Abstract

The aim of this study was to investigate the quality characteristics of steamed rice bread containing the various contents of protease (0, 0.5, 1.0, and 1.5 % Flavourzyme®), pH, and expansion of the dough during different fermentation times (0, 20, and 30 min), and hardness after different storage times (0, 1, 2, and 3 days). When the Flavourzyme® contents increased, pH of the dough gradually decreased, but expansion increased up to 30 min of the fermentation. Specific loaf volume was the greatest for steamed rice bread prepared with 1.5 % Flavourzyme®. In SDS electrophoretic patterns, the band intensity of wheat gluten (P37) decreased by 1.0 and 1.5 % Flavourzyme® treatments. The α-glutelin of rice protein clearly degraded in the samples prepared with 1.0 and 1.5 % Flavourzyme®, whereas the band intensity of β-glutelin decreased only in the sample with 1.5 % Flavourzyme®. The band intensity of soy lipoxygenase and the 7S globulin fraction (P54) of soy protein decreased in the sample with 0.5 % Flavourzyme®. The latter showed the highest water-holding capacity and the highest hardness but lowest rate of retrogradation during 3 days of storage. In microstructure of the control, pore size was the smallest and the fewest pores were observed. The greater the contents of Flavourzyme®, the greater the size and number of pores were observed. Steamed rice bread prepared with 0.5 % Flavourzyme® was thought to be optimal due to retarded retrogradation because of the highest water-holding capacity, highest scores of mouthfeel, and overall quality due to greater springiness and cohesiveness.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Introduction

Rice (Oryza sativa) is one of the leading food crops in South East Asia and is considered a suitable substitute for wheat; rice is a gluten-free and low-allergen food (Sivaramakrishnan et al. 2004; Kawamura-Konishi et al. 2013). Furthermore, rice is easy to digest and has a bland taste. Rice flour, however, is unsuitable for bread making because of inadequate properties and small amounts of gluten. In addition, rice resist swelling in water at neutral pH, because rice has relatively low amounts of proteins and most of them are very hydrophobic (Lumdubwong and Seib 2000; Kadan et al. 2001). To improve the quality of steamed rice bread, proteolysis by proteases can be used to increase the number of polar groups, water-holding capacity, and swelling. For a half of the world’s population, rice is a staple food, mostly in its original form; therefore, the variety of rice products is low. Rice consumption in Korea has been decreasing along with increased consumption of bread, fast food, and breakfast cereals owing to westernization of the diet and the official guidelines to increase protein intake. Therefore, the development of products containing rice flour should popularize rice and rice products.

Protein content of rice flour is 6.2 %, which is lower than that of wheat flour (12.7 %) (Rural Development Administration 2015) and affects bread making because proteins such as gluten contribute to the firm structure of bread. To overcome this drawback, we added defatted soybean flour, which contains 50 % protein, to steamed rice bread in our previous study (Kim 2012). Bread made of 100 % rice flour contains approximately 6 % of protein, and the steamed rice bread prepared in that study contained approximately 12 % protein, which is similar to the protein content of bread made from 100 % wheat flour. An additional advantage of defatted soybean flour is that its cost is low because it is a by-product of soybean oil production. Several studies have examined bread with minimal gluten content in light of some health problems caused by gluten. When gluten content is reduced from 17 to 14 %, volume and specific loaf volume decrease, but they increase again when an emulsifier and an enzyme are added simultaneously (Kim and Lee 2009). Other researchers have studied the effects of an emulsifier, gum, and active gluten when used together (Kang et al. 1997; Turabi et al. 2008; Moayedallaie et al. 2010). In baekseolgi made with trehalose and Novamyl (a starch-degrading enzyme), retrogradation decreases as Novamyl content increases, confirming that Novamyl is effective at slowing retrogradation (Lee et al. 2010). Kawamura-Konishi et al. (2013) investigated the effects of protease treatment on the quality of gluten-free rice bread and found that thermoase treatment improved the quality (e.g., improves crumb appearance and lowers staling rate) of gluten-free rice bread. In particular, Kim et al. (2008) reported that Flavourzyme® improves flavor and water-holding capacity of textured soy protein, and we therefore expected it to decrease the retrogradation of steamed rice bread by increasing water-holding capacity. Therefore, in the present study, we used Flavourzyme® for improving the fermentation of steamed rice bread as yeast food.

The aim of this study was to investigate the quality characteristics of steamed rice bread as a function of the amounts of added Flavourzyme®. The pH and expansion of dough, specific loaf volume, sodium dodecyl sulfate polyacrylamide gel electrophoresis (SDS-PAGE), water-holding capacity, retrogradation, scanning electron microscopy (SEM), and sensory characteristics of steamed rice breads were performed to assess the possibility of development of new rice-based foodstuffs.

Materials and methods

Materials

Rice flour (Haedooroo, Korea) was supplied by Pan-Pacific Co., Ltd. (Korea), and flour, sugar, salt, and grape seed oil (CJ Cheiljedang, Korea) were purchased from E-mart (Korea). Sweet pumpkin powder (Cedenco Foods, New Zealand), soybean residue (Soohwa, Korea), and defatted soy flour (Gaemifood, Korea) were also used. Almond powder, baking powder (RUF, Germany), and yeast (Angest, Korea) were purchased from Caufood (Korea). Sodium stearoyl lactylate was obtained from Ilshinwells (Korea), and Flavourzyme® (500 MG, Aspergillus oryzae origin protease, declared activity of 500 leucine amino peptidase units per gram; LAPU/g) was purchased from Novozyme (Denmark). All the other reagents were of first grade.

Treatment with the proteolytic enzyme

The proteolytic enzyme (Flavourzyme®) was added to steamed rice bread contents of 0.5, 1.0, and 1.5 % of total protein. The optimal temperature for Flavourzyme® activity is 40–50 °C. In this study, however, enzymatic treatment was conducted at 35 °C during fermentation of the dough. Although the treatment temperature was below the optimal temperature, adequate enzyme activity was demonstrated in a preliminary experiment. The enzyme was inactivated during steaming for 10 min.

Preparation of steamed rice bread containing various contents of the proteolytic enzyme

Steamed rice bread was made by the straight dough method as follows. All the ingredients were placed in a mixing bowl together except for oil, which was added separately three times during mixing. The ingredients were mixed for approximately 30 min to form a dough. After that, the dough was divided into 50 g portions. These fixed amounts of dough were rounded to disperse the gases equally in each sample and to make the dough surface smooth. Bread dough samples underwent fermentation in an incubator (NY-8024F, NUC Co., Korea) at 35 °C and relative humidity of 87 % for 30 min. Next, the samples were steamed in a pot for 10 min. The ingredients for steamed rice bread were rice flour (33.97 %), wheat flour (12.87 %), sweet pumpkin powder (4.12 %), soybean residue powder (0.51 %), defatted soy flour (2.57 %), almond powder (1.54 %), baking powder (0.67 %), yeast (1.54 %), water (32.94 %), salt (0.51 %), sugar (5.15 %), grape seed oil (3.35 %), and sodium stearoyl lactylate (0.26 %). The kinds and amounts of the ingredients were determined in a preliminary experiment to achieve greater protein content and to improve flavor and color (Kim 2012). Yeast was used to increase dough expansion and specific loaf volume because yeast produces CO2 gas; baking powder was used as a leavening agent.

pH

pH was measured before proofing and after 20 and 30 min of proofing. Distilled water (100 mL) was added to 10 g of each sample, which was then pulverized, left at 25 °C for 10 min, and analyzed by means of a pH meter (WTW, Germany). Each sample was analyzed three times, and an average value was calculated.

Dough expansion

To determine dough expansion during the fermentation, we placed equal portions (50 g) of dough in a graduated cylinder (diameter 6.0 cm and height 7.5 cm) and fermented them in an incubator (35 °C, relative humidity: 85 %). The dough expansion (mL; \(\pi r^{2} \times \,h\)) was measured before proofing and after 20 and 30 min of proofing.

Specific loaf volume

By means of a digital scale, the weights of the samples wrapped in polyethylene film were measured after sufficient cooling, and loaf volumes were measured by the water displacement method as follows. The samples of steamed rice bread were wrapped in two layers of polyethylene film to inhibit permeation of water. The wrapped samples were immersed in water and the volume of displaced water was determined. The specific loaf volume of each loaf was then calculated using the following formula: Specific loaf volume (mL/g) = loaf volume ÷ loaf weight.

SDS-PAGE

Sodium dodecyl sulfate polyacrylamide gel electrophoresis (SDS-PAGE) was conducted according to the method of Weber and Osborn (1969). A 10 % solution of a sample was mixed with sample buffer (SDS, glycerol, bromophenol blue, Tris–HCl pH 6.8) in the ratio 1:1 and then heated at 100 °C for 10 min. The gels (10 wells, 12 % gradient, Tris–HCl pH 8.8) were subjected to electrophoresis at 130 V, which was stopped 2.5 h after the tracking dye reached the bottom of the gel. The gels were stained with a staining solution containing Coomassie brilliant blue R250, destained in a destaining solution, and then stored in a 5 % glycerol solution for photography.

Water-holding capacity

This analysis was evaluated to confirm the increase of hydrophilicity of protein by proteolysis according to the method of Parnell-Clunies et al. (1986). Ten grams (A) of each sample was thoroughly mixed with 40 mL of distilled water in individual 50 mL tubes and then placed in a water bath at 30 °C for 30 min. The tubes were then centrifuged (Model SR 2022, Jouan Co., France) at 2862×g for 30 min, and the supernatant was removed. Next, the tubes were placed at room temperature for additional 10 min, and the supernatant was removed once more. The precipitate (B) was weighed. Water-holding capacity was calculated using the following formula: Water-holding capacity (%) = (weight of sample B ÷ weight of sample A) × 100.

Retrogradation by storage period and textural properties

The samples were wrapped in polypropylene film and stored at room temperature (25 °C) for 3 days. Samples with the average appearance were cut into cubes 15 × 15 × 15 mm. Two-bite compression by means of a Rheometer (Compact-100, Sun Scientific Co., Japan) was performed three times and the average value was calculated. Hardness was measured under the following conditions: load cell 2.0 kg, test speed 120.0 mm/min, and deformation 50 % by means of adaptor No. 14 (Ø 25 mm).

SEM

The samples were collected from the center of the steamed rice bread and freeze-dried for 24 h and then coated with an ion spotter (E-1010, Hitachi, Japan) for 60 s. The samples were examined by SEM (S-3500 N Scanning Electron Microscope, Hitachi, Japan) at an accelerated voltage of 10 kV.

Sensory evaluation

Thirty undergraduate and graduate students majoring in food and nutrition were provided with samples of steamed rice bread that had been produced in advance, stored in a freezer (−20 °C) for 24 h, and reheated for 8 min before serving. A 7-point scale was used to discern their preferences.

Statistical analysis

All the experiments were conducted at least three times and the SAS package (SAS® 9.1, SAS Institute Inc., USA) was used for statistical analysis. Significant differences that were identified by analysis of variance were evaluated by Duncan’s multiple-range test (p < 0.05).

Results and discussion

pH and dough expansion

pH and dough expansion are shown in Table 1. The pH level of dough with 1.0 % Flavourzyme® was the highest (6.44), while that with 1.5 % Flavourzyme® was the lowest (6.29) immediately after dough mixing (p < 0.01). No significant differences in pH were found among the other samples. The pH value was also the highest (6.27) in dough with 1.0 % Flavourzyme® and the lowest (6.06) in dough with 1.5 % Flavourzyme® after 20 min of fermentation (p < 0.001). The pH value was the highest (6.18) in dough with 0.5 % Flavourzyme® and the lowest (6.03) in dough with 1.5 % Flavourzyme® after 30 min fermentation (p < 0.001). In all the samples, pH tended to decrease gradually with increasing fermentation time up to 30 min. It was thought that pH was affected by CO2 gas resulting from the enzymatic treatment during fermentation.

The volume of all the dough samples was 48.04 mL before the fermentation. After 20 min of fermentation, the volume of the untreated control was the greatest (109.08 mL) and that of the dough with 1 % Flavourzyme® was the lowest (90.71 mL; p < 0.001). After 30 min of fermentation, the volume of the dough without added Flavourzyme® was the greatest (122.37 mL), but no significant differences were found among the dough samples. The volume of all the samples was greater after 30 min than after 20 min of fermentation. Therefore, optimal fermentation time was 30 min.

There was less relevance between pH and the rate of dough expansion. According to a study by Lee and Shin (2001), the rate of dough expansion is influenced by pH. In the previous study (Park et al. 2001), when pH decreased, the amount of CO2 gas increased, and the rate of dough expansion also increased; however, when pH increased, gas stability increased. As a result, the rate of dough expansion in the sample with 1.5 % Flavourzyme® was lower than that in the sample without Flavourzyme® because low pH decreased gas stability.

Specific loaf volume

The specific volumes of the steamed rice bread samples are shown in Table 2. No significant differences in weight and volume were found among the samples. Specific volume of steamed rice bread with 1.5 % Flavourzyme® was the greatest (2.05; p < 0.01), and no significant differences were found among the other samples. The reason for the greatest specific loaf volume of the sample with 1.5 % Flavourzyme® was the fact that more CO2 gas was produced than in the other samples because of more proteolysis.

As compared to the other samples, for the sample with 1.5 % Flavourzyme®, dough-specific volume was the greatest, height was lower, and the diagram was larger. As shown in Table 2, dough-specific volume decreased because of weakened extensibility by gluten and a decrease in gas-holding capacity by increasing pH (Lee and Shin 2006).

SDS gel electrophoresis patterns

The SDS-PAGE patterns of the steamed rice bread samples treated with different contents of the enzyme are shown in Fig. 1. We observed the bands of soy 7S globulin and soy 11S globulin; wheat gluten; and α-glutelin, β-glutelin, and globulin of rice. Park et al. (2004) observed SDS-PAGE patterns of gluten fractions at approximately 24, 45, 37, and 35 kDa. The band intensity of wheat gluten (P37) decreased by the 1.0 and 1.5 % Flavourzyme® treatments. The band intensity of α-glutelin of rice protein decreased almost invisible for the samples with 1.0 and 1.5 % Flavourzyme®, while that of β-glutelin decreased only with 1.5 % Flavourzyme®.

SDS-PAGE patterns of standard protein (S), steamed rice bread prepared with 0 (control), 0.5 (F0.5), 1.0 (F1.0), and 1.5 % (F1.5) Flavourzyme®. L lipoxygenase, α′ α′-subunit of 7S globulin, α α-subunit of 7S globulin, P54; 7S globulin fraction, β β-subunit of 7S globulin, A α-glutelin of rice protein, G globulin of rice protein, B β-glutelin of rice protein, P37 wheat gluten, P34 acidic subunit of 11S

The band intensity of lipoxygenase and the 7S globulin fraction (P54) of soy protein decreased for 0.5 % Flavourzyme® sample and decreased almost invisible with 1.0 % Flavourzyme®. The band intensity of the α′-subunit and β-subunit of 7S globulin, and acidic subunit of 11S globulin of soy protein decreased in the sample with 1.0 % Flavourzyme®. Band intensity of the α-subunit of 7S globulin and acidic subunit of 11S (P34) decreased almost invisible with 1.5 % Flavourzyme®.

Water-holding capacity

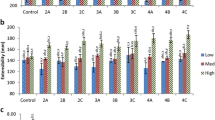

The water-holding capacities of the steamed rice bread treated with different contents of the enzyme are shown in Fig. 2. The 0.5 % Flavourzyme® sample had the highest capacity (65.92 %), and the 1.0 % Flavourzyme® sample had the lowest (62.89 %; p < 0.001). Water-holding capacity in the sample with 0.5 % Flavourzyme® improved in comparison with the control but decreased in the samples with 1.0 and 1.5 % Flavourzyme®. Reactivity with water increased in the sample with 0.5 % Flavourzyme® because either the number of more polar groups increased or hydrophilic groups were exposed by the enzymatic treatment (Lee and Oh 1999). Water-holding capacity in the samples with 1.0 and 1.5 % Flavourzyme® decreased because the protein determining water-holding capacity was degraded by the excessive enzymatic treatment. Water-holding capacity was not significantly changed by Flavourzyme® treatment but was higher in the sample treated with 0.5 % Flavourzyme® in comparison with the control.

Retrogradation by storage period

Hardness of the steamed rice breads treated with different contents of the enzyme was measured every day during 3 days of storage to assess retrogradation (Table 3). Hardness is often measured to evaluate bread crumbs and quality changes in rice bread during storage. Hardness increased as the duration of storage increased (Ji et al. 2007). The change in quality of rice bread during storage is most strongly affected by retrogradation of starch owing to physical changes in the starch-protein matrix. In the present study, hardness was the greatest (24.87 N) in the sample with 0.5 % Flavourzyme® and the lowest (14.64 N) in the sample with 1.5 % Flavourzyme® (p < 0.001). The hardness of the sample with 0.5 % Flavourzyme® was 27.81 N, which was greater than that of the sample without enzymatic treatment (26.23 N) on the first day of storage. On the second and third days of storage, the hardness of the sample without enzymatic treatment was greater than that of the sample with 0.5 % Flavourzyme®. Therefore, the addition of Flavourzyme® retarded the increase in hardness because of the increase in water-holding capacity by the increased number of hydrophilic groups. Retrogradation was delayed most effectively in the sample with 0.5 % Flavourzyme®, which showed the lowest rate of increase in hardness after 3 days.

Microstructure

Microstructure of the samples of steamed rice bread is shown in Fig. 3. Pore size of the sample without enzymatic treatment was small, and few pores were observed. The greater the amount of added Flavourzyme®, the larger the size and number of pores were observed. The pronounced differences that were observed between the samples with and without enzymatic treatment indicated that a greater amount of CO2 gas was produced in the enzyme-treated samples. No significant differences were observed between the 0.5 and 1.0 % Flavourzyme® samples, but obvious differences in pore size were detected between these samples. This result was most likely due to differences in pH, dough expansion, and textural properties. Thus, degrees of fermentation differed depending on the amount of the added enzyme; the higher the degree of fermentation, the lower was the pH value and the greater was dough expansion. Hardness decreased as pore size increased (Table 4).

Textural properties

Textural properties of steamed rice bread are shown in Table 4. The more protease was added, the more the hardness decreased. The hardness of the control was greater than that of the other samples except for the 0.5 % Flavourzyme® sample. The smaller specific loaf volume of the 0.5 % Flavourzyme® sample (Table 2) is related to the greater hardness and smaller pore size. The higher the contents of Flavourzyme®, the more degraded were the bands of rice protein, wheat protein, and soy protein (Fig. 1). Springiness and cohesiveness were the greatest in the control (44.2 and 43.62 %, respectively) but the lowest in the 1.5 % Flavourzyme® sample (29.19 and 36.71 %, respectively, p < 0.001). The higher cohesiveness of 11S globulin and its greater particle size in comparison with 7S globulin were due to the more extensive sulfhydryl-disulfide interchange (Saio 1981).

Sensory evaluation

The results of the sensory evaluation of steamed rice bread prepared with different contents of the enzyme are shown in Table 5. No significant differences were found among the samples except in appearance, mouthfeel, and overall quality. The control showed the highest score of appearance (5.77), and there were no significant differences among the other samples. The diameter and height of the control were smaller and greater, respectively; these data resulted in the highest score of appearance for the control. In terms of mouthfeel, the 1.0 % Flavourzyme® sample showed the lowest score, and there were no significant differences among the other samples. In terms of overall quality, the control and the 0.5 % Flavourzyme® sample showed the highest scores, while the 1.0 and 1.5 % Flavourzyme® sample showed the lowest. The sample with 0.5 % Flavourzyme® was thought to be the optimal steamed rice bread because of the highest water-holding capacity and good mouthfeel and overall quality.

These results might be attributed to the findings that the texture of the samples without the enzymatic treatment and with 0.5 % Flavourzyme® was more like that of regular bread, whereas the sample with 1.5 % Flavourzyme® was moist and resembled rice cake. Some participants liked the samples with bread-like texture, and others liked those with cake-like texture; therefore, these samples showed acceptable scores. On the other hand, the sample with 1.0 % Flavourzyme® showed the lowest mouthfeel score because they had neither bread-like nor cake-like texture.

Abbreviations

- SDS-PAGE:

-

Sodium dodecyl sulfate polyacrylamide gel electrophoresis,

- SEM:

-

Scanning electron microscopy

References

Ji Y, Zhu K, Qian H, Zhou H (2007) Staling of cake prepared from rice flour and sticky rice flour. Food Chem 104:53–58

Kadan RS, Robinson MG, Thibodeaux DP, Pepperman AB (2001) Texture and other physicochemical properties of whole rice bread. J Food Sci (Chic) 66:940–944

Kang MY, Choi YH, Choi HC (1997) Effects of gums, fats and glutens adding on processing and quality of milled rice bread. Korean J Food Sci Technol 29:700–704

Kawamura-Konishi Y, Shoda K, Koga H, Honda Y (2013) Improvement in gluten-free rice bread quality by protease treatment. J Cereal Sci 58:45–50

Kim EA (2012) Quality characteristics of steamed rice bread added with proteolytic enzyme and defatted soy flour. MS thesis, University of Chung-Ang, Anseong

Kim KE, Lee YT (2009) Combined effects of vital gluten, gum, emulsifier, and enzyme on the properties of rice bread. Food Eng Prog 13:320–325

Kim EB, Kim EJ, Lee HN, Lee NK, Oh JS, Kim SO, Lee SY (2008) The quality characteristics of soy cutlets using textured soy protein treated with different enzymes. Korean J Food Cult 23:507–513

Lee SY, Oh KN (1999) Effects of sweeteners and enzyme treatments on the quality attributes of soy yogurt containing soy protein isolate. J Korean Soc Food Sci 15:73–80

Lee YW, Shin DH (2001) Bread properties utilizing extracts of Mune. Korean J Food Nutr 14:305–310

Lee H, Shin M (2006) Quality characteristics of french bread with various dietary fibers. Korean J Food Cook Sci 22:477–487

Lee ES, Doo HJ, Kim YR, Shim JY (2010) A study on the quality characteristics of Backsulgi prepared with combined treatment of enzyme and trehalose. Food Eng Prog 14:235–242

Lumdubwong N, Seib PA (2000) Rice starch isolation by alkaline protease digestion of wet-milled rice flour. J Cereal Sci 31:63–74

Moayedallaie S, Mirzaei M, Paterson J (2010) Bread improvers: comparison of a range of lipases with a traditional emulsifier. Food Chem 122:495–499

Park GS, An SH, Choi MA (2001) Quality characteristics of bread added with concentrations of paecilomyces japonica powder. J East Asian Soc 11:111–120

Park JY, Ahn JY, Hong HO, Hahn YS (2004) Reduction of allergenicity of wheat flour by enzyme hydrolysis. Korean J Food Sci Technol 36:152–157

Parnell-Clunies EM, Kakuda Y, Mullen K, Arnott DR (1986) Physical properties of yogurt: a comparison of vat versus continuous heating systems of milk. J Dairy Sci 69:2593–2603

Rural Development Administration (2015) Korean food composition table. http://koreanfood.rda.go.kr/kfi/fct/fctFoodSrch/list. Accessed 15 Oct 2015

Saio K (1981) Microstructure of traditional Japanese soybean foods. Scan Electron Microsc 3:553–559

Sivaramakrishnan HP, Senge B, Chattopadhyay PK (2004) Rheological properties of rice dough for making rice bread. J Food Eng 62:37–45

Turabi E, Sumnu G, Sahin S (2008) Rheological properties and quality of rice cakes formulated with different gums and an emulsifier blend. Food Hydrocoll 22:305–312

Weber K, Osborn M (1969) The reliability of molecular weight determinations by dodecyl sulfate-polyacrylamide gel electrophoresis. J Biol Chem 244:4406–4412

Acknowledgments

This research was supported by the Business for Cooperative R&D between Industry, Academy, and Research Institute (Grant Number 20100644) funded by the Korea Small and Medium Business Administration in 2010.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kim, EA., Lee, SY. & Lee, SY. Quality characteristics of steamed rice bread prepared with different contents of proteolytic enzyme. Appl Biol Chem 59, 95–102 (2016). https://doi.org/10.1007/s13765-015-0145-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13765-015-0145-4