Abstract

Postharvest fungal pathogenic invasions are the major root cause of reduced shelf life of kinnow fruit, thereby contributing to the postharvest losses. Development of eco-friendly alternates are the need of the hour owing to health safety concerns for replacing the ongoing synthetic fungicide use. Essential oils with promising antimicrobial activities offer a promising solution but their hydrophobicity poses a big hindrance for exploiting the same. Present work was planned to explore their antimicrobial potential by developing their hydrophilic formulation with the use of nanotechnology. An in vitro study was conducted to assess the efficacy Monarda citriodora essential oil (MCEO) and its emulsions against major postharvest fungal pathogen of Kinnow; Penicillium digitatum. Both micro and nano formulations were prepared for different ratios of MCEO (0.5 to 3%) with different surfactant combinations and oil-surfactant-ratios (OSR) of 1:1 to 1:3. The influence of several process factors such as surfactant and oil phase concentrations, as well as sonication time intervals on emulsion stability was investigated by assessing attributes such as droplet diameter, Polydispersity index (PDI), zeta (ζ) potential and rheology. An emulsion formulated with 1% oil and 1:1 OSR treated with ultrasonic waves for 15 min was optimized with droplet diameter of 52.2 nm, 0.245 PDI and − 21 mV of ζ potential with consistent stability till 1 month. Further, in vitro antifungal activity of the optimized MCEO nanoemulsion exhibited the best efficacy with 100% inhibition at 200 mg L−1.

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Fruits and vegetables deteriorate rapidly due to prominent physiological and microbiological changes, thereby contributing to their postharvest losses. Fruit post-harvest infections are primarily caused by microbial pathogens, some of which are toxic to both humans and animals because of mycotoxins [1]. Fruit postharvest diseases cause a high percentage of the fruit rot; nearly 50% losses in some fruits [2]. Among various fruits, Kinnow ocupies the third position among the fruits following bananas and mangoes. Its high juice content with antispasmodic, sedative, cytophylactic, and digestive properties make it a very popular fruit in India and abroad. The primary kinnow producing regions in India are Haryana, Punjab, Himachal Pradesh, Rajasthan, Uttar Pradesh, and Jammu. There are many medicinal properties and nutrients in its juice, making it well known throughout the world. Kinnow is one of the most perishable citrus crops that contain plenty of health-promoting bioactive compounds such as Vitamin C, phenols (Flavanone, glycosides, hydroxycinnamic acids), carotenoids and pectin. However, improper post-harvest handling practices especially during the glut season, results in deterioration of its quality as well as significant postharvest losses. The severe post-harvest fungal diseases that lead to considerable losses are green mold, blue mold, and sour rot caused by Penicillium digitatum, Penicillium italicum and Geotrichum candidum respectively [3] which are managed presently by synthetic fungicides. Furthermore, with continuous and indiscriminate use, the target organisms develop resistance [4] along with the concurrent health issues. With increasing awareness, customers expect “safer alternatives” with potentially non-toxic effects on humans and animals in order to ensure microbiological food safety [5]. As a result, significant emphasis has been placed on improving the quality, safety and security of food systems against microbial deterioration and the associated toxins. Food industry is currently facing major challenges in terms of extending the shelf life, preserving quality and ensuring the stability of foodstuffs such as fruits and vegetables.

Plant essential oils (EOs) and their constituents are getting prominence in the commercial food industry due to their potential antimicrobial properties [6]. The US Food and Drug Administration (FDA) classifies EOs as “generally recognized as safe” (GRAS) secondary metabolites of aromatic plants [7]. Their applications are restricted due to their lipophilic nature that leads to problems such as lack of compatibility and solubility. The advent of nanotechnology has provided an alternate where encapsulated delivery systems of EOs can lead to their enhanced antimicrobial properties which can be harnessed for a desirable application. Oil in water (O/W) nanoemulsions are one of the best delivery systems used to encapsulate lipophilic bioactives of plant essential oils. Monarda citriodora essential oil (MCEO) extracted from its various parts especially aerial parts, has potential antimicrobial effects against food-borne diseases [8]. Popularly known as horsemint, it is a member of the Lamiaceae family with strongly fragrant citrus-scented leaves. It is planted as a decorative, medicinal and fragrant plant in most parts of the world [9].

An emulsion is a biphasic system consisting of at least two immiscible liquids, one of which is an internal or dispersed phase (dispersed as globules) within the external or continuous phase (other liquid phase), usually stabilized by an emulsifying agent termed as surfactant [10]. Emulsions are classified according to their droplet size into three categories: macroemulsions, microemulsions and nanoemulsions. Nanotechnology has resulted in significant advances in a variety of scientific fields as well as product innovation. Microemulsions (MEs) have emerged as efficient delivery systems in recent years due to their unique properties such as ease of preparation, transparency, and long-term stability. On the other hand, nanoemulsions (NEs) have received a lot of attention due to their more efficacy and potential applications in industries like food, cosmetics, pharmacology and agriculture [11]. The stability of a food emulsion is the most important criterion to consider when it comes to commercial applications and is determined by the size distribution of the dispersed phase droplets, the rheology of the continuous phase and the interactions between dispersed phase particles [12]. Rheological studies, both rotational and oscillatory, can predict emulsion stability to a large extent [13]. The strength of a stable O/W emulsion is defined by hydrogen bonds, hydrophobic bonds, electrostatic bonds and covalent bonds among the constituents [14].

Previous studies of our laboratory have indicated that the composition of aqueous and oil phases, surfactant concentration and sonication time etc. may be effective on the droplet size and hence the stability of NEs [15]. The present study was planned to investigate the incorporation of MCEO in both ME and NE forms against Penicillium digitatum, with a focus on composition, characterization and stability as well as to evaluate the rheological properties of the emulsions for their use as future coatings on kinnow fruit to replace synthetic agrochemicals.

Materials and methods

Materials

Monarda citriodora essential oil (MCEO) was procured from Fragrance and Flavour Development Centre (FFDC), Kannauj, Uttar Pradesh, India. Tween 80, Span 80 and ethanol were obtained from S.D. Fine Chemicals Limited (Mumbai, India). Sodium Chloride was obtained from Loba Chemie Private Limited (Mumbai, India). Potato Dextrose Agar was purchased from Hi-Media Laboratories Private Limited (Mumbai, India) and Distilled water (Type II) water was obtained from water purification system (Evoqua) installed in our laboratory.

Fungal strain

The reference culture of Penicillium digitatum (Ascomycota) isolated from kinnow fruit surface ITCC No. 6952 was obtained from the Indian Type Culture Collection Centre, Indian Agricultural Research Institute (IARI), New Delhi, India. A 7-day old culture of a procured test fungus was used to make the aqueous spore suspension. Suspension of test fungal spores in autoclaved saline solution was performed followed by vertexing to achieve uniform spore suspension. After serially diluting the stock spore suspension and enumerating the spores using a hemocytometer, a standard spore suspension with a spore count of 103 ml−1 was prepared. A known volume of spore suspension was deposited on the hemocytometer and the spore count was performed using an optical research microscope (Leica DM 5000B, Germany).

Identification of essential oil constituents using GC–MS

The volatile components of the MCEO were identified with the help of GC–MS. For this purpose, Rtx-5 MS capillary column (30.0 mm × 0.25 mm i.d., 0.25 µm film thickness) was used to identify different components of essential oil with GC–MS (QP2010 Plus, Shimadzu, Japan). Injector temperature was maintained at 260 °C and the sample was run in a split injection mode with a split ratio of 100.0. The split valve was closed for a min. Helium carrier gas was used at constant pressure of 69 kPa. For the first 2 min, the column oven was maintained 50 °C, then rose to 210 °C at ramp rate of 3 °C/min for 2 min and finally rose to 280 °C at 8 °C/min for 9 min. The sample was run in EI mode with an interface temperature of 270 °C. Mass selective detector was operated in scanning mode between 40 and 650 m/z. Data acquisition was initiated after 3 min of injection. The mass spectra were compared with the NIST18 and WILEY8 data banks to determine peak identification [16]. GC-FID (QP2010, Shimadzu, Japan) was operated under the following circumstances: Programmed Temperature Vaporizer (PTV) in direct inject mode at 250 °C with hydrogen as the carrier gas and a column flow rate of 2.04 ml/min at constant pressure. The column oven temperature program was initiated at 150 °C (hold 1 min), then increased at 10 °C/min to 320 °C (hold 4 min). The total time for the analysis was 22 min and the detector temperature was set to 320 °C. GC peak area (FID response) was used to calculate the relative percentages of the individual components [17].

Preparation of Monarda citriodora emulsions

The o/w emulsions were prepared by using combination of magnetic stirring, a low energy method and ultrasonication as a high energy method [18, 19] with slight modifications. Water, surfactant, co-surfactant and EO were mixed in different ratios to prepare various combinations of emulsions (Table 1) initially. The oil phase was prepared by completely mixing the oil and surfactant (w/w). The aqueous phase (water) was added drop-wise into the mixture and stirred for 20 min at 1250 rpm to prepare coarse emulsions by using the Emulsion Phase Inversion (EPI) method [20]. The coarse emulsions so prepared were subjected to probe sonication (Cole-Parmer, India) at 750 W (20 kHz) with 13 mm diameter titanium probe immersed into the emulsion at a depth of 1 cm from the bottom with pulse working time of 10 s and intermittent pause time of 5 s. A heat exchanger was used during sonication to control the inlet, operational and outlet temperatures at 10 °C. The probe sonication duration of emulsions was altered for different times (5 to 15 min) to investigate the effect of sonication time on droplet diameter, PDI, zeta potential and emulsion stability. The coarse emulsions without sonication were referred to as microemulsions.

Two types of surfactants were used to prepare emulsions: Pure surfactant (Tween 80) and mixed surfactant [Tween 80: Span 80 (1:0.5 (w/w))]. The effect of oil phase concentration (OPC) on the droplet diameter was examined by varying the weight fraction of MCEO. OPC was varied as 0.5%, 1%, 2% and 3%. Emulsions were formed by creating blend of MCEO along-with pure surfactant and mixed surfactant in various oil-surfactant ratios (OSR) of 1:1, 1:2 and 1:3.

Determination of hydrophile-lipophile balance (HLB) value

To calculate the HLB value of the emulsion, a ratio 1:0.5 was fixed for mixed surfactant (Tween 80: Span 80) and 1:0 for pure surfactant (Tween 80). The following formula was used to compute the HLB values of mixed surfactants and pure surfactants:

where the HLBT and HLBS values are for Tween 80 (T80, HLB = 15) and Span 80 (S80, HLB = 4.3), respectively, and WS and WT are the weight fractions of Tween 80 and Span 80 [21].

Centrifugation

Preliminary emulsion stability was determined by the ratio of total liquid phase volume separated after a given time of centrifugation to the volume of whole sample as well as by creaming velocity. All freshly prepared and 4-week-old emulsions were centrifuged at 10,000 rpm for 30 min at 25 °C (Sigma) in order to determine their kinetic stability.

Particle size, PDI and zeta potential measurements

The effect of different OSR, OPC and sonication time on emulsions was studied. The Litesizer 500 (Anton Paar, Graz, Austria) was used to measure the droplet diameter of the emulsions using Dynamic Light Scattering (DLS) technique. The samples were measured in a standard disposable cuvette at 25.0 °C with the measuring angle adjusted to 175° for back scatter to obtain the mean droplet diameter and PDI on 0 day as well as after 4 weeks to check the stability of MEs and NEs. Zeta potential was measured using Electrophoretic light scattering (ELS) technique by placing the sample in an Omega cuvette, which was then closed with the tips and further placed in the measurement chamber. All the measurements were taken at an angle of 15°.

Stability of emulsions

The effect of different OSR, sonication time and OPC on emulsion’s stability was studied over a period of 4 weeks at room temperature (25 °C). The droplet diameter, PDI and zeta potential of the MCEO emulsions were measured to establish their stability.

Rheological measurements

Viscosity, shear rate and shear stress were measured using a method of Kamkar et al. [22] with slightest modifications. Titanium strain-control cone and plate geometry MCR 302 (Anton Paar, Austria) was used to measure the rheology with shear rates ranging from 0.01 to 100 s−1 to determine steady flow characteristics. The measurement temperature was set at 240 ± 0.5 °C using a Peltier controller (Temperature range: − 40 to 200 °C) and 50 mm cone-plate geometry with a cone angle of 1°. Normal force range was from − 50 to 50 N.

Antifungal assay by poisoned food technique

Antifungal activity was investigated on a fungus Penicillium digitatum using MCEO according to method described by Balouiri et al. [23]. Poisoned food technique was used to perform antifungal activity. The suspension spore count was 103 CFU ml−1. The EO antifungal activity was tested in triplicate at concentrations ranging from 10 mgL−1 to 100 mgL−1 @1 ml in each plate. Also, a range of 80 mg L−1 to 200 mg L−1 was used to determine the antifungal potential of nanoemulsions @1 ml in each plate. Distilled water and solvent control @ 1 ml were used for the activity. The petri dishes were sealed with parafilm and incubated at 25˚ C. Furthermore, Inhibition (%) of mycelial growth by MCEO and MCEO emulsions was calculated from values of diameter and number of colonies in treated and control plates:

where, T = growth of pathogen in treatment, C = growth of pathogen in control.

Optical research microscopy

The morphological changes in fungus after treatment were studied by optical microscopy. The fungus samples were observed under optical microscope (Leica DM 5000B) at 20X and 100X to characterize the fungus for morphological changes. Optical micrographs were taken with help of computer attached camera (Leica DFC 420C camera).

Statistical analysis

All assays were performed in triplicates. The data were expressed in Mean ± SD. The droplet diameter and size distribution of fresh and stored nanoemulsions as well as the results of antifungal assay of essential oil and essential oil emulsions were analyzed statistically using IBM SPSS statistics 28.0. One way Analysis variance was followed. Tukey’s b test was performed for comparing the results among treatments. Differences were considered significant at p ≤ 0.05 [24].

Result and Discussion

Identification of essential oil constituents using GC–MS

A total of 35 compounds were present comprising 100% area composition based on GC–MS analysis. EO was characterized and classified as monoterpenes, monoterpenoids, monoterpenoid alcohols, monoterpenoid oxide, phenol monoterpenoids, sesquiterpenes and other components. The chemical profile of EO had thymol as major component (62.51%) followed by p-cymene (17.92%), carvacrol (3.99%), γ-terpinene (3.55%), α-terpinene (2.6026%) and other minor components (Table 2).

The results obtained by GC–MS were totally in accordance with literature. Wani and Yadav [24] confirmed the presence of thymol (76.7%), p-cymene (6.7%), carvacrol (6.0%), α-terpinene (2.5%). A study by Dorman and Deans [25] reported oil had 18 components which accounted 95.9% of oil with thymol, p-cymene, carvacrol comprising 70.6%, 10.6%, 6.1% of this total respectively. Different genotypes, plant ecotypes, geographical origins, or adaptive processes to local ecological conditions are responsible for variation in chemical composition. The Retention Index (RI) values were calculated and were in close proximity to that of the literature as stated by Gontar et al. [26] and Lawson et al. [27]. The RI values were calculated by using the Eq. 1:

where, tn and tn+1 are retention times of the reference n-alkane hydrocarbons eluting immediately before and after chemical compound “X”; tx is the retention time of compound “X”.

Centrifugation studies

Emulsions containing higher amount of EO presented signs of instability while rest of the emulsions were stable and homogenous. It can be possible that the amount of surfactant used is not enough to obtain sufficient interfacial tension in emulsions with high amount of oily phase [28]. Among different EO phases varying from 0.5 to 3%, emulsions with 3% EO showed creaming (Fig. 1a, b). However, no visible oil separation was observed for others. The emulsions were then analyzed for droplet diameter and their intrinsic stability was studied by storing the emulsions at room temperature. Hence, the emulsions with 3% EO phase were not considered for further studies.

Effect of surfactant HLB on particle size

In this study, emulsions were prepared using mixed non-ionic surfactant (Tween 80: Span 80) and pure non-ionic surfactant (Tween 80). A combination of Tween 80 and Span 80 (1:0.5) was chosen as mixed surfactant. The HLB value of mixed surfactant used for the present study was adjusted to 11.46 and was compared with pure surfactant with HLB 15. Small droplet diameter as well as better storage stability was observed with mixed surfactant (HLB = 11.46) comparing with pure surfactant (HLB = 15) which is in close agreement with the previous studies [34]. Based on the results, HLB 11.46 was chosen because it was stable and capable of producing small droplet diameter. HLB serves as a scale for selecting surfactants or combination of surfactants that are required for mixing oil and aqueous phase [29]. HLB values are used to evaluate surfactant emulsifying capacity, which impacts the characteristics of the resultant emulsions and hence the stability. Emulsions are primarily driven by hydrophobic interactions between tail groups and steric interactions between head groups mediated by single non-ionic surfactant micelles or nonionic-nonionic mixed micelles [30]. A stable emulsion is characterized by its maximal stability with the smallest possible droplet diameter. Surfactants having HLB values ranging from 8 to 16 may often stabilize O/W NEs. However, literature indicated that HLB values within 10–12 are suitable for O/W nanoemulsions, where minimum droplet diameter can be obtained with good stability [31]. In general, emulsions prepared with mixed surfactant (having a combination of Tween 80 and Span 80) are considered more stable because the lipophilic parts of both contain a double bond, more hydrophilic than a linear carbon chain [32]. These surfactants were selected for study for the reasons that there is known surfactant synergy between them and are non-toxic, cheap and easily available. As per previous studies, the variation in surfactant head group sizes can influence the synergistic effects of mixed surfactant. Because small molecule surfactants can pack well with large surfactants at the interface between the oil and water phases, larger head group-sizes disparities contributed to larger synergistic effects. Thus, the significant difference in head group size between Tween 80 and Span 80 promote a synergistic effect between them, hence enhancing the stability of emulsion system [21, 33, 34].

Effect of oil phase concentration on particle size

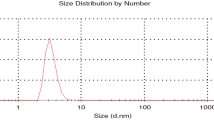

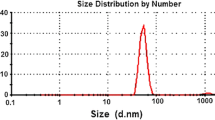

The effect of oil phase concentration on droplet diameter of emulsions was examined by preparing MEs using mixed surfactant Tween 80: Span 80 (1:0.5). The MEs were prepared by drop-wise addition of the aqueous phase to the organic phase containing mixed surfactant (1:0.5) and varied oil concentrations (0.5 to 2%) by continuous stirring. OSR ratios were varied from 1:1 to 1:3 and the effect of oil concentration was studied on the mean droplet diameter (MDD) for all OSRs. It was observed that the mean droplet diameter was affected by an increase in the concentration of oil phase (0.5, 1% and 2%). MEs with 2% oil concentration exhibited very high MDD of 1529 nm with PDI ranging from 0.20 to 0.25. MEs exhibited MDD of 435 and 410 nm for 0.5% and 1% oil concentrations, respectively indicating that both the oil concentrations were at par as far the oil concentration was concerned (Fig. 2). This might be attributed to low viscosity and interface tension of the dispersed phase to the continuous phase due to low oil concentration. 2% oil concentration had probably crossed the critical level leading to incomplete emulsification by surfactant molecules in aqueous phase. Hence, 2% oil concentration was not enough to inhibit Ostwald ripening of newly formed droplets during formulation of ME [35]. The finding was further verified by sonicating these 2% oil MEs for preparing NEs but the MDD of all 2% NES were observed > 200 nm for 5 to 15 min sonication times. The Optical Microscopy images also confirmed significantly higher MDD of 2% oil emulsions than 0.5% and 1% (Fig. 3). The droplets were found to be globular in shape with a uniform dispersion. Hence, the EO concentrations of 0.5% and 1% were chosen for further studies.

Effect of surfactant concentration on particle size

The influence of surfactant concentration on the droplet diameter and PDI of emulsions was examined by preparing a series of nanoemulsions using mixed surfactant (Tween 80: Span 80) with different OSR (1:1, 1:2 and 1:3) and sonication time (5–15 min) for two oil concentrations (0.5 and 1%) by probe sonication. MDD and PDI were measured immediately after the NE formulation. It was observed that increase in surfactant concentration from 1:1 to 1:3 led to increase in the MDD for 0.5% oil concentration from 62.3 to 169.3 nm (Fig. 4a). Further increase in oil concentration from 0.5 to 1% also showed similar behavior with increase in MDD varying from 67 to 574.3 nm (Fig. 4b). PDI values were almost consistent of all the three OSRs and were in the range of 0.1–0.4. In both cases i.e. 0.5 and 0.1% oil concentration, the least MDD values were obtained with 1:1 OSR. This may be due to the fact that optimum surfactant concentration for 1:1 OSR led to formation of a dynamic interface due to reduction in interfacial tension which may cause high turbulence between the oil and water phase leading to spontaneous and consistent formation of nano-sized droplets. It might also prevent the droplets from coalescing by forming a protective coating in 1:1 NEs [36]. Present study was in coherence with our previous study where Ocimum essential oil NEs exhibited similar behavior with increase in surfactant concentration [15]. Sarheed et al. [36] also demonstrated similar behaviour for coconut oil and beeswax formulations, MDD first decreased with increase in surfactant concentrations, however beyond a certain surfactant concentration the MDD showed further increase. Higher MDD in NEs with OSR of 1:2 and 1:3 might be due to (a) high viscosity that hampers the fluidity and hence the movement of organic phase and (b) presence of excess free surfactant molecules along with the ones that initially led to complete coverage of the oil droplet leaving behind the rest which may then form aggregates in the continuous phase, resulting in increase in MDD of NEs. The presence of excess surfactant molecules might induce flocculation and increase local osmotic pressure in the system. The results therefore suggested that optimum surfactant concentration plays a critical role in developing NEs. Whenever creating an emulsion system, we strive to use the least amount of surfactant possible while achieving the desired effect especially due to toxicity concerns apart from cost and flavor [37]. Hence, with 1:1 OSR was considered suitable for both 0.5 and 1% oil concentrations.

Effect of sonication time on particle size of MCEO-NEs

The impact of sonication time at constant OSR (1:1) and two oil phase concentrations (0.5 and 1%) on droplet diameter and size distribution (PDI) was examined. MEs prepared by magnetic stirring were sonicated for different sonication time varying from 5 to 15 min. In general, the droplet diameter for both oil phase concentrations was found to decrease with increase in sonication time from 136.03 to 58.43 nm for 0.5% and from 300.4 and 52.02 nm for 1% OPC respectively (Fig. 5). However, for both OPCs, 10- and 15-min sonication times were found to be at par with each other as far as droplet diameter was concerned. For 0.5 and 1.0% OPC, PDI values also exhibited similar behavior indicating decrease with increase in sonication time from 0.203 (ME) to 0.137 (15 min) for 0.5% and 0.28 (ME) to 0.118 (15 min) for 1%. Eriksson and Ljunggren [38] stated that range of PDI from 0.1 to 0.45 have droplets that are considered as loosely bound complexes rather than small droplets. 15 min sonication time proved to be the most appropriate to achieve the lowest MDD. During sonication for NE preparation, droplet coalescence and droplet disruption play an important role in determining the final average diameter [19]. Increment in the sonication time may lead to rise in the temperature of the emulsion due to which the oil phase entrapped in the aqueous phase may get destroyed leading to decrease in the interfacial tension [15, 18]. It is important to highlight that sonication process causes a rise in emulsion temperature and as a consequence heat is generated during the process. Hashtjin and Abbasi [39] also reported that at oil–water interface, viscosity and interfacial tension are influenced by process temperature, thereby affecting droplet diameter. Alternatively stating that lowering the treatment temperature during the sonication process can decrease the droplet coalescence rate and hence helps in achieving the kinetic equilibrium. Therefore, it is essential to regulate and decrease the temperature of container in order to protect any heat sensitive emulsion constituents. A study by Asadinezhad et al. [40] concluded that the longer the residence time in the disruption zone, the smaller the droplets. In the present case, 15 min sonication time probably led to absorption of more surfactant molecules on to the aqueous phase resulting in the establishment of thermodynamic stability. The results obtained were in accordance with Gaikwad and Pandit [41] that longer sonication time and high power of 750 W leads to smaller droplet diameters and narrower size distributions. Therefore, 15 min sonication time for 1:1 OSR found to show optimum results with the least droplet diameter as well as PDI thereby indicating stability and dispersion of both 0.5% and 1 % NEs.

Ζeta potential (ζ-potential)

O/W emulsion stabilization process involves (a) steric stability in which emulsifier molecules adhere to the surface of oil droplets to maintain stability, and (b) electrostatic stability in which droplets repel each other due to the high surface charge of the droplets and prevent oil droplets from agglomeration [42]. ζ potential is used to determine the electrostatic contribution to emulsion stability as it is a surface electrical property of colloidal particles indicating electrical attraction and repulsion between the particles at the surface through potential values. Stability of an emulsion without agglomeration is indicated by large ζ potential values. On the other hand, Brownian motion reduces the repulsive forces between the particles leading to low stability and low ζ potential value. Therefore, the electrical properties of the emulsion formulations were measured. For this purpose, the ζ potential values of fresh emulsions prepared from two different OPC (0.5 and 1%) at all OSRs (1:1 to 1:3) were obtained with both pure (Tween 80) and mixed surfactant (Tween80: span 80). For mixed OSR (1:1) both 0.5 and 1% OPC demonstrated ζ potential values of -8.3 and -15.7 mV for 10 min sonication time whereas -15.7 and -21.3 mV for 15 min sonication time, respectively (Fig. 6). The results demonstrated that 1% oil phase micro and nanoemulsions had more negative ζ potential values than the 0.5% emulsions regardless of the sonication time indicating that 1% oil concentration the appropriate concentration to form the emulsions with more stability. The outcomes of the study were in accordance with those reported by Sharma et al. [43] where it was observed that ζ potential values of curcumin loaded NEs varied from − 24.26 to − 27.6 mV and − 23.0 to − 26.4 mV when oil concentration was increased from 5 to 15 ml/100 ml of emulsion. ζ potential values were probably more negative because of increase in free fatty acid content of exposed oil droplets at a constant surfactant concentration. Another finding from the present study was that for both OPC (0.5 and 1%), the increase in surfactant concentration from 1:1 to 1:3 resulted in reduction of negative ζ potential values. As the OSR increased from 1:1 to 1:3, the ζ potential values decreased from − 15.7 to − 4.1 mV and − 21.3 to − 2.8 mV for 0.5 and 1% oil concentration respectively for 15 min sonication time. The results substantiated the fact that as the concentration of surfactant increases, the ether-oxygen groups probably come closer to the emulsion surface resulting in shielding and hence led to decrease in negative ζ potential values due to crowding effect caused by excess surfactant molecules. Furthermore, HLB values above 11 indicated more negative ζ potential. The results pointed out that instead of pure surfactant Tween 80 (HLB = 15), mixed surfactant Tween 80: Span80 (HLB = 11.4) yielded more negative ζ potential values indicating that HLB values of MCEO also lies in the similar range as that of mixed surfactant resulting in stable MCEO emulsions. A study by Wu et al. [44] stated that the more negative ζ potential values possibly are due to hydrogen bonding with the OH− groups of Tween 80 and span 80, hydrogen bonding at ether-oxygen part of polyoxyethylene chains of Tween 80 leading to formation of oxonium ion. Therefore, higher ζ potential values were the resultant of increase in polyoxyethylene group per chain. Tween80 and Span80 are nonionic surfactants, so their impact on charge was minimal. A previous study by Silva et al. [45] reported that emulsions whose ζ potential exceeds ± 30 mV are considered stable. But, according to Piorkowski and McClements [46] emulsions with absolutely high ζ potentials and low ζ potentials are not always considered unstable as emulsions may be stercially stabilized instead of electrostatic stabilization that seemed to be the reason of stability in the present study.

Stabilty Studies of Monarda citriodora emulsions

The physical stability of MCEO emulsions was investigated for duration of 4 weeks by assessing the attributes such as the droplet diameter, PDI, and ζ potential of emulsions along with physical observation of separation, creaming etc. under room temperature conditions (25 °C). As per the results of the present study taking into account the oil phase and surfactant concentration and sonication time for preparation of MCEO emulsions, 1% OPC with OSR 1:1 for 10- and 15-min sonication time were studied for their stability. The stability study of emulsions was examined at room temperature (25 °C) till one month. Physical inspection showed that the NEs retained their translucent appearance without any creaming or phase separation. Even after centrifugation at 10,000 rpm for 30 min, MCEO-NEs were stable and no phase separation was observed after 4 weeks. The droplet diameter of NEs displayed insignificant increase from 54.32 to 86 nm for 10 and 15 min of sonication time (Fig. 7a). The minor increment in the droplet diameter can be ascribed to the contribution of processes such as Ostwald ripening, flocculation, coalescence or partial coalescence. PDI values of both NEs reflected insignificant increase from 0.14 to 0.17 for 10 and 15 min of sonication time. A lower PDI value indicated a more uniform distribution of particles in an emulsion and hence the homogeneity of the emulsion [15]. The stability of the emulsions was further assured by analyzing ζ potential values where the value of ζ potential showed less deviation when compared to the results of fresh emulsions for sonication time of 15 min. The ζ potential varied from − 20.3 to − 12.7 mV and − 21.3 to − 17.6 mV for 10- and 15-min sonication time respectively (Fig. 7b). Therefore, 1% NEs prepared at sonication time of 10 and 15 min were optimized for the second part of the study i.e. antifungal assay.

Antifungal assay of Monarda citriodora essential oil

The antifungal assay of MCEO against P. digitatum was performed using different concentrations ranging from 10 to 100 mg L−1. The poisoned food technique was used to conduct assay. MCEO was evaluated against P. digitatum using Carbendazim 50 WP as the reference standard. Essential oil from Monarda citriodora plant was shown to have significant antifungal effect against P. digitatum. Table 3 summarized the in vitro activity of the essential oil investigated against this postharvest pathogen. MCEO inhibited fungal mycelial growth in an increasing concentration-dependent manner. Among the control and different concentrations, the control (without essential oil) showed the highest radial growth, whereas the 100 mg L−1 showed no growth. MCEO showed 18, 47.2, 12.5, 81.5, 84, and 100% inhibition at 10, 20, 40, 60, 80, and 100 mg L−1, respectively. P. digitatum growth was completely inhibited by the standard reference chemical Carbendazim 50 WP at 500 mg L−1 concentration. Similar to the work performed in this study, other researchers have demonstrated that plant EO have antifungal properties and recommended that these natural compounds can be used as effective alternatives to conventional citrus fruit fungicides [47]. Further, Lis-Balchin and Deans [48] have reported a critical observation that essential oil with high concentrations of thymol, carvacrol, eugenol, cinnamic aldehyde and other monoterpenes as their active and most abundant components have substantial antimicrobial action. In order to improve the antifungal properties of nano and microemulsions of the Monarda citriodora essential oil were prepared and evaluated for their antifungal assay.

Antifungal assay of Monarda citriodora essential oil micro and nanoemulsions

Sonication time of 10 and 15 min at various concentrations of 1% OPC (0, 80, 100, 150 and 200 mg L−1) was used in in vitro studies to investigate the antifungal potential of Monarda citriodora essential oil emulsions with an OSR of 1:1 (mixed surfactant) against P. digitatum. When compared to the pure essential oil, the emulsion significantly inhibited the growth of the test fungus till 15 days of inoculation. The radial growth inhibition of P. digitatum linearly increased with an increase in concentration of the MCEO micro and nanoemulsions. The data presented in Table 4 revealed that at 200 mg L−1 concentration, all micro and nanoemulsions totally prevented hyphal growth. This might be related to the higher surface area of micro- and nano-micelles formed as a result of sonication treatment which likely allowed for improved contact between active chemicals and cell surfaces of microorganisms [49, 50]. The tiny size of micelles or droplets must have resulted in increased oil bioactive component transport through the plasma membrane of the test fungus. Small size of nanoemulsions helped them better to penetrate into fungal cell and fungal cell wall [51]. Hence, NEs had greater antifungal efficacy with 1% OPC and OSR of 1:1 at sonication time for 10 and 15 min.

Optical microscopy of fungus treated with Monarda citriodora essential oil and Monarda citriodora oil emulsions

The morphological changes of P. digitatum could intuitively be observed using optical microscopy. When treated with MCEO at MIC, the control samples showed uniform and robust hyphae with a plump and smooth surface, whereas the treated samples were shrunken and collapsed. It was observed that conidiophores were present in large numbers. Typical fungal structures were observed in control hyphae: normal cell wall thickness, regular and intact plasmalemma, uniform cytoplasm. The fungal growth on control plates was densely packed with spherical spores. The solvent control did not change significantly from the control, indicating that the solvent had limited antifungal potential. The fungal morphology changed after treatment with EO and essential oil emulsions. Reduction in number of spore chains and hyphae along with decrease in hyphal diameter as compared to untreated fungus was observed with decrease being more predominant in case of essential oil and its NEs. Cytoplasmic shrinkage and severe collapse of the hyphae were evident in essential oil treated plate. Based on Del Rio and Pardo’s [52] findings, essential oils penetrate cells because the membranes are more permeable, damaging mitochondria primarily (Fig. 8). Compared to pure essential oil treatment, fungus treated with NEs of essential oil showed a large reduction in hyphal width, hyphal branches, as well as spore numbers (Figs. 9, 10). In microbial cells, the lipophilic properties of oils cause the plasma membrane to expand, increasing membrane fluidity and permeability, inhibiting cellular respiration, altering the ion transport process and allowing the contents to escape. Hence, changing the morphology of the cells and block their growth [53].

Antifungal activity of MCEO micro and nanoemulsions against P. digitatum on 14th day of inoculation a-Absolute Control, b-Solvent control, c-Essential oil at 100 mg L−1, Monarda citriodora essential oil emulsion with 1% oil; 1:1 (OSR), d-ME (150 mg L−1), e-NE 10 min (150 mg L−1), f-NE 15 min (150 mg L−1), g-ME (200 mg L−1), h-NE 10 min (200 mg L−1), i-NE 15 min (200 mg L−1)

Optical Microscopy of Monarda citriodora essential oil micro and nanoemulsions against Penicillium digitatum on 14th day of inoculation a-Absolute Control, b-Solvent control, c-Essential oil at 100 mg L−1, Monarda citriodora essential oil emulsion with 1% oil; 1:1 (OSR), d-ME (150 mg L−1), e-NE 10 min (150 mg L−1), f-NE 15 min (150 mg L−1), g-ME (200 mg L−1), h-NE 10 min (200 mg L−1), i-NE 15 min (200 mg L−1)

Rheological studies

In order to explore the optimized emulsions as future coating of kinnow, rheological measurements provide the most reliable information. For this purpose, a relationship between applied shear stress with shear rate and viscosity was measured for the optimized NEs (1:1 OSR (10- and 15-min sonication time) In order to determine the flow and viscoelasticity of O/W emulsions, amplitude sweep studies were conducted. Fig. 11 illustrated increase in shear stress with increase in shear rate which indicated the non-Newtonian and pseudoplastic behavior of the NEs [54]. The behavior of the NE’s viscosity changed as shear rate changes. Viscosity of NEs decreased with increasing shear rates which indicated the shear thinning behavior of both the formulated NEs. This may be because the shear rate is needed to be increased adequately in order to overcome Brownian motion. However, initially 15 min 1:1 OSR NE showed more viscosity than 10 min 1:1 OSR NE. Here, the emulsion droplets might have become more ordered along flow field and therefore offer a lower flow resistance, resulting in increased viscosity with increasing sonication time [55]. Belgheisi et al. [18] also observed high viscosity for lycopene NEs after 15 min of sonication. Sharp decrease in viscosity was observed till the shear rate 20 s−1 but thereafter, the emulsions started experiencing the same viscosity till 100 s−1 where breaking of bonds could not take place any longer [56]. Silva et al. [57] reported that probably the changes in viscosity can also be the result of lower surface tension and a smaller droplet diameter. It is because when ultrasonic waves are applied, pressure fluctuations can cause viscosity changes. Such fluctuations propagate into the liquid macroscopic dispersion, resulting in the formation of microscopic bubbles that tend to collapse within a few milliseconds, leading to the formation of very fine emulsions (relatively small droplets or higher droplet surface area) due to cavitations [58]. Increased droplet surface area can tend to favor interaction between oil droplets via weak attractive forces, resulting in higher viscosity and pseudoplasticity. In general, the resistance provided by weak interaction forces in emulsion systems is easily overcome by the application of shear forces, which is associated with pseudoplasticity [56]. Results showed higher viscosity with sonication time of 15 min which were further studied with amplitude sweep. The strain sweep test was done on NEs prepared with 1% OPC and sonicated for 15 min. The strain sweep of the sample can be divided into two sections of linear or non-linear. In the linear section i.e. from strain (%) 1 to 10, the G” was much higher than G’ value indicating the viscoelastic behavior of NE.

Conclusion

In this paper, MCEO exhibited promising antifungal activity against P. digitatum, a postharvest fungal pathogen of kinnow with MIC 100 mgL−1. MCEO nanoemulsion (MCEO-NEs) system was successfully optimized by the phase inversion method by using Tween 80: Span 80 (1:0.5) with HLB 11.4 and 1:1 OSR (with 1% OPC). Sonication time of 15 min was found to be the most optimum time that delivered the least droplet diameter of 52.2 nm for 1% OPC than 0.5% OPC with PDI of 0.245. 10 min sonication time was also found at par with 15 min sonication time as far as the droplet diameter was concerned. ζ potential values indicated that 1% NEs were more sterically stabilized than 0.5%. The formulated 1% MCEO NE was physically stable over 1 month storage at ambient temperature with only little variation in ζ potential from − 21.3 to − 17.6 mV. Rheological measurements exhibited high viscosity of 1% NE (O: Smix 1:1) prepared at sonication time of 15 min showed that optimized NE (15 min) had shear thinning and non-Newtonian behavior. According to the results of the MIC characterization, the formulated nanoemulsions of MCEO NE with 1%OPC and Tween 80: Span 80 (1:0.5) with HLB 11.4, 1:1 OSR and 15 min sonication time exhibited antifungal activity against P. digitatum (MIC 200 mg L−1). This makes Monarda citriodora essential oil nanoemulsions as a promising alternative to the use of hazardous chemicals and preservatives.

Data availability

Data is available on request to the corresponding author.

References

F. Peles, P. Sipos, S. Kovacs, Z. Gyori, I. Pocsi, T. Pusztahelyi, Toxins 13, 104 (2021)

I. Saleh, R. Al-Thani, Vet World 12, 1877 (2019)

W. Wang, S. Liu, L. Deng, J. Ming, S. Yao, K. Zeng, Front. Microbiol. 9, 2455 (2018)

N. Paster, R. Barkai Golan, World Mycotoxin J. 1, 385 (2008)

A.K. Chaudhari, V.K. Singh, S. Das, N.K. Dubey, Food Chem. Toxicol. 149, 112019 (2021)

S. Burt, Int. J. Food Microbiol. 94, 223 (2004)

J. Ju, X. Chen, Y. Xie, H. Yu, Y. Guo, Y. Cheng, W. Yao, Trends Food Sci. Technol. 92, 22 (2019)

J.E. Collins, C.D. Bishop, S.G. Deans, K.P. Svoboda, J. Essent, Oil Res. 6, 27 (1994)

A. Salama, R.M. Sabry, M.S. Eldin, Int. J. Pharm Tech. Res. 9, 67 (2016)

M. Fatima, M.A. Sheraz, S. Ahmed, S.H. Kazi, I. Ahmad, RADS J. Pharma Pharmaceut Sci. 2, 56 (2014)

T.J. Ashaolu, Environ. Chem. Lett. 19, 3381 (2021)

J.L. Salager, Encyclopedia of emulsion technology (Marcel Dekker Inc, New York, 1988), p.80

T. Tadros, P. Izquiedo, J. Esquena, C. Solans, Adv. Colloid Interface Sci. 108–109, 303 (2004)

I.M. Geremias-Andrade, N.P. Souki, I.C. Moraes, S.C. Pinho, Gels 2, 22 (2016)

R. Mahajan, R. Tandon, A. Kalia, B.V.C. Mahajan, J. Nanosci. Nanotech. 21, 3556 (2021)

M.A. dos Santos, M. Roehrs, C.M. de Pereira, R.A. Freitag, A.V. de Bairros, Austin. Chromatogr. 14, 2014 (2014)

F. Mir, M.A. Rather, B.A. Dar, S. Rasool, A.S. Shawl, M.S. Alam, M.A. Qurishi, J. Pharm. Res. 5, 1353 (2012)

S. Belgheisi, A. Motamedzadegan, J.M. Milani, L. Rashidi, A. Rafe, J. Food Sc. Tech. Mys. 58, 484 (2020)

A. Gupta, H.B. Eral, T.A. Hatton, P.S. Doyle, Soft Matter 12, 2826 (2016)

P.A. Rocha-Filho, M.F.P. Camargo, M. Ferrari, M. Maruno, J. Nanomed. Nanotech. 5, 2 (2014)

W.T. Chong, C.P. Tan, Y.K. Cheah, B.A.F. Lajis, N.L. Habi Mat Dian, S. Kanagaratnam, O.M. Lai, PLoS ONE 13, e0202771 (2018)

M. Kamkar, S. Sadeghi, M. Arjmand, E. Aliabadian, U. Sundararaj, Nanomaterials 10, 1257 (2020)

M. Balouiri, M. Sadiki, S.K. Ibnsouda, J. Pharm. Anal. 6, 71 (2016)

A.R. Wani, K. Yadav, Int. J. Pharm. Investig. 11, 170 (2021)

Deepika, A. Singh, A.K. Chaudhari, S. Das, N.K. Dubey, J. Food Sci. Technol. 57, 2883 (2020)

H.D. Dorman, S.G. Deans, J. Essen, Oil Res. 16, 145 (2004)

L. Gontar, A. Herman, E. Osinska, Nat. Volatiles Essent. Oils. 8, 29 (2021)

S.K. Lawson, P. Satyal, W.N. Setzer, Plants 10, 482 (2021)

L.O. Orafidiya, F.A. Oladimeji, Int. J. Pharma. 237, 241 (2002)

D.J. McClements, E.A. Decker, Y. Park, J. Weiss, Crit. Rev. Food Sci. Nutr. 49, 577 (2009)

D.J. McClements, “Emulsion stability” Food emulsions (CRC Press, Boca Raton, 2015), p.314

I.K. Hong, S.I. Kim, S.B. Lee, J. Ind. Eng. Chem. 67, 123 (2018)

J.F. Scamehorn, Phenomena in mixed surfactant systems (American Chemical Society, Washington, 1986)

V. Uskokovic, M. Drofenik, Surf. Rev. Lett. 12, 239 (2005)

K. Ziani, Y. Fang, D.J. McClements, Food Chem. 134, 1106 (2012)

O. Sarheed, M. Dibi, K.V.R.N.S. Ramesh, Pharmaceutics 12, 1223 (2020)

D. N. Do, D.P. Nguyen, H. D. Pham, T. A. Trieu, X. C. Luu Mater. Sci. Eng. 991, 012043 (IOP Publishing, 2020)

J.C. Eriksson, S. Ljunggren, Langmuir 11, 1145 (1995)

A.M. Hashtjin, S. Abbasi, Food Hydrocoll. 44, 40 (2015)

S. Asadinezhad, F. Khodaiyan, M. Salami, H. Hosseini, B. Ghanbarzadeh, J. Food Meas. Charact. 13, 2501 (2019)

S.G. Gaikwad, A.B. Pandit, Ultrason. Sonochem. 15, 554 (2008)

P.H. Campelo, L.A. Junqueira, J.V.D. Resende, R.D. Zacarias, R.V.D.B. Fernandes, D.A. Botrel, S.V. Borges, Int. J. Food Prop. 20, 564 (2017)

N. Sharma, G. Kaur, S.K. Khatkar, LWT 141, 110962 (2021)

Z. Wu, J. Wu, R. Zhang, S. Yuan, Q. Lu, Y. Yu, Carbohydr. Polym. 181, 56 (2018)

H.D. Silva, M.A. Cerqueira, A.A. Vicente, Food Bioproc. Tech. 5, 854 (2012)

D.T. Piorkowski, D.J. McClements, Food Hydrocoll. 42, 5 (2014)

N. Aligiannis, E. Kalpoutzakis, S. Mitaku, I.B. Chinou, J. Agric. Food Chem. 49, 4168 (2001)

M. Lis-Balchin, S.G. Deans, J. App. Micro. 82, 759 (1997)

H. Lboutounne, J.F. Chaulet, C. Ploton, F. Falson, F. Pirot, J. Control Release 82, 319 (2002)

A.E. Hammad, M.M.H. Hassanin, Pak. J. Nematol. 40, 245 (2022)

M.K. Khan, B.A. Khan, B. Uzair, S.I. Niaz, H. Khan, K.M. Hosny, F. Menaa, Int J Nanomed. 16, 8203 (2021)

M.J. Del Rio, C. Velez-Pardo, Archives Med. Res. 35, 185 (2004)

N. Tao, L. Jia, H. Zhou, Food Chem. 153, 265 (2014)

T.S.T. Ariffin, E. Yahya, H. Husin, Procedia Eng. 148, 1149 (2016)

M.I.D. Dg, V. Jideani, Acta Sci. Nutr Heal. 3, 105 (2019)

L.R. Costa, A. Gomes, R.L. Cunha, Food Res. Int. 107, 717 (2018)

E.K. Silva, M.T.M. Gomes, M.D. Hubinger, R.L. Cunha, M.A.A. Meireles, Food Hydrocoll. 47, 1 (2015)

L.G. Torres, R. Iturbe, M.J. Snowden, B.Z. Chowdhry, S.A. Leharne, Coll. Surf. 302, 439 (2007)

Acknowledgements

The authors would like to thank Dr. Sumit Singh, Anton Paar, India Ltd. for providing technical guidance to interpret rheological measurements.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there are no conflicts of interest regarding the publication of this manuscript.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kaur, K., Tandon, R., Kalia, A. et al. Fabrication of Monarda citriodora essential oil nanoemulsions: characterization and antifungal activity against Penicillium digitatum of kinnow. Food Measure 17, 3044–3060 (2023). https://doi.org/10.1007/s11694-023-01821-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-023-01821-y