Abstract

Jackfruit chips are very popular in South Asia; however, the quality of traditional hot air-dried jackfruit chips is not desirable due to brown color and high hardness. The effects of three drying methods, instant controlled pressure drop-assisted freeze drying (FD-DIC), instant controlled pressure drop-assisted hot air drying (AD-DIC), and freeze drying (FD), on the physicochemical characteristics, color, antioxidant activity, expansion ratio, texture, rehydration, hygroscopicity, and microstructure of jackfruit (Artocarpus heterophyllus L.) chips were investigated. The FD-DIC-dried jackfruit chips showed the highest expansion ratio (119 %), the best color (△E, 6.5) and texture (hardness 42 N, crispness 19) compared with the FD- and AD-DIC-dried samples. A substantial increase in pore size was observed in the microstructure of the FD-DIC-dried chips. Compared with AD-DIC, the FD-DIC-finished jackfruit chips exhibited stronger antioxidant capacities (DPPH· free radical scavenging activity, ferric reducing power, and ABTS·+ radical cation scavenging activity) and higher retention of phenolics (1.2 mg GAE g−1) and carotenoids (3.1 μg CE g−1). In conclusion, the jackfruit chips produced by FD-DIC obtained a superior overall quality than the AD-DIC- and FD-dried samples. Considering the relatively high production cost of FD, this novel combination (FD-DIC) could be an alternative method for obtaining high-quality fruit chips or processing valuable agro-products.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Jackfruits (Artocarpus heterophyllus L.) belongs to the Moraceae family and are widely grown in India, Bangladesh, Thailand, Indonesia, and Malaysia (Saxena et al. 2013), which are the top five producer of jackfruits in the world with a total production of approximately 3.11 million tons per year (Sidhu 2012). Jackfruits are tropical fruits rich in dietary fiber, protein, potassium, magnesium, iron, vitamin B complex, vitamin C, and many phytochemicals including phenolics and carotenoids (Jagtap et al. 2010). Due to a low yield of edible portion (around 35 % of whole fruit), transportation and storage of raw jackfruit is not particularly economical (Saxena et al. 2012a). Many preservation/processing methods have been developed to preserve this multi-nutritional and perishable fruits. However, a large amount of jackfruits still get spoilt due to lack of proper preservation/processing, an integrated supply chain, and/or storage facilities during the peak seasons of harvest.

Drying or dehydration is a traditional method to extend the shelf life of fruits and vegetables and is also an alternative solution for jackfruit preservation and transportation. Several drying methods have been conducted on jackfruit (Chowdhury et al. 2011; Giraldo-Zuñiga et al. 2006; Prasantha and Amunogoda 2013; Pua et al. 2010; Saxena et al. 2012a; Taib et al. 2013). Nowadays, hot air-drying (AD) and frying are the most frequently used techniques for processing jackfruit chips. Frying yields fruit chips with an appealing crispy texture, but the excessive absorption of oil is inevitable, which is not desired from the heath point of view. The production cost of AD is relatively low, but it has adverse effect on the color, nutrition, and texture quality of fruit chips due to the longer duration of drying (Saxena et al. 2012a; Taib et al. 2013). Combination or intermittent drying process was developed to take the advantages of different drying methods and avoid the shortcomings of a certain drying method (Kumar et al. 2014). Some combination drying methods were proved to be more energy efficient and/or producing products with higher overall quality. For instance, a study on carrot showed that microwave-vacuum drying (MV) combined freeze drying (FD) rendered a higher retention of carotene and vitamin C, and a better rehydration capacity of carrot, compared with hot air-dried samples (Cui et al. 2008). Hu et al. (2006) found that AD combined MV drying significantly shortened the drying time of edamames compared with hot air-drying and greatly decreased mass loads on the vacuum microwave dryer. These studies indicated that combination drying could be a more economical and promising way for fruit and vegetable drying.

Instant controlled pressure drop process (DIC, French for Détente instantannée contrôlée), also known as explosion puffing (EP) in some literature, was developed since 1988 (Allaf & Allaf 2014; Bi et al. 2015a, b; Mounir et al. 2012; Zou et al. 2013). This process is based on a thermomechanical effect induced by an abrupt transition from high pressure (or ambient pressure) to a vacuum, which lead to the expansion of products (Alonzo-Macias et al. 2014). DIC contributes to the special qualities of low-density, porous structure, and appealing crispy taste. In addition, the reduction in total processing time, compared with traditional AD, leads to significant improvements in nutrition retention, color, and flavors of fruit chips (Mounir et al. 2012). However, this technology requires relatively low moisture content (around 30 % db) to start the process (Allaf and Allaf 2014), which means it cannot be used alone to dry fresh fruits. Normally, AD is used as a combination/pre-drying for reducing the moisture content of a raw material for following DIC process (Bi et al. 2015a, b; He et al. 2013; Kozempel et al. 1989; Zou et al. 2013). However, collapse and shrinkage of fruits and vegetable tissues often occurs during AD process, as well as adverse effects on some other quality parameters, e.g., volume expansion ratio, color, and crispness.

Freeze drying is based on dehydration by sublimation of a frozen material. Due to low temperature and absence of liquid water during the process, many quality deteriorations are almost stopped which gives a final product with excellent quality (Geidobler and Winter 2013). But its costs are four to eight times higher compared to AD, which make it more viable for high-value products than for common vegetables and fruits (Ratti 2001). However, based on the fact that FD can build a rigid bulk structure and/or maintain the dimensional cell stability during dehydration, avoiding shrinkage and collapse of the parenchyma cells, it might have positive effects, when used as an alternative combination for DIC, on the volume expansion ratio and texture of fruit chips, as well as overall qualities. Therefore, the objective of present work was to investigate the effect of freeze drying as a pre-drying for instant controlled pressure drop process on the physicochemical and organoleptic properties of jackfruit chips, compared with freeze drying, and traditional instant controlled pressure drop-assisted hot air-drying.

Materials and Methods

Sample Preparation

The fully ripened fruits of A. heterophyllus with total soluble solid content of 10.1 ± 0.6 °Brix were purchased from Xinfadi agro-product market in Beijing, China. All the jackfruits used in this experiment were of the same batch. The edible jackfruits bulbs were selected manually to obtain those in good condition and without deterioration. It was then followed by washing, peeling, and cutting into 5.0 × 1.5 × 1.5 cm slices manually. For FD and instant controlled pressure drop-assisted freeze drying (FD-DIC) treatment, samples were frozen and stored at −40 °C before used. Fresh jackfruit slices were used for instant controlled pressure drop-assisted hot air-drying (AD-DIC). The weight of jackfruit slices used for each treatment was 200 g.

Drying Processes

Instant controlled pressure drop-assisted freeze drying (FD-DIC) consisted of three main steps. Firstly, samples were freeze dried using a laboratory freeze dryer (Alphal-4Lplus, CHRIST Co., Osterode am Harz, Germany). During FD, the pressure was 0.1 kPa with the condenser temperature of −56 °C. The temperature of secondary drying was set at 25 °C. A batch of samples were dried to final moisture content by freeze dryer, while another batch of samples were transferred to the processing vessel of an experimental DIC processor (Tianjin Qin-de New Material Scientific Development Co. Ltd., Tianjin, China) when the moisture content of jackfruit slices was decreased to 50 % db. As shown in Fig. 1, the DIC processor mainly consisted of processing vessel, vacuum tank, vacuum pump, decompression valve, air compressor, and steam generator. The processing vessel (50 L) was connected to the vacuum tank (3.6 m3) by a butterfly valve (diameter 150 mm), which was driven pneumatically. The semi-dried jackfruit slices were placed on the stainless steel grids in a single layer (loading capacity 5.2 kg m−2) in the processing vessel. The steel grids were heated by a steam generator. The samples were equilibrated at 90 °C for 10 min. During the heating, the vacuum tank was evacuated to approximately 3 kPa by a vacuum pump. Then, the decompression valves were opened to obtain an instant pressure drop (<0.2 s) to vacuum (5 kPa) in the processing vessel. After decompression, the samples were dried under continuous vacuum at 60 °C for 2.5 h.

AD-DIC also consisted of three steps. Firstly, fresh jackfruit slices were dried by using a hot air dryer (DHG-9123A, Jinghong Laboratory Instrument Co., Ltd., Shanghai, China) under air flow with a temperature, velocity, and relative humidity of 60 °C, 1.2 m s−1, and 12 %, respectively. A batch of samples were dried to final moisture content by AD, while another batch of samples were transferred to the processing vessel for DIC treatment when the moisture content was decreased to 50 % db. The parameters of the DIC process were the same as the FD-DIC process. The weights of samples were measured every 3 min during the processing by using an automatic digital balance. All samples were removed until their moisture contents were lower than 5.0 % db. Each drying process was conducted in triplicate. For chemical analysis, the dried samples were kept in a desiccator over P2O5 at −4 °C.

Physicochemical Characterization

For moisture content determination, 5.0 g jackfruit chips were dried at 105 °C to constant weight (Zou et al. 2013), using a convective dryer (DHG-9123A, Jinghong Laboratory Instrument Co., Ltd., Shanghai, China). Water activity were measured using an Aqualab 3 analyzer (Decagon Devices Inc., Pullman, USA) at 25 °C after stabilization of the samples at this temperature for 1 h (Giraldo-Zuñiga et al. 2006). Jackfruit chips (20 g) were mixed with 20 mL distilled water and ground with pestle and mortar. The mixture was filtered through muslin clothes, and the filtrate was used to measure total soluble solid (TSS) content, using a refractometer (MASTER-α, Atago Co. Ltd., Tokyo, Japan) (Cayuela 2008). Fresh jackfruit juice was used for determining the TSS of fresh sample. The above filtrate was centrifuged at 6000 g for 10 min, and the supernatant (5.0 mL) was used for titritable acidity (TA) determination, by titrating the filtrate against 0.1 N NaOH. Phenolphthalein was used as indicator, and the appearance of a light pink color was considered as the end-point. TA was calculated and expressed as percent citric acid. The supernatant (1.0 mL) was further diluted with 9.0 mL of distilled water for reducing sugar content (RS) measurement. The RS was determined by 3,5-dinitrosalicylic acid colorimetry method (Miller 1959), using a spectrophotometer (UV1800, Shimadzu Co. Ltd., Kyoto, Japan) at 540 nm. Total phenolic content (TP) was determined according to the procedure described by You et al. (2011). The TP was expressed in milligram gallic acid equivalents (GAE) per gram of dried sample. Total carotenoids content (TC) was determined according to the procedure described by Saxena et al. (2012a). The TC was expressed in microgram β-carotene equivalents (CE) per gram of dried sample. All the physicochemical tests were performed in triplicate.

Antioxidant Activities

Jackfruit chip powder (3.0 g) were dissolved in 25 mL 80 % methanol (with 1 % HCl) and extracted with ultrasonic for 15 min, stirred for 24 h at 4 °C, and centrifuged at 9000g for 10 min. The supernatant (10 mL) was then adjusted to 50 mL and used for the antioxidant activity assay. DPPH· free radical scavenging activity was determined according to the method reported by Jagtap et al. (2010). The stock reagent solution was prepared by dissolving 24 mg 1,1-diphenyl-2-picryl-hydrazyl (DPPH) to 100 mL ethanol and stored at −20 °C until use. The working solution was obtained by mixing 10 mL of stock solution with 45 mL methanol to obtain an absorbance at 517 nm. The sample diluents (0.2 mL) were mixed with 2.8 mL of DPPH solution. The mixture was stirred for 1 min, allowed to stand at room temperature in dark for 1 h and determined at the absorbance of 517 nm using a spectrophotometer. Methanol (0.2 mL), replacing the extract, was used as the blank. The standard curve was linear between 50 and 800 μM Trolox. Results are expressed in millimolar Trolox equivalents (TE) per gram of dried sample.

Ferric reducing/antioxidant power (FRAP) assay was performed as previously described by Benzie and Strain (1996). Briefly, FRAP reagent was prepared by mixing 100 mL acetate buffer (300 μM, pH 3.6), 10 mL of 10 μM 2,4,6-tripyridyl-s-triazine (TPTZ) in 40 μM HCl, and 10 mL of 20 μM FeCl3. The FRAP solution was incubating at 37 °C for 10 min. Jackfruit extract diluents (0.2 mL) were mixed with 2.8 mL of the FRAP solution, stirred for 1 min, and allowed to react for 1 h in dark. The readings of the colored product (ferrous tripyridyltriazine complex) were taken at 593 nm. Methanol (0.2 mL), replacing the extract, was used as the blank. The standard curve was linear between 50 and 800 μM Trolox. Results are expressed in millimolar TE per gram of dried sample.

ABTS·+ radical scavenging activity was measured according to the method described by Hsu et al. (2003). Peroxidase (4.4 units mL−1, 0.2 mL), H2O2 (50 μM, 0.2 mL), ABTS [2,2-azino-bis (3-ethylbenz-thiazoline-6-suflfonic acid), 100 μM, 0.2 mL], and distilled water (1.4 mL) were mixed. The mixture were stirred for 1 min and kept in dark at room temperature for 2 h to form a bluish-green complex. After adding 0.2 mL of diluted jackfruit extract, the absorbance at 734 nm was measured. Methanol (0.2 mL), replacing the extract, was used as the blank. The standard curve was linear between 50 and 600 μM Trolox. Results are expressed in millimolar TE per gram of dried sample. All the antioxidant activity assays were performed in triplicate.

Color Analysis

Color of dried samples was determined by a Hunter Lab colorimeter D25L (Hunter Associates Laboratory Inc., VA, USA). Instrumental color data were expressed as CIE L, a, b coordinates, which defined the color in a three-dimensional space: L (darkness-lightness), a (redness-greeness), and b (yellowness-blueness). △E represents total color difference and it was calculated according to Eq. 1.

where L 0, a 0, and b 0 are the color of fresh samples, and L*, a*, and b* are the color of dried samples, respectively. Three measurements were made at different location (top, middle, and bottom) on the surface of each jackfruit slice, and the procedure was repeated in quadruplicate (Saxena et al. 2012a).

Texture

Texture of the dried jackfruit chips were measured using a TA.XT2i/50 Texture Analyzer (Stable Micro System Ltd., Godalming, UK) fitted with a spherical probe (P/0.25) (Bi et al. 2015a, b). The pre-test, test, and post-test speed were 2.0, 2.0, and 1.0 mm s−1, respectively. The test distance was 15.0 mm and trigger force was 5.0 g. A force-time curve was recorded and analyzed by the software of Texture Exponent 32 (Surry, UK) to calculate peak compression force (N) and number of compression peaks, which represent hardness and crispness, respectively. Twelve measurements were performed for each treatment.

Expansion Ratio

The bulk of the jackfruit slices were measured using an exclusive method, and millets were selected as filling material (Bi et al., 2015a, b). The millets are characterized by its high degree of fluidity and high resistance to compression, which makes them well suited for volume measurement. A mass of 20 g of jackfruit chips, weighed to the nearest 0.01 g, were placed in a volumetric cylinder (200 mL). The chips were then covered with the millets, which were than tamped down by a series of mechanical shakes until a stable volume (V 1) was reached. The chips were removed, and the volume of the used millets (V 2) was measured as described above. The volume of the fresh jackfruit slices (V 0) was measured using the same procedure. The expansion ratio (ER, %) of jackfruit chips was thus calculated as Eq. 2.

Rehydration Ratio and Hygroscopicity

Rehydration ratio (RR) was determined according to the method described by Zou et al. (2013). Briefly, each chip was weighed, placed in a tea drainer, and then immersed in a water bath at 25 °C for various times. At different time intervals, the samples were removed from water. Excess water from the surface was gently wiped off using tissues, and the sample was weighed. The RR was calculated based on dividing the mass of a sample after rehydration by the mass before immerging. Hygroscopicity (HG) was determined by the method of Caparino et al. (2012). Jackfruit chips (5.0 g) were placed in aluminum specimen boxes, then put them into a humidity jars containing NaCl-saturated solution (75.5 % humidity), stored at 25 °C for 24 h, and weighed every 2 h. The HG (%) was calculated by Eq. 3.

where ∆m (g) is the increase in weight of jackfruit slices at equilibrium, M is the initial mass of jackfruit chips, and M i (% wb) is the moisture content of the chips before exposed to the humid environment. RR and HG determinations were carried out in triplicate.

Scanning Electron Microscopy

Morphological characterization of the jackfruit chip microstructure were performed using a scanning electron microscopy (SEM S-570 HITACHI Co., Tokyo, Japan) at 150 kV accelerated voltage and 10–15 mm working distance (Zhao et al. 2009). For fresh fruit slices, the samples were rinsed in phosphate buffer (0.1 M, pH 7.2) and post-fixed in 2 % osmium tetroxide (OsO4) for 2 h and again rinsed in the phosphate buffer. Dehydration was carried out by immersing the specimens serially in aqueous solutions of 30 to 100 % ethanol for 2.5 h. After dehydration, the specimens were critical point dried (43 °C and 80 kPa) using a Leica EM CPD300 device (Bal-Tec AG, Balzers, Liechtenstein). All the samples were coated with 10 nm gold before observation.

Sensory Evaluation

Sensory evaluation was performed with a 15-member evaluation panel (students and staff from the Chinese Academy of Agricultural Science). The quality attributes tested were color, odor, crispness, flavor, and overall quality. Samples were placed in labeled and capped glass containers, randomly coded by 2-digital numbers and served to each panelist in an evaluation cabin. A 9-point hedonic scale was used with a score of 1–9, where 1 represents dislike extremely and 9 represents like extremely (Zou et al. 2013).

Statistical Analysis

Statistical analysis of the experimental data was conducted using the software SPSS Statistics (v17.0, SPSS Inc., Chicago, USA), applying one-way analysis of variance (ANOVA) and Tukey’s multiple comparison tests. Significant differences were defined at p < 0.05.

Results and Discussion

Physicochemical Analysis

The moisture content, A w , TSS, RS, and TA of the jackfruit chips are presented in Table 1. The moisture content of fresh jackfruit slices were around 83 g 100 g−1 wb. There was no difference between the moisture contents of jackfruit chips dried by FD-DIC and AD-DIC (2.8 and 3.4 g 100 g−1 db, respectively); while the FD dried samples obtained higher moisture content (4.9 g 100 g−1 db). The results showed that the final moisture contents of dried jackfruit chips were lower than some previous studies (9–22 % db) (Giraldo-Zuñiga et al. 2006; Prasantha and Amunogoda 2013). However, lower moisture content might contribute to the crispness of jackfruit chips (Fernandes et al. 2011). The A w values of the jackfruit chips were 0.43 to 0.46. Similar A w of solar-dehydrated jackfruit chips (0.47 ± 0.05) was reported by Prasantha and Amunogoda (2013).

There were no significant differences among the three drying treatments in the TSS contents, indicating that the drying process had little influence on soluble solid contents. Kwok et al. (2004) reported that no differences were found in TSS between the FD- and AD-dried Saskatoon berries. The RS content of FD-DIC-dried samples were higher than that of the AD-DIC-dried samples. This difference could be attributed to the long-time exposure at relatively high temperature (60 °C) during AD pre-drying process (Huang et al. 2012). In this study, samples treated by AD-DIC stayed at 60 °C for 6 h, while FD-DIC-finished samples stayed at around 25 °C for 12 h. The TA content of the fresh jackfruit slices was 0.37 %, which was in the range of TA of jackfruits (0.19–0.59 %) reported by Jagadeesh et al. (2007). No significant differences were found in the TA among different drying methods.

Phenolics and carotenoids are two main functional compounds in jackfruits, which are important antioxidants, and play an important role in increasing health benefit (Swami et al. 2012). The TP and TC contents of jackfruit chips are shown in Table 2. The TP and TC contents for the fresh samples were 1.8 mg GAE g−1 and 7.6 μg CE g−1, respectively, which were similar to the contents in some literature (Jagtap et al. 2010; Saxena et al., 2009; Swami et al. 2012). The highest retention of TP (88.9 %) and TC (86.8 %) were observed in the FD samples, possibly because of the lower temperature (25 °C) throughout FD dehydration. The TP content of the FD-DIC-dried jackfruit was higher than that of the AD-DIC-dried sample. Together with the high retention of TP after FD, the results indicated that a considerable amount (around 22 %) of phenolics was degraded during DIC processing. Carotenoids are the main compounds that contribute to the yellow color of jackfruits, and they are susceptible to light, heat, and high oxygen tension, thus, easily be destroyed during thermal processing (Dias et al. 2014). The TC content of FD-DIC-dried jackfruit chips was higher than that of the AD-DIC-dried chips, which might due to the difference in processing temperature between AD and FD pre-drying. Saxena et al. (2012a) found that the TC content of jackfruits decreased from 8.2 μg CE g−1 to 2.2, 1.2, and 0.4 μg CE g−1 after hot air-drying at 50, 60, and 70 °C for 12 h, respectively. Maity et al. (2014) found that almost 90 % carotenoids of jackfruit chips were degraded when frying was carried out at 100 °C for 30 min. Moreover, the carotenoid molecules have characteristic conjugated polyene which is highly susceptible to degradation due to oxidation (Saxena et al., 2009). Therefore, the vacuum condition during FD pre-drying was considered to be another explanation for the higher TC content of the FD-DIC-finished products (Cui et al. 2004).

Antioxidant Activities

It is generally believe that oxidation is one of the primary factors for developing many chronic degenerative processes, including aging (McCord 2000). Generally, alkyl free radicals are formed during the induction period of lipid auto-oxidation. Hydrogen peroxide and hydrogen peroxide free radical, derived from alkyl free radicals, are the major products during the propagation period. It is corroborated that the chain reaction of lipid auto-oxidation stops if two free radicals combine together. Hence, one of the antioxidant mechanisms is to provide hydrogen atoms to free radicals and to stop the chain reaction (Benzie 2000; Hsu et al. 2003). The DPPH, ABTS, and FRAP assay, which were used in this study, are common tests developed for measuring the antioxidant activities of a plant material (Hsu et al. 2003; Jagtap et al. 2010). As shown in Table 2, the FD-dried jackfruit chips always showed the strongest DPPH· free radical scavenging activity (0.38 mM TE g−1), ferrous ion chelating capacity (0.72 mM TE g−1), and ABTS·+ radical scavenging activity (0.43 mM TE g−1) among the three drying methods. A study on yam showed that the FD-dried sample exhibited higher DPPH, ABTS·+ radical scavenging activity and ferrous ion chelating capacity compared with the AD-dried (60 °C, 48 h) samples (Hsu et al. 2003). The FD-DIC-finished jackfruit chips showed higher antioxidant properties, e.g., DPPH· free radical scavenging activity (0.27 mM TE g−1), ability to reduce Fe3+ to Fe2+ (0.64 mM TE g−1) and ABTS·+ scavenging activity (0.35 mM TE g−1), compared to the samples dried by AD-DIC. The phenolic and carotenoid phytochemicals exhibit redox properties, which play a crucial role in the antioxidant determination (Jagtap et al. 2010; Saxena et al. 2012a). As shown in Table 2, the reduction of antioxidant capacities of the dried jackfruit chips was in good agreement with the degradation of the TP and TC contents. In addition, it was reported that the DPPH, FARP, and ABTS·+ scavenging activity was closely correlated with the amount of phenolic compounds (R 2 0.966, 0.946, and 0.939, respectively) (Dudonne et al. 2009). Therefore, the fact that higher retentions of phenolics were found in the FD-DIC-finished chips might contribute to a higher antioxidant activity compared with the AD-DIC-dried samples.

Color Analysis

Color is one of the most obvious attributes of quality for fruit chips and it is also an intuitionistic sensory quality which affects consumer’s choice (Saxena et al. 2012b). The color of jackfruit chips were significantly influenced by drying process (Table 3). There were significant decreases in the L* values of jackfruits from fresh (59) to FD-DIC (56) and AD-DIC (52)-finished chips. The L* of FD dried samples was substantially increased (p < 0.05) to 64, which was the highest L* value observed in this study. FD yielded jackfruit chips with a whiter appearance, which was in consistent with Krokida et al. (2001), who found that the L* values of apple, banana, potato, and carrot were increased after FD compared with the fresh sample. Significant increases in a* values were found in the FD-DIC- and AD-DIC-dried chips compared to the fresh samples. A decrease in L* and an increase in a* indicated a tendency in browning (Saxena et al. 2012a), which might be attributed to the color of reaction products from Maillard reaction and caramelization, or due to pigment (e.g., β-carotene) degradation (López et al. 2010; Zou et al. 2013). Decreases in b* were found in all the jackfruit chips, but there were no significant differences between the FD-DIC- and AD-DIC-finished chips. The overall color changes of jackfruit chips can be reflected from its △E value. The FD-DIC-finished chips showed a lower value of △E (7.6) than the AD-DIC-finished chips, suggesting that the FD-DIC-finished products obtained a color that was more similar to the fresh jackfruits, possibly by minimizing color deterioration during pre-drying stage.

Expansion Ratio and Texture

The expansion ratio (ER) and texture properties of the jackfruit chips are shown in Table 4. The maximum ER value (119 %) was observed in the FD-DIC-treated sample. The increase in volume was attributed to the expansion effects of DIC process during depressurization phase. The internal water of jackfruit slices, which was heated to above its boiling point before depressurization, turns to pressured vapor immediately during instant pressure drop (Allaf and Allaf 2014). Thus, driven by the pressure difference (0.1 MPa), the water in the tissue vaporized and exploded rapidly to the outer vacuum environment. The depressurization, involved the rapid releasing of water, formed a puffy structure and expanded the bulk volume by 19 % in the case of FD-DIC. Study on apple chips showed that maximum volume expansion of 14 % was observed after AD-DIC processing (Bi et al., 2015a). Slight shrinkage (6 %) was observed in the FD-dried samples. Similar volume decreases in apple, strawberry, and raspberry after FD was reported by Moreira et al. (2000) and Ratti (2001). Although no difference in volume was found between the fresh and AD-DIC-dried jackfruit chips, obvious volume shrinkage (reduced about 30 % in volume, data not shown) was observed after AD pre-drying, which was consistent with some previous reports (Krokida and Maroulis 1997; Moreira et al. 2000). However, this volume reduction was approximately neutralized by the expansion effects during DIC processing; thus, the volume of the AD-DIC finished products was similar to that of the fresh samples.

The texture (hardness and crispness) of the jackfruit chips are shown in Table 4. The lowest and highest hardness values were obtained in the FD (34 N) and AD-DIC (48 N) treatments, respectively. The lowest crispness was observed in the FD-dried jackfruit chips (9.0), while the FD-DIC-dried samples showed the highest crispness (19). It is suggested that FD treatment could build a rigid bulk structure and/or maintain the dimensional cell stability during processing, avoiding shrinkage, and collapse of the parenchyma cells, thus maintaining a porous structure (Krokida et al. 1998; Rahman 2001). Although the crispness value of FD-dried jackfruit slices could be read through the instrumental texture determination, actually, the products did not show a good crispy taste, based on the results of the sensory evaluation using a 15-member panel (Table 5). On the contrary, the samples dried by FD obtained a spongy, soft, and sticky mouthfeel rather than crispy and puffy texture, which were both exhibited in FD-DIC- and AD-DIC-finished product. Possible explanation for this was the moisture contents of DIC-finished chips was lower than the FD-dried chips, which could reduce the glass transition point (T g) of the jackfruit chips (Mounir et al. 2012), leading to a stronger and more hardened porous microstructure, and thus exhibiting a higher crispness. Although the final volume of the AD-DIC-dried samples expanded to similar sizes of the fresh slices after DIC processing, higher hardness and lower crispness value were obtained for these products, which consequently contributed to negative effects on organoleptic (texture) quality (Alonzo-Macias et al. 2014).

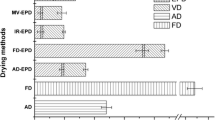

Rehydration and Hygroscopicity

The rehydration and hygroscopicity properties of the jackfruit chips are shown in Fig. 2. No significant difference in rehydration capacity were found between the jackfruit chips dried by FD and FD-DIC; however, both of their initial rehydration ratio (0–20 min) were substantially higher (p < 0.05) than that of AD-DIC-dried samples (Fig. 2a), indicating a faster initial water imbibition. Maskan (2001) found that the rehydration properties were inherently connected with structural features. In detail, since a rapid moisture uptake is due to surface and capillary suction, the rehydration kinetics of dried fruits is strongly related to porosity, and filling of capillaries and cavities near the surface yields a quick saturation (Maskan 2001; Rahman 2001). FD has a positive effect on keeping the cell wall structure and maintaining porous structure (Krokida et al. 1998), thus leading to superior rehydration properties (Lewicki 1998). Therefore, the FD pre-drying might be a partial explanation for the relatively high rehydration ratio of FD-DIC-finished products.

The FD-dried jackfruit chips showed the highest water absorption ability in the humid environment (75 % humidity), while the FD-DIC-dried samples exhibited an intermediate hygroscopicity among the three samples. In the case of AD-DIC-dried jackfruit chips, the outer layers of slices became rigid and acquired considerable mechanical strength during AD pre-drying, consequently formed a covering layer resistant to water absorption (Giovanelli et al. 2002; Lewicki 1998), contributing to its lower hygroscopicity. Higher hygroscopicity, which indicates stronger tendency of water absorption, has a negative effect on dried products preservation by shortening its shelf life through texture deteriorating and/or spoilage (Prasantha and Amunogoda 2013). Therefore, the product dried by FD with a higher hygroscopicity might need a more efficient water proof package during shelf life storage, which could enhance the total cost of production.

Microstructure

The microstructures of the jackfruit chips obtained by SEM are shown in Fig. 3. Homogenous honeycomb or porous structures were clearly observed in the fresh samples (Fig. 3a). Changes in the shape and size of cells were observed in all the jackfruit chips. Compared with the fresh sample, a substantial increase in cell size was found in both AD-DIC and FD-DIC samples (arrows in Fig. 3c, 3d). The expansion was difficult to quantify due to the large differences in cell size within the jackfruit tissue, but DIC process formed loose structure cavities nearly twice as large as in the raw jackfruit. The increase in cell size was supported by the fact that, due to the DIC process, a significant increase in volume was observed after the instant pressure drop phase. The cell structures of the FD-DIC-finished samples were more homogenous and expanded than the AD-DIC-dried samples. Moreover, pieces of cell walls sticking out of the walls and penetrating the cavity were clearly visible in Fig. 3c, proving that damage of the cell walls occurred to certain extent during AD-DIC processing. In addition, due to the volume expansion effect of the DIC process after FD pre-drying, the size of the cell in the FD-DIC-dried sample is larger than that of the FD-dried samples, which was in line with the results of volume expansion ratio (Table 4).

Sensory Evaluation

The sensory scores of the qualities of the jackfruit chips are shown in Table 5. The highest color score was found in the FD-DIC-finished chips, which exhibited an appealing golden-yellow appearance. The FD-DIC-dried samples also showed the highest crispness score, followed by the AD-DIC- and FD-dried samples. No significant differences were found in odor and flavor scores among the different jackfruit chips. According to the overall quality scores of the jackfruit chips, the FD-DIC-finished chips obtained a superior overall sensory quality than the chips dried by FD and AD-DIC. However, it is worth to notice that the production cost of FD is in most cases four to eight times as high as AD (Ratti 2001), which could jeopardize most of its applications, especially the applications on cheap agro-products. In this sense, the conventional AD-DIC is still a competitive technology for many common fruits from the economic point of view. Nevertheless, for those valuable materials or fruit chips which quality (e.g., the antioxidant activity and color of jackfruit chips) is considerably sensitive to long-time AD pre-drying, FD-DIC could be a better tradeoff between overall quality and production cost.

Conclusion

Jackfruit bulb chips were produced by FD, FD-DIC, and AD-DIC, respectively. Compared with AD-DIC process, FD-DIC was a more beneficial combination since it improved the overall qualities of jackfruit chips, especially yielded a superior crispy texture. In detail, the FD-DIC-finished products exhibited the highest expansion ratio, crispness, and the lowest ∆E value among the three drying methods. In addition, the FD-DIC-finished jackfruit chips exhibited an intermediate retention of phenolics, carotenoids, antioxidant abilities, and a relatively low hygroscopicity compared with the FD-dried products. Although significant improvement of overall quality was achieved in the FD-DIC-finished jackfruit chips, the expected increase in production cost due to the coupling of FD pre-drying should be also considered in application. In conclusion, data from jackfruit chips suggested that instant controlled pressure drop-assisted freeze drying could be an alternative method for obtaining high-quality fruit chips or processing valuable agro-products.

Abbreviations

- ΔE :

-

Total color difference

- ABTS:

-

2,2-azino-bis (3-ethylbenz-thiazoline-6-suflfonic acid)

- AD:

-

Hot air-drying

- AD-DIC:

-

Instant controlled pressure drop-assisted hot air-drying

- CE:

-

β-carotene equivalents (μg g−1)

- db:

-

Dry basis moisture content (g 100 g−1)

- DPPH:

-

1,1-diphenyl-2-picryl-hydrazyl

- ER:

-

Expansion ratio

- FD:

-

Freeze drying

- FD-DIC:

-

Instant controlled pressure drop-assisted freeze drying

- FRAP:

-

Ferric reducing/antioxidant power

- GAE:

-

Gallic acid equivalents (mg g−1)

- RS:

-

Reducing sugar content (g 100 g−1)

- RR:

-

Rehydration ratio

- TA:

-

Titritable acidity (%)

- TC:

-

Total carotenoid content (μg g−1)

- TE:

-

Trolox equivalent antioxidant capacity (mM g−1)

- TP:

-

Total phenolic content (mg g−1)

- TPTZ:

-

2,4,6-tripyridyl-s-triazine

- TSS:

-

Total soluble solid (°Brix)

- wb:

-

Wet basis moisture content (g 100 g−1)

References

Allaf, T., & Allaf, K. (2014). Instant controlled pressure drop (D.I.C.) in food processing. New York: Springer.

Alonzo-Macias, M., Montejano-Gaitan, G., & Allaf, K. (2014). Impact of drying processes on strawberry (Fragaria var. Camarosa) texture: identification of crispy and crunchy features by instrumental measurement. Journal of Texture Studies, 45(3), 246–259.

Benzie, I. F. (2000). Evolution of antioxidant defence mechanisms. European Journal of Nutrition, 39(2), 53–61.

Benzie, I. F., & Strain, J. J. (1996). The ferric reducing ability of plasma (FRAP) as a measure of “antioxidant power”: the FRAP assay. Analytical Biochemistry, 239(1), 70–76.

Bi, J., Wang, X., Chen, Q., Liu, X., Wu, X., Wang, Q., Lv, J., & Yang, A. (2015a). Evaluation indicators of explosion puffing Fuji apple chips quality from different Chinese origins. LWT-Food Science and Technology, 60(2), 1129–1135.

Bi, J., Yang, A., Liu, X., Wu, X., Chen, Q., Wang, Q., Lv, J., & Wang, X. (2015b). Effects of pretreatments on explosion puffing drying kinetics of apple chips. LWT-Food Science and Technology, 60(2), 1136–1142.

Caparino, O. A., Tang, J., Nindo, C. I., Sablani, S. S., Powers, J. R., & Fellman, J. K. (2012). Effect of drying methods on the physical properties and microstructures of mango (Philippine ‘Carabao’ var.) powder. Journal of Food Engineering, 111(1), 135–148.

Cayuela, J. A. (2008). Vis/NIR soluble solids prediction in intact oranges (Citrus sinensis L.) cv. Valencia Late by reflectance. Postharvest Biology and Technology, 47(1), 75–80.

Chowdhury, M., Bala, B. K., & Haque, M. A. (2011). Energy and exergy analysis of the solar drying of jackfruit leather. Biosystems Engineering, 110(2), 222–229.

Cui, Z., Xu, S., & Sun, D. (2004). Effect of microwave-vacuum drying on the carotenoids retention of carrot slices and chlorophyll retention of Chinese chive leaves. Drying Technology, 22(3), 563–575.

Cui, Z., Li, C., Song, C., & Song, Y. (2008). Combined microwave-vacuum and freeze drying of carrot and apple chips. Drying Technology, 26(12), 1517–1523.

Dias, M. G., Camões, M. F. G. F., & Oliveira, L. (2014). Carotenoid stability in fruits, vegetables, and working standards—effect of storage temperature and time. Food Chemistry, 156(1), 37–41.

Dudonne, S., Vitrac, X., Coutiere, P., Woillez, M., & Mérillon, J. (2009). Comparative study of antioxidant properties and total phenolic content of 30 plant extracts of industrial interest using DPPH, ABTS, FRAP, SOD, and ORAC assays. Journal of Agricultural and Food Chemistry, 57(5), 1768–1774.

Fernandes, F. A., Rodrigues, S., Law, C. L., & Mujumdar, A. S. (2011). Drying of exotic tropical fruits: a comprehensive review. Food and Bioprocess Technology, 4(2), 163–185.

Geidobler, R., & Winter, G. (2013). Controlled ice nucleation in the field of freeze-drying: fundamentals and technology review. European Journal of Pharmaceutics and Biopharmaceutics, 85(2), 214–222.

Giovanelli, G., Zanoni, B., Lavelli, V., & Nani, R. (2002). Water sorption, drying, and antioxidant properties of dried tomato products. Journal of Food Engineering, 52(2), 135–141.

Giraldo-Zuñiga, A. D., Arévalo-Pinedo, A., Rodrigues, R. M., Lima, C., & Feitosa, A. C. (2006). Kinetic drying experimental data and mathematical model for jackfruit (Artocarpus integrifolia) slices. Ciencia y Tecnologia Alimentaria, 5(2), 89–92.

He, X., Liu, J., Cheng, L., & Wang, B. (2013). Quality properties of crispy winter jujube dried by explosion puffing drying. International Journal of Food Engineering, 9(1), 99–106.

Hsu, C., Chen, W., Weng, Y., & Tseng, C. (2003). Chemical composition, physical properties, and antioxidant activities of yam flours as affected by different drying methods. Food Chemistry, 83(1), 85–92.

Hu, Q., Zhang, M., Mujumdar, A. S., Xiao, G., & Jin-cai, S. (2006). Drying of edamames by hot air and vacuum microwave combination. Journal of Food Engineering, 77(4), 977–982.

Huang, L., Zhang, M., Wang, L., Mujumdar, A. S., & Sun, D. (2012). Influence of combination drying methods on composition, texture, aroma, and microstructure of apple slices. LWT-Food Science and Technology, 47(1), 183–188.

Jagadeesh, S. L., Reddy, B. S., Swamy, G. S. K., Gorbal, K., Hegde, L., & Raghavan, G. S. V. (2007). Chemical composition of jackfruit (Artocarpus heterophyllus Lam.) selections of Western Ghats of India. Food Chemistry, 102(1), 361–365.

Jagtap, U. B., Panaskar, S. N., & Bapat, V. A. (2010). Evaluation of antioxidant capacity and phenol content in jackfruit (Artocarpus heterophyllus Lam.) fruit pulp. Plant Foods for Human Nutrition, 65(2), 99–104.

Kozempel, M. F., Sullivan, J. F., Craig, J. C., & Konstance, R. P. (1989). Explosion puffing of fruits and vegetables. Journal of Food Science, 54(3), 772–773.

Krokida, M. K., & Maroulis, Z. B. (1997). Effect of drying method on shrinkage and porosity. Drying Technology, 15(10), 2441–2458.

Krokida, M. K., Karathanos, V. T., & Maroulis, Z. B. (1998). Effect of freeze-drying conditions on shrinkage and porosity of dehydrated agricultural products. Journal of Food Engineering, 35(4), 369–380.

Krokida, M. K., Maroulis, Z. B., & Saravacos, G. D. (2001). The effect of the method of drying on the colour of dehydrated products. International Journal of Food Science and Technology, 36(1), 53–59.

Kumar, C., Karim, M. A., & Joardder, M. U. (2014). Intermittent drying of food products: a critical review. Journal of Food Engineering, 121, 48–57.

Kwok, B., Hu, C., Durance, T., & Kitts, D. D. (2004). Dehydration techniques affect phytochemical contents and free radical scavenging activities of Saskatoon berries (Amelanchier alnifolia Nutt.). Journal of Food Science, 69(3), 122–126.

Lewicki, P. P. (1998). Effect of pre-drying treatment, drying, and rehydration on plant tissue properties: a review. International Journal of Food Properties, 1(1), 1–22.

López, J., Uribe, E., Vega-Gálvez, A., Miranda, M., Vergara, J., Gonzalez, E., & Di Scala, K. (2010). Effect of air temperature on drying kinetics, vitamin C, antioxidant activity, total phenolic content, non-enzymatic browning, and firmness of blueberries variety O Neil. Food and Bioprocess Technology, 3(5), 772–777.

Maity, T., Bawa, A.S., & Raju, P.S. (2014). Effect of vacuum frying on changes in quality attributes of jackfruit (Artocarpus heterophyllus) bulb slices. International Journal of Food Science, 2014. doi:10.1155/2014/752047

Maskan, M. (2001). Drying, shrinkage and rehydration characteristics of kiwifruits during hot air and microwave drying. Journal of Food Engineering, 48(2), 177–182.

McCord, J. M. (2000). The evolution of free radicals and oxidative stress. The American Journal of Medicine, 108(8), 652–659.

Miller, G. L. (1959). Use of dinitrosalicylic acid reagent for determination of reducing sugar. Analytical Chemistry, 31(3), 426–428.

Moreira, R., Figueiredo, A., & Sereno, A. (2000). Shrinkage of apple disks during drying by warm air convection and freeze drying. Drying Technology, 18(1–2), 279–294.

Mounir, S., Allaf, T., Mujumdar, A. S., & Allaf, K. (2012). Swell drying: coupling instant controlled pressure drop DIC to standard convection drying processes to intensify transfer phenomena and improve quality—an overview. Drying Technology, 30(14), 1508–1531.

Prasantha, B. R., & Amunogoda, P. (2013). Moisture adsorption characteristics of solar-dehydrated mango and jackfruit. Food and Bioprocess Technology, 6(7), 1720–1728.

Pua, C. K., Hamid, N. S. A., Tan, C. P., Mirhosseini, H., Rahman, R. B. A., & Rusul, G. (2010). Optimization of drum drying processing parameters for production of jackfruit (Artocarpus heterophyllus) powder using response surface methodology. LWT-Food Science and Technology, 43(2), 343–349.

Rahman, M. S. (2001). Toward prediction of porosity in foods during drying: a brief review. Drying Technology, 19(1), 1–13.

Ratti, C. (2001). Hot air and freeze-drying of high-value foods: a review. Journal of Food Engineering, 49(4), 311–319.

Saxena, A., Bawa, A. S., & Raju, P. S. (2009). Phytochemical changes in fresh-cut jackfruit (Artocarpus heterophyllus L.) bulbs during modified atmosphere storage. Food Chemistry, 115(4), 1443–1449.

Saxena, A., Bawa, A. S., & Raju, P. S. (2012a). Effect of minimal processing on quality of jackfruit (Artocarpus heterophyllus L.) bulbs using response surface methodology. Food and Bioprocess Technology, 5(1), 348–358.

Saxena, A., Maity, T., Raju, P. S., & Bawa, A. S. (2012b). Degradation kinetics of colour and total carotenoids in jackfruit (Artocarpus heterophyllus) bulb slices during hot air drying. Food and Bioprocess Technology, 5(2), 672–679.

Saxena, A., Saxena, T. M., Raju, P. S., & Bawa, A. S. (2013). Effect of controlled atmosphere storage and chitosan coating on quality of fresh-cut jackfruit bulbs. Food and Bioprocess Technology, 6(8), 2182–2189.

Sidhu, A. S. (2012). Jackfruit improvement in the Asia-Pacific region—a status report. Bangkok, Thailand: Asia-Pacific Association of Agricultural Research Institutions.

Swami, S. B., Thakor, N. J., Haldankar, P. M., & Kalse, S. B. (2012). Jackfruit and its many functional components as related to human health: a review. Comprehensive Reviews in Food Science and Food Safety, 11(6), 565–576.

Taib, M. R., Muhamad, I. I., Ngo, C. L., & Ng, P. S. (2013). Drying kinetics, rehydration characteristics and sensory evaluation of microwave vacuum and convective hot air dehydrated jackfruit bulbs. Jurnal Teknologi, 65(1).

You, Q., Wang, B., Chen, F., Huang, Z., Wang, X., & Luo, P. G. (2011). Comparison of anthocyanins and phenolics in organically and conventionally grown blueberries in selected cultivars. Food Chemistry, 125(1), 201–208.

Zhao, X., Yang, Z., Gai, G., & Yang, Y. (2009). Effect of superfine grinding on properties of ginger powder. Journal of Food Engineering, 91(2), 217–222.

Zou, K., Teng, J., Huang, L., Dai, X., & Wei, B. (2013). Effect of osmotic pretreatment on quality of mango chips by explosion puffing drying. LWT-Food Science and Technology, 51(1), 253–259.

Acknowledgments

The authors would like to acknowledge the Special Fund for Agro-scientific Research in the Public Interest Program (No. 201303077) of the Chinese Ministry of Agriculture (MOA).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yi, J., Wang, P., Bi, J. et al. Developing Novel Combination Drying Method for Jackfruit Bulb Chips: Instant Controlled Pressure Drop (DIC)-Assisted Freeze Drying. Food Bioprocess Technol 9, 452–462 (2016). https://doi.org/10.1007/s11947-015-1643-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-015-1643-4