Abstract

Baking quality of frozen dough is negatively affected by dough weakening and by a reduction in both yeast viability and activity during freezing and frozen storage. The objective of this study was to investigate effects of different enzymes, such as α-amylase, xylanase, celluase, glucose oxidase, and lipase on the texture and sensory quality of bread after frozen storage, as well as on dough properties, in terms of fermentation characteristics, freezable water contents and microstructure. Except for α-amylase, other enzymes improved the bread sensory quality and got higher overall acceptability, especially xylanase. Dough fermentative behavior showed that the maximum heights of frozen dough were increased by 33.2, 19.7 and 7.4%, respectively with xylanase, cellulase and lipase. Cellulase lowered gas holding ability of dough. Thermodynamic properties indicated that addition of enzyme decreased the freezable water contents in frozen dough. Scanning electronic microscopy revealed that freezing and frozen storage disrupted dough gluten network causing separation of starch granules from the gluten matrix. Inclusion of cellulase, xylanase and lipase made the frozen dough having a more continuous gluten network and smoother surface, and glucose oxidase increased the stability of the gluten work.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The sensory quality of bread has some typical deterioration during the storage, like a drier mouth feel, an increase in crumb firmness, loss of flavor and aroma, and loss of crispiness. Dough freezing technology is introduced to solve these problems,especially for consumers’ acceptance of prepared bread, and its advantages also include constant available dough resources, lower costs, standard quality, and had the possibility to make available “fresh” baked products at any time. However, baking quality of frozen dough is negatively affected by dough weakening and by a reduction in both yeast viability and activity during the frozen storage (Steffolani et al. 2011). Frozen storage of dough not only harms the gluten network, but decreases the dough gas-holding power, and increases proofing time. The gluten matrix in dough can be severely damaged with holes forming in the gluten micelles when stored at − 18 °C for 60 days (Ribotta et al. 2004). For final bread quality, frozen storage also caused some problems, such as lower bread volume and deterioration of the texture of bread, which are caused by several factors including reduction in gluten cross-linking, ice crystallization and recrystallization, water redistribution, and the release of reducing substances from yeast (Autio and Sinda 1992; Ribotta et al. 2001; Steffolani et al. 2011).

Thus, additives, such as emulsifiers and enzymes, are used in baking industry to preserve freshness, to increase consumer acceptance and physico-chemical shelf-life of bread. In addition, the enzymes are better alternative compared with other chemical additives due to their safety. Enzymes are proteins used to catalyze chemical reactions, which can be used as additives in different baked products, such as bread, cakes, biscuits, etc. Studies have confirmed that some enzymes can improve the sensory quality of bread by improving flour quality, creating dough that has more machine tolerance, as well as enhancing bread structure (Prabhasankar et al. 2004). α-amylase (EC 3.2.1.1) exerts its effect on starch by producing small molecules, such as glucose and maltose. These small molecules can feed yeast and speed up dough fermentation (Prabhasankar et al. 2004). The α-amylase has been extensively used to make softer texture and to decrease amylose crystal formation, contributing to anti-staling properties in both yeasted dough and chemically leavened dough (Goesaert et al. 2009; Steffolani et al. 2012; Bosmans et al. 2013). Xylanase (EC 3.2.1.8), also known as pentosanases, hydrolyzes water insoluble arabinoxylans into smaller water soluble components. These water soluble compounds stabilize gas cells and increase dough viscosity (Steffolani et al. 2010, 2012). Cellulase (EC 3.2.1.4) is a complex of three kinds of enzymes which work synergistically to hydrolyse cellulase into cellobiose, glucose and oligosaccharides. It has been widely used in the chemical industry, but there is little research about its application in dough (Nigam 2013). According to Yurdugul et al. (2012), the enzyme complex, bearing cellulase activity from anaerobic fungi, were used in bread dough, which resulted in a decrease of hardness, providing a softer crumb, and a better sensory quality. Glucose oxidase (EC 1.1.3.4), in the presence of oxygen, catalyzes α-d-glucose to α-d-gluconolactone and produces H2O2 in the process, which then oxidizes hydrogen sulfide (-SH) causing an increase in dough tenacity and elasticity (Shafisoltani et al. 2014; Steffolani et al. 2012). However, glucose oxidase also have some deficiencies, like fast oxidation at the initial stage of dough development which causes rapid release of H2O2, resulting in dough over developing, low volume of bread (Tang et al. 2014). Bonet et al. (2006) found that glucose oxidase effects are dose-dependent and differ with varying flour quality. Lipase (EC 3.1.3.3) catalyzes triglyceride into mono- or di-glycerin, glycerol and free fatty acids. The application of lipase in bread is a popular research area in recent years, as well as other enzymes and emulsifiers that may help to improve characteristics in baked products (Moayedallaie et al. 2010). Li et al. (2011) investigated the beneficial effect of a new recombinant and transglutaminase, and results showed some improvement of rheofermentative characteristics, water-holding capacity and crumb structure of frozen dough.

Many researchers have focused on the application of enzymes in the fresh dough and bread, as well as specialized dough like gluten-free and wheat-cassava bread dough (Ananingsih et al. 2012; Sciarini et al. 2012; Serventi et al. 2016). Steffolani et al. (2011) used enzymes to minimize dough freezing damage. Despite these and other valuable contributions to the literature, the precise effects and mechanisms of such effects across various types of enzymes in regards to frozen dough and completed bread products yet merit further research. Considering the customers’ acceptance is really important to foodstuffs, the aim of this study was to determine the effect of α-amylase, xylanase, cellulase, glucose oxidase, and lipase on sensory quality of frozen dough bread, as well as on the dough fermentative behavior, microstructure, freezable water content, to make a contribution to the knowledge of enzyme mechanism in frozen dough.

Materials and methods

Materials

Wheat flour without any additives, with the parameters of tenacity (P) = 156 mm, extensibility (L) = 20 mm, P/L = 3.12, moisture = 13.7% (w/w, wet basis), ash = 0.5% (w/w, wet basis), and wet gluten = 33.0% (w/w, wet basis) was bought from a local company (Beijing Zuozhu fine wheat Co. Ltd). The commercial products of α-amylase(EC 3.2.1.1, Fungamyl FI 2500 BG), xylanase (EC 3.2.1.8, Pentopan Mono BG), cellulase (EC 3.2.1.4, Celluclast BG), glucose oxidase (EC 1.1.3.4, Gluzyme Mono 10000 BG), and lipase (EC 3.1.3.3, Lipopan Xtra) were produced and supplied by Novozymes Investment Co. Ltd. Addition of α-amylase, xylanase, cellulase, glucose oxidase and lipase were added to flour at the following concentrations based on calculations from a pre-experiment, 6, 60, 60, 10 and 25 mg kg −1 flour. Dough without any enzymes was used as a control.

Preparation of dough

Dough was prepared using the following formulation, 2% instant active dry yeast (Angel Yeast Co. Ltd.), 1% salt, 10% sugar, 54% water and known quantities of enzymes. Sugar and salt were dissolved in a small portion of the total water. The enzymes were mixed with water and agitated magnetically to create well-proportioned and stable solutions. Accurate quantities of enzymes were transferred to another portion of water using a pipette. Dry yeast powder was mixed with flour, followed by the addition of the sugar and enzyme solutions. Optimum dough was obtained by mixing and kneading with a Kenwood 760 mixer. The mixing procedure is as follows, dough was mixed at the mini speed gear with the “K” paddle for 5 min, then at the first speed gear for 1 min followed by the second speed gear for a minute, and finally, kneading with the “J” hook at the third speed gear for 5 min. The dough was then divided into 50-g pieces, rounded to form cylindrical samples with a diameter of about 30 mm and a height of about 50 mm. Dough pieces were then sealed in plastic bags and frozen at − 40 °C for 80 min, followed by storage in the freezer at − 18 °C for 4 weeks. Frozen dough pieces were thawed at 30 °C with a relative humidity of 85% for 40 min before analysis. Fresh dough samples were stored at 4 °C and analyzed the next day.

Preparation of bread

The fresh dough and the thawed, frozen dough were put in fermentation bowls and allowed to ferment at 85% (RH, relative humidity) at 30 ± 1 °C for 40 min. The fermented dough was divided into 100 g pieces. The dough was then rolled into a cylinder of 7 cm in length and the 4 cm in diameter. Molded dough was proofed at 85% (RH) at 37 ± 1 °C for 45 min. After proofing, the dough was baked at an upper temperature of 160 °C and a bottom temperature of 180 °C for 30 min in an electric oven (SEZ-2YG, Zhuhai, China).

Sensory analysis of bread

Sensory evaluation of control and enzyme-containing bread was performed by 10 well-trained sensory panels which is according to the criterion of the National Bread Sensory Evaluation Standard (National Standard: GB/T 14611-2008) with several modifications. Attributes evaluated were crumb volume (45 points, based on 360 mL, then increases by 1 point with the addition of volume per 12 mL), appearance (little visual flecks and clear neck), crumb color (whitish and glossy color), crumb texture (compact, resilient, and adhesive crumb) and crumb pore structure (uniformity of pore or porosity). The last four aspects were evaluated using a 5, 5, 10, 35-point intensity scale divided into 0.5 point increments respectively, with zero indicating low quality and full score signifying an extremely high quality.

Fermentative behavior of bread dough

Rheofermentometer analysis provides details of dough functional performance including its development and gassing power during fermentation (Ananingsih et al. 2012). Fermentative characteristics of bread dough were analyzed using a rheofermentometer, F3 (Chopin Technologies Ltd. Paris. France) following a previously published method with some modifications (Ananingsih et al. 2012). Based on practical experiences, fermentation time is set to 2 h. A 200 g sample of dough was placed in the fermentation room of rheofermentometer. All measurements were performed at 30 °C in triplicate.

This study monitored the gas production and retention curves as well as the Hm of dough in order to evaluate the effect of enzymes on gas-holding power and the gluten network structure. Results were expressed as gas production and gas retention curves and the maximum dough fermentation height (Hm) and gas production. These provided a comprehensive evaluation of yeast fermentation capacity and gluten gas-holding power in enzyme treated dough.

Scanning electron microscopy (SEM) analysis

Preparation of samples for SEM analysis followed the procedure proposed by Kim et al. (2003) with some modification. Fresh dough was cut into cuboids of 10 mm × 4 mm × 30 mm and then freeze dried. Frozen dough was allowed to thaw before it was cut and freeze dried. The samples were then viewed and images were taken with a Hitachi (Japan) scanning electron micrograph apparatus model S-3400 N (Japan) at a magnification of 1500× with the accelerating voltage of 5 kV.

Content of freezable water in dough

Differential scanning calorimeter (DSC) can be used to study the influence of freezing treatments and the application of additives on thermodynamic properties of dough and bread (Huang et al. 2011). The thermal phase transitions of dough were monitored using a DSC Q200 with a refrigerated cooling system. A 10 mg piece of dough was extracted from the center of each sample and pressed to the bottom of the hermetically sealed aluminum pan by Tzero Press (Bosmans et al. 2013). An empty pan was used as a reference. The procedure for analysis included two temperature control loops. First, the samples were cooled from their initial temperature to − 40 °C at the speed of 10 °C min−1 and held isothermally for 2 min. Secondly; the samples were heated from − 40 to 20 °C at the speed of 5 °C min−1. Freezable water was calculated using the equation below:

In the equation, ΔH, refers to the enthalpy obtained by the area under the endothermic peak near 0 °C (J/g); ΔH0 is the latent heat fusion of water (334 J/g); TW, is the water content of each dough piece (%), determined by freeze drying.

Statistical analysis

Experimental data were analyzed by using a one-way analysis of variance (ANOVA) (SPSS 16.0). Duncan test was performed with a significance level of p < 0.05. The design was based on at least three replicates. Values were reported as means. Error bars in figures represent standard deviation between replicates.

Results and discussion

Sensory quality of bread from fresh and frozen dough

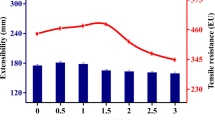

In Fig. 1, bread sensory qualities of fresh dough (Fig. 1a) and frozen dough (Fig. 1b) with different enzymes were expressed as bread volume, appearance, crumb color, texture and pore structure. Enzyme containing frozen dough breads improved sensory quality especially volume, texture and appearance with average increase of 208.9, 54.1 and 40.2% compared to control ones, respectively. Xylanase exerted the most significant positive effect, followed by lipase, cellulase and glucose oxidase, while α-amylase had the lowest effect on sensory improvement. Bread made from fresh dough containing xylanase, cellulase, lipase and α-amylase showed significantly improved sensory quality while glucose oxidase had no significant effects, especially for volume and pore structure from Fig. 1a.

For both fresh and frozen dough, enzymes made a significant difference in the sensory quality of bread. Adding polysaccharide hydrolase like xylanase, cellulase α-amylase, and lipase improved the softness and elasticity of the bread crumb, helping to delay bread aging. Each enzyme increased dough volume, but especially polysaccharide hydrolase. These enzymes could provide a sufficient source of sugar for the yeast, which allowed full fermentation for bread. Completed fermentation would create better quality bread with thin walls and exquisite porosity. Meanwhile, these enzymes also contributed to higher scores for color due to the Maillard reaction in the presence of sugars. But bread with glucose oxidase reacted differently from fresh versus frozen dough, having a hard and inelastic core and low volume, dependent on dose. We determined the dosages based on the bread volume of frozen dough, which was over-balanced in the fresh ones. This likely caused rapid oxidation, resulting in the compact network structure we observed (Bonet et al.2006; Tang et al. 2014).

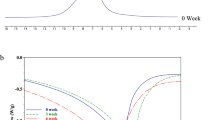

Fermentation curves of fresh and frozen dough with different enzymes

The rheofermentometer monitors the changes in dough development during fermentation by measuring gas production and gas retention (Ananingsih et al. 2012). In order to show the whole process, fermentation curves of fresh and frozen dough were analyzed. Results showed that different enzymes had diverse effects, which could be grouped into three patterns seen in the fermentation curves in Fig. 2. The first pattern was distinct from the others at the beginning phase and after gas loss. The control and dough added with xylanase and cellulase fit this pattern (Fig. 2a, c, d). At the beginning of fermentation, the gas production rate in frozen dough was very fast, much faster than in the fresh dough. As fermentation time increased, the rate of gas production in fresh dough constantly increased, while the speed in frozen dough decreased. The second pattern showed differences at the initial and middle periods of fermentation but similarities at the end period. Dough with α-amylase (Fig. 2b), and lipase (Fig. 2f) belonged to this group. Frozen dough from these samples had a faster gas production rate during the initial and middle part of the fermentation process, with better gas-holding ability towards the end. The third pattern, comprised of dough with glucose oxidase (Fig. 2e), showed that frozen dough had stronger fermentative ability than fresh ones throughout the whole test, including faster gas production and better gas holding ability. These observations coincided with the sensory result, where frozen dough yielded better bread than fresh dough when glucose oxidase was added (Fig. 1).

Besides the total volumes of carbon dioxide (CO2) production (Vt) and Hm are key indexes of dough fermentative behavior. Fermentation of yeast for long periods of time can cause dough to become wrapped in CO2, thus creating a more uniform textured bread (Gan et al. 1995). On the contrary, the loss of gas would reduce the final bread volume and directly influence consumer acceptance (Phimolsiripol et al. 2008), so the flexibility of surrounding matrix to hold the gas is also important for bread volume. The results of the total volumes of carbon dioxide (CO2) production (Vt) and Hm of different dough were showed in Table 1.

Xylanase promoted both fresh and frozen dough development as indicated by a significant positive effect on the Hm, increased by 33.2% compared to the control. It also showed the best gas production capacity in frozen dough with a 7.99% increase. Xylanase hydrolyzes water-insoluble xylan (WUAX) into a water-soluble xylan (WEAX), which produces xylose and other oligoses. These sugars promote yeast growth and improve dough gas production ability. WEAX has a higher viscosity, which increases gluten strength and extensibility by wrapping the surrounding liquid film of bubbles and thus improving gas-holding power of dough (Laura et al. 2008; Jeroen et al. 2014). Steffolani et al. (2011) found that dough with xylanase developed a large bread volume after 9 weeks of frozen storage due to enzyme action. It was also demonstrated in previous study that both fresh and frozen dough bread added with xylanase had highest sensory score due to the bread volume and texture.

Cellulase had a significantly positive effect on Hm of fresh dough similar to xylanase. Gas production increased 7.97% in fresh dough containing cellulase when compared to the control. In frozen dough, cellulase increased Hm by 19.67%, the second best enzyme for Hm increase after xylanase. However, cellulase had a negative effect on the gas production capacity, decreasing gas volume by 6.25%. The gas volume in 1-week old frozen dough with added cellulase was higher than that of fresh dough with xylanase. However, 4-week old frozen dough with cellulase had a sharp decrease in gas volume due to the formation of ice crystals during frozen storage causing injury to yeast (Data not shown). Therefore, cellulase had a lower ability to keep yeast stable than xylanase during frozen storage, which was shown in Fig. 2c, d. This improvement also appeared in the final bread: frozen dough with cellulase scored higher than fresh dough.

Lipase also increased gas production of frozen dough, increased by 5.56% compared to the control (p > 0.05). To fresh dough, lipase had some positive effects, including the increase of dough fermentation height during the first 70 min of fermentation until it reached the maximum. Stojceska and Ainsworth (2008) also reported that lipase could increase the dough extensibility by decreasing its tenacity, so it was beneficial for gas-holding ability of dough. Moayedallaie et al. (2010) reported that lipase could hydrolyze polar and nonpolar lipids in dough and increase the content of glycerol. Glycerol can improve the yeast survival rate and shorten the yeast lag phase, thus enhancing yeast activity (Li et al. 2011). Overall, lipase can increase the gas production in both fresh and frozen dough, yielding bread with enhanced volume with significantly higher sensory scores than others.

α-amylase in fresh dough had the most similar fermentation curve to the fresh dough control. There was no significant difference (p > 0.05) between the two samples. The Hm of frozen dough containing α-amylase was slightly higher than the control. Gas volume in α-amylase frozen dough increased by 1.62% when compared with the control (p < 0.05). Generally, α-amylase had a slightly positive effect on dough fermentation characteristics and gas-holding capability. This finally contributed to an increase of frozen dough bread volume in sensory quality. The mechanism may involve feeding yeast on an abundance of small molecules (Goesaert et al. 2009).

Glucose oxidase showed a great increase in total CO2 production volume (Vt) of frozen dough, 7.75% compared to the control. But in both fresh and frozen dough, there was no significant difference in this parameter between the samples with or without glucose oxidase. This result was a consequence of the increased strength of the dough, especially for the fresh dough. It has been confirmed that the high glucose oxidase level increased maximum resistance to deformation and decreased dough extensibility due to more covalent cross-linking among proteins markedly and importing S–S disulfide and dityrosine bonds into the gluten network (Steffolani et al. 2010). Steffolani et al. (2011) showed that glucose oxidase in frozen dough at a higher concentration (≥ 0.005%) than used in this study (0.001%) did show a larger dough volume when compared to the control sample. Further investigation may be needed to determine the ideal glucose oxidase concentration in bread systems.

Freezable water of fresh and frozen dough with different enzymes

There was a significant difference in freezable water content in fresh dough with different enzymes (Table 2). The control had the highest amount of freezable water, while dough with glucose oxidase, xylanase, lipase, α-amylase, cellulase had less freezable water in decreasing order, especially the last three doughs which decreased the freezable water content by 38.2, 41.4 and 75.1% compared to the control. Meanwhile, the water-binding capacity of these doughs with enzymes weakened as storage time progressed. As shown in Table 2, freezable water content in frozen dough with cellulase, glucose oxidase and lipase decreased by 51.3, 25.2 and 24.7%, respectively, when compared to the control frozen dough sample. This indicates that the addition of enzymes could help to reduce freezable water content in both fresh and frozen dough.

Water phase change and ice recrystallization in food are two key factors that affect product quality during frozen storage. Freezable water in dough forms ice crystals which degrade the quality of the product during freezing and in frozen storage. The distribution of crystal size, their intracellular or exocellular location and recrystallization all influence the state and microstructure of frozen foods (Kontogiorgos et al. 2008). When there is less freezable water in the dough, less ice is formed thus allowing a more integrated gluten network. Frozen dough with enzymes had less freezable water, indicating that the enzymes could help to maintain the integrity of the gluten network in frozen dough.

Li et al. (2011) postulated that oligose and other surface active substances have strong water absorbing capacity and thus can improve dough water-holding power. Hydrolysates, such as dextrin, maltose and glucose were generated by α-amylase, water soluble xylan and xylo-oligosaccharide were produced by xylanase, dextrin fiber and glucose are generated by cellulase, diglyceride, monoglyceride and glycerol are produced by lipase, can interact with water in dough. When these molecules interact with water, freezable water content in dough is reduced. Lu and Grant (1999) showed that when freezing storage time is extended, dough gluten and starch matrixes release water, thus increasing the freezable water content, and they also proposed that glucose oxidase makes the gluten network more closely integrated so that ions and other functional groups in the gluten network could combine with water.

Microstructure of dough by SEM

Fermented dough consists of foams in which gas bubbles are entrapped in the starch–gluten matrix; this structure has a continuous gluten network with starch granules firmly attached to gluten molecules (Zounis et al. 2002). Figure 3 shows the microstructure images of fresh and frozen dough with added enzymes extracted via SEM. In the fresh dough control sample, the gluten network had a thicker plate structure with multiple sized gluten micelles connected to each other. There were almost no fracture fragments of gluten in the control dough. The proteins make up the amorphous matrix with embedded round ball, disc and lens shaped starch granules. The boundaries between gluten and starch granules were clearly visible (Fig. 3A). This was consistent with previous data by Prabhasankar et al. (2004). Compared with the fresh samples, gluten matrixes in the frozen dough (with or without enzymes) were found to be quite damaged. For example, the microstructures of the control frozen dough (Fig. 3a) and the frozen dough with α-amylase (Fig. 3b) after thawing were much looser and appeared to have a shrunken gluten network compared to the fresh dough. Upon further examination, there seemed to be large gaps between the starch granules and the gluten network. Starch granules tended to be independent from the gluten network. The gluten network showed big pores as a result of ice crystal formation during frozen storage.

Scanning electron micrographs of fresh and frozen dough (with and without enzymes), at × 1500 magnification, fresh dough: A control, B α-amylase, C xylanase, D cellulase, E glucose oxidase and F lipase; frozen dough: a control, b α-amylase, c xylanase, d cellulase, e glucose oxidase and f lipase. P: gluten matrix. S: starch

Comparing the effects of different enzymes on the structure of dough, in fresh dough with α-amylase was very similar to the control and destroyed starch granules could not be found in the picture (Fig. 3B). Dough with xylanase had a different microstructure than the control. Part of the gluten fibril was relatively small and the dough had a smoother surface with some tiny particles found in the microstructure. This type of structure is beneficial to water distribution (Fig. 3C). Figure 3D showed the microstructure of dough with cellulase. It was similar to xylanase microstructure image. Glucose oxidase increased the fibrous gluten network in the dough. Large starch granules were not as obvious in this sample when compared to other enzyme dough. Small starch granules were clearly observable. A large increase in the gluten network wraps the large starch granules leaving them in good condition (Fig. 3E). Dough with lipase had a very smooth internal surface, a uniform and stable structure, and thick and smooth gluten micelles. Lipase can hydrolyze and produce substances with emulsification. These substances combine with protein and strengthen the gluten network (Fig. 3F).

The enzymes improved the frozen dough structure to varying extent. Thawed doughs with xylanase and cellulase also appeared to have some shrinkage in the gluten network (Fig. 3c, d). Starch granules seemed to have separated from the network. However, the whole microstructures of these two had a less obvious change when compared to the control and α-amylase dough. Since the oligosaccharides produced by these dough samples enzymes have water binding capacity, they are able to minimize damage to the gluten network by ice crystal formation. This is in accordance with previous reports that frozen dough containing these two enzymes has low freezable water content. Dough with glucose oxidase or lipase retained the gluten network to a large extent (Fig. 3e, f). Glucose oxidase induced the thawed dough to form a continuous and complete gluten network. The gluten micelles on the surface experienced some slight shrinkage while the shape of the starch granules also changed. Hydrogen peroxide, produced by glucose oxidase, could oxidize the hydrogen sulfite in gluten, thereby creating a better gluten structure (Bonet et al. 2006). Figure 3f shows that the thawed dough with lipase had a smooth surface. The starch granules were surrounded by continuous gluten and the network seemed relatively complete. Stojceska and Ainsworth (2008) suggested that the hydrolysates produced by lipase were effective emulsifiers that could interact with the gluten protein and strengthen the gluten network by the combination of a hydrophilic group with gliadine and a hydrophobic group with glutenin.

Conclusion

In general, enzymes addition improved the sensory quality of fresh and frozen dough bread in different degrees, which was related to counteracting the damage caused by frozen storage in different aspects. According to the sensory evaluation, fresh dough with added lipase, cellulase and xylanase and frozen dough with cellulase, lipase and xylanase had higher overall acceptability in turn. Frozen dough containing xylanase had the highest Hm, and fresh dough with cellulase and frozen dough with glucose oxidase had a higher gas production, and these contributed to higher volume and better sensory quality of final bread. The effect of α-amylase on improving dough fermentation characteristics was not obvious. Thermodynamic properties from DSC indicated that the addition of enzymes could decrease the freezable water in frozen dough and reduce the injury to yeast and dough caused by ice crystal formation, especially for cellulase, glucose oxidase and lipase in the frozen dough. Microstructure of the control and α-amylase frozen dough obtained from SEM indicated that there were large gaps in the dough and that starch granules seemed to have separated from the gluten. Gluten appeared to shrink slightly in xylanase and cellulase frozen dough, but similar to the fresh dough structure. Gluten micelles became smooth and the gluten network was continuous in lipase dough as a result of the emulsification of the compounds generated by lipase. Glucose oxidase had a positive effect on the stability of the gluten network. The gluten network in the glucose oxidase frozen dough was clearly observed.

Acknowledgements

This research was supported by the Planning Subject of ‘the twelfth five-year-plan’ in National Science and Technology for the Rural Development in China (2012BAD37B06-08). We gratefully acknowledge the assistance we received on the scanning electron microscopy analysis by Li Lin (China National Food and Safety supervision and Inspection Center).

References

Ananingsih VK, Gao J, Zhou W (2012) Impact of green tea extract and fungal alpha-amylase on dough proofing and steaming. Food Bioprocess Technol 6:3400–3411

Autio K, Sinda E (1992) Frozen doughs: rheological changes and yeast viability. Cereal Chem 69:409–413

Bonet A, Rosell CM, Caballero PA, Gómez M, Pérez-Munuera I, Lluch MA (2006) Glucose oxidase effect on dough rheology and bread quality: a study from macroscopic to molecular level. Food Chem 99:408–415

Bosmans GM, Lagrain B, Fierens E, Delcour JA (2013) Impact of amylases on biopolymer dynamics during storage of straight-dough wheat bread. J Agric Food Chem 61:6525–6532

Gan Z, Ellis P, Schofield J (1995) Gas cell stabilisation and gas retention in wheat bread dough. J Cereal Sci 21:215–230

GB/T 14611–2008 (National standard) General administration of quality supervision, inspection and quarantine of the People’s Republic of China, Standardization administration of People’s Republic of China (2009) Inspection of grain and oils—bread-baking test of wheat flour—straight dough method

Goesaert H, Slade L, Levine H, Delcour JA (2009) Amylases and bread firming—an integrated view. J Cereal Sci 50:345–352

Huang L, Wan J, Huang W, Rayas-Duarte P, Liu G (2011) Effects of glycerol on water properties and steaming performance of prefermented frozen dough. J Cereal Sci 53:19–24

Jeroen S, Emmie D, Delcour JA, Courtin CM (2014) Impact of wheat bran derived arabinoxylanoligosaccharides and associated ferulic acid on dough and bread properties. J Agric Food Chem 62:7190–7199

Kim HJ, Morita N, Lee SH, Moon KD (2003) Scanning electron microscopic observations of dough and bread supplemented with Gastrodia elata Blume powder. Food Res Int 36:387–397

Kontogiorgos V, Goff HD, Kasapis S (2008) Effect of aging and ice-structuring proteins on the physical properties of frozen flour—water mixtures. Food Hydrocoll 22:1135–1147

Laura F, Xavier R, Marie-Hélène M, Karin A, Tuulikki SNL, Kristiina K, Johanna B (2008) Effects of laccase and xylanase on the chemical and rheological properties of oat and wheat doughs. J Agric Food Chem 56:5732–5742

Li Z, Tang X, Huang W, Liu JG, Tilley M, Yao Y (2011) Rheology, microstructure, and baking characteristics of frozen dough containing Rhizopus chinensis lipase and transglutaminase. Cereal Chem 88:596–601

Lu W, Grant L (1999) Effects of prolonged storage at freezing temperatures on starch and baking quality of frozen doughs. Cereal Chem 76:656–662

Moayedallaie S, Mirzaei M, Paterson J (2010) Bread improvers: comparison of a range of lipases with a traditional emulsifier. Food Chem 122:495–499

Nigam PS (2013) Microbial enzymes with special characteristics for biotechnological applications. Biomolecules 3:597–611

Phimolsiripol Y, Siripatrawan U, Tulyathan V, Cleland DJ (2008) Effects of freezing and temperature fluctuations during frozen storage on frozen dough and bread quality. J Food Eng 84:48–56

Prabhasankar P, Indrani D, Jyotsna R, Venkateswara Rao G (2004) Influence of enzymes on rheological, microstructure and quality characteristics of parotta—an unleavened Indian flat bread. J Sci Food Agric 84:2128–2134

Ribotta PD, León AE, Añón MC (2001) Effect of freezing and frozen storage of doughs on bread quality. J Agric Food Chem 49:913–918

Ribotta PD, Pérez GT, León AE, Añón MC (2004) Effect of emulsifier and guar gum on micro structural, rheological and baking performance of frozen bread dough. Food Hydrocoll 18:305–313

Sciarini LS, Ribotta PD, León AE, Pérez GT (2012) Incorporation of several additives into gluten free breads: effect on dough properties and bread quality. J Food Eng 111:590–597

Serventi L, Jensen S, Skibsted LH, Kidmose (2016) Addition of enzymes to improve sensory quality of composite wheat–cassava bread. Eur Food Res Technol 242(8):1245–1252

Shafisoltani M, Salehifar M, Hashemi M (2014) Effects of enzymatic treatment using response surface methodology on the quality of bread flour. Food Chem 148:176–183

Steffolani ME, Ribotta PD, Pérez GT, León AE (2010) Effect of glucose oxidase, transglutaminase, and pentosanase on wheat proteins: relationship with dough properties and bread-making quality. J Cereal Sci 51:366–373

Steffolani ME, Ribotta PD, Perez GT, Puppo MC, León AE (2011) Use of enzymes to minimize dough freezing damage. Food Bioprocess Technol 5:2242–2255

Steffolani ME, Ribotta PD, Pérez GT, León AE (2012) Combinations of glucose oxidase, α-amylase and xylanase affect dough properties and bread quality. Int J Food Sci Technol 47:525–534

Stojceska V, Ainsworth P (2008) The effect of different enzymes on the quality of high-fibre enriched brewer’s spent grain breads. Food Chem 110:865–872

Tang L, Yang R, Hua X, Yu C, Zhang W, Zhao W (2014) Preparation of immobilized glucose oxidase and its application in improving breadmaking quality of commercial wheat flour. Food Chem 161:1–7

Yurdugul S, Pancevska NA, YiLdiZ GG, Bozoglu F (2012) The influence of a cellulase bearing enzyme complex from anaerobic fungi on bread staling. Rom Agric Res 29:2067–5720

Zounis S, Quail KJ, Wootton M, Dickson MR (2002) Studying frozen dough structure using low-temperature scanning electron microscopy. J Cereal Sci 35:135–147

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, X., Pei, D., Teng, Y. et al. Effects of enzymes to improve sensory quality of frozen dough bread and analysis on its mechanism. J Food Sci Technol 55, 389–398 (2018). https://doi.org/10.1007/s13197-017-2950-8

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-017-2950-8