Abstract

Frozen dough made using flour of higher protein content (9.5–11 %) had better resistance to freezing damage than those made using flour of lower protein content and resulted in steamed bread whose specific volume, form ratio and texture were closer to those of bread made from fresh dough. The effects of flour protein content and freezing conditions (freezing air temperature and air speed) on dough and steamed bread quality were investigated in this study. Compared to nonfrozen control, the freezing process caused a deterioration to gluten network as well as a decrease in yeast activity, which resulted in lower maximum dough height and less total gas production, leading to steamed bread of lower specific volume and form ratios, and increased hardness. Faster freezing rates resulted in dough with higher extensibility and a less damaged dough microstructure but led to a decrease in total gas production as yeast activity was compromised. The extreme freezing conditions of −20 °C and air speed of 0 m/s and −40 °C and air speed of 6 m/s had the poorest dough and steamed bread quality. Samples frozen at −30 °C had better form ratio of steamed bread than those frozen at −20 °C and −40 °C, while those frozen at −40 °C had the lowest specific volume. A moderate air speed of 3 m/s resulted in higher volume of total gas production and dough height, as well as better steamed bread texture.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

While bread is commonly associated with oven and baking, steamed bread (also known as mantou or bao) is a staple food for many Asians. The main difference steamed bread has from baked bread would be the lack of a browned crust as steaming is a much gentler heat process compared to baking. Also, steamed bread has a moister and softer crumb. Besides processing, another major contributor to the difference between baked and steamed bread is that typical steamed bread recipes use low-protein flours (7.5–11 %) according to cultural and geographic diversity in China as well as the strength of different wheat cultivars (Ananingsih et al. 2013; Hou and Popper 2006; Kondakci and Zhou 2015; Zhu et al. 2001; Zhu 2014), while baked bread uses high-protein flours (12–14 %).

Instead of distributing fresh bread, which declines in quality over distance and time, a central production of frozen dough allows for baking to be done at the point of sale such that bread can be sold and consumed fresh. Although steamed bread originated from northern China, it is currently a popular food in many Asian countries and becoming increasingly popular in the Western world as well. Consequently, frozen dough technology has become increasingly relevant for steamed bread production.

With respects to steamed bread, a number of studies examined the effects of protein content on steamed bread quality, which was generally scored based on a system developed by Huang et al. (1996) that includes parameters such as specific volume, colour and eating quality. Lin et al. (1990) reported that a high-protein flour has more gluten to retain gas in the dough with regard to baked bread. They further recommended that the protein content required for steamed bread was less important than for the conventional baked pan bread, and the lower level of protein was the optimum. On the other hand, Lukow et al. (1990) suggested that flour protein content was positively and significantly correlated with steamed bread quality and that higher levels of protein were desirable. There have not been any studies done to determine the effects of protein on the quality of steamed bread made from frozen dough; thus, it is important to investigate the effects of different levels of protein content, in combination with different freezing conditions, on the quality of dough and steamed bread.

Despite many benefits, frozen dough has still several quality issues. Thawed dough had deteriorated dough quality including decreased dough strength, decreased gas retention properties and longer fermentation time (Kenny et al. 1999; Leray et al. 2010; Ribotta et al. 2001, 2004). The deterioration in the frozen dough quality might be attributed to the effects of freezing on yeast activity and gluten network. Besides mechanical damage to yeast cells from ice crystal formation, ice crystallization has also been found to cause an increment in solute concentration (from other ingredients such as salt and sugar) in the frozen dough, which could lead to the autolysis of yeast cells (Selomulyo and Zhou 2007), thus diminishing yeast viability and activity.

In the freezing treatment of dough, freezing rate and temperature are two significant process variables. For yeast, slower freezing rates promote extracellular ice crystal formation while faster freezing rates promote intracellular ones (Myers and Attfield 1999). However, a slower freezing rate causes greater damage to the gluten network (Havet et al. 2000), of which the extent of the damage is dependent on ice crystal size, and faster freezing rates promote smaller ice crystal size formation which minimizes damage to the gluten network. Furthermore, principles guiding frozen storage temperatures are likely not the same for freezing air temperatures because in the latter, the frozen dough is exposed to the freezing air temperatures for a much shorter duration. Literature on frozen dough for steamed bread is limited to studies on the effects of water (Bao and Wang 2011) and the use of additives and emulsifiers (Bao et al. 2012). Therefore, it is necessary to conduct further research to determine for steamed bread whether the freezing air temperature and air speed have any specific effects on frozen dough quality.

This study aimed to investigate the effects of protein content on the quality of frozen dough for steamed bread, as well as to provide an understanding of how frozen dough made from flours of different protein content responded to various freezing treatments. Rheofermentometer characteristics (i.e., dough development and gaseous release), uniaxial extensibility and microstructure analysis of steamed bread dough were examined. Furthermore, the quality attributes of final steamed bread were investigated, including the specific volume, form ratio and crumb hardness of steamed bread. The results shed light on the feasibility and prospects of using frozen dough technology with different protein contents of flour and selected freezing conditions in the steamed bread industry.

Materials and Methods

Materials

Three types of commercial steamed bread flours (Primaflour, Prima, Singapore), one of high-, medium- and low-protein content each, were purchased from local suppliers. The flours have protein content of 7.5 % (low), 9.5 % (medium) and 11 % (high), which is within the range of typical steamed bread flours used commercially. Fine salt (Fairprice, Singapore) and instant dried yeast (Bake King, Singapore) were obtained from NTUC Fairprice (Singapore).

Dough and Steamed Bread Preparation

The dough samples were formulated with flour, water, salt and instant dried yeast, with 1 kg of flour in each batch. For each level of flour protein content, a Farinograph analysis was conducted to determine the amount of water needed to obtain a constant consistency (500 BU) of dough across all samples, which required 540, 570 and 590 g of water for the low-, medium- and high-protein content flours, respectively. The fine salt and instant dried yeast were constant at 10.0 g (or 1 % of flour weight) each per batch.

The dry ingredients were mixed in a spiral mixer (WAG-RN 20, Varimixer Globe, NC, USA) for 1 min at low speed (44 rpm). Water was added and the dough was further mixed for 1 min at low speed, then 3 min at medium speed (66 rpm). The dough was rested at room temperature (22 °C) for 10 min, then placed in an automatic moulder (DR. ROBOT2, Daub Bakery Machinery B.V., Netherlands) to be divided into round pieces of 50 ± 1 g each. The dough pieces without cover were placed in the tunnel of an air blast freezer (MDF-U460BR, SANYO Electronic Biomedical Co. Ltd, Japan) with various freezing treatments including air temperatures of −20, −30 and −40 °C (referred as 2, 3 and 4) and air velocity of 0, 3 and 6 m/s (referred as A, B and C) (Table 1) until the core temperature reached −18 °C which was assured by monitoring via thermocouples. After the core temperature reached −18 °C, the frozen dough samples were thawed immediately in an incubator (MR-153, SANYO Electric Biomedical Co. Ltd, Japan) at 2 °C for 20 h.

The samples to be used for steamed bread quality tests were proofed in a humidity chamber at 40 °C and 85 % RH for 45 min, then steamed in a steel steamer (Singmah Steel Refrigeration, Singapore) for 20 min, and cooled at ambient temperature (22 °C) for 30 min, before testing proceeded. For the control samples, the freezing and thawing steps were omitted. The freezing rates under the different conditions were calculated by taking the difference between the initial freezing temperature (−1.0 °C) and final temperature (−18 °C) divided by the freezing time, as defined by the International Institute of Refrigeration (International Institute of Refrigeration 1986) (Table 1). For ease of discussion, arbitrary terms ‘slow’, ‘moderate’ and ‘fast’ were used to categorize the freezing treatments.

Dough Quality Tests

Extensograph Test

The large-deformation rheological properties of dough in uniaxial extension were measured using an Extensograph-E (Brabender GmbH & Co., Duisberg, Germany). Samples of 150 g were moulded into rolls using the balling unit and dough roll of the Extensograph. The Extensograph stretched the dough samples without yeast until breakage, and the resistance against extension curve provided information on the resistance to extension, extensibility and ratio of resistance to extensibility of the dough.

Rheofermentometer Analysis

Dough development and gas retention properties of the dough were measured using a Rheofermentometer F3 (Chopin Technologies Ltd, Paris, France). After moulding of the dough, 315 g of sample was prepared. A cylindrical piston of 2 kg was placed on the dough, after which it was proofed at 40 °C for 180 min. Dough height and gas pressure were monitored by the instrument to provide information on the maximum dough height (Hm) and total volume of gas produced at the end of the test.

Scanning Electron Microscopy

The microstructure of the frozen dough samples was examined using scanning electron microscopy (SEM). The frozen dough samples were prepared for SEM by breaking dough pieces into two, then taking a small piece (approximately 1 cm × 1 cm × 0.5 cm) from the centre of the frozen dough sample. This small sample was freeze-dried for 2 days and then fractured into smaller pieces that were used for imaging. Control dough samples were frozen under liquid nitrogen to protect their original structure. Dehydrated samples were coated with platinum for 90 s at 20 mA using a sputter coater (JFC-1600 Auto Fine Coater, JEOL Ltd., Tokyo, Japan), and images were taken using a scanning electron microscope (JEOL JSM-5200, Jeol Ltd., Tokyo, Japan) with a 15-kV acceleration voltage at ×1500 magnification.

Steamed Bread Quality Tests

Specific Volume Measurement

A Volscan profiler (VSP 600, Stable Micro System Ltd, Surrey, UK) was used to determine the volume of a steamed bread sample, and the result was divided by the sample’s weight to obtain specific volume. The form ratio was also calculated by taking the maximum height divided by the maximum width of the sample, of which the measurements were determined by the Volscan profiler.

Texture Profile Analysis

Texture profile analysis (TPA) was conducted using a texture analyser (TA.XT2i, Stable Micro System, Surrey, UK) to measure crumb hardness, cohesiveness, springiness and chewiness. Measurements were taken using the middle of a 20-mm vertical slice of crumb. The parameters were determined from a two-cycle compression TPA force-time graph generated by the texture analyser, using instrumental settings described by Wang et al. (2006).

Statistical Analysis

All the experiments were conducted at least in triplicates. Results were reported as the mean values of the triplicates with their standard deviations. Analyses of results were done using one-way ANOVA or three-way ANOVA using SPSS 22 software (IBM Corporation, New York, USA). The one-way ANOVA was carried out in two approaches. In the first approach, results were split by flour protein content and the single fixed factor chosen was the freezing condition. In the second approach, results were split by freezing condition and the single fixed factor chosen was the flour protein content. For the three-way ANOVA, flour protein content, freezer temperature, and freezer air speed were the chosen fixed factors. Post hoc Duncan test was carried out to verify if there were significant differences (P < 0.05 unless otherwise stated) between the samples. Pearson correlation coefficients were calculated between H max, specific volume, hardness and other dough and steamed bread quality parameters.

Results and Discussion

Dough Rheology

Maximum Resistance to Extension (R max)

Figure 1 shows the rheological parameters determined by the extensograph measurement. For the dough samples of low-protein, freezing treatments with slow (2A, 3A) and moderately fast (3B, 3C, 4B) freezing rates resulted in higher R max values, while the other freezing treatments did not result in significant differences from the control (Fig. 1a). For the dough samples of medium protein, there was no significant difference in R max across the control and all the frozen samples. For the dough samples of high protein, those frozen at conditions 2C (−20 °C, 6 m/s) and 4C (−40 °C, 6 m/s) had R max values closer to that of the control, while the rest had lower R max values.

Dough rheological parameters obtained from the extensograph test: a dough resistance to extension (R max), b dough extensibility, and c resistance to extensibility (R/E) ratio of controls and frozen samples. Comparison of means was done within each level of protein content (letters a to e) and within each freezing conditions (letters x to z). Means with different superscript letters are significantly different (P < 0.05)

The three-way ANOVA analysis revealed that there was a significant difference in the R max values amongst dough samples of different protein content (P < 0.001), where a higher protein content led to a greater maximum resistance to extension. The magnitude of the difference in the means between the low- and medium-protein samples was much higher than the difference between the medium- and high-protein samples. With regard to freezing air temperature, samples frozen at −20 °C had a significantly higher R max than those frozen at −30 and −40 °C. There was no significant difference between the samples frozen at different air speeds.

Dough Extensibility

Figure 1b shows the extensibility of dough for steamed bread at different freezing conditions based on the protein contents. With respect to the dough samples of low protein, slow freezing rates (2A: −20 °C, 0 m/s; 3A: −30 °C, 0 m/s; 4A: −40 °C, 0 m/s) led to lower extensibilities while fast freezing rates (3C: −30 °C, 6 m/s; 4C: −40 °C, 6 m/s) resulted in higher extensibilities closer to those of the control samples. With regard to the high protein, all the frozen dough samples had significantly higher extensibilities than the control dough, and as with the dough samples of low protein, fast freezing rates (3C, 4B, 4C) produced the highest extensibilities. There was largely no significant difference in the extensibility across the medium protein dough samples for all the frozen and control treatments.

The three-way ANOVA analysis revealed that the flour protein content had a significant effect on the dough extensibility (P < 0.001), with the extensibility increasing as the flour protein content increased. The freezing air temperature had an effect on the extensibility as well, with the samples frozen at −20 °C having significantly lower extensibilities than the samples frozen at −30 and −40 °C (P < 0.05 and P < 0.001, respectively). With regard to freezing air speed, the highest air speed (6 m/s) led to higher extensibilities compared to lower air speeds (0 and 3 m/s) (P < 0.01).

Impacts of Flour Protein Content on Dough Rheology

It was found that both R max and extensibility increased with protein levels for frozen dough, and this is in agreement with results reported by other researchers (Abbasi et al. 2012; Faegestad et al. 2000; Lin et al. 2003; Uthayakumaran et al. 1999). Using flours with protein contents of 10–13 %, Abbasi et al. (2012) showed a positive correlation between protein content and extensibility, and between protein content and resistance to extension, with correlation coefficients of 0.4 and 0.3, respectively. Those cited studies above were done on fresh dough, and thus, the results of this study provided evidence that frozen dough maintained similar relationships between extensional rheological properties and protein content as compared to fresh dough.

Impacts of Freezing Condition on Dough Rheology

The generally recognized effect of freezing is damage to the gluten network, which would lead to a decrease in R max and an increase in extensibility. Depolymerisation of proteins due to water redistribution as well as mechanical damage from ice crystallization during freezing could cause a reduction in gluten strength, which is a well-established effect for the flours with protein content of 13.7–14.4 % as suggested in several studies (Inoue and Bushuk 1992; Meziani et al. 2011; Nicolas et al. 2000; Wang et al. 2006). Other studies have also reported that a deteriorated gluten network caused a significant decrease in dough resistance and an increment in dough extensibility for the flours with protein content of 13.7–16.9 % (Bhattacharya et al. 2003; Inoue and Bushuk 1991). Therefore, it is recommended that declines in R max and increments in extensibility compared to their control for high-protein samples observed in this study can likewise be attributed to freezing damage of the dough gluten network as well.

Interactive Impacts Between Flour Protein Content and Freezing Condition on Dough Rheology

The dough samples of high protein showed such rheological changes (i.e. decreased R max and increased extensibility compared to their control) after the freezing treatments, but not the dough samples of medium or low protein. In fact, the dough samples of low protein displayed an opposite trend of increased R max and decreased extensibility as compared to its control. However, this does not conclusively prove that the dough samples of medium and low protein did not suffer from freezing damage to the gluten network, because the other parameters measured in this study including dough development and dough microstructure analysis indicated otherwise (ref. ‘Dough Microstructure’ and ‘Volscan Profiling of Steamed Bread’ Sections). There were several confounding factors involved, including flour composition and stiffening effects due to low temperatures. Uthayakumaran et al. (1999) suggested that besides protein content, the rheological properties of dough were also subject to wheat cultivar variations for the flours with protein content of 9.2–13 %. Also, a number of studies reported the effects of protein and starch quality on dough rheology for the flours with protein content of 9.44–17.24 % (Goesaert et al. 2005; Lin et al. 2003; Zhu et al. 2001). Therefore, it is possible that the direction and magnitude of the effect of freezing on the rheological properties of dough would vary depending on the wheat cultivar and consequent flour composition.

Nicolas et al. (2000) reported an increased stiffness of gluten-water mixtures with increased storage durations at sub-zero temperatures, especially during storage at −5 °C. In this study, frozen dough was thawed at 2 °C for 20 h and would thus have been at sub-zero temperatures for an extended period as the dough thawed from −18 to 2 °C. Therefore, this thawing step could hence have caused dough stiffening resulting in an increase in R max and decrease in extensibility of the thawed dough (as observed for the dough samples of low protein). Thus, it is possible that dough of varying protein contents (and protein or starch quality) experienced dough stiffening to different extents which was not the scope of this study.

The interactive impacts on dough rheology were enlightened by a three-way ANOVA analysis in which flour protein content, freezer temperature and freezer air speed were the chosen fixed factors. Frozen dough samples at −20 °C had higher R max and lower extensibility than the samples frozen at −30 and −40 °C (P < 0.05 and P < 0.001, respectively), which could most likely be due to a higher dough stiffening effect at higher sub-zero temperatures as mentioned above. According to the three-way ANOVA analysis, frozen dough samples at 6 m/s air speeds had higher extensibilities compared to lower air speeds (0 and 3 m/s) (P < 0.01) without an accompanying decrease in R max, suggesting a gluten network that was better retained because of higher freezing rates at higher air speeds. Protein network integrity was affected by the freezing rate; high freezing rates minimized water migration in the dough network and promoted the smaller local ice crystals formation; thus, less damage was done to the gluten network (Meziani et al. 2011). In addition, slow freezing rates have been found to result in protein aggregation because of a reduction in the amount of α-helix structures and an increased content of β-sheet structures (Meziani et al. 2011), showing a higher extent of damage to the gluten network.

Rheofermentometer Analysis

Gas Production

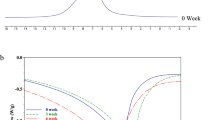

Figure 2 shows the fermentation performance of frozen dough based on flour protein content and different freezing treatments. The total gas production of the control samples was higher than those of the frozen samples, and there was no significant difference between the controls (Fig. 2a). Generally, across all the protein levels, freezing treatments with the fastest freezing rates (3C: −30 °C, 6 m/s; 4C: −40 °C, 6 m/s) resulted in the lowest total gas produced.

Dough fermentation performance parameters acquired from the rheofermentometer analysis: a total gas production and b maximum dough height (H max) of controls and frozen samples. Comparison of means was done within each level of protein content (letters a to e) and within each freezing conditions (letters x to z). Means with different superscript letters are significantly different (P < 0.05)

The three-way ANOVA analysis showed that the dough samples of low protein had a small but significant decrease in the total gas production as compared to the high protein (P < 0.05). There was no significant difference between the samples frozen at the different freezing air temperatures (i.e. −20 °C, −30 °C, −40 °C). There was, however, a significant effect caused by freezing air speed. The samples frozen with a moderate air speed of 3 m/s had higher total gas productions than those of 0 and 6 m/s (P < 0.01).

As a reduction in the total gas production was observed when comparing the frozen samples to the controls, the results demonstrated that the freezing process itself, without frozen storage, had a significant impact on yeast activity. A number of studies were mostly relying on the frozen storage without focusing on the isolated effect of the freezing and suggested that yeast activity and gas production rate diminished with lengthened frozen storage compared to fresh control samples (Baguena et al. 1991; Phimolsiripol et al. 2008; Yi and Kerr 2009a), This is because the viability of Saccharomyces cerevisiae is affected by both the freezing process and storage time (Baguena et al. 1991) which is attributed to ice crystal formation that mechanically damages or causes osmotic pressure effects on the yeast cells, leading to a decrease in yeast viability (Meziani et al. 2012). Indeed, results of this study showed that freezing process itself had an impact on yeast activity, and the ice crystal formation was initiated and primarily completed during the freezing process.

The fastest freezing rate (4C: −40 °C, 6 m/s) resulted in the largest reduction in total volume, which was also supported by Meziani et al. (2012) that showed a correlation between high freezing rates and more yeast cell damage and yeast activity loss in frozen sweet dough due to the formation of intracellular ice crystal. On the other hand, an air speed of 3 m/s resulted in the highest volume of gas production and hence yeast activity, which appeared to oppose the common view that slow freezing rates favour the protection of yeast activity. Meziani et al. (2012) reported that yeast exposure to hyperosmotic stress could lead to faster dehydration of cells, limiting their carbon dioxide production and consequently causing a decrease in specific volume. Therefore, it is possible that in this study, the 1 % salt addition as part of the dough formulation could have contributed to osmotic pressure on the yeast cells, consequently leading to decreased yeast activity and total gas production in particular during slow freezing. Clearly, an optimal freezing condition exists for different formulation of dough, and in this study, samples were made using different protein levels of flours for their dough formulation.

Dough Development

Figure 2b shows the maximum dough height of frozen dough with regard to flour protein content and different freezing treatments. Generally, the control samples had higher maximum dough height (H max) as compared to the frozen samples, while there was no significant difference between the controls. With respect to the dough samples of low and high protein, there was a small difference in H max across the different freezing conditions. For the dough samples of medium protein, the frozen dough that had moderate freezing rates (2C, 3B) usually had higher H max values.

With the three-way ANOVA analysis, it was found that the H max values of the dough samples of low protein was significantly lower (P < 0.001) than those of the medium- and high-protein samples, with no significant difference between the latter two. There was no significant difference in H max observed across the use of different freezing air temperatures. On the other hand, with regard to freezing air speed, a moderate speed of 3 m/s had significantly higher H max as compared to 0 and 6 m/s (P < 0.01), with no significant difference between the latter two.

Maximum dough height is a good indicator of proofing performance as it combines the effects of the two key elements in dough and bread quality—yeast activity and gluten network integrity. It was hence able to give an indication of steamed bread quality and was found to positively correlate with specific volume, form ratio and hardness (correlation coefficients of 0.42, 0.53 and −0.56, respectively) (Table 2). The maximum dough height of the frozen dough was dependent on the relative extents of the damage to yeast and gluten and was found to correlate with numerous dough quality measurements including total gas production (correlation coefficient of 0.64) which reflected yeast activity and R/E (resistance to extension) ratio (correlation coefficient of 0.62) which indicated gluten network integrity (Table 2).

The 26 % average reduction in H max of the frozen dough samples of low protein as compared to its control was higher than that of the medium- and high-protein dough (average decrease of 11 and 18 %, respectively), which was consistent with earlier studies reporting that dough made from strong flours (referring the flours of higher protein content) was generally resistant to freeze damage (Bhattacharya et al. 2003; Inoue and Bushuk 1991). These studies were carried out on bread flours that had higher protein contents of 13–16 %, as opposed to 7.5–11 % used in this study for steamed bread, suggesting that even at lower value range of protein content, flours with relatively higher protein content are still generally more resistant to freezing damage. Consequently, dough made from low-protein flours for steamed bread was more susceptible to freezing damage and caused the highest reduction in H max as compared to fresh dough.

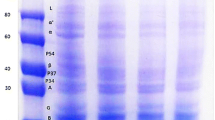

Dough Microstructure

SEM allows the visualization of dough microstructure, including gluten-starch association and state of gluten strands in the network. Figures 3 and 4 show the comparisons between the control and the frozen dough samples, as well as within the different freezing treatments. The control samples (Fig. 3(Ia–c)) showed continuous gluten matrices closely wrapping around starch granules and were used as a benchmark for frozen samples. With regard to the dough samples of low protein, there was noticeable thinning and disruption of the gluten matrix for all the frozen samples, especially at slow freezing rates (Fig. 3(IIa, b, d): 2A, 2B, 3A, respectively).

I SEM images of frozen dough control samples: (a) low protein, (b) medium protein, and (c) high protein. The symbols S and G represent starch granules and gluten matrix, respectively. II SEM images of frozen dough samples made from low-protein flour. Freezing conditions from top left: (a) 2A, (b) 2B, (c) 2C, (d) 3A, (e) 3B, (f) 3C, (g) 4A, (h) 4B, (i) 4C. Arrows point to damaged gluten strands

III SEM images of frozen dough samples made from medium-protein flour. Freezing conditions from top left: (a) 2A, (b) 2B, (c) 2C, (d) 3A, (e) 3B, (f) 3C, (g) 4A, (h) 4B, (i) 4C. IV SEM images of frozen dough samples made from high-protein flour. Freezing conditions from top left: (a) 2A, (b) 2B, (c) 2C, (d) 3A, (e) 3B, (f) 3C, (g) 4A, (h) 4B, (i) 4C. The symbols S and G represent starch granules and gluten matrix, respectively, while arrows point to damaged gluten strands

With respect to the dough samples of medium and high protein, moderate freezing rates produced relatively continuous gluten matrices comparable to those of the controls, and similar signs of thinning and disruption were showed at the slow and fast freezing rates (Fig. 4(IIIa ,d, g and IVa, c, i)). Generally, the high-protein samples (Fig. 4(IV)) had the largest regions of continuous gluten matrices of all the protein levels. Similar to the findings of this study, Yi and Kerr (2009b) used cryo-SEM and reported that frozen dough (protein content of 11.5 %) produced at slower rates had gluten matrices that were less uniform and had thinner strands, while frozen dough produced at faster freezing rates showed less disrupted structure. In this study, the freezing process was isolated and the effects of frozen storage were omitted, thus providing evidence that the freezing process itself caused gluten network deterioration, the extent of which was dependent on the freezing rate.

As suggested by Yi and Kerr (2009b), microstructural observations could help to explain the observed rheological properties of dough and lower extensibility could be attributed to the thinner, more disrupted bonding in the gluten. Based on the extensibility findings of this study, amongst the frozen samples, the slower freezing rates resulted in lower extensibilities while the faster freezing rates produced higher extensibilities, revealing that the gluten network integrity was preserved better at faster freezing rates, as shown through the SEM images (Figs. 3 and 4).

It was observed that the gluten network in the dough samples of low protein was the most damaged after freezing treatments, indicating obvious gluten thinning and disruption at all freezing rates, as compared to the dough samples of medium and high protein which were only severely affected at slow freezing rates. In addition, the dough samples of high protein had the largest regions of continuous gluten matrices. These suggest that the extent of freezing damage decreased as flour protein content increased.

Volscan Profiling of Steamed Bread

Specific Volume

Figure 5a shows the specific volumes of the control and the frozen samples after steaming. The low-, medium- and high-protein steamed bread samples showed lower specific volumes compared to their corresponding control for all the freezing conditions. With regard to all protein levels, the fastest freezing rate (4C −40 °C, 6 m/s) resulted in the lowest specific volume compared to other freezing conditions. For the low-protein steamed bread samples, moderately slow freezing rates (2B, 3A, 3B, 4A) produced higher specific volumes. With respect to the medium- and high-protein steamed bread samples, there were largely no significant differences in specific volume across the various freezing conditions.

Specific volume (a) and form ratio (b) (height/width) of control and frozen samples after steaming. Comparison of means was done within each level of protein content (letters a to e) and within each freezing conditions (letters x to z). Means with different superscript letters are significantly different (P < 0.05)

Comparing protein levels, the low-protein steamed bread samples had significantly lower specific volumes (P < 0.001) than the medium- and high-protein samples. The freezing air temperature of −40 °C resulted in significantly lower specific volumes than −20 and −30 °C. The freezing air speed of 6 m/s also resulted in significantly lower specific volumes compared to 0 and 3 m/s air speeds.

Freezing of dough led to a decrease in specific volume after steaming, which was likely a result of a decline in yeast activity coupled with a weakened gluten network, as described in ‘Gas Production’ and ‘Dough Microstructure’ Sections, respectively. Huang et al. (2011) reported a reduction in the specific volume of steamed bread made from pre-fermented frozen dough. Baked bread from frozen dough had also been found to have a reduction in specific volume (Ribotta et al. 2001; Yi and Kerr 2009b).

While fast freezing rates should preserve the integrity of the gluten network better, total gas production results showed that at the fastest freezing rate (4C: −40 °C, 6 m/s), there was a large drop in yeast activity. This would consequently lead to a large reduction in specific volume for the samples frozen at that rate, as observed. Moreover, a significant positive correlation with a coefficient of 0.55 (P < 0.01) was found between the specific volume and the total gas production (Table 2), thus supporting the importance of yeast activity in determining steamed bread specific volume.

A correlation analysis was also carried out between the specific volume of steamed bread and the other dough quality parameters (Table 2). Large-deformation dough rheology is especially related to specific volume because during proofing and steaming, the rheological properties of the gas cell walls determine the extent of gas loss as a result of gas cell wall collapse (Dobraszczyk and Morgenstern 2003), which would in turn affect the volume of the bread. Huang et al. (1996) reported that specific volume was positively correlated with maximum resistance and extensibility (P < 0.001) for steamed bread with correlation coefficients of 0.53 and 0.63, respectively, for the flours of the protein content of 7.9 to 15.3 %. In our study, the specific volume of the steamed bread was found to only weakly correlate positively with R max and the R/E ratio, but not with the extensibility. This could be because of the varying effects of yeast activity as a result of different freezing treatments, which weakened the correlation of the dough’s rheological parameters with the specific volume. Particularly, it could be due to the extents of yeast activity and gluten network damage which typically are oppositely affected by varying freezing conditions. As with the specific volume, H max was affected by the combined effects of yeast activity and gluten network integrity, thus their positive correlation is as expected.

Form Ratio

Figure 5b shows the form ratio (height/width) values of the control and the frozen samples after steaming. The protein content had a significant impact on the form ratio (P < 0.001). The low-protein steamed bread had the lowest form ratios, followed by the high- then the medium-protein steamed bread. The freezing air temperature of −20 °C resulted in lower form ratios than −30 and −40 °C (P < 0.01), while the freezing air speed did not have any significant effect.

This study showed clearly that steamed bread made from frozen dough had lower form ratios. In addition, the low-protein steamed bread had the lowest form ratios at every freezing condition, indicating that it had the poorest resistance to freezing damage as supported by H max and SEM analyses, as well as steamed bread specific volume results.

Ribotta et al. (2001) and Faegestad et al. (2000) both reported the relationship between dough rheological properties and form ratios for baked bread, which was positively related to dough elasticity or resistance. A lower R/E ratio will thus result in poorer form ratios, which is supported by the results of this study, as the low-protein dough samples had the lowest R/E ratios as well as the poorest steamed bread form ratios, followed by the high- then the medium-protein samples.

Steamed Bread Texture

Figure 6 shows the hardness of the control and the frozen samples after steaming. For all the protein contents, the slowest (2A: −20 °C, 0 m/s) and fastest (4C: −40 °C, 6 m/s) freezing rates led to an increment in hardness. In low-protein samples, slow and moderate freezing rates (2B, 3B, 3A, 4A) resulted in lower hardness that was statistically comparable to the control samples. For the medium protein samples, moderately fast freezing rates (3B, 4B) produced the lowest hardness that was comparable to the control samples. With respect to the high-protein samples, hardness was less affected by the different freezing conditions and most samples had comparable hardness to the control samples.

Hardness of steamed bread made from control and frozen dough samples after steaming. Comparison of means was done within each level of protein content (letters a to e) and within each freezing conditions (letters x to z). Means with different superscript letters are significantly different (P < 0.05)

In this study, the three-way ANOVA analysis indicated that the protein content affected the hardness of steamed bread, with the low-protein steamed bread samples having a higher hardness compared to the medium- and high-protein samples (P < 0.001), but there was no significant difference between the latter two. The freezing air temperature did not have a significant effect on the hardness of steamed bread, while for freezing air speed, 3 m/s resulted in the lowest hardness, followed by 0 and 6 m/s. Fast freezing rates resulting in higher hardness of different baked products have been reported by several researchers. Yi and Kerr (2009a) showed that faster freezing rates caused higher baked bread firmness, and Meziani et al. (2012) also reported that hardness of the baked product obtained from frozen sweet dough increased significantly as freezing rates increased. Meziani et al. (2012) further found that no significant difference in hardness was obtained across sweet dough treated with different freezing rates when the yeast amount was doubled, suggesting that hardness was more affected by changes in yeast activity than in gluten network integrity. This might explain why some slow freezing rates (3A, 4A, 2B) did not result in significant increases in hardness as compared to the control, and only the slowest freezing rate 2A resulted in significantly increased hardness for steamed bread.

Pearson correlation analysis results further indicated that there were significantly negative correlations between hardness and dough quality parameters (R max, R/E ratio, H max, total gas production), as well as between hardness and specific volume (Table 2), which implies that increases in these parameters (i.e. R max, R/E ratio, H max, total gas production and specific volume) would generally produce softer steamed bread.

Conclusions

The effects of flour protein content and freezing conditions (freezing air temperature and freezing air speed) on dough quality and steamed bread quality were examined. The freezing process caused a damage to gluten network as well as a decrease in yeast activity, which resulted in lower H max and total gas production in Rheofermentometer analysis, and lower specific volume and form ratio and increased hardness of steamed bread.

Protein contents affected the extent of freezing damage to dough quality; the low-protein dough samples were the most damaged by freezing, as shown by the greatest decrease in average H max and form ratio after freezing, as well as the most disrupted gluten network observed in SEM analysis and lowest steamed bread specific volume. However, few quality parameters were found to have a clear dependence on protein content for frozen dough; dough extensibility and R max increased with protein content, while R/E ratio and H max of dough and specific volume, form ratio, and hardness of steamed bread did not show clear trends as protein content varied. Therefore, protein content alone could not explain the differences in dough quality parameters.

Freezing rate of the dough also affected the extent of damage to the gluten network and yeast activity; moderate freezing rates resulted in dough with higher extensibility and a less damaged dough microstructure with more continuous gluten matrices as observed in SEM analysis.

Fast freezing rates, however, led to a decrease in total gas production as the yeast activity was compromised. These resulted in a lower specific volume and higher hardness for steamed bread made from the dough that was frozen at fast freezing rates, especially for low-protein samples. Generally, the extreme freezing conditions 2A (−20 °C, 0 m/s) and 4C (−40 °C, 6 m/s) had the poorest dough and steamed bread quality.

Freezing air temperature and air speed had significant effects on several dough and steamed bread quality parameters. Samples frozen at −20 °C had poorer form ratio of steamed bread than those frozen at −30 and −40 °C, while those frozen at −40 °C, 6 m/s had the lowest specific volume compared to lower air speeds (0 and 3 m/s). The volume of total gas produced and H max were higher at a moderate air speed of 3 m/s, possibly due to the resultant moderate freezing rate that preserved a better balance between both yeast activity and gluten network.

Lastly, there are practical insights that are relevant to the industry for making steamed bread from frozen dough. Steamed bread is typically made from flours with protein contents of 7.5–11 %, but frozen dough made with higher protein content (9.5–11 %) had better resistance to freezing damage, resulting in a final product of closer specific volume, form ratio and texture to those of bread made from fresh dough. Low freezing air temperatures are costly to maintain for practical applications in the industry. Therefore, it is recommended that to achieve a particular freezing rate, a combination of relatively higher freezing air temperature and moderate air speed should be employed.

References

Abbasi, H., Ardabili, S. M. S., Emam-Djomeh, Z., Mohammadifar, M. A., Zekri, M., & Aghagholizadeh, R. (2012). Prediction of extensograph properties of wheat-flour dough: artificial neural networks and a genetic algorithm approach. Journal of Texture Studies, 43(4), 326–337.

Ananingsih, V. K., Gao, J., & Zhou, W. (2013). Impact of green tea extract and fungal alpha-amylase on dough proofing and steaming. Food and Bioprocess Technology, 6(12), 3400–3411.

Baguena, R., Soriano, M. D., Martinezanaya, M. A., & Debarber, C. B. (1991). Viability and performance of pure yeast strains in frozen wheat dough. Journal of Food Science, 56(6), 1690–1694.

Bao YR & Wang XL (2011). Research on water’s influences on the quality of frozen dough. In: Dan Y (ed) 2011 International Conference on Environment Science and Biotechnology. Procedia Environmental Sciences. Amsterdam: Elsevier Science Bv, pp 313-318.

Bao YR, Wang XL & Ren SC (2012). Emulsifier’s influence on the quality of frozen dough. In: Wang D (ed) Materials for environmental protection and energy application. Advanced Materials Research. Kuala Lumpur: Trans Tech Publications Ltd, pp 423-429.

Bhattacharya, M., Langstaff, T. M., & Berzonsky, W. A. (2003). Effect of frozen storage and freeze–thaw cycles on the rheological and baking properties of frozen doughs. Food Research International, 36(4), 365–372.

Dobraszczyk, B. J., & Morgenstern, M. (2003). Rheology and the breadmaking process. Journal of Cereal Science, 38(3), 229–245.

Faegestad, E. M., Molteberg, E. L., & Magnus, E. M. (2000). Interrelationships of protein composition, protein level, baking process and the characteristics of hearth bread and pan bread. Journal of Cereal Science, 31(3), 309–320.

Goesaert, H., Brijs, K., Veraverbeke, W. S., Courtin, C. M., Gebruers, K., & Delcour, J. A. (2005). Wheat flour constituents: how they impact bread quality, and how to impact their functionality. Trends in Food Science & Technology, 16(1-3), 12–30.

Havet, M., Mankai, M., & Le Bail, A. (2000). Influence of the freezing condition on the baking performances of French frozen dough. Journal of Food Engineering, 45(3), 139–145.

Hou, G. G., & Popper, L. (2006). Chinese steamed bread. In L. Popper (Ed.), Future of Flour: A compendium of flour improvement (pp. 309–318). Germany: AgriMedia.

Huang, S. D., Yun, S. H., Quail, K., & Moss, R. (1996). Establishment of flour quality guidelines for northern style Chinese steamed bread. Journal of Cereal Science, 24(2), 179–185.

Huang, L. Q., Wan, J. J., Huang, W. N., Rayas-Duarte, P., & Liu, G. (2011). Effects of glycerol on water properties and steaming performance of prefermented frozen dough. Journal of Cereal Science, 53(1), 19–24.

Inoue, Y., & Bushuk, W. (1991). Studies on frozen doughs 1. Effects of frozen storage and freeze-thaw cycles on baking and rheological properties. Cereal Chemistry, 68(6), 627–631.

Inoue, Y., & Bushuk, W. (1992). Studies on frozen doughs 2. Flour quality requirements for bread production from frozen dough. Cereal Chemistry, 69(4), 423–428.

International Institute of Refrigeration (1986) Recommendations for the processing and handling of frozen foods. 3rd edn., Paris

Kenny, S., Wehrle, K., Dennehy, T., & Arendt, E. K. (1999). Correlations between empirical and fundamental rheology measurements and baking performance of frozen bread dough. Cereal Chemistry, 76(3), 421–425.

Kondakci T & Zhou W (2015) Impact of sodium alginate and xanthan gum on the quality of steamed bread made from frozen dough. Cereal Chemistry. in press. doi:10.1094/CCHEM-03-14-0036-R

Leray, G., Oliete, B., Mezaize, S., Chevallier, S., & de Lamballerie, M. (2010). Effects of freezing and frozen storage conditions on the rheological properties of different formulations of non-yeasted wheat and gluten-free bread dough. Journal of Food Engineering, 100(1), 70–76.

Lin, Z. J., Miskelly, D. M., & Moss, H. J. (1990). Suitability of various Australian wheats for Chinese-style steamed bread. Journal of the Science of Food and Agriculture, 53(2), 203–213.

Lin, P. F., Chiang, S. H., & Chang, C. Y. (2003). Comparison of rheological properties of dough prepared with different wheat flours. Journal of Food and Drug Analysis, 11(3), 220–225.

Lukow, O. M., Zhang, H., & Czarnecki, E. (1990). Milling, rheological, and end-use quality of Chinese and Canadian spring wheat cultivars. Cereal Chemistry, 67(2), 170–176.

Meziani, S., Jasniewski, J., Gaiani, C., Ioannou, I., Muller, J.-M., Ghoul, M., & Desobry, S. (2011). Effects of freezing treatments on viscoelastic and structural behavior of frozen sweet dough. Journal of Food Engineering, 107(3–4), 358–365.

Meziani, S., Kaci, M., Jacquot, M., Jasniewski, J., Ribotta, P., Muller, J. M., Ghoul, M., & Desobry, S. (2012). Effect of freezing treatments and yeast amount on sensory and physical properties of sweet bakery products. Journal of Food Engineering, 111(2), 336–342.

Myers, D. K., & Attfield, P. V. (1999). Intracellular concentration of exogenous glycerol in Saccharomyces cerevisiae provides for improved leavening of frozen sweet doughs. Food Microbiology, 16(1), 45–51.

Nicolas, Y., Smit, R., & Agterof, W. (2000). Wheat gluten proteins: how rheological properties change during frozen storage. In P. R. Shewry & A. S. Tatham (Eds.), Wheat Gluten (Royal Society of Chemistry Special Publications, Vol. 261, pp. 451–453).

Phimolsiripol, Y., Siripatrawan, U., Tulyathan, V., & Cleland, D. J. (2008). Effects of freezing and temperature fluctuations during frozen storage on frozen dough and bread quality. Journal of Food Engineering, 84(1), 48–56.

Ribotta, P. D., Leon, A. E., & Anon, M. C. (2001). Effect of freezing and frozen storage of doughs on bread quality. Journal of Agricultural and Food Chemistry, 49(2), 913–918.

Ribotta, P. D., Perez, G. T., Leon, A. E., & Anon, M. C. (2004). Effect of emulsifier and guar gum on micro structural, rheological and baking performance of frozen bread dough. Food Hydrocolloids, 18(2), 305–313.

Selomulyo, V. O., & Zhou, W. (2007). Frozen bread dough: effects of freezing storage and dough improvers. Journal of Cereal Science, 45(1), 1–17.

Uthayakumaran, S., Gras, P. W., Stoddard, F. L., & Bekes, F. (1999). Effect of varying protein content and glutenin-to-gliadin ratio on the functional properties of wheat dough. Cereal Chemistry, 76(3), 389–394.

Wang, R., Zhou, W., Yu, H. H., & Chow, W. F. (2006). Effects of green tea extract on the quality of bread made from unfrozen and frozen dough processes. Journal of the Science of Food and Agriculture, 86(6), 857–864.

Yi, J., & Kerr, W. L. (2009a). Combined effects of dough freezing and storage conditions on bread quality factors. Journal of Food Engineering, 93(4), 495–501.

Yi, J., & Kerr, W. L. (2009b). Combined effects of freezing rate, storage temperature and time on bread dough and baking properties. LWT--Food Science and Technology, 42(9), 1474–1483.

Zhu, F. (2014). Influence of ingredients and chemical components on the quality of Chinese steamed bread. Food Chemistry, 163, 154–162.

Zhu, J., Huang, S., Khan, K., & O’Brien, L. (2001). Relationship of protein quantity, quality and dough properties with Chinese steamed bread quality. Journal of Cereal Science, 33(2), 205–212.

Acknowledgments

The authors are grateful to the Singapore Ministry of Education for funding the project through the Academic Research Fund Tier 1 research grant R143-000-404-112 and the National University of Singapore (Suzhou) Research Institute under the grant number NUSRI2011-007 and Jiangsu Province under the Scientific Research Platform scheme. The first author also likes to thank the Agency for Science, Technology and Research (A*STAR) and the National University of Singapore (NUS) for financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kondakci, T., Zhang, J.W. & Zhou, W. Impact of Flour Protein Content and Freezing Conditions on the Quality of Frozen Dough and Corresponding Steamed Bread. Food Bioprocess Technol 8, 1877–1889 (2015). https://doi.org/10.1007/s11947-015-1544-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-015-1544-6