Abstract

An extracellular halophilic α-amylase was purified from Nesterenkonia sp. strain F using 80 % ethanol precipitation and Q-Sepharose anion exchange chromatography. The enzyme showed a single band with an apparent molecular weight of 110 kDa by SDS-PAGE. The amylase exhibited maximal activity at pH 7–7.5, being relatively stable at pH 6.5–7.5. Optimal temperature for the amylase activity and stability was 45 °C. The purified enzyme was highly active in the broad range of NaCl concentrations (0–4 M) with optimal activity at 0.25 M NaCl. The amylase was highly stable in the presence of 3–4 M NaCl. Amylase activity was not influenced by Ca2+, Rb+, Li+, Cs+, Mg2+ and Hg2+, whereas Fe3+, Cu2+, Zn2+ and Al3+ strongly inhibited the enzyme activity. The α-amylase was inhibited by EDTA, but was not inhibited by PMSF and β-mercaptoethanol. K m value of the amylase for soluble starch was 6.6 mg/ml. Amylolytic activity of the enzyme was enhanced not only by 20 % of water-immiscible organic solvents but also by acetone, ethanol and chloroform. Higher concentration (50 %) of the water-miscible organic solvents had no significant effect on the amylase activity. To the best of our knowledge, this is the first report on increased activity of a microbial α-amylase in the presence of organic solvents.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Microorganisms requiring extreme environments for growth are called extremophiles. Extreme environments include those with either high or low temperatures, high salinity and either high alkalinity or high acidity. Extremophiles are a source of enzymes with extreme stability and activity under conditions that were previously regarded as incompatible with biological molecules (Gomes and Steiner 2004). The microorganisms, which are specialized for living in hypersaline environments, are designated halophiles and can be a source of halophilic enzymes (Ventosa and Nieto 1995). Being intrinsically stable and active at high salt concentrations, halophilic enzymes offer important potential biotechnological applications, such as food processing, environmental bioremediation and biosynthetic processes. However, moderately halophilic bacteria that grow optimally in media containing 3–15 % NaCl, might serve as a source of enzymes with novel activities and applications (Ventosa et al. 1998).

α-amylases are a class of hydrolases widely distributed in microbes, plants and animals. They can specifically cleave the O-glycosidic bonds in starch. These enzymes are one of the most important industrial enzymes that have a wide variety of applications ranging from food, fermentation, and textile to paper industries (Pandey et al. 2000). Amylases constitute 25 % of the sales in enzyme market (Burhan et al. 2003). The α-amylases with desirable properties such as high pH stability, thermostability, raw starch digestibility and halophilicity can be very useful in related applications. Due to increasing demand for these enzymes in various industries, there is enormous interest in developing new enzymes with better properties suitable for industrial applications and their cost effective isolation techniques (Pandey et al. 2000). In this respect, halophilic amylases have been isolated and characterized from various halophilic bacteria (Prakash et al. 2009).

Technological utility of enzymes can be enhanced greatly by using them in organic solvents rather than their natural aqueous reaction media (Klibanov 2001). Despite the industrial advantages of using organic solvents as enzymatic reaction media compared to aqueous systems, native enzymes almost universally are easily denaturated and exhibit low activities and/or stabilities in the presence of organic solvents (Doukyu and Ogino 2010). Organic solvents may distort enzyme molecules or may become competitive inhibitors through specific interactions with enzymes, which could lead to changes in the reaction kinetics and substrate specificity. Several methods for stabilizing enzymes in organic media such as immobilization, chemical or physical modification and molecular engineering have been used to obtain organic solvent-stable enzymes (Ogino and Ishikawa 2001). Natural enzymes with high activity and stability in the presence of organic solvents without the need for special stabilization could be very useful for biotechnological applications employing organic solvents as reaction media (Ogino et al. 2000). Halophilic proteins compete effectively with salts for hydration, a property that may result in resistance to other low-water-activity environments, such as in the presence of organic solvents (Marhuenda-Egea and Bonete 2002). Therefore, study on isolation of halophilic enzymes from halophilic bacteria may lead to obtain new enzymes with organic solvent-stable property. However, there are only few reports on the organic solvent-tolerant halophilic enzymes from halophilic microorganisms. Organic solvent-tolerant halophilic proteases were isolated from Salinivibrio sp. strain AF-2004 and Streptomyces clavuligerus strain Mit-1 (Karbalaei-Heidari et al. 2007; Thumar and Singh 2009). Also, a halophilic amylase with organic solvent-tolerant property from the extremely halophilic Haloarcula sp. strain S-1 has been reported (Fukushima et al. 2005). In the previous studies, we purified and characterized two halophilic α-amylase with raw starch digesting property (Shafiei et al. 2010) and organic solvent tolerance (Shafiei et al. 2011) from Nesterenkonia sp. strain F. Although organic solvent-tolerant α-amylases were reported from some microorganisms (Doukyu and Ogino 2010), to the best of our knowledge, there has been no report about the increased activity of α-amylase in the presence of organic solvents. In this paper, we report the purification processes and biochemical characterization of another halophilic α-amylase from the moderately halophile bacteria Nesterenkonia sp. strain F and describe the effect of organic solvents on the activity of the enzyme.

Materials and methods

Bacterial strain and production

Nesterenkonia sp. strain F, the amylase producing strain, was isolated from Aran-Bidgol Lake in the center of Iran. The culture medium used for amylase production of the strain contained (w/v): 1 % peptone, 0.5 % yeast extract, 1 % soluble starch and 7.5 % NaCl (pH 7.0). Amylase production was carried out by inoculating 0.5 ml of the strain suspension containing 1.5 × 108 cfu/ml in 20 ml culture medium in a 100 ml conical flask and incubated at 33 °C on a rotary shaker at 220 rpm for 24 h. 1 ml of the pre-culture was used to inoculate 500 ml conical flasks containing 100 ml of the culture medium and cultured aerobically for 72 h at the same condition as pre-culture medium. The culture was centrifuged at 25000×g for 80 min at 4 °C to remove the cells and the supernatant was used for amylase purification.

Amylase purification

All purification steps were carried out at 4 °C. To the clear supernatant, ethanol previously chilled to −20 °C was added slowly with continuous stirring to the final concentration of 80 % and solution was left at 4 °C for 2 h. The precipitate was collected by centrifugation for 20 min at 12000×g and dissolved in a minimum volume of buffer A (20 mM Tris–HCl, pH 7.5 containing 10 mM CaCl2 and 0.3 M NaCl). The concentrated enzyme was dialyzed against the same buffer overnight. This solution was loaded on a Q-Sepharose HP column (1.6 cm × 14 cm) previously equilibrated with buffer A. The column was washed with the same buffer until no absorbance at 280 nm was detected in the eluent. The absorbed proteins were then eluted with a stepwise gradient of NaCl concentrations (0.325, 0.35, 0.375 and 0.4 M) in 20 mM Tris–HCl, pH 7.5 containing 10 mM CaCl2 at a flow rate of 1 ml/min. Fractions containing amylase activity were pooled and concentrated by ultrafiltration (Centricon, Amicon, USA). The purified enzyme was used for further analysis.

Amylase assay

Amylase activity was determined by the soluble starch hydrolysis method as described previously (Shafiei et al. 2010). In brief, 450 μl of 1 % (w/v) starch in 20 mM Tris–HCl, pH 7.0 containing 0.25 M NaCl (buffer B) was maintained at 45 °C for 5 min, then 50 μl of appropriately diluted enzyme sample was added. After 15 min, the enzyme reaction was stopped by the addition of dinitrosalicylic acid (DNS) solution. After appropriate dilution, the reducing sugar in the dilute was determined using the DNS method (Bernfeld 1955). One unit of amylase activity was defined as the amount of enzyme that produced 1 μmol reducing sugars as maltose per minute in the reaction. The specific activity is expressed in the units of enzyme activity per milligram of protein.

Determination of protein concentration

Protein concentration was measured by the method of Bradford (1976). Bovine serum albumin was used as standard.

Polyacrylamide gel electrophoresis

Sodium dodecyl sulfate-polyacrylamide gel electrophoresis (SDS-PAGE) was used to determine protein purity and the molecular mass of the purified enzyme under denaturing conditions using a 12 % acrylamide gel containing 0.1 % SDS at 4 °C, as described by Laemmli (1970). After the electrophoresis, protein bands were stained with Coomassie Brilliant Blue R-250. A ready-to-use molecular weight marker (Fermentas; SM #0431) was used as standard.

Characterization of the amylase

Effect of pH on activity and stability

The pH profile and pH optima of the enzyme were determined at 45 °C by varying the pH of the reaction mixtures using the following mix buffer (100 mM): sodium acetate (pH 4.0–5.5), sodium phosphate (pH 6.0–7.5), Tris–HCl (pH 8.0–9.0), and glycine–NaOH (pH 9.5–12.0). For measurement of pH stability, the enzyme was incubated at 25 °C for 30 min in the mix buffer at different pH and the residual activity was determined under enzyme assay conditions.

Effect of temperature on activity and stability

The effect of temperature on the enzyme activity was studied by incubating the reaction mixture at various temperatures ranging from 15 to 70 °C. Thermostability of the amylase was determined by measuring the residual activity after 30 min pre-incubation of the enzyme solution at temperatures ranging from 40 to 65 °C.

Effect of NaCl concentrations on activity and stability

The effect of NaCl concentrations on enzyme activity was tested by measuring the activity in the reaction mixture containing different NaCl concentrations from 0 to 4 M. For determination of salt stability, the amylase was incubated at 25 °C in 20 mM Tris–HCl, pH 7.0 containing various NaCl concentrations from 0 to 4 M for 30 min. The residual activity was measured using the standard assay as mentioned above.

Effect of different metal ions and chemical reagents

In order to determine the effect of different metal ions on the enzyme activity, the enzyme assay was performed in the reaction mixture as described above in the presence of various metal ions at a final concentration of 10 mM. The activity of the enzyme without any additives was taken as 100 %. The influence of EDTA, PMSF and β-mercaptoethanol (10 mM) on amylase activity was studied by pre-incubating the enzyme with the compounds for 30 min at 25 °C. Then, the remaining activity was determined using the standard enzyme assay. The activity assayed in the absence of inhibitor was taken as 100 %.

Determination of the V max and K m values

The kinetic parameters V max and K m were determined by incubating the amylase with various concentrations of soluble starch ranging from 0.25 to 4 % (w/v) in buffer B for 15 min at 45 °C. V max and K m values were obtained from Lineweaver–Burk plot.

Chromatographic analysis of the starch hydrolysis products

Products released through hydrolysis of soluble starch by the amylase were identified by thin-layer chromatography (TLC) with Silica gel plate (silica gel 60, Merck, Germany). The purified amylase was incubated with 1 % soluble starch in buffer B at 45 °C. Samples were removed after 15, 30, 60, 120 min and 24 h incubation, and hydrolysis was stopped by heating the samples in boiling water for 10 min. Then, the products were detected by TLC, as described previously (Shafiei et al. 2010).

Organic solvent stability of the amylase

The stability of the purified amylase was determined in the presence of various organic solvents. 0.25 ml of organic solvent was added to 1 ml of the amylase solution in a 2.5-ml microcentrifuge tube with a screw cap. The mixture was shaken at 150 rpm for 2 h at 25 °C. Then, the remaining activity was measured under the enzyme assay conditions. The effect of the solvents at concentration of 50 % on amylase stability was also studied in the same manner.

Results

Microorganism and amylase production

The strain F isolated from Aran-Bidgol Lake, the largest hypersaline seasonal playa in Iran. According to its physicochemical properties, this inland lake was classified as thalassohaline (Makhdoumi-Kakhki et al. 2012). Maximal growth of strain F occurred at 33 °C and pH of 7.0. The strain grew well at various NaCl concentrations ranging from 3 to 17 % with an optimum growth at 7.5 % (w/v). Maximum amylase production was achieved at pH 7.0 and 33 °C in medium containing 7.5 % (w/v) NaCl (data not shown).

Purification of the amylase

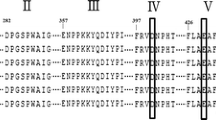

Simple purification of the amylase from Nesterenkonia sp. strain F was carried out by ethanol precipitation and ion exchange chromatography method. The ethanol precipitated supernatant was applied to the Q-Sepharose ion exchange chromatography column and the amylase was eluted by NaCl treatment at concentration of 0.375 M. The simple purification method gave a 7.2 yield with a specific activity of 158 U/mg and 9.5-fold purification. Purification results are summarized in Table 1. The electrophoresis behavior of the crude extract and the purified amylase is shown in Fig. 1. One band with a molecular weight of approximately 110 kDa was detected on the gel after Q-Sepharose ion exchange column chromatography (lane 3), indicating the homogeneity of the purified enzyme.

SDS-PAGE analysis of the purified α-amylases from Nesterenkonia sp. strain F. Lane 1 molecular mass markers, lane 2 the 100 kDa α-amylase purified by Sephacryl S-200 and Q-Sepharose (Shafiei et al. 2010), lane 3 the 110 kDa α-amylase purified by Q-Sepharose column, lane 4 the 57 kDa α-amylase purified by Sephacryl S-200 and Q-Sepharose (Shafiei et al. 2011), lane 5 ethanol precipitated crud extract

Characterization of the amylase

Influence of pH, temperature and NaCl concentration on the activity and stability

The effect of pH on amylase activity and stability is shown in Fig. 2. The optimal activity of the enzyme was at pH = 7–7.5. Activity dropped off quickly in more acidic and alkaline conditions, as more than 80 and 65 % of activity was lost at pH 6 and 8.5, respectively. The enzyme was stable in a pH range of 6.5–7.5 after 30 min pre-incubation at 25 °C. The enzyme retained 65 % of its original activity at pH 5.5 and 8, while the residual activity of the enzyme at pH 5 and 9 was about 30 %. The temperature profile of amylase activity is shown in Fig. 3. The amylase displayed optimal activity at 45–50 °C and the enzyme retained 45 % of its maximal activity at 55 °C. To examine thermostability, the amylase was incubated for 30 min at various temperatures and the remaining activity was measured. As shown in Fig. 3, the enzyme was stable at 45 °C and retained 60 % of its activity at 50 °C. At 55 °C, the enzyme retained only 24 % of its original activity and the activity was completely lost after 30 min incubation at 60 °C. Activity of the amylase was also measured in the presence of NaCl concentration range of 0–4 M and the enzyme showed maximum activity at 0.25 M NaCl (Fig. 4). The amylase retained 62 and 65 % of activity in the presence of 0 and 4 M NaCl, respectively. To examine salt stability, the amylase was incubated for 30 min at various NaCl concentration and residual activity was measured. Results in Fig. 4 revealed that the enzyme was stable at NaCl concentration of 3–4 M and retained 80 % of its activity in the presence of 0.75 M NaCl. However, more than 61 % of the enzyme activity could be detected even at 0 M NaCl.

Effect of pH on the amylase activity (filled circle) and stability (open circle). The relative activities were defined as the percentage of the maximum activity detected in the assay. For determining pH stability, the amylase was incubated at different pH for 30 min at 25 °C and the remaining activity was determined under standard assay. Values are mean ± SD of three independent experiments

Effect of temperature on the amylase activity (filled circle) and stability (open circle). The relative activities were defined as the percentage of the maximum activity detected in the assay. For determining thermostability, the amylase was incubated for 30 min at different temperature and cooled for 30 min on ice. The remaining activity was determined under standard assay. Values are mean ± SD of three independent experiments

Effect of NaCl concentrations on the amylase activity (filled circle) and stability (open circle). The activity was measured in the reaction mixture containing various concentrations of NaCl. The relative activity was defined as the percentage of the maximum activity detected in each assay. For determining salt stability, the amylase was incubated at 25 °C in 20 mM Tris–HCl, pH 7.0 containing various concentrations of NaCl for 30 min and the remaining activity was determined under standard assay. Values are mean ± SD of three independent experiments

Influence of different metal ions and chemical reagents on the amylase

The influence of various metal ions on the activity of Nesterenkonia sp. strain F α-amylase is presented in Table 2. Metal ions have different effects on the enzyme activity. None of the metal ion stimulated enzyme activity. Fe3+, Cu2+, Al3+ and Zn2+ completely inhibited amylase activity. Ca2+, Rb+, Li+, Cs+ and Mg2+ had no significant effect on the enzyme activity. However, the addition of 10 mM of Mn2+ and Ni2+ reduced the activity to 88 and 33.5 %, respectively. Hg2+ ion, which inactivates most amylases at 0.1 mM (Gupta et al. 2003), did not have a strong inhibitory effect on this amylase; 84 % activity remained at the concentration of 10 mM. When the amylase was incubated with 10 mM EDTA, the enzyme retained 54 % of its original activity, whereas PMSF- and β-mercaptoethanol-treated amylase did not show any inhibition.

Kinetic parameters and hydrolysis products

The α-amylase produced by Nesterenkonia sp. strain F showed Michaelis-Menten type kinetics with soluble starch. A Lineweaver–Burk plot indicates that this enzyme has a K m of 6.6 mg of starch per milliliter and a V max of 1.07 mg of maltose per milliliter per min (Fig. 5). The hydrolysis products of starch were separated and identified by TLC (Fig. 6). When the amylase was incubated with soluble starch (1 % w/v), large maltoligosaccharides with the main products of maltotriose and maltotetraose were produced during the early stage of reaction. However, main products of the 24 h reaction were maltose, maltotriose and maltotetraose.

Thin-layer chromatography analysis of the products from starch hydrolysis by the amylase. Reaction products for 15 min (lane 2), 30 min (lane 3), 1 h (lane 4), 2 h (lane 5) and 24 h (lane 6) were detected by TLC as described in "Materials and methods". Lane 1 indicates the standard sugars: glucose (G1), maltose (G2), maltotriose (G3), maltotetraose (G4), maltopentaose (G5) and maltohexaose (G6)

Organic solvent stability of the amylase

The effects of organic solvents on the stability of the amylase were determined. The amylase was incubated in the presence of 20 % of various organic solvents at 25 °C with shaking for 2 h and the remaining activity was measured. The data in Table 3 elucidated that this enzyme was highly stable to all organic solvents tested and it showed only 9 % loss of activity in the presence of 1-butanol. Cyclohexanol had no significant effect on the enzyme activity. Other organic solvents stimulated amylolytic activity of the enzyme and the highest activity was observed in the presence of cyclohexane (increased activity of 25 %). Stability of the amylase in the presence of 50 % of the organic solvents was also tested. The amylase activity was not significantly influenced by 50 % each of ethanol, acetone and cyclohexanol. The amylase was found to be relatively stable to 1-butanol as enzyme retained 80 % of its activity when incubated in the presence of 50 % of this organic solvent. Other water-immiscible organic solvents had activating effect on the purified enzyme, and maximum activity (157 %) was observed in the presence of 50 % toluene.

Discussion

Halophilic enzymes from moderate halophiles present a great biotechnological interest, since they are stable without salt and active in the presence of high salt concentration (Ventosa et al. 1998). This paper describes the purification and characterization of the α-amylase secreted by the moderately halophilic bacterium, Nesterenkonia sp. strain F. The α-amylase was purified using very simple method; ethanol precipitation followed by ion exchange chromatography. SDS-PAGE analysis showed that single band with amylase activity was eluted from Q-Sepharose column with 0.375 M NaCl. Thus, there is no need to extra purification steps and the α-amylase purification procedure is a cost effective and economical protocol. The molecular weight of this α-amylase was calculated to be 110 kDa on reducing SDS-PAGE (Fig. 1), indicating that the enzyme is a monomer. Similar molecular weight has not been reported for other halophilic α-amylases. However, the other α-amylases from strain F have molecular weight of 57 and 100 kDa (Shafiei et al. 2010, 2011) (see Fig. 1). The molecular weights of above 100 kDa have been reported for α-amylases from various microorganisms (Burhan et al. 2003).

The optimal pH range for the catalytic reaction ranged from 7 to 7.5. Similar pH optima have been reported for α-amylases from Halomonas meridiana (Coronado et al. 2000) and Micrococcus sp. 4 (Khire 1994). The pH stability of 6.5–7.5 found for the α-amylase is similar to that found for the halophilic α-amylase from Nesterenkonia halobia (Onishi and Sonoda 1979). Temperature studies revealed that the optimal temperature for the α-amylase activity was 45–50 °C and that for stability was 45 °C. This behavior is different to that exhibited by the other α-amylase purified from strain F, with an optimum temperature for activity at 45 °C and thermostability at 55 °C (Shafiei et al. 2010). The α-amylases from other halophilic microorganisms have higher optimal temperature for activity. Thermostability of the α-amylase may favor its application in processes that require complete inactivation of enzyme with increasing temperature process, i.e., in the baking industry (Coronado et al. 2000). The α-amylase produced by strain F showed maximum activity at 0.25 M NaCl. This salt optimum activity is similar to that observed for amylase produced by moderately halophilic Nesterenkonia halobia (Onishi and Sonoda 1979). Also, the α-amylase was active over a wide range of the salt concentrations, as it shows 62 and 65 % activity at 0 and 4 M NaCl, respectively. This property is an important point from the view of biotechnology and helps to use the α-amylase in both situations in industrial processes. Halophilic α-amylases from various halophiles exhibited similar activities (Prakash et al. 2009).

Most of the halophilic enzymes studied are inactivated when the NaCl concentration decreases to less than 2 M (Madern et al. 2000). However, the amylase from strain F is stable and does not unfold at low salt concentration. The high stability of the α-amylase at 0 M of salt concentrations, as well as the broad range of salt concentrations it is able to endure, may be related to fact that it is an excreted enzyme and has function under high salt conditions that lead to precipitation or denaturation of most proteins (Danson and Hough 1997). Similar salt stability has been observed in halophilic α-amylases from Bacillus sp. TSCVKK (Kiran and Chandra 2008) and Archaeon Haloarcula hispanica (Hutcheon et al. 2005). In contrast, halophilic α-amylases with complete inactivation in the absence of NaCl have been reported from various halophiles (Fukushima et al. 2005; Kobayashi et al. 1992; Perez-Pomares et al. 2003).

Influence of metal ions on the activity of the enzyme revealed that the amylase did not have an obligate requirement for divalent metal ions to be active and its activity was not stimulated in the presence of metal ions. However, the α-amylase was inhibited by 10 mM of EDTA. This loss of activity has been related to the conserved calcium ion tightly bounded to the enzyme molecule and affected on the amylase conformation. Thus, similar to other α-amylases, the amylase is a metalloenzyme (Nielsen and Borchert 2000). No inhibitory effect of Hg2+ on the amylase activity indicating that indole amino acid residues are not essential for the enzyme function (Li et al. 2007). Similar activity has been reported for halophilic α-amylase from Haloalkaliphilic archaebacterium Natronococcus sp. strain Ah-36 (Kobayashi et al. 1992). This finding has not been observed for other α-amylases purified from strain F. β-mercaptoethanol had no inhibitory effect on the enzyme activity, indicating that disulfide bonds do not exist in amylase structure. The K m value of the α-amylase with soluble starch as substrate (6.6 mg/ml) indicates that compared to the other halophilic α-amylase from strain F (Shafiei et al. 2010, 2011), the enzyme has lower affinity (higher K m) for starch. However, the K m value was within the range of many α-amylases (0.35–11.66 mg/ml) (Najafi and Kembhavi 2005). It is difficult to compare the kinetic values of amylases obtained by other workers in view of the usage of different starch substrates or assay conditions. The earlier α-amylase purified from strain F produces maltose, maltotriose and maltotetraose from early stages of the reaction (Shafiei et al. 2010) and the other α-amylase only produces maltotriose and maltotetraose as the main end products from soluble starch (Shafiei et al. 2011). The α-amylase described here did not produce maltose at the early stages of the reaction and it was observed as one of the main end products. The hydrolysis pattern presented by the amylase shows that it is an α-amylase. With respect to the main end products, this amylase can be recommended for liquefication of starch and production of oligosaccharides with different sizes. Halophilic α-amylases from other halophiles produce glucose, maltose, maltotriose and maltotetraose as the main products from the first stages of reaction and in increasing amounts as the reaction proceeds (Kobayashi et al. 1992; Onishi and Sonoda 1979; Prakash et al. 2009).

The data in Table 3 show that the α-amylase was not only stable but also its activity was increased in the presence of 20 % of all organic solvents tested, with the exception of 1-butanol. The stability and increased activity of the α-amylase in aqueous-organic mixtures indicated that the solvents maintain the enzyme in open conformation; the lid of the enzyme does not cover the active site crevice, and thus keeping maintains the flexible conformation. Also, this enzyme forms multiple hydrogen bonds with water either on the surface or on the catalytic site of the enzyme for structural flexibility and conformational mobility for optimal activity (Klibanov 2001). The effect of higher concentrations (50 %) of the solvents on the stability of the enzyme revealed that hydrophilic solvents had no significant effect on the amylase activity and the activity was decreased in the presence of 1-butanol. In contrast, hydrophobic solvents increased the activity of the amylase. Hydrophobic solvents are usually superior to hydrophilic ones as enzymatic reaction media because the latter have a greater tendency to strip tightly bound water (which is essential for catalytic activity) from the enzyme molecule. So, the enzyme is less stable in higher concentration of hydrophilic solvents and there may be change in the conformation of the enzyme molecule (Serdakowski and Dordick 2008). Highly polar solvents with log P ow values less than 2 inactivate most enzymes through structural denaturation (Laane et al. 1987). The α-amylase from Brachybacterium sp. strain LB 25 partially inactivated by the addition of 20 % water-miscible organic solvents, such as acetone, ethanol and 2-propanol (Doukyu et al. 2007). The α-amylase from extremely halophilic archaea, Haloarcula sp. strain S-1, retained 70 % of its activity after 1 h incubation in the presence of water-insoluble organic solvents and chloroform, and was completely inhibited by water-soluble organic solvents (Fukushima et al. 2005). To the best of our knowledge, this is the first report on a microbial α-amylase with increased activity in the presence of organic solvents. The α-amylase should be useful for technological applications with organic solvents. In particular, this enzyme can be used for the economical enzymatic hydrolysis of starch in the presence of high salt concentrations and/or organic solvents.

References

Bernfeld P (1955) Amylase α and β. Methods Enzymol 1:3

Bradford M (1976) A rapid and sensitive for the quantitation of microgram quantities of protein utilizing the principle of protein-dye binding. Anal Biochem 72:7

Burhan A, Nisa U, Gokhan C, Omer C, Ashabil A, Osman G (2003) Enzymatic properties of a novel thermostable, thermophilic, alkaline and chelator resistant amylase from an alkaliphilic Bacillus sp isolate ANT-6. Process Biochem 38:1397–1403

Coronado M, Vargas C, Hofemeister J, Ventosa A, Nieto JJ (2000) Production and biochemical characterization of an α-amylase from the moderate halophile Halomonas meridiana. FEMS Microbiol Lett 183:67–71

Danson MJ, Hough DW (1997) The structural basis of protein halophilicity. Comp Biochem Physiol a-Physiol 117:307–312

Doukyu N, Ogino H (2010) Organic solvent-tolerant enzymes. Biochem Eng J 48:270–282

Doukyu N, Yamagishi W, Kuwahara H, Ogino H, Furuki N (2007) Purification and characterization of a maltooligosaccharide-forming amylase that improves product selectivity in water-miscible organic solvents, from dimethylsulfoxide-tolerant Brachybacterium sp. strain LB25. Extremophiles 11:781–788

Fukushima T, Mizuki T, Echigo A, Inoue A, Usami R (2005) Organic solvent tolerance of halophilic α-amylase from a Haloarchaeon, Haloarcula sp. strain S-1. Extremophiles 9:85–89

Gomes J, Steiner W (2004) The biocatalytic potential of extremophiles and extremozymes. Food Technol Biotechnol 42:223–235

Gupta R, Gigras P, Mohapatra H, Goswami VK, Chauhan B (2003) Microbial α-amylases: a biotechnological perspective. Process Biochem 38:1599–1616

Hutcheon GW, Vasisht N, Bolhuis A (2005) Characterisation of a highly stable α-amylase from the halophilic archaeon Haloarcula hispanica. Extremophiles 9:487–495

Karbalaei-Heidari H, Ziaee A–A, Amoozegar M (2007) Purification and biochemical characterization of a protease secreted by the Salinivibrio sp. strain AF-2004 and its behavior in organic solvents. Extremophiles 11:237–243

Khire JM (1994) Production of moderately halophilic amylase by newly isolated Micrococcus sp. 4 from a salt-pan. Lett Appl Microbiol 19:210–212

Kiran KK, Chandra TS (2008) Production of surfactant and detergent-stable, halophilic, and alkalitolerant alpha-amylase by a moderately halophilic Bacillus sp. strain TSCVKK. Appl Microbiol Biotechnol 77:1023–1031

Klibanov AM (2001) Improving enzymes by using them in organic solvents. Nature 409:241–246

Kobayashi T, Kanai H, Hayashi T, Akiba T, Akaboshi R, Horikoshi K (1992) Haloalkaliphilic maltotriose-forming α-amylase from the archaebacterium Natronococcus sp. strain Ah-36. J Bacteriol 174:3439–3444

Laane C, Boeren S, Vos K, Veeger C (1987) Rules for optimization of biocatalysis in organic solvents. Biotechnol Bioeng 30:81–87

Laemmli U (1970) Cleavage of structural proteins during the assembly of the head of bacteriophage T4. Nature 227:6

Li H, Chi Z, Wang X, Duan X, Ma L, Gao L (2007) Purification and characterization of extracellular amylase from the marine yeast Aureobasidium pullulans N13d and its raw potato starch digestion. Enzyme Microbial Technol 40:1006–1012

Madern D, Ebel C, Zaccai G (2000) Halophilic adaptation of enzymes. Extremophiles 4:91–98

Makhdoumi-Kakhki A, Amoozegar MA, Kazemi B, Paic L, Ventosa A (2012) Prokaryotic diversity in aran-bidgol salt lake, the largest hypersaline playa in Iran. Microbes Environ 27:87–93

Marhuenda-Egea FC, Bonete MJ (2002) Extreme halophilic enzymes in organic solvents. Curr Opin Biotechnol 13:385–389

Najafi MF, Kembhavi A (2005) One step purification and characterization of an extracellular α-amylase from marine Vibrio sp. Enzyme Microb Technol 36:535–539

Nielsen JE, Borchert TV (2000) Protein engineering of bacterial α-amylases. Biochim Biophys Acta 1543:253–274

Ogino H, Ishikawa H (2001) Enzymes which are stable in the presence of organic solvents. J Biosci Bioeng 91:109–116

Ogino H, Nakagawa S, Shinya K, Muto T, Fujimura N, Yasuda M, Ishikawa H (2000) Purification and characterization of organic solvent-stable lipase from organic solvent-tolerant Pseudomonas aeruginosa LST-03. J Biosci Bioeng 89:451–457

Onishi H, Sonoda K (1979) Purification and some properties of an extracellular amylase from a moderate halophile, Micrococcus halobius. Appl Environ Microbiol 38:616–620

Pandey A, Nigam P, Soccol CR, Soccol VT, Singh D, Mohan R (2000) Advances in microbial amylases. Biotechnol Appl Biochem 31:135–152

Perez-Pomares F, Bautista V, Ferrer J, Pire C, Marhuenda-Egea FC, Bonete MJ (2003) α-Amylase activity from the halophilic archaeon Haloferax mediterranei. Extremophiles 7:299–306

Prakash B, Vidyasagar M, Madhukumar MS, Muralikrishna G, Sreeramulu K (2009) Production, purification, and characterization of two extremely halotolerant, thermostable, and alkali-stable α-amylases from Chromohalobacter sp. TVSP 101. Process Biochem 44:210–215

Serdakowski AL, Dordick JS (2008) Enzyme activation for organic solvents made easy. Trends Biotechnol 26:48–54

Shafiei M, Ziaee A–A, Amoozegar MA (2010) Purification and biochemical characterization of a novel SDS and surfactant stable, raw starch digesting, and halophilic α-amylase from a moderately halophilic bacterium Nesterenkonia sp. strain F. Process Biochem 45:694–699

Shafiei M, Ziaee AA, Amoozegar MA (2011) Purification and characterization of an organic-solvent-tolerant halophilic alpha-amylase from the moderately halophilic Nesterenkonia sp. strain F. J Ind Microbiol Biotechnol 38:275–281

Thumar JT, Singh SP (2009) Organic solvent tolerance of an alkaline protease from salt-tolerant alkaliphilic Streptomyces clavuligerus strain Mit-1. J Ind Microbiol Biotechnol 36:211–218

Ventosa A, Nieto JJ (1995) Biotechnological applications and potentialities of halophilic microorganisms. World J Microbiol Biotechnol 11:85–94

Ventosa A, Nieto JJ, Oren A (1998) Biology of moderately halophilic aerobic bacteria. Microbiol Mol Biol Rev 62:504–544

Author information

Authors and Affiliations

Corresponding author

Additional information

Communicated by A. Driessen.

Rights and permissions

About this article

Cite this article

Shafiei, M., Ziaee, AA. & Amoozegar, M.A. Purification and characterization of a halophilic α-amylase with increased activity in the presence of organic solvents from the moderately halophilic Nesterenkonia sp. strain F. Extremophiles 16, 627–635 (2012). https://doi.org/10.1007/s00792-012-0462-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00792-012-0462-z