Abstract

Ohmic heating or Joule heating has immense potential for achieving rapid and uniform heating in foods, providing microbiologically safe and high quality foods. This review discusses the technology behind ohmic heating, the current applications and thermal modeling of the process. The success of ohmic heating depends on the rate of heat generation in the system, the electrical conductivity of the food, electrical field strength, residence time and the method by which the food flows through the system. Ohmic heating is appropriate for processing of particulate and protein rich foods. A vast amount of work is still necessary to understand food properties in order to refine system design and maximize performance of this technology in the field of packaged foods and space food product development. Various economic studies will also play an important role in understanding the overall cost and viability of commercial application of this technology in food processing. Some of the demerits of the technology are also discussed.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

A century ago, mostly unprocessed agriculture products were available to consumer for food preparation at home. However, most of the food products purchased by consumer today are processed foods. The main goals of conventional thermal processing of foods are to ensure microbiological safety, enhance shelf life of food through destruction of enzymes, toxins etc. Despite the effectiveness of traditional technologies from a microbial safety standpoint, they cause sensorial and nutritional food deterioration. Although food fortification can overcome certain nutritional degradation, sensorial attributes such as flavor, aroma, texture and appearance are difficult to retain in conventional thermal processing

In order to comply with governmental regulations concerning microbial lethality in food products, heating methods are applied at the coldest point of a system, which is generally the center of the largest particle. In conventional heating, the time it takes to increase the temperature at this cold point may over process the remaining particles and the surrounding liquid. This over processing leads to a destruction of nutrients and decreased flavor.

Novel thermal and non thermal processing technologies based on physical techniques for food preservation have the potential to address the demands of the consumer and deliver high quality processed foods with an extended shelf life that are additive free and have not been subjected to extensive heat treatment. The research and developments in non thermal or “çold” processing techniques are mainly with the aim that undesirable microorganisms, allergens and enzymes should be inactivated without damage to nutritional and sensory properties resulting normally from thermal treatment.

Conventional food heating methods require heat energy to be generated externally and then transferred to the food material by conduction, convection or radiation. For products containing particulates, especially when particulates are very large, conventional heating methods require such excessive heat processing that the degradation of outer portion of particulates occurs. There is therefore, considerable need for technologies that perform rapid, uniform heating that result in desired microbial lethality without altering or degrading overall food quality.

Ohmic heating is one of those alternative processing techniques to emerge in the last 20 years. It is referred to as joule heating, electrical resistance heating or electro conductive heating. This review will (1) consider the major technological aspects and current applications of ohmic heating (2) discuss the potential use of mathematical modeling for the design of the heating system and (3) indicate the major challenges in using ohmic heating in food processing and preservation.

Fundamental principles of ohmic heating

Ohmic heating method is one of the several electromagnetic based methods such as capacitive dielectric, radiative dielectric, inductive and radiative magnetic heating. Ohmic heating is somewhat similar to microwave heating but with very different frequencies (de Alwis and Fryer 1990). Ohmic heating (direct resistance heating) is a process in which food liquids and solids are heated simultaneously by passing an electric current through them

The advantage of ohmic heating is that it uniformly heats in contrast with the non-uniform distribution of microwave heating (Datta and Hu 1992; Decareau 1985). In the absence of a hot wall, ohmic heating provides a considerable advantage for foodstuff applications, by not only avoiding the degradation of thermo-sensitive compounds through over-heating but also by reducing the fouling of treated food surfaces during processing (Ayadi et al. 2005a, b). Special advantage is that ohmic heating can improve food quality and saves cost and energy to processors. Ohmic heating can produce safe, high quality food, and to validate any commercial process by experimentally demonstrating its application. The shelf life of ohmically processed foods is comparable to that of canned and sterile, aseptically processed products.

The success of ohmic heating depends on the rate of heat generation in the system, the electrical conductivity of the food, electrical field strength, residence time and the method by which the food flows through the system (Takhistov 2007; Halden et al. 1990; Imai et al. 1995). The food acts as an electrical resistor. The substance is heated by the dissipation of electrical energy. Electrical resistance heating allows particles and liquids to heat at the same rate and permits the rapid heating of mixtures with high solids fractions. To understand the process, it is necessary to study food electrical conductivity and predict the resulting heating patterns. Using electric current, food can be pasteurized, fermented, or sterilized in a manner that is equally comparable to the current methods of processing (USFDA 2000). Understanding the influence of ohmic heating on the sensorial and microbiological quality of foods is a pertinent matter.

The experimental design usually consists of electrodes that contact the food; thereby electricity is passed through the substance using a variety of voltage and current combinations. The food industry has shown a renewed interest in ohmic technology in recent years, with new systems being designed since the early 1990’s. A review on ohmic heating process has been published by Knirsch et al. 2010. They have reviewed the topic in relation to the microbial inactivation, electroporation effects and the critical process parameters. Design aspects, mathematical modeling and current applications of the process are not given much emphasis in this paper.

The most critical factors to be fully measured and determined in a continuous sterilization process can be classified into the temperature of the coldest spot and the shortest residence times spent in the heating and holding system. Sastry (1992) observed that if a particle of low conductivity is surrounded by a high-conductivity environment, this particle will thermally lag the fluid. If isolated low-conductivity particles enter the system, the danger of under processing exists. From the safety point of view, it is important to determine the worst-case scenario, and this is most likely associated with undetected low-conductivity particles in the system. Di Geronimo and Garthright (1997) stated that a distribution-free method was the most appropriate method to determine reliably the characteristic fastest particle of the system. Ramaswamy et al. (1995), Sastry (1997) and Sastry and Cornelius (2002) reviewed several techniques developed for studying and investigating the Residence time distribution (RTD) of solid–liquid flow such as magnetic methods and radio frequency identification methods.

The use of magnetic methods involve introduction of tagged particles containing small magnets (Chandarana and Unverferth 1996; Segner et al. 1989). Their principal limitation, however, is the inability to distinguish between multiple particles passing through the detector at the same time. This necessitates that operator wait for each magnetic tracer to enter and exit the system before introduction of the next tracer (Sastry and Cornelius 2002).

Radio Frequency Identification (RFID) technology allows tracking of multiple particles inside the system, thus obviating the waiting time needed in magnetic method (Tulsiyan et al. 2008). RTD of food particles inside ohmic heaters depends on system variables like system dimensions, orientation, rotational speed of the agitators, and product flow rate; particle variables like concentration, shape, size, type, and density; and the fluid viscosity. There is a need to study, in detail, the effect of these variables on the RTD in the ohmic heaters.

The residence times and RTD of solid potato particles in starch solution were determined using Radio Frequency Identification (RFID) technique. The effect of solid concentration and the rotation speed of the agitators on the RTD were studied. Mean particle residence time increased with the rotational speed, and no particular relationship was observed between the measured mean particle residence time and the solid concentration. The velocity of the fastest particle was 1.62 times the bulk mean product velocity which is important for food safety design considerations. As with any continuous flow process, in-situ temperature monitoring remains a challenge, hence, adequate mathematical models as well as experimental verification are critical.

For in-container processing, the regulatory requirements are similar to that of traditional thermal processing in the United States. For continuous flow processing with aseptic packaging, the approaches are currently in development in a project funded by the USDA National Integrated Food Safety Initiative. The Food and Drug Administration (FDA) is responsible for evaluating and monitoring the safety of ohmically processed foods, unless the product contains a specified minimum amount of meat and poultry. In such cases, it falls under USDA’s purview.

The following technological aspects are crucial for ensuring excellent product quality such as equipment design, process parameters, heat and mass transfer and process modeling.

Equipment design

There are endless possibilities for the design of an ohmic heating system, but there are several key elements that will be present in each one. A power supply (generator) is needed to produce the electricity. Electrodes connected to the power supply must be in physical contact with the substance in order to pass the electric current through. The electrode gap (distance between the electrodes in the system) can fluctuate depending on the size of the system, but by changing this distance, the electric field strength, expressed in volts per centimeter [V/cm], can be varied. Currently ohmic heaters are specifically engineered to interface with continuous, as opposed to batch, process lines. Two possible geometries can be considered the transverse field and collinear field modes (Stirling 1987). With the transverse mode the applied electric field and current flux are at right angles to the mass flow, and with the collinear mode they are parallel.

-

Transverse configuration: the product flows parallel to the electrodes and perpendicularly to the electric field. In this case the electrodes are generally plane or coaxial; although apparently offering the benefits of simple mechanical construction, the transverse mode poses two electrical problems—the presence of a live electrode in close proximity to both inlet and outlet pipe work can give rise to large leakage currents to earth through the product material. Also phase-to-neutral current density in the direction of mass flow can be grossly non uniform at the electrode edges. Here localised overheating, boiling and electrode erosion have been observed. Development of the transverse mode heater has therefore been restricted to fluids containing no particles, and is at a lesser stage of advancement than the particulate heater which follows

-

Collinear configuration: the product flows from one electrode to the other one and the flow is parallel to the electric field; A collinear heater is assembled from two basic units—the electrode housing and the spacer tube. By alternately joining electrode housing/spacer-tube/electrode-housing one arrives at progressively higher-power heaters. Operational voltages can reach 3–3 kV between electrodes and to the externally earthed heater casing. It is essential, therefore, that all internal surfaces in contact with the food are constructed from insulating material capable of long and reliable service under what are fairly arduous environmental conditions.

-

A moving system, such as a conveyor or tube, can be categorized as in field and cross field systems based on the position of electrodes with respect to product flow path.

-

In-line field system: Electrodes are placed at various positions along the length of the product flow path. The material upstream experiences higher field strength than the material downstream due to the drop in voltage throughout the system.

-

Cross-field system: Electrodes are placed perpendicular to the flow path. The electric field strength is constant throughout. APV Intl. Ltd. (England) developed commercial ohmic heating units for continuous sterilization of food products (Skudder and Biss 1987). A static ohmic heating system was developed to remove protein from fish mince washwater collected from a surimi production plant in order to improve water quality (Kanjanapongkul et al. 2008). The static ohmic heating system consisted of an ohmic cell, an ordinary manual on-off variable transformer (0–240 V), a digital recordable power meter, and a mercury thermometer. The ohmic cell was made from an acrylic tube with a length and internal diameter of 300 mm and 50 mm, respectively. Two circular 316 stainless steel electrodes (50 mm diameter) were fixed at each side of the cell with the distance of 75 mm between each other.

-

Ayadi and co-workers (Ayadi et al. 2003, 2004, 2005a, b) have investigated the performance of a plate-type ohmic heater for thermal treatment of dairy products. An example of ohmic heating system would be the ohmic heating of a liquid food takes place in an apparatus where the food is the conductive media and therefore liquid food sterilization. Electrodes are in intimate contact with the product (Goullieux and Pain 2005). These electrodes are generally separated by a tube which is electrically insulating. There are two main generic industrial configurations for continuous operations (Stirling 1987)

-

Carrot cubes were ohmically heated with 2 different frequencies 1 Hz and 60 Hz to evaluate change in color, texture and rehydration properties. For ohmic heating the sample cubes were placed between the two specially coated titanium electrodes taking care that sides of the sample cubes had good contact with the electrodes. The schematic diagram of ohmic heating process is shown in Fig. 1. In the figure, the power supply and flow of electricity are shown. The sample is held between the two electrodes and an insulator cap is also shown near the electrodes. The flow of electricity is through the food sample where it acts as a conductor.

-

A power supply of 60 Hz and an alternator was used for the experiment. Voltage and current transducers (Ohio Semitronics Inc., Hilliard, OH) were used to change from Volts to Amperes and vice-versa. A Teflon coated k-type thermocouple was used to monitor the geometric center temperature of the sample. The voltage, current and temperature were continuously measured using a CR 10× data logger which was connected to a computer. When sample reached the desired end point temperature the power was switched off and the data was obtained for the sample to reach the desired end point temperature of 40 °C. A 120 V power supply was used to provide alternating current of frequencies 1 Hz or 60 Hz and to heat the samples until its geometric center reached the desired endpoint temperatures (EPT) which are 40 °C. Extensive studies on the product properties as functions of composition, temperature, frequency need to be carried out for the optimum design of an ohmic heating system.

Critical process parameters

Ohmic heating is a thermal-based process; therefore the electric field strength, residence time, and the electric conductivity of a food product are the major critical process factors, which strongly influence temperature generation and ohmic heating efficacy. The critical parameters that affect different electromagnetic methods with their common frequency range of applications are described by several authors (Zhao et al. 2000; Cheremisinoff et al. 1985; Orfeuil 1987; Houben et al. 1991; Beatty et al. 1992; Ishii 1995). The parameters used during ohmic heating are frequency of alternating current (50 or 60 Hz), applied voltage and the temperature to which the sample is heated. The primary property affecting ohmic heating is the electrical conductivity of the food (Sastry and Palaniappan 1992).

Takhistov (2007) suggested analytical models based on the dimensionless analysis of major process variables and physical properties of food products. In general, most of the food products can express both dielectric and ionic types of polarization, since their electric properties are non-linear with respect to changes in their temperature and composition. The dominating energy transfer/dissipation mechanism and process efficacy can be determined by the ratio between dielectric and conductive properties of a product. This unified approach is important to the engineers and scientists working in the area of non-thermal food processing technologies. It provides information useful in understanding of food behavior (polarization) during the processing, in improving the protocols, and increasing the quality and safety of the processed foods.

Electrical conductivity

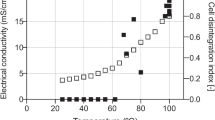

The most critical property affecting ohmic heating rate is food electrical conductivity. It is a function mainly of food chemistry and structure and temperature. The electrical conductivity is affected by parameters such as ionic strength, free water and material microstructure (Lima and Sastry 1999a, b). The presence of ionic substances such as acids and salts increases conductivity, while the presence of non polar constituents like fats and lipids decreases it (Wang and Sastry 1993a, b; Sastry and Palaniappan 1992). The electrical conductivity depends on the temperature, ionic breakup and microstructure setup of the food material undergoing heating and field strength of the experimental setup (Parrott 1992). Heat generation rate obtained during ohmic heating is proportional to the electrical conductivity at a constant voltage gradient; this property has direct implications on heat transfer.

The efficiency of ohmic heating is dependent on the conductive nature of the food to be processed (Zoltai and Swearingen 1996). The electrical conductivity of various fruits and meats increased linearly with the temperature during ohmic heating at constant voltage gradient. In designing processes for ohmic heating of meat cuts, the anatomical location of the cut may influence the efficacy of heating though further work is needed to verify this (Mckenna et al. 2006). Lower electrical conductivity may be observed for highly porous materials like apples. There was no strong relationship between the measured fat content of the lean muscle cuts and their electrical conductivity. Fat distribution or marbling might be an important factor affecting the electrical conductivity of meat. For pork cuts no particular trend could be observed between the conductivity and the total fat content. Shirsat et al. (2004) measured electrical conductivity of fresh pork cuts of leg (topside), shoulder (picnic), and back and belly fat. Brunton et al. (2005) reported that meat emulsion batters (prepared without Red-2G) cooked very rapidly using ohmic heating. Published conductivity values for various food samples during ohmic heating are summarised in Table 1

A number of effects which occur during conventional heating, such as starch transition, melting of fats and cell structure changes, are shown to affect the electrical conductivity (Halden et al. 1990). In some cases the presence of an electric field induces enhanced diffusion of cell fluids in the food which increases the rate of change of conductivity with temperature above that found by conventional heating. Preheating is found to increase the electrical conductivity of some foods, making them acceptable for ohmic processing.

Frequency and form of wave

The common frequencies employed for ohmic heating of foods are 50 Hz and 60 Hz (Kolbe et al. 2001). Lima et al. (1999) showed that frequency and waveform of applied voltage affects the electrical conductivity values and the process of heating the samples. Some studies (Lima et al. 2001) also suggested that with low frequency electrical conductivity values were high and further electrical conductivity of turnip tissue used in the experiment was significantly higher for sine and saw tooth waves as compared to the square waves at 4 Hz. The lowest effective frequency would be a worthwhile subject for further research, since improved mass transfer has been reported for frequencies as low as 4 Hz (Lima and Sastry 1999a, b). Experiments conducted by Kim and Pyun (1995) and Imai et al. (1995) suggested that the frequency of alternating current affects the efficiency of extraction and the heating rate. Altering the frequency and wave form of alternating current during ohmic heating has been shown to influence the heat and mass transfer properties of foods.

Product size, heat capacity and viscosity

Smaller particles like emulsions, colloids (which were less than 5 mm), the effect of orientation on the conductivity can be ignored but for larger particles (15–25 mm), orientation relative to the electrical field has a significant influence on electrical properties as well as the relative heating rates of the phases (Mckenna et al. 2006). When solid particles suspended in a fluid medium both have similar electrical conductivities, the component among them having lower heat capacity will have the tendency to heat faster. Foods having high densities and high specific heat values are conducive to slower heating (Palaniappan and Sastry 1991). Fluid viscosity also influences ohmic heating; higher viscosity fluids tend to result in faster ohmic heating than lower viscosity fluids (Marcotte et al. 2000).

Thermal modeling of ohmic heating

Heating rates of solid and liquid phases during ohmic heating depend on the electrical conductivities of both phases. An ideal processing condition can be achieved when conductivities of both the phases are equal, since, under such a condition, both phases will heat at the same rate.

Under static ohmic heating conditions particle-liquid mixture heat at rates depending on relative conductivities of the phases and the volume fractions of the respective phases (Sastry and Palaniappan 1992). Solids of low conductivity compared to the liquid will lag thermally if they are in low concentration, but under high concentration conditions, particles may heat faster than fluid. This occurs because as solids content increases, current paths through the fluid become more tortuous, forcing a greater proportion of the total current to flow through the particles. This can result in higher energy generation rates within the particles and consequently a greater relative particle heating rate.

Relatively few studies exist concerning mass transfer during ohmic heating. The study of mass transfer under ohmic heating conditions could have industrial applications. Schreier et al. (1993) studied the diffusion of beet dye from beetroot tissue into a fluid during conventional and ohmic heating as a function of steady-state temperature. The beetroot was heated from 20 to 80 °C and the amount of beet dye diffusing into solution was measured.. The volume of beet dye diffusing into solution during ohmic heating was enhanced with respect to conventional heating. At lower temperatures the authors reported a 40 % enhanced diffusion effect for ohmic heating.

Katrokha et al. (1984) used electrical heating to aid the extraction of sucrose from sugar beets, while Kim and Pyun (1995) used ohmic heating to extract soymilk from soybeans. Lima and Sastry (1999a, b) and Wang and Sastry (2000) found that ohmic heating of apple tissue prior to mechanical juice extraction significantly increased apple juice yields and that the hot-air drying rate of vegetable tissue was accelerated with ohmic heating pretreatment. Because ohmic heating accelerates moisture loss and improves extraction yields, it could have important commercial uses. Thus, work to further elucidate mass transfer mechanisms during ohmic heating is important A study conducted by Lima et al. (2001) aimed at understanding electrical diffusion enhancement under a continuous electric field, and under constant temperature. Their results suggested that choosing conditions in which the electrical conductivity of a sample under ohmic conditions is maximized can enhance food processes involving mass transfer.

Electro osmosis has been proposed by Halden et al. (1990) and Schreier et al. (1993) respectively, to explain the increase in electrical conductivity and dye diffusion. This phenomenon involves the increased diffusion of materials across cell membranes by virtue of an applied electric field. Diffusion of salt in foods such as vegetables, pork, beef and fish has been studied by many researchers (Dussap and Gros 1980; Liu 1992; Drusas and Vagenas 1988; Wang and Sastry 1993a, b).

Mathematical modeling is a useful tool for designing an ohimc heating unit for pasteurization of solid foods (Zell et al. 2008). Pasteurization of a solid food undergoing ohmic heating has been analyzed using a mathematical model based on a previously validated (Marra et al. 2009) multi-physic model solved with COMSOL 3.3. Modelling ohmic pasteurization involved simultaneous solution of: 1) Laplace’s equation which describes the distribution of electrical potential within a food; 2) heat transfer equation using a source term involving the displacement of electrical potential; 3) kinetics of inactivation of microorganisms likely to be contaminating the product. In the model, thermo-physical and electrical properties as function of temperature are used. The model predicted that, when temperature gradients established in the proximity of the outer curved surface, more cold areas were present at junctions of electrodes with lateral sample surface. For these reasons, colder external shells were the critical areas to be monitored, instead of internal points (typically geometrical center) as in classical pure conductive heat transfer.

The thermal analysis of an ohmic heater requires the simultaneous solution of the electric and thermal fields (de Alwis and Fryer 1990). A deep review on these topics is given by Goullieux and Pain (2005). Pesso and Piva (2009) carried out the thermo-fluid analysis of a collinear cylindrical ohmic heater in laminar flow treatment of apricot puree. All the other fluid properties, but the electrical conductivity, are considered to be constant. The fluid is assumed to be homogeneous. Since it is commonly supposed that the presence of small solid particles in the fluid has negligible effects on the flow (Benabderrahmane and Pain 2000), the assumption of homogeneous fluid is also valid for the applications treating liquids with small solid particles.

A numerical Solution of a non-local problem modelling Ohmic Heating of Foods was given by Nikolopoulos and Tzanetis (2004). An upwind and a Lax-Wendroff scheme are introduced for the solution of a one dimensional non-local problem modelling ohmic heating of Foods. The schemes are studied regarding their consistency, stability and the rate of convergence for the cases that the problem attains a global solution in time. A high resolution scheme is also introduced and it is shown that it is total-variation-stable.

Residence time of the fastest-moving particle is necessary for designing a process via mathematical modeling to ensure commercial sterility, and for biological validation of the model. The RTD experiment must be able to demonstrate with a high degree of confidence that the fastest particle has indeed been sampled and therefore the sample size becomes critical. Modeling and experimental studies to identify the worst-case heating scenario during ohmic processing of particulate foods were carried out by de Alwis and Fryer (1990); Sastry (1992), Sastry and Palaniappan (1992), Fryer et al. (1993), Zhang and Fryer (1993), Khalaf and Sastry (1996), Orangi et al. (1997).

Modeling of the thermal behavior of multiphase food products with various electrical conductivities under ohmic heating has been a challenge. Distortion of electric field due to heterogeneous food properties and electrical conductivity distribution should be taken into consideration for accurate prediction of the thermal performance of ohmic heaters. A study was conducted to model ohmic heating pattern of solid–liquid food complex that contain three different solid particles with substantially different electrical conductivities and 3 % NaCl solution. (Shim et al. 2010). The solid food samples used in this experiment were potato, meat, and carrot, which are less conductive than carrier medium. The transient heating patterns of each solid food and carrier medium were simulated using computational fluid dynamics (CFD) codes with user defined functions (UDFs) for electric field equations. The predicted temperature values were in good agreement with the experimental data with the maximum prediction error of 6 °C. Hot spots existed on the continuous phase in zones perpendicular to the solid cubes and cold spots were in between the particles where the current density lacks. CFD model prediction of detailed thermal profiles of multiphase food mixtures under the static ohmic heating will assist in designing of a continuous flow ohmic heater with pursuit of heating uniformity, furthermore, ensuring food safety and quality.

Three dimensional numerical simulations of ohmic heating (OH) of highly viscous chicken chow mein sauce in typical and modified pilot scale ohmic heating chambers with sidewise parallel electrodes arrangement were undertaken by Shynkaryk and Sastry 2012. The fully coupled momentum, electrostatic and energy transfer partial differential equations were solved using commercial finite element modeling (FEM) software. The residence time (RT) of sauce in the OH treatment chambers was studied by solving the convection and diffusion equation for a tracer species injected in the system. The key parameters affecting the process, including electrical conductivity, r, thermal conductivity, k, specific heat capacitance, Cp, density, q and viscosity, g, were measured experimentally. For the model validation, the predicted current delivered by each generator and temperatures in selected locations were compared with those obtained from trials performed under the same conditions.

Advantages of ohmic heating

The advantages of ohmic heating include better product quality, less cooking time, lower capital cost, better energy efficiency and also that it is an environment friendly process. It requires lower capital cost compared to other electro heating methods. It also has an advantage over microwave processing where processing can be limited by the depth to which energy can penetrate the food material (Fryer et al. 1993). It is possible to process large particulate foods (up to 1 in.) that would be difficult to process using conventional heat exchangers. Additionally, ohmic heater cleaning requirements are comparatively less than those of traditional heat exchangers due to reduced product fouling on the food contact surface. Previous research has shown that combined ohmic and plate cooking can improve cooking time of hamburger patties over conventional plate cooking process. Brunton et al. (2005) reported that meat emulsion batters cooked very rapidly using ohmic heating. The development of a prototype ohmic heating cell has made rapid cooking of Bologna hams possible on a laboratory scale (de Halleux et al. 2005) compared to the traditional smoke-house cooking method, the cooking time was reduced by 90 to 95 %. To achieve rapid cooking that meets minimal pasteurization criteria, a cooking temperature greater than 75 °C is required. The major benefits claimed for ohmic heating technology are continuous processing without heat transfer surfaces, uniform heating of liquids and carrier fluids at comparable rates, thus making it possible to use High Temperature Short Time (HTST) technique (Parrott 1992; Tucker and Withers 1994; Pereira et al. 2007). Industrial application of ohmic cooking would allow energy efficiencies greater than 90 %.

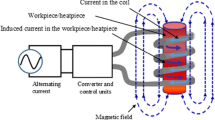

Induction heating is the process of heating an electrically conducting object (usually a metal) by electromagnetic induction, where eddy currents (also called Foucault currents) are generated within the metal and resistance leads to Joule heating of the metal. Induction heating allows the targeted heating of an applicable item for applications including surface hardening, melting, brazing and soldering and heating to fit. Iron and its alloys respond best to induction heating, due to their ferromagnetic nature. Eddy currents can, however, be generated in any conductor, and magnetic hysteresis can occur in any magnetic material. Induction heating is often used for cooking applications where the food material is placed in an electricity conducting container This involves the risk of product damage due to burning as hot surfaces are used for heat transfer.

Radio frequency (RF) heating is akin to microwave heating but utilises another part of the electromagnetic spectrum. Instead of the 2,450 MHz (or 900 MHz) frequency used for microwave heating, RF uses frequencies of 13, 27 or 40 MHz. The longer wavelength of radio frequency compared to microwave energy means that radio frequency processing can give better penetration and better heating uniformity throughout a product. Engineering of RF systems can also be simpler than microwave units. Applications of radio frequency heating are broadly similar to those of microwave heating. There are subtle differences between the two techniques making radio frequency heating more appropriate than microwave heating in a number of instances. Radio frequency heating is used extensively in polymer and food processing, as well as many other industries, for applications such as enhanced drying, curing, melting/defrosting and baking. The benefits of RF heating can often be maximised through combining the use of RF with other energy sources, such as hot air, infra-red and radiant heat.

In general, Ohmic heating systems are advantageous

-

Due to an optimization of investment (increased efficiency, low capital cost),

-

Instant shutdown of the system,

-

Reduced maintenance costs because of the lack of moving parts

-

It can heat particulate foods and Liquid–particle mixtures.

-

By ohmic heating, high temperatures can be rapidly achieved. For e.g. temperatures for ultra high temperature (UHT) processing

-

As there are no hot surfaces for heat transfer, there is low risk of product damage due to burning

Applications

In the early nineties electric pasteurization of milk was carried out by passing it between two plates with an electrical potential difference (Anderson and Finkelstein 1919). In the late 1980s researchers started investigating its practical potential use in food processing. Ohmic heating is now receiving increasing attention from the food industry, once it is considered an alternative for the indirect heating methods of food processing (Castro et al. 2004; Pereira et al. 2007). Applications existing for Ohmic heating include: blanching, thawing, on-line detection of starch gelatinization, fermentation, peeling, evaporation, dehydration, fermentation and extraction (Sastry et al. 1999). Earlier work focused on viscous food and foods containing solid particles. It has been reported that ohmic heating can be used for meat batters and also in preparation of fish based products Several studies have investigated a number of aspects for the application of ohmic heating within the food industry, for example, its potential to increase dye diffusion in beet (Halden et al. 1990), extraction of fruit juices (Lima and Sastry 1999a, b; Wang and Sastry 2000) and the enhancement of the drying process of sweet potato (Zhong and Lima 2003). Lakkakula et al. (2004) reported that ohmic heating was an alternative method for stabilisation of rice bran because it increased the oil yield of rice bran to a maximum of 92 %, whilst only 53 % of oil was extracted from the control samples. Juices can be treated to inactivate enzymes without affecting the flavor. A study was carried out to investigate the effect of ohmic heating on lipase activity, to evaluate the effect of ohmic heating on phytochemicals and antioxidant activity of rice bran obtained from different ohmic heating conditions. (Loypimai et al. 2009).

Over the past few decades, aseptic processing has been widely used in the food industry for the pasteurization or sterilization of liquid foods, such as milk and fruit juices. The core of the processing plant is the heat exchanger followed in the production line by an aseptic filling system (Parrott 1992). However, the use of this sanitization technique for liquid foods containing solid particles, with a particle size and concentration above 15 mm and 30–40 g/100 g respectively, is limited due to the low heat transfer rate by conduction to the center of the large solid particles, necessary to achieve the proper sterilization. In order to overcome this problem, in the industrial practice the liquid is overheated to provide a higher driving force for the heat transfer process. This often causes the over processing of the liquid phase as well as the surface of the suspended particles drastically reducing the overall quality of stabilized products.

Due to these drawbacks, the use of direct heating through a Joule effect, such as ohmic heating, has gained increased attention in the food industry. This is due to the possibility to extend the application of continuous aseptic processing to particulate foods. In an ohmic heating processing, the product is directly in contact with the electrodes, thus acting as part of the electric circuit through which the alternating electric current flows. As a consequence, heat generation takes place in the whole mass of the food material as a result of its inherent electrical resistance.

To date, ohmic heating was employed in the rector system which is considered as one type of aseptic processing. Ohmic heating is a continuous high temperature short time (HTST) sterilization process. Continuous flow ohmic heating is a valuable technique to extend a high temperature-short time processing concept to thermal sanitization of highly concentrated particulate solid liquid mixtures such as fruit pieces in syrup; coupling of ohmic heating treatment with aseptic filling is a straightforward industrial solution to simplify the processing line to prepare fruit preserves, due to the unnecessary further thermal treatment of products after packaging; The application of ohmic heating in the future may be defined as follows:

-

a.

Aseptic Process using Ohmic heating

-

b.

Inactivation of Food Enzymes

-

c.

Pasteurization and Sterilization

-

d.

Ohmic Thawing

Ohmic heating technology, after future regulatory approval, will provide potential as one of the future technology insertions of the rnilitary ration program for improving shelf stability and quality enhancement of both individual and group fied feeding entries.(Yang et al. 1997). Table 2 summarises the applications of ohmic heating and the advantages reported in literature.

Pasteurization and sterilization

Ohmic heating technology has been accepted by the industry for processing liquids and solid liquid mixtures (Stirling 1987). In a recent study, the use of ohmic heating on sterilization of guava juice is reported (Elzubier et al. 2009). Ohmic heating is very often used in pasteurization/sterilization of food products resulting in excellent quality. Past research as done by Lima et al. (1999) also underlines the role of ohmic heating technique enhancing the air-drying rate. The resistance heating technique was used for milk pasteurization in the early 20th century (Quarini 1995). Ohmic heating can be used for ultra high temperature (UHT) sterilization of foods, and especially those that contain large particles (up to 2.5 cm) that are difficult to sterilize by other means.

A mild electroporation process can occur during ohmic heating according to recent literature and research (Kuang and Nelson 1998. Electroporation is the formation of holes in a cell membrane due to individual ion pressure, which cause change in permeability of cell membrane, due to the varying the electric field (Weaver 1987). The low frequency used in ohmic heating (50–60 Hz) allows cell wall to build up charges and form pores, which is not the case with high frequency methods such as microwave heating, where the electric field is reversed before sufficient charge build up occurs at the cell walls. The past researchers also found that electricity applied later during the microbial growth cycle can prove hazardous, possibly due to the enhanced transport of inhibitory substances across the cell membranes.

Sea food processing

Surimi is stabilized fish myofibrillar protein and is a major ingredient for seafood products; such as, surimi crab, shrimp, lobster and scallop products. The microbiological quality of these seafood products is very high. The FDA considers regulatory action when enterotoxigenic Escherichia coli (ETEC) is present at 13103/g in processed seafood which requires minimal or no processing by the consumer (Ward and Price 1992). According to the informal guideline for Staphylococcus aureus, the product may be actionable if tested positive for the toxin or if 13 × 104/g organisms are found. The FDA has established zero tolerance for Listeria monocytogenes in cooled and ready-to-eat foods and also for Salmonella in seafood. Ohmic heating experiments were conducted for fish mince by Wu et al. 1998. Pacific whiting surimi paste and stabilized mince in the 20–70 °C range were tested at frequencies from 55 Hz to 200 kHz. Sample impedance decreased slightly with frequency. The DC electrical conductivity and absolute dielectric loss of Pacific whiting surimi paste increased with temperature and salt concentration and those of the stabilized mince increased with temperature.

Particulate foods

In an ohmic heating process for particulate foods, the most desirable situation is that in which the electrical conductivities of fluid and solid particles are equal (Wang and Sastry 1993a), thus close matching of electrical conductivities between phases would be highly desirable. Ohmic heating for thermal processing of low-acid foods containing solid particulates was reported by Sarang et al. (2008). In low-acid foods containing solid particulates like chicken chowmein the sauce was more conductive than all the solid components. By blanching the solids in highly conductive sauce it was possible to increase their ionic content and hence their electrical conductivity. Product containing pretreated solids heated more uniformly during ohmic heating. Sensory test results suggested that the blanching pre treatment did not compromise the quality of the product. A number of processing plants currently produce sliced, diced, and whole fruit within sauces in various countries, including Italy, Greece, France, Mexico, and Japan. In the United States, ohmic heating has been used to produce a low-acid particulate product in a can, as well as pasteurized liquid egg.

Ohmic thawing

Ohmic heating can be used to thaw frozen foods placed between two electrodes and applying an alternating current to it. The advantages of this process include, water and waste water is not generated, thawing can be relatively uniform due to volume heating and the process can be easy to control. Potential problem in ohmic thawing has also been mentioned in literature. As the frozen product thaws current passes through the thawed portion of the block more rapidly since frozen shrimp has 100 times lower conductivity than thawed shrimp (Luzuriaga et al. 1996). With the current flowing through the thawed portion of the block, shrimp in that portion may cook, while the rest of the block is still frozen. This is called runaway heating, or formation of hot spots. If this problem is solved, a new method to thaw foods will be available.

Commercial applications

Ohmic heating systems made for commercial applications can vary greatly, but one example has 7 electrode columns, each comprised of polytetrafluoroethylene (PTFE) coverings and a single stainless steel cantilever electrode. The processing capacities of such systems can range from 3 to 6 t an hour. One emerging application of ohmic heating is fruit peeling, which may greatly reduce the use of lye that is common to such operations, and results in environmental benefits. Another application is to process between 10,000 and 20,000 lb of liquid eggs per hour. This system heats the liquid eggs to 140–148 °F and holds for 3.5 min. After processing, the eggs are given a 12-week shelf life for consumers, but cartons regularly surpass this shelf life at Papetti’s plant. A shelf-life study was done by Raztek to compare conventional heating to ohmic heating using pasteurized liquid eggs for a measurement of microbial inactivation. The ohmic heating process was originally developed by the United Kingdom Electricity Research and Development Centre and was licensed to APV Baker Ltd for commercial applications (Skudder 1992). In commercial ohmic heating systems in England, food is heated by pumping between a series of electrodes to which alternating current is applied (Skudder 1992). Typically, dwell in time in ohmic heater is not more than 90s, after which food is pumped through a series of holding tubes or to a holding tank to equillibriate temperature. Using the APV Baker system, Yang et al. (1997) conducted the microbiological and sensory studies of six commercially produced ohmically heated stew type foods. The products were demonstrated to be commercially sterile and free from post processing contamination. They had good quality retention after 3 years of storage.

An economic analysis conducted at the University of Minnesota in the early 1990s indicated that ohmic heating would be economically viable for premium quality foods. However, costs of ohmic systems have decreased greatly since that time, and the range of products for which ohmic heating is economical has expanded considerably. According to a case study on ohmic heating of vegetable soup (Bertolini and Romagnoli 1996), in order to achieve the same UDPCs of the cold chain for a frozen minestrone, the target processing and packaging unit cost for an ohmic product is 42,306 €/kg. This cost was calculated in the same boundary conditions, i.e. same recipe, same logistics and same storage times (both pre- and post- production). Since the quality of the products is similar, the superior keepability and functional quality of the ohmic product could make it a competitive choice. Nonetheless, the post-production logistics of an ohmic product doesn’t need a cold chain and therefore avoids its costs and risks. Further developments of this work could extend the analysis to different products, such as vegetable purees, other vegetables or fish soups. Allen et al. (1996) conducted an economic engineering study of ohmic heating process.

Fouling is a common problem during ohmic heating. The research of fouling during ohmic heating of food concentrates revealed that the deposit creation on electrodes is pertinent to the problem of the electrodes corrosion. Effect of the corrosion of electrodes can be eliminated using higher frequencies (about 10 kHz) from a pulsed power supply. Fouling creation of milk was studied by Ayadi et al. (2004). Although the mechanism and reactions between all milk components are not yet fully understood, a relationship has been described between the denaturation of native β-lactoglobulin and fouling of heat exchangers De Jong (1996); Toyoda (1994). The rate of the denaturation and agglomeration of proteins depend upon temperature and composition of milk. Roughness of electrode surface–sharp edges form singularities of electric field, with the possible risk of local overheating. Thus a microlayer of deposits can be formed by thermal denaturation of proteins. Electrochemical reactions in the system electrode and electrolyte (redox reactions and electrochemical corrosion processes) start immediately after the power supply is connected. A primary micro layer can be formed on electrodes owing to oxidation or reduction reactions at relatively high values of the current density. This layer forms a part of electric circuit as an additional electric resistance. Because the relative electric resistance value of the primary micro layer is quite high, more electric energy is dissipated into heat in this layer, thus promoting biochemical changes in whey proteins. The corrosion effects can be suppressed either by using noble material like gold or platinum for electrodes or by using increased frequency above the 50 Hz. The positive effect of higher frequencies was known for a long time.

Undesirable electrochemical phenomena at electrode solution interfaces during ohmic heating can be effectively inhibited by choosing an appropriate electrode material. Samaranayake and Sastry (2005) attempted to understand the electrochemical behavior of four types of electrode materials: titanium, stainless steel, platinized-titanium, and graphite at pH 3.5, 5.0, and 6.5. The electrodes were examined comparatively using a 60 Hz sinusoidal alternating current. The results highlight the relatively inert electrochemical behavior of platinized-titanium electrodes at all the pH values. A pilot scale study at 39.8 kW further demonstrates the potential use of platinized-titanium electrodes for ohmic heating of foods with commonly available low-frequency alternating currents (Samaranayake and Sastry 2005).

Research is being carried to investigate skim milk fouling during ohmic heating (Bansal and Chen 2005; Bansal et al. 2005). The heating of the milk solution resulted in deposit formation on both electrodes. These deposits provided additional electrical resistance and the current passing through the milk solution dropped by up to 45 % within 4 h of operation. The applied voltage increased slightly during this time period. The deposit formation was reasonably uniform at any cross-section. Lowering the milk temperature at the inlet of the ohmic heater enhanced the rate of fouling. In contrast, increasing the milk solution flow rate by a factor of two was found to have almost no effect on the fouling rate.

Conventional ohmic heating under typical low frequency alternating current (50 or 60 Hz) could cause hydrogen and oxygen evolution due to electrolysis of water (Amatore et al. 1998). In a microgravity environment, where gas bubbles would have no preferred direction of movement, a gas blanket could develop over the electrodes and stop heating altogether. Thus, attention needs to be paid to gas bubbles in a closed environment of a transit vehicle or a planetary base. Any decay or corrosion of electrodes should be studied since it could shorten the life time and contaminate the food (Perchonok and Bourland 2002).

Conclusion

Ohmic heating is specially advantageous in processing semi solid, particulate foods. It has proven advantages over conventional thermal processing and novel thermal alternative technologies like microwave heating, radiofrequency heating and induction heating. Better product quality, less cooking time, lower capital cost, better energy efficiency and an environment friendly process are the key advantages. It requires lower capital cost compared to other electro heating methods. The major applications of this technology are for sterilization of high proteinaceous materials, sea food processing, pretreatments for water removal, thawing, detection of starch gelatinization and extraction enhancement. The potential of direct ohmic heating for foods in retort pouches at the household level as well as the mass production level, ensuring food safety has been well demonstrated. Ohmically heated stew type products that are commercially sterile and have shelf life of 3 years are considered for inclusion in military rations. The corrosion problems with different kinds of electrodes at varying frequencies and the varying efficiency of the process depending on electrical conductivity of material used are interesting areas for further research.

References

Allen K, Eidman V, Kinsey J (1996) An economic-engineering study of ohmic food processing. Food Tech 50:269–273

Amatore C, Berthou M, Hebert S (1998) Fundamental principles of electrochemical ohmic heating of solutions. J Electroanal Chem 457:191–203

Anderson A, Finkelstein R (1919) Study of the electro pure process of treating milk. J Dairy Sci 2:374–406

Ayadi MA, Bouvier L, Chopard F, Berthou M, Fillaudea L, Leuliet JC (2003) In: Heat treatment improvement of dairy products via ohmic heating processes: thermal and hydrodynamic effect on fouling. Proceedings of heat exchanger fouling and cleaning—fundamentals and applications. Santa Fe, N.M., U.S.A.; May 18–22. 2003 Engineering Conferences International, New York, U.S.A

Ayadi MA, Leuliet JC, Chopard F, Berthou M, Lebouche M (2004) Continuous ohmic heating unit under whey protein fouling. Innovat Food Sci Emerg Tech 5:465–473

Ayadi MA, Benezech T, Chopard F, Berthou M, Leuliet JC (2005a) Heat treatment of dairy product by a flat ohmic cell: impact of the Reynolds number, fluid rheology and deposit presence on the electrode surface temperature. Heat Exchanger Fouling and Cleaning: Challenges and Opportunities, Engineering Conferences Intl.; Kloster Irsee, Germany; June 5–10: Engineering Conferences International, New York, U. S. A 2005

Ayadi MA, Leuliet JC, Chopard F, Berthou M, Lebouché M (2005b) Experimental study of hydrodynamics in a flat ohmic cell—impact on fouling by dairy products. J Food Eng 70:489–498

Bansal B, Chen XD (2005) Modelling of milk fouling during ohmic heating. CHEMECA Conference; Brisbane, Australia; 2005 Sept 25–8. Institute of Engineers, Australia

Bansal B, Chen XD, Lin SXQ (2005) Skim milk fouling during ohmic heating. Heatexchanger fouling and cleaning: challenges and opportunities. Engineering Conferences Intl.; Kloster Irsee, Germany; 2005 June 5–10: Engineering Conferences International, New York, U.S.A

Beatty RL, Sutto WH, Iskander MF (1992) Microwave processing of materials. Materials Research Society Symposium Proceedings, San Francisco, Ca

Benabderrahmane Y, Pain JP (2000) Thermal behaviour of a solid/liquid mixture in an ohmic heating sterilizer–slip phase model. Chem Eng Sci 55:1371–1384

Bertolini MA, Romagnoli G (1996) Target cost evaluation for the ohmic treatment of a vegetable soup: an Italian comparative case study international conference on food innovation, Food Innova 2010, 25–29 0ctober 2010 Universidad politecnica de Valencia

Bozkurt H, Icier F (2009) Electrical conductivity changes of minced beef–fat blends during ohmic cooking. J Food Eng 96:86–92

Brunton NP, Lyng JG, Li W, Cronin DA, Morgan D, McKenna B (2005) Effect of radio frequency (RF) heating on the texture, colour and sensory properties of a comminuted pork meat product. Food Res Int 38(3):337–344

Castro I, Teixeira JA, Salengke S, Sastry SK, Vicente AA (2004) Ohmic heating of strawberry products: electrical conductivity measurements and ascorbic acid degradation kinetics. Innovat Food Sci Emerg Tech 5:27–36

Chandarana DI, Unverferth JA (1996) Residence time distribution of particulate foods at aseptic processing temperatures. J Food Eng 28:349–360

Cheremisinoff PN, Farah OG, Ouellette RP (1985) Radio frequency/radiation and plasma processing: industrial applications & advances. Technomic Publishing Co, Lancaster

Datta AK, Hu W (1992) Optimization of quality in microwave heating. Food Tech 46(12):53–56

de Alwis AAP, Fryer PJ (1990) The use of direct resistance heating in the food industry. J Food Eng 11:3–27

de Halleux G, Piett M, Buteau ML, Dostie A (2005) Ohmic cooking of processed meats: energy evaluation and food safety considerations. Can Biosyst Eng 47:3.41–3.47

De Jong P (1996) Modeling and optimization of thermal processes in the dairy industry. NIZO Verslag, Ede, p 341

Decareau RV (1985) Microwave in the food processing industry. Academic, Orlando

Di Geronimo M, Garthright LJ (1997) Statistical design and analysis. Food Tech 51(10):52–54

Drusas A, Vagenas GK (1988) Diffusion of sodium chloride in green olives. J Food Eng 7:211–222

Dussap G, Gros JB (1980) Diffusion sorption model for salt in pork and beef muscle. In: Linko P, Malkki Y, Olkku J, Laringkari J (eds) Food Proc Engg Applied Science Publishers, London, pp 407–411

Elzubier AS, Thomas CSY, Sergie SY, Chin NL, Ibrahim OM (2009) The effect of buoyancy force in computational fluid dynamics simulation of a two-dimensional continuous ohmic heating process. Am J Appl Sci 6(11):1902–1908

Fryer PJ, deAlwis AAP, Koury E, Stapley AGF, Zhang L (1993) Ohmic processing of solid–liquid mixtures: heat generation and convection effects. J Food Eng 18:101–125

Goullieux A, Pain J (2005) Ohmic heating. Emerging technologies for food. Elsevier Academic Press, London, pp 469–505

Halden K, de Alwis AAP, Fryer PJ (1990) Changes in electrical conductivity of foods during ohmic heating. Int J Food Sci Tech 25:9–25

Houben J, Schoenmakers L, Van Pu’iten E, Van Roon P, Krol B (1991) Radio-frequency pasteurization of sausage emulsions as a continuous process. J Microw Power Electromagn Energ 26(4):1.171–1.177

Içi’er F, Yildiz H, Baysal T (2008) Polyphenoloxidase deactivation kinetics during ohmic heating of grape juice. J Food Eng 85(3):410–417

Icier F, Ilicali C (2005) Temperature dependent electrical conductivities of fruit purees during ohmic heating. Food Res Int 38:1135–1142

Imai T, Uemura K, Ishida N, Yoshizaki S, Noguchi A (1995) Ohmic heating of Japanese white radish Raphanus sativus L. Int J Food Sci Technol 30:461–472

Ishii TK (1995) Handbook of microwave technology: vol. 2. Applications. Academic, San Diego

Jun S, Sastry S (2005) Modeling and optimization of ohmic heating of foods inside a flexible package. J Food Process Eng 28:417–436

Jun S, Sastry S, Samaranayake C (2007) Migration of electrode components during ohmic heating of foods in retort pouches. Innovat Food Sci Emerg Tech 8:237–243

Kanjanapongkul K, Yoovidhya T, Tia S, Wongsa-Ngasri P (2008) Protein removal from fish mince washwater using ohmic heating. Songklanakarin J Sci Technol 30(3):413–419

Katrokha I, Matvienko A, Vorona I, Kupchik M, Zaets V (1984) Intensification of sugar extraction from sweet sugar beet cossettes in an electric field. Sakharnaya Promyshlennost 7:28–31

Khalaf WG, Sastry SK (1996) Effect of fluid viscosity on the ohmic heating rate of solid–liquid mixtures. J Food Eng 27:125–158

Kim J, Pyun Y (1995) Extraction of soy milk using ohmic heating. Abstract, 9th Congress of Food Sci. Technol., Budapest, Hungary 1995

Knirsch MC, Santos CA, Martins AA, Vincente OA, Penne TCV (2010) Ohmic heating—a review. Trends Food Sci Tech 21:436–441

Kolbe E, Park JW, Well JH, Flugstad BA, Zhao Y (2001) Capacitive dielectric heating system. U.S. Patent, 6,303,166. Issued October 16, 2001

Kuang W, Nelson SO (1998) Low-frequency dielectric properties of biological tissue: a review with some new insights. Trans ASAE 41(1):173–178

Lakkakula N, Lima M, Walker T (2004) Rice bran stabilization and rice bran oil extraction using ohmic heating. J Biores Technol 92:157–161

Lima M, Sastry SK (1999a) The effects of ohmic heating frequency on hot-air drying rate and juice yield. J Food Sci 41:115–119

Lima M, Sastry SK (1999b) The effects of ohmic heating frequency on hot-air drying and juice yield. J Food Eng 41:115–119

Lima M, Heskett BF, Sastry SK (1999) The effect of frequency and waveform on the electrical conductivity-temperature profiles of turnip tissue. J Food Process Eng 22:41–54

Lima M, Hesket BF, Sastry SK (2001) The effect of frequency andwaveform on the electrical conductivity-temperature profiles of turnip tissue. J Food Process Eng 22:41–54

Liu HA (1992) Kinetic study of salt diffusion in potato at high temperature. Int J Food Sci Technol 27:443–455

Liu Z, Jayasinghe S, Gao W, Farid M (2007) Corrosion mechanism of electrodes in ohmic cooking. Asia-Pac J Chem Eng 2:487–492

Loypimai P, Moonggarm A, Chottano P (2009) Effects of ohmic heating on lipase activity, bioactive compounds and antioxidant activity of rice bran. Aust J Basic Appl Sci 3(4):3642–3652

Luzuriaga DA, Roberts JS, Balaban MO (1996) Electrical conductivity of frozen shrimp and flounder at different temperatures and voltage levels. J Agric Food Proc Technol 3(5):41–63

Marcotte M, Trigui M, Ramaswamy HS (2000) Effect of salt and citric acid on electrical conductivities and ohmic heating of viscous liquids. J Food Process Preserve 24:389–406

Marra F, Zell M, Lyng JG, Morgan DJ, Cronin DA (2009) Analysis of heat transfer during ohmic processing of a solid food. J Food Eng 91:56–63

McKenna BM, Lyng J, Brunton N, Shirsat N (2006) Advances in radio frequency and ohmic heating of meats. J Food Eng 77:215–229

Nikolopoulos CV, Tzanetis DE (2004) Estimates of blow-up time for a non-local reactive-convective problem modelling ohmic heating of foods. Proceedings of the Edinburgh Mathematical Society December 2004

Orangi S, Sastry SK, Li QA (1997) Numerical investigation of electroconductive heating in solid–liquid mixtures. Int J Heat Mass Trans 41:2211–2220

Orfeuil M (1987) Electric process heating: technologies/equipment/applications. Battelle, Columbus

Palaniappan S, Sastry SK (1991) Electrical conductivities of selected foods during ohmic heating. J Food Process Eng 14:221–236

Parrott DL (1992) Use of ohmic heating for aseptic processing of food particulates. Food Tech 46(245):239–241

Pataro G, Donsì G, Ferrari G (2011) Aseptic processing of apricots in syrup by means of a continuous pilot scale ohmic unit. LWT–Food Sci Tech 44:1546–1554

Perchonok M, Bourland C (2002) NASA food systems: past, present, and future. Nutr 18:913–920

Pereira R, Martins J, Mateus C, Teixeira JA, Vicente AA (2007) Death kinetics of Escherichia coli in goat milk and Bacillus licheniformis in cloudberry jam treated by ohmic heating. Chem Pap 61(2):121–126

Pesso T, Piva S (2009) Thermo-fluid analysis of a cylindrical collinear ohmic sterilizer in laminar flow Proceedings of ITP2009 Interdisciplinary Transport Phenomena VI: Fluid, Thermal, Biological, Materials and Space Sciences October 4–9, 2009, Volterra, Italy

Piette G, Buteau ME, Halleux D, Chiu L, Raymond Y, Ramaswany HS (2004) Ohmic cooking of processed meats and its effects on product quality. J Food Sci 69:71–78

Quarini GL (1995) Thermalhydraulic aspects of the ohmic heating process. J Food Eng 24:561–574

Ramaswamy HS, Abdelrahim KA, Simpson BK, Smith JP (1995) Residence time distribution (RTD) in aseptic processing of particulate foods: a review. Food Res Int 28(3):291–310

Roberts J, Balaben M, Luziriaga D (1996) Automated ohmic thawing of shrimp blocks. Seafood science and technology Society of the America (1996), pp 72–81

Samaranayake CP, Sastry SK (2005) Electrode and pH effects on electrochemical reactions during ohmic heating. J Electroanal Chem 577:125–135

Sandrine C, Eliot-Godéreauxa, François Zuberb, Goullieux A (2001) Processing and stabilisation of cauliflower by ohmic heating technology. Innov Food Sci Emerging Technol 2Ž 2001: 279–287

Sarang S, Sastry SK, Knipe L (2008) Electrical conductivity of fruits and meats during ohmic heating. J Food Eng 87:351–356

Sastry SK (1992) A model for heating of liquid-particle mixtures in a continuous flow ohmic heater. J Food Process Eng 15:263–278

Sastry SK (1997) Measuring residence time and modeling the system. Food Tech 51(10):44–48

Sastry SK, Cornelius BD (2002) Aseptic processing of foods containing solid particulates. John Wiley and Sons, Inc, New York

Sastry SK, Palaniappan S (1992) Ohmic heating of liquid–particle mixtures. Food Tech 46(12):68–72

Schreier P, Reid D, Fryer P (1993) Enhanced diffusion during the electrical heating of foods. Int J Food Sci Tech 28:249–260

Segner WP, Ragusa TJ, Marcus CL, Soutter EA (1989) Biological evaluation of a heat transfer simulation for sterilizing low-acid large particulate foods for aseptic packaging. J Food Process Preserve 13:257–274

Shim JY, Lee SH, Jun S (2010) Modeling of ohmic heating patterns of multiphase food products using computational fluid dynamics codes. J Food Eng 99:136–141

Shirsat N, Lyng JG, Brunton NP, McKenna B (2004) Ohmic processing: electrical conductivities of pork cuts. Meat Sci 67:507–514

Shynkaryk M, Sastry SK (2012) Simulation and optimization of the ohmic processing of highly viscous food product in chambers with sidewise parallel electrodes. J Food Eng 110:448–456

Skudder PJL (1992) Long life products by ohmic heating. Int Food Ingre 4:36–41

Skudder P, Biss C (1987) Aseptic processing of food products using ohmic heating. Chem Eng 2:26–28

Stirling R (1987) Ohmic heating-a new process for the food industry. J Power Eng 6:365–371

Takhistov P (2007) Dimensionless analysis of the electric field based food processes for scale-up and validation. J Food Eng 78:746–754

Toyoda IA (1994) Computational model for reaction fouling from whey protein solutions. Fouling and cleaning in food processing. Jesus College Cambridge, 23–25. March, 1994, pp 222–229. ISBN 92-827-4360-8

Tucker GS, Withers PM (1994) Determination of residence time distribution of nonsettling food particulates in viscous food carrier fluids using Hall effect sensors. J Food Process Eng 17:401–422

Tulsiyan P, Sarang S, Sastry SK (2008) Electrical conductivity of multi component systems during ohmic heating. Int J Food Prop 11:233–241

USA-FDA. United States of America, Food and Drug Administration, Center for Food Safety and Applied Nutrition Kinetics of microbial inactivation for alternative food processing technologies: ohmic and inductive heating 2000. http://www.cfsan.fda.gov/wcomm/ IFT-OHM. html. at: February 17th, 2009. Accessed on 14/08/2011

Wang W, Sastry S (1993a) Salt diffusion into vegetable tissue as a pre-treatment for ohmic heating: electrical conductivity profiles and vacuum infusion studies. J Food Eng 20:299–309

Wang W, Sastry S (1993b) Salt diffusion into vegetable tissue as a pretreatment for ohmic heating: determination of parameters and mathematical model verification. J Food Eng 20:311–323

Wang W, Sastry S (2000) Effects of thermal and electrotermal pretreatments on hot air drying rate of vegetable tissue. J Food Process Eng 23(4):299–319

Ward DR, Price RJ (1992) Food microbiology: exact use of an inexact science. In The NFI Green Book, vol 3, pp 34–42. National Fisheries Institute, Washington, DC. 1992

Weaver JC (1987) Transient aqueous pores: a mechanism for coupling electric fields to bilayer and cell membranes. In: Blank M, Findl E (eds) Mechanistic approaches to interactions of electric and electromagnetic fields with living systems. Plenum Press, New York, pp 249–270

Wills TM, de Witt CAM, Sigfusson H, Bellmer D (2006) Effect of cooking method and ethanolic tocopherol on oxidative stability and quality of beef patties during refrigerated storage (oxidative stability of cooked patties). J Food Sci 71:109–114

Wu H, Kolbe E, Flugstad B, Park JW, Yongsawatdigul J (1998) Electrical properties of fish mince during multi-frequency ohmic heating. J Food Sci 63(6):1029–1032

Yang TCS, Cohen JS, Kluter RA, Tempest P, Manvell C, Blackmore SJ, Adams S (1997) Microbiological and sensory evaluation of six ohmically heated stew type products. J Food Qual 20:303–313

Zell M, Cronin DA, Morgan DJ, Marra F, Lyng JG (2008) Solid food pasteurization by ohmic heating: influence of process parameters excerpt from the proceedings of the COMSOL Conference Boston. 2008

Zell M, Lyng JG, Cronin DA, Morgan DJ (2009) Ohmic heating of meats: electrical conductivities of whole meats and processed meat ingredients. Meat Sci 83:563–570

Zell M, Lyng JG, Cronin DA, Morgan DJ (2010) Ohmic cooking of whole beef muscle—evaluation of the impact of a novel rapid ohmic cooking method on product quality. Meat Sci 86:258–264

Zhang L, Fryer PJ (1993) Models for the electrical heating of solid–liquid mixtures. Chem Eng Sci 48:633–643

Zhao Y, Flugstad B, Kolbe E, Park JW, Well JH (2000) Using capacitative (radiofrequency) dielectric heating in food processing and preservation. J Food Process Eng 23:25–50

Zhong T, Lima M (2003) The effect of ohmic heating on vacuum drying rate of sweet potato tissue. Bioresour Technol 87:215–220

Zoltai P, Swearingen P (1996) Product development considerations for ohmic processing. Food Tech 50:263–266

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Varghese, K.S., Pandey, M.C., Radhakrishna, K. et al. Technology, applications and modelling of ohmic heating: a review. J Food Sci Technol 51, 2304–2317 (2014). https://doi.org/10.1007/s13197-012-0710-3

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-012-0710-3