. 2) and by 48–49 h had been totally consumed producing 63.3 g CDW l−1 (=0.42 g CDW g glucose−1). As no further glucose was added into this fermentation medium, growth then ceased with glucose depletion. However, in other fermentation runs, further glucose was added after 60 h to give an additional 65 g glucose/l but this only increased the cell density from ∼60 g l−1 to ∼65 g l−1 after a further 50 h cultivation (data not shown).

As the initial growth of the cultures was not restricted by nutrient limitation, including nitrogen source, the cells did not enter a lipid-accumulation phase during the course of the fermentation run (Fig. 2b). This was in accordance with expectation as lipid accumulation is triggered by the exhaustion of a nutrient other than carbon (usually this is nitrogen) (see Ratledge and Wynn 2002). The total fatty acid content of the cells remained at about 25% (w/w) throughout growth and thus was entirely growth-associated (Fig. 2c). The profile of fatty acids (see Table 2) remained approximately constant throughout growth though there were small changes in the levels of palmitic acid (16:0) and DHA (22:6). At the end of active growth (49 h), the profile of the fatty acids was similar to that reported for the SCO derived from a commercial strain of Schizochytrium (Barclay et al. 2005) in which the long chain fatty acids (DHA and docosapentaenoic acid, 20:5, n−6) were, respectively, 17% and 41% of the total fatty acids.

Thus, polyunsaturated fatty acid synthesis is occurring in cells undergoing balanced growth and is not specifically engendered by nitrogen becoming limited in the medium. This accords with previous suggestions that lipid accumulation does not occur by increased activity of lipid-synthesising enzymes when nitrogen limitation is reached but by the cessation of other enzyme activities associated with cell growth and proliferation (Ratledge and Wynn 2002).

The overall performance of the cells grown without nitrogen limitation is shown in Fig. 2; there was no limitation of O2 to the cultures (see Fig. 2d) and microscopic examination of the cells made at the highest agitation rate (700 rpm) did not reveal any damage due to shear stress. The overall DHA volumetric productivity (τDHA) was 125 mg DHA l−1 h−1.

Discussion

Schizochytrium spp. are commercially cultivated for the production of Single Cell Oils (SCO) in batch culture with a nitrogen-limiting medium. Under these conditions, cell yields above 200 g CDW l−1 containing around 40% lipids have been claimed (Bailey et al. 2003) although this is not likely to be attained in the commercial process because of the viscosity of the cultures and difficulties in pumping out such a high density of cells from the fermenter and subsequent down-stream processing. This present study was carried out using non-limiting nitrogen conditions as the ammonia consumed by the organism was automatically replaced by the pH control facility using NH4OH as the titrant. Although this condition does not induce lipid accumulation (which needs exhaustion of the N source in order to channel the carbon flux from glucose into fatty acids rather than other cell components), any large-scale production process of an SCO will use a sequence of ever-larger fermenters in which the objective is to grow the cells as quickly as possible and to the highest practical density. It will not be until the final stage is reached that the medium will be formulated to become N-limiting. Up to this point, the medium will be designed to ensure maximum biomass (rather than lipid) production—i.e. will use a balanced composition of nutrients. This is, therefore, what we have done here.

Both glucose and ammonium were well utilised by Schizochytrium strain G13/2S. Further, and in agreement with the work of Yaguchi et al. (1997), we demonstrated that ammonium (as its tartrate salt) was not toxic at 30 g l−1, however, the growth rate was faster with lower concentrations of NH +4 (∼1.7 g l−1), indicating that an NH +4 -fed-batch cultivation would be advantageous for attaining the fastest growth rate. Accordingly, the biomass productivity attained here (1.3 g CDW l−1 h−1) was more than double that achieved by Yaguchi et al. (1997) at 0.53 g CDW l−1 h−1. Although the organism tolerates high concentrations of glucose (∼150 g l−1), these may not be necessarily sufficient to attain the optimal cell densities (60–80 g l−1) and maximal lipid contents (40%–45%) during commercial production, suggesting that a fed-batch culture of glucose would also be beneficial.

Although lipid accumulation was not specifically pursued in this work, because of the very fast growth rates that were attained, DHA productivities were nevertheless still within the range described by Yaguchi et al. (1997) using a nitrogen-limited medium to optimize lipid accumulation and, concomitantly, DHA accumulation: Yaguchi et al. (1997) achieved 140 mg DHA l−1 h−1 compared with 125 mg l−1 h−1 reported here. These values, however, are over twice the values recorded for the production of DHA using Crypthecodinium cohnii, the other commercial DHA-producing microorganism (see Sijtsma et al. 2005). The total fatty acid content in these present experiments was 25% CDW, indicating that more than half the lipid content of the commercially-available Schizochytrium sp. biomass had already been reached in the first phase of the culture (Barclay et al. 2005). Such a high level of lipid in cells undergoing balanced growth has not been reported before. (This phenomenon may be a simple aid to floatation of the cells in their natural marine environment.) Thus, once the cell density in the fermenter had reached, say, 50 g l−1 with 25% lipid, a simple switching from NH4OH to KOH would result in the cells entering the lipid accumulation phase in which the lipid would increase to its final value of about 45%. This would result in a final biomass of about 68 g/l without there being any further increase in the lipid-free biomass. All the increase in biomass would therefore be due to the increased lipid content of the cells.

We would also point out that we have grown this species of Schizochytrium on an entirely chemically-defined medium using only NaCl to maintain an adequate osmotic pressure without the need for artificial seawater salts that are so often used to cultivate these marine organisms. NaCl itself might be replaceable with an equivalent amount of NaSO4 to avoid corrosion of the stainless steel used in the construction of large fermenters (Barclay 2006). Avoidance of complex medium constituents, such as peptones or yeast extracts, also avoids introducing proteins or amino acids from which propionic acid may be derived. This is readily incorporated into odd-chain length fatty acids that are often reported in this organism (Shirasaka et al. 2005).

In conclusion, the NH4-pH-auxostat system is proposed as a promising technique for the first stage production of Schizochytrium sp.biomass. The system allows the fastest possible growth rate to be achieved. The species used, perhaps surprisingly under these conditions, produces a considerable amount of lipid (25% CDW) and DHA(∼40% total fatty acids) prior to the initiation of lipid accumulation.

References

Bailey RB, DiMasi D, Hansen JM et al (2003) Enhanced production of lipids containing polyenoic fatty acid by very high density cultures of eukaryotic microbes in fermentors. US Patent 6,607,900 B2, 19 Aug 2003

Barclay WR (2006) Method of producing lipids by growing microorganisms of the order Thraustochyriales. US Patent 7,011,962 B2, 14 Mar 2006

Barclay W, Weaver C, Metz J (2005) Development of a docosahexaenoic acid production technology using Schizochytrium: a historical perspective. In: Cohen Z, Ratledge C (eds) Single cell oils. AOCS Press, Champaign, Illinois, pp 36–47

Ganuza E, Izquierdo MS (2007) Lipid accumulation in Schizochytrium G13/2S produced in continuous culture. Appl Microbiol Biotechnol 270:985–990

Ganuza E, Benítez-Santana T, Atalah E et al (2008) Crypthecodinium cohnii and Schizochytrium sp. as potential substitutes to fisheries derived oils in Sparus aurata microdiets. Aquaculture (in press)

Izquierdo MS (2005) Essential fatty acid requirements in Mediterranean fish species. Cah Options Mediterr 63:91–102

Martin AA, Hempfling WP (1976) A method for the regulation of microbial population density during continuous culture at high growth rates. Arch Microbiol 107:41–47

Ratledge C, Wynn JP (2002) The biochemistry and molecular biology of lipid accumulation in oleaginous microorganisms. Adv Appl Microbiol 51:1–51

Ratledge C, Kanagachandran K, Anderson AJ et al (2001). Production of docosahexaenoic acid by Crypthecodinium cohnii grown in a pH-auxostat culture with acetic acid as principal carbon source. Lipids 36:1241–1246

Rodríguez-Ruiz J, Belarbi EH, Sánchez JLG et al (1998) Rapid simultaneous lipid extraction and transesterification for fatty acid analyses. Biotechnol Tech 12:689–691

Shirasaka N, Hirai Y, Nakabayashi H, Yoshizumi H (2005) Effect of cyanocobalamin and p-toluic acid on the fatty acid composition of Schizochytrium limacinum (Thraustochytriaceae, Labyrinthulomycota). Mycoscience 46:358–363

Sijtsma L, de Swaaf ME (2004) Biotechnological production and applications of the omega-3 polyunsaturated fatty acid docosahexaenoic acid. Appl Microbiol Biotechnol 64:146–153

Sijtsma L, Anderson A, Ratledge C (2005) Alternative carbon sources for heterotrophic production of docosahexaenoic acid by the marine algae Crypthecodinium cohnii. In: Cohen Z, Ratledge C (eds) Single cell oils, AOCS Press, Champaign, pp.107–123

Sinclair A, Attar-Bashi N, Jayasooriya A et al (2005) Nutritional aspects of single cell oils: Uses and applications of arachidonic acid and docosahexaenoic acid oils. In: Cohen Z, Ratledge C (eds) Single cell oils. AOCS Press, Champaign, pp. 182–201

de Swaaf ME, Sijtsma L, Pronk JT (2003) High-cell-density fed-batch cultivation of the docosahexaenoic acid producing marine alga Crypthecodinium cohnii. Biotechnol Bioeng 81:666–672

Wynn JP, Ratledge C (2007) Microbial oils: production, processing and markets for specialty long-chain omega-3 polyunsaturated fatty acids. In: Breivik H (ed) Long-chain omega-3 specialty oils. The Oily Press, Bridgwater, pp. 43–72

Yaguchi T, Tanaka S, Yokochi T et al (1997) Production of high yields of docosahexaenoic acid by Schizochytrium sp strain SR21. J Am Oil Chem Soc 74:1431–1434

Yokochi T, Honda D, Higashihara T et al (1998) Optimization of docosahexaenoic acid production by Schizochytrium limacinum SR21. Appl Microbiol Biotechnol 29:72–76

Acknowledgements

This work was partially supported by the Tomás de Zárate Grant (Cabildo de Gran Canaria) and by a grant from the EU: Q5RS-2000-30271(PUFAfeed).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ganuza, E., Anderson, A.J. & Ratledge, C. High-cell-density cultivation of Schizochytrium sp. in an ammonium/pH-auxostat fed-batch system. Biotechnol Lett 30, 1559–1564 (2008). https://doi.org/10.1007/s10529-008-9723-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10529-008-9723-4