Abstract

In order to obtain pumpkin chips, hot air drying (HAD), freeze-drying (FD), combinations of hot air drying + explosive puffing drying (HAD + EPD) and freeze-drying + explosive puffing drying (FD + EPD) were studied and, the impacts of various methods and conditions (temperature, vacuum pressure and decreased the moisture content level after pre-drying) on the physical, antioxidant and textural properties of pumpkin slices have been examined.The best texture attributes, the highest rehydration ratio (RR), the highest volumetric expansion (VE), and the lowest bulk density were obtained from FD + EPD products. Otherwise, when FD samples were compared with FD + EPD ones, it was clearly seen that higher retention of total phenolic content, antioxidant capacity, total carotenoids and a better color quality were obtained. However, the combination of FD + EPD allows drying at a slightly shorter processing time that is compared to a single FD. FD + EPD products provided the highest crispness when it is compared with HAD + EPD. This fact indicated that the pre-drying method (FD) and the reduction of moisture level had a major impact on textural properties. Consequently, the FD + EPD combination proved that it is a more promising process when it was compared to other drying techniques in order to produce nutritious pumpkin chips.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Pumpkin (Cucurbita moschata) is a highly nutritious and antioxidant-rich fruit which is grown widespread at all around the world, especially in Turkey, United States, China, Egypt, and India. It is a fibrous and orange-colored fruit that is also a rich source of vitamin A with high amounts of carotenoids especially β-carotene and lutein, B6, K, C, thiamine, riboflavin, minerals and phenolic compounds. At the same time, pumpkin is rich in dietary polyphenols that have anti-inflammatory, antioxidative, chemopreventive, and neuroprotective activities [1]. Therefore, the pumpkin has become a beneficial nutrient for the health of both children and adults and can be consumed directly or widely used in recipes of different meals [2]. Due to rich nutritional content of pumpkin, it is used as a medicine in many different nations such as China, Yugoslavia, Argentina, India, Mexico, Brazil, and America [3]. Due to high moisture content and microbial and biochemical sensitivity to the storage, drying process extends pumpkin shelf life, reduces transportation and storage costs, and gives a chance for developing a new product. Recently, popularity of fruit chips has shown an upward trend for the diet of modern consumers because those chips do not only extend shelf life but also appeal a crispy feel inside the mouth in addition to the fact that they are original nutritions as well [4].

In order to obtain fruit chips, a lot of processing technologies have been applied such as deep-fat frying and drying with different methods (hot air drying, vacuum drying, microwave drying, freeze-drying, microwave vacuum drying, explosive puffing drying). The selection of the most appropriate process mainly depends on the required quality characteristic of the final product. Hot air drying which is one of the most widely used method, leads to crucial losses in physical, chemical, nutritional and organoleptic qualities of the products during the removal of moisture from the product [5]. Freeze-drying, the best dehydration method for sensible foods and based on dehydration by sublimation of a frozen product, involves high equipment costs, energy requirements, and long processing period. Therefore, it limits the usage in the production of high added value products [6]. Among these drying methods that are used for snack foods, explosive puffing drying (EPD) is an emerging technology with a lot of advantages [7]. In case of the most essential advantage, it provides a porous and crispy structure while the other advantages of EPD are ensuring the maintanence of color and flavor and the improvement of rehydration capacity and the texture of snack foods [7].

The basic principle of the explosive puffing drying system is to loosen the texture of the product under high pressure (average 0.4 MPa) and high temperature (about 100 °C) and after that to remove the moisture from the product under the atmospheric pressure (under vacuum) as much and as quickly as possible to obtain a porous structure. The effect of high pressure and temperature during the explosive puffing drying process could evaporate the water from food materials fastly and this process could give a viscoelastic structure to the food [8]. According to the literature, this method is generally used together with other drying methods such as hot air, microwave, and freeze-drying. In general, the moisture content of the food is reduced to the desired value with the pre-drying method before explosive puffing drying [9]. During the past decade, there has been seen an increasing interest in the impacts of explosive puffing drying on different fruits and vegetables, such as apple [10, 11], pear [4], pepper [12], mango, pitaya and papaya [7], peach [9], etc. However, there is no study that has been reported on explosive puffing drying of pumpkins in the literature.

The purpose that lies beyond this work, was obtaining nutritious pumpkin chips as a snack by using explosive puffing drying technology which is combined with pre-drying methods such as hot air drying (HAD + EPD) and freeze-drying (FD + EPD) and studying the effects of pre-drying methods and conditions on the quality of pumpkin snacks in terms of moisture content, water activity, total phenolic content, antioxidant capacity, total carotenoid content, color, textural properties (crispness and hardness), volumetric expansion rate, bulk density, and rehydration ratio. The physical and chemical properties of puffing dried pumpkins were compared with the properties of pumpkin slices which were dried by single hot air (HAD) and single freeze-drying (FD).

Material and methods

Material

Fresh pumpkin (Cucurbita moschata) was used as raw material. 100 g of fresh pumpkin contain approximately 1 g protein, 0.1 g total fat, 0.8 g ash, 6.5 g carbohydrate, and 0.5 g fiber. The fresh pumpkin was purchased from a local market in Izmir, Turkey. After washing and peeling processes, the pumpkin was cut into 3 cm × 2 cm × 0.1 cm slices (thin slices). Fresh pumpkin slices (~ 750 g) were used for each drying experiment.

Drying process

Hot air drying

The hot air drying process was carried out with a tray drier (Eksis Makine, Isparta, Turkey). The samples were spread on the tray as thin layers and dried under three different temperatures of 50, 60, and 70 °C at a constant airflow of 1.8 m/s until the samples reached an equilibrium moisture content.

Freeze drying

For freeze-drying, the pumpkin samples as thin slices were frozen at − 18 °C for 24 h. Then, they were dried with a freeze dryer (Telstar Lyoquest − 55 Plus Eco) under three different vacuum pressures of 0.2, 0.15, and 0.1 mbar and a constant condenser temperature of − 55 °C until the samples reached an equilibrium moisture content.

Explosion puffing drying

The explosive puffing drying process was carried out by the explosive puffing drier which was developed in this study (Rapid Gıda Teknolojileri, Izmir, Turkey). As seen in Fig. 1, the explosive puffing dryer includes a compressor which can be used for increasing the pressure in the medium and a vacuum pump that provides the vacuum of the system, infrared plate heaters which were used as a heating medium, infrared thermometer, illuminator and sample tray (covered with Teflon/PTFE and the material is stainless steel). The machine works at a maximum of 1.9 bar (absolute pressure) and minimum of (vacuum condition) 0.25 bar (absolute pressure).Materials can be heated until 150 °C at puffing condition. In order to produce pumpkin snacks by the explosive puffing drying, HAD and FD was applied as pre-drying treatments before explosive puffing drying. The pumpkin samples were pre-dried with hot air at 60 °C, at an air velocity of 1.8 m/s (HAD + EPD1, HAD + EPD2, and HAD + EPD3) and FD which is under 0.15 mbar of vacuum pressure with the condenser temperature of − 55 °C (FD + EPD1, FD + EPD2, and FD + EPD3) until the moisture content of samples was reduced to 65%, 55% and 45% (wb), respectively. After that, the pre-dried pumpkin samples were placed on a plate in the puffing chamber for 10 min for puffing under an elevated pressure of 190 kPa by an air compressor and an explosion temperature of 90 °C by heated air. Then puffed samples were dried under a continuous vacuum of 25 kPa at 70 °C until they reach the final moisture content. All experiments were conducted in triplicate. The drying conditions in case of different drying methods and drying times are presented in Table 1. The moisture contents of dried pumpkins were all-around 6–8% (wb).

Analysis

Moisture content and water activity

The moisture content of samples was determined by the oven method according to Bodily [13], by gravimetric determination after dehydration at 105◦C until they reach the constant weight. Water activity (aw) of the samples was measured by a water activity measurement device (Testo-AG 400, Germany) at room temperature (25 °C).

Total phenolic content, antioxidant capacity, and total carotenoids

Total phenolic content (TPC) was determined by the Folin-Ciocalteu method and the absorbance values of the samples were measured at 765 nm by the spectrophotometer against a mixture of 80% methanol–water. The total phenolic content of the samples was calculated using the gallic acid standard [14] and was expressed as mg Gallic acid that equivalents per gram dry matter (mg GAE/g DM) of the sample.

Antioxidant activity was determined by the 2,2‐diphenyl‐1‐picrylhydrazyl (DPPH) radical‐scavenging method. Antioxidant capacity analysis and sample extraction process were carried out by modifying the procedure of Sanchez–Moreno et al.[15]. 3.9 ml of 0.06 mM DPPH solution was taken in methanol, added to the sample solution which was prepared by dissolving 0.1 ml of methanol and shaken with a vortex. The changes in the absorbance of the samples were measured at 515 nm by using a spectrophotometer (Agilent Technologies Cary 60 UV‐Vis) and 80% methanol as a blank. Radical scavenging activity was expressed as the inhibition percentage by using the Eq. 1

where, ADPPH and Asample are absorbance values of DPPH solution and sample solution at wavelength 515 nm, respectively.

The quantity of total carotenoids (TC) in the pumpkin samples was determined by the extraction of carotenoids using 80% acetone, according to Nawirska et al. [16]. It is measured with colorimetric method at 470, 646, 663 nm wavelengths, respectively. Total carotenoid content was calculated by the following equation (mg/100 g dry basis) (Eq. 2).

where, Ca = 12.71 × A663 − 2.81 × A646; Cb = 20.13 × A646 − 5.03 × A663; A470, A646, A663 are absorbance values at wavelengths 470, 646, and 663 nm, respectively.

Color

The color properties of the samples which are i.e. L* (lightness), a*(redness), and b* (yellowness), were measured with a Minolta CR-400 Colorimeter (Japan). The results were expressed by the following CIE Lab System. Hue, Chroma, and ∆E values of the samples were calculated by Eqs. 3, 4, and 5, respectively [17].

Fresh pumpkin was used as the reference and a larger ∆E denotes greater color change from the reference material. Measurements were obtained in triplicate; ten measurements were taken for each sample.

Hardness and crispness

Texture Analyzer TA-XT2, (Stable Micro Systems, Haslemere, UK) fitted with a flat-head cylindrical probe (P/36R was used to measure hardness and crispness, using a TPA model. During the penetration tests, the hardness value was expressed as the maximum compression force (g) that works to break the chips and the crispness value was expressed as the number of compression peaks [6]. Meanwhile, the pre-test, test, and post-test speeds were 2.0, 2.0, and 2.0 mm/s, respectively. The test distance was 5 mm and the trigger force was 5.0 g. Ten measurements were performed for each treatment and after that, average values were calculated.

Volumetric expansion and bulk density

The volumetric expansion (VE) value was calculated by using Eq. 6 [17]. The volumetric expansion was measured with the volume of the same sample of pre-dried pumpkin which was taken both before and after EPD.

where V2 is the volume of explosive puffing dried pumpkin or the volume of hot air/freeze-dried pumpkin (m3) and V1 is the volume of fresh pumpkin (m3).

The bulk density value of explosive puffing dried pumpkin was calculated using the ratio of sample weight to volume (kg /m3).

Rehydration ratio

The rehydration ratio was determined according to Chen et al. [8]. Basically, 5 g of explosive puffing dried pumpkin samples were immersed in a water bath at 70 °C for 10 min and the Rehydration Ratio (RR) was calculated by using the following equation (Eq. 7).

where M0 and Mr are the first and last mass (g) of explosive puffing dried samples in the specified time interval.

Statistical analysis

In order to evaluate the significance of differences, one-way analysis of variance (ANOVA) and Duncan’s test at the level of p < 0.05 were applied by using the SPSS 15.0 packaged program that works for Windows (SPSS Statistical Software, Inc, Chicago, IL, USA). Correlation analysis was done to determine the relationships among different quality attiributes of dried pumpkin slices.

Results and discussion

Drying time, moisture content and water activity

The drying times of the pumpkin slices in case of different drying methods and drying conditions are given in Table 1. Since the samples consist of thin slices that are 0.5 cm, the drying times are very short. The reason that lied beyond this short duration, was the short distance of diffusion and high surface area exposed per unit volume [18]. As seen in Table 1, freeze-drying had the longest drying time when it was compared with other drying methods. Furthermore, the drying times decreased with increasing vacuum pressure in the freeze-drying method. The chamber pressure is one of the most significant variables for freeze-drying. Pressure has a combined effect of controlling the sublimation temperature and changing parameters affecting the drying kinetics. At constant temperature, the drop in the chamber pressure caused a decrease in the vapor pressure on the product surface. Thus, the driving force required for the drying process increased and the total drying time was shortened [19]. The time that was required for HAD, was shorter than FD. In case of HAD, the increase in temperature reduced the drying time in order to reach the definite moisture content value. Similarly, Mewa et al. [20] reported that the shorter drying time was determined at the higher drying temperature. The thermal energy, which was increased due to the increase of temperature, increased the transfer rate of the water molecules and caused the shorter drying time [21]. In case of explosive puffing drying, the longest total drying time was seen in drying with a combination of FD + EPD. Similarly,Yi et al. [4] obtained pear chips with different drying methods and reported that the longest drying time was consist of FD and FD + EPD combination, which was a little shorter than freeze-drying time. The FD + EPD combination enabled to dry in a shorter processing time when it was compared with FD in this study (Table 1). During the pre-drying stages for both FD and HAD, the required drying times increased as the moisture content level decreased. This affected the time of the puffing drying and the drying time under the vacuum decreased as the moisture content decreased. In an explosive puffing drying system, 10 min process was applied in terms of a constant for the explosive process. Therefore, the total drying times depend on the pre-drying process.

The moisture content of food plays an essential role in protecting the desired product quality. Moisture content data is required for safe storage or proper processing of food. Depending on this fact, water activity can be seen as an important parameter for most of the foods. One of the most important factors that affects the quality, safety, and shelf life of food, is the presence of water which is required for microbial growth, spore germination, and enzymatic activity. The effect of HAD at different temperatures, FD under different vacuum pressures and EPD combined with HAD and FD on the moisture content and water activity (aw) of pumpkin chips are shown in Fig. 2. The initial water content and aw of fresh pumpkin was 88.73 ± 0.90% (wb) and 0.98 ± 0.002, respectively.

Among the drying methods, the lowest moisture content and water activity values were obtained for HAD, when the highest values were observed for FD (Fig. 2). The moisture content values of the samples dried with HAD at different temperatures ranged between 6 and 9% (wb) and the water activity values ranged between 0.3 and 0.4 (Fig. 2). The moisture content and water activity values of the samples which were dried by using HA, decreased because of the increase in drying air temperature. In case of FD, the moisture content values were below 10% and water activity values changed between 0.46 and 0.49 (Fig. 2). It is known that the internal porosity increased directly proportional with the increase in the volumetric expansion during the drying process of the samples. Depending on this situation, samples which have high volumetric expansion, have lower water activity value [12]. Therefore, even though the samples have the same moisture content, they showed different water activity values which depends on the internal porosity that is created by the different drying techniques used in this study.

When the combination of HAD + EPD was used, the samples which were pre-dried up to 45% moisture content by HAD, had higher water activity values than FD + EPD ones. As shown in Fig. 2, the moisture content and water activity values of the samples decreased after the puffing drying process directly proportional with the decrease of the moisture content value in the pre-drying step. In general, the moisture content and water activities of the pumpkin chips were found to be higher than other dried products because of the higher fiber content and the structure of the pumpkin which contains a large amount of bound water.

Total phenolic content, antioxidant capacity, total carotenoids

Phenolic materials include various components especially antioxidants which have been widely found in fruits and vegetables, play an important role in case of increasing health benefits. The effect of different drying methods and conditions of the total phenolic content, total carotenoid content and DPPH inhibition % of the pumpkin chips are given in Table 2.

The temperature usually causes degradation in the phenolic materials of the product during the drying process [22]. Therefore, the samples that were dried by HAD (1193.73 ± 6.00 mg/100 g DM) and HAD + EPD,exhibited lower total phenolic content (1065.85 ± 0.06 mg/100 g DM). Similarly, Arslan et al. [23] dried jujube by using HAD and EPD methods and compared these two drying methods with each other. As a result of this study, it was observed that total phenolic content values were lower in the HAD process when it was compared to EPD process. Total phenolic content decreased with the increase of drying temperature. The results in Table 2, showed that about 81% of TPC was retained even after hot air drying at 70 °C (HAD3). On the other hand, higher total phenolic content values were observed for products dried by FD + EPD (close to 85% retention) and FD (close to 91% retention) (Table 2). Since, freeze-drying takes place at very low temperatures, the phenolic substances of the samples are not degraded as stated by Yi et al. [4]. Chen et al. [8] have studied on the mulberry fruit and investigated the effect of different pretreatments and drying methods on the quality of that material. When the total phenolic content results were evaluated, no decreasing trend was observed when it was compared with the fresh sample. Furthermore, it was found that the total phenolic content values of FD samples were higher than HAD samples. FD pre-treatment provided to have better results with EPD. Que et al. [24] found a similar result in their study of drying pumpkin with HAD and FD.

The antioxidant capacity as DPPH radical scavenging capacity of fresh and dried pumpkins is also given in Table 2. The highest residual DPPH was observed in FD and FD + EPD products. The lowest antioxidant capacity as inhibition % was observed in the products dried by HAD + EPD products (Table2) (p < 0.05). Arslan et al. [23] stated that the antioxidant capacity of jujube which was dried by HAD was lower. Thermal drying caused more losses of antioxidant capacity than freeze-drying. Meanwhile, higher temperatures and longer drying times were responsible for the loss of natural existed antioxidants. The freeze-drying process produced higher total phenolic content (TPC) and DPPH scavenging activity as it was compared to the other drying methods. Similar results were also found in the study of black mulberries [8], ginger species, and sour cherries [25, 26]. This was attributed to the absence of liquid water and oxygen during FD as well as the lower temperature, which could hold most of the degradation reactions or enzymatic reactions back.

Carotenoids are yellow, orange, and red pigments that are found in many common fruits and vegetables. Determining the total carotenoid content is an important criterion in order to determine the quality of the pumpkin chips. Table 2 includes the values of total carotenoid content for pumpkin slices which were dried by different methods. The highest average carotenoid content was determined with the freeze-dried (FD) samples, then FD + EPD, and the lowest with the HAD method. Nawirska- Olszańska et al. [14] found that the total amount of carotenoid content varied between 3 and 379.71 mg/100 g DM according to the study on different pumpkin types. Carotenoid compounds are sensitive against factors such as heat, oxygen, light, and enzymes [27]. When the carotenoid results of samples with FD were examined with themselves, total carotenoid content values decreased with the increase of vacuum pressure (p < 0.05) (Table 2). Pumpkin samples dried up to higher moisture content (65% wb) showed higher total phenolic substance loss and antioxidant loss due to shorter time in freeze-drying and longer time in puff drying. In this study, it was seen that the amount of total carotenoid content decreased with the EPD process for each pre-drying method. The reason that lied beyond this fact was the product that was exposed to excessive heat by applying the second drying process (Tables 1 and 2).

Color attributes

Color is an important parameter of dried fruits that influences consumers choice. Color values are substantial properties in order to determine the quality losses and the physical reflection of some chemical changes in the foods with the processing. Physical or chemical effects of many processes, can damage or cause losses in food colors like oxygen or light. Processed foods that maintain some properties of the fresh material, are well accepted by the consumers. The color properties of the pumpkin samples in terms of L*, a*, b*, Hue, Chroma, and ∆E values are given in Table 3.

The value of the parameter L*, which indicates the lightness of pumpkin slices, varied from 45.90 to 75.24 (Table 3). The products dried by HAD and HAD + EPD showed the lowest L* and b* values and the products were darker due to the extended time of heat exposure. Among all drying methods, freeze-drying resulted in a high L* value, in agreement with the literature for the freeze-dried pumpkin [28]. Alibas [29], used a microwave, hot air, and combined microwave and hot air for drying of pumpkin slices and after that, he has obtained darker materials with L* values ranged from 22 to 27.91. Significant differences in L*, a*, and b* values of pumpkin slices which were dried by using different methods (p < 0.05), were observed. Products that were dried by FD + EPD, had higher values of L*and b* than HAD + EPD. Pigment degradation and Maillard reaction occurred during the thermal processing of the HAD stage while more pigments were obtained when they were exposed to a vacuum during the FD stage [26].

In order to evaluate the color change before and after drying, C* and Hue values were used. Only FD + EPD pumpkin products were found to have the highest C* values. A significant positive correlation was found between C* and b* values (r = 0.981). The change in color parameters during HAD + EPD is related to the browning reactions where a decrease in L* value, an increase in a* value, and a decrease in hue angle indicate the result of more browning. Only pumpkin samples dried by HAD showed a higher value of b* and all dried samples showed that reduced colors of the parameter a*. Thus, FD + EPD can produce dried pumpkin chips with uniform color without burned regions. FD samples were found that they have a higher ∆E value than HAD samples in this study. The L*, a* and b* values of the fresh sample are taken as a reference during the measurement of the ∆E value. There was whitening on the surface of the pumpkin samples in the FD process. The high ∆E value was determined by the large difference between the color values of samples in the FD drying system and the color values of the fresh sample. Guine and Barroca, [30] have studied the effect of different drying methods and parameters on the colors of pumpkin as well. The authors reported that ∆E values of HAD and FD samples were close to each other and in agreement with this study. Chen et al. [8] have studied the effects of different drying methods on the quality of the mulberry and have reported that HAD + EPD and FD + EPD samples had generally better color results than HAD and FD samples.

Rehydration, bulk density, and volumetric expansion behaviors

Volumetric expansion, rehydration ratio and bulk density values of dried pumpkin chips are shown in Table 2. The volumetric expansion helps researchers to understand that the dried material puffing degree. Rehydration is a prevalent analysis of dried samples. Dried products could be consumed not only as a snack but also with products such as cereals, milk, yogurt even with meals. Rehydration values of dried samples are substantial for consuming other products and to estimate the shelf life.

The FD + EPD pumpkin slices had the highest volumetric expansion (VE) and highest rehydration ratio (RR) due to a well-expanded porous structure.Also, it could be observed that freeze-dried (FD) samples showed lower RR and lower VE than FD + EPD slices. Besides that, the vacuum pressure in freeze-drying increased, while the rehydration ratio decreased (p < 0.05). In general, due to the instantaneous decompression stage during puffing drying, the movement of the material that it went towards the outer vacuum environment, caused the expansion of volume and porous formation [7]. The combination of HAD and explosive puffing drying did not give a successful result in terms of rehydration and volumetric expansion as seen in Table 2. The lowest RR and volumetric expansion were found in HAD + EPD samples that were exposed to high temperatures for a long period of time due to the damage of cell structure that occurred inside the material or cellular shrinkage [31].

Especially, rehydration ratio and bulk density were highly influenced by the pore size of the products internal structure [32]. Thus, pumpkin slices dried by hot air and puffing drying combination (HAD + EPD) had the highest bulk density followed by HAD at different temperatures. According to the comparison between them, samples treated with combined HAD + EPD showed much lower RR, lower VE and higher bulk density. The explosive puffing drying with HAD failed to provide the VE of the samples so, they showed the lowest VE and the highest bulk density values. Contrary to expectations, this result showed that the successful crust formation in the pre-drying with hot air and sufficient volume expansion in the subsequent puffing drying of the samples could not be achieved due to rapid moisture transfer. Que et al. [24] also stated that pumpkin slices which were dried by hot air, had higher bulk density values than that freeze-dried ones. In case of freeze-drying, bulk density increased and volumetric expansion and RR decreased with the increase in vacuum pressure (p < 0.05). Yi et al. [7] were obtained similar results with pear chips that showed an FD + EPD method had the highest rehydration ratio samples.

Chen et al. [8] showed a significant negative correlation between the bulk density and rehydration ratio (r = − 0.991). According to our results, a considerable negative correlation between the bulk density and volumetric expansion was found (r = − 0.917).

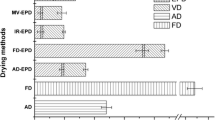

Texture attributes

The texture is a very important quality attribute that affects the food acceptance and is evaluated hardness besides crispness [33]. The effect of different drying methods and conditions on the hardness and crispness of dried pumpkin slices is shown in Fig. 3. Sample structures are substantial issues that express the hardness-crispness relation. The high porosity and low shrinkage on the sample often present low hardness values. However, the less porous structure especially the one that determined in the HAD process, had led to harder samples because of the uniform firmness and fibrous structures of the pumpkin slices [7].

Pumpkin slices dried by HAD showed the highest hardness values (1346 N) whereas FD products presented the lowest (129.7 N) hardness value that indicates FD chips have a soft texture after drying. The temperature in HAD increased directly proportional with the increase in hardness (p < 0.05) whereas the vacuum pressure did not affect hardness (p > 0.05).

In comparison with HAD samples, the hardness of the puffed pumpkin slices (HAD + EPD) reached an intermediate level (580.3 N) that indicated the puffing (EPD) process significantly changed the texture profiles of the HAD pre-dried samples. Nevertheless, the hardness of FD + EPD chips was much lower than that of HAD + EPD chips.

Besides that, the highest crispness level was found in FD + EPD chips and FD chips, whereas the lowest level was found in HAD and HAD + EPD chips. The low hardness and high crispness of the freeze-dried products could be attributed to the fact that in the FD process, the frozen water in the material sublimated directly from the solid phase to the gas phase. Therefore, the porous structure was obtained. In the EPD process, an abrupt transition from high pressure to vacuum, led to the expansion of the products and the formation of the porous structure, thus it was resulted in products that have higher crispness.

The level of moisture content reached after pre-drying, had a significant effect on the hardness of HAD + EPD samples (p < 0.05). The pumpkin slices predried by HAD up to 45% moisture content exhibited the highest hardness (580.3 N) among the samples. Guine and Barroca [30], have studied with pumpkins and determined that the effect of hot air and freeze-drying methods and different parameters on the quality of the pumpkins. In contrast with this study, it was reported that increasing drying temperature was provided with less hardness values and the FD process was provided better texture than HAD. Furthermore, Bi et al. [10] detected that the EPD process significantly affects the textural properties of the products when it is compared to the pre-drying processes.

Conclusion

Pumpkin slices were dried by both the combined drying methods (HAD + EPD and FD + EPD) and single drying methods (HAD and FD). Physicochemical, antioxidant, and textural properties were used to evaluate the quality of the pumpkin chips. Although FD products presented the best color, higher retention of antioxidant capacity, total phenolic content, and total carotenoids, FD + EPD showed the lowest hardness, highest crispness, highest volumetric expansion, and highest rehydration ratio. The total drying time of the pumpkin chips with a combined FD + EPD method was reduced 23% as it was compared to the single drying of FD. However, the lowest drying time was obtained with HAD at higher temperatures as well as the lowest moisture content and water activity. In comparison with HAD + EPD, FD + EPD products showed the highest crispness and this fact indicated that pre dying method and moisture level reduction had a significant effect on textural properties. Therefore, the FD + EPD method is an alternative drying method in order to convert pumpkin slices into a snack food as chips while preserving its functional and textural characteristics with less energy consumption.

References

K. Hanhineva, R. Törrönen, I. Bondia-Pons, J. Pekkinen, M. Kolehmainen, H. Mykkänen, K. Poutanen, Int. J. Mol. Sci. 11(4), 1365–1402 (2010)

M. Sojak, S. Głowacki, J. Food Eng. 99(3), 323–329 (2010)

F.U. Caili, S. Huan, L.I. Quanhong, Plant Foods Hum. Nutr. 61(2), 70–77 (2006)

J. Yi, L. Zhou, J. Bi, Q. Chen, X. Liu, X. Wu, J. Food Process Preserv. 40(5), 863–873 (2016)

M. Maskan, J. Food Eng. 48(2), 177–182 (2001)

J. Yi, L. Zhou, J. Bi, Q. Chen, X. Liu, X. Wu, J. Food Sci. Technol. 53(2), 1120–1129 (2016)

J.Y. Yi, J. Lyu, J.F. Bi, L.Y. Zhou, M. Zhou, J. Food Process Preserv. 41(6), e13300 (2017)

Q. Chen, Z. Li, J. Bi, L. Zhou, J. Yi, X. Wu, LWT - Food Sci. Technol. 80, 178–184 (2017)

J. Lyu, L.Y. Zhou, J.F. Bi, X. Liu, X.Y. Wu, J. Food Sci. Technol. 52(12), 8204–8211 (2015)

J. Bi, A. Yang, X. Liu, X. Wu, Q. Chen, Q. Wang, J. Lv, X. Wang, LWT - Food Sci. Technol. 60(2), 1136–1142 (2015)

J.Y. Yi, L.Y. Zhou, J.F. Bi, P. Wang, X. Liu, X.Y. Wu, Dry. Technol. 34(7), 773–782 (2016)

C. Téllez-Pérez, V. Sobolik, J.G. Montejano-Gaitán, G. Abdulla, K. Allaf, Dry. Technol. 33(2), 131–142 (2015)

H.L. Bodily, Am. J. Public Health N. Health. 46(7), 916–916 (1956)

A. Nawirska-Olszańska, B. Stępień, A. Biesiada, LWT - Food Sci. Technol. 77, 276–281 (2017)

C. Sanchez-Moreno, J.A. Larrauri, F. Saura-Calixto, J. Sci. Food Agric. 76, 270–327 (1999)

A. Nawirska, A. Figiel, A.Z. Kucharska, A. Sokół-Łętowska, A. Biesiada, J. Food Eng. 94(1), 14–20 (2009)

S. Chudy, A. Makowska, M. Piątek, M. Krzywdzińska-Bartkowiak, Int. J. Dairy Technol. 72(1), 82–88 (2019)

C. Ertekin, O. Yaldiz, J. Food Eng. 63(3), 349–359 (2004)

J. Lombraña, M.C. Villarán, Food Res. Int. 30(3–4), 213–222 (1997)

E.A. Mewa, M.W. Okoth, C.N. Kunyanga, M.N. Rugiri, LWT - Food Sci. Technol. 92, 484–489 (2018)

A. Maskan, S. Kaya, M. Maskan, J. Food Eng. 54(1), 81–88 (2002)

G. Adiletta, W.D.C.C. Wijerathne, W. Senadeera, P. Russo, A. Crescitelli, M. Di Matteo, Ital. J. Food Sci. 30(4), 684–706 (2018)

M. Arslan, M. Zareef, H.E. Tahir, S. Ali, H. Xiaowei, A. Rakha, J. Shi, Z. Xiaobo, J. Food Measurement Character 15(1), 1–11 (2020)

F. Que, L. Mao, X. Fang, T. Wu, Int. J. Food Sci. Technol. 43, 499–507 (2008)

E.W.C. Chan, Y.Y. Lim, S.K. Wong, K.K. Lim, S.P. Tan, F.S. Lianto, M.Y. Yong, Food Chem. 113(1), 166–172 (2009)

A. Wojdyło, A. Figiel, K. Lech, P. Nowicka, J. Oszmiański, Food Bioprocess Technol. 7(3), 829–841 (2014)

M.L. Rojas, I. Silveira, P.E.D. Augusto, Food Bioprod Process. 119, 20–30 (2020)

J.A. Osuna-Garcia, M.M. Wall, C.A. Waddell, J. Food Sci. 62(5), 1017–1021 (1997)

I. Alibas, LWT - Food Sci. Technol. 40(8), 1445–1451 (2007)

R.P. Guiné, M.J. Barroca, Food Bioprod. Process. 90(1), 58–63 (2012)

M.K. Krokida, Z.B. Maroulis, G.D. Saravacos, Int. J. Food Sci. Technol. 36(1), 53–59 (2001)

V.T. Karathanos, N.K. Kanellopoulos, V.G. Belessiotis, J. Food Eng. 29(2), 167–183 (1996)

D.A. Booth, Trends Food Sci. Technol. 35(2), 129–137 (2014)

Acknowledgements

This research was supported by the Scientific Research Projects of Ege University (BAP FLP-2018-20443). The authors thank to the students Deniz Arıcı, Hüseyin Tuncer and Ahmet Gürhan Akçan for lab support.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Ethical approval

Ethics approval was not required for this research.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Köprüalan, Ö., Altay, Ö., Bodruk, A. et al. Effect of hybrid drying method on physical, textural and antioxidant properties of pumpkin chips. Food Measure 15, 2995–3004 (2021). https://doi.org/10.1007/s11694-021-00866-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-021-00866-1