Abstract

Plant-based proteins show poor functional properties and when a balanced source of amino acids is required, it cannot be provided only by a single source of plant-based protein. This study aims to enhance the functional and digestibility properties of hemp seed meal (HSM) protein by hydrolyzation (HPH) through ultrasonication and enzymatic treatment. The blending of HPH with pea protein isolate (PPI) was conducted to improve the amino acid profile. During ultrasonication, the protein content was significantly affected (p < 0.05) by ultrasonication time and solid-to-solvent ratio but not by the amplitude. Degree of hydrolysis was significantly (p < 0.05) affected by all three variables. Optimal hydrolysate was prepared by ultrasonication at 80% amplitude for 10 min and solid-to-solvent ratio of 1:30, with a protein content of 64.57% and a degree of hydrolysis (DH) of 6.25%. Under these conditions, papain treated HPH exhibited an increase in protein concentration (84.2%) and DH (17.3%). The blend of HPH and PPI in the ratio of 1:1 showed improved protein content (85.5%) with significant (p < 0.05) increase in solubility (72.8% at pH 7). This blend showed a good emulsifying activity index (33.4 m2/g) emulsifying stability (35.3 min), oil holding capacity (2 g/g), water holding capacity (1.8 g/g), foaming capacity (195.8%), and foaming stability (85.2%). This blend also displayed a balanced amino acid profile, with methionine and lysine contents of 1.63 mg/g and 5.88 mg/g, respectively. The blend of PPI:HPH (1:1) showed integration of HPH into the PPI matrix, due water bridging between protein particle as observed by scanning electron microscopy (SEM). The amide I at 1627.6 cm−1 in HSM shifted to 1633.7 cm−1 in HPH and amid II at 1518.7 cm−1 in HSM shifted to 1535.3 cm−1 in HPH indicating a change in secondary structure of HSM due to ultrasonication and enzymatic hydrolysis. In Vitro protein digestibility of 1:1 blend was also higher compared to other samples. The blend of HPH and PPI blend have good potential for creating nutritionally enhanced and functionally superior plant-based food products.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Hemp (Cannabis sativa L.) seeds have garnered significant attention as alternative proteins due to their substantial oil and protein content (~ 25% w/w). The hemp seed protein comprises of 75% (w/w) of salt-soluble edestin and 25% (w/w) of water-soluble albumin and rich in arginine contributing to their nutritional value [1] but deficient in the lysine and tryptophan [2]. The acidic subunit of hemp protein is quite homogeneous and has a molecular weight of around 34.0 kDa, whereas the basic subunit is largely composed of components with molecular weights of about 20.0 and 18.0 kDa [3], Most of 7S-rich components are essential subunits, which have a molecular weight of 4.8 kDa. The by-products of oil processing from hemp seeds is referred to as hemp seed meal (HSM) which contain protein content of 50–60% (w/w) [4].

Despite the high protein quality of hemp seed protein, it contains poor solubility and functional properties compared to other plant-based proteins like soy protein. The poor solubility (at pH 7), is associated with aggregated globular edestin proteins, comprising of 60–80% of the total protein content [5]. However, green technology-based processing techniques like ultrasonication and enzymatic hydrolysis have proven to improve the functionality of plant-based proteins. The protein hydrolysates and bioactive peptides derived from these extractions are of high quality and purity and possess latent bioactivities, such as antioxidant, antimicrobial, and antihypertensive effects [6]. Enzymatic treatment, such as hydrolysis or cross-linking, is also a method to enhance the solubility and functionalities found in plant proteins [7]. Moreover, when a balanced source of amino acids is required for diet, it cannot be provided only by a single source of plant-based protein. Balandrán-Quintana et al. [8] revealed that consuming a single plant protein only rarely provides the essential amino acid profile that is required for the body to be deemed nutritionally balanced. The nutritional profile of cereal protein can be improved by mixing it with legume proteins [9]. For instance, PPI is a good source of plant protein with significant quantities of glutamate, arginine, and aspartate but it lacks certain essential amino acids, such as methionine and cysteine [10]. Similarly, hemp protein is rich in these amino acids but lacks in lysine content. Pea proteins comprise 11S legumin globulin fractions, while hemp proteins mostly contain albumins [11]. The globulins, especially 11S legumin and 7S vicilin, are the primary pea proteins that makeup around 65–80% of the total protein content. Due to their greater digestibility and lower allergenicity in comparison to soybeans, PPI and concentrates have gained substantial attention in the food industry [12]. Therefore, there is a critical need to investigate the potential synergistic effects of blending hemp and pea proteins to produce a balanced amino acid profile while enhancing the overall functional properties of the blend.

The present study is novel to produce the hemp protein hydrolysate (HPH) using ultrasonication and enzymatic hydrolysis to improve the functional and digestibility properties. The HPH and PPI were mixed to obtain a blend with improved nutritional profile and functional properties to expand the application of hemp and pea protein in various food formulations. The blending of HPH and PPI provided a balanced amino acid profile with improved digestibility of hemp protein and offered significant health and nutritional benefits, catering to diverse dietary needs.

Materials and methods

Raw material and chemicals

Hemp seed meal (HSM, moisture 5.6%, protein 50.7%, fat 5.8%, ash 6.5%, carbohydrate 31.2%, and total solid 94.4) was purchased from Organic Way Food Ingredients Inc, Bangkok, Thailand. PPI (moisture 5.5%, protein 86.3%, ash 5.2%, and total solids 95.5%) and all other chemicals and enzymes including NaOH, phosphate buffer, petroleum ether, bovine serum albumin (BSA), Sodium dodecyl sulfate (SDS), 2,2-diphenyl-1-picrylhydrazyl (DPPH), HCl, H2SO4, trichloroacetic acid (TCA), di-Na tetraborate decahydrate (sodium borate), o-phthaldialdehyde (OPA), dithiothreitol (DTT), boric acid, pepsin, papain, and pancreatin enzymes were procured from CTi and Science Co. Ltd, Thailand.

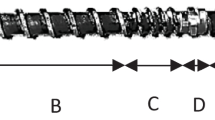

Ultrasonication and enzymatic hydrolysis of HSM

Total solids, protein, fat, and ash content were estimated following the methods described by Umar et al. [13] with slight modifications. HSM in phosphate buffer (pH 7) was subjected to ultrasonication (UP 200S, 200W, Hielscher, Teltow, Germany) at different solid to solvent ratios (X3, 1:10, 1:20, and 1:30 w/v), amplitudes (X1, 40%, 60%, and 80%) and time (X2,5, 10, and 15 min) with fixed frequency of 24 GHz. After ultrasonication, the solution was filtered and centrifuged at 6000×g for 20 min to determine the protein content and DH of the supernatant as responses. Ultrasonication treated hydrolysate (UHPH) was optimized using response surface methodology (RSM) with Box–Behnken experimental design of 15 experimental runs and 3 replicates at the center point. A quadratic polynomial regression model was used to analyze the data as shown:

where Y represents the response variable, \({\beta }_{0}\) is constant, \({\beta }_{i}, {\beta }_{ii}, and {\beta }_{ij}\) are the linear, quadratic, and interactive coefficients determined by the model, and \({X}_{i} and {X}_{j}\) are the independent variables, respectively.

Enzymatic hydrolysis (EHPH) after ultrasonication was performed according to the method described by the Cui et al. [14] with slight modification. Sample was incubated at 55 °C (pH 7.0) for 15 min and different enzyme (papain) concentrations (1.0, 1.5, and 2.0% w/w) were added into the sample. Samples were again incubated at 55 °C for 8 h and after incubation, the enzymatic activity was stopped by boiling the sample at 90 °C for 5 min. After cooling the samples, supernatant was collected for estimation of protein content and DH. Samples were subjected to freeze-drying for 24 h. at − 52 °C using a laboratory-scale freeze drier (Scanvac Coolsafe 55-4, Thailand) to obtain hemp protein hydrolysate (HPH).

Degree of hydrolysis

The degree of hydrolysis (DH) is used to estimate the percentage of cleaved peptide bonds during the hydrolysis process. The 200 mg of SDS and 7.62 g of sodium borate were dissolved in 150 mL of deionized water and 160 mg of (OPA, 97%) was added in 4 mL of ethanol (99.99%). Both solutions were mixed and 176 mg of DTT (99%) was added to this solution and total volume of this OPA reagent was adjusted to 200 mL using deionized water. The sample mixtures were prepared (1% w/v) in deionized water and diluted to 10×. The 3 mL of OPA reagent was mixed with 400 μL of sample and incubated for 2 min. The absorbance was measured at 340 nm using UV–Vis spectrophotometer (UNICAM, Alva, UK) with a solution of the amino acid serine as standard [15].

PPI and HSH blend preparation

The powder samples of HPH and PPI were stirred overnight magnetically (200 rpm) for complete hydrated in distilled water. The PPI and HSH were mixed in 1:0.25, 1:0.5, 1:0.75, and 1:1 ratios to obtain a blend. Mixtures were further stirred for 2 h at 200 rpm using a magnetic stirrer for the complete mixing of proteins. The samples were freeze-dried for 24 h using a laboratory-scale freeze drier (Scanvac Coolsafe 55-4, Thailand) at − 52 °C. Micronization of powders was performed using a high-shear homogenizer (IKA, Germany) for 2 min at 2000 rpm. The powdered samples were packed in zip-locked high-density polyethylene bags and stored in a desiccator at 25 °C for further analysis [16].

Functional properties of samples

The emulsifying activity index (EAI) and the emulsion stability (ES) of the protein hydrolysates were determined according to the method described by Umar et al. [13] with slight modifications. The sample (1% w/v) was added to 30 mL of distilled water and 10 mL of soybean oil followed by homogenized at 2000 rpm for 1 min using a high-speed blender (RW-20, IKA, Germany). The 50 μL of the emulsion was diluted with SDS solution (0.1% w/v) and absorbance after 0 (Ao) and 10 (A10) min was recorded at 500 nm using UV–Vis spectrophotometer (UNICAM, Alva, UK).

The 2 mg/mL of sample was added into the beaker to estimate the foaming capacity (FC) and stability (FS), and the initial volume was recorded (A1). The sample was mixed well at for 5 min at 900 rpm using a homogenizer (Model 50000-25, USA), and volume was recorded (A2) after homogenization. Sample was placed at 25 °C and again volume was recorded (A3) after 30 min [13].

Water and oil absorption capacities (WAC and OAC) were measured by mixing 1 g of sample with 10 mL of distilled water and soybean oil in a centrifuged tube respectively. Samples were mixed for 30 s and incubated at 25 °C for 30 min. After incubation, samples were centrifuged for 20 min at 3000 rpm using a centrifuge (EBA 8S, Hettich, Germany). The supernatant or excess oil was removed, and tubes were inverted for 20 min to remove excess oil. The final weight of the sample was measured to estimate the WAC and OAC [17].

The solubility of HPH and PPI powders was estimated by dispersing the 5 g of sample in of distilled water (100 mL at pH 7.0) at 25 °C. The solutions were centrifuged for 10 min at 1000×g and total soluble protein content was estimated [13].

Amino acid profile

Samples were mixed with HCl (6 M) and incubated for 24 h at 110 °C in oven. After incubation samples were reconstituted in distilled water and filtered using Millipore membrane filter (0.45 μm). The analysis of amino acid was carried out using Biochrom 30 + Amino Acid Analyzer (Biochrom, Cambridge, UK) after the pre-column derivatization with phenyl isothiocyanate [18].

Fourier transform infrared spectroscopy (FTIR)

An FTIR spectroscopy was used to examine the effects of mixing the HPH and PPI to make the blend powder. The powder samples (2 mg) were pressed into pellets on the surface of optical crystal cell, and spectra were recorded over the frequency range of 4000 to 500 cm−1 at a resolution of 4 cm−1 with 32 scans at 25 °C by using the FTIR spectrometer (Nicolet iS500, Thermo Scientific, USA) equipped with OMNIC software [19].

Scanning electron microscopy (SEM)

A scanning electron microscope (JSM-7800F, JEOL Ltd., Japan) at an accelerating voltage (10 kV) was used to examine the morphological properties of samples. The samples were coated on a double-sided carbon adhesive tape attached to the specimen stub. The loose sample was blown away from the carbon adhesive tape using nitrogen. A thin layer of gold was smeared on the sample for 45 s, with a sputter coater at sputter current of 23 mA. (Ion Sputter, HITACHI, E-1010, Japan). The observations were recorded at ×100, ×500, ×1000, and ×5000 magnifications [20].

In vitro protein digestibility (IVPD)

The IVPD assay of samples was carried out according to method described by Bebartta et al. [16] with some modifications. A sample of 250 mg was combined with 15 mL of HCl (0.1 M) containing the pepsin (1.5 mg/mL). Samples were incubated in a water bath for at 37 °C for 3 h. After incubation 7.5 mL of NaOH (0.5 M) was added to stop the enzymatic activity of pepsin. In this sample, 10 mL of phosphate buffer (0.2 M, pH 8.0) containing 10 mg of pancreatin and 1 mL of NaN3 (0.005 M) was added to initiate the pancreatic digestion. Samples were incubated at 37 °C in a water bath for 4 h and centrifuged at 503×g for 20 min. The total protein content in digesta (Ns1), sample (Ns2), and blank (Nb) was estimated using standard AOAC method number 979.09.

Statistical analysis

Response surface methodology was used through Design Expert (version 9.0.3, Stat-Ease Inc., USA) to analyze the ultrasonication dat. The SPSS software (SPSS Version 16, Chicago, IL, USA) was used to conduct the statistical analysis of triplicate reading. One-way Analysis of Variance (ANOVA) was carried out with post hoc Tukey's test to observe the significant differences among the samples with a confidence interval of 95%.

Results and discussion

Ultrasonic-assisted extraction of hydrolysate (UHPH)

To determine the impact that ultrasonication on protein content and DH of HSM, the effect of amplitude (X1), ultrasonication time (X2), and the solid-to-solvent ratio (X3) was analyzed using a Box–Behnken design (Table 1). The model F-value for concentration of protein and DH; degree of hydrolysis was 50.16 and 21.77 obtained during analysis implies the model is significant (p < 0.05). The protein content was significantly affected by ultrasonication time and solid-to-solvent ratio (p < 0.05) but not by amplitude while the degree of hydrolysis was significantly (p < 0.05) effected by all three variables. Using the desirability function, the optimal conditions for ultrasonic extraction were ultrasonic amplitude of 78.14%, time 13.24 min, and solid: solvent ratio of 1:30 which produced the best results with a desirability value of 1. Under these conditions, the reported highest protein concentration and degree of hydrolysis were 64.57% and 6.2%, respectively. Experimental values are closely aligned with predicted values, affirming the validity of the response model. Ultrasonication effectively hydrolyzed hemp proteins, as evidenced by the experimental protein concentration (64.9%). However, prolonged ultrasonication for 15 min had an adverse effect, resulting in lower degrees of hydrolysis. This is due to the larger aggregation of proteins exposed to ultrasonic waves over an extended period, hindering efficient hydrolysis [21]. A control sample that without ultrasonication produced a protein content within the range of 50.7%. Optimal conditions of ultrasonication increased the protein content significantly (p < 0.05) to 64.9%.

The response surface graphs were used to evaluate the interactive impact that independent factors have on the responses (Fig. 1). These plots depict the functional relationship that exists between any two independent variables while maintaining the third variable at a constant status to facilitate the understanding of the interaction effects between variables. There were significant interactions between amplitude and the solid-to-solvent ratio, and with time (p < 0.05) and solid-to-solvent ratio (p < 0.05) but the interaction between amplitude and time was not significant (p > 0.05) as demonstrated by the surface response analysis for protein concentration. Jiang et al. (2014) also discovered that increasing the ultrasonication power (up to 300 W) and treatment time (12 min) increased the solubility of black bean protein isolates. On the other hand, the research found that the solubility decreased when the ultrasonic conditions were increased further. According to Malik et al. [22], the protein content of sunflower isolates was directly proportional to treatment time (up to 20 min), however when the treatment time was increased this linear relation disappeared. According to Nazari et al. [23], the yield of millet protein concentrate was affected in a manner that was comparable by ultrasonic treatments of varied intensities and durations. During the ultrasonic applications, it was discovered that the findings were comparable for chickpea protein isolate [4], perilla seed protein isolate [24].

Enzymatic extraction of hemp protein hydrolysates (EHPH)

The effects of papain concentration and treatment time on the protein concentration and DH of ultrasonicated and untreated HMS is presented in Table 2. During enzymatic hydrolysis, a significant (p < 0.05) gradual increase in protein concentration was observed, with the highest protein concentration (91.3%) and DH (17.3%) at 2% (w/w) papain after 8 h. A similar increase in protein concentration due to an increase in enzyme concentration and incubation time was also observed in a previous study by Stefanović et al. [25]. Prolonged exposure to enzymes led to the breakdown of higher molecular weight insoluble proteins into smaller, soluble peptides, hence increasing the protein concentration [7]. The DH exhibited also increased with hydrolysis time, indicating a gradual accumulation of peptides during the hydrolysis process. However, a reduction in the rate of DH was observed for hydrolysate obtained after 6 h, possibly due to substrate depletion, enzyme inactivation, or inhibition [26]. After 6 h, the rate of DH remained relatively unchanged indicating the significant influence (p < 0.05) of enzyme concentration on the DH. After ultrasonication under optimal conditions, protein concentration and DH values were higher than untreated HSM. This indicated that the ultrasonic pretreatment increased the protein content and DH of HSM by inducing structural alterations in proteins [25].

Proximate analysis of samples

The nutritional composition of HSM and hydrolysates is shown in Table 3. The HSM has substantial amount of protein (50.7%) which makes it a good candidate to be used in food and pharmaceutical products. The moisture, ash, protein, and fat content of PPI was 6.1%, 3.8%, 81.1%, and 1.7%, respectively while the moisture, fat, protein, and ash content of HPH was determined as 3.3%, 0.3%, 84.2%, and 2.1% respectively. The ultrasonication and enzymatic hydrolysis shown a significant (p < 0.05) effect on the protein, ash, fat, and carbohydrate content of samples. Each sample showed changes in the proximate composition due to hydrolysis. The blends of PPI: HPH showed no significant difference (p > 0.05) in moisture and protein content but showed significant (p < 0.05) change in fat and ash and carbohydrate content of samples. Slight increase in TS was also observed due to higher amount of HPH. Miedzianka et al. [27] also observed similar pattern for potato protein hydrolysates where due to hydrolysis the solubilization of protein was increased causing the higher protein content. The protein concentration was also affected by the elimination of insoluble, undigested non-protein compound. The protein hydrolysates and peptides can be synthesized which is usually dormant in native protein structures, using the combination of ultrasonication and enzymatic hydrolysis.

Functional properties of hemp protein hydrolysates and blend

The HPH showed significantly higher EAI (54.8 m2/g) and ESI (39.2 min) as compared to HSM, UHPH, and EHPH (Table 4) due to improved protein content and higher DH. The smaller hydrolysate can swiftly adsorb at the oil–water interface which improves their emulsifying ability.

The EAI and ESI of PPI was 34.2 m2/g and 20.5 min respectively which was also reported by Zhao et al., [24]. The EAI and ESI of HSM was 18.8 m2/g and 15.9 min respectively which significantly increased due to ultrasonication (21.8 m2/g and 20.1 min) and enzymatic (38.2 m2/g and 23.7 min) treatment. Similar results for the emulsifying properties of hemp protein isolates were by Ding et al. [28]. The blending of pea protein with hemp protein hydrolysate resulted in a significant (p < 0.05) improvement of ESI (35.36 min) while reducing the EAI (33.4 m2/g) as compared to HPH. The blend with a lower proportion of HPH (1:0.25) demonstrated the lowest ESI (22.1 min). In a previous study, with the increase in hydrolysate content similar results were obtained for ESI and EAI. Smaller peptides can easily adsorb on oil water interface and maintain the stability for longer duration [29].

The FC and FS were 103.6% and 72.2 for PPI and 108.2% and 59.4% for HSM respectively. The FC (184%) and FS (92%) of HPH was significantly higher (p < 0.05) than other samples at a concentration of 0.5% (w/v) (Table 4). Similar results of foaming capacity for PPI were also observed in a previous study by Moll et al. [30]. The foaming capacity is directly related to the DH, the foaming capacity increases with increasing DH. This is because smaller hydrolysates can easily migrate to the interface, which allows them to reduce surface tension and ultimately leads to enhanced foam expansion [31]. The ultrasonication increases the flexibility of proteins and exposes hydrophobic residues, which may have resulted in improved foaming capabilities in the hydrolysates [19]. Hydrolysis of proteins resulted in a reduction in molecular mass, which facilitated a more rapid migration to the interface and enhanced the flexibility for reorganization at the interface. In addition, the amphiphilic character of the proteins was altered by the enzyme treatment [32]. It appears that the ultrasonication and enzymatic treatment of HSM have good potential for emulsion and foam formations. The FC and FS for PPI:HPH (1:1) were 195.8% and 85.2% for 1:1 ratio while these values were 127.2% and 76.5% for 1:0.25 ratio respectively. There was significant increase in the foaming properties due to increase in the HPH concentration which contain higher concentration of soluble proteins. The blends with higher HPH were more soluble, which in turn reduced interfacial tension and allowed the formation of strong elastic films surrounding scattered air bubbles [33]. The FS depends on proteins interacting strongly with each other around the air bubbles in the matrix. The soluble protein has potential to greatly reduce surface tension through unfolding and interacting with other proteins [34]. Studies have shown that enzymatic treatment of plant proteins can enhanced the foaming stability [35].

The WAC and OAC values were 2.1 and 1.1 g/g for PPI and 1.2 and 1.7 g/g for HSM respectively. Similar results of OAC for HPI were observed in a previous study with higher value of OAC than HSM in this study[36]. Significant (p < 0.05) improvement in WAC and OAC was observed in HSM after ultrasonication, enzymatic treatment, and both treatments combined. Yin et al. [11] showed an increase in OAC for hemp protein due to trypsin treatment (DH 6.7%), a similar finding was observed in our study with higher OAC value due to higher DH (17.3%). The WAC and OAC values were 1.6 and 2.6 g/g for HPH, 1.4 and 2.3 g/g for EHPH, and 1.4 and 1.9 g/g for UHPH respectively (Table 4). The HPH has the maximum WAC and OAC value due to ultrasonication and enzyme treatment which alter the protein structure, decreases the antinutritional components and increases the smaller loose peptides of protein with less molecular weight [32, 37]. Due to higher OAC value, HPH can be used to increase the mouthfeel and decrease the moisture content of processed foods and prolonging their shelf life [38]. The blend of PPI: HPH in 1:1 ratio showed WAC of 1.8 g/g and OAC of 2.2 g/g respectively. Blending of PPI and HPH resulted in significant decrease of WAC and increase in OAC with the blend containing a higher proportion of PPI (1:0.25) demonstrated a higher WAC (2.0 g/g) compared to the blend of 1:1 ratio of PPI and HPH (1.8 g/g). In a previous study, an increase in OAC of flour hydrolysate was observed due to addition of PPI [39].

The solubility of PPI, HSM, UHPH, EHPH, and HPH was 62.5, 56.2, 63.9, 51.6, and 75.7% respectively (Table 4). The PPI typically demonstrates a less solubility (62.5%), primarily due to salt-soluble globulins [40]. Similarly, HSM exhibit a solubility of approximately 55.3%, which can be increased to 83.7% through hydrolysis process. The hemp protein solubility is mainly governed by the presence of salt soluble globulin (edestin) and by the presence of water-soluble albumin. Significant (p < 0.05) improvements in solubility were observed due to enzymatic and ultrasonication treatments of HSM, as observed in previous studies [11, 41]. The decrease in the molecular weight and release of smaller peptides that occurs during papain hydrolysis are responsible for the highest solubility (75.7%) HPH at pH 7.0 [42]. Furthermore, the ultrasonic procedure is expected to cause protein unfolding, and the polar amino acids are exposed which can establish hydrogen bonds with water, hence increasing the solubility of the protein [43]. Slight increase in solubility of different ratios of PP and HPH was observed due to increase in HPH. According to Ghribi et al. [44] proteolytic activity on small-sized polypeptides exposes hydrophilic areas, such as ionic, polar, and charged amino acids on their surface. This exposure enhances protein-water interactions. These findings suggest the potential of such treatments in improving the solubility and functionality of protein-based food products.

Amino acid profile

The usage of mixed protein blends is aimed to prepare a nutritionally balanced formulation with improved functional properties. This synergistic approach yielded a complete essential amino acid profile, showcasing potential as a substitute for animal protein sources. PPI is good source of glutamate, arginine and aspartate but contains less concentration of methionine and cysteine [10]. Similarly, hemp protein is rich in these amino acids but lacks in lysine content. The amino acid compositions of PPI, HSM, HPH, and PPI:HPH (1:1) was analyzed and presented in Table 5. The blend of PPI:HPH (1:1) showed improved amino acid profile as compared to PPI and HSM. It showed improved concentration of glutamic acid (18.3 mg/g), arginine (9.51 mg/g), aspartic acid (10.2 mg/g), methionine (1.63 mg/g), and lysine (5.9 mg/g). Similar amino acid profile was observed for hemp protein in a previous study [3].

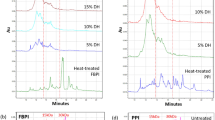

Fourier transform infrared spectroscopy

FTIR analysis provides valuable insights into the molecular transformations occurring in proteins, indicating alterations in secondary structure or the presence of different functional groups [45]. The FTIR spectra of HSM, PPI, HPH, and blend of PPI:HPH (1:1) was recorded and presented in Fig. 2. The C=O stretching/N–H bending (amide I) in the region of 1700–1600 cm−1 and the C–N stretching/N–H bending (amide II) in the region of 1600–1500 cm−1 [20] were examined, and significant differences were observed for HPH as compared to HSM. The amide I at 1627.6 cm−1 in HSM shifted to 1633.7 cm−1 in HPH and amid II at 1518.7 cm−1 in HSM shifted to 1535.3 cm−1 in HPH. These alterations indicate a change in secondary structure of HSM due to ultrasonication and enzymatic hydrolysis. Functional group reorganization and possible changes in protein secondary structure in-plane bending of N–H and C–N vibrations were caused by acoustic cavitation during ultrasonication resulting in peaks shift towards higher wavelengths [46]. The blend of PPI and HPH displayed combined features of both proteins. The N–H stretching in the blend was at 3273.7 cm−1 which was at 3270.4 cm−1 for PPI and at 3276.1 cm−1 for HPH. Similarly, the C=O stretching/N–H bending for PPI was at 1629.5 cm−1, for HPH at 1633.7 cm−1 and for blend it shifted to 1630.4 cm−1. The C–N stretching/N–H bending for PPI was at 1533.7 cm−1, at 1535 cm−1 for HPH and at 1531.1 cm−1 for blend. The variations observed in these bands indicate potential interactions between proteins causing changes in the secondary structures of proteins [47].

Morphological analysis

The SEM images of HSM, PPI, HPH and blend of PPI:HPH (1:1) presented the morphological observation of samples after treatments (Fig. 3). Due to the ultrasonication, structure of HSM particle transformed from compact large structures to small disordered, irregular fragments. Ultrasound treatment effectively reduced large particle aggregates into smaller ones by generating powerful cavitation forces inducing intense shear forces in the medium. The observation of irregular shapes in particles is possible, with smaller particle size and irregular shapes attributed to protein micronization [48]. Prior to ultrasonic treatment, protein particles were aggregated, but treatment broke down these aggregates into smaller, irregular particles. However, small irregular particles do not hinder reconstitution, offering a larger surface area [49]. The blend of PPI:HPH showed integration of HPH into the PPI matrix, due water bridging between protein particles [50]. Protein structure was modified to porous structures with cracks. Hu et al. [51] observed a similar effect in rice protein and soy protein isolate structures. This complex structure can facilitate transporting bioactive substances.

In vitro protein digestibility (IVPD)

Protein digestibility, referring to the breakdown of protein by digestive enzymes and its absorption by the body, depends on various factors such as protein type, structure, processing methods, and the presence of anti-nutritional components. Generally, plant proteins exhibit lower digestibility (75–80%) due to anti-nutritional factor. The PPI showed a digestibility of 77.2% (Fig. 4), similar to findings of Sá et al. [52]. The observations revealed that ultrasonic-assisted enzymatic hydrolysis increased the digestibility of HSM. The protein digestibility for HSM, HPH, and blend (1:1) were 68.2, 89.5, and 82.4% respectively. Wang et al. [3] also reported similar digestibility of 89–91% for trypsin and pepsin treated proteins. Moreover, blending of PPI and HPH increased the digestibility of PPI. The blend (1:1) showed higher protein digestibility (82.4%), as compared to the individual proteins (PPI and HPH). These results support existing research suggesting that protein blends, especially in a 1:1 ratio, enhance overall protein quality. These results are similar to studies indicating that protein blends can improve the nutritional value of plant-derived proteins [53].

Conclusion

This study was conducted to improve the functional, and digestibility properties of hemp protein by preparing its hydrolysates using ultrasonication and enzymatic treatment and blends with pea protein to improve the amino acid profile and enhanced digestibility of hemp protein. The ultrasonication showed significant effect on the hydrolyzation of hemp protein and improved the functional properties. However, the papain pretreatment was also significantly effective to enhance the protein concentration and protein. The functional properties of HPH were improved as compared to control sample due to enzyme-assisted ultrasonic hydrolyzation of protein. The study blending of HPH and PPI (1:1), significantly heightened the protein content and showed increase in functional properties of proteins. This blend also showed improved digestibility and more balanced amino acid profile with higher concentration of methionine and lysine. These findings emphasize the potential of these blends to meet the increasing consumer demand for alternative, nutritionally balanced, and functionally superior plant-based proteins. The enhanced functional and nutritional profiles of these blends can tackle the current limitations in inferior functional properties of protein isolates.

References

H. Chen, H. Wooten, L. Thompson, K. Pan, Nanoparticles of casein micelles for encapsulation of food ingredients, in Biopolymer Nanostructures for Food Encapsulation Purposes. (Elsevier, Amsterdam, 2019), pp.39–68

G. Wu, C.J. Meininger, Regulation of nitric oxide synthesis by dietary factors. Annu. Rev. Nutr.. Rev. Nutr. 22(1), 61–86 (2002)

X.-S. Wang, C.-H. Tang, X.-Q. Yang, W.-R. Gao, Characterization, amino acid composition and in vitro digestibility of hemp (Cannabis sativa L.) proteins. Food Chem. 107(1), 11–18 (2008)

Q. Wang, Y.L. Xiong, Processing, nutrition, and functionality of hempseed protein: a review. Comp. Rev. Food Sci. Food Saf. 18(4), 936–952 (2019)

C. Ajibola, Structural and functional properties of hemp seed storage proteins. (2020).

H. Korhonen, A. Pihlanto, Food-derived bioactive peptides-opportunities for designing future foods. Curr. Pharm. Des.. Pharm. Des. 9(16), 1297–1308 (2003)

A.G.B. Wouters, I. Rombouts, E. Fierens, K. Brijs, J.A. Delcour, Relevance of the functional properties of enzymatic plant protein hydrolysates in food systems. Comp. Rev. Food Sci. Food Saf. 15(4), 786–800 (2016)

R.R. Balandrán-Quintana, A.M. Mendoza-Wilson, G.R.-C. Montfort, J.Á. Huerta-Ocampo, Plant-based proteins, in Proteins: Sustainable Source, Processing and Applications. ed. by C.M. Galanakis (Elsevier, Amsterdam, 2019), pp.97–130

A.-F. Monnet, K. Laleg, C. Michon, V. Micard, Legume enriched cereal products: A generic approach derived from material science to predict their structuring by the process and their final properties. Trends Food Sci. Technol. 86, 131–143 (2019)

M. C. Tulbek, Pulse flours as functional ingredients. IUFOST Annual Conference, Montreal QC, Canada. (2014)

S.-W. Yin, C.-H. Tang, J.-S. Cao, E.-K. Hu, Q.-B. Wen, X.-Q. Yang, Effects of limited enzymatic hydrolysis with trypsin on the functional properties of hemp (Cannabis sativa L.) protein isolate. Food Chem. 106(3), 1004–1013 (2008)

Z.X. Lu, J.F. He, Y.C. Zhang, D.J. Bing, Composition, physicochemical properties of pea protein and its application in functional foods. Crit. Rev. Food Sci. Nutr.Nutr. 60(15), 2593–2605 (2020)

M. Umar, U.R. Ruktanonchai, D. Makararpong, A.K. Anal, Compositional and functional analysis of freeze-dried bovine skim colostrum powders. J. Food Meas. Charact. (2023). https://doi.org/10.2139/ssrn.4226729

S. Cui, S. Zhang, S. Ge, L. Xiong, Q. Sun, Green preparation and characterization of size-controlled nanocrystalline cellulose via ultrasonic-assisted enzymatic hydrolysis. Ind. Crops Prod. 83, 346–352 (2016)

P.M. Nielsen, D. Petersen, C. Dambmann, Improved method for determining food protein degree of hydrolysis. J. Food Sci. 66(5), 642–646 (2001)

R.P. Bebartta, M. Umar, U.R. Ruktanonchai, A.K. Anal, Development of cyrodesiccated micronized protein conglomerates; effect of maltodextrin on stability, functionality and digestibility. Food Process. Eng. 46(7), e14350 (2023). https://doi.org/10.1111/jfpe.14350

S. Chandra, S. Singh, D. Kumari, Evaluation of functional properties of composite flours and sensorial attributes of composite flour biscuits. J. Food Sci. Technol. 52, 3681–3688 (2015)

M. Verni, Determination of the content of free amino acids and their profiling, in Basic Methods and Protocols on Sourdough. ed. by M. Gobbetti, C.G. Rizzello (Springer, New York, 2024), pp.71–79

M. Umar, U.R. Ruktanonchai, D. Makararpong, A. Panya, A.K. Anal, Fabrication of biopolymeric nanoparticles of colostrum whey-caseinate, characterization, and in vitro digestibility. J. Food Eng. 369, 111933 (2024)

M. Umar, U.R. Ruktanonchai, D. Makararpong, A.K. Anal, Effects of pH and concentrations of colostrum whey and caseinate on fabrication of nanoparticles and evaluation of their techno-functionalities and in vitro digestibility. J. Food Meas. Charact. 17, 1–12 (2023)

A.P. Bonto, R.N. Tiozon Jr., N. Sreenivasulu, D.H. Camacho, Impact of ultrasonic treatment on rice starch and grain functional properties: a review. Ultrason. Sonochem.. Sonochem. 71, 105383 (2021)

M.A. Malik, H.K. Sharma, C.S. Saini, High intensity ultrasound treatment of protein isolate extracted from dephenolized sunflower meal: effect on physicochemical and functional properties. Ultrason. Sonochem.. Sonochem. 39, 511–519 (2017)

B. Nazari, M.A. Mohammadifar, S. Shojaee-Aliabadi, E. Feizollahi, L. Mirmoghtadaie, Effect of ultrasound treatments on functional properties and structure of millet protein concentrate. Ultrason. Sonochem. Sonochem. 41, 382–388 (2018)

Q. Zhao, T. Xie, X. Hong, Y. Zhou, L. Fan, Y. Liu, J. Li, Modification of functional properties of perilla protein isolate by high-intensity ultrasonic treatment and the stability of o/w emulsion. Food Chem. 368, 130848 (2022)

A.B. Stefanović, J.R. Jovanović, B.D. Balanč, N.Ž Šekuljica, S.M.J. Tanasković, M.B. Dojčinović, Z.D. Knežević-Jugović, Influence of ultrasound probe treatment time and protease type on functional and physicochemical characteristics of egg white protein hydrolysates. Poult. Sci.. Sci. 97(6), 2218–2229 (2018)

S. Jung, C. Roussel-Philippe, J.L. Briggs, P.A. Murphy, L.A. Johnson, Limited hydrolysis of soy proteins with endo-and exoproteases. J. Am. Oil Chem. Soc. 81(10), 953 (2004)

J. Miedzianka, A. Pęksa, M. Pokora, E. Rytel, A. Tajner-Czopek, A. Kita, Improving the properties of fodder potato protein concentrate by enzymatic hydrolysis. Food Chem. 159, 512–518 (2014)

Z. Ding, F. Jiang, K. Liu, F. Gong, Y. Liu, Z. Zheng, Y.-J. Xu, Structural and functional characteristics of hemp protein isolate-pullulan polysaccharide glycosylation conjugate in an aqueous model system. Foods 12(7), 1416 (2023)

M. Hamouda, A. Sboui, A. Omrani, M. Dbara, S. Zaidi, M. Hammadi, T. Khorchani, Effect of thermal treatments on the fatty acids composition, antioxidant and anti-inflammatory properties of camel milk. J. Food Eng. Technol. 11(2), 55–61 (2022)

P. Moll, H. Salminen, E. Griesshaber, C. Schmitt, J. Weiss, Homogenization improves foaming properties of insoluble pea proteins. J. Food Sci. 87(10), 4622–4635 (2022)

J.M.R. Patino, C.C. Sánchez, M.R.R. Niño, Implications of interfacial characteristics of food foaming agents in foam formulations. Adv. Coll. Interface. Sci. 140(2), 95–113 (2008)

S.A. Malomo, R.E. Aluko, A comparative study of the structural and functional properties of isolated hemp seed (Cannabis sativa L.) albumin and globulin fractions. Food Hydrocolloids 43, 743–752 (2015)

P.G. Kougias, K. Boe, E.S. Einarsdottir, I. Angelidaki, Counteracting foaming caused by lipids or proteins in biogas reactors using rapeseed oil or oleic acid as antifoaming agents. Water Res. 79, 119–127 (2015)

I.A. Wani, D.S. Sogi, B.S. Gill, Physico-chemical and functional properties of native and hydrolysed protein isolates from Indian black gram (Phaseolus mungo L.) cultivars. LWT 60(2), 848–854 (2015)

M. del Mar Yust, J. Pedroche, M. del Carmen Millán-Linares, J.M. Alcaide-Hidalgo, F. Millán, Improvement of functional properties of chickpea proteins by hydrolysis with immobilised alcalase. Food Chem. 122(4), 1212–1217 (2010)

S.A. Malomo, R.E. Aluko, Conversion of a low protein hemp seed meal into a functional protein concentrate through enzymatic digestion of fibre coupled with membrane ultrafiltration. Innov. Food Sci. Emerg. Technol. 31, 151–159 (2015)

R.K. Bhaskaracharya, S. Kentish, M. Ashokkumar, Selected applications of ultrasonics in food processing. Food Eng. Rev. 1, 31–49 (2009)

H. Twinomuhwezi, C.G. Awuchi, M. Rachael, Comparative study of the proximate composition and functional properties of composite flours of amaranth, rice, millet, and soybean. Am. J. Food Sci. Nutr. 6(1), 6–19 (2020)

D. Konieczny, A.K. Stone, D.R. Korber, M.T. Nickerson, T. Tanaka, Physicochemical properties of enzymatically modified pea protein-enriched flour treated by different enzymes to varying levels of hydrolysis. Cereal Chem. 97(2), 326–338 (2020)

G. Sonali, C. Nirmala, D. Saroj et al., Genetic variability, correlation and path analysis studies in pea (Pisum sativum L.). Crop Res. (Hisar) 38(1/3), 179–183 (2009)

X. Kong, H. Zhou, H. Qian, Enzymatic hydrolysis of wheat gluten by proteases and properties of the resulting hydrolysates. Food Chem. 102(3), 759–763 (2007)

Y. Luo, K. Pan, Q. Zhong, Physical, chemical and biochemical properties of casein hydrolyzed by three proteases: partial characterizations. Food Chem. 155, 146–154 (2014)

A. Connolly, C.O. Piggott, R.J. FitzGerald, Technofunctional properties of a brewers’ spent grain protein-enriched isolate and its associated enzymatic hydrolysates. LWT 59(2), 1061–1067 (2014)

A.M. Ghribi, I.M. Gafsi, A. Sila, C. Blecker, S. Danthine, H. Attia, A. Bougatef, S. Besbes, Effects of enzymatic hydrolysis on conformational and functional properties of chickpea protein isolate. Food Chem. 187, 322–330 (2015)

C. Ozuna, I. Paniagua-Martínez, E. Castaño-Tostado, L. Ozimek, S.L. Amaya-Llano, Innovative applications of high-intensity ultrasound in the development of functional food ingredients: production of protein hydrolysates and bioactive peptides. Food Res. Int. 77, 685–696 (2015)

M. Liu, J.A. Toth, M. Childs, L.B. Smart, A. Abbaspourrad, Composition and functional properties of hemp seed protein isolates from various hemp cultivars. J. Food Sci. 88(3), 942–951 (2023)

J. De Meutter, E. Goormaghtigh, Evaluation of protein secondary structure from FTIR spectra improved after partial deuteration. Eur. Biophys. J.Biophys. J. 50, 613–628 (2021)

F. Chemat, N. Rombaut, A.G. Sicaire, A. Meullemiestre, A.S. Fabiano-Tixier, M. Abert-Vian, Ultrasound assisted extraction of food and natural products. Mechanisms, techniques, combinations, protocols and applications. A review. Ultrason. Sonochem. 34, 540–560 (2017). https://doi.org/10.1016/j.ultsonch.2016.06.035

D. M. Kadam, M. Sharma, S. Chadha, and R. A. Wilson, Effect of particle size of foam mat dried tomato juice powder on various physical and sensory attributes. 2012 Dallas, Texas, July 29-August 1, 2012, 1. (2012).

K. Sarabandi, S.H. Peighambardoust, A.S. Mahoonak, S.P. Samaei, Effect of carrier types and compositions on the production yield, microstructure and physical characteristics of spray dried sour cherry juice concentrate. J. Food Meas. Charact. 11(4), 1602–1612 (2017)

T. Hu, J. Chen, X. He, Y. Tang, J. Sun, C. Liu, T. Dai, Complex plant protein prepared from rice protein and pea protein: improve the thermal stability of betanin. Food Res. Int. 164, 112341 (2023)

A.G.A. Sá, Y.M.F. Moreno, B.A.M. Carciofi, Plant proteins as high-quality nutritional source for human diet. Trends Food Sci. Technol. 97, 170–184 (2020)

L.M. Jiménez-Munoz, G.M. Tavares, M. Corredig, Design future foods using plant protein blends for best nutritional and technological functionality. Trends Food Sci. Technol. 113, 139–150 (2021)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Bhetwal, P., Umar, M. & Anal, A.K. Enhanced functional characteristics and digestibility of blends of hemp protein hydrolysate and pea protein isolate. Food Measure 18, 7112–7123 (2024). https://doi.org/10.1007/s11694-024-02722-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-024-02722-4