Abstract

Isoxazole, pyrazole, pyran, pyridine and pyrimidine derivatives of fatty acids were synthesized as surface and bioactive heterocycles. Hydroxylation of these intermediates by propylene oxide produced easy-to-handle, efficient and quickly biodegradable surface active agents, which revealed the importance of their applications in safety for humans as well as the environment. These compounds showed good activity against bacteria and fungi, showing promise in applications of drugs, cosmetics, and pesticides.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

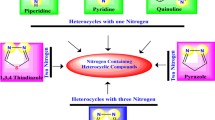

Heterocyclic compounds are playing an important role in the discovery and design of new pharmaceutical active moieties [1, 2]. Chalcone derivatives, one of the main categories of natural products found in fruits and vegetables, spices, food, has been reported to possess many of the activities of antimicrobial as anti-inflammatory [3, 4], antibacterial [5, 6], anti-fungal [7, 8] and antitumor actions [9]. These important characteristics of chalcones are due to their ability to react as intermediates for the preparation of various of antimicrobial heterocyclic derivatives [10, 11]. The heteroatoms in the structure explain various applications, for example, in biological science [12]. Chalcone derivatives are acknowledged to be a tool in the synthesis of pharmacologically interesting heterocyclic systems such as pyrazoles, which are attracting interest due to their bioactivity [13]. Oleochemicals are necessary to a variety of applications such as plastics, surface treatments, paints, lubricants, pharmaceuticals, pesticides, detergents, soaps, textiles, and cosmetic [14–20]. Extending our past research in this area [21–26], we sought to prepare some new isoxazole, pyrazole, puran, pyridine and pyrimidine derivatives and evaluating their surface and biological activities to determine suitability for the applications above.

Experimental Section

An FTIR 8300 Shimadzu spectrophotometer (ν/cm−1) was used to record the infrared spectra using KBr discs. A Bruker AC300 spectrometer (600 MHz for proton and 150 MHz for carbon) was used to determine the nuclear magnetic resonance spectra using solvent as (CDCl3). The mass spectra were recorded on a GC/MS Agilent MSD (7890A/5975C) USA at 70 eV, located at Core Labs & Major Facilities, King Abdullah University of Science and Technology, Saudi Arabia. A Gallenkamp apparatus was used to record the melting points using the open capillary method. CHNS elemental analyzer EA3000 EURO VECTOR was used for the elemental analysis. Biological activity was screened using the disc diffusion technique at the Microbiology Department, Faculty of Applied Science, Umm Al-Qura University, Saudi Arabia.

Synthesis of N-(4-(3-Phenylacryloyl)phenyl)stearamide (3)

A solution of compound 2 (0.8 g, 2 mmol) (prepared by stirring of p-aminoacetophenone with stearoyl chloride 1 in dry acetone at −5 °C, in the presence of triethylamine) in ethanol (20 mL) and sodium hydroxide (2 N) was added dropwise to benzaldehyde (0.21 g, 2 mmol) over a period of 1 h [27]. The reaction mixture was stirred at 60 °C for 24 h, and then cooled and poured onto crushed ice with a few drops of hydrochloric acid. The resulting product was filtered and crystallized from EtOH. Yellow crystals were formed. Yield (0.65 g, 82%), m.p. 111–113 °C, IR (ν/cm−1); 3320 (NH), 2847–2914 (CH-aliph), 1677, 1657 (CO) and 1599 (C=C). 1H NMR (δ, ppm): 8.00 (s, 1H, NH), 7.25–7.47 (m, 9H, ArH), 6.93, 6.89 (2d, 1H, CH=CH), 1.26–1.76 (s, 32H, CH2 aliph), and 0.89 (t, 3H, CH3). Anal. Calc. (%) for C33H47NO2 (489.73); C, 80.93; H, 9.67; N, 2.86. Found C, 80.69; H, 9.45; N, 3.07.

Synthesis of N-(4-(5-Cyano-6-oxo-4-phenyl-1,6-dihydropyridine-2-yl)phenyl)stearamide (4)

Equimolar amounts of chalcone 3 (1 g, 2 mmol), ethyl cyanoacetate (0.22 g, 2 mmol) with ammonium acetate (1 g) in EtOH (25 mL) were refluxed for 8 h, and then poured upon ice water. The separated solid was filtered and crystallized from benzene. A pale yellow powder was formed. Yield (0.74 g, 74%), m.p. 148–150 °C, IR (ν/cm−1); 3324, 3245 (2NH), 2848–2915 (CH-aliph), 2202 (CN), and 1692, 1677 (CO). 1H NMR (δ, ppm): 7.95, 7.67 (s, 2H, 2NH), 6.89–7.65 (m, 9H, ArH), 6.78 (s, 1H, CH of pyridine ring), 1.26–1.76 (s, 32H, CH2 aliph), and 0.79 (t, 3H, CH3), 13C NMR: δ 178.22, 171.85 (2C=O), 165.63, 159.16 (2C-Ph of pyridine ring), 132.70, 130.27, 129.89, 129.79, 128.78, 128.56, 127.94, 125.92, 120.03 (carbons of aromatic), 118.79 (CN), 116.31 (C–CN), 114.55 (C-CPh of pyridine ring), 33.87, 31.95, 31.83, 29.72, 29.68, 29.50, 29.39, 29.27, 29.17, 29.11, 26.49, 25.47, 24.78, 22.72 (carbons of aliphatic side chain), 14.27 (terminal CH3). Mass spectrum (m/z, %) (M+−2) at (551, 4.3). Anal. Calc. (%) for C36H47N3O2 (553.78); C, 78.08; H, 8.55; N,7.59. Found C, 77.82; H, 8.31; N, 7.73.

Synthesis of N-(4-(6-Amino-5-cyano-4-phenylpyridine-2-yl)phenyl)stearamide (5)

A mixture of chalcone 3 (1 g, 2 mmol) in EtOH (15 mL) with ammonium acetate (1 g) and malononitrile (0.13 g, 2 mmol) was heated for 10 h, then poured onto ice water. The reaction mixture was filtered and crystallized from EtOH. A reddish yellow solid was formed. Yield (0.78 g, 78%), m.p. 145–147 °C, IR (ν/cm−1); 3366, 3336, 3277 (NH and NH2), 2849–2916 (CH-aliph), 2208 (CN), 1677 (CO), 1596 (C=N). 1H NMR (δ, ppm); 7.94 (s, 1H, NH), 7.28–7.93 (m, 10H, ArH and CH of pyridine), 6.68, (s, 2H, NH2), 1.26–1.75 (s, 32H, CH2 aliph) and 0.88 (t, 3H, CH3), 13C NMR: δ 187.20 (C=O), 161.65 (C–NH2), 144.51, 142.51 (2C-CPh of pyridine), 139.19, 132.62, 131.53, 130.41, 130.27, 129.87, 129.77, 127.63, 119.39, 118.91 (carbons of aromatic), 114.41 (CN), 113.61 (C-CPh), 93.43 (C–CN), 37.87, 33.86, 31.94, 29.71, 29.69, 29.67, 29.49, 29.30, 29.14, 26.47, 25.50, 24.86, 22.71, 18.50 (carbons of aliphatic side chain), 14.13 (terminal CH3). Anal. Calc. (%) for C36H48N4O (552.79); C, 78.22; H, 8.75; N, 10.14. Found C,78.36; H, 8.88; N, 10.26.

Synthesis of N-(4-(6-Amino-5-cyano-4-phenyl-4H-pyran-2-yl)phenyl)stearamide (6)

A mixture of chalcone 3 (1 g, 2 mmol) with malononitrile (0.13 g, 2 mmol) in pyridine (25 mL) was heated for 10 h. After cooling the reaction mixture was poured upon ice water (20 mL), filtered and crystallized from toluene. A deep yellow solid was formed. Yield (0.63 g, 63%), m.p. 101–102 °C, IR (ν/cm−1); 3376, 3237 (NH and NH2), 2849–2915 (CH-aliph), 2200 (CN), 1660 (CO) and 1295 (C–O–C), 1H NMR (δ, ppm): 8.05 (s, 1H, NH), 7.11–7.35 (m, 9H, ArH), 6.97 (d, 1H, CH-pyran), 6.80 (s, 2H, NH2), 3.89 (d, 1H, CH-pyran), 1.27–1.67 (s, 32H, CH2 aliph), and 0.91 (t, 3H, CH3). Anal. Calc. (%) for C36H49N3O2 (555.79); C, 77.80; H, 8.89; N, 7.56. Found C, 77.65; H, 8.77; N, 7.74.

General Method for Synthesis of Pyrazole Derivatives (7a,b)

A mixture of chalcone 3 (1 g, 2 mmol), hydrazine hydrate (0.1 g, 2 mmol) and/or phenyl hydrazine (0.22 g, 2 mmol) in EtOH (15 mL) containing piperidine (0.5 mL) was heated for 7 h, cooled and poured onto crushed ice/water/dil HCl. The precipitate was filtered and crystallized from a mixture of DMF/EtOH (1:2).

N-(4-(5-Phenyl-4,5-dihydro-1H-pyrazol-3-yl)phenyl)stearamide (7a)

A white yellow solid was formed. Yield (0.68 g, 68%), m.p. 124–126 °C, IR (ν/cm−1); 3339, 3299 (2NH), 2849–2916 (CH-aliph), and 1678 (CO); 1H NMR (δ, ppm); 7.71 (s, 1H, NH), 7.26–7.56 (m, 10H, ArH and NH), 4.12 (t, 1H, CH of pyrazole), 3.86 (s, 2H, CH2), 1.26–1.69 (s, 32H, CH2 aliph) and 0.89 (t, 3H, CH3), 13C NMR: δ 177.74 (C=O), 160.05 (C=N of pyrazole ring), 147.69, 147.43, 130.26, 129.78, 128.69, 128.55, 127.33, 120.24 (CH aromatic), 52.16 (CH-Ph of pyrazole ring), 44.61 (CH2 of pyrazole ring), 37.92, 34.42, 33.80, 31.95, 29.72, 29.67, 29.54, 29.39, 29.29, 29.16, 26.48, 25.61, 24.77, 22.83 (CH of aliphatic chain), 14.28 (terminal CH3). Anal. Calc. (%) for C33H49N3O (503.76); C, 78.68; H, 9.80; N, 8.34. Found C, 78.82; H, 9.96; N, 8.50.

N-(4-(1,5-Diphenyl-4,5-dihydro-1H-pyrazol-3-yl)phenyl)stearamide (7b)

A white solid was formed. Yield (0.66 g, 66%), m.p. 146–148 °C, IR (ν/cm−1); 3312 (NH), 2849–2915 (CH-aliph), and 1662 (CO), 1H NMR (δ, ppm); 7.87 (s, 1H, NH), 7.8–7.85 (m, 14H, ArH), 4.87 (t, 1H, CH), 3.70 (s, 2H, CH2), 1.21–1.66 (s, 32H, CH2 aliph) and 0.87 (t, 3H, CH3). Anal. Calc. (%) for C39H53N3O (579.86); C, 80.78; H, 9.21; N, 7.25. Found C, 80.69; H, 9.03; N, 7.39.

Synthesis of N-(4-(5-Phenyl-4,5-dihydroisoxazol-3-yl)phenyl)stearamide (8)

Equimolar amounts of hydroxylamine hydrochloride (0.14 g, 2 mmol) and compound 3 (1 g, 2 mmol) in EtOH (15 mL) with sodium acetate (0.2 g, 2 mmol) were heated for 7 h, and then left to cool. The mixture was poured on ice cold water, filtered and crystallized from EtOH/DMF (3:1). An orange solid was formed. Yield (0.74 g, 74%), m.p. 104–106 °C, IR (ν/cm−1); 3317 (NH), 2849–2916 (CH-aliph) and 1661 (CO). 1H NMR (δ, ppm); 8.67 (s, 1H, NH), 7.28–7.66 (m, 9H, ArH), 5.65 (t, 1H, CH), 3.79 (s, 2H, CH2),1.30–1.76 (s, 32H, CH2 aliph) and 0.91 (t, 3H, CH3). Mass spectrum (m/z, %) (M+) at (504, 5.7). Anal. Calc. (%) for C33H48N2O2 (504.75); C, 78.53; H, 9.59; N, 5.55. Found C, 78.81; H, 9.78; N, 5.71.

Synthesis of N-(4-(6-Phenyl-2-thioxo-1,2,3,6-tetrahydropyrimidin-4-yl)phenyl)stearamide (9)

To a solution of chalcone 3 (1 g, 2 mmol) in EtOH (25 mL) with sodium hydroxide (0.2 g in 1 mL water), thiourea (0.15 g, 2 mmol) was added. The mixture was refluxed for 5 h, and then cooled, filtered and crystallized from the ethanol. A light brown powder was formed. Yield (0.78 g, 78%), m.p. 143–145 °C, IR (ν/cm−1); 3378, 3312 (3NH), 2850–2916 (CH-aliph), 1662 (CO), 1249 (CS). 1H NMR (δ, ppm): 11.02, (s, 1H, NH), 8.57, (s, 1H, NH), 7.26–7.88 (m, 9H, ArH), 6.81 (d, 1H, CH of pyrimidine), 4.15 (d, 1H, CH of pyrimidine), 2.54 (s, 1H, NH), 1.22–1.69 (s, 32H, CH2 aliph) and 0.87 (t, 3H, CH3), 13C NMR: δ 179.81 (C=O), 175.61 (C=S), 148.44 (C–NH of pyrimidine ring), 142.41, 129.81, 128.86, 128.76, 126.81, 126.48, 125.76, 122.45, 121.15, 118.76 (CH aromatic), 99.98 (=CH− of pyrimidine), 65.22 (CH-Ph of pyrimidine), 37.99, 34.43, 33.99, 31.96, 29.73, 29.62, 29.49, 29.46, 29.40, 29.27, 29.17, 29.08, 26.49, 25.48, 25.01 (sp3 carbons of aliphatic side chain), 14.47 (terminal CH3). Anal. Calc. (%) for C34H49N3OS (547.84); C, 74.54; H, 9.02; N, 7.67; S, 5.85. Found C, 74.21; H, 8.83; N, 7.56; S, 5.66.

Synthesis of N-(4-(2-oxo-6-Phenyl-1,2-dihydropyrimidin-4-yl)phenyl)stearamide (10)

A solution of chalcone 3 (1 g, 2 mmol) in EtOH/AcOH (25/0.5 mL) and urea (0.12 g, 2 mmol) was heated for 8 h. After cooling, the mixture was poured onto ice-water (50 mL), and then filtered and crystallized from EtOH. A dark yellow powder was formed. Yield (0.68 g, 68%); m.p. 150–152 °C, IR (ν/cm−1); 3327 (2NH), 2848–2915 (CH-aliph), 1691, 1678 (CO), 1578 (C=C) and 1568 (C=N). 1H NMR (δ, ppm): 8.49, (s, 1H, NH), 8.33 (s, 1H, NH), 7.19–7.99 (m, 9H, ArH), 6.61 (s, 1H, CH of pyrimidine), 1.27–1.66 (s, 32H, CH2 aliph) and 0.89 (t, 3H, CH3). Anal. Calc. (%) for C34H47N3O2 (529.76): C, 77.09; H, 8.94; N, 7.93. Found: C, 77.22; H, 9.12; N, 7.77.

Synthesis of N-(4-(2-Amino-6-phenylpyrimidine-4-yl)phenyl)stearamide (11)

A mixture of chalcone 3 (1 g, 2 mmol) and guanidine hydrochloride (0.12 g, 2 mmol), in EtOH (20 mL) with sodium acetate (0.2 g) in water (1 mL) was heated for 8 h, and then the mixture was poured upon cold water with HCl. The solid product was filtered, dried and crystallized from EtOH. A reddish yellow powder was formed. Yield (0.65 g, 65%), m.p. 138–140 °C; IR (ν/cm−1); 3383–3221 (NH and NH2), 2848–2916 (CH-aliph), 1683 (CO), 1620 (C=C) and 1598 (C=N). 1H NMR (δ, ppm); 8.38, (s, 1H, NH), 7.26–7.67 (m, 9H, ArH), 6.59 (s, 2H, NH2), 1.29–1.67 (s, 32H, CH2 aliph) and 0.88 (t, 3H, CH3). Anal. Calc. (%) for C34H48N4O (528.77); C, 77.23; H, 9.15; N, 10.60. Found C, 77.47; H, 9.34; N, 10.83.

Synthesis of N-(4-(2-Phenyl-2,3-dihydro-1H-benzo[b][1,4]diazepine-4-yl)phenyl)stearamide (12)

A solution of compound 3 (1 g, 2 mmol), o-phenylenediamine (0.22 g, 2 mmol) in EtOH/AcOH (20:1 mL) was refluxed for 5 h, and then poured upon ice water. The product was filtered and crystallized from benzene. A pale yellow powder was formed. Yield (0.64 g, 64%), m.p. 161–163 °C, IR (ν/cm−1); 3298 (2NH), 2848–2914 (CH-aliph), 1658 (CO), 1606 (C=C) and 1580 (C=N). 1H NMR (δ, ppm); 7.94, (s, 1H, NH), 6.94–7.66 (m, 13H, ArH), 4.95 (s, 1H, NH diazepine), 3.87 (t, 1H, CH of pyrimidine), 2.58, 2.54 (d, 2H, CH2), 1.22–1.76 (s, 32H, CH2 aliph) and 0.87 (t, 3H, CH3), 13C NMR: δ 189.16 (C=O), 161.65 (C=N of diazepine ring), 142.48, 138.45, 133.69, 129. 94, 129.78, 129.71, 129.61, 129.57, 129.22, 129.12, 127.63, 126.83, 120.44, 114.41 (CH of aromatic), 58.51 (CH–NH of diazepine ring), 37.99 (CH2 of diazepine ring), 36.05, 32.06, 31.95, 29.72, 29.68, 29.62, 29.53, 29.48, 29.39, 29.17, 29.11, 26.50, 25.63, 24.76, 22.72, 18.40 (CH2 of aliphatic side chain), 14.19 (terminal CH3). Anal. Calc. (%) for C39H53N3O (579.86); C, 80.78; H, 9.21; N, 7.25. Found C, 80.91; H, 9.36; N, 7.48.

Synthesis of Pyrimidine Derivatives (13a,b)

A mixture of chalcone 3 (1 g, 2 mmol), barbituric acid (0.26 g, 2 mmol) and/or thiobarbituric acid (0.29 g, 2 mmol) in AcOH (20 mL) was heated for 12 h. The contents left to cool, and then poured into ice, filtered and crystallized from DMF.

(E)-N-(4-(3-Phenyl-1-(2,4,6-trioxotetrahydropyrimidine-5(2H)-ylidene)allyl)phenyl)stearamide (13a)

A pale orange solid was formed. Yield (0.63 g, 63%), m.p. 149–151 °C, IR (ν/cm−1); 3321–3201 (3NH), 2848–2914 (CH-aliph), 1717, 1677, 1658 (CO), 1600 (C=C). 1H NMR (δ, ppm); 8.74 (s, 2H, 2NH of pyrimidine), 7.92 (s, 1H, NH), 7.29–7.46 (m, 9H, ArH), 6.95, 6.97 (2d, 2H, CH=CH), 1.36–1.76 (s, 32H, CH2 aliph) and 0.89 (t, 3H, CH3),13C NMR; δ 189.27, 175.65, 169.81, 162.23 (4C=O), 147.27, 142.33, 132.47 (3 CH olefins), 131.27 (=C of pyrimidine ring), 130.07, 129.91, 129.81, 126.55, 119.37, 118.90, 118.78, 114.42 (CH aromatic), 37.95, 34.02, 31.95, 29.73, 29.69, 29.68, 29.64, 29.62, 29.50, 29.47, 29.40, 29.27, 29.17, 29.09, 26.48 (CH2 of aliphatic chain), 14.23 (terminal CH3). Mass spectrum (m/z, %) (M+) at (600, 4.2). Anal. Calc. (%) for C37H49N3O4 (599.80); C, 74.09; H, 8.23; N, 7.01. Found C, 74.36; H, 8.49; N, 7.28.

(E)-N-(4-(1-(4,6-Dioxo-2-thioxotetrahydropyrimidine-5(2H)-ylidene)-3-phenylallyl)phenyl)stearamide (13b)

A brown powder was formed. Yield (0.60 g, 60%), m.p. 156–158 °C; IR (ν/cm−1); 3337 (3NH), 2848–2915 (CH-aliph), 1714, 1677, 1661 (CO), 1601 (C=C),1536 (C=N), 1259 (C=S). 1H NMR (δ, ppm): 8.76 (s, 2H, 2NH of pyrimidine), 8.24 (s, 1H, NH), 7.25–7.46 (m, 9H, ArH), 6.84, 6.85 (d, 2H, CH=CH), 1.30–1.76 (s, 32H, CH2 aliph) and 0.87 (t, 3H, CH3). Anal. Calc. (%) for C37H49N3O3S (615.87); C, 72.16; H, 8.02; N, 6.82; S, 5.21. Found C, 72.37; H, 8.26; N, 6.55; S, 5.47.

General Procedure for Synthesis of Pyridines (14a, b) and Fused Pyridine Derivatives (15–17)

A solution of chalcone 3 (1 g, 2 mmol) in AcOH (15 mL), acetylacetone (0.2 g, 2 mmol), benzoylacetone (0.32 g, 2 mmol), 1, 3-indandione (0.3 g, 2 mmol), cyclopentanone (0.17 g, 2 mmol), and/or cyclohexanone (0.2 g, 2 mmol) with ammonium acetate (0.4 g), in each case, was heated for 4 h. After cooling, the solution was poured upon ice water (20 mL), filtered and crystallized from EtOH.

N-(4-(5-Acetyl-6-methyl-4-phenyl-1,4-dihydropyridine-2-yl)phenyl)stearamide (14a)

A brown powder was formed. Yield (0.67 g, 67%), m.p. 144–146 °C, IR (ν/cm−1); 3357 (2NH), 2915–2848 (CH-aliph), 1680, 1660 (CO), 1598 (C=C). 1H NMR (δ, ppm); 7.91 (s, 1H, NH), 6.90–7.55 (m, 10H, ArH and NH), 3.82 (d, 1H, CH of dihydropyridine), 3.78 (d, 1H, CH of dihydropyridine), 2.32 (s, 3H, COCH3), 1.97 (t, 3H, CH3), 1.18–1.69 (s, 32H, CH2 aliph) and 0.80 (t, 3H, CH3). Anal. Calc. (%) for C38H54N2O2 (570.85); C, 79.95; H, 9.53; N, 4.91. Found C, 80.21; H, 9.78; N, 4.70.

N-(4-(5-Acetyl-4,6-diphenyl-1,4-dihydropyridine-2-yl)phenyl)stearamide (14b)

A deep yellow powder was formed. Yield (0.63 g, 63%), m.p. 151–153 °C, IR (ν/cm−1); 3316 (2NH), 2848–2915 (CH-aliph), 1677, 1660 (CO), 1596 (C=C). 1H NMR (δ, ppm); 6.75–8.04 (m, 15H, ArH and NH), 6.11 (s, 1H, NH), 3.71 (d, 1H, CH of dihydropyridine), 3.66 (d, 1H, CH of dihydropyridine), 2.43 (s, 3H, COCH3), 1.17–1.66 (s, 32H, CH2 aliphatic) and 0.7 (t, 3H, CH3). Anal. Calc. (%) for C43H56N2O2 (632.92); C, 81.60; H, 8.92; N, 4.43. Found C, 81.38; H, 8.66; N, 4.20.

N-(4-(5-oxo-4-Phenyl-4,5-dihydro-1H-indeno[1,2-b]pyridine-2-yl)phenyl)stearamide (15)

A brown powder was formed. Yield (0.76 g, 76%), m.p. 155–157 °C; IR (ν/cm−1): 3322 (2NH), 2848–2914 (CH-aliph), 1676, 1658 (CO); 1H NMR (δ, ppm): 7.09–7.76 (m, 14H, ArH and NH), 5.20 (s, 1H, C5–H pyridine), 5.18 (s, 1H, C4–H pyridine), 3.69 (s, 3H, NH), 1.08–1.56 (s, 32H, CH2 aliph) and 0.70 (s, 3H, CH3). Anal. Calc. (%) for C42H52N2O2 (616.87): C, 81.78; H, 8.50; N, 4.54. Found: C, 82.04; H, 8.74; N, 4.76.

N-(4-(4-Phenyl-4,5,6,7-tetrahydro-1H-cyclopenta[b]pyridine-2-yl)phenyl)stearamide (16)

A deep yellow solid was formed. Yield (0.58 g, 58%), m.p. 147–149 °C, IR (ν/cm−1); 3314 (2NH), 2848–2915 (CH-aliph), 1662 (CO). 1H NMR (δ, ppm); 8.04 (s, 1H, NH), 8.03 (s, 1H, NH), 6.95–7.96 (m, 9H, ArH), 3.90 (d, 1H, C5–H pyridine), 3.88 (d, 1H, C4–H pyridine), 2.40–2.59 (m, 4H, 2CH2 cyclopentyl), 1.77 (s, 2H, CH2 cyclopentyl), 1.27–1.75 (s, 32H, CH2 aliph) and 0.88 (t, 3H, CH3). 13C NMR; δ 181.01 (C=O), 145.56 (=C-NH of pyridine ring), 144.41, 140.35, 138.03, 133.93, 130.25, 129.79, 129.57, 129.37, 128.23, 119.66 (CH aromatic), 132.73, 113.62 (C=C of cyclopentane), 96.13 (CH of pyridine ring), 42.05 (CH-Ph of pyridine ring), 37.81, 34.78, 33.70, 31.95, 30.83, 29.72, 29.64, 29.49, 29.39, 29.31, 29.28, 29.14, 26.49, 25.61, 23.62 (CH2 of aliphatic chain and cyclopentane), 14.17 (terminal CH3). Anal. Calc. (%) for C38H54N2O (554.85); C, 82.26; H, 9.81; N, 5.05. Found C, 82.51; H, 10.08; N, 5.24.

N-(4-(4-Phenyl-1,4,5,6,7,8-hexahydroquinolin-2-yl)phenyl)stearamide (17)

A pale yellow solid was formed. Yield (0.55 g, 55%), m.p. 137–139 °C, IR (ν/cm−1); 3317 (2NH), 2849–2915 (CH-aliph), 1660 (CO). 1H NMR (δ, ppm); 7.73 (s, 1H, NH), 7.06–7.71 (m, 10H, ArH and NH), 3.66 (d, 1H, C5–H pyridine), 3.64 (d, 1H, C4–H pyridine), 1.51–1.53 (m, 8H, 4CH2 cyclohexanyl), 1.04–1.15 (s, 32H, CH2 aliph) and 0.67 (t, 3H, CH3). Anal. Calc. (%) for C39H56N2O (568.87); C, 82.34; H, 9.92; N, 4.92. Found C, 82.27; H, 9.77; N, 4.76.

Synthesis of N-(4-(3-Phenyloxirane-2-carbonyl)phenyl)stearamide (18)

A stirred solution of compound 3 (1 g, 2 mmol) in acetone/methanol (20:10 mL) was treated with 8% NaOH (12 mL), followed by 30% H2O2 (5 mL). The solution left at room temperature for 24 h, whereby the product was filtered and crystallized from benzene. A yellow solid was formed. Yield (0.61 g, 61%), m.p. 82–84 °C, IR (ν/cm−1); 3319 (NH), 2848–2915 (CH-aliph), 1677, 1658 (CO), 1275 (epoxy linkage). 1H NMR (δ, ppm); 7.19–7.88 (m, 10H, ArH and NH), 3.88, 3.80 (2d, 2H, 2CH), 1.18–1.66 (s, 32H, CH2 aliph) and 0.79 (t, 3H, CH3). Anal. Calc. (%) for C33H47NO3 (505.73); C, 78.37; H, 9.37; N, 2.77. Found C, 78.52; H, 9.55; N, 2.93.

Synthesis of N-(4-(4-Hydroxy-5-phenyl-4,5-dihydroisoxazol-3-yl)phenyl)stearamide (19)

A solution of compound 18 (1 g, 2 mmol) and hydroxylamine hydrochloride (0.14 g, 2 mmol) in EtOH (20 mL) with pyridine (0.5 mL) was heated for 8 h, and poured onto ice water/dil HCl, filtered and crystallized from EtOH. A deep yellow solid was formed. Yield (0.65 g, 65%); m.p. 114–116 °C, IR (ν/cm−1); 3385 (OH), 3225 (NH), 2849–2915 (CH-aliph), 1661 (CO). 1H NMR (δ, ppm); 7.11–7.63 (m, 10H, ArH and NH), 4.14 (d, 1H, CH of isoxazole), 3.47 (d, 1H, CH of isoxazole), 2.60 (s, 1H, OH), 1.27–1.76 (s, 32H, CH2 aliph) and 0.89 (t, 3H, CH3). Anal. Calc. (%) for C33H48N2O3 (520.75); C, 76.11; H, 9.29; N, 5.38. Found C, 76.26; H, 9.43; N, 5.56.

Synthesis of N-(4-(4-Hydroxy-5-phenyl-4,5-dihydro-1H-pyrazol-3-yl)phenyl)stearamide (20)

A mixture of hydrazine hydrate (0.1 g, 2 mmol) and compound 18 (1 g, 2 mmol) in EtOH (20 mL) was heated for 6 h, and then the obtained product filtered and crystallized. An orange powder was formed. Yield (0.68 g, 68%), m.p. 128–130 °C, IR(ν/cm−1); 3375 (OH and 2NH), 1662 (CO); 1H NMR (δ, ppm): 7.95 (s, 1H, NH), 6.87–7.79 (m, 10H, ArH and NH), 3.83 (d, 1H, CH of pyrazole), 3.79 (d, 1H, CH of pyrazole), 2.59 (s, 1H, OH), 1.27–1.76 (s, 32H, CH2 aliph) and 0.88 (t, 3H, CH3). Anal. Calc. (%) for C33H49N3O2 (519.76); C, 76.26; H, 9.50; N, 8.08. Found C, 76.49; H, 9.76; N, 8.30.

Preparation of the Surface Active Agents

A solution of the synthesized compound (0.01 mol) containing 0.5 wt% KOH was stirred and heated to 100 °C while passing a slow stream of nitrogen through the system to flush out oxygen and remove the water from the catalyst. The nitrogen stream was stopped and propylene oxide was added drop-wise with continuous stirring and heating under an efficient reflux system to retain the propylene oxide. The reaction was conducted for different intervals of time ranging from 1 to 10 h. The apparatus was then filled with nitrogen and cooled. The reaction vessel was weighed. The amount of reacted propylene oxide and the average degree of propoxylation were determined from the increment in the mass of the reaction mixture. The yield was determined through the extraction process using chloroform solvent; after evaporation of the solvent, the weight was then calculated [28]. The structure of the synthesized surfactants was established via IR and 1H NMR spectra. Thus, the IR spectra revealed a broad band in the region (3453–2500) cm−1 (υ OH) and two other bands in the region (1150–1020) and (975–860) cm−1 for the ether bond of the chain. The 1H NMR spectra exhibited the propyloxy group protons which appear as broad multiple signals in the region (3.00–3.88) ppm.

Surface and Interfacial Tension

The surface and interfacial tension measurements of the synthesized surfactants (γ) were done at 25 °C according to Du Noüy tensiometer (Krüss GmbH, Hamburg, Instrument Nr. K6) using a platinum/iridium ring at constant temperature. Paraffin oil was used for the interfacial tension measurements. The tensiometer was calibrated using the method described in ASTM Designation: D1331-01 [29–31].

Cloud Point

A solution of the tested sample (1.0 wt%) was heated gradually up to the clear solution became turbid and then the temperature of the solution was recorded [32].

Wetting Ability

Draves method was used to measure the wetting time by dipping a cotton skein (1 g) in a 1 wt% solution of the surfactants in distilled water at 25 °C and the time measured in seconds [33].

Foaming Height

The Ross Miles technique was used to determine the foaming height [34].

Emulsification Properties

An aqueous solution of the surfactant (10 mL) and paraffin oil (5 mL) in a 100-mL graduated tube, stirred at 25 °C by Cimarec™ magnetic stirring (Thermo Scientific). The time taken for the separation of emulsion shows the emulsion stability [35].

Biodegradability

Die-Away method was used to perform the biodegradation tests using Nile river water [36]. In this experiment, a stirred solution of surfactant (1000 ppm) incubated at 25 °C. The surface tension was measured using a Du Noüy tensiometer (Krüss K6), and then repeated over 7 days.

Antimicrobial Evaluation

The newly synthesized surface active agents were investigated in vitro for their antibacterial activities against Bacillus subtilis (MTCC 741), Streptococcus mutans (MTCC 890), and Staphylococcus aureus (ATCC 29,213) as Gram positive bacteria; Pseudomonas aeruginosa (MTCC 741), Salmonella typhi (MTCC 733), and Escherichia. Coli (ATCC 25922) as Gram negative bacteria; and fungi as Aspergillus flavus (AIIMS), Aspergillus niger (AIIMS) and Candida albicans (MTCC 1637). Nalidixic acid, ampicillin and amphotericin B were used as reference drugs. The antimicrobial activity measurements were performed in vitro using the disc diffusion technique [37].

Results and Discussion

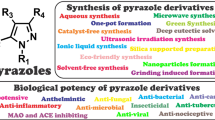

The α,β-unsaturated carbonyl system of chalcones possesses two electrophilic reactive centers, allowing them to participate in addition reactions via attack to (CO) (1, 2-addition) or the β-carbon (1,4-addition), leading to the synthesis of promising bioactive heterocyclic compounds. The key precursor 3 was a useful intermediate for the synthesis of a variety of heterocyclic derivatives. For example, 4-aminoacetophenone was stirred with stearoyl chloride (1) in dry ethanol containing a catalytic amount of triethylamine to afford the acyl derivative 2, followed by treatment with benzaldehyde in alkoxide solution to give N-(4-(3-phenylacryloyl)phenyl)stearamide (3). The 1H-NMR spectrum displayed two doublets at δ 6.93 and 6.89 ppm attributable to ethylenic protons. When chalcone 3 refluxed with ethyl cyanoacetate and/or malononitrile containing a base catalyst, the pyridine derivatives 4 and/or 5 were produced, respectively, in good yield. The IR spectra showed the presence of CN stretching bands at 2202 and 2208 cm−1. When chalcone 3 is subjected to react with malononitrile in boiling pyridine N-(4-(6-amino-5-cyano-4-phenyl-4H-pyran-2-yl) phenyl) stearamide (6) was obtained in good yield. The IR spectrum exhibited frequencies at 3376 and 3237 cm−1 for (NH and NH2), 2200 cm−1 for (C≡N), 1660 cm−1 for (CO), and 1292 cm−1 due to (C–O–C) function. In addition, reaction of chalcone 3 with hydrazine hydrate, phenylhydrazine and/or hydroxylamine hydrochloride in ethanol containing a base catalyst furnished the desired pyrazoles 7a, b and/or isoxazoline 8 derivatives, respectively (Fig. 1).

The versatility of compound 3 is demonstrated with thiourea, urea and/or guanidine hydrochloride by heating under reflux in ethanol led to formation of pyrimidine derivatives 9–11. Microanalysis and spectral data of compounds 9–11 were fully consistent with the proposed structures. In addition, the reaction of binucleophiles like ortho phenylenediamine with α,β-unsaturated carbonyl compound 3 can yield azepine derivative 12. A formation of 12 was indicated by the presence of an absorption band at 3298 cm−1 for NH stretching in the IR spectrum as well as a singlet for NH proton at δ 4.95 ppm in the 1H NMR spectrum. At the other extreme, condensation of the chalcone 3 with barbituric acid and/or thiobarbituric acid in boiling glacial acetic acid led to formation of pyrimidine derivatives 13a, b. Similarly, condensation of chalcone 3 with acetylacetone and/or benzoylacetone in boiling glacial acetic acid containing ammonium acetate produced pyridine derivatives 14a, b.

A fused pyridine ring is known to exhibit a broad spectrum of biological activities, such as antimicrobial agents, antitumor, anti-inflammatory, anti-neoplastic agents [38, 39]. This prompted us to synthesize a new fused pyridine system. Thus, compound 15 has been prepared via the reaction of chalcone 3 with 1, 3-indandione in boiling glacial acetic acid containing ammonium acetate. Similarly, refluxing of chalcone 3 with cyclopentanone and/or cyclohexanone in boiling glacial acetic acid containing ammonium acetate furnished pyridine derivatives 16, 17. Finally, treatment of chalcone 3 with hydrogen peroxide in basic medium gave the oxirane derivative 18, which reacted with hydroxyl amine hydrochloride and/or hydrazine hydrate in boiling ethanol and gave the corresponding isoxazole and/or pyrazole derivatives 19, 20, respectively (Fig. 2).

Surface Activity of the Synthesized Compounds

These surface active agents are inexpensive to produce and have various applications in industry, because of applications as emulsifiers, foam stabilization, wetting agents, facilitate solubilization and several biotechnological processes [40–46]. Addition of number of moles of propylene oxide (10 moles) to the synthesized compounds (4–20) which have active hydrogen atoms in the presence of KOH as a catalyst produced nonionic surface active agents (21–37), respectively, which may have broader formulation flexibility. The structure of propoxylated products (21–37) confirmed via IR and 1H NMR spectra. The reaction conditions of propoxylated compounds showed in Table 1. Figure 3 show the propoxylation of compounds 11 and 20 as a general example.

Performance Properties

In order to verify the industrial feasibility of these nonionic surfactants as substitutes for commercial surfactants, the performance characters such as surface and interfacial tension, cloud points, wetting ability, foaming height and emulsion stability were evaluated; results are presented in Table 2.

Surface and Interfacial Tension

Surfactant molecules in the aqueous medium experience two balanced forces. The first is the repulsion of water exerted by the hydrophobic chain (hydrophobic effect) which encourages adsorption at the air–water interface, as well as self-assembly above the critical micelle concentration. The second is the attraction between the water molecules and the partially charge of the nonionic chain (hydrophilic effect), which increases the solubility of the surfactant molecules in the aqueous bulk via hydrogen bond formation between the water molecules and the electronegative oxygen atoms. A significant decrease in surface tension indicates that the surfactant molecules have a significant tendency toward adsorption at the interface between air and water. Adsorption of molecules on the surface at the interface between air and water reduces the surface tension of the solution, and a gradual increase in adsorbed surfactant is followed by gradual decrease in surface tension. The results listed in Table 2 and revealed that the pyrimidine derivative 28 has maximum ability to reduce surface tension, while pyridine derivative 32 has a lower efficiency. Comparing pyridine derivatives (21, 22 and 31a, b) showed that, derivative 21 is more effective in decreasing the surface tension than derivatives (22 and 31a, b). Pyrazole derivative 37 revealed higher efficacy than pyrazole derivatives 24a, b. In addition, the isoxazole derivative 35 induced a higher reduction in surface tension than isoxazole derivative 25. Moreover, the pyrimidine derivative 28 induced the highest reduction in surface tension compared to other related structures.

For the interfacial tension values of the synthesized surfactants (21–37) ranged between 9.4 and 13.4 mN/m at 25 °C. The results indicated that the compounds (23, 26 and 35) have a greater ability to locate at the interface between the oil and the water phase than other compounds.

Cloud Point

The cloud point is an important factor for measuring the performance of nonionic surfactants. A common and characteristic observation is that they exhibit a reverse solubility versus temperature behavior in water, therefore their solutions tend to become visibly turbid at a well-defined temperature, and this is known as the cloud point. The cloud point is a critical factor in the performance of nonionic surfactants, which helps us to determine the storage stability since storing at temperatures significantly higher than the cloud point may result in phase separation and instability. The measured values of cloud points for nonionic compounds are depicted in Table 2. Since water solubility of nonionic surfactants varies inversely with temperature, all synthesized compounds showed high cloud points, which gave a good performance in hot water (71–93 °C). This is a fact behind all synthesized compounds having a high commercial quality at room temperature. Furthermore, the rise in cloud points can be attributed to the formation of hydrogen bonds with water.

Wetting Ability

One of the main criteria for the selection of surfactants is their wetting ability. The strength of wetting of surfactants may accelerate the deployment or penetration of the alkaline chemicals, dyes in the fibers, improve the detergency or dyeing effects. In this investigation, we used cotton fabric to test the wettability of the surfactants. The better the wetting agent, the shorter time is required for sinking to occur. As revealed in Table 2, all of our dissolved products have the ability to wet cotton fabric. As it can be clearly seen, the pyridine derivative 31b exhibited the shortest sinking time than other surfactants, while the pyrimidine derivative 30a showed the longer sinking time than other surfactants. These results indicate that the pyridine 31b is the most efficient wetting agent among the studied groups. On the other hand, the wetting ability of pyrazole derivative 24a is better than pyrazole 24b and 37. In addition, the pyran 23 exhibited a good wetting ability.

Foaming Properties

Nonionic surfactants are useful in various applications that require a large or little amount of foam. For example, when washing hair, the foam from the shampoo not only surrounds the grease but also imparts a lather; it would feel unpleasant if the foam were to disappear immediately. In dyeing processes, however, foams can be unwanted; they are created through passage of gas into the liquid during the motion of the machinery. If too much foam is present, contact between the dye solution and the fibers could be obstructed, resulting in uneven dyeing. Foams can be produced by a soluble surfactant being spread at the air–water interface. In addition, during the protein adsorption process, the surface or interfacial tension of the air–water and/or oil water interface decreases an important attribute for optimizing the input of energy involved in the foaming or emulsification process and for the production of smaller bubbles or droplets (an important factor affecting the stability of the dispersions). Table 2 displays the foaming properties of our synthetic products. Their foam heights ranged between 76 and 106 mm. Among these surfactants, pyrimidine derivative 28 had the best foaming properties. Enhancing the hydrophilicity of surfactants (e.g., by increasing the P.O group length) usually leads to an increase in the foaming properties.

Emulsion Stability

The emulsification ability of the surfactants was determined by the rate of diffusion of surfactant from bulk solution to the interface between oil and water and the physical properties of the adsorbed layers formed from surfactant molecules around the inner phase droplet. The two main factors determining emulsion ability are low surface tension and mechanical strength of the interfacial film. The stability of paraffin oil-in-water emulsions in the presence of the synthesized surfactants was investigated. Emulsification relies on surfactant adsorption forming a protective film at the surface of the dispersed droplets, which can delay or prevent coalescence. Nonionic surfactants enhance stability by imparting an electrostatic charge on the droplet surface thus reducing the physical contact between the droplets. As shown in Table 2, for oxirane derivative 36, it takes 65 min for separation of the aqueous layer from the emulsion, whereas for pyrazole derivative 24a, 106 min is required. In general, better emulsion stability of these synthesized surfactants was observed.

The Biodegradability

The biological degradation of the synthesized heterocyclic surfactants after degradation for 7 days at 25 °C is given in Table 3, which shows a gradual increase in the surface tension of the surfactant solutions with increasing time. The surface tension values of the surfactant solutions in the river water reached a maximum after 7 days. The gradual increase in the surface tension is ascribed to the loss of the surface activity of the surfactant dissolved in the river water. The loss of surface activity is due to the breaking of the surfactant molecules due to biodegradation [47]. The biodegradation products in the start of the test period (i.e., 1–3 days) have surface active character, which retains the surface activity of the solutions. At the end of the test period (4–7 days), the products lose their surface activity due to the severe degradation. The biodegradation ratios of the surfactants ranged between 96 and 98% after 7 days. The biodegradation values of these surfactants specifies them as biodegradable compounds and pass the international level (80% after 6 days). In general, we can see that all the synthesized surfactants have good biodegradability.

Antimicrobial Evaluation

Some of the synthesized compounds were screened in vitro against Bacillus subtilis (MTCC 741), Streptococcus mutans (MTCC 890), and Staphylococcus aureus (ATCC 29213) as Gram positive bacteria Pseudomonas aeruginosa (MTCC 741), Salmonella typhi (MTCC 733), and Escherichia Coli (ATCC 25922) as Gram negative bacteria, and Aspergillus flavus (AIIMS), Aspergillus niger (AIIMS) and Candida albicans (MTCC 1637) as fungi. Nalidixic acid, ampicillin and amphotericin B were used as reference drugs.

The structure-activity studies showed that depending on the nature of the heterocyclic skeleton and its substituent, the synthesized compounds exhibit varying degrees of microbial inhibition. The surfactant molecules which contain a heterocyclic moiety are the most important class of surface active agents because their double characteristics, one due to the surface active properties and a second one that is due to the heterocyclic moiety combined with a hydrophilic moiety (propylene oxide) to give biological activity. It should be noted that, the investigated compounds have the same hydrophobic and the hydrophilic structure (propylene oxide) but the difference in their structures for heterocyclic moieties as pyridine, pyran, pyrazole, isoxazole, oxirane and pyrimidine derivatives which containing the phenyl (Ph), nitrile (CN), acetyl (COCH3), carbonyl (CO), thione (CS) and/or hydroxy groups as function groups, which recorded higher activity. Therefore, it can be deduced that the specific skeletons in their structures are responsible for the antibacterial and antifungal activities.

The results depicted in Table 4 reveal that most of the tested compounds displayed variable inhibitory effects on the growth of the tested Gram-positive, Gram-negative, and antifungal strains. The results exposed that the compounds exhibited various inhibitory efficiency for the tested bacterial strains. Pyrimidine (26, 27, 30a,b) and pyridine (31b, 32) derivatives exhibited high activity against Bacillus subtilis. Pyran 23, pyrimidine 26, 30a, diaepine 29 and pyridine 33 derivatives showed high activity against Streptococcus mutans. Pyridine (22, 32) and pyrimidine (26, 27, 30a,b) derivatives exhibited high activity against Staphylococcus aureus. Pyridine 21 and pyrimidine (26, 30a,b) derivatives showed high responses against Pseudomonas aeruginosa and Salmonella typhi. Diaepine 29 and pyridine 32 derivatives showed high activity against Escherichia coli.

As can be seen in Table 5, the pyrimidine 30b, pyridine 31a derivatives exhibited high activity against Aspergillus flavus. Moreover, we noticed that, the pyridine 21, 30b, pyrazole 24b and pyrimidine 31b derivatives showed more activity against Aspergillus niger. Furthermore, pyridine (21, 22, 31a) and pyrimidine 26, 27 derivatives showed good activity against Candida albicans.

In conclusion, the nature of substituents and the heterocyclic skeleton of molecules have a strong influence on the extent of antibacterial and antifungal activities.

Conclusion

The synthesis of bioactive heterocycles such as isoxazole, pyrazole, pyran, pyridines and pyrimidine derivatives from inexpensive sourcing materials exhibited good surface activities and biodegradability and biological activities towards bacteria and fungi. This means that these compounds show promise for the manufacture of drugs, cosmetics, pesticides, textiles, moderate emulsifiers and dyes.

References

Kale M, Patwardhan K. Synthesis of heterocyclic scaffolds with anti-hyperlipidemic potential: a review. Der Pharma Chemica. 2013;5(5):213–22.

Yusuf M, Jain P. Synthesis and biological significances of 1,3,4-thiadiazolines and related heterocyclic compounds. Arab J Chem. 2014;7(5):525–52.

Liu YT, Sun XM, Yin DW, Yuan F. Syntheses and biological activity of chalcones-imidazole derivatives. Res Chem Intermed. 2013;39:1037–48.

Albuquerque HMT, Santos CMM, Cavaleiro JAS, Silva AMS. Chalcones as versatile synthons for the synthesis of 5- and 6-membered nitrogen heterocycles. Curr Org Chem. 2014;18(21):2750–75.

Sortino M, Delgado P, Juárez S, Quiroga J, Abonía R, Insuasty B, Nogueras M, Rodero L, Garibotto FM, Enriz RD, Zacchino SA. Synthesis and antifungal activity of (Z)-5-arylidenerhodanines. Bioorg Med Chem. 2007;15:484–94.

Ghosh R, Das A. Synthesis and biological activities of chalcones and their heterocyclic derivatives: a review. World J Pharm Pharm Sci. 2014;3(3):578–95.

Cheng JH, Hung CF, Yang SC, Wang JP, Won SJ, Lin CN. Synthesis and cytotoxic, anti-inflammatory, and anti-oxidant activities of 2′, 5′-dialkoxylchalcones as cancer chemo-preventive agents. Bioorg Med Chem. 2008;16:7270–6.

Sankappa Rai U, Isloor AM, Shetty P, Pai KSR, Fun HK. Synthesis and in vitro biological evaluation of new pyrazole chalcones and heterocyclic diamides as potential anticancer agents. Arab J Chem. 2015;8:317–21.

Katsori AM, Hadjipavlou-Litina D. Chalcones in cancer: understanding their role in terms of QSAR. Curr Med Chem. 2009;16:1062–81.

Abdelhafez OM, Abdel-Latif NA, Badria FA. DNA, antiviral activities and cytotoxicity of new furochromone and benzofuran derivatives. Arch Pharm Res. 2011;34(10):1623–32.

Kalirajan R, Sivakumar SU, Jubie S, Gowramma B, Suresh B. Synthesis and biological evaluation of some heterocyclic derivatives of chalcones. Int J Chem Tech Res. 2009;1(1):27–34.

Al-Jamali NM. Preparation and bio-chemical identification of series organic compounds. J Chem Chem Sci. 2013;3(2):70–8.

Kandeel MM, Abdou NA, Kadry HH, El-Masry RM. Synthesis and antitumor activity of some novel heterocyclic compounds derived from chalcone analogues. Org Chem Ind J (OCAIJ). 2014;10(8):295–307.

Basri M, Abd Raman RNZR, Salleh AB. Specialty oleochemicals from palm oil via enzymatic synthesis. J Oil Palm Res. 2013;25:22–35.

Yıldırım A, Öztürk S, Çetin M. Long-chain alkylthia-benzimidazoles as corrosion inhibitors for carbon steel in H2SO4 solution. Phosphorus Sulfur Silicon. 2013;188(7):855–63.

Yadav S, Kumar P, DeClerq E, Balzarini J, Pannecouque C, Dewan SK, Narasimhan B. 4-[1-(Substituted aryl/alkyl carbonyl)-benzoimidazol-2-yl]-benzenesulfonic acids: synthesis, antimicrobial activity, QSAR studies, and antiviral evaluation. Eur J Med Chem. 2010;45:5985–97.

Jing L, Qiao W, Luo L, Peng H. Design and surface/interfacial properties of asymmetric triazine carboxyl betaine surfactants. J Surf Deterg. 2014;17:629–36.

El-Sayed R. Synthesis, antibacterial and surface activity of 1,2,4-triazole derivatives. Grasas Aceites. 2006;57(2):180–8.

El-Sayed R, Saleh AA. Utility of octadecyl amine in the synthesis of various nitrogen heterocycles: a preliminary investigation on their surface and biological activities. J Heterocycl Chem. 2016;53:1183–93.

Zielińska A, Nowak I. Fatty acids in vegetable oils and their importance in cosmetic industry. Chemik. 2014;68(2):103–10.

El-Sayed R, Saleh AA. Synthesis of some new thiazole, oxazole, pyrimidine and pyridazine derivatives from 2-cyano-N-octadecyl-acetamide as antimicrobial and surface active agents. J Heterocycl Chem. 2016;53:121–8.

El-Sayed R, Shaldom A, Al Mazrouee L. Synthesis and evaluation of poly-functionally substituted heterocyclic compounds derived from 2-cyano-n-(5-pentadecyl-1,3,4-thiadiazol-2-yl)acetamide. Synth Commun. 2015;45:886–97.

El-Sayed R. Substituted thiadiazole, oxadiazole, triazole and triazinone as antimicrobial and surface activity compounds. J Surf Deterg. 2013;16(1):39–47.

El-Sayed R, Asghar BH. Synthesis of various nitrogen heterocycles as antimicrobial surface agents. J Heterocycl Chem. 2014;51:1251–6.

El-Sayed R. Synthesis and heteroannulation of pyridine and related heterocyclic systems having surface and biological activities. J Oleo Sci. 2015;64(7):761–74.

El-Sayed R, Althagafi I. Potential biosignificant interest and surface activity of an efficient heterocyclic derivatives. J Oleo Sci. 2016;65:177–92.

El Sayed Aly MR, El Razek Abd, Fodah HH, Saleh SY. Antiobesity, antioxidant and cytotoxicity activities of newly synthesized chalcone derivatives and their metal complexes. Eur J Med Chem. 2014;76:517–53.

Morgós J, Sallay P, Farkas L, Rusznák I. Nitrogen containing compounds. J Am Oil Chem Soc. 1986;63:1209–10.

Findlay A. Practical physical chemistry. 6th ed. London: Longmans; 1935. p. 1040–69.

Weil JK, Stirton AJ, Nuñez-Ponzoa MV. Ether alcohol sulfates. The effect of oxypropylation and oxybutylation on surface active properties. J Am Oil Soc. 1966;43:603–6.

ASTM D1331–01. Standard test method for surface and interfacial tension of solutions of surface active agents. West Conshohocken: ASTM International; 2001.

Durham K. Properties of detergent solutions-amphipathy and adsorption, vol. 1. London: Surf Activity Deterg. MacMillan & Co., Ltd.; 1961. p. 1–28.

Draves CZ, Clarkson RG. A new method for the evaluation of wetting agents. J Am Dye Stuff Rep. 1931;20:201.

Ross J, Miles GD. Apparatus for comparison of foaming properties of soaps and detergents. Oil Soap. 1941;18:99–102.

Scholnick F, Linfield WM. Lactose-derived surfactants (III): fatty esters of oxy-alkylated lactitol. J Am Oil Chem Soc. 1977;54:430–5.

Throckmorton PE, Egan RR, Aelony D, Mulberry GK, Otey FH. Biodegradable surfactants derived from corn starch. J Am Oil Chem Soc. 1974;51:486–94.

National Committee for Clinical Laboratory Standards. Performance standards for antimicrobial disk susceptibility tests; approved standard M2-A8. Wayne: Clinical and Laboratory Standards Institute; 2003.

Kaushik NK, Kaushik N, Attri P, Kumar N, Kim CH, Verma AK, Choi EH. Biomedical importance of indoles. Molecules. 2013;18:6620–62.

Ren Y, Zhang L, Zhou CH, Geng RX. Recent development of benzotriazole-based medicinal drugs. Med Chem. 2014;4(9):640–62.

El-Sayed R, Khairou KS. Propoxylated fatty thiazole, pyrazole, triazole, and pyrrole derivatives with antimicrobial and surface activity. J Surf Deterg. 2015;18:661–73.

Negm NA, Badr EA, Zakaria K, Abd El-Raouf M. Environmentally friendly nonionic surfactants derived from jatropha oil fatty acids as inhibitors for carbon steel corrosion in acidic medium. J Surf Deterg. 2015;18(6):1011–24.

Negm NA, Ahmed SA, Badr EA, Ghani MA, Abd El-Raouf M. Synthesis and evaluation of nonionic surfactants derived from tannic acid as corrosion inhibitors for carbon steel in acidic medium. J Surf Deterg. 2015;18:989–1001.

Abd El-Ghaffar MA, Sherif MH, El-Habab AT. Synthesis, characterization, and evaluation of ethoxylated lauryl-myrisityl alcohol nonionic surfactants as wetting agents, anti-foamers, and minimum film forming temperature reducers in emulsion polymer lattices. J Surfact Deterg. 2017;20:117–28.

Myers D. Surfactant science and technology. 3rd ed. New York: John Wiley; 2006.

Ivanković T, Hrenović J. Surfactants in the environment. Arh Hig Rada Toksikol. 2010;61:95–110.

Shaker NO, Abd El-Salaam FH, El-Sadek BM, Kandeel EM, Baker SA. Anionic schiff base amphiphiles: synthesis, surface, biocidal and antitumor activities. J Am Sci. 2011;7(5):427–36.

Negm NA, El-Tabl AS, Aiad IA, Zakareya K, Moustafa AH. Synthesis, characterization, biodegradation and evaluation of the surface active properties of nonionic surfactants derived from Jatropha oil. J Surf Deterg. 2013;16:857–63.

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Howsaway, H.O., El-Sayed, R. Synthesis of Potential Pharmaceutical Heterocycles as Surface Active Agents. J Surfact Deterg 20, 681–694 (2017). https://doi.org/10.1007/s11743-017-1936-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11743-017-1936-x