Abstract

Hibiscus (Hibiscus sabidariffa L.) is a flower known for its amount of anthocyanins that can be used as a natural dye for food application. The objective of this paper was to perform two extraction techniques (thermosonication and conventional extraction) from hibiscus, followed by freeze-drying and encapsulation by ionic gelation, and evaluate the application of the best sample in yogurt. The encapsulated samples (obtained by thermosonication and conventional extraction) showed longer half-lives and less color variation (ΔE), indicating that they are more stable (especially in the absence of light) and thus were chosen for application in yogurt. Both encapsulated samples were suitable to yogurt produced, and did not presented significative difference between each in major the evaluated characteristics in yogurts. The yogurt with the capsule obtained by the termosonification process showed to be darker (lower brightness value) and with a greater tendency towards red. Therefore, is more indicated for this type of product, and potentially recommended for use as a natural food dye.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Sensory attributes such as color and appearance affect food quality, these parameters are evaluated by consumers at the moment of purchase [1]. Dyes are widely used in the food industry, mostly synthetic dyes that are applied due to it is high stability and low cost. On the other hand, natural dyes have lower pigmentation power and low stability [2].

One of the main responsible compounds for coloring natural products belongs to the class of flavonoids, with an emphasis on the group of anthocyanidins which has colors ranging from blue to red [3]. These pigments aim to provide coloring in food, contributing to the acceptability of products by consumers [4]. Considering this context, the replacement of synthetic dyes with natural ones has been gaining notoriety [5], which challenges the industry in the application of natural dyes in food products [6].

Hibiscus is a flower known for its amount of anthocyanins, mainly delphinidin 3-O-sambubioside and cyanidin 3-O-sambubioside [7]. In addition, it is calyxes have other bioactive compounds, which also are responsible for antioxidant properties [8], and functional properties. The citrus flavor of its calyxes is a notable characteristic, and it can be consumed in the form of salads, infusions, liqueurs, jellies, etc. [9].

Natural dyes usually have high costs, and some can have lower stability under processing and storage conditions. Considering this fact, encapsulation by different techniques of natural dyes has been widely explored by researchers as a way to increase their stability when applied to foods [10], which is still challenging.

Thus, this is a work of innovative character, using water as a solvent in extraction techniques combined with encapsulation, aiming to improve the stability of the natural hibiscus dye. The use of one clean extraction as an ultrasound extraction technique is ecologically correct, low-cost, fast, and efficient for the extraction of phenolic compounds. Ultrasound waves cause acoustic cavitation and occur collapse of microbubbles on the solid surface, this results in the rupture of cell walls, allowing the penetration of the solvent used and improving mass transfer, resulting in a shorter extraction time and increased yield [11,12,13].

Ionic gelation techniques are interesting and the most used wall encapsulation material is alginate, a natural anionic polymer of (1,4)-linked β-D-mannuronate (M) and α-L-guluronate (G), used in the pharmaceutical and food industries, due to its biocompatibility, bioavailability, and ease of gelation by adding Ca2+. Romanini et al. [14] present for the first time the use of ultrasound extraction of grape residue followed by encapsulation, and observed that the extract encapsulated in alginate-Ca2+, when stored under light, showed higher degradation of bioactive compounds, indicating that such capsules are recommended for food applications that require light protection.

Therefore, this work aimed to develop a natural dye of hibiscus (Hibiscus Sabdariffa L.) through its aqueous extract with an application of ultrasound and conventional extraction and subsequent freeze-drying and encapsulation by ionic gelation. The kinetics of degradation of this dye and its application in yogurts were also evaluated.

Methodology

The hibiscus (Hibiscus Sabdariffa L.) were purchased from a local producer in Maringá, Brazil, being from a 2021 harvest. Other components such as Ultra High-Temperature milk, powdered milk, BioRich lactic yeast, and sugar for the yogurt production were also obtained from the local market in Maringá, Brazil.

Obtention of extracts

Initially, aiming to obtain hibiscus calyces, the seeds were removed and the calyces were immersed in a 200 ppm sodium hypochlorite solution for a period of 15 min and washed in water. After that, calyces were dried at 60 °C for 22 h in a forced air chamber (Cienlab). Then, the calyces were ground in an electric mill and classified according to granulometry using the Tyler sieves series. After preliminary tests, the material was chosen with an average diameter of 0.45 to 0.60 mm for conducting the experiments.

In order to develop thermosonified extraction, the hibiscus samples were put in an ultrasonic bath, model Ultracleaner 1650 Unique, frequency of 40 kHz at 60 ºC for 45 min in a ratio of 1:10 hibiscus: water. The acquired extract was filtered using Whatman no 4 filter paper and stored in the dark at 25 °C for further analysis [15].

For the conventional extraction, the methodology described by Paraíso et al. [16] was followed with some adaptations, in which the samples were placed in a bath at 25ºC for 45 min in a ratio of 1:10 hibiscus: water. The acquired extract was filtered using Whatman no 4 filter paper and stored in the dark at 25 °C for further analysis.

Obtention of powders (freeze-drying and encapsulation by ionic gelation)

The obtained extracts (conventional and thermosonified) were submitted to two processes, freeze-drying and encapsulation by ionic gelation.

For the freeze-drying process, the extracts (conventional and thermosonified) were frozen at − 18 °C/4 h and submitted to a lyophilizer (Liobras, lyophilizer L108, Brazil) for 2 days at -36ºC in order to ensure the complete drying of the product. The freeze-dried products were stored at -18ºC in plastic packaging for further analysis. After this step, two samples were acquired: freeze-dried thermosonified hibiscus extract (TL), and freeze-dried conventional hibiscus extract (CL).

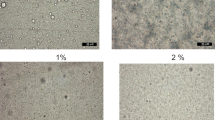

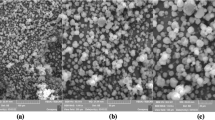

For the encapsulation by ionic gelation, sodium alginate (2% w/v) was added to 100 mL of water followed by the addition of 50 mg/g of the extract, maintained under stirring and heating of 70 °C ± 4 °C until complete dispersion. The alginate capsule was made by using the Caviar Box® kit dripping the alginate-extract solution in an aqueous solution of calcium chloride at (1% w/v). The formed capsules were kept in the calcium chloride solution for 10 min, after that they were sieved and washed with deionized water for removing the calcium excess and for stopping the complexation process [17]. After the washing process, the capsules were frozen at − 18 °C/4 h and submitted to a lyophilizer (Liobras, lyophilizer L108, Brazil) for 2 days at -36ºC in order to ensure the complete drying of the product. After this step, the following samples were obtained: freeze-dried encapsulated thermosonified hibiscus extract (TE) and (CE) freeze-dried conventional encapsulated hibiscus extract.

The encapsulation efficiency (EE%) was measured according to Eq. 1 [18]:

Where FT is the anthocyanins content inside the capsules and FS is the compounds present on the surface.

For the extraction of bioactive compounds, the disintegration of the capsules was carried out with distilled water, agitation, and centrifugation at 4000 rpm for 10 min [19].

Characterization of obtained powders

For controlling the process and standardizing the products, the moisture analysis was performed by drying the sample in an oven at 105ºC until constant weight, and the pH one was done by direct reading on the sample according to the methods described by the [20].

The parameters described below were also evaluated in triplicate.

Determination of bioactive compounds

The determination of total phenolics was realized using the methodology described by Pierpoint [21] and Singleton and Rossi [22]. The results are shown in µg of gallic acid equivalent (GAE)/mg of the product.

In order to determine the total content of flavonoids and anthocyanins, the methodology described by Lees and Francis [23] was used. The total flavonoid content was expressed in mg equivalent of quercetin/100 g of hibiscus and the total content of anthocyanins in mg equivalent of cyanidin-3-glucoside/100 g of hibiscus.

Antioxidant analysis (DPPH, FRAP and ABTS methods)

The reduction of stable radical DPPH (2,2-diphenyl-1-picrylhydrazyl) was determined according to the methodology described by Thaipong et al. [24]. Absorbance was measured at 515 nm and antioxidant activity was calculated from the Trolox standard curve and expressed in mM TE/ g of the sample. The ABTS assay was performed at the maximum absorption of 734 nm according to Meng et al. [25].

The Ferric Reducing Antioxidant Power (FRAP) was determined according to the methodology described by Pulido [26]. Absorbance was measured at 595 nm and antioxidant activity was calculated from the ferrous sulfate standard curve (R2 = 0.99) and expressed in µM ferrous sulfate (FS)/g of sample. The spectrophotometer (Jenway 6705 UV / Vis) was used in all analyses.

Phytochemical profile by UPLC – MS/MS

UPLC-MS/MS was used to identify the bioactive compounds in the extracts. Samples were injected into an ethane-bridged hybrid UPLC Acquity UPLC® (BEH) system coupled to the Xevo TQD™ Triple Quadrupole Mass Spectrometer (Mil Ford, MA, USA) and equipped with a Waters Electrospray Ionization Source (ESI) Zspray™ (Milford, MA, USA). The mass spectrometer was operated in both positive and negative modes using the following conditions: Collision gas pressure of 3.5 mbar, desolvation gas temperature of 500 °C, desolvation gas flow of 800 l h− 1 and capillary voltage of 3 kV. The analyzed molecules were separated on an Acquity UPLC® (BEH) hybrid ethane bridged C18 column (50 mm × 2.1 mm, 1.7 μm), maintained at 40 °C and injection volume of 4 µL. The mobile phase consisted of water, which was acidified with 0.1% of formic acid (A) and methanol (B). The gradient developed for separation was 0.22 mL min − 1, with 87 A: 13B from 0 to 3 min, 35 A:65B from 3 to 7.2 min, 0 A: 100B from 7.2 to 8.3 min. After that, the mobile phase returned to the initial conditions generating a total chromatographic run of 12 min [27].

Color analysis

In order to evaluate color, the portable colorimeter Minolta® CR400 with Cielab system was used, identifying the parameters of luminosity (L), red (a+), green (a-), yellow (b+), blue (b-), and color difference (ΔE). The instrument was calibrated on a standard white plate in each analysis at different times. The color difference (ΔE) was calculated according to Eq. 2, following the method detailed by Silva et al. [28].

Where: L*, a* and b* are color parameters; day 1 = first day of storage; day 40 = 40 days of storage.

Stability to the storage (Degradation Kinetics)

In order to evaluate the stability of samples, CL, TL, CE, and TE samples were stored in plastic bags in a BOD incubator in the presence of light (two 20 W fluorescent lamps, working as an artificial light source) and in the dark at 25 °C ± 1 ºC for 40 days of storage [29]. uring this period, the parameters of color, anthocyanins, and phenolic compounds were determined as a measure of stability. The assay and readings were performed in triplicate. The results of the color analysis were expressed as a function of the ΔE value (Eq. 2) and the experimental data of anthocyanins and phenolics were adjusted for the first-order reaction kinetics and half-life time (t1/2) [30] according to Eqs. (3) and (4). Previous research has shown that the degradation of natural dyes follows the first-order kinetics during storage [31,32,33].

Where: T means the time (day), A is the level of anthocyanin or phenolics, A0 is the initial level of anthocyanin or phenolics at time zero, and k is the rate constant (day− 1).

Application of powders in yogurt

For yogurt production, Ultra High-Temperature milk was used, sugar and BioRich® (CRH-Hansen) lactic ferment, composed of Lactobacillus acidophilus LA-5 (1 × 106 CFU/g), Bifidobacterium BB-12 (1 × 106 CFU/g), and Streptococcus thermophillus cultures. Initially, the culture was prepared according to the supplier’s guidelines, after that, the milk and sugar were heated to 45ºC and 3% of culture was added. Then, it was incubated for a period of 3 h until reaching a pH between 4.5 and 4.65, and then it was cooled to 15ºC. Then, the yogurt was divided into two parts, 1% of the encapsulated dyes obtained (TE and CE) were added to each part. For analyzing the antioxidant activity, it was necessary to perform the precipitation of proteins from the yogurt samples with 20% trichloroacetic acid in water, in a 1:1 proportion of yogurt and trichloroacetic acid [34]. The samples were shaken for 30 s and incubated in a heating bath at 42 °C for 10 min. In the end, they were centrifuged (750 × g) for 15 min and the supernatant was used for analysis.

Yogurt samples were evaluated considering on the following aspects: antioxidant, color, pH, moisture, and rheology. The rheological properties were determined considering the methodology of Fernandes et al. [35]. A viscometer model DV2T (Brookfield, Middleboro, Massachusetts, USA) was used. Steady-state flow curve tests were performed using an SC4-18 spindle at a constant temperature of 11 °C. Two rheological measurements were performed at the ascending shear rate (0–300 s− 1) and then at the decreasing shear (300–0 s− 1). Data were adjusted to the power-law model using nonlinear regression analysis and Rheocalc T1.2.19 software. The rheological parameters were determined at 11 °C since the drinks are sold and bought at refrigerated temperatures.

Statistics analysis

All analyses were performed in triplicate and also submitted to the analysis of variance and Tukey’s test for minimum significant difference (p < 0.05) between means using the software Sisvar version 5.6.

Results and discussions

Initially, a total of 14.425 kg of hibiscus were obtained. In order to obtain the calyces, the seeds were removed, and after the drying process reached a yield of 10.71%.

Characteristics of the extracts (conventional and thermosonified)

Table 1 shows the characteristics of the extracts, both conventional and thermosonified. Antioxidant activity in thermosonified extract was higher (p < 0.05) than the one in the conventional extract, in all methods of evaluation (FRAP, DPPH, and ABTS), being increased respectively by 1.16, 1 0.27, and 1.12 times.

Antioxidant activity in hibiscus extract could be related to phenolic compounds, flavonoids, and anthocyanins [36]. Despite phenolic compounds, flavonoids and anthocyanins did not present significant differences between samples, the higher antioxidant activity of thermosionified extract could be related mainly to anthocyanins and flavonoids. Anthocyanins have a structure that is strongly related to their antioxidant activity, different type, number, and position of the substituents in the flavylium cation can influence the antioxidant activity [36]. Also, their structures and properties are dependent on different factors such as pH, temperature, and solvents [37]. Regarding the color, it was observed that the samples tended towards the red color (H°), probably due to the reddish color of the hibiscus calyces, which have anthocyanins [8].

Literature has shown that the diffusion and solubility rates, between solute and solvent, tend to increase with increasing temperature. However, excessive temperatures are associated with the degradation of anthocyanins and phenolic compounds, in which this temperature has to be limited and find the optimal extraction temperature [38, 39]. Paraíso et al.[15] mentioned that the sonication time variables and temperature increase had a positive effect, providing greater extraction of anthocyanins and phenolic compounds in hibiscus calyces, affirming that the best condition was 45 min, 65 °C, confirming that this method is more effective than conventional extraction and that the use of 25% ethanol: water as the solvent, which may have aided in the extraction. Nevertheless, in the present study, an increase in the extraction of anthocyanins and phenolic compounds was not observed, probably because it was chosen to use just water as a solvent, considered to have an eco-friendly process.

In general, thermosonification is relevant and interesting for obtaining an extract rich in antioxidant compounds. However, the technique did not present major influences on the other parameters evaluated such as anthocyanins, phenolics compounds, color, pH, and moisture.

Table 2 presents the freeze-dried extracts and encapsulated. Similar to Table 1, after the extracts’ freeze-drying process, the antioxidant activity was higher (1.42-times for flavonoids, 1.07-times for phenolic compounds, 1.48-times for FRAP, and 1.14-times for ABTS) for the sample that was thermosonified and freeze-dried. Romanini et al. [14] performed ultrasound-assisted (high-intensity) extraction of bioactive compounds from grape pomace followed by encapsulation of alginate-Ca2+ obtaining similar results, and the levels of antioxidant capacity were higher in extracts obtained by ultrasound when compared to extraction conventional. Santos et al. [12] compared the conventional extraction of anthocyanins from blackberry pomace with ultrasound-assisted extraction, and also found similar results. Still, according to the literature, ultrasonic energy can break the cell wall, increasing the contact between the compounds and solvent, which favors the reduction of sonication time [40, 41].

The thermosification process followed by freeze-drying (Table 2) extracted more compounds such as quercetin and rutin, respectively 2.67 and 1.22 times higher for the TL sample than the conventional one (CL). Corroborating the present study, the compounds identified have already been reported in previous studies in aqueous and ethanolic hibiscus extract [7, 42, 43].

In the extraction process followed by the encapsulation by ionic gelation (Table 3), the powders that were obtained after the thermosonification (TE) presented, when compared to the conventional process (CE), more phenolic compounds (1.05 times higher) and gallic acid (1.23 times higher). It is also relevant to mention that the thermosonified sample (TE) showed compounds such as chlorogenic acid, cyanidin 3-glucoside, quercetin, and rutin, that were not detected in the conventional sample (CE), probably due to the low concentration. On the other hand, the conventional sample (CE) showed a higher content of delphinidin (on average 50%) indicating that thermosification may have degraded this compound. Previous studies have shown that, by increasing the temperature, cleavage into cyanidin and delphinidin can occur, thus forming degradation products such as protocatechuic acid and gallic acid, respectively [7]. Besides, the capsules have lower values due to the fact that the extract is dispersed within the wall material, protecting it from its direct and complete dispersion.

The encapsulation efficiency was higher in encapsulated thermosonified hibiscus extract (77.44%) than in encapsulated conventional (75.94%). Romanini et al. [14] obtained similar results in the study of the same encapsulation technique for grape residue in which the use of ultrasound combined with a temperature of 55 °C (thermo-sonication) was significantly better, presenting higher values (EE of 62.52%)when compared to conventional extraction.

Stability to the storage (degradation kinetics)

The degradation kinetics (Table 4) of phenolic compounds and anthocyanins was evaluated, and the time and incidence of light negatively affected these compounds. Regarding the half-life, the incidence of light influenced the decrease in half-life, for both extracts. In a similar study, with hibiscus extract from the same region, light and temperature factors affected the stability of phenolic compounds and anthocyanins throughout storage where the levels of anthocyanins and phenolic compounds decreased significantly, for extracts with light exposure, with a loss of 41.95% and 38.02% [15]. Santos et al. [29]. evaluated anthocyanin degradation under light in blackberry pomace microencapsulated with maltodextrin and observed a reduction of 30.04% aftr 36 days of storage. Anthocyanin loss has been reported in the literature during the storage of jabuticaba bark tea, registering a loss of monomeric anthocyanins occurring after 72 h of refrigerated storage at 5 °C [28].

The half-life time was greater in encapsulated samples, both for anthocyanins and phenolic compounds. An increase of 45,04% in half-life time anthocyanins was observed in TE when compared to TL in absence of light., besides an increase of 118,11% in half-life time to phenolic compounds. That indicates, that the encapsulation process was effective to protect bioactive compounds from samples, and increasing the half-life time. The same occurred in Santos et al. [29] work, in which the process of microencapsulation with maltodextrin was efficient in protecting phenolic compounds and anthocyanins during the storage period and, regarding the loss of bioactive compounds, the influence of light was more remarkable than that of temperature. Romanini [14] in his study shows that light degrades anthocyanins and phenolic compounds, whereas the extracts encapsulated in alginate-Ca2+ have greater efficiency when they were protected from light. In addition, Paraíso et al. [15] also portray in their work that light and temperature are factors that affect the stability of phenolic compounds and anthocyanins during the storage period under the different conditions studied. Santos et al. [44] evaluated ionic gelation encapsulation in blackberry pomace and notice higher stability of ionic gelation capsule in both the absence and presence of light than in other capsules produced.

Obón et al. [45] mention that color changes can be measured as the modulus of the distance vector between the initial color values and the actual color coordinates in the CIELAB three-dimensional color space (ΔE). Besides, differences in perceptible color can be defined as small (ΔE < 1.5), distinct (1.5 < ΔE < 3), and highly distinct (ΔE > 3) the author also mentions that the color variation is only evident for ΔE > 5. Freeze-dried powders showed a variation of ΔE between 1.78 and 8.43. When comparing encapsulated and unencapsulated samples, color variations were smaller in all encapsulated samples both in the presence and absence of light. Also, the thermosonified samples (TL and TE) showed greater color stability (ΔE of 1.78 for the powder and 2.00 for the capsule) and also better half-life, whereas the conventionally extracted samples showed greater color variability (ΔE) in the presence of light.

Silva et al. [46] mention in their study that low values of ΔE are widely wanted for the general view of color variations, they indicate that the powder pigment has the original extract color after the reconstitution. The color change can happen due to the loss of anthocyanins during the storage period, which can also be related to the co-pigmentation of anthocyanins with other phenolic compounds. A recent study evaluated the thermal processing and subsequent storage of hibiscus extract and observed the clarification of the extracts with storage at 4 °C for 20 days [47].

Overall, the encapsulated samples (TE and CE) presented longer half-life and smaller color variations (ΔE) showing to be more stable, mainly in the absence of light. They were chosen for application in the food matrix.

Application in a food matrix – yogurt

Yogurt was the food matrix chosen for the application of capsules. Since yogurt consumption increases according to the need for its diversity in the market, the consumers have been looking for dairy products with exotic and different flavors, with the incorporation of new ingredients in order to improve the flavor, color, diversifying nutritional properties and standing out in consumer preference [48, 49].

Both capsules was suitable to yogurt application, the use of different extraction techniques did not influence in major the evaluated characteristics in yogurts (Table 5). For the parameters of moisture, pH, flavonoids, phenolic compounds, antioxidant by DPPH and FRAP methods, color parameter (b* and H) and texture profile, there were no significant differences between the samples (p < 0.05).

The yogurt sample with the thermosonified capsule presented antioxidant content (ABTS) 8.88% higher than the conventional sample. Regarding color, the thermosonified encapsulated sample (TE) was presented as darker (lower luminosity value) and tending to red, while CE showed greater luminosity (L*), and greater chromaticity (C) with values that tended to yellow. A possible explanation is the type of wall material used and even though the capsule performs a controlled release, in addition to having a part of wall material and extract. Apart from that, the homogenization of the encapsulating agents is smaller than the powder.

Santos et al. [44] also evaluated the application of anthocyanins-rich capsules in yogurts, and show that yogurt added to microcapsules presented higher percentages of bioactive compounds than the pristine microcapsules, which could be essential to the absorption of these compounds by humans.

Conclusion

Overall, the thermosonified extract showed better results for bioactive compounds and antioxidant activity, in relation to stability it showed high values of half-life (between 38.23 and 376.23 days). The presence of light negatively affected the samples color and the parameters of anthocyanins and phenolic compounds. By comparing encapsulated and unencapsulated samples, color variations were smaller in all encapsulated samples. In addition, the thermosonified samples showed greater color stability and also better half-life, whereas the conventionally extracted samples showed greater color variability (ΔE) in the presence of light. Thus, it is concluded that the ultrasonic extraction method using water as a solvent is eco-friendly and feasible to use followed by the encapsulation by ionic gelation is efficient in protecting against the degradation of phenolic compounds, anthocyanins, and also the color of hibiscus powders. When applied to yogurt, the thermosonified encapsulated (TE) sample showed to be darker (lower brightness value) and with a greater tendency towards red, being more indicated for this type of product, and potentially recommended for use as a natural food dye.

Data availability

Data sharing is not applicable to this article.

References

S. Damodaran, K.L. Parkin, Química de Alimentos de Fennema, 5th edn. (Artmed, Porto Alegre, 2019)

G.T. Sigurdson, P. Tang, M.M. Giusti, Annu. Rev. Food Sci. Technol. 8, 261 (2017)

W. Guimarães, M.I.R. Alves, N.R. Antoniosi, Filho, Quim. Nova 35, 1673 (2012)

L. de B. Anastácio, D.A. Oliveira, C.R. Delmaschio, L.M.G. Antunes, F.M.D. Chequer, J. Appl. Pharm. Sci. 2, 16 (2016)

M.A.G. de Menezes, F.B. de O. Neto, L.M. Bertino, F. F. M. da Silva, and L.A. Alves, HOLOS 1, 30 (2015)

K. Nachay, Food Technol. 71, 83 (2017)

A. Sinela, N. Rawat, C. Mertz, N. Achir, H. Fulcrand, M. Dornier, Food Chem. 214, 234 (2017)

S. Cid-Ortega, J.A. Guerrero-Beltrán, J. Food Sci. Technol. 52, 6859 (2015)

A.B. Da Silva, J.M. Wiest, H. Helena, C. Carvalho, Brazilian Journal of Food Technology 19, (2016)

J.L.D. Antigo, A.P. Stafussa, R. de Cassia, Bergamasco, G.S. Madrona, J. Food Eng. 285, 110101 (2020)

I. Nicolau-Lapeña, T. Lafarga, I. Viñas, M. Abadias, G. Bobo, and I. Aguiló-Aguayo, Food and Bioprocess Technology 2019 12:9 12, 1452 (2019)

S.S. dos Santos, F. de S. Magalhães, C.M. Paraíso, C.Y.L. Ogawa, F. Sato, O. de O. Santos Junior, J.V. Visentainer, G.S. Madrona, M.H.M. Reis, J Food Process Eng e14077 (2022)

Y. Tao, Z. Zhang, D.W. Sun, Ultrason. Sonochem 21, 1461 (2014)

E.B. Romanini, L.M. Rodrigues, A. Finger, T.P.C. Chierrito, M.R. da S. Scapim, G.S. Madrona, Food Chem 338, 128101 (2021)

C.M. Paraíso, S.S. dos Santos, C.Y.L. Ogawa, F. Sato, O. A. A. dos Santos, and G.S. Madrona, Emir J Food Agric 32, 55 (2020)

C.M. Paraíso, S.S. dos Santos, V.G. Correa, T. Magon, R.M. Peralta, J.V. Visentainer, G.S. Madrona, J. Food Sci. Technol. 2019 56(10 56), 4667 (2019)

A.G. da S. Carvalho, M.T. da C. Machado, H.D. de F.Q. Barros, C.B.B. Cazarin, M.R. Maróstica, Junior, M.D. Hubinger, Powder Technol 345, 283 (2019)

S.N. Selamat, I.I. Muhamad, M.R. Sarmidi, in The 3rd South East 33 Asian Technical University Consortium (SEATUC) Symposium (2009)

D.I. Díaz, C.I. Beristain, E. Azuara, G. Luna, M. Jimenez, J. Microencapsul. 32, 247 (2015)

I.A.L. IAL, Métodos Físico-Químicos Para Análise de Alimentos, 4th edn. (IMESP, São Paulo, 2008)

W.S. Pierpoint, Methods Mol. Biol 244, 65 (2004)

V.L. Singleton, J.A. Rossi, Am. J. Enol. Vitic 16, 144 (1965)

D.H. Lees, F.J. Francis, Hortscience 7, 83 (1972)

K. Thaipong, U. Boonprakob, K. Crosby, L. Cisneros-Zevallos, D. Hawkins, Byrne, J. Food Compos. Anal 19, 669 (2006)

D. Meng, P. Zhang, L. Zhang, H. Wang, C.T. Ho, S. Li, F. Shahidi, H. Zhao, J. Funct. Foods 37, 467 (2017)

R. Pulido, L. Bravo, F. Saura-calixto, Food Chem. 48, 3396 (2000)

C.M. Paraíso, J.G.B. Januário, A.G. Mizuta, S.S. dos Santos, T.F. dos Santos Magon, C.Y.L. Ogawa, J.V. de Oliveira, F. Silva, J.V. Sato, J.M.G. Visentainer, Mikcha, G.S. Madrona, Journal of Food Measurement and Characterization 2021 15:4 15, 3531 (2021)

J.K. da Silva, ÂG. Batista, C.B.B. Cazarin, A.P. Dionísio, E.S. de Brito, A.T.B. Marques, M.R. Maróstica, Junior, LWT - Food Science and Technology 76, 292 (2017)

S.S. Santos, L.M. Rodrigues, S.C. Costa, R.C. Bergamasco, S. Madrona, Chem. Eng. Trans. 57, 1837 (2017)

J.A. Stamp, T.P. Labuza, J. Food Sci. 48, 543 (1983)

G.S. Serris, C.G. Biliaderis, J. Sci. Food Agric. 81, 691 (2001)

C. Bustos-Garza, J. Yáñez-Fernández, and B. E. Barragán-Huerta, Food Research International 54, 641 (2013)

D.M. Cano-Higuita, C.R. Malacrida, V.R.N. Telis, J. Food Process. Preserv 39, 2049 (2015)

A. Zulueta, A. Maurizi, A. Frígola, M.J. Esteve, R. Coli, G. Burini, Int. Dairy. J. 19, 380 (2009)

A.B.C. Fernandes, V.A. Marcolino, C. Silva, C.E. Barão, T.C. Pimentel, Food Biosci. 42, 101200 (2021)

L.G. Maciel, M.A.V. do Carmo, L. Azevedo, H. Daguer, L. Molognoni, M.M. de Almeida, D. Granato, N.D. Rosso, Food Chem. Toxicol 113, 187 (2018)

N. Tena, J. Martín, A.G. Asuero, Antioxidants (Basel) 9, (2020)

L.G. D’Alessandro, K. Kriaa, I. Nikov, K. Dimitrov, Sep. Purif. Technol. 93, 42 (2012)

A.C. Pedro, D. Granato, N.D. Rosso, Food Chem. 191, 12 (2016)

J. Azmir, I.S.M. Zaidul, M.M. Rahman, K.M. Sharif, A. Mohamed, F. Sahena, M.H.A. Jahurul, K. Ghafoor, N. A. N. Norulaini, and A. K. M. Omar, J. Food Eng. 117, 426 (2013)

L.G. D’Alessandro, K. Dimitrov, P. Vauchel, I. Nikov, Chem. Eng. Res. Des 92, 1818 (2014)

S. Pimentel-Moral, I. Borrás-Linares, J. Lozano-Sánchez, D. Arráez-Román, A. Martínez-Férez, A. Segura-Carretero, J. Pharm. Biomed. Anal. 156, 313 (2018)

C.M. Paraíso, S.S. dos Santos, V.G. Correa, T. Magon, R.M. Peralta, J.V. Visentainer, G.S. Madrona, J. Food Sci. Technol. 56, 4667 (2019)

S.S. dos Santos, C.M. Paraíso, E.B. Romanini, V.G. Correa, R.M. Peralta, S.C. da Costa, O. de O. Santos Junior, J.V. Visentainer, M.H.M. Reis, G.S. Madrona, Innovative Food Science & Emerging Technologies 81, 103111 (2022)

J.M. Obón, M.R. Castellar, M. Alacid, J.A. Fernández-López, J. Food Eng. 90, 471 (2009)

P. Ibrahim Silva, P.C. Stringheta, R.F. Teof́ilo, I.R.N. De Oliveira, J. Food Eng. 117, 538 (2013)

X. Sui, S. Bary, W. Zhou, Food Chem. 192, 516 (2016)

M. Barkallah, M. Dammak, I. Louati, F. Hentati, B. Hadrich, T. Mechichi, M.A. Ayadi, I. Fendri, H. Attia, S. Abdelkafi, LWT 84, 323 (2017)

E. Mohammadi-Gouraji, S. Soleimanian-Zad, M. Ghiaci, LWT 102, 230 (2019)

Funding

This paper received research support funding from the National Council for Scientific and Technological Development (CNPq) and the Coordination for the Improvement of Higher Education Personnel (CAPES).

Author information

Authors and Affiliations

Contributions

Thainá Rodrigues Stella: Conceptualization, Data curation, Formal analysis, Investigation, Methodology, Software, Writing - original draft, Writing - review & editing. Carolina Moser Paraíso: Formal analysis, Investigation, Methodology, Writing – original draft. Jessica dos Santos Pizzo: Formal analysis, Investigation, Methodology. Jesuí Vergílio Visentainer: Formal analysis, Supervision, Visualization. Suelen Siqueira dos Santos: Writing - original draft, Writing - review & editing. Grasiele Scaramal Madrona: Conceptualization, Data curation, Funding acquisition, Investigation, Methodology, Project administration, Resources, Software, Supervision, Validation, Visualization, Writing - original draft, Writing - review & editing.

Corresponding author

Ethics declarations

Conflict of interest

I declare that the authors have no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Stella, T.R., Paraíso, C.M., dos Santos Pizzo, J. et al. Hibiscus (Hibiscus Sabdariffa L.) extracts freeze-dried and encapsulated by ionic gelation: an approach for yogurt application. Food Measure 17, 2630–2638 (2023). https://doi.org/10.1007/s11694-023-01818-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-023-01818-7