Abstract

A novel gene encoding an acidic and SDS tolerant halophilic lipase from moderately halophilic bacterium, Nesterenkonia sp. strain F (lipF) was cloned in Escherichia coli and the recombinant lipase (LipF) was characterized. The gene had 819 bp and encoded a protein of 272 amino acids residues (pI=7.0). No sequence similarity between LipF and other halophilic lipolytic enzymes was observed. LipF was grouped into the lipase family XIII because it contained a highly conserved motif GISMG. In contrast to halophilic proteins, equal amount of acidic and basic residues were observed in LipF. Also, a small amount of acidic residues was demonstrated on the surface of the LipF structure. After purification of the recombinant protein, it showed 28.5 kDa on SDS-PAGE. The enzyme was active over a pH range of 3.5 to 8.0 with optimum activity at pH 5.0. The optimum temperature was 55 °C and it was active at 25 to 85 °C. Although LipF was active at 0-4 M of NaCl and KCl, increasing activity was observed with increasing concentration of the salts and maximum activity was at 4 M. LipF was stimulated by Ca2+, Cu2+ and Al3+ but inhibited with Ni2+, PMSF and EDTA. While 50% of the activity was remained in the presence of 0.1% SDS, 0.5% Tween 20 and Triton X-100, 1% SDS increased the activity to 120%. These characteristics indicate wide potential applications of the halophilic lipase in industries. This is the first cloning and characterization of an acidic halophilic lipase from a moderately halophilic bacterium.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Enzymes display a diversity of applications in different industries and the enzymes which belong to hydrolyzing groups have potential applications in many biotechnological fields. Among these enzymes, lipases have a wide variety of industrial applications and account for about 5–10% of the worldwide enzyme market (Salihu and Alam 2012). Lipases (glycerol ester hydrolase, EC 3.1.1.3) catalyze hydrolysis of acyl glycerols into di-acyl glycerols, mono-acyl glycerols, free fatty acids, and glycerol (Schreck and Grunden 2014). Also, these enzymes are capable to catalyze transesterification, alcoholysis, acidolysis and aminolysis of acyl donors (Dhake et al. 2013). Lipases belong to α/β hydrolase fold superfamily and have a network of hydrogen bonds at their active site containing triad of Ser, Asp (Glu) and His. They are a group of water-soluble enzymes, which exhibit the ability to act at the interface between aqueous and organic phases (Gupta et al. 2004).

With the biochemical properties, lipases are commercially significant and have a wide range of potential industrial applications, especially in food, leather, cosmetic, paper, pulp, textile, detergents, pharmaceutical industries and industrial wastes management (Sharma et al. 2011). The lipases used in those applications are selected based on their specificity and activity under an exceptional environment, for instance, high or low temperatures, the presence of organic solvents, and alkaline or acidic conditions. Acidic lipases exhibit high catalytic activity in acidic conditions and have the potential for different industrial applications, including synthesizing isoamyl acetate in the food industry, acid bating of fur and wool in textile industry, helping fat digestion in the animal feed industry, and treating wastewater from restaurant and factories (Adina et al. 2021). Given the diversity of biotechnological processes and their need for specific properties, many existing lipases cannot withstand the harsh conditions of industry and often lose their effectiveness in these conditions. So, search to prepare lipase harboring unique characteristics and retainig their optimal activity under these industry-specific conditions has always been of interest.

Although lipases are produced by animals, plants and microorganisms, many attempts have been made to isolate microbial lipases because of a great variety of catalytic activities in various conditions, high productivity efficiency and ease of genetic manipulation (Gupta et al. 2015). Extremophiles are a source of enzymes often show extreme activity under extreme conditions include either high or low temperatures, high salinity and either high alkalinity or high acidity (Gomes and Steiner 2004). Extremozymes, enzymes from extremophilic microorganisms, are stable and active under conditions in which enzymes of non-extremophilic organisms usually cannot be stable and active. So, extremozymes have become objects of special interest for industrial applications (Hough and Danson 1999; Van Den Burg 2003). Among extremophiles, halophiles are microorganisms that live in high salt concentrations, and the enzymes they produce are highly active and stable under these saline conditions (Madern et al. 2000). Moderately halophilic bacteria that grow optimally in media containing 3-15% NaCl, might be a source of halophilic enzymes that can be active in a wide range of salt concentrations even in the absence of salt (Ventosa et al. 1998). Due to their activity and stability at high salt concentration, lipases from halophiles have potential biotechnological applications in environmental bioremediation, food processing and pharmaceuticals (Oren 2010). Despite the functional importance of halophilic enzymes, to date, limited numbers of halophilic lipases have been purified and characterized from halophiles (Moreno et al. 2016; Amoozegar et al. 2019).

Halophiles can be good candidates for the production of halophilic enzymes, but the use of their enzymes is often impractical due to their low expression levels. The limitation could be overcome by employing recombinant DNA technology. Molecular cloning and expression of functional foreign protein in heterologous hosts has become a good alternative to achieve high level expression and economically obtain bulk production of enzymes. On the other hand, cloning and analysis of the enzyme gene achieves the enzyme protein sequence. By sequence analysis as well as protein engineering, targeted changes in the enzyme structure can be made to increase its application in various biotechnological processes. Many microbial lipase genes have been cloned during past few decades (Contesini et al. 2020) and an increasing number of lipases have been commercially manufactured using recombinant bacteria and yeasts (Borrelli and Trono 2015). Despite the potential applications of recombinant halophilic enzymes, very few halophilic lipases have been cloned, expressed and characterized.

Due to the importance of halophilic enzymes and their wide application in modern biotechnology industries, we purified and characterized three halophilic alpha-amylase enzymes with SDS (Shafiei et al. 2010) and organic solvent resistance property (Shafiei et al. 2011, 2012) from moderately halophilic bacterium Nesterenkonia sp. strain F. Also, with respect to the importance of molecular cloning studies and the need of different industries for recombinant halophilic enzymes, recently a recombinant halophilic amylase with pH resistance property from this strain has been cloned and characterized (Solat and Shafiei 2021). In the present study we report cloning and heterologous expression of a novel lipase encoding gene from Nesterenkonia sp. strain F and describe biochemical properties of the recombinant enzyme. This is the first report of cloning, purification and characterization of an acidic and SDS tolerant halophilic lipase from a moderately halophilic bacterium.

Materials and methods

Bacterial strains, plasmids and media

Nesterenkonia sp. strain F used in this study was isolated from Aran-Bidgol Lake in the center of Iran (Sarikhan et al. 2011). Escherichia coli DH5α was used for cloning and plasmid maintenance host. E. coli BL21 (DE3) was used as protein expression host. T/A vector pTG-19T from Vivantis (Vivantis Technologies, Malaysia) and pET-26b+ vector from Novagen were used for gene cloning and gene expression, respectively. pET-26b+ contains an IPTG inducible T7 promoter and a histidine tag. The tag was fused at C-terminal of the enzyme and used for purification of the recombinant enzyme with Nickel Resin. The E. coli strains were grown in Luria-Bertani medium (1% tryptone, 0.5% yeast extract, and 1% NaCl, pH7.0).

Cloning of the lipase gene

Nesterenkonia sp. strain F was grown in starch medium (15 g/L tryptone, 5 g/L yeast extract, 10 g/L starch and 70 g/L NaCl, pH 7.5) at 33 °C and 200 rpm for 72 h. The genomic DNA was extracted according to the phenol-chloroform extraction protocol. The DNA was used as a template for polymerase chain reaction (PCR) amplification of the halophilic lipase gene. The primers were designed according to the sequences of draft genome of Nesterenkonia sp. strain F in GeneBank (AFRW01000000) (Sarikhan et al. 2011). The full-length sequence of the lipase gene was amplified with the following primers; F primer (5’-GAATTCGATGATGGAGGACGTCGGAATG-3’) and R primer (5’-AAGCTTTCGGTCCTCCACCTCTG-3’). The underlined nucleotides indicate EcoRI and HindIII restriction sites, respectively. PCR conditions were as follows: an initial denaturation step at 95 °C extended to 5 min, followed by 35 cycles of 95 °C for 30 s, 63 °C for 45 s, and 72 °C for 2 min, and ending with one cycle at 72 °C for 10 min. The amplified gene was cloned into T/A vector pTG-19T and transformed in competent cell of E. coli DH5α. After isolation of the recombinant pTG-lipF plasmid, it was double digested with EcoRI and HindIII endonucleases. Then, the fragment was purified from agarose gel and subcloned into pET26b+ previously double digested with the same restriction enzymes. The resulting pET-lipF plasmid was transformed into competent E. coli BL21(DE3). The integrity of the lipase sequence in the pET-lipF expression vector was confirmed by DNA sequencing using T7 promoter and T7 terminator primers by ABI Automated Sequencer 3050 (Applied Biosystems, USA).

Sequences analysis of the lipase gene

Homology and sequence similarity of the halophilic lipase gene with other lipase sequences was obtained using BLASTn program of NCBI database (https://blast.ncbi.nlm.nih.gov/Blast.cgi). The NCBI BLASTp program was used to identify similar protein sequences that encoded lipases (http://www.ncbi.nlm.nih.gov/BLAST). Supper family and conserved domains of the halophilic lipase were obtained from structure program of NCBI (https://www.ncbi.nlm.nih.gov/Structure). The ESTHER database (http://bioweb.supagro.inra.fr/ESTHER/) was used to obtain the lipase family. ESTHER is a broad database, having information on a large diversity of α/β hydrolases fold super family that includes lipases (Lenfant et al. 2013). Multiple alignments of deduced amino acid sequence were performed using ESPript 3.0 program (http://espript.ibcp.fr/ESPript/ESPript/). Classification and sequence analysis of the lipase was performed using lipase engineering database (LED) (http://www.led.uni-stuttgart.de/) (Widmann et al. 2010). ProtParam tool of ExPASy bioinformatic resource portal (https://web.expasy.org/protparam/) was applied to calculate theoretical isoelectric point value and molecular mass for the halophilic lipase.

Structural modeling

To predict the three-dimensional structure of the lipase, the homology model was constructed using I-TASSER (https://zhanglab.ccmb.med.umich.edu/I-TASSER/) (Yang et al. 2015), SWISS-MODEL (https://swissmodel.expasy.org/) (Arnold et al. 2006) and Phyre2 (http://www.sbg.bio.ic.ac.uk/phyre2) (Kelley et al. 2015). The three dimensional structures were validated by proSA-web software (https://prosa.services.came.sbg.ac.at/prosa.php). This software evaluates the predicted model based on z-score that indicates overall model quality and measures the deviation of the total energy of the structure with respect to an energy distribution derived from random conformations (Wiederstein and Sippl 2007). Also, stereochemical quality and Ramachandran plot parameters of the model were analyzed by the PROCHECK program from SAVES server (http://nihserver.mbi.ucla.edu/SAVES/). PROCHECK program checks the stereochemical quality of a protein structure by analyzing residue-by-residue geometry and overall structure geometry (Laskowski et al. 1993).

Expression and purification of the recombinant lipase

For expression of the halophilic lipase, E. coli BL21 (DE3) containing pET-lipF was incubated in 50 mL Luria-Bertani medium containing 30 µg/mL kanamycin at 37 °C until the cell density (OD600) reached 0.6. Induction of the recombinant protein expression was performed by adding isopropyl-β-D-thiogalactopyranoside (IPTG) to a final concentration of 0.1 mM and the culture was incubated for 6 h at 20 °C while shaking at 200 rpm.

Purification of the recombinant lipase was carried out by a one-step histidine-tagged protein purification method using Nickel NTA Agarose Resin (ABT, Spain). Following centrifugation (5000×g, 20 min, 4 ˚C), cells were resuspended in 700 µL of lysis buffer (50 mM NaH2PO4, 300 mM NaCl, 10 mM imidazole, 10 mg/mL lysozyme (pH 8.0)), and sonicated on ice for three sets of 30-second pulses (100 mHz) with 1 min intervals. The suspention was incubated for 20 min on ice and centrifuged at 12,000×g for 20 min at 4 ˚C. The supernatant as lysis extract was added to the Nickel NTA Resin previously equilibrated with binding buffer (50 mM NaH2PO4, 300 mM NaCl, 10 mM imidazole (pH 8.0)) and mixed for 30-60 min at room temperature. After centrifugation at 500×g for 5 min, the pelet was washed with wash buffer (50 mM NaH2PO4, 300 mM NaCl, 20 mM imidazole (pH 8.0)), mixed and centrifuged at 500×g for 5 min. The wash step was repeated twice. The supernatant was dicarded and ellution buffer (50 mM NaH2PO4, 300 mM NaCl, 250 mM imidazole (pH 8.0)) was added to the pelet and mixed for 10 min in room temperature. The suspension was centrifuged at 500×g for 5 min and the supernatant as purified recombinant halophilic lipase was collected. Protein concentration was determined by Bradford method (Bradford 1976) with bovine serum albumin as the standard.

Polyacrylamide gel electrophoresis

For the determination of purity and molecular weight of the recombinant lipase, sodium dodecyl sulphate–polyacrylamide gel electrophoresis (SDS–PAGE) was carried out as described by Laemmli (Laemmli 1970), using a 5% (w/v) stacking gel and a 12% (w/v) separating gel. The gels were stained with Coomassie Brilliant Blue R250 dye. The molecular weight of the recombinant enzyme was estimated using a molecular weight marker with molecular weight ranging from 14.8 to 116 kDa.

Lipase activity assay

The spectrophotometric method was used for measurement of lipase activity using p-nitrophenylpalmitate (pNPP) as the substrate. The assay was performed by measuring the absorbance at 410 nm that represents the amount of p-nitro phenol (pNP) released as the result of the enzyme activity (Nawani et al. 2006). For detection of lipase activity in expression and purification steps, the reaction mixture was composed of 100 µL pNPP solution (0.8 mM pNPP in 2-propanol) and 300 µL Tris-HCl buffer (50 mM, pH 7.5). 400 µL of the reaction mixture was pre-incubated at 35 °C for 5 min, and then, 100 µL of the lipase solution was added and incubated at 35 °C for 10 min. For characterization of the purified enzyme, the standard assay was used. The reaction mixture consisted of 100 µL pNPP solution (20 mM pNPP in 2-propanol) and 300 µL Tris-HCl buffer (50 mM, pH 5.0) containing 3 M NaCl was pre-incubated at 55 °C for 5 min. Then, 100 µL of the purified lipase was added and incubated at 55 °C for 10 min. The release of pNP was measured at 410 nm against a blank containing only the reaction mixture. One unit of enzyme activity was defined as the amount of enzyme that released 1 µmole pNP per minute under the described condition.

Determination of Michaelis-Menten kinetics

Kinetic parameters maximum reaction rate (Vmax) and Michaelis–Menten constant (Km) for the purified lipase were determined with the standard assay condition using different concentrations (0.05–10 mM) of pNPP as substrates. Lineweaver-Burk plot was used to calculate the kinetic parameters.

Substrate specificity

Substrate specificity of the enzyme was analyzed under standard conditions using different p-nitrophenyl ester substrates p-nitrophenyl butyrate (pNPB) (C4), p-nitrophenyl caprylate (pNPC) (C8), p-nitrophenyl laurate (pNPL) (C12), and p-nitrophenyl palmitate (pNPP) (C16).

Characterization of the recombinant lipase

Effect of pH, temperature and salts

To determine the effect of temperature on lipolytic activity of the recombinant enzyme, the standard reaction mixture was pre-incubated at temperatures ranging from 20 to 100 °C for 5 min, and then the enzyme activity was assayed at the temperatures for 10 min. The effect of pH on the lipase activity was determined by performing the standard activity assay in the pH range of 3.0 to 12, using the appropriate buffers at a concentration of 50 mM (sodium acetate (pH 4.0–5.5), sodium phosphate (pH 6.0–7.5), Tris–HCl (pH 8.0–9.0), and glycine–NaOH (pH 9.5–12.0)). The effect of NaCl and KCl concentrations on the enzyme activity was studied by measuring the activity in the reaction mixture containing different NaCl and KCl concentrations from 0 to 5 M. The activity was measured using the standard assay as mentioned above.

Effect of different metal ions, inhibitors and detergents

In order to determine the effect of various metal ions, the standard enzyme assay was performed in the presence of various metal ions at a final concentration of 10 mM. To obtain the effect of inhibitors phenyl methane sulfonyl fluoride (PMSF) and ethylene diamine tetra acetic acid (EDTA) on activity of the recombinant lipase, the enzyme assay was carried out in the presence of the inhibitors at final concentration of 10 mM. The influence of SDS, Triton X-100 and Tween detergents on the lipase activity was tested by measuring the activity in the reaction mixture containing different concentrations of the detergents. The enzyme assays were performed according to the standard assay conditions, and the activity of the enzyme without any additives was taken as 100%.

Results

Nucleotide sequence analysis of lipF gene

A lipase encoding gene was isolated from Nesterenkonia sp. strain F and cloned in T/A vector pTG-19T. The recombinant plasmid, pTG-lipF, was transformed into E. coli DH5α and the inserted lipase gene was confirmed by the sequence analysis. The lipase nucleotide sequence showed one major open reading frame of 819 bp, starting with an ATG codon and terminating with TGA stop codon. This nucleotide sequence is deposited in NCBI database (https://www.ncbi.nlm.nih.gov/) with the accession number MN879737.1 and the full-length sequence of the halophilic lipase gene was termed lipF. Nucleotide similarity analysis showed that lipF sequence is not similar to any of the lipase gene sequences in the database. The data indicated that this is a novel lipase gene.

Protein sequence analysis and family of LipF

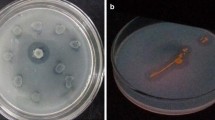

Amino acid sequence analysis of the halophilic lipase (LipF) from the strain revealed that LipF is composed of 272 amino acid residues with a calculated molecular weight of 28.3 kDa and isoelectric point (pI) of 7.0. The molecular mass was in agreement with the value also estimated by SDS-PAGE of about 28.5 kDa (Fig. 1). Homology sequence analysis indicated that LipF showed the highest amino acid sequence identity (88%) to a putative (hypothetical protein) alpha/beta fold hydrolase from Nesterenkonia halophila (GeneBank ID: WP_153143953.1). Lower sequence similarity of LipF was observed with other putative enzymes such as alpha/beta fold hydrolases from Nesterenkonia sp. PF2B19 (GeneBank ID: WP_085437117.1) (61%), Nesterenkonia xinjiangensis (GeneBank ID: WP_179542485.1) (60%), Nesterenkonia lacusekhoensis (GeneBank ID: WP_210048784.1) (59%) and Nesterenkonia sp. AN1 (GeneBank ID: WP_084479512.1) (56%). The putative enzyme sequences were recorded only in the NCBI database and none of them has been cloned and characterized on a biochemical basis. However, no sequence similarity was observed between LipF and other cloned, sequenced and functionally characterized halophilic lipolytic enzymes, suggesting the novelty of the enzyme.

SDS-PAGE analysis of recombinant LipF. Lane 1, protein marker; Lane 2, uninduced cell lysate of E.coli BL21 harboring pET-LipF; Lane 3, IPTG-induced cell lysate of E. coli BL21 harboring pET-LipF after 2 h induction; Lane 4, IPTG-induced cell lysate of E. coli BL21 harboring pET-LipF after 6 h induction; Lane 5, the purified LipF after two washes in the washing step

Analysis of amino acid composition of the halophilic lipase revealed that the amino acid sequence is predominantly composed of hydrophobic residues (Ala, Leu, Phe, Val, Ile and Trp) (43.4%). Acidic amino acids (Asp and Glu), arginine and proline content of the enzyme were 11.7%, 11.8% and 7.4%, respectively (Table 1). Lys residue has not been found in the amino acid sequence of LipF.

A conserved domain analysis using NCBI/Structure database was performed to determine super family and conserved domains of the recombinant protein. The data indicated that the enzyme was belonged to alpha/beta hydrolases super family; functionally diverse super family containing proteases, lipases, peroxidases, esterases, epoxide hydrolases and dehalogenases. These enzymes all share the same folding pattern consisting of a catalytically active core domain (the α/β-hydrolase fold) and catalyze a hydrolysis reaction (Jaeger et al. 1999). To determine family of the halophilic lipase, blast of the LipF amino acid sequence was performed using LED database and the data indicated that the lipase from Nesterenkonia sp. strain F as a member of abH11family was belong to GX class of lipases. Also, based on the blast in the ESTHER database (α/β hydrolases fold super family database), the lipase was placed in CarbLipBact_2 ESTHER family. This family corresponds to family XIII of the classification of lipases by Arpigny and Jaeger (Kovacic et al. 2019).

To determine the conserved regions, multiple amino acid sequence alignment of LipF with the lipolytic enzymes from Nesterenkonia sp. AN1, Streptomyces bingchenggensis, Arthrobacter sp. IHBB, Arthrobacter arilaitensis and Micrococcus luteus of family XIII was done using ESPript 3.0 program (Fig. 2). Similar to other lipases (Contesini et al. 2020), the active core domain of LipF was composed of eight β strands surrounded by eight α helices. The conserved region was from Asp29 to Ala256. The sequence alignment revealed a conserved pentapeptide motif GISMG (102 to 106) that corresponds to Gly-X-Ser-X-Gly (where X is any amino acid) which was known as a lipase-specific consensus sequence. The motif found in all proteins belonging to the alpha / beta hydrolase superfamily and plays an essential role in cognition of the substrate and binding. Also, the three amino acids (serine, aspartic acid and histidine) of the consensus catalytic triad found in most lipases active site were also present in the deduced amino acid sequence. The catalytic triad of the halophilic lipase of Nesterenkonia sp. strain F was composed of a nucleophile Ser104 located in α4 helix (within the pentapeptide), a catalytic acid residue Asp203 located after the β7 strand and a general base catalytic residue His 233 located in a loop after the β8 strand of the α/β hydrolase fold.

Multiple sequence alignment of LipF (QOJ43509.1) with lipolytic enzymes from Nesterenkonia sp. AN1 (EXF25202.1), Arthrobacter sp. IHBB (AJT42829.1), Streptomyces bingchenggensis (ADI10959.1), Arthrobacter arilaitensis (CBT75412.1) and Micrococcus luteus (EZP33814.1) of family XIII. Symbols above the sequences represented the secondary structure. Identical amino acids are shown in white character and boxed in red, while similar residues are shown in red characters. The conserved pentapeptide motif GISMG is boxed with black frame. Amino acid residues belonging to the catalytic triad are indicated with asterisks and the oxyanion hole residues are indicated with black dots

The oxyanion hole, which stabilizes the tetrahedral intermediate formed during the reaction mechanism, consists of two residues (Graziano and Merlino 2014). To determine the oxyanion hole residues, comparison of the lipase amino acid sequence with other amino acid sequences of abH11family was performed using LED database. The data revealed that similar to all members of GX class lipases, the first oxyanion hole residue of the lipase is Phe 36 located next to a Gly residue and the second oxyanion hole residue of is Met 105 positioned next to the catalytic serine (Fig. 2).

Three-dimensional structure of LipF

Three-dimensional structure (3D structure) and active site of the protein were predicted using I-TASSER, SWISS-MODEL and Phyre2. In I-TASSER, 3D structure modeling for an amino acid sequence is performed by retrieving template proteins of similar folds (or super-secondary structures) from the protein data bank (PDB) library (https://www.rcsb.org/) and the continuous fragments excised from the PDB templates are reassembled into full-length models. In SWISS-MODEL, structural template for a target sequence is identified from PDB database. Then, alignment of the target sequence and the template structure is performed to generate 3D protein model. In Phyre2, multiple-sequence alignment and secondary structure prediction of a sequence is combined and the data scanned against a fold library composed of a representative set of experimentally determined protein structures. Then, the top-scoring alignments from this search are used to construct 3D structure model.

The top template identified by all three servers I-TASSER, SWISS-MODEL and Phyre2 for homology modeling was crystal structure of monoacylglycerol lipase from thermophilic Geobacillus sp. 12AMOR (PDB ID: 5XKS). The lipase amino acid sequence identity with LipF was 35.22% with 92% coverage. The TM-score (Template Modeling score) of the predicted structure by I-TASSER, GMQE (Global Model Quality Estimate) score by SWISS-MODEL and Confidence (probability of true matching between LipF sequence and the template) by Phyre2 were 0.92%, 0.67% and 99.98%, respectively. Also, the modeling was validated by Ramachandran plot: 91.7% residues were in the most favored regions, 7.8% residues were in the allowed regions and only 0.5% residues (1 residue) were in the disallowed regions. The data indicated high reliability of the modeling. The overall quality of the predicted structure was validated by ProSA-web program and the model z-score was -7.55. Therefore, the structure was a reliable structure. The predicted 3D structure shows that, LipF has the typical active core domain (8 α-helixes surrounding 7 β-sheets) of lipolytic enzymes containing the catalytic triad and oxyanion hole (Fig. 3).

Predicted 3D structure and surface electrostatic potential of LipF. (a) The structure of LipF constructed by Swiss-Model based on the crystal structure of monoacylglycerol lipase from thermophilic Geobacillus sp. 12AMOR (PDB ID: 5XKS). (b) Position of the catalytic triad (Ser104, Asp203 and His 233) is indicated by green arrows in structure of (a). (c) Show surface electrostatic potentials for (a). (d) is the 180° rotated view of (c). Red and blue indicate the negative and positive electrostatic potentials, respectively

Expression and purification of LipF

For expression of the recombinant halophilic lipase, pET-lipF expression plasmid was constructed and successfully transformed into E. coli BL21(DE3). PCR-sequencing of the recombinant vector with T7 promoter and T7 terminator primers confirmed accuracy of the target gene. lipF expression was induced with various concentration of IPTG and the lipase activity of cellular extract was measured at various hours after induction. The optimum expression for recombinant protein was achieved after 6 h of induction with 0.1 mM IPTG at 20 °C. For further characterization of Nesterenkonia sp. strain F lipase, the expressed proteins from the bacterial lysate were extracted and the recombinant lipase was purified using Nickel NTA Agarose Resin. A single band corresponding to expressed recombinant lipase was observed on SDS-PAGE (Fig. 1). The specific activity of the lipase in the cellular extract was 0.75 U/mg and the final specific activity of the purified enzyme was estimated to be 5.37 U/mg.

The Effects of pH, temperature and salts on the lipase activity

The effect of pH on the activity of LipF was determined in the presence of various range of pH 3.0 to12.0. As shown in Fig. 4a the lipase exhibited maximum activity at pH 5.0 and enzyme was active at acidic pH values, as 85% and 37% of the maximum activity remained at pH of 4.0 and 3.0, respectively. Also, the enzyme retained 40% of its maximal activity at alkaline pH of 8.0 and 25% of the activity at pH=9.0. According to the relative activity profile of LipF at different temperatures (Fig. 4b), the optimum temperature of the enzyme was 55 °C. The enzyme retained 53% and 42% of its maximal activity at 75 and 85 °C, respectively. However, it was active at low-temperatures, as 35% of the maximum activity was measured at 20 °C.

The Effects of pH and temperature on the activity of LipF. (a) The effect of pH was assayed in various buffers from pH 3.0 to pH 12.0 under standard conditions. (b) The effect of temperature was determined according to the standard assay at temperatures from 20 to 100 °C. The relative activities were defined as the percentage of activity detected with respect to the maximum enzyme activity. Values are mean ± SD of three independent experiments

The effect of NaCl and KCl concentrations on the activity of LipF was determined by measuring the enzyme activity in the presence of various concentrations of each salt (Fig. 5). The data indicated that the enzyme showed increased activity along with the increasing concentration of the salts and maximum activity of the enzyme was observed at 4 M of NaCl and KCl. LipF showed 93% and 90% of its maximum activity at 5 M of NaCl and KCl, respectively. However, the enzyme retained its activity at relatively low salt concentrations. More than 20% and 25% of the maximum activity remained at 0.5 M of NaCl and KCl, respectively. The enzyme activity was remained even in the absence of the salts.

The effect of NaCl (a) and KCl (b) concentrations on LipF. The activities were determined in the presence of 0-5 M of each salt under standard assay conditions. The relative activities were defined as the percentage of activity detected with respect to the maximum enzyme activity. Values are mean ± SD of three independent experiments

The Effects of different metal ions and inhibitors on LipF

The influence of various metal ions on LipF activity was determined at their final concentrations of 10 mM (Table 2). Metal ions have different effects on the enzyme activity. While 60% of the lipolytic activity was maintained in the presence of Mg2+, Ca2+ has increasing effect on the enzyme activity (132%). Also, Cu2+ and Al3+ ions strongly activated the recombinant lipase as the activity was increased to 376% and 500% in the presence of the ions, respectively. However, Ni2+ ion completely inhibited the activity of LipF. PMSF and EDTA (at final concentrations of 10 mM) strongly inhibited the recombinant halophilic lipase and no enzyme activity was observed in the presence of these inhibitors.

The Effects of various detergents on the lipase activity

Activity of the halophilic lipase was assayed in the presence of various detergents and the relative activities are presented in Table 2. Low concentrations of the ionic detergent SDS (0.1% and 0.5% (w/v)) were found to decrease the lipase activity (49% and 45%, respectively), whereas higher concentration revealed stimulatory effect as the relative activity in the presence of 1% concentration of SDS was increased to 124%. Concentrations of 0.1% and 0.5% the non-ionic detergent Tween 20 and concentration of 0.5% Triton X-100 decreased LipF lipolytic activity to 46%, 52% and 40%, respectively.

Determination of the Kinetic Parameters

The kinetic parameters of the purified recombinant lipase were determined from Lineweaver-Burk plots (not shown). Km and Vmax values of LipF were determined to be 2 mM and 0.76 mM min−1, respectively.

Substrate specificity

The LipF substrate specificity assay indicated that long chain fatty acid esters were more preferred substrates than ester of short chain fatty acid. Maximum activity of the enzyme was measured in the presence of pNPP and the enzyme showed 60%, 41% and 23% of the activity towards pNPL, pNPC and pNPB, respectively.

Discussion

Halophiles constitute an important group of extremophilic microorganisms adapted to live in diverse hypersaline environments and offer a multitude of actual or potential applications in various fields of biotechnology (Margesin and Schinner 2001). Halophilic microorganisms produce enzymes that have optimal activities at different salt concentrations. Due to the fact that many available enzymes cannot be used in harsh industrial conditions, increasingly, attentions have turned to halophilic enzymes as catalysts in environments where high salt stability is desired (Schreck and Grunden 2014). In this context, we reported purification and biochemical characterization of halophilic alpha-amylases from moderately halophilic bacterium Nesterenkonia sp. strain F (Shafiei et al. 2010, 2011, 2012; Solat and Shafiei 2021). Among halophilic enzymes, a limited number of studies on purification and characterizations of halophilic lipases have been reported (Table 1). Molecular genetic studies, protein engineering and targeted manipulation in the structure of halophilic enzymes can increase their application in biotechnology. Also, determination of 3D structure of halophilic enzymes enhances the performance of comparative analysis between halophilic enzymes and their non-halophilic homologs in order to understand the relationships between structure and particular biochemical and biophysical properties (Ventosa et al. 2005). So far, the cloning, bacterial expression and characterization of halophilic lipolytic enzymes were only reported from Pseudoalteromonas lipolytica SCSIO 04301 (Su et al. 2016), Alkalispirillum sp. NM-ROO2 (Mesbah 2019), Lactobacillus plantarum WCFS1 (Esteban-Torres et al. 2015), Haloarcula marismortui (ATCC 43,049) (Rao et al. 2009), Marinobacter lipolyticus SM19 (Perez et al. 2011), Pelagibacterium halotolerans B2 (Jiang et al. 2012) and Haloarcula marismortui (Müller-Santos et al. 2009), and there is no report about the cloning and characterization of a gene encoding acidic lipase from moderately halophilic bacteria. Here, we studied the cloning, expression and characterization of an acidic and SDS tolerant halophilic lipase from moderately halophilic bacterium Nesterenkonia sp. strain F.

Compared to other expressed recombinant halophilic lipases that were cloned in pET28a+ (Mesbah 2019; Rao et al. 2009; Jiang et al. 2012), pET22 b+ (Su et al. 2016) and pET14b (Müller-Santos et al. 2009), the halophilic lipase gene from Nesterenkonia sp. strain F was successfully cloned in pET26b+ expression vector and expressed in E. coli BL21(DE3). Optimization of the recombinant gene expression induction is very important for minimizing potential problems due to product insolubility, growth inhibition and cell lysis. For this purpose, attempts were made to optimize the concentration of inducer IPTG, temperature and time of induction (data not shown). The results indicated that optimal concentration of IPTG and induction time for high level expression of active recombinant lipase was 0.1 mM and 6 h induction at 20 °C.

The functional purified lipase showed one band on SDS-PAGE corresponding to about 28.5 kDa. The low molecular mass value of LipF was close to the value obtained for halophilic lipases from Alkalispirillum sp. NM-ROO2 (32 kDa) (Mesbah 2019), Lactobacillus plantarum WCFS1 (30 kDa) (Esteban-Torres et al. 2015), Halobacillus sp. AP-MSU 8 (25 kDa) (Esakkiraj et al. 2016) and the halophilic esterase from Pelagibacterium halotolerans B2 (30 kDa) (Jiang et al. 2012). Other biochemically characterized halophilic lipases have shown higher molecular weights as the molecular weight for the halophilic lipolytic enzyme from Pseudoalteromonas lipolytica SCSIO 04301 was 80 kDa (Su et al. 2016); Bacillus atrophaeus FSHM2, 85 kDa (Ameri et al. 2017); from Marinobacter sp. EMB5, 172 kDa (Hemamalini and Khare 2018); from Idiomarina sp. W33, 67 kDa (Li et al. 2014) and from Chromohalobacter sp., 58 kDa (Ai et al. 2018).

Blast of LipF protein sequence results indicated that LipF protein sequence has middle similarity to putative hydrolases, none of which has been cloned and characterized so far. The lack of identity with functionally characterized lipases and halophilic counterparts highlights the importance of this molecular study on a halophilic lipase and suggest that the halophilic lipase from Nesterenkonia sp. strain F is a new lipase with great research and application potential.

Detail analysis by comparing the amino acid sequence of LipF with the sequences of halophilic enzymes that active at high salt concentrations showed several differences. The amount of acidic amino acids compared to the basic amino acids of LipF was lower than that in other halophilic lipases studied (Table 1) and the percentage of acidic amino acids was equal to that for basic amino acids in this protein. In the sequence of other putative halophilic lipolytic enzymes, the amount of acidic amino acids is more than basic amino acids (Delgado-García et al. 2018). Also, in the alpha amylase studied from Nesterenkonia sp. strain F, higher levels of acidic amino acids were observed than basic amino acids (Solat and Shafiei 2021). The same amount of acidic and basic amino acids has not been observed in halophilic enzymes so far, and this is in contrast to the statement that halophilic enzymes are characterized by higher frequency of acidic over basic residues (Madern et al. 2000; Graziano and Merlino 2014). Based on the results of amino acid composition and high activity of LipF in the presence of high concentrations of salt (Fig. 5), it can be concluded that even with the same ratio of acidic and basic amino acids, the halophilic protein can be active in the presence of high salt concentrations.

Correlation with this amino acid composition (equal amount of acidic and basic residues), the isoelectric point of LipF was neutral. The pI value of 7.0 was the highest pI value of the halophilic lipolytic enzymes studied (Table 1). Due to a high number of acidic residues, halophilic proteins have low pI values in the range of 4.3 to 6.8 (Graziano and Merlino 2014).

Studies indicate that halophilic proteins are characterized by lower frequency of hydrophobic residues (Schreck and Grunden 2014), while about half of the structural amino acids in LipF are hydrophobic amino acids residues. Among halophilic lipases, halophilic bacterium Marinobacter lipolyticus SM19 lipase has the closest acidic amino acid (10.9%) and basic amino acid (9.9%) contents to those of LipF. However, the amount of hydrophobic amino acids of the halophilic lipase is less than that of LipF and its pI was 6.22 (Perez et al. 2011). The highest percentage of acidic amino acids compared to basic amino acids and also the lowest percentage of hydrophobic residues are found in the halophilic lipase from Haloarcula marismortui (Müller-Santos et al. 2009). A significant decrease of lysine residues observed in halophilic proteins (Bolhuis et al. 2008) was also observed for LipF and there was no lysine amino acid in the structure of the halophilic lipase. The only similar characteristics between the amino acid content of halophilic proteins and LipF is the low percentage of lysine amino acid.

According to lipases sequence similarity and physiological properties, bacterial lipolytic enzymes was first classified into eight families (Arpigny and Jaeger 1999). This classification has been revised several times and currently lipolytic enzymes are classified into 19 families based on phylogenetic criteria, conserved sequence motifs, and biological functions. With reference to the above lipolytic enzyme families and the results of ESTHER database blast, the halophilic lipase from Nesterenkonia sp. strain F can be grouped into family XIII. Correlated to the predicted molecular weight of LipF (28.5 kDa), the lipolytic enzymes from this family have a molecular weight of approximately 28 kDa (Kovacic et al. 2019). Also, the results showed that LipF contains the highly conserved pentapeptide motif GISMG, which is not present in the most lipolytic enzymes of family XIII. The conserved sequence for the most lipolytic enzymes of family XIII was GLSLG or GLSMG. The motif of GISMG is only presented in the putative lipases of Cupriavidus sp. HMR-1, Halanaerobium saccharolyticum, Rothia dentocariosa M567, Kineococcus radiotolerans and Rothia dentocariosa ATCC 17,931 of family XIII. While the oxyanion hole side chain is generally not involved in interaction with the substrate, it is well conserved in lipase families and has been suggested to be involved in oxyanion stabilization (Pleiss et al. 2000). The data from LED database indicated that LipF was belong to GX class of lipases and the first hydrophobic oxyanion hole residue phe 36 (located next to a Gly) is stabilized by binding to hydrophobic pockets (anchor residues) (Fischer and Pleiss 2003). Oxyanion hole residue and anchor residues line the bottom of the deep hydrophobic cleft to which the scissile fatty acid binds (Pleiss et al. 1998).

3D structure prediction data indicated that although the amino acid sequence of monoacylglycerol lipase from thermophilic Geobacillus sp. 12AMOR has 35.22% identity with the LipF sequence, the lipase structure (PDB ID: 5XKS) was the best template for structure modeling of LipF. The model of LipF is characterized by the α/β hydrolase fold, which is typical for lipolytic enzymes and conserved the catalytic triad of aspartate, glutamate, and aspartate in the active site. Various studies have been reported the presence of a higher proportion of acidic residues on the surface of halophilic proteins when compared with their non-halophilic homolouges (Flores-Gallegos et al. 2019). The high surface density of negative charges stabilizes the structure of halophilic proteins to have activity in the high salt concentrations (Graziano and Merlino 2014; Sinha and Khare 2014). Although the structure of halophilic amylase from Nesterenkonia sp. strain F also showed the same accumulation of acidic amino acids on its surface (Solat and Shafiei 2021), however, a small amount of hydrophilic amino acids including acidic ones are displayed on the surface of halophilic LipF from the bacterium (Fig. 3). The only report of a lack of acidic amino acids at the surface of halophilic proteins has been for the enzyme of an alpha amylase from Halothermothrix orenii (Sivakumar et al. 2006). The equal percentage of acidic and alkaline amino acids, the average amount of hydrophobic amino acids and the lack of accumulation of negative charges at the protein surface indicate the uniqueness of the halophilic LipF.

The recombinant halophilic lipase exhibited high activity at acidic pH levels (3.5 – 7.5), and its optimum pH value of 5.0 indicates the acidic property of this enzyme. However, the enzyme remains active at alkaline pH of 8.0 and 9.0. The enzyme property of activity in both acidic and alkaline condition is desirable for many industrial applications such as wastewater treatment, leather processing, flavor synthesis and bioremediation (Salihu and Alam, 2015). Biochemically characterized halophilic lipases active at highly acidic pH have not been reported so far from moderately halophilic microbial sources and this study is the first report of molecular and biochemical characterization of a halophilic acidic lipase from halophilic microorganisms. The halophilic lipases studied so far have optimum pH values from 7.0 to 9.0 (Table 1) and among them those from Lactobacillus plantarum WCFS1 (Esteban-Torres et al. 2015), Marinobacter lipolyticus SM19 (Perez et al. 2011), Chromohalobacter sp. (Ai et al. 2018), Idiomarina sp. W33 (Li et al. 2014), Chromohalobacter sp LY7-8 (Li and Yu 2012), Haloarcula sp. G41 is (Li and Yu 2014) and Pelagibacterium halotolerans B2 (Jiang et al. 2012) had about 50% activity at pH of 6.0 with optimum pH of higher than pH=7.0.

Experiments to determine the optimum temperature revealed that LipF showed its maximum activity at 55 °C. This value is similar to that obtained for halophilic lipases from Chromohalobacter sp. (Ai et al. 2018) and Alkalispirillum sp. NM-ROO2 (Mesbah 2019). Also, LipF showed more than 40% activity up to 85 °C, which could indicate the potential of using this enzyme in industrial processes where high temperatures are required. Optimum temperature for LipF is higher than the ones reported for halophilic lipases from Pseudoalteromonas lipolytica SCSIO 04301 (45 °C) (Su et al. 2016), Lactobacillus plantarum WCFS1 (40 °C) (Esteban-Torres et al. 2015), Haloarcula marismortui (ATCC 43,049) (45 °C) (Rao et al. 2009), Pelagibacterium halotolerans B2 (45 °C) (Jiang et al. 2012) and Halobacillus sp. AP-MSU 8 (40 °C) (Esakkiraj et al. 2016). However, compared to the optimum temperature for LipF, other halophilic lipases had higher optimum temperatures (Table 1) and the highest optimum temperature (80 °C) has been reported for the halophilic lipase from Marinobacter lipolyticus SM19 (Perez et al. 2011).

Lipases active at elevated salt concentrations may have interesting food applications in the production of structured lipids, emulsifiers, flavors, and other valuable products (Delgado-García et al. 2018). Activity of LipF was increased with increasing concentration of NaCl and KCl and maximal activity of the enzyme was observed at 4 M of the salts. Maximum activity at very high salt concentration (4 M) has also been reported for halophilic lipase from Bacillus atrophaeus FSHM2 (Ameri et al. 2017). Presence of salt is a prerequisite for functioning of halophilic proteins. However, many halophilic enzymes functioning in high saline conditions lose their activity when they are in low salt environments (Sinha and Khare 2014). In contrast, LipF remains active at low salt concentration and shows its activity even in the absence of salt. At low salt concentrations, the high amount of acidic amino acids causes the electrostatic repulsions to increase, the protein structure to be unstable and the activity of the enzyme to lack (Hutcheon et al. 2005). Retaining activity of LipF at low concentration of salt could be due to a medium amount (11.7%) of acidic residues. Similarly, the halophilic lipolytic enzymes from Pseudoalteromonas lipolytica SCSIO 04301 (Su et al. 2016), Lactobacillus plantarum WCFS1 (Esteban-Torres et al. 2015), Marinobacter lipolyticus SM19 (Perez et al. 2011) and Pelagibacterium halotolerans B2 (Jiang et al. 2012) that have medium amount of acidic residues (9.8-10.7%) in their structure retained their activity in the absence of salts. Activity over a wide range of salt concentration indicates the potential of LipF for use in various industrial processes.

LipF activity was found to be stimulated in the presence of Ca2+ (132%). Stimulatory effects of Ca2+ were reported for several bacterial lipases (Andualema and Gessesse 2012). The positive effect of Ca2+ on the hydrolysis process of the lipases are ascribed to the structural role of the ion and suppression of the inhibitory activity of the formed fatty acids (released during enzymatic hydrolysis) due to the formation of insoluble Ca2+-salts of the fatty acids and remove them from the active site. Thus the interfacial substrate–water relationship is changed to conditions favorable for enzyme action (Guncheva and Zhiryakova 2011; Sheng et al. 2012). Similar stimulation of activity in the presence of Ca2+ has been reported for halophilic lipases from Chromohalobacter sp. (Ai et al. 2018), Idiomarina sp. W33 (Li et al. 2014), Bacillus atrophaeus FSHM2 (Ameri et al. 2017) and Haloarcula sp. G41 (Li and Yu 2014). Data presented herein showed activation of LipF by Cu2+ and Al3+, while Ni2+ greatly inhibited the enzyme activity. Similarly, The halophilic lapase from Pseudoalteromonas lipolytica SCSIO 04301 (Su et al. 2016) was strongly inhibited by Ni2+. This positive effect of Cu2+ and Al3+ has not been previously reported for halophilic lipases. Lipolytic activity of the enzyme was severely inhibited by the metal chelating agent EDTA and PMSF which indicated that LipF was a metalloenzyme and serine is involve in its active center.

In order to have applications in washing industries, the lipase must be active in the presence of various detergents. Examination of the enzyme activity in the presence of detergents indicated that although the tested non-ionic detergents Triton X-100, and Tween 20 were found to decrease the activity of LipF, this enzyme retains about 50% of its activity in their presence. On the other hand, while the lipase activity was reduced in the presence of 0.1% of SDS, the addition of 1% of the ionic surfactant increased the LipF activity strongly, the residual activity increased to 120% in comparison to the control sample. The same result was observed for non-halophilic lipases from Microbacterium sp. and Trichoderma lentiforme ACCC30425 when treated with SDS (Tripathi et al. 2014; Wang et al. 2018). However, SDS is a non-specific reversible inhibitor for most lipases (Gupta et al. 2004). Among halophilic lipases, the halophilic lipase from Chromohalobacter sp. was inhibited in the presence of SDS (Ai et al. 2018), while Triton X-100, Tween 80 and Tween 20 increased its activity. However, the halophilic lipase from Bacillus atrophaeus FSHM2 (Ameri et al. 2017) was inhibited in the presence of all the detergents. The activity of the halophilic lipase from Pseudoalteromonas lipolytica SCSIO 04301 (Su et al. 2016) was not change in the presence of detergents. Catalytic reaction of lipolysis can be described as a reversible lipase adsorption/desorption step occurring at the oil/water interface, followed by the formation of an interfacial enzyme substrate complex and the release of lipolysis products (Panaitov and Verger 2000). Depending on the specific structure of lipases as well as the various properties of the surfactants, two different behaviors of the surfactants are observed at various concentrations: (1) they can locate at the interfaces and disperse oil droplets in water, promoting the lipase activity by increasing the specific area of substrate accessible to the enzyme. (2) They can have inhibitory effects by binding to the protein and desorbing it or by impairing lipase adsorption at lipid/water interfaces (Delorme et al. 2011). With all these properties, we can suggest that LipF is a potential candidate for use in detergent industries.

Conclusions

In this study, we cloned a novel halophilic lipase gene from Nesterenkonia sp. strain F and the corresponding protein was expressed, purified and biochemically characterized. Protein sequence and homology modeling analysis confirmed that LipF is a novel lipase with unique structure characteristics. To the best of our knowledge, this is the first cloning, purification and characterization of a gene encoding halophilic acidic lipase from moderately halophilic microorganisms. Biochemical characterization of the lipase indicated that, in addition to activity in a wide range of salt concentrations, LipF had a strong catalytic ability in the presence of acidic pH and showed appropriate activity in high temperatures. The biochemical characteristics showed by LipF suggest that it can be used for various applications in food fermentation, leather processing, flavor synthesis, waste treatment and detergent industries.

Abbreviations

- lipF:

-

Lipase gene of Nesterenkonia sp. strain F

- LipF:

-

Lipase enzyme from Nesterenkonia sp. strain F

- PMSF:

-

Phenyl methane sulfonyl fluoride

- EDTA:

-

Ethylene diamine tetra acetic acid

- SDS:

-

Sodium dodecyl sulphate

- E. coli :

-

Escherichia coli

- PCR:

-

Polymerase chain reaction

- LED:

-

Lipase engineering database

- IPTG:

-

Isopropyl-β-D-thiogalactopyranoside

- PAGE:

-

Polyacrylamide gel electrophoresis

- pNPP:

-

p-Nitrophenylpalmitate

- pNP:

-

p-Nitro phenol

- pNPB:

-

p-Nitrophenyl butyrate

- pNPC :

-

p-Nitrophenyl caprylate

- pNPL :

-

p-Nitrophenyl laurate

- Vmax:

-

Maximum reaction rate

- Km:

-

Michaelis–Menten constant

- PDB:

-

Protein data bank

References

Adina SR, Suwanto A, Meryandini A, Puspitasari E (2021) Expression of novel acidic lipase from Micrococcus luteus in Pichia pastoris and its application in transesterification. J Genet Eng Biotechnol 19:55. https://doi.org/10.1186/s43141-021-00155-w

Ai L, Huang Y, Wang C (2018) Purification and characterization of halophilic lipase of Chromohalobacter sp. from ancient salt well. J Basic Microbiol 58:647–657. https://doi.org/10.1002/jobm.201800116

Ameri A, Shakibaie M, Faramarzi MA, Ameri A, Amirpour-Rostami S, Rahimi HR, Forootanfar H (2017) Thermoalkalophilic lipase from an extremely halophilic bacterial strain Bacillus atrophaeus FSHM2: Purification, biochemical characterization and application. Biocatal Biotransform 35:151–160. https://doi.org/10.1080/10242422.2017.1308494

Amoozegar MA, Safarpour A, Noghabi KA, Bakhtiary T, Ventosa A (2019) Halophiles and their vast potential in biofuel production. Front Microbiol 10:1895. https://doi.org/10.3389/fmicb.2019.01895

Andualema B, Gessesse A (2012) Microbial lipases and their industrial applications: review. Biotechnol 11:100–118. https://doi.org/10.3923/biotech.2012.100.118

Arnold K, Bordoli L, Kopp J, Schwede T (2006) The SWISSMODEL workspace: a web-based environment for protein structure homology modelling. Bioinformatics 22:195–201. https://doi.org/10.1093/bioinformatics/bti770

Arpigny JL, Jaeger KE (1999) Bacterial lipolytic enzymes: classification and properties. Biochem J 343:177–183. https://doi.org/10.1042/bj3430177

Asyari M, Aditiawati P, Akhmaloka, Hertadi R (2015) Cloning and sequence analysis of lipase gene of halophilic bacteria isolated from mud crater of Bledug Kuwu, Central Java, Indonesia. Biosci Biotech Res Asia 12:1903–1912. https://doi.org/10.13005/bbra/1856

Bolhuis A, Kwan D, Thomas JR (2008) Halophilic adaptations of proteins. In: Siddiqui KS, Thomas T, Uversky V (eds) Protein adaptation in extremophiles: Design, selection and applications. Nova Science Publishers, New York, pp 71–104

Borrelli GM, Trono D (2015) Recombinant lipases and phospholipases and their use as biocatalysts for industrial applications. Int J Mol Sci 16:20774–20840. https://doi.org/10.3390/ijms160920774

Bradford MM (1976) A rapid and sensitive for the quantitation of microgram quantitites of protein utilizing the principle of protein-dye binding. Anal Biochem 72:248–254. https://doi.org/10.1016/0003-2697(76)90527-3

Contesini FJ, Davanço MG, Borin GP, Vanegas KG, Cirino JPG, Melo RRd, Mortensen UH, Hildén K, Campos DR, Carvalho PdO (2020) Advances in recombinant lipases: Production, engineering, immobilization and application in the pharmaceutical industry. Catalysts 10:1032. https://doi.org/10.3390/catal10091032

Delgado-García M, Rodríguez JA, Mateos-Díaz JC, Aguilar CN, Rodríguez-Herrera R, Camacho-Ruíz RM (2018) Halophilic archaeal lipases and esterases: Activity, stability, and food applications. In: Kuddus M (ed) Enzymes in food technology. Springer, Singapore, pp 243–262. https://doi.org/10.1007/978-981-13-1933-4_12

Delorme V, Dhouib R, Canaan S, Fotiadu F, Carrière F, Cavalier JF (2011) Effects of surfactants on lipase structure, activity, and inhibition. Pharm Res 28:1831–1842. https://doi.org/10.1007/s11095-010-0362-9

Dhake KP, Thakare DD, Bhanage BM (2013) Lipase: a potential biocatalyst for the synthesis of valuable flavour and fragrance ester compounds. Flavour Frag J 28:71–83. https://doi.org/10.1002/ffj.3140

Esakkiraj P, Prabakaran G, Maruthiah T, Immanuel G, Palavesam A (2016) Purification and characterization of halophilic alkaline lipase from Halobacillus sp. Proc Natl Acad Sci India Sect B Biol Sci 86:309–314. https://doi.org/10.1007/s40011-014-0437-1

Esteban-Torres M, Mancheno JM, De Las Rivas B, Munoz R (2015) Characterization of a halotolerant lipase from the lactic acid bacteria Lactobacillus plantarum useful in food fermentations. Food Sci Technol 60:246–252. https://doi.org/10.1016/j.lwt.2014.05.063

Fischer M, Pleiss J (2003) The lipase engineering database: a navigation and analysis tool for protein families. Nucleic Acid Res 31:319–321. https://doi.org/10.1093/nar/gkg015

Flores-Gallegos AC, Delgado-García M, Ascacio-Valdés JA, Villareal-Morales S, Michel-Michel MR, Aguilar-González CN, Rodríguez-Herrera R (2019) Chapter 13 - Hydrolases of halophilic origin with importance for the food industry. In: Kuddus M (ed) Enzymes in food biotechnology. Academic, Cambridge, pp 197–219. https://doi.org/10.1016/B978-0-12-813280-7.00013-X

Gomes J, Steiner W (2004) The biocatalytic potential of extremophiles and extremozymes: Review. Food Tech Biotech 42:223–235

Graziano G, Merlino A (2014) Molecular bases of protein halotolerance. Biochim Biophys Acta 1844:850–858. https://doi.org/10.1016/j.bbapap.2014.02.018

Guncheva M, Zhiryakova D (2011) Catalytic properties and potential applications of Bacillus lipases. J Mol Catal B Enzym 68:1–21. https://doi.org/10.1016/j.molcatb.2010.09.002

Gupta R, Gupta N, Rathi P (2004) Bacterial lipases: an overview of production, purification and biochemical properties. Appl Microbiol Biotechnol 64:763–781. https://doi.org/10.1007/s00253-004-1568-8

Gupta R, Kumari A, Syal P, Singh Y (2015) Molecular and functional diversity of yeast and fungal lipases: Their role in biotechnology and cellular physiology. Prog Lipid Res 57:40–54. https://doi.org/10.1016/j.plipres.2014.12.001

Hemamalini R, Khare SK (2018) Halophilic lipase does forms catalytically active aggregates: Evidence from Marinobacter sp. EMB5 lipase (LipEMB5). Int J Biol Macromol 119:172–179. https://doi.org/10.1016/j.ijbiomac.2018.07.097

Hutcheon GW, Vasisht N, Bolhuis A (2005) Characterization of a highly stable alpha-amylase from the halophilic archaeon Haloarcula hispanica. Extremophiles 9:487–495. https://doi.org/10.1007/s00792-005-0471-2

Hough DW, Danson MJ (1999) Extremozymes. Curr Opin Chem Biol 3:39–46. https://doi.org/10.1016/S1367-5931(99)80008-8

Jaeger KE, Dijkstra BW, Reetz MT (1999) Bacterial biocatalysts: molecular biology, three-dimensional structures, and biotechnological applications of lipases. Annu Rev Microbiol 53:315–351. https://doi.org/10.1146/annurev.micro.53.1.315

Jiang X, Huo Y, Cheng H, Zhang X, Zhu X, Wu M (2012) Cloning, expression and characterization of a halotolerant esterase from a marine bacterium Pelagibacterium halotolerans B2T. Extremophiles 16:427–435. https://doi.org/10.1007/s00792-012-0442-3

Kelley LA, Mezulis S, Yates CM, Wass MN, Sternberg MJ (2015) The Phyre2 web portal for protein modeling, prediction and analysis. Nat Protoc 10:845–858. https://doi.org/10.1038/nprot.2015.053

Kovacic F, Babic N, Krauss U, Jaeger KE (2019) Classification of lipolytic enzymes from bacteria. In: Rojo F (ed) Aerobic utilization of hydrocarbons, oils, and lipids. Hand book of hydrocarbon and lipid microbiology. Springer, Cham, pp 1–35. https://doi.org/10.1007/978-3-319-50418-6_39

Laemmli UK (1970) Cleavage of structural proteins during the assembly of the head of bacteriophage T4. Nature 227:680–685. https://doi.org/10.1038/227680a0

Laskowski RA, MacArthur MW, Moss DS, Thornton JM (1993) PROCHECK - a program to check the stereochemical quality of protein structures. J App Cryst 26:283–291. https://doi.org/10.1107/S0021889892009944

Lenfant N, Hotelier T, Velluet E, Bourne Y, Marchot P, Chatonnet A (2013) ESTHER, the database of the α/β-hydrolase fold superfamily of proteins: tools to explore diversity of functions. Nucleic Acids Res 41:D423–D429. https://doi.org/10.1093/nar/gks1154. )

Li X, Yu HY (2012) Characterization of a novel extracellular lipase from a halophilic isolate, Chromohalobacter sp LY7-8. African J Microbiol Res 6:3516–3522. https://doi.org/10.5897/AJMR12.071

Li X, Yu HY (2014) Characterization of an organic solvent-tolerant lipase from Haloarcula sp. G41 and its application for biodiesel production. Folia Microbiol 59:455–463. https://doi.org/10.1007/s12223-014-0320-8

Li X, Qian P, Wu SG, Yu HY (2014) Characterization of an organic solvent-tolerant lipase from Idiomarina sp. W33 and its application for biodiesel production using Jatropha oil. Extremophiles 18:171–178. https://doi.org/10.1007/s00792-013-0610-0

Madern D, Ebel C, Zaccai G (2000) Halophilic adaptation of enzymes. Extremophiles 4:91–98. https://doi.org/10.1007/s007920050142

Margesin R, Schinner F (2001) Potential of halotolerant and halophilic microorganisms for biotechnology. Extremophiles 5:73–83. https://doi.org/10.1007/s007920100184

Mesbah NM (2019) Covalent immobilization of a halophilic, alkalithermostable lipase LipR2 on Florisil® nanoparticles for production of alkyl levulinates. Arch Biochem Biophys 667:22–29. https://doi.org/10.1016/j.abb.2019.04.004

Moreno ML, Márquez MC, García MT, Mellado E (2016) Halophilic bacteria and archaea as producers of lipolytic enzymes. In: Rampelotto P (ed) Biotechnology of extremophiles: Grand challenges in biology and biotechnology, vol 1. Springer, Cham, pp 375–397. https://doi.org/10.1007/978-3-319-13521-2_13

Müller-Santos M, de Souza EM, Pedrosa Fde O, Mitchell DA, Longhi S, Carrière F, Canaan S, Krieger N (2009) First evidence for the salt dependent folding and activity of an esterase from the halophilic archaea Haloarcula marismortui. Biochim Biophys Acta 1791:719–729. https://doi.org/10.1016/j.bbalip.2009.03.006

Nawani N, Khurana J, Kaur J (2006) A thermostable lipolytic enzyme from a thermophilic Bacillus sp.: Purification and characterization. Mol Cell Biochem 290:17–22. https://doi.org/10.1007/s11010-005-9076-4

Oren A (2010) Industrial and environmental applications of halophilic microorganisms. Environ Technol 31:825–834. https://doi.org/10.1080/09593330903370026

Panaitov I, Verger R (2000) Enzymatic reactions at interfaces: interfacial and temporal organization of enzymatic lipolysis. In: Baszkin A, Norde W (eds) Physical chemistry of biological interfaces. Marcel Dekker, New York, pp 359–400

Perez D, Martin S, Fernandez-Lorente G, Filice M, Guisan JM, Ventosa A, Garcia MT, Mellado E (2011) A novel halophilic lipase, LipBL, showing high efficiency in the production of eicosapentaenoic acid (EPA). PLoS ONE 6:e23325. https://doi.org/10.1371/journal.pone.0023325. )

Pleiss J, Fischer M, Schmid RD (1998) Anatomy of lipase binding sites: the scissile fatty acid binding site. Chem Phys Lipids 93:67–80. https://doi.org/10.1016/s0009-3084(98)00030-9. )

Pleiss J, Fischer M, Peiker M, Thiele C, Schmid RD (2000) Lipase engineering database - understanding and exploiting sequence-structure-function relationships. J Mol Catal B- Enzym10:491–508. https://doi.org/10.1016/S1381-1177(00)00092-8

Rao L, Zhao X, Pan F, Li Y, Xue Y et al (2009) Solution behavior and activity of a halophilic esterase under high salt concentration. PLoS ONE 4:e6980. https://doi.org/10.1371/journal.pone.0006980

Salihu A, Alam MZ (2012) Production and applications of microbial lipases: a review. Sci Res Essays 7:2667–2677. https://doi.org/10.5897/SRE11.2023

Salihu A, Alam MZ (2015) Solvent tolerant lipases: A review. Process Biochem 50:86–96. https://doi.org/10.1016/j.procbio.2014.10.019

Sarikhan S, Azarbaijani R, Yeganeh LP, Fazeli AS, Amoozegar MA, Salekdeh GH (2011) Draft genome sequence of Nesterenkonia sp. strain F, isolated from Aran-Bidgol salt lake in Iran. J Bacteriol 193:5580–5580. https://doi.org/10.1128/JB.05808-11

Schreck SD, Grunden AM (2014) Biotechnological applications of halophilic lipases and thioesterases. Appl Microbiol Biotechnol 98:1011–1021. https://doi.org/10.1007/s00253-013-5417-5

Shafiei M, Ziaee AA, Amoozegar MA (2010) Purification and biochemical characterization of a novel SDS and surfactant stable, raw starch digesting, and halophilic α-amylase from a moderately halophilic bacterium, Nesterenkonia sp. strain F. Process Biochem 45:694–699. https://doi.org/10.1016/j.procbio.2010.01.003

Shafiei M, Ziaee AA, Amoozegar MA (2011) Purification and characterization of an organic-solvent-tolerant halophilic α-amylase from the moderately halophilic Nesterenkonia sp. strain F. J Ind Microbiol Biotechnol 38:275–281. https://doi.org/10.1007/s10295-010-0770-1

Shafiei M, Ziaee AA, Amoozegar MA (2012) Purification and characterization of a halophilic alpha-amylase with increased activity in the presence of organic solvents from the moderately halophilic Nesterenkonia sp. strain F. Extremophiles 16:627–635. https://doi.org/10.1007/s00792-012-0462-z

Sharma D, Sharma B, Shukla AK (2011) Biotechnological approach of microbial lipase: a review. Biotechnology 10:23–40. https://doi.org/10.3923/biotech.2011.23.40

Sheng J, Wang F, Wang H, Sun M (2012) Cloning, characterization and expression of a novel lipase gene from marine psychrotrophic Yarrowia lipolytica. Ann Microbiol 62:1071–1077. https://doi.org/10.1007/s13213-011-0348-9

Sinha R, Khare SK (2014) Protective role of salt in catalysis and maintaining structure of halophilic proteins against denaturation. Front Microbiol 5:165. https://doi.org/10.3389/fmicb.2014.00165

Sivakumar N, Li N, Tang JW, Patel BK, Swaminathan K (2006) Crystal structure of AmyA lacks acidic surface and provide insights into protein stability at poly-extreme condition. FEBS Lett 580:2646–2652. https://doi.org/10.1016/j.febslet.2006.04.017

Solat N, Shafiei M (2021) A novel pH and thermo-tolerant halophilic alpha-amylase from moderate halophile Nesterenkonia sp. strain F: gene analysis, molecular cloning, heterologous expression and biochemical characterization. Arch Microbiol 203:3641–3655. https://doi.org/10.1007/s00203-021-02359-7

Su H, Mai Z, Zhang S (2016) Cloning, expression and characterization of a lipase gene from marine bacterium Pseudoalteromonas lipolytica SCSIO 04301. J Ocean Univ China 15:1051–1058. https://doi.org/10.1007/s11802-016-3071-0

Tripathi R, Singh J, Bharti RK, Thakur IS (2014) Isolation, purification and characterization of lipase from Microbacterium sp. and its application in biodiesel production. Energy Procedia 54:518–529. https://doi.org/10.1016/j.egypro.2014.07.293

Van Den Burg B (2003) Extremophiles as a source for novel enzymes. Curr Opin Microbiol 6:213–218. https://doi.org/10.1016/S1369-5274(03)00060-2

Ventosa A, Nieto JJ, Oren A (1998) Biology of moderately halophilic aerobic bacteria. Microbiol Mol Biol Rev 62:504–544. https://doi.org/10.1128/MMBR.62.2.504-544.1998

Ventosa A, Sanches-Porro C, Martin S, Mellado E (2005) Halophilic archaea and bacteria as a source of extracellular hydrolytic enzymes. In: Gunde-Cimerman N, Oren A, Plemenitaš A (eds) Adaptation to life at high salt concentrations in archaea, bacteria, and eukarya. Cellular origin, life in extreme habitats and astrobiology, vol 9. Springer, Dordrecht, pp 339–354. https://doi.org/10.1007/1-4020-3633-7_23

Wang Y, Ma R, Li S, Gong M, Yao B, Bai Y, Gu J (2018) An alkaline and surfactant-tolerant lipase from Trichoderma lentiforme ACCC30425 with high application potential in the detergent industry. AMB Expr 8. https://doi.org/10.1186/s13568-018-0618-z

Widmann M, Juhl PB, Pleiss J (2010) Structural classification by the lipase engineering database: a case study of candida antarctica lipase A. BMC Genomics 11. https://doi.org/10.1186/1471-2164-11-123

Wiederstein M, Sippl MJ (2007) ProSA-web: interactive web service for the recognition of errors in three-dimensional structures of proteins. Nucleic Acids Res 35:W407–W410. https://doi.org/10.1093/nar/gkm290

Yang J, Yan R, Roy A, Xu D, Poisson J, Zhang Y (2015) The I-TASSER suite: protein structure and function prediction. Nat Methods 12:7–8. https://doi.org/10.1038/nmeth.3213

Acknowledgements

The authors would like to thank research council of Shahid Chamran University of Ahvaz for the financial support (code: 99/3/02/18287).

Funding

Shahid Chamran University of Ahvaz.

Author information

Authors and Affiliations

Contributions

Fatemeh Khara performed experiments and analyzed the results. Mohammad Shafiei supervised the study, designed the research and prepared the manuscript. Hamid Galehdari helped in conducting experiments.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Khara, F., Shafiei, M. & Galehdari, H. A novel acidic and SDS tolerant halophilic lipase from moderate halophile Nesterenkonia sp. strain F: molecular cloning, structure analysis and biochemical characterization. Biologia 77, 1135–1150 (2022). https://doi.org/10.1007/s11756-021-01005-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11756-021-01005-3