Abstract

The food and drink industry is gradually gaining sustainability pressure due to the high carbon emissions rate and limited availability of traditional energy supplies. Thus, it is essential to consider energy efficiency and decarbonisation of the ever-expanding food and drink industry. Ohmic heating technology is a highly energy-efficient and quick method of electrically heating food products. It uses the resistance of the food material to convert electrical energy into heat. However, the heating rate of ohmic heating depends on several process variables, such as electrical conductivity, voltage gradient, and voltage frequency. Therefore, it is important to study and understand the effects of these process variables to optimise the modelling and control of ohmic heating systems to obtain desirable output from food products. Hence, this study presents a review of the effects of process parameters on nutritional and organoleptic qualities, product yields, and energy efficiency of ohmic heating, along with its various industrial applications. The technology shows promising advancements in colour and nutritional quality, increasing energy efficiency, shorter processing times, and higher product yields compared to conventional heating processes.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The food and drink industry (FDI) is rapidly growing around the world and is forecasted to expand with a compound annual growth rate (CAGR) of 10.5% until 2029 (Food & Drink - United Kingdom, n.d.). It has been researched that if the current food production growth rate stays constant, the FDI will produce 1.4 trillion metric tons of greenhouse gases (GHG) by 2100 (Sustainability Times 2022). Consequently, it will be among the largest CO2 emitters, leading to intense climate changes and imposing significant sustainability pressure on the food industry. Therefore, it is essential for the food and drink industry to adapt to energy-efficient and greener technologies for food processes.

The food industry is considered challenging to decarbonise due to the involvement of energy-intensive, wide range of thermodynamic processes (Atuonwu et al., 2019). Most of the energy requirements in food processing are met by conventional heating (CH) methods of fuel burning (primarily by the combustion of coal, oil, or natural gas). Subsequently, burning these fossil fuels corresponds to approximately 7.5 Gt of CO2 emissions per year (World Energy Outlook, 2018).

Additionally, heat transfer via CH occurs through thermal conduction, a time-consuming process with uncontrolled distribution, potentially leading to overtreatment or undertreatment of the food product. This compromises both food safety and quality. Furthermore, conventional heating methods are neither environmentally friendly nor energy efficient, as they rely on slow surface-to-centre heat transmission mechanisms. As a result, CH systems are inadequate for meeting today’s demand for minimally processed products that retain food freshness (Ibarz, Barbosa-Canovas 2014). Owing to these problems, rapid and volumetric heating technologies, such as electromagnetic heating (microwave or radiofrequency) and ohmic heating (OH), have garnered significant attention in food processing systems (Abea et al., 2023; Ekezie et al., 2017, Sastry, Heskitt et al. 2014). This review will focus on the latter, with a particular emphasis on the impacts of this technology on food product quality.

Ohmic heating involves the passage of electric current directly through the food material, increasing its temperature and altering its resistance properties. Heat is volumetrically generated within the material by the Joule effect (Jaeger et al., 2016). Therefore, this method is considered highly efficient and uniform, which significantly reduces cooking times compared to conventional heating.

The technology has significant potential in industrial food applications, such as pasteurisation (Atuonwu, Tassou 2021, Porras-Parral et al., 2011; Cappato et al., 2017), sterilisation (Alkanan et al., 2021; Gratz et al., 2021a, 2021b, 2021c, 2021d), enzyme inactivation (Rocha, C. M. R., Genisheva et al. 2018, Syed, Popa, Makroo et al., 2017a, 2017b), fermentation (Salari & Jafari, 2020; Reta et al., 2020), peeling, blanching, and thawing of fruits and vegetables (Aurina & Sari, 2022; Jafarpour & Hashemi, 2022; Rinaldi et al., 2020; Kadam et al., 2015). It is also suitable for meat products and fluids, such as milk, juices, and beverages. Soups, mixtures, sauces, and slurries containing diced ingredients can also be processed (Syed, Popa, Aurina, Sari 2022, Cappato et al., 2017; Shim et al., 2010; Ribeiro et al., 2022; Ferreira et al., 2019a; Rodrigues et al., 2015; Ni et al., 2015; Rocha, C. M. R., Genisheva et al. 2018, Stojceska et al., 2019).

However, heating rates and distribution for processing any food product depend on the nature of the applied electric fields, necessitating precise control of the electric field magnitude. This requirement has led to the development of two categories of ohmic heating processes: Moderate Electric Field (MEF) and Pulsed Electric Field (PEF) (Abbas Syed 2017). PEF generally involves electric fields exceeding 1000 V/cm, whereas MEF processes use electric fields less than 1000 V/cm (Astráin-Redín et al., 2024).

Research indicates that the application of electric fields also has nonthermal effects, which may alter the physicochemical properties of food (Silva et al., 2022). Additionally, the nonuniform electrical conductivity due to the heterogeneous composition of food can result in uneven heat distribution, negatively impacting the food quality (Dornoush & Bagher, 2022). These observations highlight the importance of understanding the governing factors, such as the magnitude of the applied electric field, its frequency, and waveform, their influence on the product’s physicochemical properties, and their impact on food quality.

Addressing this need requires the development of ohmic heating models that can provide a comprehensive understanding of system dynamics and the effects of varying process variables on product properties prior to the application of OH for industrial processes. Therefore, it is vital to create precise mathematical or physical models that can accurately characterise the behaviour of the OH system. These models are imperative for effective optimisation of process parameters, and development of control strategies before their implementation in real-time industrial applications.

Mathematical models and computational fluid dynamics (CFD) models have been developed for various products for laboratory scale experiments. Shim et al. (2010) conducted a study on modelling ohmic heating patterns in solid–liquid food mixtures with significantly varying electrical conductivities. This research utilised CFD to identify cold and hot spots within the product medium. Moreover, numerical analysis techniques have also been developed to simulate temperature distribution for specific applications. Choi et al. (2020) focused on the pasteurisation of orange juice, while Khodeir et al. (2021) examined the processing of pre-bake cake batter using batch ohmic heating. Similarly, work by Zhang et al. (2021) also presents mathematical model for a colinear batch OH system. These models effectively capture the dynamic behaviour of ohmic heating systems but do not account for the impact of variations in the physical properties of food products.

Although several reviews presented in literature are based on the applications and impacts of OH on food quality, none, to the best of our knowledge, has focused on studying the critical parameters for modelling to compare and discuss their impact on food properties. Therefore, to comprehend the maximum potential of ohmic heating, this research aims to review critical parameters involved in modelling an OH system and their effects on the physicochemical properties, nutritional qualities, organoleptic properties, and shelf life of food processed with ohmic heating, along with its potential application in industrial processes.

Critical Process Parameters in Modelling and Design of an Ohmic Heating System

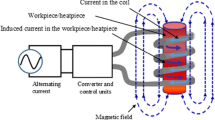

An ohmic heating system comprises a heating chamber installed with a pair of electrodes. These electrodes are powered by an alternating current (AC) source, which provides electrical energy to the system. Electrical energy is converted to thermal energy due to the resistive effect of the food product when current passes through it (Kumar 2018). However, most food products are composed of numerous elements, which can somewhat affect the heating rates and the degree of heat transferred to the product (Varghese et al., 2014). Important factors that have been found to influence heat transfer rates are physical properties of food elements, such as electrical conductivity, particle size, heat capacity, and density (Darvishi et al., 2020b; Jafarpour & Hashemi 2022). On the contrary, the parameters of the system design may include voltage gradient, electrode material, and the frequency of the applied AC source (Kumar 2018).

Electrical Conductivity (σ)

Electrical conductivity (EC) is an essential factor influencing the rate and efficiency of ohmic heating. The microstructural configuration, ionic structure, density, particle size, and texture are the main factors determining the variation in electrical conductivity of the food material (Liu et al., 2017; Goullieux & Pain, 2014; Fadavi & Salari, 2019). Hence, the material’s ionic components increase the EC, whereas the presence of nonpolar elements such as fats, sugars, and lipids reduces it. The rate of heat produced (Q) by ohmic heating is directly proportional to the EC of the product (σ) and the square of applied electric field strength (V) as described by Eq. (1) (Shim et al., 2010; Silva et al., 2020). Therefore, due to the heterogeneous composition of the food elements, there are differences in the electrical conductivity that lead to an irregular temperature distribution within a product (Jaeger et al., 2016).

EC also determines the electric field distribution within the material, affecting the heat generation rate (Banti 2020). This can impact the efficacy of the ohmic heating based food processing applications such as extraction, microbial inactivation, or heat treatment (Cevik & Icier, 2018; Kim et al., 2017).

These observations are corroborated by several other researchers, who also indicated linear or quadratic dependence of EC on temperature, according to the textural properties of the product (Fadavi & Salari 2019). Studies by Chakrabortya and Athmaselvi (2014), Ishita and Athmaselvi (2017), Fadavi and Salari (2019, and Icier (2012) observed a linear relationship between the temperature and electrical conductivity in watermelon juice, grapefruit juice, apricot puree, and strawberry products, respectively. However, a declined rise in EC regarding temperature was recorded in the presence of gas bubbles or air in the product by Darvishi et al. (2020b) and Kamonpatana and Sastry (2022). These variations can be attributed to factors such as insulation effect of air bubbles, decreased water content, reduced density, and increased ionic mobility (Darvishi et al., 2013; Fadavi & Salari, 2019; Ishita & Athmaselvi, 2017).

In the research on rice cooking, Gavahian et al. (2019) reported an increase of EC from 1.5 to 3.5 S/m with rising temperature of the rice-water mixture. This increase was gradually plateaued as the starch gelatinisation stage approached. The research also reflected a sharp decrease in electrical conductivity after the boiling was reached in the rice-water mixture which resulted in slowing down of the overall process as shown in Fig. 1.

Electrical conductivity of rice mixture as affected by processing time and temperature (Gavahian et al., 2019)

Nevertheless, the application of an electric field and a rise in electrical conductivity corresponding to the temperature rise leads to the product’s rearrangement or destruction of microstructural bonds. It also affects biological processes by altering molecular spacing and enhancing interchain reactions. Consequently, during ohmic heating, the applied voltage and higher temperatures accelerate microbial and enzyme inactivation, which prevents products like meat from microbial spoilage, as suggested by (Suleman et al., 2020).

The rise in EC also suggests a loss in cell membrane integrity of food material tissues and cells being treated with ohmic heating technology (Ahmed et al., 2010). Research experiments have been performed by Jantapirak et al. (2024) on chicken sausages, which indicate that overheating (considerably raising EC with temperature) of the food product leads to the structural breakdown and formation of large holes in the slices. Likewise, in Estrada-Solis et al. (2016), the study of microstructural changes in lamb meat indicates that with the help of advanced cooking methods like ohmic heating, meat tenderisation and protein solubilisation can modify the texture and juiciness of the product as well. Hence, all these food qualities can be regulated by thoroughly understanding the heating characteristics and optimising the variation in electrical conductivity of the product, as this physical parameter is suggested to be a good indicator of cell membrane permeability, firmness, and organoleptic qualities (Ahmed et al., 2010).

Electric Field Strength

Another characteristic that significantly impacts the physicochemical properties of the material under treatment of ohmic heating is the electric field strength. Increasing the strength of the electric field in the velocity of the OH causes an increase in fluid through the capillaries in product samples. This increases electrical conductivity (Cevik & Icier 2018). As a result, increased ionic mobility and membrane permeability is observed. This causes faster heating rates and a rapid reduction in the moisture content of the material due to an elevated evaporation rate. The study of rice cooking (Kanjanapongkul, 2017) reported a rise in heating rate and reduction in cooking time with respect to increased electric field strength. Consequently, water in the food samples also significantly decreased. These observations are supported by Torkian Boldaji et al. (2015) in research on tomato paste being treated by ohmic heating.

Torkian Boldaji et al. (2015) further explain that when the voltage gradient increased from 6 to 14 V/cm, the cooking time decreased by approximately 83.2% for rice cooking by OH. Costa et al. (2018) also illustrate this in their research on sweet whey. They describe that applying medium to high electric fields (5 to 9 V/cm) to the product reduced the processing time by 50–87%. Moreover, research on the effects of voltage gradient on infant formula also indicated that cooking time and rise time for temperature are highly dependent on the applied electric field (Pires et al., 2020). Applying medium to high electric field strength (12 to 24 V/cm) to infant formula reduced the time needed to achieve processing temperature.

The reduced cooking time due to a high rate of uniform temperature rises within the product is beneficial in preserving its natural colour under OH. It proved to be quite favourable for fruits and vegetables, as well as for meat products. Makroo et al., (2017a, 2017b) observed a notable difference between the processing times of conventionally heated (5 min) and ohmically heated (1 min at 24 V/cm) tomato paste. The work reported an improved retention of the red colour and a reduced browning effect in tomato paste when comparing conventional and ohmic heating methods. Moreover, Chakrabortya and Athmaselvi (2014) also studied colour changes in guava juice after applying electric field strength from 13.33 to 23.33 V/cm. They concluded that the OH-treated juice retains its physicochemical properties longer than conventionally heated guava juice. These properties were better preserved with ohmic heating at high-voltage gradients as degradation of polyphenol oxidase and peroxidase enzyme activity occurred, preventing browning and improving luminance (Kusnadi & Sastry, 2012).

However, Sarkis et al. (2013) recorded a continuous rise in the browning effect of ohmic heated orange juice, whereas conventionally heated orange juice was observed to maintain its colour for a longer time in the same storage conditions. This observation may be explained by metal ions and oxygen that might be added due to electrochemical reactions (hydrolysis) stimulated by high-voltage gradients. Furthermore, hydrolysis reactions lead to the release of more hydrogen ions, which affects the pH of the treated products. Studies on sour cherry juice (Sabanci & Icier, 2017), mulberry juice (Darvishi et al., 2020b), orange juice (Darvishi et al., 2019), pomegranate juice (Darvishi et al., 2013), and grape juice (Darvishi et al., 2020b) reported a decrease in pH values after ohmic heating. It has also been demonstrated by Ashitha et al. (2020) and Fadavi et al. (2018) that changes in pH are influenced by processing time and heating rates, both of which are impacted by variations in electric field strength.

On the other hand, Norouzi et al., in their research on sour cherry juice, observed higher pH at high voltage gradients during ohmic heating than conventionally heated juice (Norouzi et al., 2021). Various explanations for pH changes in OH-treated products have been presented. Some researchers attribute pH rises to electrode corrosion and juice electrolysis that could occur in ohmic heating processes. In contrast, the effects of electric field strength are sometimes not entirely evident in food products which leads to electroporation effects and cell membrane permeabilisation (Makroo et al., 2020).

Furthermore, research shows that the presence of electric field strength through ohmic heating considerably influences ascorbic acid (AA), total phenolic content (TPC), and other antioxidants in fruit juices. Doan et al. compared the quantities of AA and TPC in OH-treated and fresh pomelo juice (Doan et al., 2021). It was observed that AA concentration at 30 V/cm enzyme inactivation occurred, which resulted in the elimination of the AA degrading factor, due to which ascorbic acid values did not significantly change (Salari & Jafari 2020). In addition, AA concentration is expected to increase at higher electric fields after ohmic heating. This was because ascorbic acid created bonds with water molecules that broke down when voltage was applied in the ohmic heating process, and ascorbic acid molecules were released (Mercali et al., 2014).

Compared to fresh pomelo juice, TPC values increased by 2.8–10% in pomelo juice after ohmic heating (Doan et al., 2021). Aloe vera gel also gave similar observations where TPC increased up to 40% after its ohmic pasteurisation at 90 degrees owing to the breakdown of polyphenol-protein structures (Saberian et al., 2015). Salari (2020) explains this observation of an increase in total phenolic content such that the electric field stimulates the inactivation of polyphenyl oxidase, which weakens cell membranes and releases TPC from cells (Manzoor et al., 2019). However, TPC concentration trends are inconsistent throughout the literature and vary with each product and experimental condition. Therefore, to fully achieve the desired results in any food product, it is important to understand, characterise, and model the correct ranges of electric field strength for each type of product to optimise and conceive the desired effects on ohmically treated products.

Waveform and Frequency

The waveform and frequency of applied voltage to the food products also significantly impact the quality and efficiency of the ohmic heating process due to the existing correlation of frequency and impedance (Silva et al., 2017). In a study on shredded cabbage and radish cubes conducted by (Duguay et al., 2016), it was demonstrated that the frequency and waveform of the applied voltage significantly influence the heating process and electrical conductivity of the products. The experiments were conducted with applied voltages ranging from 65 to 135 V and frequencies of 60, 2070, 5030, 7990, and 10,000 Hz. The results indicated that the processing times varied between the two samples, with radish cubes requiring 6 min and shredded cabbage needing 128 min to cook. For radish, the heating rate increased with frequency at high voltage, while an opposite trend was observed for cabbage. Additionally, the study found that heating efficiency was higher at elevated voltages and increased salt concentration.

Another study by Mercali et al. (2014) presented the effects of voltage frequency (ranging from 10 to 10,000 Hz) on the degradation of ascorbic acid (AA) from acerola pulp. The results confirmed that colour changes and ascorbic acid degradation rates were higher at frequencies below 100 Hz. Furthermore, Doan et al. (2021) compared the ascorbic acid content of fresh and OH-treated pomelo juice at different frequencies. They observed degradation of ascorbic acid of approximately 21.5% at 50 Hz and 20 kHz, while no difference was observed in AA at other frequencies (60, 300, 500, and 1000 Hz). The occurrence of electrochemical reactions and water electrolysis can theoretically explain the observations.

Therefore, the increase in oxygen concentration due to water electrolysis leads to the oxidation of ascorbic acid that results in the overall degradation of AA content in the food product (Assiry et al., 2003). Likewise, Lee et al. (2013) explained that at frequencies ≤ 100 Hz (low frequency), the movement of electric charge was slower, allowing electrochemical reactions to occur. This caused the migration of metal ions from the electrode into the food sample, resulting in higher oxidation reactions and, hence, the degradation of AA.

Additionally, Gratz et al. (2021b) indicated that electroporation of cell membranes is higher at low frequencies, which causes higher diffusion rates of conductive elements in and out of cells. These factors combine and increase the material’s electrical conductivity, resulting in higher heating rates at low frequencies.

Singh et al. conducted experiments to investigate variations in electrical conductivity and viscosity of fruit juices under ohmic heating (Singh et al., 2008). Consistent with previous research, they also reported that electrical conductivity was higher at 1 kHz than at 10 kHz, implying that the heating rate is high at low frequencies. This is supported by another research on pomelo juice, which was tested with a frequency range of 50 to 20,000 Hz. The study shows a sharp decrease in heating rate with increasing frequency. A comparison of heating rates at 10 kHz and 20 kHz with 50 Hz frequency demonstrated that it was approximately 2.1 times and 4.3 times higher at 50 Hz, respectively (Doan et al., 2021). These observations can similarly be attributed to a higher rate of electrolytic reactions due to slow movement of electrons at low frequency causing oxidation of food product.

However, the voltage frequency does not affect the food materials’ properties like pH, acidity, and total soluble solids (TSS) density. This is also related to the high heating rate due to increased electrical conductivity at low frequencies. Darvishi et al. explained that with a higher rate of heating, minimum pH changes occur due to short heating time (Darvishi et al. 2020a). In addition, Makroo et al., (2017a, 2017b) presented research on watermelon juice where TSS was observed to be unaltered following ohmic heating treatment. Similarly, Igual et al. (2010) presented that the pH and TSS of grapefruit juice were unaffected at high temperatures (80 degrees) and holding time during ohmic heating. The total phenolic content (TPC) in pomelo juice was also observed to be uninfluenced by the variations in frequency (Doan et al., 2021).

Despite the effect of different frequencies being tested on a variety of fruits and vegetables, owing to practical reasons, the most applied frequencies in industrial ohmic heaters are 50 and 60 Hz (Gratz et al., 2021a). This means that the frequency values are moderate and quite considerable for ohmic treatment. Therefore, OH is perceived as a promising technology that contributes to better quality product and food safety with optimised processing conditions (Table 1).

Material Size, Viscosity, and Heat Capacity

Material density, particle size, and orientation of the particles in the electric field influence the electrical conductivity and, hence, the heating rate during ohmic heating. The electrical conductivity is considerably reduced as the particle size increases (Kumar 2018). Silva et al. (2020) presented that the electrical conductivity of the dulce de leche decreased due to crystallisation of lactose. This also reduced consistency and viscosity of the sample. This indicates that the heating rate reduces, whereas heating time increases with the presence of particle size and viscosity. Benabderrahmane (2000) demonstrated similar observations that exhibited reduced efficiency of heating with increasing particle size.

Subsequently, particle concentration also critically impacts the heating rate of the material. In the case of a two-phase product system, electrical conductivity uniformly decreases with increasing particle concentration (Kaur et al., 2016). Similarly, studies by Deleu et al. (2019) on pound cake batter also revealed that electrical conductivity values relatively reduce when the particle concentration is high. When a mixture of solid and liquid particles of similar electrical conductivity is heated, the temperature for the material having lower heat capacity rises rapidly, and vice versa (Varghese et al., 2014; Indiarto & Rezaharsamto, 2020). However, solid particles having lower EC than the fluid lag in temperature rise behind the fluid but may heat faster than the fluid if they are in high concentration. Nevertheless, in the case of fruit juices, where an increase in concentration implies a rise in sugar content, electrical conductivity reduces with increased juice concentrations. This is because sugar is a nonelectrolyte and does not promote electrical conduction (Jafarpour & Hashemi 2022).

Similarly, material density and viscosity influence the rate of temperature rise, such that the higher the viscosity, the higher the temperature rise. This phenomenon is attributed to reduced convective motion in the fluid, resulting in temperature rise due to high current flow. The trend was quite promising, with considerable significance concerning continuous flow ohmic heating. Contrarily, materials with high density and specific heat capacity tend to slowly rise in temperature (Ribeiro, Xavier-Santos et al. 2022). This may be because these substances have high resistivity due to a denser arrangement of molecules that would demand a greater electric field to generate the required current flow for the desired temperature rise. Therefore, it is plausible that heterogeneous mixtures may result in varied trends of heat flow rate during ohmic. Further studies need to be conducted to understand and develop ohmic heating control systems for commercial purposes.

Electrode Design

During ohmic heating, electrodes can be a source of heat losses, which may result in an excessively high temperature gradient. Subsequently, the process temperature gradient reduces with the increase in the thickness of the electrodes (Cappato et al., 2017). This reflects that the mass of the electrode is quite large while the electrical resistance is low, which results in lower temperature rise (Kaur & Singh, 2016). Various researchers have observed and reported a high-temperature difference between the surface of the electrodes and the centre of the ohmic heating chamber.

Moreover, the electrode material is a significant factor that affects the efficiency of the ohmic heating system. Zell et al. experimented with and evaluated the performance of various metal electrodes (such as aluminium, stainless steel, titanium, and platinized titanium) in ohmic heating (Zell et al., 2011). According to the findings, the titanium electrode was at a higher temperature than that of stainless steel with the same thickness. The highest temperature was observed at thinner aluminium electrode surfaces. Meanwhile, platinized aluminium electrodes gained minimum temperature.

Additionally, stainless steel and aluminium electrodes were also observed to be prone to electrolysis, which led to contamination of the food product being processed. However, platinized titanium electrodes exhibited no electrolytic reactions. Hence, it was concluded that titanium electrodes provide an inert and optimum temperature environment for the product, and they are the most suitable material to be deployed in ohmic heating systems.

Figure 2 illustrates the significant impacts of various critical parameters on the food quality, sensory attributes, and rheological properties of products processed by ohmic heating. The review highlights the high potential of ohmic heating technology for implementation in the food processing industry due to its ability to produce high-quality products with improved energy efficiency. However, it also notes that ohmic heating may affect shelf life or sensory properties due to its impact on the cellular structure of food products. Consequently, there is a clear need for further research on a wide range of fruit, vegetable, and dairy products to comprehensively understand the effects of ohmic heating on food quality.

Modelling of Ohmic Heating System

Various mathematical models of the OH process for different types of food products have been developed, and these models differ in how they solve the OH process’ mathematical equations.

Somavat et al. (2012) describe the general energy transfer equations of the OH system, shown in Eq. (2). This equation consists of the thermal conduction and internal energy generation equation that serves as the foundation of the mathematical model.

Here, T represents the instantaneous temperature, ρ denotes density, Cp is specific heat, k is thermal conductivity of the product, and S is the source term.

Marra F. (2014) showed that the general energy transfer equation involves the simultaneous solution of the Laplace equation, which describes the electrical potential within the food and the heat transfer equation using a source term that involves the displacement of the electrical potential. This Laplace equation is presented in Eq. (3).

The solution to the Laplacian equation to describe the electrical potential within food also gives the predicted temperature gradient established on curved areas of the food surface (Varghese et al., 2014). Guo et al. (2017) showed that the Laplace equation model does not consider the electric field distortion efficiently due to varying electrical conductivity within some food. In contrast to Marra (2014) where a batch OH system was modelled, Pesso and Piva (2017) used another approach by carrying out thermofluid analysis on a collinear cylindrical ohmic heater in laminar flow. This approach considered the electrical conductivity of the fluid to be varying and the fluid was assumed to be homogenous. Furthermore, it was presented that the radial temperature distribution did not change with increasing or decreasing mass flow rate.

The thermal characteristics of fluid food products with different electrical conductivities under ohmic heating using computational fluid dynamics (CFD) codes were modelled by Shim et al. (2010). This model gave a maximum prediction error of 6 °C. After obtaining the process mathematical model, factors affecting the OH performance, such as food composition, electrical conductivity, density, specific heat, electrical field intensity, and configurations of the ohmic heater and electrodes, can be determined.

Chávez-Campos et al. (2020) studied the modelling of OH processes using the thermal circuit method by evaluating thermal resistance and capacitance as steady-state and transient analogue parameters. Chávez-Campos et al. (2020) also showed that the batch ohmic heating system can be modelled based on the analogous relationship between thermal and electrical quantities, and an electrical component replaces each one of the three terms involved. They further explained that the energy input is modelled as a current source, the differential term in the function of the temperature is modelled as a capacitance, and the voltage in the circuit is related to the temperature in the ohmic heating system. Therefore, the linear term is modelled as a resistance device.

A significant advantage described by Chávez-Campos et al. (2020) is that the system transfer function of the ohmic heater system, which links a variable response to an excitation signal, can be determined using the Laplace transform for understanding the system’s response and to design a suitable controller for the system (Chávez-Campos, del Carmen Téllez-Anguiano et al. 2020). However, this modelling technique is not immune to errors due to the boundary and initial condition, the number of RC circuit lumps, and the ratio of the time in which the measurement of the model’s R-C (resistance-capacitance) product is present.

A comparison study done by Guo et al. (2017) on the reliability of the OH mathematical model for heated two-component solid food mixture showed that when the fluid and solid varied in electrical conductivity, traditional mathematical models yielded complexities with the variation in electrical conductivity affecting the electric field distribution in the sample. However, the computational model shows better results while temperature distribution and uniformity in multi-component food samples is yet to be explored.

Generally, the proposed models aim to solve the OH energy balance and thermal equations. The validated simulated model helped to improve the understanding of the effect of different critical process parameters of foods with a variety of initial conditions. The validated model could accurately predict the heating temperature under varying electric fields and food products with different thermo–physical properties (Oluwole-Ojo et al., 2021).

Energy Analysis of Ohmic Heating

Various authors have shown that ohmic heating (OH) is a very energy-efficient heating method in food. Silva et al. (2017) explains that due to the direct passage of electric current through food products, electrical energy is converted to heat within the food medium with a very high efficiency (> 90%) compared to conventional heating methods. In other standard conventional heating methods, such as convection, conduction, and radiation, slow heating times and heat loss to the surrounding area are inefficient (Gavahian & Farahnaky, 2018). Inefficiencies are caused by but are not limited to the heat transfer step from the surroundings to the medium by means of temperature gradients or hot surfaces (Silva et al., 2017).

The basis for comparing the energy efficiency of OH to other conventional heating (CH) methods was to calculate the ratio of energy input to energy output and the heating times (Darvishi et al., 2015). Kanjanapongkul (2017) assessed the efficiency of the commercial rice cooker and ohmic heating-based rice cooking, and it was reported that OH cooking significantly decreased energy consumption by 70%. These results have been also supported by several other studies based on rice cooking (Gavahian et al., 2019; Ramaswamy et al., 2014).

The heating time was observed to be reduced by more than half when OH is used compared to CH (Zell et al., 2010b). A comparative study by Aydin et al. (2020) agrees with (Zell et al., 2010b) where pate fish samples were heated using OH and CH in a water bath showed faster heating times and reduced energy consumption with OH. According to Aydin et al. (2020), the energy efficiency of heating pate fish samples when using OH was 89.89% compared to the CH efficiency of 9.25%.

A similar study by Sofi’i and Arifin (2022) comparing the energy consumption of OH to CH for patchouli oil extraction showed that using OH requires less energy than using an electric stove. The highest electrical energy required in the extraction process using an electric stove is 4386.69 kJ, while the lowest is used for ohmic heating with a voltage of 110 V of 3313.77 kJ. Sofi’i and Arifin (2022) attribute this to the property of OH where heat is generated volumetrically within and is not wasted to the environment in the form of convection and radiation. The authors, however, noted that during the extraction of patchouli oil, in the early minutes, a pattern of increased energy consumption was noted using OH, and towards the end, a reduced energy pattern was observed. This trend was observed while using the ohmic heater, which can be attributed to the electrical conductivity of the food medium. As the temperature rises, the electrical conductivity and the heating rate rise which then requires reduced energy consumption (Lascorz et al., 2016).

In contrast to the trend of OH being energy efficient, Tumpanuvatr and Jittanit (2022) observed that the OH technique did not have a higher energy efficiency by default when cooking brown rice using OH and CH techniques with a conventional rice cooker. The reverse trend in the study of Tumpanuvatr and Jittanit (2022) can be attributed to energy losses in the transformer, heat loss to the agitator, ohmic cell, and surrounding air. This seems to imply that the design and components of the ohmic heater will also determine how energy-efficient the process can be. These results are presented in Table 2, as below.

Industrial Applications

Ohmic heating has excellent potential for application in the food industry. The technology can be an alternative to conventional processing methods for applications such as cooking, extraction, blanching, fermentation, peeling, gelatinization, pasteurisation, microbial inactivation, and thawing. Various studies have been conducted to explore the range of applications for ohmic heating, and they show promising results in terms of cooking time and preservation of the colour and organoleptic qualities. However, most research is conducted under laboratory conditions; hence, its applicability in the industry has yet to be confirmed via implementation.

Cooking

Ohmic cooking is a prospective industrial application that has shown some positive observations on solid food products. Paper (Farahnaky et al., 2012) subjected red beet and carrot to conventional heating, microwave, and ohmic heating methods to analyse their textural properties after cooking. They recorded that samples cooked by ohmic heating had a softer final texture compared to other methods. Softening rates were also observed to be higher with ohmic heating. Similarly, Kanjanapongkul (2017) illustrated an increased cooking rate by ohmic heating for rice grains. It was explained that the grains expanded faster when the diffusion rate accelerated with higher temperatures. Furthermore, the energy consumption of rice cooked by ohmic heating was noted to be ¼ times lesser compared to electric rice cookers.

Several researchers have frequently tested the cooking of meat by ohmic heating. Zell et al. (2010a) analysed turkey meat properties after cooking through ohmic heating and compared them with conventional cooking methods. Ohmic cooked meat displayed a significantly uniform and lighter colour tone in contrast to conventionally cooked meat samples. Cooking time was also reduced by 8- to tenfold with ohmic heating. Bozkurt and Icier (2010) also experimented with ground beef with ohmic heating and agreed with the previous studies regarding shortened cooking time and improved textural properties. Furthermore, Sengun et al. (2014) precooked meatballs with ohmic heating and the observations were quite agreeable with previous research regarding meat sensory properties. It was also noted that microbial activity was diminished, resulting in enhanced meat quality.

These studies demonstrate that ohmic heating has considerable potential for cooking applications for various food products, especially meat. However, further research must be carried out to understand the effect of ohmic heating on nutritional properties in industrial setups.

Fermentation

Fermentation is a complex biological process that cannot be effective if the required physical conditions (pH, temperature, etc.), enzymes, microorganisms, and adequate water supplies are not optimised for the necessary time. Therefore, to achieve this objective, research has been carried out on ohmic heating to regulate these necessary conditions for fermentation. The common purpose for employing ohmic technology in fermentation applications is to control the optimum temperature conditions and duration throughout all stages of fermentation to attain the greatest product yield and quality. Moreover, the electroporation effect induced by ohmic heating is believed to aid microorganism growth at appropriate temperatures, accelerating the fermentation process (Knirsch et al., 2010; Gally et al., 2017).

Studies have been conducted to assess the impact of conventional and ohmic-heated environments on fermentation. For instance, Gavahian and Tiwari (2020) analysed the growth and lag-phase of Lactobacillus, Streptococcus, and Saccharomyces in cultures of bakery, dairy, and alcoholic products. The evaluation of both methods concluded that the lag period as well as fermentation time was dramatically reduced due to stress response of the microorganisms. The result may be attributed to better nutrient transfer into the cell due to the electroporation effect of ohmic heating. Similar results were also obtained by Gally et al. (2017), Gavahian et al. (2016), Masure et al. (2019), and Qu et al. (2020) where bacteriocin activity was reduced at the initial stages of fermentation. However, the application of ohmic heating in later stages of fermentation reduced productivity, and hence, it is suggested that it be avoided.

Furthermore, studies have shown that ohmic heating can improve the fermentation process of bread. Gally et al. (2017) noted that the ohmic heating environment has a higher heating rate, which is a key factor in reducing the time for bread dough proofing by 50% compared to traditional methods. It also enables yeasts to rapidly achieve their optimal activity temperature, decreasing the time required to reach the desired expansion ratio of bread. An OH-based fermenter was also used to prove gluten-free bread (Masure et al., 2019). They found it to be quite suitable for the formation of crumb structures and fermentation temperature control.

Likewise, fermentation is an essential stage in the coffee industry for various coffee processing methods. It has a significant effect on the rate of mucus layer decomposition of the coffee fruit (Reta et al., 2020). Although warm environmental conditions speed up sugar breakdown in this application, an unregulated fermentation process leads to a browning response, resulting in reduced flavour quality (Sagita et al., 2021). Therefore, ohmic heating is used to maintain the appropriate temperature. Research by Reta et al. reported that fermentation using an ohmic heating approach produced coffee with a substantially lower total acidity value of 0.18% compared to the traditional fermentation process (acidity 0.53%) (Reta et al., 2017). To study its sensory characteristics, more research was conducted on ohmically fermented Robusta coffee (Reta, M., Muhidong). It was concluded that this coffee was characterised as specialty coffee, with the cupping score ranging from 81.81 to 85.25 and an average score of 84.03.

Similarly, cocoa beans are fermented to break down the mucilage of the beans. Currently, many industries use conventional techniques, such as bamboo or Styrofoam containers, for cocoa fermentation. These conventional processes are quite time-consuming, since fermenting one batch of cocoa beans takes about 5 to 7 days. Therefore, cocoa commodities need faster fermentation methods where fermentation conditions can be optimally monitored with an accelerated reaction while maintaining the taste quality by retaining most beneficial components in the beans. Supratomo et al. (2019) developed an OH-based fermenter to compare time and yield percentage using ohmic and conventional fermentation methods on cocoa beans. The results concluded that both methods’ yields were almost equal, id est, 95% from OH fermentation and 96% from conventional fermentation. However, with the deployment of an OH-based fermenter, the fermentation period was reduced to 3 days from 5 to 7 days with conventional fermentation. This reduction in time was achieved because, with ohmic heating, the initial desired temperature for yeast development can be efficiently controlled, which helps minimise microbial lag in the initial stages of fermentation. However, further investigation is required to determine the impact of ohmic-assisted heating on the complete fermentation procedure and the various microorganisms involved in this process.

Although limited studies have been conducted on ohmic heating with regard to industrial fermentation processes, on the acquired results, it can be interpreted that the effects of OH-based fermentation can be quite promising and the technology has exceptional potential to improve the speed of chemical reactions and product yields.

Blanching

Fresh fruits and vegetables begin to decay after harvesting if not treated appropriately. Therefore, it is very important to process or transform them into products that may maintain their taste, shelf life, and nutritional quality. Blanching is a technique to prepare vegetables or fruits for freezing, dehydration, and canning. Traditionally, the blanching method involves hot water or steam, which is neither rapid nor energy efficient. Therefore, ohmic heating can be used alternatively. Previous research shows that ohmic heating is advantageous for the quality of the food product, as the electric field aids in achieving the desired temperature rapidly, which shortens the blanching time.

Research claims that, unlike conventional blanching, ohmic blanching does not require the dicing of the vegetables, while still reducing the time of the process. Therefore, non-diced vegetables lower the surface-to-volume ratio, which helps reduce the level of solute leaching. However, applying an electric field enhances the degree of moisture loss from the product mixture. Therefore, this effect may be beneficial for osmotic dehydration to obtain dry mass products.

Allali et al. (2010) studied the impact of ohmic heating on the kinetics of osmotic dehydration in strawberries. Observations revealed that blanching by ohmic heating was more effective since the dry mass of the strawberry increased from 20.3% (without OH) to 68% (with OH). A significant decline in blanching time from 4 h to 3 min was also seen with and without ohmic heating, respectively. These results are supported by another research in Mannozzi et al. (2019) on ohmic blanching of pea puree. The study compared the conventional and ohmic blanching time for inactivation of peroxidase with a range of voltage gradients (20 to 50 V/cm). The shortest enzyme inactivation time of 54 s was detected with 50 V/cm for ohmic blanching. In addition, a considerably uniform heat distribution and minimum changes in puree texture and colour were observed compared to the conventional blanching method. These results can be easily explained by increased electrical conductivity leading to high dehydration rates, electroporation effects, and hence faster enzyme inactivation.

Furthermore, a short blanching time with ohmic heating helps to maintain the solid structure of the particles throughout blanching, as opposed to the traditional blanching method (Kamble et al., 2023). In a blanching study in Lyng et al. (2018) on chicken chow mein, the sauce was recorded to be more conductive as compared to the solid particles in the mixture. Although blanching the solid particulates made the ohmic heating process more uniform, no compromise was observed in the product’s organoleptic qualities.

Therefore, results of previous studies support the use of OH-based blanching as it is quite favourable in terms of required blanching time as well as the colour, textural, and nutritional qualities of the products. However, studies are still limited, and more work is needed to validate the technology in various product types so that ohmic heating can be promoted and implemented in the industrial setting.

Pasteurisation

Pasteurisation is a heating treatment used to inactivate endogenous enzymes and microorganisms in a food material. This procedure prevents the formation of pathogens and allows the product to be hermetically sealed and stored at room temperature for a long time. The conventional pasteurisation process is done through heat exchangers, where the heat is conducted by hot water or steam. The efficiency of this procedure depends mainly on the design of the pasteuriser. However, pasteurisation by ohmic heating ensures thermal efficiency and uniform heating and prevents overprocessing of the product. Hence, pasteurisation is becoming prominent at an industrial scale (Demirdöven & Baysal, 2015).

Pasteurisation by ohmic heating is being commercially used for different types of food products, e.g. dairy products and fruit juice, et cetera. The fat content plays an integral role in defining the electrical conductivity of dairy products. (Kim & Kang, 2015) investigated the impact of fat on electrical conductivity and, hence, the heating rate of milk. The results were also compared with conventional methods. It was discovered that a decrease in fat content significantly increased the electrical conductivity and heating rates of milk, whereas similar behaviour was not observed with traditional pasteurisation. Another critical observation was that increasing the fat content resulted in non-uniform heat distribution due to high concentrations of lipids that behave as electrical insulators. This results in the formation of cold spots around fat globules, where heating rates are very low. Reduced heating rate leads to increased microbiological instability owing to decreased microbial inactivation rates. Nevertheless, ohmic pasteurisation is commonly used to pasteurise lactose-free milk as it has high electrical conductivity (Suebsiri et al., 2019a, 2019b).

However, fouling is a major concern in the thermal processing of dairy products. It creates the problem of reduced heat transfer rates, promotes microbiological instability, and increases the need for frequent cleaning of the processing plants. Negligence towards equipment cleaning can cause operational problems such as non-uniform electric field distribution across the electrodes and product and microbial adherence, causing biofilm formation on the equipment surface (Stojceska et al., 2019). Nevertheless, the extent of fouling by ohmic heating is lesser than that of conventional pasteurisation methods (Stancl & Zitny, 2010).

Ohmic heating has the capability to enhance the production of fruit-based liquid consumables, e.g. citrus fruit juices. Orange juice treatment involves the denaturation of heat-resistant enzyme pectin esterase (PE), which is associated with the degradation of post-extraction sensory properties (Timmermans et al., 2011; Jolie et al., 2010; Aghajanzadeh & Ziaiifar, 2018). Therefore, orange juice is pasteurised to reduce PE activity and preserve the taste for longer. Research by Funcia et al. (2020) compared the effects of pasteurisation by ohmic heating and conventional heating on orange juice. The outcomes suggested that OH-assisted pasteurisation reduced pasteurisation time with higher retention of flavour compounds in comparison to conventional pasteurisation. Furthermore, the shelf life of OH-treated orange juice was almost two times higher (> 100 days) than that of traditionally pasteurised juice. Research in Baysal and Icier (2010) and Khue et al. (2020) on orange and pomelo juice, respectively, is also consistent with previous studies in terms of shelf-life extension, taste, and nutritional preservation.

Similarly, studies on apple juice, tomato juice, and fermented red pepper also show that pasteurisation by ohmic heating is an effective technology to optimise temperature controls to maintain the nutritional, organoleptic, and microbiological qualities of food products (Kim et al., 2019; Cho et al., 2016; Suebsiri et al., 2019b). Ohmic pasteurisation of coconut water also gave promising results with complete inactivation of peroxidase and no discolouration to pink during storage, whereas conventionally pasteurised coconut changed colour to pink even in cold storage (Kanjanapongkul & Baibua, 2021).

Therefore, ohmic heating can be considered a favourable technology for pasteurisation on an industrial scale as research suggests that microbiological stability and nutritional quality are maintained, whereas time consumption is reduced. However, an important factor to consider still is the formation of cold spots and how these zones can be treated for uniform heat distribution in the material. Moreover, fouling during the pasteurisation of dairy products is a problem that needs to be studied to reduce its effects on the final product.

Extraction

The application of an electric field in the ohmic heating process causes the electropermeability of cell membranes. The membrane permeability may rise further with the product medium’s increasing temperature, leading to higher diffusion rates from the cellular structure (Indiarto & Rezaharsamto, 2020). Various studies have proven that extraction by ohmic heating can produce better yields than conventional methods. Conventionally, extraction has been performed with the help of large volumes of organic solvents, resulting in long extraction times. Therefore, ohmic heating has been studied and tested on several food materials to explore its applicability in industries.

Ohmic heating has proven to boost extraction percentages of sucrose from sweet sugar beets, beet roots, soybeans, and apple juice (Varzakas et al., 2016; Butu & Rodino, 2019; Dhiman et al., 2021). Similarly, phytochemical extraction of anthocyanins and phenolic compounds from coloured potatoes has been shown to yield greater extraction results with shorter treatment periods, less energy usage, and without any organic solvents when employing ohmic heating techniques (Pereira et al., 2016). Likewise, ohmic heating was applied to tepurang fruit for oil extraction. This study also revealed higher β-carotene and lycopene yields, better efficiency, and improved colour quality (Aamir & Jittanit, 2017). Moreover, Termrittikul et al. (2018) applied ohmic heating to Jerusalem artichoke bulbs for inulin extraction and determined that the product yield was significantly higher than the conventional extraction method. This happens because diffusion and extraction rates increase when a strong electric field is applied to the samples as a result of a rise in membrane permeability.

Several research projects have been carried out on rice bran for oil extraction and stabilisation. SC et al. (2020) compared oil yields extracted by ohmic heating, microwave heating, and control process. It was observed that bran samples treated by ohmic heating produced up to 82% of total lipids. Furthermore, the results also show that a decrease in frequency boosted extraction yields, possibly due to the electroporation effects on the cell wall. However, the extracted oil was darker in colour compared to the conventionally treated product. Another study on solvent extraction of anthocyanins from black rice bran yielded higher colourant powder yields by ohmic heating than byteam heating conventional extraction method (Loypimai et al., 2015). These findings suggest that ohmic heating is an effective and suitable method for treating products like rice and its bran. It can be efficiently deployed in industrial processes to improve stabilisation and phytochemical and oil extractions.

In addition, the extraction of phenolic compounds from citrus fruits has also been tested, which shows that ohmic heating is a fast, uniform, and efficient technique for treating food products for extraction. The application of ohmic heating allows higher membrane permeability, resulting in higher yields in conjunction with low energy consumption (El Darra et al., 2013). Research by Saberian et al. (2017) and Kutlu et al. (2021) on the extraction of pectin from orange juice waste and phenolic compounds from cornelian cherry, respectively, supported previous research. Treatment for extraction at the same time and temperature by ohmic heating yielded products higher than conventional methods. They also determined the microscopic structure of orange juice waste and observed that the degree of cell wall rupture is greater by ohmic heating, which leads to enhanced extraction efficiency. Pectin quality was also recorded to be significantly better in terms of viscosity than that extracted by traditional methods. Reduction in treatment time helps preserve the anthocyanin quality of the extracted products (Kutlu et al., 2021).

Therefore, it is evident from earlier studies that the application results of ohmic heating are very promising regarding energy consumption, time reduction, product yields, and quality. However, a more significant challenge for the adoption of this technology on an industrial scale is the optimisation and control of critical parameters for each type of food material.

Enzyme Inactivation

Enzymes play an important role in food products to enhance food flavours, recover by-products, and achieve greater extraction rates. On the contrary, they can also have a detrimental impact on food quality by producing off-odours, deteriorating taste, and modifying textural qualities (Saberian et al., 2017). As a result, many stages of food processing require enzyme activity regulation to improve bioactivity during processing.

Several studies have been conducted to study enzyme degradation kinetics and the impacts of electric fields on enzyme inactivation. Studies reveal that ohmic heating has higher inactivation rates for numerous enzymes in fruits and vegetables. Ohmic heating outperforms conventional methods in terms of retaining natural colour, pH, organoleptic qualities, nutritional value, and bioactive chemicals because of its fast and uniform heat transfer capability. However, the issue of electrochemical reactions must be further researched and overcome before industrial-scale implementation (Brochier et al., 2016). Abedelmaksoud et al. (2018) studied some essential food processing enzymes, such as polyphenol oxidase (PPO) and pectinmethylesterase (PME) of mango juice.

Thawing

Another application of ohmic heating is thawing or defrosting of frozen food items. Thawing is an important step in ensuring the microbiological integrity of a product. It must be completed quickly at low treatment temperatures to maintain the physicochemical properties of the product. During traditional thawing, more extended periods may result in microbial development on the product surface. It may also lead to a degradation of nutritional quality due to soluble protein leaching, increased use of freshwater, and a significant amount of contaminated wastewater. Therefore, it is necessary to introduce more quick and efficient thawing techniques in the industry.

Ohmic heating holds a high potential of increasing process efficiency for thawing due to the volumetric heating effect. Previous research has observed process time shortening with the application of ohmic heating. Icier et al. (2017) observed the shortening of thawing time by 99.1% for potato cubes with a softer texture and less colour discrepancy in samples. Similarly, a study on frozen beef cuts (Bozkurt & Icier, 2012) reflected that an increase in voltage gradient during ohmic heating considerably increased the thawing rate and, consequently, decreased the thawing time. Moreover, lesser colour changes and improved energy utilisation ratio (EUR) was observed with ohmic thawing as compared to conventional methods of thawing.

Furthermore, ohmic thawing has been tested in sour cherry juice. The results of this study also show the potential applicability of this technology. Cokgezme and Icier (2019) studied that heating time was reduced by almost 89% for the thawing of cherry concentrate. However, because of density differences, the frozen blocks were raised to the surface by melting the juice. This resulted in nonuniformity of temperature rise, which may cause organoleptic changes because of overheating in some regions. Similar behaviour was examined in the ohmic thawing of shrimps (Lascorz et al., 2016). The product was non-homogeneously cooked, as the entire shrimp did not melt simultaneously. Consequently, electrical conductivity rises in melted portions of the product; hence, increased temperature leads to overcooking of the melted part while the rest of the shrimp is still frozen. This is a prospective disadvantage of the technology that needs further exploration and study to optimise the process. In addition, further research is required to identify the extent to which changes in food quality have occurred.

Wastewater Treatment

Surimi production is a common industrial activity that requires wastewater treatment because of high volume and biological oxygen demand (BOD). BOD can be minimised by heating the wastewater produced during the process, which is very high in protein concentration. Heating this wastewater solution results in the coagulation of protein structures. Ohmic heating has been applied for this purpose, and it has been observed to be very efficient for this application. Kanjanapongkul et al. (2009) designed a continuous ohmic heater for heating wastewater that would lower its BOD. This pilot-scale experiment performed quite well, with a protein coagulation of approximately 60% from surimi wastewater. Heating the solution with the application of higher electric fields and decreased mass flow rate resulted in a higher temperature gradient. Therefore, the use of ohmic heating in wastewater treatment is expected to have benefits in terms of faster processing. Other advantages of the ohmic heating system include reduced chemical requirements and greater plant controllability to achieve precise temperatures for protein coagulation required for wastewater (Assiry et al., 2010; Assiry, 2011). However, further studies are still needed for this ohmic-heating-based application on an industrial scale, as relatively few studies have been conducted in this area.

Limitations and Future Work

Ohmic heating technology is one of the most advanced and promising methods for processing food and drinks. It has significant potential for widespread industry applications. The current research has demonstrated that this technology can produce high-quality food products. However, the detailed effects and underlying mechanisms of OH on food products remain insufficiently explored and poorly understood. To facilitate large-scale application and potentially revolutionise the food and drink industry, systematic studies are necessary to evaluate both process and product parameters for precise system design. Therefore, developing OH simulation models for process control and optimisation is essential for deploying this technology at an industrial level.

The selection of electrode material and design presents significant challenges regarding the durability of the device. Electrodes must be meticulously designed to account for specific OH conditions, as electrochemical reactions between the electrode and food material can lead to electrode corrosion. These reactions depend on various factors, including electrode material, applied electric field strength, frequency, and food composition. The inherent complexity and variability of food composition further complicate this issue, as different compositions influence conductivity and heating rates, resulting in varied heating efficiencies.

Furthermore, the technology and process parameters of ohmic heating (OH) can vary significantly between the processing of liquid and solid food products. Solid foods introduce additional complexity due to the presence of various conductive and non-conductive compounds, which can result in the formation of hot and cold spots. To understand system dynamics and heat distribution within the product under different immersion conditions, numerical, physical, and computational fluid dynamic (CFD) model simulations can be highly beneficial. These simulations and models provide insights into the thermal behaviour of foods during OH processing, enabling the optimisation of process parameters to ensure uniform heating and product safety.

Further research is required to compare the effects of Pulsed Electric Field (PEF)- and Moderate Electric Field (MEF)-based ohmic heating. It is likely that the nature of the electric field may yield better results for different types of food products, with one method being more advantageous for certain products while another method showing positive results for others. Therefore, research should focus on the electrical effects on heating uniformity, system efficiency, and the impact on the sensory and nutritional properties of food. Additionally, the impact of these methods on shelf life has not been thoroughly investigated in previous studies. Hence, researchers should also focus to examine the effects of different ohmic heating technologies on market-ready industrial products to achieve valid and reliable comparisons with conventional heating methods.

Conclusions

Conventional thermal technologies, such as conduction or convection, used in industrial food processing applications involve burning fossil fuels that are sources of high greenhouse gas emissions, making them detrimental to the environment. These methods are neither energy-efficient nor time-efficient, based on surface-to-centre heat transfers. Therefore, there is a dire need to introduce efficient and environmentally friendly methods in the food and drink industry. Ohmic heating is an alternative method that shows that this technology has great potential to revolutionise the food industry. It has promising results in various food products, such as fruits, vegetables, meat, juices, purees, and sauces. These products have been tested with several industrial applications, for example, cooking, pasteurisation, fermentation, blanching, and enzyme inactivation, and have shown that ohmic heating systems can achieve better energy efficiency, reduced processing time, and higher product yields while retaining nutritional and sensory properties of food materials. However, process parameters such as electrical conductivity, voltage gradient, waveform frequency, and electrode material greatly influence the biological structure, sensory properties, and nutritional qualities of different food products. Therefore, this review summarises the effects of these parameters on product qualities and current progress in the applications of ohmic heating. It has been concluded that optimising each of the parameters according to product type is highly important to retain the natural quality of food products.

Furthermore, despite the positive findings regarding ohmic heating applicability, the presence of nonconductive elements, such as fats and lipids, leads to the formation of cold spots that make it challenging for uniform heat transfers. Therefore, research on improvement in uniform heating and computation of temperature differences between conductive and nonconductive regions can be possible research areas in future. Additionally, most studies for ohmic heating applications have been conducted in laboratory setups. Therefore, further studies should be carried out to implement ohmic heating systems on an industrial scale to analyse its impacts on the sustainability of the industry itself. Nevertheless, relatively high investments required to replace the standard heating equipment with ohmic heating technology may be the most significant barrier to the industrialisation of this approach.

Data Availability

No datasets were generated or analysed during the current study.

References

Aamir, M., & Jittanit, W. (2017). Ohmic heating treatment for Gac aril oil extraction: Effects on extraction efficiency, physical properties and some bioactive compounds. Innovative Food Science & Emerging Technologies, 41, 224–234.

Abbas Syed, Q., 2017. Pulsed electric field technology in food preservation: A review. Journal of Nutritional Health & Food Engineering, 6(6) https://doi.org/10.15406/jnhfe.2017.06.00219.

Abea, A., Gou, P., Guàrdia, M. D., Picouet, P., Kravets, M., Bañón, S., & Muñoz, I. (2023). Dielectric heating: A review of liquid foods processing applications. Food Reviews International, 39(8), 5684–5702.

Abedelmaksoud, T., Mohsen, S. M., Duedahl-Olesen, L., Elnikeety, M. M., & Feyissa, A. H. (2018). Effect of ohmic heating parameters on inactivation of enzymes and quality of not-from-concentrate mango juice. Asian Journal of Scientific Research, 11(3), 383–392.

Aghajanzadeh, S., & Ziaiifar, A. M. (2018). A review of pectin methylesterase inactivation in citrus juice during pasteurization. Trends in Food Science & Technology, 71, 1–12.

Ahmed, D. M., Yousef, A. R., & Hassan, H. (2010). Relationship between electrical conductivity, softening and color of Fuerte avocado fruits during ripening. Agriculture and Biology Journal of North America, 1(5), 878–885.

Alamprese, C., Cigarini, M., & Brutti, A. (2019). Effects of ohmic heating on technological properties of whole egg. Innovative Food Science & Emerging Technologies, 58, 102244.

Alkanan, Z. T., Altemimi, A. B., Al-Hilphy, A. R., Watson, D. G., & Pratap-Singh, A. (2021). Ohmic heating in the food industry: Developments in concepts and applications during 2013–2020. Applied Sciences, 11(6), 2507.

Allali, H., Marchal, L., & Vorobiev, E. (2010). Blanching of strawberries by ohmic heating: Effects on the kinetics of mass transfer during osmotic dehydration. Food and Bioprocess Technology, 3(3), 406–414.

Ashitha, G.N., Prince, M.V. and Sudheer, K.P., 2020. Mild thermal processing of cashew apple juice using ohmic heating. Journal of Tropical Agriculture, 58(1) https://jtropag.kau.in/index.php/ojs2/article/view/934

Assiry, A., Sastry, S. K., & Samaranayake, C. (2003). Degradation kinetics of ascorbic acid during ohmic heating with stainless steel electrodes. Journal of Applied Electrochemistry, 33(2), 187–196.

Assiry, A. M., Gaily, M. H., Alsamee, M., & Sarifudin, A. (2010). Electrical conductivity of seawater during ohmic heating. Desalination, 260(1–3), 9–17.

Assiry, A. M. (2011). Application of ohmic heating technique to approach near-ZLD during the evaporation process of seawater. Desalination, 280(1–3), 217–223.

Astráin-Redín, L., Ospina, S., Cebrián, G., & Álvarez-Lanzarote, I. (2024). Ohmic heating technology for food applications, from ohmic systems to moderate electric fields and pulsed electric fields. Food Engineering Reviews, 16(2), 225–251.

Atuonwu, J., & Tassou, S. (2021). Decarbonisation of food manufacturing by the electrification of heat: A review of developments, technology options and future directions. Trends in Food Science & Technology, 107, 168–182.

Atuonwu, J., Tassou, S., & Foster, T. (2019). Development of food structure via sustainable processing systems. Handbook of Food Structure Development, 18, 405.

Aurina, K. and Sari, A., 2022. Ohmic heating: A review and application in food industry. Atlantis Press.

Aydin, C., Kurt, Ü., & Kaya, Y. (2020). Comparison of the effects of ohmic and conventional heating methods on some quality parameters of the hot-smoked fish Pâté. Journal of Aquatic Food Product Technology, 29(4), 407–416.

Banti, M. (2020). Review on electrical conductivity in food, the case in fruits and vegetables. World Journal of Food Science and Technology, 4, 80–89.

Baysal, A. H., & Icier, F. (2010). Inactivation kinetics of Alicyclobacillus acidoterrestris spores in orange juice by ohmic heating: Effects of voltage gradient and temperature on inactivation. Journal of Food Protection, 73(2), 299–304.

Benabderrahmane, Y., & Pain, J. (2000). Thermal behaviour of a solid/liquid mixture in an ohmic heating sterilizer-slip phase model. Chemical Engineering Science, 55(8), 1371–1384.

Bozkurt, H., & Icier, F. (2010). Ohmic cooking of ground beef: Effects on quality. Journal of Food Engineering, 96(4), 481–490.

Bozkurt, H., & Icier, F. (2012). Ohmic thawing of frozen beef cuts. Journal of Food Process Engineering, 35(1), 16–36.

Brochier, B., Mercali, G. D., & Marczak, L. D. F. (2016). Influence of moderate electric field on inactivation kinetics of peroxidase and polyphenol oxidase and on phenolic compounds of sugarcane juice treated by ohmic heating. LWT, 74, 396–403.

Butu, M., & Rodino, S. (2019). Fruit and vegetable-based beverages—Nutritional properties and health benefits. In Natural beverages (pp. 303–338). Academic Press.

Cappato, L. P., Ferreira, M. V. S., Guimaraes, J. T., Portela, J. B., Costa, A. L. R., Freitas, M. Q., Cunha, R. L., Oliveira, C. A. F., Mercali, G. D., Marzack, L. D. F., & Cruz, A. G. (2017). Ohmic heating in dairy processing: Relevant aspects for safety and quality. Trends in Food Science & Technology, 62, 104–112.

Cevik, M., & Icier, F. (2018). Effects of voltage gradient and fat content on changes of electrical conductivity of frozen minced beef meat during ohmic thawing. Journal of Food Process Engineering, 41(4), e12675.

Chakrabortya, I., & Athmaselvi, K. A. (2014). Changes in physicochemical properties of guava juice during ohmic heating. Journal of Ready to Eat Food, 1(4), 152–157.

GM Chávez-Campos, Adriana del Carmen Téllez-Anguiano, Juan Alfonso Salazar-Torres, Héctor Javier Vergara-Hernández, Octavio Vazquez-Gómez., 2020. An ohmic heating model based on the thermal circuit method: Case of study for parameter determination. Journal of Thermal Science and Engineering Applications, 12(2) https://doi.org/10.1115/1.4043897.

Cho, W., Yi, J. Y., & Chung, M. (2016). Pasteurization of fermented red pepper paste by ohmic heating. Innovative Food Science & Emerging Technologies, 34, 180–186.

Cho, W., Kim, E., Hwang, H., Cha, Y., Cheon, H. S., Choi, J., & Chung, M. (2017). Continuous ohmic heating system for the pasteurization of fermented red pepper paste. Innovative Food Science & Emerging Technologies, 42, 190–196.

Choi, W., Kim, S., Park, S., Ahn, J., & Kang, D. (2020). Numerical analysis of rectangular type batch ohmic heater to identify the cold point. Food Science & Nutrition, 8(1), 648–658.

Coimbra, L. O., Vidal, V. A., Silva, R., Rocha, R. S., Guimarães, J. T., Balthazar, C. F., Pimentel, T. C., Silva, M. C., Granato, D., & Freitas, M. Q. (2020). Are ohmic heating-treated whey dairy beverages an innovation? Insights of the Q Methodology. LWT, 134, 110052.

Cokgezme, O. F., & Icier, F. (2019). Effect of voltage gradient on ohmic thawing characteristics of sour cherry juice concentrates for the temperature range of− 18℃ to 4℃. Food Science and Technology International, 25(8), 659–670.

Costa, N. R., Cappato, L. P., Ferreira, M. V. S., Pires, R. P., Moraes, J., Esmerino, E. A., Silva, R., Neto, R. P., Tavares, M. I. B., & Freitas, M. Q. (2018). Ohmic heating: A potential technology for sweet whey processing. Food Research International, 106, 771–779.

Darvishi, H., Khostaghaza, M. H., & Najafi, G. (2013). Ohmic heating of pomegranate juice: Electrical conductivity and pH change. Journal of the Saudi Society of Agricultural Sciences, 12(2), 101–108.

Darvishi, H., Hosainpour, A., Nargesi, F., & Fadavi, A. (2015). Exergy and energy analyses of liquid food in an Ohmic heating process: A case study of tomato production. Innovative Food Science & Emerging Technologies, 31, 73–82.

Darvishi, H., Mohammadi, P., Fadavi, A., Saba, M. K., & Behroozi-Khazaei, N. (2019). Quality preservation of orange concentrate by using hybrid ohmic–Vacuum heating. Food Chemistry, 289, 292–298.

Darvishi, H., Koushesh Saba, M., Behroozi-Khazaei, N., & Nourbakhsh, H. (2020a). Improving quality and quantity attributes of grape juice concentrate (molasses) using ohmic heating. Journal of Food Science and Technology, 57(4), 1362–1370.

Darvishi, H., Salami, P., Fadavi, A., & Saba, M. K. (2020b). Processing kinetics, quality and thermodynamic evaluation of mulberry juice concentration process using ohmic heating. Food and Bioproducts Processing, 123, 102–110.

de Oliveira, C. F., Giordani, D., Gurak, P. D., Cladera-Olivera, F., & Marczak, L. D. F. (2015). Extraction of pectin from passion fruit peel using moderate electric field and conventional heating extraction methods. Innovative Food Science & Emerging Technologies, 29, 201–208.

Deleu, L. J., Luyts, A., Wilderjans, E., van Haesendonck, I., Brijs, K., & Delcour, J. A. (2019). Ohmic versus conventional heating for studying molecular changes during pound cake baking. Journal of Cereal Science, 89, 102708.

Demirdöven, A., & Baysal, T. (2015). Effects of electrical pre-treatment and alternative heat treatment applications on orange juice production and storage. Food and Bioproducts Processing, 94, 443–452.

Dhiman, A., Suhag, R., Chauhan, D. S., Thakur, D., Chhikara, S., & Prabhakar, P. K. (2021). Status of beetroot processing and processed products: Thermal and emerging technologies intervention. Trends in Food Science & Technology, 114, 443–458.

Doan, N. K., Lai, Q. D., Le, T. K. P., & Le, N. T. (2021). Influences of AC frequency and electric field strength on changes in bioactive compounds in ohmic heating of pomelo juice. Innovative Food Science & Emerging Technologies, 72, 102754.

Dornoush, J., & Bagher, H. S. M. (2022). Ohmic heating application in food processing: Recent achievements and perspectives. Foods and Raw Materials, 10(2), 216–223.

Duguay, A., Ramaswamy, H. S., Zareifard, R., Zhu, S., Grabowski, S., & Marcotte, M. (2016). Ohmic heating behaviour of cabbage and daikon radish. Food and Bioprocess Technology, 9, 430–440.

Ekezie, F. C., Sun, D., Han, Z., & Cheng, J. (2017). Microwave-assisted food processing technologies for enhancing product quality and process efficiency: A review of recent developments. Trends in Food Science & Technology, 67, 58–69.

el Darra, N., Grimi, N., Vorobiev, E., Louka, N., & Maroun, R. (2013). Extraction of polyphenols from red grape pomace assisted by pulsed ohmic heating. Food and Bioprocess Technology, 6(5), 1281–1289.