Abstract

Condensed tannins, also known as proanthocyanidins, have been added as functional additives to acrylic-based clear coatings to promote polymer coating longevity and also stabilize timber color on accelerated and exterior weathering. When added at < 0.5% w/w content, native tannins and tannins modified with maleate groups extended coating performance > 20% compared to commercial hindered amine light stabilizers (HALS) and phenolic stabilizers used at comparable coating loadings. Other tannin chemical modifications such as methylcarboxylate groups were also associated with greater coating longevity beyond that achieved with the synthetic UV and antioxidant additives. This study has also revealed that tannin addition to acrylic coatings can act to photostabilize timber coloring on exterior exposure. While tannin use can contribute color to coatings, any color was rapidly bleached on UV exposure with a dependency on tannin content, degree of modification, and coating formulation pH. Moreover, through manipulating tannin addition levels, this tannin decolorization could offset typical wood darkening associated with UV exposure to provide low or no wood color change over longer exposure periods. With the photooxidative stability efficacy of tannins established on exterior exposure, condensed tannins in native and modified form offer potential as sustainable functional additives for the coatings sector.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

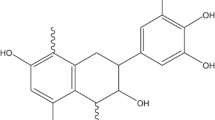

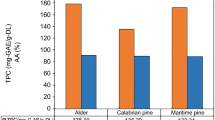

The use of proteins and vegetable oils in coating polymers is an example of employing renewables to improve the sustainability of the paint and coating industry.1 Functional additives such as UV stabilizers, wetting agents, and coalescence aids are used in coatings to promote the performance and longevity of paints and coatings2 with these typically derived from petrochemical sources. Potentially, such additives could also be based on renewables and provide equivalent performance in coatings as their synthetic counterparts. Condensed tannins are polyphenolic compounds found in the leaf, stem, and bark of plants and trees and have been trialled as functional additives in resins and plastics.3,4,5,–6 Extractable into water, condensed tannins have varying uses in the pharma, nutraceutical, adhesives, and leather tanning industries7 related to their biochemistry and function in planta. Being polyphenolics, condensed tannins have a high antioxidant capacity and UV absorption potential.8 When added to resins and plastics in high quantity, the polyphenolics act to fortify these materials, increasing the rigidity of thermoset resins or providing stiffness to plastics.6,9 However, added in low quantity (< 1%) as functional additives, condensed tannins can provide a stabilizing role, acting to inhibit photooxidative aging of synthetic and bio-derived thermoplastics.4,10 The UV absorbing and antioxidant activities were observed to promote polymer longevity, extending the service life beyond that of comparable synthetic additives. More recently, this application of condensed tannins has been extended to an initial demonstration of improving acrylic-based surface coating performance.11

Due to their nature, condensed tannins can be highly colored with this color inherently associated with their biochemical role in plants and extent of oxidation.8 When added to plastics and coatings, this color can manifest in the modified material,4,11 which may be undesirable for some applications. Typically, a noticeable color will result with additions above a weight percent, but when added as a functional additive (< 0.5% w/w), only a small perceivable color change is introduced to the modified plastic or coating.4,11 In acrylic-based paints, the tannin imparts a brown color to a white-base coating even at low loadings. However, in clear coating systems, this color was considered insignificant when applied over natural timbers nor do these tannin materials leach from the coating polymer matrix.11 Moreover, while colored, the polyphenolic tannins appear to photobleach in these systems due to a susceptibility of tannin to light.12,13,–14 High tannin-content timbers, tanned leather, and plastics modified with functionalized tannins have been observed to lighten on exposure to sunlight which may be an attribute unsuited to surface coatings. Oxidative cleavage of phenolic rings promoted by UV light has been attributed to this process, which causes a loss in the inherent phenolic coloring12 and formation of hydroxylated benzoic acid monomers or lower molecular weight oligomers with carboxylic acid functionality.13 In contrast, tannins crosslinked within adhesive systems appear photostable retaining their darker color on exterior exposure testing15 and suggest a chemical modification of polyphenolic rings may reduce this photodegradation process.

In the first part of a greater study, acrylic-based clear coating systems containing various native and modified tannins were initially found to extend coating longevity and reduce the inherent darkening of the clear coated wood on UV exposure under laboratory accelerated weathering.3,11 A focus of this current paper is to build on these initial findings and further extend this beneficial activity of tannin-modified acrylic-based coatings on exterior exposure. It is hypothesized that the photooxidative stability provided by tannins in acrylic coatings achieved under artificial weathering conditions will be similarly promoted under natural sunlight. In addition to assessing coating longevity, an unanticipated finding of the decolorization of tannin-modified coatings has led to an explanation of how condensed tannins may act to aid the photostabilization of wood surfaces exposed to UV light.

Methods and materials

Materials

The two base coating resins used were styrene-acrylic copolymer resins Viscopol 6191 (Coating 1, high pH, low styrene content) and Viscopol 6756 (Coating 2, low alkaline pH, higher styrene content), which were both sourced from Allnex (New Zealand, formerly Nuplex Ltd NZ). Both coating formulations (ca. 25–30% solids) were obtained as the base resin coating without any post-polymerization additives and used as received. Chimassorb™ 90 (Chim) and UV stabilizer Tinuvin 292 (HALS) were the commercial additives and also obtained from Allnex. The native tannin extracts (as dry powders) were from aqueous extraction of pine bark (Pinus radiata) with each obtained by either hot water extraction (> 90°C, HWT) or hydroethanolic extraction (< 50°C, PBT) of this bark (Table 1, Supplementary Materials). From the HWT extract, the tannin esters and ethers were prepared according to published procedures to give tannin maleate (TanMal), tannin maleate acetate (TanMalAc), and sodium tannin methylcarboxylate (TanMC) described elsewhere.5,16,17,18,–19 Additionally, as in Table 1, a relatively higher molecular weight fraction of the HWT was produced by passing a hot water bark extract through an industrial clarifier to obtain a suspension which was freeze dried to give a brown powder (HMTan). In the case of the refined hot water pine bark extract (RFTan), this was obtained by cooling the hot water extract, then recovering, and freeze drying the precipitated material.

Modification of coatings

Following an established procedure,11 modified coatings were produced by adding either a commercial or tannin-based additive to a base coating formulation. Each additive was typically added at ca. 0.2% loading w/w on the wet emulsion (Table 1). In the case of the commercial additives, these were added as aqueous slurry by first adding this material to a minimum amount of water. For modified tannins, each was dissolved in polyethylene glycol (PEG 400) as ca. 20% solutions before adding to the base resin with sufficient stirring.11

Coating application and evaluation

The preparation of coated substrates, accelerated weathering, exterior exposure, and coating assessments were conducted according to the AS/NZS1580 Standard. The timber was untreated radiata pine (280 × 60 × 10 mm) and was first sanded (150 grit) and then each coating applied via brush application. In each case, the base resin or modified coatings were applied directly to the timber at an overall application rate of ca. 50–75 g/m2. Two coatings were applied per specimen (both sides) allowing at least 2 h between applications. Coated white substrates were also prepared by first precoating the timber substrates with a commercial exterior grade white acrylic coating and then applying either the base resin or modified coatings as above. All coated specimens were then end-sealed with an exterior grade white acrylic coating to limit moisture and water ingress.

Accelerated weathering

Artificial weathering was undertaken with a QUV accelerated weather tester made by Q Panel Lab Products. Protocols for AS/NZS1580 483.1 were followed, where both UV (8 h) and condensation (4 h) cycles were undertaken at 45°C for up to 1500 h. UV exposure was achieved through the use of UVA-340 lamps at an irradiance of 0.89 W/m2. Two specimens were used per sample, with specimens each having two exposure areas (50 × 80 mm). Specimens were randomly rotated every 250 h to ensure even exposure to QUV conditions with specimens photographed, color measurements made and coating evaluations undertaken at this time.

Exterior exposure weathering

Two specimens per sample were deployed locally in Rotorua (New Zealand) by mounting the specimens in racks located at the Scion field testing facility. The racks were at 45° with racks facing north toward the sun. At this site, the average sunlight exposure rate was 5.15–6.17 kWh/m2 during the period of sample exposure. Samples were assessed approximately every 25 days. As above, specimens were photographed and then color measurements and coating evaluations undertaken at this time.

Color assessments

The color of coated samples was measured using a Konica Minolta Chroma CR-400 colorimeter. For weathered samples, each exposure area (50 × 80 mm, two per specimen) had a total of five measurements comprising the four corners and center of this area (total of ten per specimen and 20 measurements per sample). Measurements were referenced to the CIE L × a × b × color spectrum. Changes in sample color were converted to ΔL, Δa, Δb, and ΔE values compared with original, unexposed measurements.

Coating evaluations

Each coating sample was evaluated using AS/NZS1580 481 criteria. This included assessment of the general appearance and gloss of the coating as well as several specific evaluations including checking and cracking, blistering, flaking or chalking, and color change. In each case, evaluations were undertaken comparing any changes to the reference (original, unexposed) specimen of the same sample which had not been exposed to any light or weathering.

Results and discussion

Native and modified tannins were introduced into each styrene-acrylic copolymer coating systems at typical additive loadings (< 0.5% w/w). This was based on weight percentage substitution rather than activity of functional groups given the variety in tannin content and hydroxyl substitution present (Table 1). In addition, the native tannin samples were added over a range of differing weight percentages and complemented by evaluating higher oligomeric and refined fractions of this native tannin. The differing tannin chemical modifications have already provided initial enhancements to coating performance and include derivatives with methylcarboxylate (TanMC), maleate (TanMal) and maleate/acetate (TanMalAc) groups with all demonstrated not to leach from acrylic-based coatings.3,11 When applied as clear coatings over a white substrate, these tannin-modified coatings contributed a light yellow-brown color to the coating (Fig. 1). The native tannins provided a relatively higher color component compared to the modified tannins, consistent with their inherent chemistries and tannin composition (Table 1 and Supplementary Materials). Native tannin gave ΔL* values of 4–12 with L* values which were dependent on both tannin loading and the base coating used (Fig. 1, Supplementary Materials). The copolymer system at pH 9.4 gave relatively darker samples with both PBT (D) and TanMal (J) having ΔL* values of 8–12, whereas their incorporation into the pH 8.5 coating gave relatively lighter samples (ΔL* ca. 4). This may be attributed to the greater alkalinity enhancing phenolate ion formation with the flavonoid chromophore manifesting as a darker color. This pH effect also has the benefit of broadening UV absorption by the tannin component.11 On application to a timber substrate, tannin-modified coatings show a relatively lower degree of darkening (ΔL* = 7–8) when compared with the reference samples (Figs. 2 and 3 and Supplementary Materials). Tannin methylenecarboxylate (M) addition similarly led to darkening of the applied coating as above. In contrast, TanMalAc (F), even at 0.4% loading, contributed to a relatively lighter color owing to the full esterification of the tannin hydroxyls and, arguably, a lower tannin content due to the high degree of substitution (DS, Table 1).

Artificial weathering evaluation

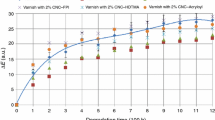

Accelerated weathering of coated timber samples, conducted under UVA light (340 nm) and condensation cycling, was used to initially evaluate tannin efficacy in each styrene-acrylate copolymer system relative to that established in acrylic systems.11 On accelerated weathering, timber samples typically darken (L* value, Figs. 3 and 4 and Supplementary Materials). This was relatively rapid, occurring within the first 300 h and a consequence of wood components such as lignin reacting to UV light exposure.20 After this time, the rate of darkening reduces and, from ca. 800 h, the L* values remain relatively unchanged. Both the Δa* (red-green) and Δb* (yellow-blue) profiles also similarly exhibited rapid change in the first 300 h before stabilizing at longer times (Fig. 5). In the case of b* values, these increase above 1000 h as the samples yellowed, which is indicative of the changes in wood chemistry of the timber substrate.20 Across the coating series, samples have minor differences attributable to tannin modification and content as well as coating pH. The reference samples, including the base, unmodified coating (A) and those containing commercial additives (B, P, Q, R) all show rapid darkening of the timber substrate (250 h) with a more gradual change at longer times (Supplementary Materials). These samples were also associated with the largest ΔL* values after 1500 h. In contrast, the native tannin (D) and TanMal (J) modified samples show the least darkening, with other coatings containing variously modified tannins having intermediate ΔL* values. Moreover, within this modified coating series, the extent of tannin chemical modification appeared to contribute to differences in ΔL* values. Partial esterification with maleate groups (TanMal, DS = 2) led to a relatively small change in L* values, whereas full esterification with both maleate and acetate groups (TanMalAc, DS > 5) led to a relatively greater L* change. Furthermore, higher tannin content (0.4%, C) led to relatively lower ΔL* values, whereas 0.1% addition gave relatively large ΔL* values for both native tannin (E) and TanMalAc (H). These trends have been similarly observed in acrylic coatings11 for which native tannin had exhibited relative color stability through small or no change in L* values on artificial weathering. In this series of coated timber samples, there appeared only minor differences between coating pH and styrene content.

L* profiles for selected clear coated timber samples for various styrene-acrylic coatings during accelerated weathering exposure. Where: HALS (green); 0.2% PBT (black); 0.2% TanMal (brown); and HWT (purple) use Coating 1 and base resin (red, dotted); HALS/Chim coating 2 (black, dotted); and TanMal (blue, dotted) use Coating 2 (Color figure online)

Comparisons of Δa* (left) and Δb* (right) values of selected clear coated timber samples on accelerated weathering exposure. Where: HALS (green); HALS/Chim (red); 0.2% PBT (black); and 0.2% TanMal (brown) HWT (purple) use Coating 1 and base resin (red, dotted); HALS/Chim coating 2 (black, dotted); and TanMal (blue, dotted) use Coating 2 (Color figure online)

Inherent in styrene-acrylic copolymer coatings was a relatively short coating life with surface whitening and coating failure evident after just 1000 h accelerated weathering (Supplementary Materials). As an example, samples (S–V) prepared with the higher styrene content resin system show significant coating degradation and whitening at ca. 1000 h. This coating failure was also reflected in the observed L* color values (whitening) with extended time (Fig. 4). With a lower styrene content, the reference coating systems containing commercial additives or PEG (B, P, Q, R) were deemed to have failed prior to 1250 h. All tannin-modified coatings including PBT (D2) and TanMal (J2) modified coatings stored for 6 months prior to application proved satisfactory to at least 1250 h with extended exposure leading to some degree of coating failure for most of these samples.

For those samples in which the modified coatings were applied over a white substrate, accelerated aging revealed contrasting results to those over timber. Instead of samples darkening as above, the tannin-containing coatings (O, U, V, Z) were observed to decolorize on exposure (Fig. 3). Tannin bleaching is not unexpected, having been reported previously for tannin-containing wood, leather, and plastic products exposed to sunlight.5,13,14 However, in the current study, the native tannin (Z) and TanMal (O) samples exhibit comparatively rapid decolorization within 200 h to give relatively higher L* values (Fig. 6). These same tannin materials (HWT, U, and TanMal, V) in the lower pH styrene-acrylic coating were observed to also lighten, but this was more gradual, taking some 500–600 h to decolorize. These L* differences attributable to coating pH were not discernible with clear coated timber under the same accelerated weathering conditions (Fig. 4). Moreover, the differing rate of decoloration with pH may provide insights to the flavonoid chromophore and extent of UV absorption of the phenolate ion formed at alkaline pH.11 In the case of a* and b* values of coatings applied to white substrates, the changes (Δa*, Δb* < 5) were consistent with the red-brown color loss of each coating sample (Fig. 7, Supplementary Materials). As noted above for L* values, the high pH styrene-acrylic coating samples HWT (Z) and TanMal (O) show greater change (< 250 h) in b* values than the lower pH samples U and V, respectively. Collectively, together with visual observations of aged samples (Fig. 3), the L*, a* and b* changes across Figs. 4, 5 and 6 suggest photobleaching of the tannin components was occurring, which also has implications for the observed color stability of the clear coated timber samples.

L* profiles of various styrene-acrylic coating samples applied over a white substrate on accelerated weathering exposure. Where: 0.2% HWT (black) and 0.2% TanMal (green) use Coating 1 and base resin (blue); HALS/Chim (pink); 0.2% HWT (red); and 0.2% TanMal (brown) use Coating 2 (Color figure online)

Comparisons of Δa* (left) and Δb* (right) values of various styrene-acrylic coating samples applied over a white substrate on accelerated weathering exposure. Where: 0.2% HWT (black) and 0.2% TanMal (green) use Coating 1 and base resin (blue); HALS/Chim (pink); 0.2% HWT (red); and 0.2% TanMal (brown) use Coating 2 (Color figure online)

Exterior weathering evaluation

To establish the tannin contribution to coating and wood color stability in exterior environments, both styrene-acrylic coating series were evaluated outdoors. With styrene-acrylic coatings unsuited for long-term exterior exposure, their use allowed a rapid assessment to correlate coating failure and wood color changes with those observed in artificial weathering. Outdoor exposure revealed initial coating failures within 50 days, but showed similar trends in both coating stability and wood color to those established in accelerated testing (Table 2, Figs. 8 and 9). Evident in Fig. 8 was the failure of the reference samples (Base resin, A and Chim, B) at 50 days. These reference samples had significant coating cracking over > 50% of the specimen surface and were also associated with mold growth. Both the 0.1% PBT (E) and 0.1% TanMalAc (H) samples also showed cracking and mold development, but to a lesser degree with the remaining tannin-modified coating samples exhibiting signs of imminent failure. Exposure was continued beyond 75 days with the physical appearance of samples assessed to estimate sample longevity. Based on both the general appearance and lack of any widespread cracking, the 0.4% PBT (C) and 0.2% TanMal (J) samples performed the best in outdoor exposure (Table 2). Those samples also providing a relatively greater degree of efficacy were the 0.4% TanMalAc (F), 0.2% PBT (D), and the corresponding 0.2% refined HMTan (K) and RFTan (L) samples. These samples showed relatively greater degradation after 75 days when compared to the 0.4% PBT (C) and 0.2% TanMal (J) samples. From estimates of coating longevity (Table 2), it was evident both the tannin content and type of modification contributed to their efficacy as functional additives in the styrene-acrylic coatings.

Photograph showing various exterior exposure samples (as per Table 1) after 54 days outdoors. Samples A–F (bottom row) and samples G–M (top row), two specimens per sample are shown

Shown in Fig. 10 are profiles of L* values for both timber and white substrates on outdoor exposure. Generally, the trends in L* values were similar to those of accelerated weathering (Figs. 4 and 6). While marred by mold development, the PBT (D, N) and TanMal (J) clear coated timber samples show a relative lightening in color with the remaining samples darkening. Beyond 50 days, these samples exhibit relatively similar L* values with the 0.4% PBT sample (C) having the lightest color, which was similarly observed with accelerated aging (Fig. 4). While coating cracking and failure also visually marred the reference coating samples (A, B), these samples had relatively lower L* values (darker) as did the 1% TanMalAc sample (H). For the clear coated white substrates, tannin decolorization was visually evident (Fig. 9) with lighter L* values achieved after 38 days. In the case of the 0.4% TanMalAc (F), this sample appeared to retain its base color through to 86 days. This TanMalAc material had comparable performance in accelerated weathering and previous studies.5,11 Unlike accelerated aging, exterior exposure evaluations did not determine any differences in tannin decolorization due to coating pH or tannin modification.

L* profiles of selected samples exposed to outdoor weathering. clear coated timber samples (left) and coating samples applied over a white substrate (right). Where: PEG (purple, dotted); HALS/Chim (brown, dotted); 0.2% PBT (brown); 0.2% TanMal (blue); 0.2% HWT (green); and HALS/Chim (black) use Coating 1 and base resin (blue, dotted); HALS/Chim (green, dotted); 0.2% HWT (red, dotted); and 0.4% TanMalAc (purple) use Coating 2 (Color figure online)

Coating color contributed by tannin

Coating color contribution by tannin components on initial formulation11 (Supplementary Materials) after coating application and subsequent exposure to UV light was dynamic. However, the observed tannin decolorization on UV exposure is key to explaining the relative color stability of some timber samples coated with tannin-modified coatings (Figs. 3 and 8). The presence of tannin in the coatings imparts an initial darker color to the substrate with this dependent on tannin content and modification (Figs. 1 and 2). When exposed either to accelerated or outdoor weathering, the timber samples appear to retain a similar color compared to the reference samples which typically darkened and were associated with relatively lower L* values (Figs. 6 and 10). The tannin component decolorizes, appearing to maintain a relatively lighter L* value than reference samples. Given these same modified coatings had exhibited relatively lower initial L* values, this suggests the tannin component is preferentially absorbing UV irradiation resulting in its decolorization, which avoids significant darkening of wood components. Any difference in L* values after UV exposure was typically small, or in the case of the 0.4% PBT sample, found to be relatively lighter. This has the combined effect of imparting the relative color stability of the timber substrate observed for these coatings as well as promoting coating longevity. Furthermore, while decolorized rapidly and perhaps viewed as sacrificial, the presence of tannins promoted coating longevity beyond the time frame of tannin decolorization.

Differences in styrene-acrylic coating pH also led to differences in initial coloring provided by the native and modified tannins in coatings. This was likely attributable to differences in degree of phenolate ion formation promoted by the alkaline pH of each coating. The extent of phenolate ion formation in coatings can also broaden the UV absorption potential of both native and modified tannins having free hydroxyl groups.11 Differing pH of the coating formulation also led to varying decolorization rates revealed by accelerated aging of coatings over white substrates (Fig. 6). This may be explained by the extent of phenolate formation and their differing UV absorption rates. Tannin chemical modification via esterification had the effect of both reducing the effective tannin content (Table 1) and the perceived darkening of these modified coatings (Fig. 2). With partially esterified TanMal, there was only a minimal reduction in color contribution due to retention of free hydroxyl groups (low DS) and phenolate formation. Full esterification, as with TanMalAc, led to considerable lightening of the initial color contributed by the tannin content, and arguably due to a lack of free hydroxyl groups (DS > 5) affected by the alkaline pH. However, interestingly, 0.4% TanMalAc content (F) also provided some color stability with time (Fig. 10). Darkening of applied coatings was also observed with TanMC which had free tannin hydroxyls present. The observation of tannin decoloration coupled with the initial color contributed by tannins and coating pH can assist in explaining the relative color stability observed with accelerated weathering and outdoor samples from this current, and earlier parts of this study.11

While study outcomes have focused on the relative color stability of clear coated timber samples, the presence of tannin also contributed to increased coating longevity. Importantly, this was beyond the time frames of initial tannin decolorization and that provided by the commercial additives (Chim and HALS). This was visually evident in Figs. 3 and 8 together with physical assessments of weathered coatings (Table 2) and confirms tannin-containing samples outperform the reference styrene-acrylic samples containing synthetic antioxidant and UV stabilizers at similar loadings. In the case of TanMal (J), styrene-acrylic coating performance was extended beyond 1500 h (> 20%) of accelerated weathering and similarly found to promote longevity on outdoor exposure. Tannin activity does not appear lost when initially decolorized, but demonstrated longer-term efficacy as an antioxidant and UV absorber in acrylic coating performance. This suggests despite the initial decolorization of the condensed tannins, the retention of initial wood color and coating efficacy indicates the tannins were providing longer-term photooxidative stability to the modified coatings. Moreover, this finding may support the suggestion that UV-promoted oxidation of tannins and phlobaphenes results in low molecular weight oligomers with carboxylic acid functionality13 rather than forming leachable hydroxylated benzoic acid monomers described by Colombini et al. on UV degradation of polyphenolics.12

Summary

This study has brought together several key findings which collectively have established tannins as functional coating additives acting to stabilize acrylic coatings on exposure to photooxidative aging. In applying clear coats over a white substrate, tannin addition variously imparts color to the coating. The contribution to the color was dependent on the tannin material, tannin content, degree of modification, and coating formulation pH. Fully esterified tannin such as TanMalAc gave the least coloring, but even their pale yellow-brown contribution may be too colored for some clear coating applications. However, while perhaps unsuited for many clear coating applications, the color imparted by tannins was considered minimal when applied over timber. Moreover, the imparted color to clear coated timber may be controlled and minimized by selecting the appropriate tannin material, chemical modification and concentration.

When exposed to UV light, native and chemically modified tannins decolorize relatively rapidly. However, the presence of these tannins had the effect of imparting color stability to timber substrates. Both accelerated weathering and outdoor exposure revealed this to be more effective than addition of commercial UV absorbing and antioxidant additives. Tannin decolorization acted to balance the typical wood darkening observed with reference samples and has potential for interior and exterior application. This lighter wood coloring was retained at longer exposure times indicating that tannin efficacy and UV absorption extended beyond the initially observed tannin decolorization. Furthermore, this provides the opportunity for how wood color stability may be managed in practice through selecting an initial tannin concentration envisaged to match expected wood color change with time. The finding that tannin efficacy did not deteriorate after 6 months storage of the coating formulation suggests tannins may be commercially viable additives to aid coating performance and protection.

Findings from this, and the greater study,11 show addition of tannin materials as functional additives to coatings can promote protection and aid coating longevity. This has now been demonstrated in both accelerated aging studies and outdoor exposure trials. A variety of tannins and chemically modified derivatives, coating concentrations and differing acrylic coating systems have been evaluated.3,11 Addition of tannin is undertaken at additive levels < 0.5% as tannins added at higher concentrations offer highly colored systems. At 0.4% loading, some modified tannins can produce a neutral wood color coating, which offers coating longevity well beyond that of current commercial additives. Native or partially modified tannins with a minimum of 0.2% content offer photooxidative stability extending coating performance and longevity in addition to preserving the initial color of clear coated timber.

References

Mash, A, Sustainability in the coatings industry. PCI Paints & Coatings Industry Magazine (2015). http://www.pcimag.com/articles/100363-sustainability-in-the-coatings-industry

Hare, CH, “Protective Coatings.” In: S.f.p. coatings (ed.) Fundamentals of Chemistry and Composition. Technology Publishing Company, Pittsburgh (1994)

Grigsby, WJ, “Simulating the Protective Role of Bark Proanthocyanidins in Surface Coatings: Unexpected Beneficial Photo-Stabilisation of Exposed Timber.” Prog. Organ. Coat., 110 55–61 (2017)

Grigsby, WJ, et al., “Esterification of Condensed Tannins and Their Impact on the Properties of Poly(Lactic Acid).” Polymers, 5 (2) 344–360 (2013)

Grigsby, WJ, et al., “Evaluating Modified Tannin Esters as Functional Additives in Polypropylene and Biodegradable Aliphatic Polyester.” Macromol. Mater. Eng., 299 (10) 1251–1258 (2014)

Luo, C, et al., “Vegetable Oil Thermosets Reinforced by Tannin–Lipid Formulations.” Acta Biomater., 9 (2) 5226–5233 (2013)

Hagerman, AE, Tannin Handbook. University of Miami, Ohio (2002) ftp://217.148.94.129/

Hemingway, RW, Karchesy, JJ, Branham, SJ, The Chemistry and Significance of Condensed Tannins. Plenum Press, New York (1989)

Grigsby, WJ, Kadla, JF, “Evaluating Poly (Lactic Acid) Fiber Reinforcement with Modified Tannins.” Macromol. Mater. Eng., 299 (3) 368–378 (2014)

Grigsby, WJ, Bridson, JH, Schrade, C, “Modifying Biodegradable Plastics with Additives Based on Condensed Tannin Esters.” J. Appl. Polym. Sci., 132 (11) 41626 (2014). https://doi.org/10.1002/app.41626

Grigsby, W, Steward D, “Applying the Protective Role of Condensed Tannins to Acrylic-Based Surface Coatings Exposed to Accelerated Weathering.” J. Polym. Environ., 26 (3) 895–905 (2018). https://doi.org/10.1007/s10924-017-0999-0

Colombini, MP, et al., “Colour Fading in Textiles: A Model Study on the Decomposition of Natural Dyes.” Microchem. J, 85 (1 SPEC. ISS) 174–182 (2007)

Durán, N, et al., “Biomass Photochemistry: VI-Light-Induced Oxidation of Phlobaphene from Wood.” Polym. Photochem., 6 (5) 393–402 (1985)

Pizzi, A, et al., “Tannin Antioxidant Characteristics in Leather Versus Leather Light Stability: Models.” J. Appl. Polym. Sci., 91 (2) 1030–1040 (2004)

Pizzi, A, Stephanou, A, “Fast vs. Slow-Reacting Non-modified Tannin Extracts for Exterior Particleboard Adhesives.” Holz als Roh- und Werkstoff Eur. J. Wood Wood Ind., 52 (4) 218–222 (1994)

Arbenz, A, Avérous, L, “Chemical Modification of Tannins to Elaborate Aromatic Biobased Macromolecular Architectures.” Green Chem., 17 (5) 2626–2646 (2015)

Bridson, JH, Derivatisation of Polyphenols. MSc thesis, University of Waikato, Hamilton, New Zealand (2007). https://waikato.researchgateway.ac.nz/handle/10289/4952

Bridson, JH, Grigsby, WJ, Main, L, “Synthesis and Characterization of Flavonoid Laurate Esters by Transesterification.” J. Appl. Polym. Sci., 129 (1) 181–186 (2013)

Grigsby, WJ, Kadla, JF, “Evaluating Poly(lactic acid) Fiber Reinforcement with Modified Tannins.” Macromol. Mater. Eng., 299 (3) 368–378 (2014). https://doi.org/10.1002/mame.201300174

Tolvaj, L, Mitsui, K, “Light Source Dependence of the Photodegradation of Wood.” J. Wood Sci., 51 (5) 468–473 (2005)

Acknowledgments

This work was supported by Biopolymer Network Ltd, through funding by the New Zealand Ministry of Business, Innovation and Employment.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Grigsby, W.J. Photooxidative stability provided by condensed tannin additives in acrylic-based surface coatings on exterior exposure. J Coat Technol Res 15, 1273–1282 (2018). https://doi.org/10.1007/s11998-018-0086-z

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11998-018-0086-z