Abstract

The investigation dealt with the effect of the replacement of a part of wheat flour by pea flour on the properties of batters and cakes. As the protein composition of pea flour differs from that of wheat, the effect of its incorporation on batter formation and cake properties was monitored throughout the different steps of cake processing. The incorporation of air, which influences the cell structure and density of the cake, was the subject of particular attention. Four orders of incorporation were first investigated to identify their effects on a standard recipe made with 100% wheat flour. Mixing first egg and sugar together allows introducing air, but most of it is lost after oil and flour introduction. Whatever the order of incorporation, the density of the batter ends around 1.1 ± 0.2 g.cm−1. However, batter consistencies are significantly different and resulting cakes show different crumb structures. These results are discussed in terms of physicochemical mechanisms, and a schematic representation of the phenomena occurring at the different steps of mixing depending on the order of ingredient incorporation is proposed. When 20 and 40% of the wheat flour was replaced by pea flour using the two most energy-efficient orders of incorporation, more air was incorporated into the batter. However, the resulting cakes were denser, but surprisingly softer. Differences in cell structure explain this apparent contradiction.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The sustainability of food systems has become a priority area for research, particularly because of their impact on the environment and health. Livestock supply chains are being targeted for their negative environmental externalities and low protein yield (Reijnders and Soret 2003; FAO 2011). Plant proteins are interesting substitutes but their essential amino acid profiles are poorly balanced compared to those of animal proteins and to those of human needs. Cereal proteins are deficient in lysine while legume proteins are deficient in sulfur amino acids (Young and Pellett 1994). The idea of combining them in enriched cereal products has been widely promoted, and many authors have investigated the nutritional, structural and sensory impacts involved (Asif et al. 2013; Noorfarahzilah et al. 2014). Up to now, only a few studies have been focused on incorporating legume flour in cakes, and even fewer have investigated the effect on the properties at different spatial scales (Gómez et al. 2008b, 2012; De la Hera et al. 2012; Ozkahraman et al. 2016). Cake are composed of equivalent proportions of flour and sugar, lower to-equal proportions of eggs and fat, plus raising agents, and are usually studied in the form of layer or pound cakes (Wilderjans et al. 2008, 2013). It is possible to form aerated and emulsified batters using different mixing methods: single stage methods (“all-in” methods), or multi-stage methods in which the order of ingredient incorporation may vary (Wilderjans et al. 2013; Dewaest et al. 2017a). Regardless of the method used, a multiphase structure is obtained composed of a continuous aqueous phase of proteins and dissolved dry ingredients, and three dispersed phases of air, oil (in non-solid fat formulas), and starch granules. Baking sets the structure thanks to the gelatinization of starch and the denaturation of egg and flour proteins, and leads to the formation of a soft aerated crumb surrounded by a brown crust (Donovan 1977; Dewaest et al. 2017b). Replacing some of the wheat flour by legume flour changes the proportions and nature of the starch and proteins. This implies differences in the functional properties of proteins during mixing, and in the thermal transitions of both starch and proteins (Monnet et al. 2019a). When replacing in a cake recipe a part of wheat flour by legume flour it is interesting to be able to predict the impact of such a change on the properties of the product. Moreover, it would be helpful to be able to limit the impact of such recipe modifications by playing on the manufacturing process.

The aim of this study was to improve the knowledge about the physicochemical mechanisms at work throughout the batter and cake manufacturing processes and when adding pea flour in a cake recipe. The effects of the order of incorporation of the ingredients on the properties of batters and cakes at the different spatial scales were studied. A simplified pound cake formula was used to maximize the effects of replacing the flour and of the interactions with the three other main ingredients (eggs, sugar, oil). A multi-stage mixing method was chosen and several orders of ingredient incorporation were studied using 100% wheat batter. Two orders of incorporation were selected to study the influence of replacing 20% and 40% of the wheat flour by pea flour on the incorporation of air during mixing and on the properties of the final cake.

Materials and methods

Materials

The preliminary experiment wheat flour (45% extraction rate, 8.7% protein, 12.2% moisture, 0.4% ash) was purchased at a local retail outlet (Carrefour, Boulogne-Billancourt, France). The main experiment wheat flour (55% extraction rate, 8.1% protein, 13.8% moisture, 0.4% ash) was supplied by Grands Moulins de Paris (Ivry-sur-Seine, France) and pea flour (19.5% protein, 9.8% moisture, 1.9% ash) by Moulin Meckert-Diemer (Krautwiller, France). Moisture contents were determined by oven drying for 90 min at 130 °C (French norm NF V03-707) and ash contents by dry combustion for 90 min at 900 °C (French norm NF V03-720). Protein contents were analyzed using the Kjeldahl procedure (AACC 46–12 standard method) with conversion factors of 5.7 for wheat and 6.25 for pea. All contents are expressed on a wet basis. The other ingredients of the cake recipe were the following: pasteurized liquid whole eggs (Ovoteam, Locminé, France), white sugar (Saint Louis Sucre, Paris, France), rapeseed oil (Lesieur, Asnieres-sur-Seine, France), baking powder (Dr. Oetker France S.A.S, Schirmeck, France) and commercial-grade salt.

Preparation of the batter and the cake

The recipe was formulated based on seven French domestic cake recipes. It was close to a pound cake formula: 292 g flour, 246 g eggs, 224 g sugar, 218 g fat, 20 g baking powder and 2 g salt for a batch of 1 kg of batter. The melted butter used in the domestic recipes was replaced by rapeseed oil to be more representative of industrial practices (Dewaest et al. 2017a). In the main experiment, 0, 20 and 40% of wheat flour was replaced by pea flour.

Different multi-stage mixing processes were tested, all composed of three steps. The nature of the ingredients mixed at every step are shown in Table 1. A planetary mixer equipped with a vertical whisk was used (Kitchen Aid 5KSM150, St. Joseph, MI, USA).

In the preliminary experiment, four mixing processes were studied (Table 1). Process 1 corresponded to the mixing order used in the industry for oil-containing batters (Dewaest et al. 2017a). Flour, sugar and salt were first mixed (step 1). Eggs were added and mixed (step 2), followed by oil (step 3). Process 2 corresponded to process 1 with an inversion of steps 2 and 3. Process 3 started by whisking the egg, sugar and salt, commonly used in affiliated formulas such as sponge cake. Flour and oil were added at steps 2 and 3, respectively. Process 4 corresponded to process 3 with an inversion of steps 2 and 3. In an exploratory approach, the speed and duration of each step were adjusted depending on the mixing process in order to optimize air incorporation and/or to prevent the batter splattering. Generally, the eggs were whisked at maximum speed for 3 to 4 min, oil was mixed at intermediate to maximum speed for 2 to 3 min, and flour at low to intermediate speed for 2 min. The total length of the mixing process ranged from 7 to 9 min. Batter was prepared once, from step1 to step 3, for each mixing process. During the development phase, step 1 was repeated several times for each mixing process. The density values obtained were so close that the error bars are not visible on the graph.

In the main experiment, only processes 1 and 2 were studied using duration and speed setting values given in Table 1. The total length of the processes was 8 min. Three batches were made for each combination of mixing process and pea flour content (0, 20 and 40% of total flour), giving a total of 18 batches. After mixing, the batter was left to stand for 20 min before baking. Sixteen aluminum pans (length 98 mm, width 62 mm, depth 33 mm) were greased with oil, then filled with 50 g of batter. The cakes were baked at 180 °C for 16 min in a forced air convection oven (Bongard, Wolfisheim, France). The cakes were then cooled at room temperature for 35 min, sealed in individual polyethylene bags and stored at room temperature for 24 h to 1 week before physical measurements. From each batch, three cakes were used for density measurement and cell structure characterization, three cakes were used to measure the mechanical properties, one cake was used for photographs of the top and side, and one cake was used for Size Exclusion High-Performance Liquid Chromatography (SE-HPLC) characterization.

Properties of the batter

Changes in batter density were monitored in all mixing processes from the time a liquid batter was formed. Mixing was stopped every minute and batter density was measured in a 40 mL container. Density (g cm−3) was calculated from the ratio of the mass of the batter (g) to the volume of the container (cm3) defined using water (1 g cm−3). One replicate of density measurement was made in the preliminary experiment and three in the main experiment.

In the main experiment, the three samples were then used to measure the consistency. A texture analyzer (TA-XT2i, Stable Micro Systems, Surrey, UK) equipped with a 5 kg load cell was used, using a back extrusion method. The level of the batter inside the container (height 62 mm, diameter 22 mm) was reduced to approximately 50 mm to prevent batter overflow. A 20 mm diameter aluminum plate was driven 30 mm into the batter at a speed of 0.5 mm s−1. The force of resistance to compression of the batter (N) versus the distance traveled in the sample (mm) was measured. Batter consistency was estimated from the average value of force over the constant part of the curve (5–25 mm).

Cake properties

Cake density was determined after 24 h storage. Immediately after being unwrapped, the cakes were weighed and their volume was measured using a laser-based scanner (VolScan Profiler, Stable Micro Systems, Surrey, UK). Cake density (g cm−3) was calculated from the ratio of their mass (g) to their volume (cm3). Complementary observation of external appearance was made with top and side photographs taken with a photo booth ScanCube 308 (Altawak, Paris, France).

The cell structure of the crumb was characterized using image analysis by mathematical morphology described in Dewaest et al. (2017a). Three cakes per batch were cut with a bread knife along their longitudinal axis. Both sides were gently cleaned with a brush and the sample was placed on a flatbed scanner (HP Scanjet G31110, Hewlett-Packard, Palo Alto, CA, USA). A black box was placed on top of the sample, and a full color image was acquired at a resolution of 600 dpi. The program for image processing was run using Matlab Software version 7.9.1.705 (The MathWorks, Natick, MA, USA), and the PCA was performed using XLSTAT Software version 18.06 (Addinsoft, Paris, France). In this study, interpretation of the similarity map of the cake crumb structures gave PC1 as the expression of cell fineness, PC2 as the expression of cell wall thickness, and D3 (the diagonal in the 2nd quartile) as the expression of the degree of openness.

The mechanical properties of three cakes per batch were determined after 1 week of storage using a TAHD plus texture analyzer (Stable Micro Systems, Surrey, UK) equipped with a 750 kg load cell. Immediately after the cake was unwrapped, its crust was cut parallel to the bottom of the cake at a height of 25 mm. Two cylinders of crumb (height 25 mm, diameter 22 mm) were sampled using a cylindrical die-cutter. Ninety percent uniaxial compression was applied at 2 mm s−1 to each sample with a 10 cm diameter aluminum plate. The apparent Young modulus of the aerated crumb (Ea), representing crumb stiffness, was calculated as the initial slope of the stress-versus-strain curve. The apparent Young modulus of the cell walls (Ec), representing cell wall stiffness, was calculated from the slope of the stress-versus-strain curve at large deformation (end of the compression curve).

The protein size distribution was determined by grinding and freeze-drying three cakes per batch and sequentially extracting proteins with sodium dodecyl sulfate (SDS) and dithioerythritol (DTE) following the protocol detailed in Dewaest et al. (2017b). Extraction with SDS disrupted the electrostatic, hydrophobic and hydrophilic interactions between proteins, and extraction with SDS + DTE followed by sonication disrupted disulfide bonds. All protein extracts including a remaining fraction of non-extractible proteins were analyzed by SE-HPLC, according to the adapted method of Morel et al. (2000) described by Dewaest et al. (2017b). For each sample, the peak areas of SDS-soluble, DTE-soluble and non-extractible proteins were calculated and expressed as percentages of the total calculated area. Two batches were analyzed for each combination of a mixing process and a given pea flour content.

Statistical analysis

Analysis of variance (ANOVA) was used to study differences in batter and cake characteristics according to the mixing process and/or pea flour content. Mean values were calculated from the replicates and the mean separations were performed by Tukey’s HSD test (P < 0.05) using XLSTAT Software Version 18.06 (Addinsoft, Paris, France).

Results and Discussion

Impact of mixing process on the introduction of air and the consistency of the batter

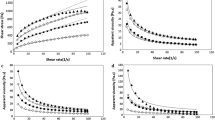

Variations in batter density during mixing in the four mixing processes along with final batter consistencies are shown in Fig. 1. A proposal for induced changes in batter microstructure is given in Fig. 2 along with photographs of the final batters.

In all mixing processes except process 2, density successively decreased and increased due to the successive introduction and loss of air, to finally stabilize (Fig. 1a). Error bars in Fig. 1a are smaller than the circles and triangles, which is why they cannot be seen. The range of variation in batter density was lower in mixing processes 1 and 2 (0.9–1.0 g cm−3 and 1.0–1.3 g cm−3 respectively) than in mixing processes 3 and 4 (0.4–1.2 g cm−3). Processes 3 and 4 exhibited a marked decrease in density between 0 and 4 min ( − 70%) corresponding to the incorporation of a large amount of air in the continuous phase of egg and sugar (Fig. 2). This resulted from the surface-active properties of egg proteins and/or phospholipids that stabilized the bubbles in the foam. However, most of the air was lost between minutes 4 and 5 after the addition of oil or flour (Fig. 1a), because of the disruption of bubble interfaces leading to bubble coalescence and escape from the batter. In process 3, flour particles caused a mechanical disruption of the interfaces. Then, the density of the batter was not modified by the addition of oil (step 3), and remained around 1.03 g cm−3 until the end of mixing. In process 4, the disruption was due to the antifoaming properties of the oil. The addition of flour particles caused an increase in batter density, to finally reach 1.05 g cm−3.

In process 1, adding egg at the beginning of step 2 caused a moderate decrease in density ( − 11%). The presence of flour particles limited the foaming potential compared to step 1 of processes 3 and 4. During step 3, the density of the batter increased (+ 9%) because of the antifoaming properties of oil. Here again, the effect was limited compared to the presence of egg and sugar (step 2 of process 4). Batter density stabilized at 1.00 g.cm−3. In process 2, the density of the batter did not decrease when mixing oil to flour and sugar (step 2). Indeed, no air bubble could be trapped in a mix in which proteins have not been functionalized yet. However, this step enabled all flour particles to be covered with oil, thereby slowing down their hydration (Fig. 2). Adding egg in step 3 rapidly reduced the density (−19%), which stabilized to finally reach 0.99 g cm−3.

The final consistencies of the batters differed significantly (Fig. 1b), ranking as follows: process 2 ≤ process 1 < process 3 < process 4 (P < 0.05). Even if their macroscopic appearance was rather similar, this indicated that their structures were different. Batters resulting from processes 1 and 2 showed the limited viscous behavior typical of cake making (Wilderjans et al. 2013) (Fig. 2). Batter resulting from process 2 had the lowest final consistency probably because the contact time between flour and water was reduced (3 min vs. 5 min in process 1). Moreover, the oil coating slowed down the hydration of the flour particles. Indeed, as soon as flour particles get in touch with water, they start to absorb water and their components (starch, proteins) undergo glass transition, which increases their ability to fragment under the action of the whisk. Upon fragmentation, the starch granules that were trapped in the protein matrix, are set free (Fig. 2). The proteins are dispersed, hydrate, and express their functional properties. Wheat proteins, mostly insoluble in water at neutral pH, increase batter consistency (Wilderjans et al. 2013). Thus, the longer the contact time between flour and water, the more the particles fragment and the higher the consistency of the batter (Figs. 1b and 2). Batters from processes 3 and 4 showed higher consistencies than those in processes 1 and 2, although the hydration time of flour was the same or shorter. This could be because sugar had priority access to water which favored its solvation compared to processes 1 and 2 in which it is in competition with flour. Its better solvation could increase the consistency of the continuous phase (Yang and Foegeding 2010). Consequently, batter from process 3 was still in a liquid state, but showed an increased viscosity (Fig. 1b and 2). As for process 4, the very important consistency of its batter could be due to the formation of a water-in-oil emulsion at maximum speed during step 2, in which some small air bubbles and starch granules would be dispersed (Fig. 2). The batter behaved like a semi-solid matrix with a visual consistency close to that of mayonnaise (Fig. 2).

Final batter densities, obtained using the four processes, were close (1.01 ± 0.03 g cm−3). However, the kinetics of variation in density differed. Processes 3 and 4 were less energy efficient than processes 1 and 2, because they required a lot of energy to introduce air in step 1 most of which was lost in step 2. That is why processes 3 and 4 were discarded, and only processes 1 and 2 were studied in the main experiment.

Impact of the incorporation of pea flour on the properties of the batter and cake

Impact on the introduction of air and the consistency of the batter

The variation in batter density during mixing in processes 1 and 2 and with three pea flour percentages is shown in Fig. 3. With slightly modified processes and another wheat flour, the patterns of variation in density for batters containing 0% pea flour (solid lines) were similar to those observed in the preliminary experiment (Fig. 1a).

The introduction of pea flour had a more spectacular effect on process 1 than on process 2 (Fig. 3a and 3b). During step 2 of process 1 (2–6 min), the higher the proportion of pea flour, the bigger the decrease in density. At the end of step 2, batter density was reduced by 12% and 16% compared to the 0% pea batter, for 20% and 40% of pea flour respectively. The decrease in density was not proportional to the amount of pea flour incorporated. Pea proteins are mostly soluble in water at neutral pH and exhibit better foaming activity and stability than wheat proteins (Wang et al. 2006; Boye et al. 2010; Toews and Wang 2013). However, the addition of oil in step 3 increased the density and dramatically reduced the gap between the batter densities. Thus, the interfaces of air bubbles stabilized by the pea proteins were particularly sensitive to the defoaming action of oil. However, at the end of mixing, the average densities still differed significantly as a function of pea flour content: 0.989 ± 0.003 g cm−3, 0.976 ± 0.003 g cm−3, and 0.967 ± 0.003 g cm−3 for 0, 20, and 40% pea, respectively.

In process 2, batter density remained stable during step 2 (1–3 min), like in the preliminary experiment (Fig. 1a and 3b). Density was lower with 0% pea batter (1.20 g cm−3) than with 20 and 40% pea batters (1.22 g cm−3). During step 3 batter densities first rapidly decreased (3–4 min) and then stabilized (4–8 min). The decrease in density was larger with 0% pea batter (−21%) than with 20 and 40% pea batters (−19% and −18%, respectively). The contribution of the foaming properties of the pea proteins was lower than in process 1. At the end of mixing, the average densities were close, but still significantly different: 0.974 ± 0.004 g cm−3, 0.967 ± 0.005 g cm−3, and 0.955 ± 0.006 g cm−3 for 0, 20, and 40% pea batters, respectively.

Thus, in both processes, the introduction of pea flour caused a slight, but significant decrease in batter density (−1 and − 2% with respectively, 20 and 40% of pea flour). In layer cakes, Gómez et al. (2008b) and De la Hera et al. (2012) reported − 3 to − 10% decreases in batter density with the incorporation of 50% to 100% of chickpea or lentil flour. Figure 4a represents the densities of batters as a function of their consistencies. The densities and consistencies of the batters resulting from process 2 were significantly lower than those of the batters resulting from process 1 with the same amount of additional pea flour. This is consistent with the observations made in the preliminary experiment with 0% pea batter. Chesterton et al. (2011) showed that an increase in the volume fraction of air in layer cake batters with volume fractions of air ranging from 10 to 50% (i.e. densities ranging from 0.6 to 1.1 g cm−3 for a density of unaerated batter of 1.2 g cm−3) was associated with an increase in batter viscosity. However, in their result, the batter density increased by at least 0.04 g cm−3 while in the present study, between process 2 and process 1, the increase was 0.01 g cm−3 for each pea flour content. Thus the effect of density on consistency was minor and the lower consistencies resulting from process 2 were rather due to the limited hydration of flour particles during mixing.

a Batter densities as a function of their consistencies in process 1 (black symbols) and in process 2 (white symbols): 0% of pea flour ( ,

,  ), 20% of pea flour (

), 20% of pea flour ( ,

,  ), 40% of pea flour (

), 40% of pea flour ( ,

,  ). Legends of the points refer to consistency and density; b Side and top views of the cakes, and close-ups of the crumb to characterize cell structure

). Legends of the points refer to consistency and density; b Side and top views of the cakes, and close-ups of the crumb to characterize cell structure

For each process, batter consistency significantly decreased from 0 to 20% of added pea flour and significantly increased from 20 to 40% (P < 0.05). The consistencies of 0% and 40% pea batters did not significantly differ. De la Hera et al. (2012) showed that the viscosity of a layer cake batter gradually increased, when the proportion of lentil flour was increased to 50% and to 100%. Interestingly, Gómez et al. (2012) observed a decrease in the viscosity of a layer cake batter, when the proportion of pea flour was increased from 0 to 25%, followed by a gradual increase when the proportion was increased to 50 and to 100%. Monnet et al. (2019b) also reported a quadratic trend effect of the proportion of pea flour on batter consistency in the case of an industrial layer cake formula. The existence of a more complex relationship between legume flour content and batter consistency (e.g. quadratic relationship) suggests the presence of competing effects related to the structure of the dispersed phases (number and size of bubbles and oil droplets) and/or to the structure of the continuous phase (the proteins and starch granules embedded in them).

Impact on the structural and mechanical properties of the cake

Observations about cake structure were made at macroscopic, mesoscopic, and macromolecular scales (Table 2).

At macroscopic scale, the density of cakes resulting from process 2 was systematically and significantly lower than that resulting from process 1 with the same amount of pea flour (Table 2). These results are in line with the results obtained on batters. According to Handleman, Conn, and Lyons (1961), batters with lower densities are expected to result in cakes with lower densities. Moreover, a lower batter consistency can facilitate cake expansion (Sahi and Alava 2003), providing that it is high enough to retain air bubbles in the first stages of baking (Gómez et al. 2008a).

In each process, cake density increased significantly with an increase in the proportion of pea flour (Table 2 and Fig. 4b). Density increased by 3% when 20% of pea flour was added in process 1 and when 40% of pea flour was added in process 2. Several authors reported the absence of a relationship between batter and cake properties in the case of legume-enriched cakes (Gómez et al. 2008b, 2012; De la Hera et al. 2012). This was attributed to the reduced capability of legume enriched batters to retain air bubbles during baking linked to their viscosity and to changes in viscosity during baking, or to the distribution of bubbles in the batter (Ronda et al. 2011). Batter viscosity increases during baking due to starch gelatinization and protein thermosetting that enable the cake structure to set. Pasted starch granules are essential in the process, as they play the role of “bricks” surrounded by “mortar” made of denatured proteins (Donovan 1977). In legume-enriched cakes, the smaller proportion of starch granules is hypothesized to prevent the formation of a structure capable of retaining air after gelatinization (De la Hera et al. 2012; Gómez et al. 2012). Furthermore the temperature of gelatinization of legume starches and the denaturation temperature of legume proteins are hypothesized to be higher than their wheat counterparts (Monnet et al. 2019a). This would delay setting with respect to expansion, causing the cake to shrink. Photographs of the surface of the cakes revealed the presence of cracks (Fig. 4b). The depth of the cracks increased with the proportion of pea flour, and were particularly deep in cakes including 20 and 40% of pea flour in process 1 that exhibited the highest densities. The formation of cracks is due to the effect of the expansion pressure against the crust. The crust, formed in the first stages of baking, ruptures and fresh batter is pushed outside. The pressure inside the cake decreases as the vapor escapes and the cake structure needs to set rapidly to avoid shrinking. When pea flour is incorporated, more particularly in process 1, the setting of the structure is delayed, and the cakes shrink after cracks form. De la Hera et al. (2012), Gómez et al. (2012), and Gómez et al. (2008b) also reported shrinking of legume-enriched cakes at the end of baking.

At mesoscopic scale, the stiffness of the aerated crumb and of the cell walls were analyzed by measuring their apparent Young moduli (Table 2). The stiffness of the aerated crumb significantly decreased when 20% or 40% of pea flour was added, in processes 1 and 2, respectively (P < 0.05). Cell wall stiffness showed the opposite tendency, i.e. stiffness increased with an increase in pea flour content (significant in cakes with 40% pea flour in process 1). Consequently, the reduction in crumb stiffness in cakes enriched in pea flour cannot be explained by lower densities or cell wall stiffness. Gibson and Ashby (1982) proposed an equation linking the Young moduli of aerated crumb and cell walls (Ea and Ec, respectively) to their densities (\({\rho }_{a}\) and \({\rho }_{c}\), respectively) by a constant C accounting for the geometry of the cell structure. In the present study, this equation was used to deduct the contribution of cake density and cell wall stiffness to crumb stiffness in order to only consider the contribution of the geometry of the cell structure. A ratio was calculated that only depended on the constant C, assuming that the density of the cell walls \({(\rho }_{c}\)) remained constant in all formulas. Results indicated the presence of two cake groups with significantly different Ea /[ρa2*Ec] ratios (P < 0.05, Table 2): process 1 with 0% of pea flour and process 2 with 0 or 20% of pea flour, in one hand, process 1 with 20 or 40% of pea flour and process 2 with 40% of pea flour on the other hand. According to this assumption, the cakes with 0% pea flour resulting from process 1 and the cakes with 0 or20% pea flour resulting from process 2 would have a similar cell structure. They would differ in structure from cakes with 20 or 40% pea flour resulting from process 1 and from cakes with 40% pea flour resulting from process 2. Extracts of crumb images in Fig. 4b provide insights into these differences. The images were analyzed using the method of Dewaest et al. (2017a) and interpreted in terms of cell fineness, cell wall thickness, and the degree of openness of the structure (Table 2. The incorporation of pea flour caused a decrease in cell fineness, forming two statistical groups similar to those distinguished by the equation of Gibson and Ashby (1982). This is in agreement with the observation of Ozkahraman et al. (2016), who showed a decrease in the number of cells when 10% of legume flour was substituted to wheat flour in cakes.

The incorporation of pea flour also caused a decrease in the degree of openness, and a slight increase in cell wall thickness (Fig. 4b). For a 100% wheat layer cake, Dewaest et al. (2017a) showed that crumb stiffness decreases when the cell fineness and degree of openness increase and cell wall thickness decreases. For a pound cake formula, it seems that the variations in cell structure had an opposite effect on crumb stiffness.

Using the same formula as Dewaest et al., Monnet et al. (2019b) observed a decrease in cell fineness and an increase in crumb stiffness when pea flour was introduced. Thus, the addition of pea flour caused a decrease in cell fineness whatever the formula. However, the relationship of cell fineness to crumb stiffness was different for the pound cake formula. The presence of larger cells was probably caused by coalescence phenomena occurring during baking due to the delayed setting of the structure. Such cells could have irregular shapes. During compression at macroscopic scale, it is most likely that this structure would be more prone to fragment, at least in the case of pound cake.

The protein size distribution, determined by SE-HPLC, provided information on the cake structure at macromolecular scale (Table 2). The incorporation of pea flour increased the proportion of proteins linked by weak interactions (SDS-soluble), reflecting the initial composition of pea proteins (Monnet et al. 2019a). This increase was offset by a decrease in the proportion of non-extractible proteins rather than in proteins linked by disulfide bonds (DTE-soluble) as might be expected from the initial composition of wheat proteins. Dewaest et al. (2017b) showed that the aggregation of gluten and egg proteins during baking leads to the formation of DTE-soluble and non-extractible proteins. However the amount of non-extractible proteins was lower than in gluten-free or egg-free cakes due to limited aggregation caused by steric hindrance. In the present study, the pea proteins may have increased steric hindrance, thereby reducing the proportion of gluten and egg non-extractible proteins. The concomitant increase in DTE-soluble proteins due to aggregation offset the decrease due to the smaller proportion of gluten proteins in cakes enriched in pea flour. Overall, the incorporation of pea flour caused a reduction in the degree of protein aggregation that contributed to the less-efficient stiffening of the structure during baking. There was no effect of the mixing process on protein size distribution, except a tendency for process 2 to exhibit more DTE-soluble and fewer non-extractible proteins than process 1 (Table 2). This could be explained by the later hydration and functionalization of the proteins in process 2 that were covered by oil in the flour particles.

Conclusion

Replacing some of the wheat flour with pea flour in a cake domestic formula modifies the structuring of the batter and the cake. For the first time, the batter density was followed all along the process. It gave information about the evolution of air incorporation in the batter depending on the proportion of pea flour and on the order of ingredient incorporation. Pea flour incorporation led to a variation in batter consistency but also to a slight increase in incorporated air quantity. However, the resulting wheat-pea cakes are denser due to shrinking during baking. They contain less starch, which gelatinizes at higher temperature. Moreover, pea proteins denature at higher temperatures, resulting in reduced protein aggregation in comparison to wheat ones. During cooking, larger and potentially irregular cells appear. The resulting wheat-pea cake crumb is denser but surprisingly softer. Studying the effect of the order of ingredient incorporation at each step of the mixing process helped understand the contribution of each one. Differences in density, air incorporation and crumb structure could be explained by physicochemical mechanisms. A schematic representation was proposed to illustrate their effects in terms of air incorporation, and (de)stabilization of air bubbles and oil droplets. For instances, an early incorporation of egg leads to a high rate of air incorporation which is subsequently almost entirely lost when flour and oil are added. It is thus better to postpone egg incorporation until the end of the mixing process or at least after flour incorporation. For a similar formula, a different order of incorporation can lead to different cake density and degree of protein aggregation. All these conclusions, laying on physicochemical phenomena, are very useful for industry and for further works on wheat and wheat-legume cakes. From a nutritional point of view, a percentage of about 30% of wheat flour replacement by pea flour gives a well-equilibrated amino acid profile. By only modifying the process parameters, a limitation of the impact of such a recipe modification on the cake structure can be carried out.

References

AACC Approved Methods of Analysis, 11th Ed. Method 46–12.01, Crude Protein—Kjeldahl Method, Boric Acid Modification. Cereals & Grains Association, St. Paul, MN, U.S.A. http://dx.doi.org/https://doi.org/10.1094/AACCIntMethod-46-12.01

Asif M, Rooney LW, Ali R, Riaz MN (2013) Application and opportunities of pulses in food system: a review. Crit Rev Food Sci Nutr 53:1168–1179. https://doi.org/10.1080/10408398.2011.574804

Boye JI, Aksay S, Roufik S et al (2010) Comparison of the functional properties of pea, chickpea and lentil protein concentrates processed using ultrafiltration and isoelectric precipitation techniques. Food Res Int 43:537–546. https://doi.org/10.1016/j.foodres.2009.07.021

Chesterton AKS, Meza BE, Moggridge GD et al (2011) Rheological characterisation of cake batters generated by planetary mixing: Elastic versus viscous effects. J Food Eng 105:332–342. https://doi.org/10.1016/j.jfoodeng.2011.02.043

De la Hera E, Ruiz-París E, Oliete B, Gómez M (2012) Studies of the quality of cakes made with wheat-lentil composite flours. LWT—Food Sci Technol 49:48–54. https://doi.org/10.1016/j.lwt.2012.05.009

Dewaest M, Villemejane C, Berland S et al (2017a) Effect of crumb cellular structure characterized by image analysis on cake softness. J Texture Stud 49:328–338. https://doi.org/10.1111/jtxs.12303

Dewaest M, Villemejane C, Berland S et al (2017b) Changes in protein size distribution during wheat flour cake processing. LWT—Food Sci Technol 79:333–341. https://doi.org/10.1016/j.lwt.2017.01.036

Donovan JW (1977) A study of the baking process by differential scanning calorimetry. J Sci Food Agric 28:571–578. https://doi.org/10.1002/jsfa.2740280616

FAO (2011) Feeding the future. In: McLeod A (ed) World Livestock 2011—Livestock in food security. FAO, Rome, pp 77–97

Gómez M, Doyagüe MJ, de la Hera E (2012) Addition of pin-milled pea flour and air-classified fractions in layer and sponge cakes. LWT—Food Sci Technol 46:142–147. https://doi.org/10.1016/j.lwt.2011.10.014

Gómez M, Oliete B, García-Álvarez J et al (2008) Characterization of cake batters by ultrasound measurements. J Food Eng 89:408–413

Gómez M, Oliete B, Rosell CM et al (2008) Studies on cake quality made of wheat–chickpea flour blends. LWT—Food Sci Technol 41:1701–1709

Monnet A-F, Laleg K, Michon C, Micard V (2019a) Legume enriched cereal products: A generic approach derived from material science to predict their structuring by the process and their final properties. Trends Food Sci Technol. 86:131–143

Monnet A-F, Michon C, Jeuffroy M-H, Blumenthal D (2019b) Taking into account upstream variability of flours with processing variables in legume-enriched soft cakes: conception of a multiobjective model for the monitoring of physical properties. Food Bioprocess Technol 12:625–635

Morel M-H, Dehlon P, Autran JC et al (2000) Effects of temperature, sonication time, and power settings on size distribution and extractability of total wheat flour proteins as determined by size-exclusion high-performance liquid chromatography. Cereal Chem 77:685–691. https://doi.org/10.1094/CCHEM.2000.77.5.685NFENISO2171,V03-720(2010).Céréales,légumineusesetproduitsdérivés-Dosagedutauxdecendresparincinération.17p

NF EN ISO 712, V03–707 (2010). Céréales et produits céréaliers—Détermination de la teneur en eau - Méthode de référence. 23 p.

Noorfarahzilah M, Lee JS, Sharifudin MS et al (2014) Applications of composite flour in development of food products. Int Food Res J 21:2061–2074

Ozkahraman BC, Sumnu G, Sahin S (2016) Effect of different flours on quality of legume cakes to be baked in microwave-infrared combination oven and conventional oven. J Food Sci Technol 53:1567–1575

Reijnders L, Soret S (2003) Quantification of the environmental impact of different dietary protein choices. Am J Clin Nutr 78:664S-668S

Ronda F, Oliete B, Gómez M et al (2011) Rheological study of layer cake batters made with soybean protein isolate and different starch sources. J Food Eng 102:272–277. https://doi.org/10.1016/j.jfoodeng.2010.09.001

Sahi SS, Alava JM (2003) Functionality of emulsifiers in sponge cake production. J Sci Food Agric 83:1419–1429

Toews R, Wang N (2013) Physicochemical and functional properties of protein concentrates from pulses. Food Res Int 52:445–451. https://doi.org/10.1016/j.foodres.2012.12.009

Wang J, Zhao M, Yang X, Jiang Y (2006) Improvement on functional properties of wheat gluten by enzymatic hydrolysis and ultrafiltration. J Cereal Sci 44:93–100. https://doi.org/10.1016/j.jcs.2006.04.002

Wilderjans E, Luyts A, Brijs K, Delcour J, a. (2013) Ingredient functionality in batter type cake making. Trends Food Sci Technol 30:6–15. https://doi.org/10.1016/j.tifs.2013.01.001

Wilderjans E, Pareyt B, Goesaert H et al (2008) The role of gluten in a pound cake system: A model approach based on gluten–starch blends. Food Chem 110:909–915. https://doi.org/10.1016/j.foodchem.2008.02.079

Yang X, Foegeding EA (2010) Effects of sucrose on egg white protein and whey protein isolate foams: Factors determining properties of wet and dry foams (cakes). Food Hydrocoll 24:227–238. https://doi.org/10.1016/j.foodhyd.2009.09.011

Young VR, Pellett PL (1994) Plant proteins in relation to human protein and amino acid nutrition. Am J Clin Nutr 59:1203S-1212S

Acknowledgments

The authors thank Margaux Chevaleyre for help with the experiments, and Joëlle Bonicel and Valérie Micard for the measurement of protein size distribution by SE-HPLC.

This work was carried out in the framework of the FLEXIPROCESS project with financial support from the Carnot institute Qualiment. The authors acknowledge the Carnot institute Qualiment, AgroParisTech, and the French Ministry of Higher Education and Research for their financial support of the authors.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Monnet, A.F., Jeuffroy, M.H., Villemejane, C. et al. Effect of the order of incorporation of cake ingredients on the formation of batter and the final properties: contribution of the addition of pea flour. J Food Sci Technol 58, 4252–4262 (2021). https://doi.org/10.1007/s13197-020-04899-0

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-020-04899-0

), process 2 (

), process 2 ( ), process 3 (

), process 3 ( ) and process 4 (

) and process 4 ( )

)

,

, ), 40% of pea flour (

), 40% of pea flour ( ,

, )

)