Abstract

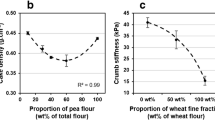

Managing the quality of pea-enriched cakes made from mixes of wheat and pea flours in various proportions (10, 35, and 60 wt% of pea, flour basis) and with various particle size distributions (0, 50, and 100 wt% of particles < 63 µm) is a challenge for the industry. A “multiobjective” model based on an I-optimal response surface design was set up in a previous study. It allows obtaining target cake structural and textural properties by adjusting several processing parameters (mixing speed and time, baking program). As the model’s ability to correct the variations in cake properties due to variations in flour properties remained to be proven, two case studies concerning the proportion and the particle size of pea flour were studied. A variation of crumb stiffness (24 to 37 kPa), lightness (85.4 to 79.6 in L*), and cell fineness (4.9 to –4.8 in PC1 score) could be observed with the increase in the proportion of pea flour from 0 to 35 wt%, and these variations were properly corrected by the model (corrected values: 28 kPa; 83.2 in L*; 3.7 in PC1 score). A change in the particle size of pea flour caused variations in cake properties inferior to those due to processing reproducibility, except for cake symmetry (7.5 to 10.1 in symmetry index; corrected value: 7.2). A selection of products representative of the diversity of cakes from the original design space was investigated by 11 trained panelists through quantitative descriptive analysis. A convergence between sensory and instrumental results was found concerning structural and textural properties. Additional sensory perceptions such as beany attributes or in-mouth drying aftertaste were pointed out.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

There is an urgent need for an agroecological transition to improve the sustainability of our food chains from fields to foods. The increasing pressure of climate change will affect cultural conditions. Moreover, better agricultural practices will have to be adopted such as removing chemical inputs (pesticides and fertilizers). Thus, it is highly likely that one will have to face an increase in the variability of raw materials in the future. Intercropping wheat and legume crops is an agroecological practice that allows to significantly decrease the carbon footprint and greenhouse gas emissions associated to wheat growing (Nemecek et al., 2008). Thus, the formulation of legume-enriched cakes could promote the development of sustainable food chains including the use of composite flours made from wheat and legume grains grown and harvested together.

However, in these conditions, the composite flours would present consequential variations in their properties, among which the proportions of both species in the mix and the particle sizes of both flours in the mix (Monnet et al., 2019a). In our current standardized food chains, the quality of manufactured products needs to be stable to guarantee stable sensory properties (texture, flavor, structure) to be perceived by the consumer, with the least processing constraints possible. Indeed, processing is usually rather inflexible and the raw materials are as standardized as possible. Being able to handle raw materials with more variability requires juggling the processing variables (De Vries et al., 2017). To be able to do so, specially designed tools are needed to monitor the quality of the end product as a function of the processing variables.

In baked cereal products such as soft cakes, the main raw material is flour, and the functionalities of its two main components, protein and starch, are essential to the structure of the final product. Proteins enhance batter viscosity and thermoset during baking through the formation of intermolecular disulfide bonds (Dewaest et al., 2017). Starch granules swell and gelatinize during baking, to form the structuring “bricks” of the cell walls surrounded by a protein “mortar” (Donovan, 1977). Beyond the agricultural benefits of intercropping, introducing legume flour in 100% wheat cakes is a way to improve their nutritional properties, as the essential amino acid profiles of wheat and legume proteins are complementary (Berrazaga et al., 2019; Floret et al., 2021). While most wheat proteins are not suitable for emulsification or foaming due to their poor solubility in water at neutral pH, legume proteins have moderate to high emulsifying and foaming properties (Boye et al., 2010). Furthermore, higher protein denaturation and starch gelatinization temperatures have been reported for legumes (Monnet et al., 2019b). Cake quality thus depends on both the raw materials and the conditions under which these are functionalized, which depend on the processing parameters. Processing comprises single or multistage mixing followed by baking. Monnet et al. (2019c) showed that, in multistage mixing, the order, speed, and length of the mixing steps of the ingredients might influence the cake end structure. Taking into account both raw material variability and influential processing parameters, these authors built an experimental design to study the effect of 7 explanatory variables on 6 dependent variables of cake structure (cake density, cake symmetry, crumb stiffness, cell fineness, thickness of cell walls, and crumb lightness). Experimental designs generally aim to account for a large number of effects with a minimum number of trials (Hunter & Muir, 1991; Weissman & Anderson, 2015). However, a review of existing food studies on product optimization shows that experimental designs usually include only two or three explanatory variables (Battaiotto et al., 2013; Bitaraf et al., 2012; Kayacier et al., 2014; Milde et al., 2012; Saxena et al., 2012; Tan et al., 2012; Turabi et al., 2008).

Among the explanatory variables chosen by Monnet et al. (2019c), flour quality variables included the proportion of pea flour in the total mass of flour, the particle size of the pea flour, and the particle size of the wheat flour. These properties were identified as the most likely variabilities associated to the production of composite flours from wheat and legume intercrops harvested and ground together. The remaining explanatory variables corresponded to processing variables used to adjust cake quality; they were related to batter mixing (liquids and oil mixing speeds, oil mixing time) and to the baking program. They were chosen as the most influential among a broader set of variables following a phase of preliminary tests (Monnet et al., 2019c).

A full factorial experimental design with the quadratic variations of the dependent variables would require a total of 19,683 trials. Consequently, the choice was made of an optimal design. Optimal designs are custom designs that make it possible to reduce further the number of trials and to include specific constraints such as blocking factors while minimizing the variance of the estimators of parameters (Del Castillo, 2007; Goos & Jones, 2011). An I-optimal design was chosen. I-optimality refers to the orientation of the design towards a good prediction capacity of the model through the minimization of the average variance of prediction, while D-optimality aims to minimize the variance of factor-effect estimates thus giving priority to modelling precision (Del Castillo, 2007; Goos & Jones, 2011; Goos et al., 2016). In order to build an efficient correction tool, I-optimality was thus preferred to D-optimality. This choice was supported by the diagnosis of simulated optimal designs as well as existing literature guidelines (Jones & Goos, 2012).

The resulting experimental design only required 56 trials and 8 days of experiments, which was much more feasible. This I-optimal design allowed the building of a multiobjective model to correct variations in the physical properties of the cake by adjusting the processing parameters. The multiobjective model was obtained by taking all responses into account simultaneously in the selection of the most significant effects. The prediction capacity of the model was validated with two trials within the space design repeated three times each, several weeks apart.

This specific approach from Monnet et al. (2019c) was contrasting with existing literature on modeling and optimization based on experimental designs. Indeed, with two or three explanatory variables, experimental designs include generally less than 20 trials (Battaiotto et al., 2013; Bitaraf et al., 2012; Kayacier et al., 2014; Milde et al., 2012; Saxena et al., 2012; Tan et al., 2012; Turabi et al., 2008). They define the models for the variation of the responses independently and predict an optimum condition with no experimental validation of the model. However, the study from Monnet et al. (2019c) shared some gaps with available literature. In the literature, the prediction capacity of the models is rarely used to simulate variations in responses following a change in the variables or to simulate a correction of the variables needed to reach a goal. Moreover, while the relationship between instrumental and sensory data has been widely studied with the aim of reducing dependence on human involvement in predicting sensory perception (Jha et al., 2013; Lassoued et al., 2008; Penci et al., 2013), the correction efficiency of a model designed using a response surface methodology has never been evaluated from the viewpoint of descriptive sensory analysis. In the study of Monnet et al. (2019c), similarly, the efficiency of the model in correcting variations in flour quality was not evaluated, and the resulting corrections were not compared with the differences perceived by consumers.

The aim of the present study was to evaluate and explain the correction efficiency of a multiobjective model based on instrumental evaluation of cake properties. To this end, two case studies were designed to evaluate variations in flour quality. A desirability function (Costa et al., 2011) was used to define the changes in the processing settings required to obtain the properties of the target product despite variations in the quality of the raw material. The physical properties of the original, degraded, and corrected products obtained were compared to evaluate the correction efficiency at instrumental level. Based on a broad range of sensory attributes, their differences were then assessed by a trained panel through descriptive sensory analysis. The products were tested alongside a set of products representative of the diversity of cakes generated by the I-optimal design.

Materials and Methods

Materials

Wheat flour (55% extraction rate, 9.5 wt% protein, 13.9 wt% moisture, 0.5 wt% ash) was supplied by Grands Moulins de Paris (Ivry-sur-Seine, France), and pea flour (21.4 wt% protein, 9.8 wt% moisture, 2.1 wt% ash) was supplied by Moulin Meckert-Diemer (Krautwiller, France). Moisture contents were determined by oven drying for 90 min at 130°C (French standard NF V03-707) and ash contents by dry combustion for 90 min at 900°C (French standard NF V03-720). Protein contents were analyzed using the Kjeldahl procedure (AACC 46-12 standard method) with the most usual conversion factors of 5.7 for wheat flours and 6.25 for legume flours. The pea fine fraction, which was found to impact the cell structure of cakes (Monnet et al., 2019c), was obtained by sieving pea flour and characterized as described in Monnet et al. (2019a). Other cake ingredients and their suppliers are as follows: pasteurized liquid whole eggs containing 9.5 wt% of proteins and 82.6 wt% of water (Ovoteam, Locminé, France); rapeseed oil (Lesieur, Asnières-sur-Seine, France); white sugar (Saint Louis Sucre, Paris, France); glucose syrup DE40 containing 17.40 wt% of water (Louis François, Croissy-Beaubourg, France); glycerol (Louis François, Croissy-Beaubourg, France); emulsifier Spongolit® 542 (BASF France S.A.S, Levallois-Perret, France) containing 6.8 wt% of proteins, 1.2 wt% of water, and 92 wt% of lactic and acetic esters of mono- and diglycerides of fatty acids; baking powder (Dr. Oetker France S.A.S, Schirmeck, France); and salt of commercial grade.

Batter and Cake Preparation

The cake formula was an industrial formula taken from Dewaest et al. (2017). It was composed of 350 g flour, 135 g eggs, 125 g sugar, 118 g glucose syrup, 110 g water, 80 g rapeseed oil, 62 g glycerin, 17 g emulsifier, 12 g baking powder, and 2 g salt for a total batch of 1011 g of batter. The batter and cake were prepared following the reference procedure in Monnet et al. (2019c) based on industrial standards. All baking conditions (temperature, time) were chosen in order to obtain cakes with 0.75 as aw value. Cake water content and water activity were verified to be the same for all trials (data available in Online Resource 1).

Two sets of products were prepared giving a total of 12 products. The first set was a selection of seven products amongst the 56 trials generated by the I-optimal design (Monnet et al., 2019c). The selection logic is described and discussed in the “Results and Discussion” section. The settings of the explanatory variables for these products are presented in Table 1. The second set of products was related to the correction case studies.

In the first case study, the proportion of pea flour was increased from 0 to 35% in a cake produced following the reference procedure. The proportion of 35% was chosen because it corresponded to the best estimated balance in the essential amino acid profile. The 0% pea cake was the “target product” (T1); its settings are listed in Table 2. Its physical properties were measured to define the target for the desirability function. The “degraded product” (D1) was the cake with 35% pea flour produced using the same processing settings as T1 above (Table 2). The desirability function was used to define the processing settings of the “corrected” 35% pea cake (C1). The correction consisted in increasing the liquids mixing speed from speed 171 to 266 rpm (rotation of the mixing arm in the planetary movement, corresponding to an increase of the KitchenAid setting from 4 to 8), the oil mixing time from 1 to 5 min, and decreasing the baking temperature from 180 to 179 °C. Baking time changed as a result from 18.0 to 18.3 min, following a linear dependency of cake water activity to baking time that was established previously in the range of baking temperatures covered by the study (results not shown). This temperature and time adjustments were very small and might become negligible in real industry conditions. However, baking temperature was shown to be the second most influential explanatory variable after the proportion of pea flour and before the mixing parameters (Monnet et al., 2019c).

In the second case study, the proportion of the pea fine fraction was increased from 50 to 100% in a cake with 35% pea flour produced following the reference procedure. The target product (T2) was a 35% pea cake with 50% pea fine fraction like product D1; it was experimentally the same product as the degraded product D1 (same batch of production). The degraded product (D2) was a 35% pea cake with 100% pea fine fraction produced following the same procedure (Table 2). The desirability function, set with the physical properties of T2 as the target, proposed the following changes to produce the corrected product C2: a decrease in liquids mixing speed from 171 to 104 rpm (KitchenAid setting from 4 to 1), an increase in oil mixing speed from 104 to 115 rpm (Kitchen Aid setting from 1 to 2), and a decrease in baking temperature from 180 to 165 °C.

After the experimental conditions were defined, all the products were produced in duplicate for assessment of their physical and sensory properties and evaluation of the reproducibility of cake processing at a given time. Moreover, the repetitions of target products T1 and T2, already produced a few months earlier for the desirability function, were named T1’ and T2’. Some differences in the physical properties of these repetitions were observed. The differences can be explained by seasonal variations in room temperature during the 6-month period of the experiments and represent cake processing reproducibility taking into account flour aging phenomenon as pointed out by Dewaest et al. (2018).

Cake Instrumental Properties

The set of cake physical properties measured corresponded to the response variables taken into account in the I-optimal design described in Monnet et al. (2019c). They comprised cake density (g.cm−3), symmetry index, crumb stiffness (kPa), cell fineness (PC1 score), cell wall thickness (PC2 score), and crumb lightness (L).

The cakes were weighed immediately after being unwrapped, and their volume was measured using a laser-based scanner (VolScan Profiler, Stable Micro Systems, Surrey, UK) with an increment of 2 mm and a rotation speed of 1 rps. Cake density (g cm−3) was calculated from the ratio of their mass (g) to their volume (cm3). The laser-based scanner provided a profile of the cake representing the change in its circumference along its longitudinal axis through the succession of 46 to 47 slices separated by an increment of 2 mm (total cake length was approximately 90 mm). This data was used to calculate an adapted symmetry index as defined by the AACC method 10-91 (AACC, 2010). The height in the center of the slice was measured on three slices situated respectively at one-fourth (B), one-half (C), and three-fourths (D) of the cake length, and the usual calculation was done (symmetry index = 2 × C − B − D).

The mechanical properties of the cake were determined after 1 week of storage using a TAHD plus texture analyzer (Stable Micro Systems, Surrey, UK) equipped with a 750-kg load cell. Just after the cake was unwrapped, a cutting template and a bread knife were used to remove its top crust and a part of the four sides to obtain rectangular crumb samples (length 58 mm, width 26 mm, height 26 mm) located in the bottom center of the cakes. Each sample was subjected to 90% uniaxial compression with a 10-cm-diameter aluminum plate at a constant speed of 2 mm/s (pre-test speed 1 mm/s, trigger force 0.5 N). The resulting curves of force (N) versus distance (mm) were converted into stress-versus-strain curves using the sample dimensions. The apparent Young modulus of the aerated crumb, representing crumb stiffness, was calculated as the initial slope of the stress-versus-strain curve.

The cell structure of the crumb was characterized using image analysis by mathematical morphology described in Dewaest et al. (2018). For image acquisition, the cakes were cut with a bread knife along their longitudinal axis. Both sides were gently cleaned with a brush to remove loose crumbs from the cellular structure and the sample was placed on a flatbed scanner (HP Scanjet G31110, Hewlett-Packard, Palo Alto, CA, USA). A black box was placed on top of the sample, and a full color image was acquired at a resolution of 600 dpi. The program for image processing was run using MATLAB software version 7.9.1.705 (The MathWorks, Natick, MA, USA), and the PCA was realized with XLSTAT Software version 18.06 (Addinsoft, Paris, France). In this study, interpretation of the similarity map of the cake crumb structures gave PC1 as the expression of cell fineness and PC2 as the expression of cell wall thickness.

Crumb color was measured using a spectrophotometer (Spectro-guide 6834, BYK-Chemie GmbH, Wesel, Germany) with standard illuminant D65. One cake per batch was cut with a bread knife along its longitudinal axis, and one of the two sides was chosen for color measurement. After calibration and verification of the measurement repeatability on the first sample, color measurement was made one time at the center of the longitudinal slice for each cake. Results are expressed in the CIE L*a*b space.

Descriptive Sensory Analysis

A panel of 11 volunteers (10 females, 1 male, aged between 22 and 56) were recruited among AgroParisTech staff. The panelists were recruited based on their willingness to participate, and all the panelists gave their free and informed consent. They were in good health at the time of testing and were compensated for their participation at the end of the study. The descriptive analysis procedure was based on conventional quantitative descriptive analysis (Lawless & Heymann, 2010). A total of six sessions was necessary to set up the panel: two sessions were dedicated to the generation and selection of attributes and four sessions to training in the use of these attributes for quantitative description of the products. All 12 products were used but were grouped differently in each session.

The first training session was devoted to generating the attributes. During this session, the panelists developed a vocabulary including appearance, texture when touched, oral texture, flavor, and aftertaste in order to describe differences between the products. During the second training session, they selected 16 attributes to distinguish between the products, agreed on their definition and on the limits of the intensity line scales (Table 3). The panelists were trained in the proper use of a 10-cm unstructured linear scale in which extremities were defined as “very weak” and “very intense” perceptions.

During the four following training sessions, they were trained to evaluate the intensities of the attributes on series of five products. Sessions were designed so that panelists were trained on all products, and all sessions were repeated twice. Then, evaluation of the 12 products was organized over six sessions, including repetitions. Only four samples were evaluated during a session. The products were presented to the panelists successively and each attribute was rated on the 10-cm unstructured line scale. The cakes (small individual, approx. 40 g) were presented on 3-digit coded plastic plates, in monadic sequential order according to the Williams Latin Square to balance the order of presentation. As cake formula contained emulsifiers, the evolution of the crumb texture due to staling was so slow that it became noticeable only after several weeks (Dewaest et al. 2018). Thus, samples were evaluated between 1 day and 1 week after fabrication without any noticeable sensory bias. Training and evaluation sessions were conducted in individual booths under white light in an air-conditioned room (20 °C). The panelists were asked to rinse their mouth with mineral water between samples.

Statistical Analysis

JMP software version 13.1.0 (SAS Institute Inc., Cary, SC, USA) was used for multiobjective optimization of the responses based on the I-optimal design presented in Monnet et al. (2019c). A composite desirability function was used to define the changes in the settings of the processing variables between degraded products (D1, D2) and corrected products (C1, C2) in order to target the physical properties of the target products (T1, T2). The composite desirability function corresponded to the weighted geometric average of individual desirability functions for the six responses of §2.3 (weight = 1).

XLSTAT software version 18.06 (Addinsoft, Paris, France) was used to perform hierarchical cluster analysis (HCA), principal component analysis (PCA), analysis of variance (ANOVA), and generalized Procrustes analysis (GPA) (Gower, 1975). An HCA (Euclidian distances, Ward’s criterion) and a PCA were performed on the instrumental properties of the 56 trials from the I-optimal design to select a set of products representative of the design space among the clusters of distinctive properties and to illustrate the distribution of the clusters as a function of the most distinctive response variables, respectively. The instrumental properties of the 56 trials from the I-optimal design from Monnet et al. (2019c) used for the analyses are available in Online Resource 2.

A second PCA was performed of the instrumental properties of the 56 trials as principal observations and the instrumental properties of the products representative of the design space and of the products from the case studies as supplementary observations. This PCA revealed variations in instrumental properties through correction in the two case studies expressed as a function of the most distinctive response variables. The overall and individual homogeneity, discrimination ability, and repeatability of the panel performances were validated using ANOVA; the consensus among panelists was checked with GPA. For each attribute, a three-way ANOVA (overall performance) or a two-way ANOVA (individual performance) was performed on the effects of product, repetition, and panelist (only for overall performance) with their estimable interactions. In the ANOVA, when significant differences between products were revealed (P ≤ 0.05), mean intensities were compared using Tukey’s HSD test (P ≤ 0.05). The conclusion of the test was an ability of the panel to evaluate the cake sensory properties using the 16 attributes and to discriminate them in a homogeneous and repeatable way. Finally, a PCA was performed on the sensory properties of the 12 products tested by the panel with their instrumental properties as supplementary observations.

Results and Discussion

Selection of Products Representative of the Design Space

A hierarchical cluster analysis (HCA) was performed to select a reduced number of products to represent the differences in instrumental properties of the 56 trials generated by the I-optimal design. This approach assumed that two products with similar instrumental properties must have similar sensory properties. The dendrogram obtained from the HCA is shown in Fig. 1a. Six clusters of products were identified among the 56 trials. The clusters were unequal in size, containing between four (clusters A, B, F) and 18 products (clusters C and D). They are represented on the product maps of the principal component analysis (PCA) of the instrumental properties according to principal components 1 and 2 (Fig. 1c) and principal components 2 and 3 (Fig. 1e). The corresponding loadings plots are presented in Fig. 1b and d. The six clusters were well separated according to the two first components that accounted for 72% of the variance (Fig. 1c). The first component mainly represented the variation in crumb stiffness and discriminated cluster F from cluster E, and from clusters A to D. The second component, accounting for 24% of the variance, did not directly represent the variation of any response. Density and cell wall thickness (CWT) were expressed in the first quartile and discriminated cluster F and cluster D from the other clusters. Crumb lightness and cell fineness (CF) were expressed in the last quartile and discriminated cluster B from clusters A and C and from clusters D to F. Thus, density and CWT were not correlated with crumb lightness and CF. The third component, accounting for 15% of the variance, mainly represented the variation in symmetry index (Fig. 1d), but it was not used by the HCA to discriminate the products.

Hierarchical cluster analysis dendogram (a) showing the distribution of the 56 trials in clusters according to their instrumental properties; (b–e) principal component analysis (PCA) of instrumental properties with loadings plots (b, d) and product maps with qualitative identification of the clusters (c, e): (b–c) PCA on the PC1 and PC2 plan (71.6% of information); (d–e) PCA on the PC2 and PC3 plan (38.7% of information)

Clusters represent groups of products with similar instrumental properties. The clusters were used to identify the products whose value was the closest to the minimum, mean, or maximum of the response distribution for each of the six instrumental responses. The products that fulfilled this condition for several responses at the same time were selected in order to reduce the number of products to test in sensory analysis. Fig. 2 shows photos of the seven products selected (3 and 17 from cluster A, 19 and 29 from cluster C, 9 from cluster D, 7 from cluster E, 18 from cluster F) plus product 8 from cluster B that was eliminated because its highly fragmented cell structure was judged unsuitable for sensory analysis. Indeed, cluster B comprised the maximum values of the fineness and lightness distributions. Consequently, product 8 was replaced by product 19 from cluster C and product 3 from cluster A; these products exhibited, respectively, the closest values of lightness and fineness at the time of the I-optimal design (product 3 exhibited a lower value of fineness when it was produced in the present study). The presence of a second product in clusters A and C (products 17 and 29) made it possible to cover the broadest range of symmetry values (Fig. 1d, e). The photos in Fig. 2 reveal the range of the instrumental properties, illustrated for example by products 18 and 19 that differ in density, crumb stiffness, CF, and crumb lightness.

Photos of the longitudinal sections of the cakes and (on the right) close ups of the crumb structure of the products representative of the six clusters. Mean values of the instrumental properties are given for each product, with minimum and maximum values in italics and bold. CF, cell fineness; CWT, cell wall thickness; L*, crumb lightness

Instrumental Correction Efficiency of the Model

To visualize the instrumental correction efficiency, the paths between the target, degraded, and corrected products were drawn on the product maps of the PCA of the instrumental properties according to principal components 1 and 2 (Fig. 3a for case study 1; Fig. 3b for case study 2) and principal components 2 and 3 (Fig. 3c for case study 1; Fig. 3d for case study 2). The most influent response variables of the loadings plots (Fig. 1b, c) are identified by the gray arrows on the product maps to help interpretation. The target products T1 and T2 used for the definition of the desirability function were not superimposed with their repetitions T1’ and T2’ on any of the maps. This corresponded to the differences due to cake processing reproducibility over the 6-month interval. The differences can be seen in Figs. 4 and 5. These differences were used as a benchmark in the analysis of the correction efficiency of the model; they were considered as the maximum acceptable difference between two products in the case studies for the model to correct efficiently.

Paths for the optimization of cake quality for case studies 1 (a, c) and 2 (b, d) on the product maps of the PCAs of the instrumental properties in the 56 trials as principal observations (gray-filled circle) and instrumental properties of the products representative of the design space (black-filled circle) and of the products from the case studies (open triangle) as supplementary observations: a, b PCAs on PC1 and PC2 (71.6% of information) from case studies 1 and 2 respectively; b, d PCAs on PC2 and PC3 (38.7% of information) from case studies 1 and 2, respectively

Photos of the longitudinal sections and (on the right) close ups of the crumb structure of the products of case study 1. T1, initial target for the desirability function; T1’, target assessed by descriptive sensory analysis; D1, degraded product; C1, corrected product. CF, cell fineness; CWT, cell wall thickness; L*, crumb lightness

Photos of the longitudinal sections and (on the right) close ups of the crumb structure of the products of case study 2. T2, initial target for the desirability function; T2’, target assessed by descriptive sensory analysis; D2, degraded product; C2, corrected product. CF, cell fineness; CWT, cell wall thickness; L*, crumb lightness

In the first case study, D1 shifted to the right of the map in comparison to T1 and T1’. The introduction of 35% of pea flour in a 0% pea cake caused an increase in crumb stiffness according to the first component, that was further corrected as C1 shifted back near T1 and T1’ (Fig. 3a). According to the other significant response variables in the PC1–PC2 map, there was a decrease in crumb lightness and cell fineness for D1 in comparison to T1 and T1’ that was also corrected in C1. While the variation in crumb lightness is visible (Fig. 4), it is doubtful whether the variation in cell fineness would be perceived by trained panelists. Finally, the addition of pea flour did not cause any perceptible change in density and cell wall thickness, neither did the correction by adjusting the processing parameters (Fig. 3a). In the PC2–PC3 map, all symmetry variations between the products are smaller than the distance between T1 and T’1 (Fig. 3c) so it cannot be concluded a perceptible variation in symmetry.

In the second case study, the increase in the proportion of pea fine fraction from 50 to 100% in a 35% pea cake caused a modification of instrumental properties that barely outweighed the differences due to processing reproducibility (Fig. 3b) except for symmetry (Fig. 3d). Indeed, the photos of the cakes revealed fewer differences between the target and degraded products than in the first case study (Fig. 5). The position of C2 in comparison to D2 and T2 and T2’ showed that the changes in processing parameters satisfactorily corrected symmetry (Fig. 3d). However, the other variables were not corrected (stiffness and crumb lightness), degraded (cell fineness), or overcorrected (density and wall thickness) (Fig. 3b). Overall, these results show that the multiobjective model was able to satisfactorily correct some modifications in the cake properties when they exceed the differences corresponding to processing reproducibility. To further evaluate the model efficiency, the instrumental correction of the properties should now be compared to the changes in properties actually perceived by trained panelists.

Sensory Characterization

A principal component analysis (PCA) was performed of the sensory properties of the 12 products according to the 16 attributes with their instrumental properties as supplementary observations. Fig. 6a shows the loadings plot according to the two first dimensions with categorization of the attributes depending on their orientation. The first component accounted for 55% of the variance and expressed the attribute “pasty-sticky” versus, on one hand, the firmness attributes (oral firmness and firmness when touched) correlated with crumb color and, on the other hand, the “toasted” attribute correlated with crust color (Fig. 6a). Instrumentally, it was observed that crumb stiffness varied inversely with crumb lightness and cell fineness (Fig. 1b). Here, instrumental crumb lightness and cell fineness were negatively correlated with sensory “firmness when touched” (−0.798 and −0.854 respectively) and crumb color (−0.865 and −0.839) and positively correlated with the “pasty-sticky” attribute (+ 0.900 and + 0.853). Instrumental crumb stiffness was positively correlated with sensory “firmness when touched” (+ 0.726) and oral firmness (+ 0.685) although it did not appear clearly in the PC1–PC2 plane. The lower firmness value and the darker color of the crumb perceived by the panelists were thus related to a lower cell fineness measured instrumentally. The cakes with lighter and softer crumbs were perceived as stickier after chewing and before swallowing. The finer cell structure of these cakes could result in faster kinetics of hydration by saliva that would enhance cell breakage and collapse, and early amylolysis, giving rise to a more adhesive bolus. The correlation between toasted flavor and crust color reflected the baking intensity of the cake, driven by baking temperature. Cakes baked at a higher temperature (200 °C, 180 °C, 160 °C) were perceived as less sticky.

Principal component analysis (PCA) on the PC1 and PC2 plan (80.1% of information) of sensory properties as principal observations and instrumental properties as supplementary observations: a loadings plot with sensory variables relative to PC1 axis (

), PC2 axis (

), PC2 axis (

), relative to PC1 & PC2 axes (

), relative to PC1 & PC2 axes (

), and instrumental variables (

), and instrumental variables (

); b product map with the paths for the optimization of cake quality. In a, the variables that are statistically significant in the plane are represented in bold characters

); b product map with the paths for the optimization of cake quality. In a, the variables that are statistically significant in the plane are represented in bold characters

The second component accounted for 25% of the variance and expressed the “in-mouth drying” attribute versus the “crumbliness” attribute (Fig. 6a). The “volume,” “brightness,” and “crumb aeration” attributes grouped in the third quartile. Crumb aeration, defined as the dense or aerated aspect of the crumb, appeared to be related to the total amount of air incorporated in the cake rather than to cell fineness per se. The measurement of cell fineness at the millimetric scale, as well as cell wall thickness, provided additional information to that provided by the panelists’ perceptions. According to the regression coefficients of the multiobjective model (Monnet et al., 2019c), cake density decreases with an increase in mixing speed or baking temperature. The higher volume, crumb aeration, and brightness of the cakes perceived by the panelists could result from these factors. The “beany” and “beany persistency” attributes were grouped in the fourth quartile. Finally, the perceptions of “sweet,” “friability,” and “crack intensity” were slightly less well represented in the plane of the two first dimensions. This was due to a very high degree of similarity between the products as indicated by the three-way ANOVA on the panel performances (§2.5). The depth of the crack in the crust was perceived as high as the volume of the cake, in accordance with physical observations made on pound cake structure (Monnet et al., 2020). The correlation of the “sweet” perception with the instrumental cell fineness is an original result that brings reflection back to the understanding of perception during oral processing. One can assume that a very fine crumb is more extensively comminuted in the mouth after one or two bites, as well as more extensively soaked by saliva which quickly absorbs through the cellular structure thanks to efficient capillary mechanisms. Thus, saliva gets in a faster contact with all cellular surface area, solubilizing more sucrose than for a coarser crumb.

Fig. 6b shows the product map. The 12 products were evenly distributed in all directions. In the first case study, the introduction of 35% of pea flour in a 0% pea cake caused a modification according to the first component that was properly corrected (Fig. 6b). Degraded 35% pea cakes (D1) were perceived as less sticky, with firmer and darker crumb, with a darker crust and a more toasted flavor than target 0% cakes and corrected 35% pea cakes. The addition of pea flour using the same processing settings led to the formation of a coarser and stiffer crumb as described in Monnet et al. (2020). Bigger cells were obtained because of the reduced capability of the legume-enriched batter to retain air bubbles during baking, due to its lower viscosity and/or the distribution of bubbles in the batter (Ronda et al., 2011). For the corrected 35% pea cakes, the increase in both egg and sugar mixing rate and oil mixing time led to a decrease in bubble sizes in the batter and thus in the crumb cell sizes (i.e., an increase of the crumb fineness) (Monnet et al., 2020). This is in agreement with the variation observed in instrumental crumb firmness and lightness. However, according to the second component, one modification was not corrected and was even increased by correction. It corresponded to the decrease in crumbliness and to the increase in the “in-mouth drying” attribute. Products 9 and 29 that also received high “in-mouth drying” scores were characterized by a high pea flour content (60%) and high mixing speeds (Table 1). The addition of pea flour from 0 to 35% caused a first increase in the “in-mouth drying” perception and the correction with a higher liquids mixing speed exacerbated it because this dimension was not taken into account in the multiobjective model which focused only on structure and texture properties. Furthermore, the addition of pea flour caused an increase in the “beany” and “beany persistency” perceptions that was not corrected. The presence of these sensory off-notes in high protein foods were described in literature. Indeed, legume proteins are known to introduce unpleasant off-notes (bitter, beany notes, etc.) whatever the food applications (Chumchuere et al., 2000; Jayasena & Nasar-Abbas, 2012; Roland et al., 2017). The reason of the increased perceptions of in-mouth drying, pasty, sticky attributes, and the reduced perception of crumbliness in the corrected 35% pea cake could be related to oral processing. The crumb of the corrected 35% pea cake might be more extensively soaked by saliva than that of the degraded 35% pea cake, becoming stickier on the tongue, without breaking into small pieces. This phenomenon might contribute to a slightly increased residence time in mouth, which could promote off-flavor perception. These off-notes could induce disliking by the consumers. This was also a dimension that was not monitored by the model, but that could be corrected — if desired — by a flavoring of the formula. Finally, the panelists perceived no change in the “volume,” “crumb aeration,” and “brightness” attributes between T1’ and D1, but a decrease in them for C1. Compared to the instrumental variation in density, one can say that the panelists were highly sensitive to a small instrumental variation.

In the second case study, displacement of the products within the PCA map was much less important. Only a slight modification according to the second component was observed between T2’ and D2, the latter being grouped with C2. Thus, the panelists perceived the degraded and corrected product as a little less crumbly and a little more “in-mouth drying” than the target product. This confirmed that the modification was barely perceptible from a sensory point of view like from an instrumental point of view. Secondly, this confirmed that the use of our multiobjective model for flour granulometry variations was neither necessary nor efficient for modifications smaller than differences corresponding to processing reproducibility. Interestingly, the panelists perceived C2 as almost the same as D2, while its instrumental properties were closer to D2 than were those of T2’ because of several overcorrections (Fig. 3b, d).

Conclusions

Multiobjective models that make it possible to predict the best settings of several processing parameters to reach a trade-off between several target properties are very valuable tools for industry. Our model enabled monitoring of cake properties after a variation in flour quality (wheat-pea blend composition, pea fine fraction proportion) among a range of cake physical properties. Through two different case studies, it was shown that correction proposed by the model was effective when the modification caused by flour variation exceeded model sensitivity (i.e., when the difference in properties to be corrected is less than once the difference due to usual processing reproducibility, for at least one property). Otherwise, treatment by the model could lead to overcorrections like in the second case study. Sensory analysis of the products enabled the identification of convergences between measured physical properties and sensory attributes concerning cake volume or density, crumb firmness, color, cell fineness measured directly, or through indirect attributes like “pasty-sticky.” In this respect, the sensory correction efficiency of the model was adequate. Moreover, the sensory analysis revealed additional modifications like beany taste, aftertaste, and in-mouth drying that were not taken into account in the model, but could be overcome by a change in the formula or could be considered as new aromatic profiles. Beany notes are unusual notes that consumers are not familiar with at the moment. However, one can imagine that these appreciations might change with time. Even if the multiobjective model is based on instrumental variables, it was shown to be a very efficient tool to manage variations in flour composition simply by modifying processing parameters.

Data Availability

The authors declare that the data supporting the findings of this study are available within the article and its supplementary information files.

References

AACC Approved Methods of Analysis, 11th Ed. Method 10-91.01. Use of Layer Cake Measuring Template. Approved. (2010). Cereals & Grains Association, St. Paul, MN, U.S.A. http://dx.doi.org/10.1094/AACCIntMethod-10-91.01

Battaiotto, L. L., Lupano, C. E., & Bevilacqua, A. E. (2013). Optimization of basic ingredient combination for sandwich cookie filling using response surface methodology. Food and Bioprocess Technology, 6(7), 1847–1855. https://doi.org/10.1007/s11947-012-0853-2

Berrazaga, I., Micard, V., Gueugneau, M., & Walrand, S. (2019). The role of the anabolic properties of plant-versus animal-based protein sources in supporting muscle mass maintenance: A critical review. Nutrients, 11(8), 1825. https://doi.org/10.3390/nu11081825

Bitaraf, M. S., Khodaiyan, F., Mohammadifar, M. A., & Mousavi, S. M. (2012). Application of response surface methodology to improve fermentation time and rheological properties of probiotic yogurt containing Lactobacillus reuteri. Food and Bioprocess Technology, 5(4), 1394–1401. https://doi.org/10.1007/s11947-010-0433-2

Boye, J., Zare, F., & Pletch, A. (2010). Pulse proteins: Processing, characterization, functional properties and applications in food and feed. Food Research International, 43(2), 414–431. https://doi.org/10.1016/j.foodres.2009.09.003

Chumchuere, S., MacDougall, D. B., & Robinson, R. K. (2000). Production and properties of a semi-hard cheese made from soya milk. International Journal of Food Science & Technology, 35(6), 577–581. https://doi.org/10.1111/j.1365-2621.2000.00414.x

Costa, N. R., Lourenço, J., & Pereira, Z. L. (2011). Desirability function approach: A review and performance evaluation in adverse conditions. Chemometrics and Intelligent Laboratory Systems, 107(2), 233–244. https://doi.org/10.1016/j.chemolab.2011.04.004

Del Castillo, E. (2007). Process optimization: A statistical approach (Vol. 105). Springer Science & Business Media.

De Vries, H., Mikolajczak, M., Salmon, J.-M., Abecassis, J., Chaunier, L., Guessasma, S., Lourdin, D., Belhabib, S., Leroy, E., & Trystram, G. (2017). Small-scale food process engineering — Challenges and perspectives. Innovative Food Science & Emerging Technologies, 46, 122–130. https://doi.org/10.1016/J.IFSET.2017.09.009

Dewaest, M., Villemejane, C., Berland, S., Michon, C., Verel, A., & Morel, M. H. (2017). Use of SE-HPLC to follow protein profile evolution within cake batter during process. LWT- Food Science and Technology, 79, 333–341. https://doi.org/10.1016/j.lwt.2017.01.036

Dewaest, M., Villemejane, C., Berland, S., Néron, S., Clément, J., Verel, A., & Michon, C. (2018). Effect of crumb cellular structure characterized by image analysis on cake softness. Journal of Texture Studies, 49(3), 328–338. https://doi.org/10.1111/jtxs.12303

Donovan, J. W. (1977). A study of the baking process by differential scanning calorimetry. Journal of the Science of Food and Agriculture, 28(6), 571–578. https://doi.org/10.1002/jsfa.2740280616

Floret, C., Monnet, A.-F., Micard, V., Walrand, S., & Michon, C. (2021). Replacement of animal proteins in food: how to incorporate nutritional and gelling properties of alternative protein sources. Critical Reviews in Food Science and Nutrition. https://doi.org/10.1080/10408398.2021.1956426

Goos, P., & Jones, B. (2011). Optimal design of experiments: A case study approach. John Wiley & Sons.

Goos, P., Jones, B., & Syafitri, U. (2016). I-optimal design of mixture experiments. Journal of the American Statistical Association, 111(514), 899–911. https://doi.org/10.1080/01621459.2015.1136632

Gower, J. C. (1975). Generalized Procrustes analysis. Psychometrika, 40, 33–51. https://doi.org/10.1007/BF02291478

Hunter, E. A., & Muir, D. D. (1991). Statistical approaches to minimising experimentation. Food Quality and Preference, 3(2), 109–114. https://doi.org/10.1016/0950-3293(91)90030-i

Jayasena, V., & Nasar-Abbas, S. M. (2012). Development and quality evaluation of high-protein and high-dietary-fiber pasta using lupin flour. Journal of Texture Studies, 43(2), 153–163. https://doi.org/10.1111/j.1745-4603.2011.00326.x

Jha, S. N., Jaiswal, P., Narsaiah, K., Singh, A. K., Kaur, P. P., Sharma, R., Kumar, R., & Bhardwaj, R. (2013). Prediction of sensory profile of mango using textural attributes during ripening. Food and Bioprocess Technology, 6(3), 734–745. https://doi.org/10.1007/s11947-011-0720-6

Jones, B., & Goos, P. (2012). I-optimal versus D-optimal split-plot response surface designs. Journal of Quality Technology, 44(2), 85–101.

Kayacier, A., Yüksel, F., & Karaman, S. (2014). Response surface methodology study for optimization of effects of fiber level, frying temperature, and frying time on some physicochemical, textural, and sensory properties of wheat chips enriched with apple fiber. Food and Bioprocess Technology, 7(1), 133–147. https://doi.org/10.1007/s11947-013-1096-6

Lassoued, N., Delarue, J., Launay, B., & Michon, C. (2008). Baked product texture: Correlations between instrumental and sensory characterization using Flash Profile. Journal of Cereal Science, 48(1), 133–143. https://doi.org/10.1016/j.jcs.2007.08.014

Lawless, H. T., & Heymann, H. (2010). Sensory evaluation of food: Principles and practices. Springer Science & Business Media.

Milde, L. B., Ramallo, L. A., & Puppo, M. C. (2012). Gluten-free bread based on tapioca starch: Texture and sensory studies. Food and Bioprocess Technology, 5(3), 888–896. https://doi.org/10.1007/s11947-010-0381-x

Monnet, A. F., Eurieult, A., Berland, S., Almeida, G., Jeuffroy, M. H., & Michon, C. (2019a). Damaged starch in pea versus wheat flours: Fragmentation behavior and contribution of fine and coarse fractions. Cereal Chemistry, 96(3), 465–477. https://doi.org/10.1002/cche.10146

Monnet, A.-F., Laleg, K., Michon, C., & Micard, V. (2019b). Legume-enriched cereal products: A generic approach derived from material science to predict their structuring by the process and their final properties. Trends in Food Science & Technology, 86, 131–143. https://doi.org/10.1016/j.tifs.2019.02.027

Monnet, A.-F., Jeuffroy, M.-H., Michon, C., & Blumenthal, D. (2019c). Taking into account upstream variability of flours with processing variables in legume-enriched soft cakes: Conception of a multiobjective model for the monitoring of physical properties. Food and Bioprocess Technology, 12(4), 625–635. https://doi.org/10.1007/s11947-018-2230-2

Monnet, A.-F., Jeuffroy, M.-H., Villemejane, C., & Michon, C. (2020). Effect of the order of incorporation of cake ingredients on the formation of batter and the final properties: Contribution of the addition of pea flour. Journal of Food Science and Technology, 33, 1–11. https://doi.org/10.1007/s13197-020-04899-0

Nemecek, T., von Richthofen, J.-S., Dubois, G., Casta, P., Charles, R., & Pahl, H. (2008). Environmental impacts of introducing grain legumes into European crop rotations. European Journal of Agronomy, 28(3), 380–394. https://doi.org/10.1016/j.eja.2007.11.004

Penci, M. C., Martinez, M. L., Fabani, M. P., Feresin, G. E., Tapia, A., Ighani, M., Ribotta, P. D., & Wunderlin, D. A. (2013). Matching changes in sensory evaluation with physical and chemical parameters. Food and Bioprocess Technology, 6(12), 3305–3316. https://doi.org/10.1007/s11947-012-0993-4

Roland, W. S. U., Pouvreau, L., Curran, J., Van de Velde, F., & De Kok, P. M. T. (2017). Flavor aspects of pulse ingredients. Cereal Chemistry, 94(1), 58–65. https://doi.org/10.1094/CCHEM-06-16-0161-FI

Ronda, F., Oliete, B., Gomez, M., Caballero, P. A., & Pando, V. (2011). Rheological study of layer cake batters made with soybean protein isolate and different starch sources. Journal of Food Engineering, 102(3), 272–277. https://doi.org/10.1016/j.jfoodeng.2010.09.001

Saxena, A., Bawa, A. S., & Raju, P. S. (2012). Effect of minimal processing on quality of jackfruit (Artocarpus heterophyllus L.) bulbs using response surface methodology. Food and Bioprocess Technology, 5(1), 348–358. https://doi.org/10.1007/s11947-009-0276-x.

Tan, M. C., Chin, N. L., & Yusof, Y. A. (2012). A Box-Behnken design for determining the optimum experimental condition of cake batter mixing. Food and Bioprocess Technology, 5(3), 972–982. https://doi.org/10.1007/s11947-010-0394-5

Turabi, E., Sumnu, G., & Sahin, S. (2008). Optimization of baking of rice cakes in infrared–microwave combination oven by response surface methodology. Food and Bioprocess Technology, 1(1), 64–73. https://doi.org/10.1007/s11947-007-0003-4

Weissman, S. A., & Anderson, N. G. (2015). Design of experiments (DoE) and process optimization. A review of recent publications. Organic Process Research & Development, 19(11), 1605-1633. https://doi.org/10.1021/op500169m

Acknowledgements

The authors thank Marion Beugin and Clotilde Baron for their help with the sensory experiments.

Funding

This work was carried out in the framework of the FLEXIPROCESS project with financial support from the Carnot institute Qualiment. The Carnot Institute Qualiment, AgroParisTech, and the French Ministry of Higher Education, Research and Innovation provided financial support to the authors.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

• Flour variability effects were corrected by the process thanks to an I-optimal response surface design.

• The correction efficiency of the multiobjective model was proved for pea/wheat proportions variations.

• A set of instrumental cake properties was shown to be representative of sensory perceptions.

• Target instrumental cake properties were used to find adjusted processing parameters.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Monnet, A.F., Saint-Eve, A., Michon, C. et al. Tailoring the Properties of Pea-Enriched Soft Cakes Using a Multiobjective Model Based on Sensory-Relevant Instrumental Characterization. Food Bioprocess Technol 15, 459–473 (2022). https://doi.org/10.1007/s11947-021-02679-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-021-02679-y