Abstract

The use of composite wheat-pea flours is of nutritional interest because their essential amino acid profile is closer to human needs than that of wheat alone. However, composite flours might be more variable than wheat flour alone, so manufacturers need to be able to monitor the quality of the cakes. The effects of the quality of the raw material and cake manufacturing process variables on cake density and shape and crumb color, texture, and cell structure were studied. An experimental design with seven flour quality and processing variables was implemented (56 trials). A multiobjective model was built, and its prediction capacity was validated. It is able to compensate for variations in flour quality by adjusting the levels of the processing variables.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The wheat supply chain is organized for the regular production of grain, flour and end products of high quality, leading to a very large commodity market. However, wheat still depends on high levels of synthetic inputs, mostly nitrogen fertilizers. Agricultural research has demonstrated the benefits of intercropping cereals with legume species to reduce the quantity of such inputs (Nemecek et al. 2008). Mixing wheat and legume flours in foods also improves protein quality by balancing the essential amino acid profiles (Farooq and Boye 2011; Young and Pellett 1994). The formulation of legume-enriched cereal products is one possible way to promote the development of more sustainable food chains including production and processing steps that are the same for the legume and cereal grains. This would enable the production of composite flour, i.e., a mix of flours milled either together or separately. This would require being able to handle more variable grain quality (the proportions of both grains in a mix, the mechanical properties of the grain resulting from the growing conditions) and the quality of the resulting composite flour (composition and particle size) by introducing more flexibility in the processing steps (De Vries et al. 2017). Many studies have shown that including legume flour in cereal foods modifies their properties (color, texture, structure, and sensory acceptability) (Monnet et al. under revision; Noorfarahzilah et al. 2014).

To provide products of constant satisfactory quality, it is thus necessary to provide the secondary processing industry with tools to adjust processing variables as a function of flour quality and of the properties of the desired end product (Farooq and Boye 2011). Such an approach, sometimes referred as “reverse engineering” or “quality driven design”, can be achieved through process modeling and optimization using response surface methodology (De Vries et al. 2017; Esveld et al. 2008; Noorfarahzilah et al. 2014). According to Esveld et al. (2008), the longtime expertise of the bakery industry is mostly rooted in empirical knowledge that may be lost if not carefully saved, and what is more, this empirical knowledge has not been extensively translated into numerical models. Nevertheless, a few studies aimed at optimizing bread or cake processing with response surface methodology. Such studies use central composite designs (Ferrari et al. 2013; Sanchez et al. 2004) or Box-Behnken designs (Tan et al. 2012; Turabi et al. 2008) to model the effect of several processing and/or formula variables on each quality parameter of the product, i.e., the “responses”. One model per response is generally proposed, followed by single or multiple optimization of the responses using contour plots or desirability functions. In a study on the optimization of wine filtration, Gergely et al. (2003) argued that technological optimization tasks are always multiobjective problems. An integrated multiobjective optimization approach consists in taking all the responses into account simultaneously in the selection of the most significant effects. This gives rise to a “multiobjective model” that is the aggregate of the models of all responses with the same list of effects. Using a desirability function, this approach makes it possible to obtain the best solution, i.e., a trade-off between all responses even if they are of different dimensions, orders of magnitude, or importance (Gergely et al. 2003). Multiobjective models that enable to predict the best settings of the processing variables to reach the target properties of a given product are very valuable tools for industry, and also hold great promise for the future of food process design (Asselman et al. 2007).

In the study of cakes, a set of physical variables can be defined as quality criteria relevant to the consumers. Soft cakes are chemically leavened products characterized by an aerated crumb whose textural attributes (expressed as softness or freshness) are crucial to the definition of quality, as are the specific appearance of the crumb and the flavor attributes (Heenan et al. 2010). Texture is a multidimensional sensorial property that results from the expression of the structural and mechanical properties of the product (Szczesniak 2002). Consequently, soft cakes can be defined as solid foams of variable density, symmetry, and cellular structure, with a crumb varying in stiffness and color.

The aim of this study was to design a tool to optimize the quality of soft cakes enriched with pea flour as a function of upstream—uncontrolled but measurable—flour quality variables using controlled processing variables. After screening the processing variables in preliminary tests using a “one-variable-at-a-time” technique, an I-optimal experimental design was set up with seven independent variables (three concerning flour quality and four concerning processing) and six response variables (cake density, cake symmetry index, crumb stiffness, cell fineness, cell wall thickness, and crumb lightness). A multiobjective model was designed, and its prediction capacity was checked in validation trials.

Materials and Methods

Materials

Wheat flour (55% extraction rate, 9.5% protein, 13.9% moisture, 0.5% ash) was supplied by Grands Moulins de Paris (Ivry-sur-Seine, France) and pea flour (21.4% protein, 9.8% moisture, 2.1% ash) was supplied by Moulin Meckert-Diemer (Krautwiller, France). Moisture contents were determined by oven drying for 90 min at 130 °C (French standard NF V03-707), and ash contents by dry combustion for 90 min at 900 °C (French standard NF V03-720). Protein contents were analyzed using the Kjeldahl procedure (AACC 46-12 standard method) with the most usual conversion factors of 5.7 for wheat flours and 6.25 for legume flours. All contents are expressed on a wet basis. Other cake ingredients were pasteurized liquid whole eggs (Ovoteam, Locminé, France), rapeseed oil (Lesieur, Asnières-sur-Seine, France), white sugar (Saint Louis Sucre, Paris, France), glucose syrup (Louis François, Croissy-Beaubourg, France), glycerol (Louis François, Croissy-Beaubourg, France), Spongolit® 542 emulsifier (BASF France S.A.S, Levallois-Perret, France) composed of lactic and acetic esters of mono- and diglycerides of fatty acids, baking powder (Dr. Oetker France S.A.S, Schirmeck, France), and commercial grade salt. In the preliminary tests, vital wheat gluten from Roquette Frères (Lestrem, France) was used to produce 100% wheat reference formulas (0 wt% of pea flour of the total mass of flour) with an equal amount of proteins to formulas containing 29 wt% of pea flour of the total mass of flour.

Preparation of Flour Fractions

Particle size distribution of wheat and pea flours was determined by laser diffraction using a Mastersizer 2000 equipped with the Scirocco 2000 dry dispersion unit (Malvern Instruments, Worcestershire, UK). Both flours had a bimodal particle size distribution composed of a “fine” fraction mostly composed of particles the size of starch granules (23 μm mean particle size for both flours) and a “coarse” fraction mostly composed of particles the size of cells or groups of cells (91 μm and 182 μm mean particle sizes for wheat and pea flours, respectively). Six-hundred grams of flour were weighed and sieved with an Analysette 3 SPARTAN vibratory sieve shaker (FRITSCH GmbH, Idar-Oberstein, Germany) equipped with three sieves of 63 μm, 80 μm, and 125 μm stacked in decreasing size order. The flour was separated for 90 min at an amplitude setting of 2.5 mm. Fractions above 63 μm formed the “coarse fraction”, while fraction below 63 μm formed the “fine fraction”.

Batter and Cake Preparation

The cake formula was an industrial formula taken from Dewaest et al. (2017a). It was composed of 350 g flour, 135 g eggs, 125 g sugar, 118 g glucose syrup, 110 g water, 62 g glycerin, 17 g emulsifier, 12 g baking powder, and 2 g salt for a total batch of 1011 g of batter. In the preliminary tests, 17 g of wheat gluten was added to the 100% wheat reference formula.

The day before the experiment, a mix of liquids was prepared for every batter batch by weighing glucose syrup, glycerin, and water in a bowl and stirring the mix with a whisk until complete dissolution. Eggs were added. The resulting mix of liquids was stored at 4 °C for 24 h in a bowl covered with aluminum foil. The batter was prepared following a three-stage mixing procedure in a planetary mixer equipped with a vertical whisk (Kitchen Aid 5KSM150, St. Joseph, MI, USA). The reference procedure for preparation of the batter for both preliminary tests and the experimental plan was as follows. First the dry ingredients (flour, sugar, emulsifier, baking powder, salt) were homogenized at speed 1 for 1 min. The liquids were added and mixed at speed 1 for 30 s and at speed 4 for 1 min 30 s. The oil was added and mixed at speed 1 for 1 min during which the batter was continuously scraped down towards the center with a rubber scraper for better homogenization.

After mixing, the batter was left to stand for 30 min before baking. During the waiting period, the consistency of the batter was measured and the batter was transferred into previously coded disposable aluminum pans (length 98 mm, width 62 mm, height 33 mm). The pans were oil coated, filled with 50 g of batter each, and placed on the baking rack in a specific spatial design to ensure a zone of good heat homogeneity. The oven was a forced air convective type specially designed by the constructor (Bongard, Wolfisheim, France) for experimental purposes. The reference baking temperature and time was 180 °C for 13 to 14 min for the preliminary tests and for 18 min for the experimental plan. After baking, cakes were cooled at room temperature for 45 min and then sealed in individual polyethylene bags in their pans using a thermosealing machine (C 200, Multivac, Wolfertschwenden, Germany). They were stored at room temperature for at least 1 week before physical measurements. The mechanical properties of the cakes were measured exactly 1 week after manufacturing, and they were followed by the other measurements within a week.

Preliminary Tests

Preliminary tests were performed to select the most influential independent variables. Six processing variables that could affect the quality parameters of the cakes were listed: order of the mixing stages (dry ingredients-liquids-oil or dry ingredients-oil-liquids), liquids and oil mixing speeds and times, and baking temperature with adjusted time. Three variables were also tested for flour quality: the proportion of pea flour in the total mass of flour, pea flour particle size, and wheat flour particle size (expressed as the proportion of fine fraction to the total mass of flour in both cases). In order to check for the presence of quadratic trend effects and to screen the variation ranges of the factors, a “one-variable-at-a-time” technique was used (Baş and Boyacı 2007). Classical screening designs such as fractional factorial designs or Plackett-Burman designs enable to study the effect of a high number of factors in a reduced number of trials, implying that only two levels are tested for each factor. However, to screen precisely the variation ranges of the factors and to identify quadratic trend effects, at least three levels per factor are necessary, which was easily performed using the “one-variable-at-a-time” technique. Starting from the reference batter and cake preparation procedure, the level of each factor was varied one after the other within the widest possible range while keeping all the other factors constant at the reference level. The widest possible range was either the widest range allowed by the equipment (liquids and oil mixing speeds), the widest range in regard to what was known of the industrial practice and seemed realistic (liquids and oil mixing times, baking temperature), or the widest range per se (proportion of pea flour and flours particle size) (Table 2). Each factor was varied at three levels to detect quadratic trend effects, except for the proportion of pea flour that was varied at five levels for a more precise representation. One batter and cake preparation procedure (i.e., one batch) was carried out for each combination. The reference batter and cake preparation procedure was carried out five times across the preliminary tests: three times with a baking time of 13 min and twice with 14 min, respectively. Measured responses in the preliminary tests included: batter density, batter consistency, cake density, two variables related to cake mechanical properties (crumb stiffness and cell wall stiffness), and two variables related to cake cellular structure (cell fineness and cell wall thickness). No interaction effect was tested except for oil mixing time, which was tested with two different levels of oil mixing speed (speed 1 corresponding to the reference procedure and speed 10) because an interaction was expected to occur. A total of 34 trials (34 batches) were performed.

Methodology of Experimental Design

The preliminary tests led to the selection of four processing variables and to the identification of quadratic trend effects, meaning that a second-order model equation was required. In order to check and to counterbalance the effect of the day of preparation on the response variables, a blocking factor was included in the design. This led to the choice of an optimal design with seven independent variables at three coded levels (− 1, 0, + 1). The chosen model was a second-order polynomial model with all linear, quadratic, and second-order interaction effects. Four repetitions were performed at the center of the domain to estimate experimental error. The total number of trials for these conditions was 56, split into seven blocks. The order of the trials within the blocks was fully randomized.

The levels for the seven independent variables are listed in Table 1. They were chosen to explore the widest range of variation for each factor while being centered on the level of the reference batter and cake preparation procedures used by industry. All speed settings were converted into revolutions per minute in the experimental design (Table 1). Baking trials were performed in order to identify the baking times that would enable to reach a constant water activity of 0.75 (standard target for good conservation) at all baking temperatures. The proportion of pea flour in the total mass of flour was varied between 10 and 60% to obtain an intermediate level, 35%, that corresponded to the best estimated balance in the essential amino acid profiles.

Response variables for the experimental design are listed in Table 1. Batter properties and cell wall stiffness were measured but not included in the multiobjective model because they were not considered as direct quality criteria for consumers. Indeed, batter properties are only indicative of cake properties and were not impacted by the baking variables. The reduction of the number of responses for the optimization of the prediction capacity of the model led also to eliminate cell wall stiffness which was considered redundant with cell fineness in terms of quality perceived by the consumer. However, the measurement of crumb color (CIE L*a*b) was added to the physical measurements, and crumb lightness (L*) was selected as the most significant variable to include in the multiobjective model.

Batter Properties

Batter density was measured just after the end of mixing using a 40-mL container. Density (g cm−3) was calculated from the ratio of the mass of the batter (g) to the volume of the container (cm3) defined using water (1 g cm−3). The measurement was performed in triplicate.

The consistency of the final batters was measured on the same three samples used for the measurement of density (i.e., in triplicate). A texture analyzer (TA-XT2i, Stable Micro Systems, Surrey, UK) equipped with a 5-kg load cell was used, following a back extrusion method. The level of batter inside the container (height 62 mm, diameter 22 mm) was reduced to approximately 50 mm with a spatula to prevent batter overflow. A 20-mm diameter aluminum plate was driven 30 mm into the batter at a constant speed of 0.5 mm/s (pre-test speed 1 mm/s, trigger force 0.01 N). The force of resistance to compression of the batter (N) was followed versus the distance in the sample (mm). Batter consistency was estimated from the average value of force over the constant part of the curve (5–25 mm).

Cake Properties

The cakes were weighed immediately after being unwrapped, and their volume was measured using a laser-based scanner (VolScan Profiler, Stable Micro Systems, Surrey, UK) with an increment of 2 mm and a rotation speed of 1 rps. Cake density (g cm−3) was calculated from the ratio of their mass (g) to their volume (cm3). The laser-based scanner provided a profile of the cake representing the change in its circumference along its longitudinal axis through the succession of 46 to 47 slices separated by an increment of 2 mm (total cake length was approximately 90 mm). This data was used to calculate an adapted symmetry index as defined by the AACC method 10-91 (AACC, 2010). The height in the center of the slice was measured on three slices situated respectively at one fourth (B), one half (C), and three fourths (D) of the cake length, and the usual calculation was done (symmetry index = 2 × C – B − D). Density and symmetry measurements were done on three cakes per batch (i.e., per trial), and the same cakes were kept for the characterization of cell structure.

The mechanical properties of the cake were determined after 1 week of storage using a TAHD plus texture analyzer (Stable Micro Systems, Surrey, UK) equipped with a 750-kg load cell. Just after the cake was unwrapped, a cutting template and a bread knife were used to remove its top crust and a part of the four sides to obtain rectangular crumb samples (length 58 mm, width 26 mm, height 26 mm) located in the bottom center of the cakes. Each sample was subjected to 90% uniaxial compression with a 10-cm diameter aluminum plate at a constant speed of 2 mm/s (pre-test speed 1 mm/s, trigger force 0.5 N). The resulting curves of force (N) versus distance (mm) were converted into stress-versus-strain curves using the sample dimensions. The apparent Young modulus of the aerated crumb, representing crumb stiffness, was calculated as the initial slope of the stress-versus-strain curve. The apparent Young modulus of the cell walls, representing cell wall stiffness, was calculated from the slope of the stress-versus-strain curve at large deformation (end of the compression curve). Texture was measured on three cakes per batch (i.e., per trial).

The cell structure of the crumb was characterized using image analysis by mathematical morphology described in Dewaest et al. (2017b). For image acquisition, the cakes were cut with a bread knife along their longitudinal axis. Both sides were gently cleaned with a brush to remove loose crumbs from the cellular structure and the sample was placed on a flatbed scanner (HP Scanjet G31110, Hewlett-Packard, Palo Alto, CA, USA). A black box was placed on top of the sample, and a full color image was acquired at a resolution of 600 dpi. The program for image processing was run using Matlab Software version 7.9.1.705 (The MathWorks, Natick, MA, USA), and the PCA was realized with XLSTAT Software version 18.06 (Addinsoft, Paris, France). In this study, interpretation of the similarity map of the cake crumb structures gave PC1 as the expression of cell fineness and PC2 as the expression of cell wall thickness. Two values were obtained for each one of the three cakes per batch (i.e., per trial), giving a total of six values per batch.

Crumb color was measured using a spectrophotometer (Spectro-guide 6834, BYK-Chemie GmbH, Wesel, Germany) with standard illuminant D65. One cake per batch was cut with a bread knife along its longitudinal axis, and one of the two sides was chosen for color measurement. After calibration and verification of the measurement repeatability on the first sample, color measurement was made one time at the center of the longitudinal slice for each cake. Results are expressed in the CIE L*a*b space.

Statistical Analysis

JMP software version 13.1.0 (SAS Institute Inc., Cary, SC, USA) was used for I-optimal design and analysis. I-optimality refers to the orientation of the design towards a good prediction capacity of the model through the minimization of the average variance of prediction. Multiple regression analysis was performed to model the variation of each response variable and evaluate the significance of the effects of all independent variables (i.e., all regression coefficients) that contributed to it. In a multiobjective approach, the software ranked the effects of all the independent variables on all response variables in order of decreasing significance. In the ranking, the p value of each effect corresponded to the lowest p value of the effect among all models for the response variables, and was expressed as a LogWorth value (LogWorth = − log10(p value)). The most significant effects (p ≤ 0.05) were selected from the ranking using a backward elimination procedure. Regression coefficients were calculated for each model. An analysis of variance (ANOVA) for the evaluation of model performance was performed (F-test for significance, lack-of-fit test, and coefficient of determination R2). To illustrate the distribution of all trials as a function of the most distinctive response variables, a principle component analysis (PCA) was performed using XLSTAT Software version 18.06 (Addinsoft, Paris, France).

Results and Discussion

Preliminary Tests for the Selection of the Independent Variables

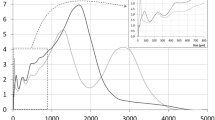

The influences of the seven processing variables chosen and three flour quality variables were investigated on seven physical properties of batter and cake using the “one-variable-at-a-time” technique. An illustration of four trend effects is shown in Fig. 1. An increase in liquid mixing time appeared to have a minor effect on cake density (Fig. 1a), whereas an increase in the proportion of pea flour had a quadratic trend effect on cake density (Fig. 1b). Indeed, cake density decreased from 10 to 60% of added pea flour and increased from 60 to 100%. A similar trend effect was observed on batter consistency (Table 2) that could explain the effect on cake density. It is known that there is an optimal batter consistency to obtain (Ronda et al. 2011) that should be high enough to retain the bubbles in the batter but not be too high to allow the structure to rise (Sahi and Alava 2003; Gómez et al. 2008). Here, the optimal batter consistency for a low cake density was obtained for a proportion of pea flour comprised between 40 and 60%. The quadratic variation of batter consistency as a function of legume flour introduction has already been observed by Gómez et al. (2012) when 0 to 25% (decrease), 25 to 50%, and 100% of pea flour (increase) were added to layer cakes. This variation suggests the presence of competing effects related to the structure of the dispersed phases (distribution of air bubbles or oil droplets) and/or to the structure of the continuous phase (viscosity lowering or enhancing effect of legume proteins). The increase in the proportion of the wheat fine fraction had a logarithmic decreasing trend effect on crumb stiffness (Fig. 1c). This could either be due to a decrease in cake density, a decrease in cell wall stiffness, or a change in the cell structure according to the results of Gibson and Ashby (1982). The other trend effects observed showed that there was no decrease in cake density or in cell wall stiffness (Table 2). However, the increase in the proportion of the wheat fine fraction caused an increase in cell fineness and a decrease in cell wall thickness that could explain the decrease in crumb stiffness. The presence of the wheat fine fraction composed mostly of particles the size of starch granules compared to particles the size of cells for the coarse fraction could help to maintain a distribution of small air bubbles throughout baking. Indeed, starch granules are the structuring “bricks” of the cell walls (Donovan 1977). The predominance of individual starch granules vs. bigger structural elements (endosperm cells containing several starch granules) prevents the mechanical disruption of the bubble interfaces in the first stages of baking and contributes to make the cell walls thinner. The increase in liquid mixing time had a linear increasing trend effect on cell fineness (Fig. 1d). During the second stage of mixing, the liquids are added to the dry ingredients and mixed at medium speed which enables the expression of the surface-active properties of the egg compounds and of the emulsifier. Massey et al. (2001) have shown that the mean size of the bubble size distribution in a cake batter decreased with mixing time until the maximum volume fraction of air was reached. Beyond the maximum, an increase in the mixing time decreased the air volume fraction and increased the mean bubble size. Here, the increase in the liquid mixing time from 1.5 to 6 min did not allow to reach the maximum air volume fraction but allowed to decrease the mean bubble size in the batter. This advantage was maintained throughout the third stage of mixing (oil addition) and the baking step, leading to cakes with higher cell fineness.

Illustration of various effects of independent variables on dependent variables: a cake density evolution versus liquids mixing time, b cake density evolution versus the proportion of pea flour, c cake stiffness evolution versus the proportion wheat fine fraction, d cell fineness evolution versus liquids mixing time. The standard error bars represent the standard deviation on mean values

The observations of all 70 trend effects are summarized in Table 2, which lists independent variables versus responses. This gives a quick overview of which factors influenced which responses. No factor impacted all the responses, and each response was impacted by a different set of factors. Some decreasing-increasing or increasing-decreasing trend effects were detected that could correspond to quadratic trend effects, and were even more obvious in the case of the proportion of pea flour. For the selection of the independent variables, priority was given to those impacting responses that were directly related to cake quality as perceived by the consumers, i.e., cake density, crumb stiffness, cell fineness, and cell wall thickness (in bold in Table 2). The order of the mixing stages was left out because it had no effect on any responses except on cell fineness. Among other processing variables, all affected two out of four of the target responses, except liquids mixing time, which only affected cell fineness. Oil mixing time had different effects when tested at speed 1 or 10, confirming the need to study two-way interactions. Finally, four processing variables were selected: liquids mixing speed, oil mixing speed, oil mixing time, and baking temperature. They were added to the three independent flour quality variables that were implicitly included in the study. The presence of suspected quadratic effects confirmed the need to fit the responses with second-order models. Furthermore these preliminary tests confirmed that the broadest ranges should be investigated for the ranges of variation of the selected factors.

Response Surface Regression Analysis

An I-optimal design with seven independent variables generated 56 soft cakes with very distinctive properties. The responses varied between 0.31–0.48 g cm−3 for cake density, − 5.4–17.1 for symmetry index, 11–104 kPa for crumb stiffness, − 11.5–18.5 for cell fineness, − 6.4–7.0 for cell wall thickness, and 77–89 for crumb lightness. The principal component analysis of the response variables is shown in Fig. 2. The two first principal components accounted for more than 70% of the variance. The loadings plot (Fig. 2a) indicated some correlations between response variables, mainly a positive correlation between crumb lightness and cell fineness (+ 0.765) and a negative correlation between crumb lightness and crumb stiffness (− 0.686). It also identified a low degree of correlation between the response variables and the independent variables introduced as supplementary data. The only remarkable correlations were negative correlations between the proportion of pea flour and cell fineness and crumb lightness (− 0.676 and − 0.639, respectively). Overall, these results show that the variation in dependent variables was explained by multiple regression of independent variables rather than by single correlations. The product map in Fig. 2b shows the distribution of all trials according to the directions of the response variables on the loadings plot (Fig. 2a). All products from the upper to the lower right (18, 4, 54, 41, 44, 7, 26) contained 35 to 60 wt% of pea flour. They corresponded to very stiff crumbs with thick cell walls (18, 4, 54, 41) or stiff crumbs with low fineness and lightness (44, 7, 26). Gómez et al. (2008, 2012) and De la Hera et al. (2012) showed that including legume flour in similar layer type formulas increased crumb stiffness and decreased crumb lightness. Using a pound cake formula containing more fat, Monnet et al. (unpublished works) showed a decrease in cell fineness and a slight increase in cell wall thickness with an increase of the proportion in pea flour. However, in this case, it was associated with lower stiffness of the crumbs showing that the effect depended on several variables (as established by Gibson and Ashby (1982)). Products in the third quartile were defined by low density and thin cell walls. Products from the center to the upper left (45, 19, 12, 46, 8) corresponded to cakes containing 10 wt% of pea flour produced under extensive mixing conditions (high mixing speeds and/or longer times), thus exhibiting crumbs with low stiffness, high lightness and high cell fineness. Overall, the product map shows that the combination of all the factors enabled the creation of a diversity of structures that were correctly distinguished by the response variables.

Table 3 presents the regression coefficients for the second-order models of all responses with their p values. Selection of the most significant effects (p ≤ 0.05) among the ranking of all the response variables resulted in a list of 23 significant effects from an original total of 35. Table 3 lists them in the form of LogWorth values with their significance levels (last column on the right). These effects represent the core of the multiobjective approach because they model and optimize all responses simultaneously. The effects with the highest significance were the proportion of pea flour (LogWorth = 11.7) for its significant impact on crumb stiffness, cell fineness, and crumb lightness, and the baking program (LogWorth = 10.0) for its significant impact on cake density, symmetry, and crumb lightness. The increase in crumb stiffness and the decrease in cell fineness due to the introduction of pea flour are linked, as demonstrated by Gibson and Ashby (1982). The decrease in cell fineness in pea-enriched cakes can be explained by a late or less efficient structuring of the cakes during baking, due to their reduced starch content, late starch gelatinization, and protein denaturation (Monnet et al. under revision). The decrease in crumb lightness is related to the greenish color of the pea flour. It is known that the baking temperature has an impact on the kinetics of cake expansion (Lostie et al. 2002). Sato et al. (1987) have shown that an increase in baking temperature caused an increase in the volume and in the symmetry index. The temperature also impacts the Maillard reactions that are responsible for a decrease of lightness of the product, even if it is classically more observed in the crust than in the crumb. The following effects in the order of decreasing significance were the oil mixing speed (LogWorth = 7.1) and the oil mixing time (LogWorth = 4.9) that both had a global impact on several response variables. The fact that processing variables were among the most significantly influential variables means their ability to correct the impact of uncontrolled variations in flour quality shows promise.

Compared to a standard selection of effects executed in the model of each response individually, multiobjective selection keeps the same number of effects for all models, and a higher number of effects in each model. This is illustrated in Table 3 by the fact that all models included a high number of non-significant effects. However, this did not compromise the performance of the models whose F ratios ranged between 4.9 and 12.3 with p values below 0.01%. They also exhibited insignificant lack-of-fit and high coefficients of determination, explaining 78 to 90% of the variation of the responses. This shows a good quality fit (even if R2 values were artificially raised by the presence of non-significant effects).

The number of significant coefficients in the models varied between six and 11. All dependent variables did not affect the same responses so that each response was explained by a different set of variables. Flour quality variables and processing variables could be compared for their significant effects on the responses and the sign of such effects. An increase in the proportion of pea flour significantly increased crumb stiffness and decreased cell fineness and crumb lightness. These impacts could be counteracted by an increase in one to four of the processing variables. However, an increase in the proportion of the pea or wheat fine fraction decreased crumb stiffness and increased cell fineness that could not be counteracted by any processing variable, except by the effect of the interaction between liquids mixing speed and oil mixing time in the case of crumb stiffness (Table 3). Moreover, an increase in the proportion of the pea fine fraction caused an increase in cake symmetry and a decrease in cell wall thickness. Cake symmetry could be either decreased or increased by an increase in processing variables. Cell wall thickness was decreased by an increase in oil mixing speed and time, but was increased by an increase in the interactions between liquids mixing speed and oil mixing speed and time, respectively. Overall, the processing variables appear to provide rather good flexibility to compensate for uncontrolled variations in flour quality. However, crumb stiffness and cell structure (cell fineness and cell wall thickness) appear to be a little more difficult to monitor by processing variables with regard to their dependence on flour particle size.

Validation of the Multiobjective Model

To validate the prediction capacity of the multiobjective model, two trials that were not included in the experimental design were defined and repeated three times each, several weeks apart. The settings of the independent variables for these trials are listed in Table 4. Given that the average variance of prediction of the model varies in all points of the space design, the two trials corresponded to different variances of prediction (Table 5). Because the lowest average variance of prediction corresponds to the central point (settings 35; 50; 50; 4; 6; 3; 180), the variance of prediction for product 2 (0.81) was higher than that of product 1 (0.56). The comparison between experimental and predicted responses is shown in Table 5. In most cases, the mean measured value was in the 95% confidence interval of prediction (calculated according to Student’s law). Only in the case of crumb stiffness, cell wall thickness, and crumb lightness for product 1, and cell wall thickness for product 2, the mean measured value was slightly out of the predicted confidence interval, but the measured and predicted confidence intervals still overlapped. The good agreement between experimental and predicted responses indicated a good prediction capacity of the multiobjective model.

In order to confirm this interpretation, the results of two other sets of trials were analyzed. These trials were set up to evaluate the capacity of the multiobjective model to correct the physical and sensory properties of the product in the case of invented case studies (results not shown in this article). One set of seven trials corresponded to the repetitions of the seven most different trials from the 56 original trials defined by hierarchical cluster analysis. The remaining three trials corresponded to external trials (like the two validation trials presented above) that were set up in the case of the case studies. The results of these two sets enabled respectively to confirm good data repeatability (cake processing repeatability and measurement repeatability) and to confirm a good prediction capacity of the multiobjective model (results not shown).

Conclusions

An I-optimal design was used to study the effect of upstream flour variability and process parameters on the quality of pea flour enriched cakes. Fifty-six cakes were obtained with very distinctive properties that were properly distinguished by the response variables. All the response variables were taken into account simultaneously in the selection of the most significant effects in order to build a multiobjective model. The models for the individual responses constitutive of the multiobjective model performed well, and the predicting capacity of the multiobjective model was validated. A rapid comparison of the impact of flour quality variables and processing variables on the responses indicated that the multiobjective model is able to compensate very satisfactorily for variations in flour quality by adjusting the levels of the processing variables.

References

Asselman, A., van Straten, G., Boom, R. M., Esveld, D. C., & van Boxtel, A. J. B. (2007). Quality prediction of bakery products in the initial phase of process design. Innovative Food Science & Emerging Technologies, 8(2), 285–298. https://doi.org/10.1016/j.ifset.2007.01.006.

Baş, D., & Boyacı, I. H. (2007). Modeling and optimization I: usability of response surface methodology. Journal of Food Engineering, 78(3), 836–845. https://doi.org/10.1016/j.jfoodeng.2005.11.024.

De la Hera, E., Ruiz-París, E., Oliete, B., & Gómez, M. (2012). Studies of the quality of cakes made with wheat-lentil composite flours. LWT - Food Science and Technology, 49(1), 48–54. https://doi.org/10.1016/j.lwt.2012.05.009.

De Vries, H., Mikolajczak, M., Salmon, J.-M., Abecassis, J., Chaunier, L., Guessasma, S., et al. (2017). Small-scale food process engineering — challenges and perspectives. Innovative Food Science & Emerging Technologies, 46, 122–130. https://doi.org/10.1016/J.IFSET.2017.09.009.

Dewaest, M., Villemejane, C., Berland, S., Michon, C., Verel, A., & Morel, M.-H. (2017a). Changes in protein size distribution during wheat flour cake processing. LWT - Food Science and Technology, 79, 333–341. https://doi.org/10.1016/j.lwt.2017.01.036.

Dewaest, M., Villemejane, C., Berland, S., Neron, S., Clement, J., Verel, A., & Michon, C. (2017b). Effect of crumb cellular structure characterized by image analysis on cake softness. Journal of Texture Studies, 49(3), 328–338. https://doi.org/10.1111/jtxs.12303.

Donovan, J. W. (1977). A study of the baking process by differential scanning calorimetry. Journal of the Science of Food and Agriculture, 28(6), 571–578. https://doi.org/10.1002/jsfa.2740280616.

Esveld, D. C., Boom, R. M., Van Straten, G., & Van Boxtel, A. J. B. (2008). Product quality driven design of bakery operations using dynamic optimization. Journal of Food Engineering, 86(3), 399–413. https://doi.org/10.1016/j.jfoodeng.2007.10.015.

Farooq, Z., & Boye, J. I. (2011). Novel food and industrial applications of pulse flours and fractions. In B. K. Tiwari, A. Gowen, & B. McKenna (Eds.), Pulse Foods: Processing, Quality and Nutraceutical Applications (pp. 283–323). Academic Press.

Ferrari, I., Alamprese, C., Mariotti, M., Lucisano, M., & Rossi, M. (2013). Optimisation of cake fat quantity and composition using response surface methodology. International Journal of Food Science & Technology, 48(3), 468–476. https://doi.org/10.1111/ijfs.12018.

Gergely, S., Bekassy-Molnar, E., & Vatai, G. (2003). The use of multiobjective optimization to improve wine filtration. Journal of Food Engineering, 58(4), 311–316. https://doi.org/10.1016/S0260-8774(02)00376-X.

Gibson, L. J., & Ashby, M. F. (1982). The mechanics of three-dimensional cellular materials. Proceedings of the Royal Society A: Mathematical, Physical and Engineering Sciences, 382(1782), 43–59. https://doi.org/10.1098/rspa.1982.0088.

Gómez, M., Oliete, B., Rosell, C. M., Pando, V., & Fernández, E. (2008). Studies on cake quality made of wheat–chickpea flour blends. LWT - Food Science and Technology, 41(9), 1701–1709. https://doi.org/10.1016/j.lwt.2007.11.024.

Gómez, M., Doyagüe, M. J., & De Hera, E. (2012). Addition of pin-milled pea flour and air-classified fractions in layer and sponge cakes. LWT - Food Science and Technology, 46(1), 142–147. https://doi.org/10.1016/j.lwt.2011.10.014.

Heenan, S. P., Dufour, J.-P., Hamid, N., Harvey, W., & Delahunty, C. M. (2010). The influence of ingredients and time from baking on sensory quality and consumer freshness perceptions in a baked model cake system. LWT - Food Science and Technology, 43(7), 1032–1041. https://doi.org/10.1016/j.lwt.2009.12.009.

Lostie, M., Peczalski, R., Andrieu, J., & Laurent, M. (2002). Study of sponge cake batter baking process. Part I: experimental data. Journal of Food Engineering, 51(2), 131–137. https://doi.org/10.1016/S0260-8774(01)00049-8.

Massey, A. H., Khare, A. S., & Niranjan, K. (2001). Air inclusion into a model cake batter using a pressure whisk: development of gas hold-up and bubble size distribution. Journal of Food Science, 66(8), 1152–1157.

Monnet, A.-F., Laleg, K., Michon, C., & Micard, V. (under revision). Legume-enriched cereal products: a generic approach derived from material science to predict their structuring by the process and their final properties. Trends in Food Science & Technology.

Nemecek, T., von Richthofen, J.-S., Dubois, G., Casta, P., Charles, R., & Pahl, H. (2008). Environmental impacts of introducing grain legumes into European crop rotations. European Journal of Agronomy, 28(3), 380–393. https://doi.org/10.1016/j.eja.2007.11.004.

Noorfarahzilah, M., Lee, J. S., Sharifufin, M. S., Mohd Fadzelly, A. B., & Hasmadi, M. (2014). Applications of composite flour in development of food products. International Food Research Journal, 21(6), 2061–2074.

Ronda, F., Oliete, B., Gómez, M., Caballero, P. A., & Pandon, V. (2011). Rheological study of layer cake batters made with soybean protein isolate and different starch sources. Journal of Food Engineering, 102(3), 272–277. https://doi.org/10.1016/j.jfoodeng.2010.09.001.

Sahi, S. S., & Alava, J. M. (2003). Functionality of emulsifiers in sponge cake production. Journal of the Science of Food and Agriculture, 83(14), 1419–1429. https://doi.org/10.1002/jsfa.1557.

Sanchez, H. D., Osella, C. A., & De La Torre, M. A. (2004). Use of response surface methodology to optimize gluten-free bread fortified with soy flour and dry milk. Food Science and Technology International, 10(1), 5–9. https://doi.org/10.1177/1082013204042067.

Sato, H., Matsumura, T., & Shibukawa, S. (1987). Apparent heat transfer in a forced convection oven and properties of baked food. Journal of Food Science, 52(1), 185–188.

Szczesniak, A. S. (2002). Texture is a sensory property. Food Quality and Preference, 13(4), 215–225. https://doi.org/10.1016/S0950-3293(01)00039-8.

Tan, M. C., Chin, N. L., & Yusof, Y. A. (2012). A Box–Behnken design for determining the optimum experimental condition of cake batter mixing. Food and Bioprocess Technology, 5(3), 972–982. https://doi.org/10.1007/s11947-010-0394-5.

Turabi, E., Sumnu, G., & Sahin, S. (2008). Optimization of baking of rice cakes in infrared–microwave combination oven by response surface methodology. Food and Bioprocess Technology, 1(1), 64–73. https://doi.org/10.1007/s11947-007-0003-4.

Young, V. R., & Pellett, P. L. (1994). Plant proteins in relation to human protein and amino acid nutrition. The American Journal of Clinical Nutrition, 59(5 Suppl), 1203S–1212S.

Acknowledgements

The authors thank Brigitte Deau, Anne-Marie Gibon, and Alexandre Eurieult for the help with the experiments.

Funding

This work was carried out in the framework of the FLEXIPROCESS project with financial support from the Carnot Qualiment Agency. The authors thank the Carnot Qualiment, AgroParisTech, and the French Ministry of Higher Education and Research for their financial support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Monnet, AF., Michon, C., Jeuffroy, MH. et al. Taking into Account Upstream Variability of Flours with Processing Variables in Legume-Enriched Soft Cakes: Conception of a Multiobjective Model for the Monitoring of Physical Properties. Food Bioprocess Technol 12, 625–635 (2019). https://doi.org/10.1007/s11947-018-2230-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-018-2230-2

ᅟ, bold characters) and independent variables as supplementary variables (

ᅟ, bold characters) and independent variables as supplementary variables ( ᅟ). b Product map showing the repartition of the 56 trials

ᅟ). b Product map showing the repartition of the 56 trials