Abstract

Encapsulation techniques can protect active components from degradation during storage while maintaining their functionality. The purpose of this study was to evaluate the use of double emulsion followed by ionic gelation in the encapsulation of the extract of Hibiscus sabdariffa L. anthocyanin (HE) in the application of the microparticles in a yogurt food matrix. The ionic gelation methods used were dripping-extrusion—D (Encapsulator Büchi B-390)—and atomization—A (Spray Dryer Büchi B-290). Double emulsion (HE/rapeseed oil/pectin) and a cross-linked solution (CaCl2) were employed. Yogurt matrix was characterized for total dry matter, total lipids, protein content, total lactic bacteria, pH/acidity, phenolic compounds (Folin-Ciocalteu), total anthocyanins (differential pH), antioxidant activity (DPPH), color (colorimeter), and morphology (optical microscopy) and was subjected to a sensory appearance acceptability test (80 panelists). The samples were stored in the absence of light (5 ± 1 °C) and monitored every 7 days for total polyphenols, total anthocyanins, color, pH/acidity, and syneresis, for a period of at least 30 days. The use of microparticles obtained by double emulsion followed by ionic gelation and incorporated in yogurt matrix presented technical feasibility, providing color and functionality to the product. The yogurt matrix with microparticles obtained by the atomization technique presented high acceptability of appearance. Microparticles obtained by the dripping-extrusion technique showed greater stability of anthocyanins (48%) and color (ΔE = 1.42) during the yogurt matrix shelf life.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

There is a global trend indicating the need for food to be seen not only as a source of nutrients with sensory appeal but also as a source of well-being and health (World Health Organization 2018). Functional foods aiming at digestive health, child nutrition, elderly nutrition, weight management, obesity prevention, and beauty enhancement have been gaining considerable importance in the market (Sun-Waterhouse and Wadhwa 2013). Bioactive compounds having properties for these health targets include alkaloids, anthocyanins, carotenoids, flavonoids, glucosinolate, isoflavone, phenolic acid, tannin, and terpenic phytochemicals, as well as protein hydrolysates (Sun-Waterhouse and Wadhwa 2013; Jansen-Alves et al. 2018).

The main constituents of H. sabdariffa which are relevant for food and pharmacological use are organic acids, anthocyanins, polysaccharides, and flavonoids. Several studies have identified delphinidin-3-sambubioside and cyanidin-3-sambubioside as the main anthocyanins present in hibiscus calyx and leaves extract. In the food industry, the calyx is the most used part of the plant, from which several types of product can be elaborated, such as teas, fermented beverages, juices, jam, ice cream, chocolate, and cakes (Da-Costa-Rocha et al. 2014).

The dairy industry is one of the most innovative in the food sector and has been following the healthfulness and well-being trend in the past few years. This industry has strongly invested in products with functional appeal, probiotics, prebiotics, and natural antioxidants (Lucey 2016; Zacarchenco et al. 2017).

The use of functional ingredients that may add value to the final product focusing on promoting population’s health and well-being has leveraged the food market (Nachay 2017). To that effect, vegetables have been a highly demanded raw material in order to create new ingredients for innovative utilization.

The incorporation of functional ingredients into food is often limited by their taste and instability during processing and storage. Encapsulation techniques are commonly used to overcome these limitations and to develop higher value-added products (Celli et al. 2015).

The use of açaí (Euterpe oleracea Mart.) juice in yogurt evaluating the phenolic composition, as well as its potential use as food ingredient and natural pigment, was studied by Coısson et al. (2005). The results showed yogurt enriched with açaí juice (10 g/100 g) had color characteristics which were similar to commercial yogurt added with blueberry juice, being stable during 2 days at 4 °C in the presence of air (visual evaluation). On the other hand, total anthocyanin content and the antioxidant capacity of yogurt with açaí juice were lower than the values observed in commercial yogurt with blueberry juice.

A reduction in the total antioxidant activity (23%) and total phenolic content (14%) was observed by Oliveira et al. (2015) soon after adding strawberry preparation to the yogurt. Total anthocyanin content did not immediately change, but it was diminished by 24% during the yogurt shelf life (30 days). The authors concluded interactions may have occurred among yogurt proteins, phenolic compounds of strawberry, and hydrocolloids (carrageenan and starch) used in the formulation, thus reducing the total polyphenol content and suggesting its replacement with neutral hydrocolloids (e.g., xanthan gum, guar, LBG).

Bilek et al. (2017) studied the use of black carrot concentrate in microcapsule based on whey protein (thermal gelation emulsion method) in yogurt manufacturing. The authors observed the reduction of antioxidant potential, which may have occurred due to interaction of phenolic compounds with yogurt proteins. In addition, encapsulated concentrate showed homogenous distribution of pink color in yogurt when added to capsule concentrations of 5 to 20%, preserving the color and increasing its stability.

The encapsulation of a shrimp lipid extract by complex coacervation and its application in yogurt was employed by Gomez-Estaca et al. (2018). A trained sensory team concluded that the encapsulation effectively reduced the characteristic odor of the lipid extract, while providing a uniform and attractive color compared with the unencapsulated extract.

The use of O/W emulsion followed by ionic gelling was employed by Ghaderi-Ghahfarokhi et al. (2016) in the encapsulation of thyme essential oil (TEO) to control lipid oxidation, microbial deterioration, and sensory alteration of fresh beef burgers during refrigerated storage. Based on these authors’ results, food industries would benefit from the use of encapsulation technology to improve microbial, chemical, and sensory quality.

Therefore, the objective of this work was to employ microparticles of anthocyanin extract derived from the calyx of hibiscus using double emulsion followed by ionic gelation (dripping-extrusion and atomization) in yogurt matrix followed by samples’ characterization and evaluation of the sensorial acceptance of appearance. The stability of bioactive compounds, color parameters, pH/acidity, syneresis, and viability of lactic acid bacteria were evaluated during the yogurt matrix shelf life.

Material and Methods

Material

The following were used: food grade (30 g/100 g) hibiscus extract (Hibiscus sabdariffa L.) provided by Heide Extratos Vegetais company, Pinhais/PR, GENU® amidated low methoxyl pectin (CP Kelco, Limeira/SP), food grade calcium chloride (Dinâmica, Diadema/SP), rapeseed oil: commercial brand Liza oil (Cargill Agrícola S.A., Mairinque/SP), analytical grade reagents—PA, PGPR (polyglycerol polyricinoleate) surfactant (Danisco Brasil Ltda, São Paulo, Brazil), pasteurized skim light milk type A Xandô® (Laticínios Xandô, Araras/SP), skim powdered milk Molico® (Nestlé/Araçatuba/SP), and commercial thermophilic culture for yogurt—LYOFAST Y 450B (Sacco Srl System/Italy) composed by microorganisms Streptococcus thermophilus and Lactobacillus delbrueckii ssp. bulgaricus.

Methods

Extract Characterization

Content of Total Phenolic Compounds

The content of total phenolic compounds was determined according to the Folin-Ciocalteu spectrophotometric method described in Singleton and Rossi (1965) and used by Turkyılmaz et al. (2013). For determination of total phenolic compounds and anthocyanins content, amounts of 5.000 g ± 0.001 g were used and absorbance readings (in triplicate) were made in UV/visible spectrophotometer (Varian, model Cary 50).

Anthocyanin Content

Total anthocyanins were determined by using the pH differential method, by AOAC (2006). Dilution was performed in a solution at pH 1 and 4.5, with quantification of absorbance on a wavelength of 520 and 700 nm.

Antioxidant Capacity—DPPH

The antioxidant capacity by DPPH method was measured according to the Brand-Williams et al. (1995) methodology and applied in Arend et al. (2017). For antioxidant capacity determination, sample amounts of 0.120 ± 0.001 g were weighted in a 100-mL volumetric flask and volume was completed with ethyl alcohol 70%, with absorbance readings (in triplicate) being made in the same spectrophotometer.

Antioxidant Capacity—ABTS

The antioxidant capacity by ABTS method was measured according to the Arts et al. (2001) and applied in Turkyılmaz et al. (2013).

Color Measurement

Colorimetric determinations were conducted by using Chromameter CR-400 (Konica-Minolta Sensing Inc., Osaka, Japan), programmed in CieLab system. Color reading was performed after the samples were put in test tubes. The readings were made in quadruplicate. Equipment was calibrated with the white calibration plate before any reading.

Chroma and hue values were also calculated by Eqs. (1) and (2).

Production of Emulsion

In order to enable the hydrosoluble extract to be retained in gel matrix (also rich in water), a strategy was used based on multiple A/O/A emulsion, with A corresponding to hydrosoluble extract/O—hydrophobic retention barrier/A—hydrocolloid solution. For appropriate formation, initially, the simple emulsion (A/O) was studied, by using rapeseed oil (Cargill) as continuous phase and surfactant (PGPR 90, brand Tovani Benzaquen Ingredientes).

To prepare the A/O emulsion, surfactant PGPR was initially solubilized in rapeseed oil under magnetic stirring (400 rpm/5 min), at 42 ± 2 °C. After the procedure, mixture was maintained in the environment until reaching 25 °C. Applications varying from 1 to 4 g/100 g of surfactant PGPR were tested.

Dispersion of rapeseed oil/PGPR happened in a jacketed reactor connected to ultra-thermostatic bath in order to keep the emulsion temperature controlled at 25 ± 2 °C. Aqueous phase (hibiscus extract) was added to the dispersion (mean flow of 2.5 mL/min) and homogenized in Turratec disperser (brand Tecnal model TE102, Piracicaba, Brazil) at 15,000 rpm. After complete incorporation of aqueous phase (15 min), rotation speed has been reduced to 11,000 rpm and system was homogenized for 5 min.

A/O emulsions studied had fixed phase ratio of 35:65 (gextract:goil + PGPR) and variable surfactant concentrations (1, 2, 3, and 4 g/100 g).

To select the best emulsion, stability on sedimentation, optical microscopy, mean size and size distribution of droplets, interfacial tension, rheological behavior, and color were evaluated. Methodologies are described in the following section.

Sedimentation Rate

Immediately after emulsions preparation, each sample was transferred to 100-mL graduated test tubes (27 mm of diameter and 173 mm of height), which were sealed and placed on the bench at room temperature for 24 h. Stability evaluation was performed by observing if emulsion phase separation had occurred 24 h following the emulsification procedure (Frascareli et al. 2012).

Stability was measured in triplicate by upper phase height, with sedimentation rate (SR) being described by Eq. (3).

where H0 corresponds to initial height and H represents the upper phase height after 24 h.

Microstructure

Droplets’ microstructure was assessed by a methodology adapted from Alvim et al. (2013), by using optical microscope (model BX41, brand Olympus) for visualization at a magnification of 1000×, after 24 h of storage.

Mean Diameter and Size Distribution

Sample mean diameters and size distribution were determined in Laser Light Scattering Analyzer LA-950V2 (Horiba Instruments, Inc., Japan) by light scattering, using the equipment module (quartz plates) appropriate for pasty samples. Sample dispersant was rapeseed oil of commercial brand Liza (Cargill Agrícola S.A., Mairinque/SP), at a dilution of 1:6 (gemulsion:grapeseed oil).

Measurements were taken at 25 °C, after 24 h. Mean diameter was determined considering the mean diameter of a sphere with the same area (surface mean diameter—D[3,2] or Sauter diameter), shown in Eq. (4). Samples were analyzed in quadruplicate, as per the adapted method of Carvalho et al. (2014).

where di is the droplet diameter and ni is the number of droplets.

Polydispersity index (PDI) was calculated according to Jafari et al. (2007), using Eq. (5).

where d10, d50, and d90 are the diameters at 10%, 50%, and 90% of accumulated volume, respectively. That is, d90 − d10 is the data interval and d50 is the mean diameter.

Interfacial Tension

Interfacial tension between rapeseed oil and hibiscus extract was measured using tensiometer Traker-S (Teclis, France) by pendant drop method. Analyses were conducted at 25 ± 1 °C, forming a droplet of extract in the oil phase.

On a second step, the effect of surfactant concentration on the interfacial tension was assessed. In order to evaluate the PGPR concentration effect, a dispersion of such compound (1, 2, 3, and 4 g/100 g) in rapeseed oil was conducted under magnetic stirring at 42 ± 2 °C. After cooling, formation of a hibiscus extract droplet took place in the continuous phase, which was composed of PGPR/rapeseed oil for interfacial tension measurement. Droplets volume used was 2 μL, and analyses were made in duplicate.

Rheological Behavior

Rheological behavior of emulsions was determined in a Brookfield rheometer, model R/S+ SST (Stoughton, MA, USA), with system of measurement CC3-45. Every measurement was made in duplicate, at a temperature of 25 °C.

Emulsion characterization was performed through flow behavior. Ascending and descending curves were elaborated with a strain rate ranging from 0 to 700 s−1, in order to eliminate potential thixotropy effects. Equation (6) for power law fluid was used to adjust the flow behavior, and parameters n and k were estimated by non-linear regression solution method, using Statistica® version 12 (StatSoft Inc., Tulsa, USA).

where σ is the shear stress (Pa), Ῠ is the strain rate (s−1), n is the behavior index, and k is the consistency index (Pa sn).

Model adjustment was evaluated based on the coefficient of determination (R2). Apparent viscosity in the strain rate of 100 s−1 (ηap) was also evaluated, since it is a typical value for several processes such as flow, stirring, and milling (Mcclements 2005).

Analysis of Color

Parameters of L*, a*, b*, C*, and H* were assessed 24 h after emulsion elaboration. Equipment was previously calibrated with white calibration plate, and emulsion color reading was made in quadruplicate, after the samples were put in test tubes.

Encapsulation of Anthocyanin Extract

In order to obtain hydrosoluble extract retention in gel matrix (also rich in water), a double emulsion (W/O/W) was produced with rapeseed oil) at a ratio of 35:65 w/w and a pectin solution (2 g/100 g) at a 20:80 w/w ratio. Detailed methodology description can be found in Moura et al. (2018).

Encapsulation by Using Dripping-Extrusion Method

Particles were produced using the encapsulator equipment (Büchi B-390). The cross-linking solution was CaCl2 3 g/100 g. The parameters considered were nozzle diameter of 300 μm, air pressure of 200 mbar, vibration frequency of 100 Hz, and electrode tension of 400 V.

Encapsulation by Atomization Method

The particles were formatted by spraying and applying a double-fluid atomizer (mini spray dryer B-290—nozzle 0.7 mm, adapted outside equipment), where double emulsion was sprayed on the cross-linking solution (CaCl2 3 g/100 g). For the experiments, the following variables were considered: air pressure of 0.15 bar and feeding rate of 1.30 mL/min.

Application of Microparticles in Yogurt Matrix

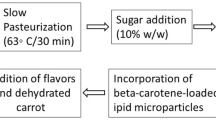

Yogurt Production

Pasteurized skim milk Type A (9 g/L of total solids) was used for yogurt samples production. In order to maintain the adequate total solid content and to avoid whey release, 3 g/L of skim milk powder were added. Mixture was thermally treated in a water bath at 85 ± 2 °C for 30 min and cooled to 42 ± 2 °C. Then commercial thermophilic culture for yogurt was inoculated at the dose recommended by the manufacturer, keeping inoculated milk incubated in BOD at 43 ± 1 °C until a pH value of 4.65–4.75 was reached. Subsequently, the sample was cooled between 20 and 25 °C and three formulations were prepared: yogurt with 1.5 g/100 g of hibiscus anthocyanin free extract, yogurt with 20 g/100 g of anthocyanin microparticles obtained by atomization, and yogurt with 20 g/100 g of anthocyanin microparticles obtained by dripping. The extract amount in all three yogurt formulations is equivalent, being defined based on Brazilian legislation (Brasil 2007). Samples were stored in white high-density polyethylene plastic pots (120 g) (Embagel – Embalagens de plástico, São Paulo/SP) and stored at 5 ± 2 °C, for 36 days, considering the high use of such package in Brazil and the conditions used by those consumers.

For studies of particles application in yogurt matrix, particles generated in the following conditions were used: dripping at 100 Hz/400 V and atomization at 0.15 bar/1.30 mL/min. Microparticle application in yogurt was conducted in a laminar flow hood, avoiding environmental contamination and assuring a safe handling.

Yogurt Characterization

Total Dry Matter (TDM)

Dry extract content was determined by drying of sample plus treated sand in oven at 102 ± 2 °C, according to methodology described at Instituto Adolfo Lutz (2008).

Total Lipids

Mojonnier method was used, according to methodology described in Hooi et al. (2004).

Protein Content

Protein content was obtained by determining total nitrogen (TN) by the Kjeldahl method (Hooi et al. 2004).

Total Lactic Bacteria

Anaerobic incubation in MRS agar pH 6.5 at 37 ± 1 °C for 72 h was conducted. Medium: MRS agar pH 6.5, brand Kasvi, incubator: B.O.D. SL - 200/364 brand Solab, anaerobiosis generator: GasPak-ez, seeding technique: pour plate (Frank and Yousef 2004). Analyses were made at time 1 and 30 days after storage at 5 ± 2 °C.

pH

pH was measured in a potentiometer (Digimed, model DM 20, Brazil), according to the methodology described at Instituto Adolfo Lutz (Brasil 2005).

Titratable Acidity

AOAC acidimetric method no. 942.15 B (Official Methods of Analysis of the Association of Official Analytical Chemists—AOAC 2006) was used.

Total Phenolic Compounds

Yogurt with free extract (80 ± 0.01 g) proceeded to direct extraction. Yogurt with microparticles was initially dissolved in distilled water at a 1:10 ratio (yogurt: water) using 50 ± 0.01 g of yogurt and let rest in a separating funnel. After separating yogurt solids (lower part of the separatory funnel), particles were vacuum filtered. For dissolution of particles, EDTA (0.2 M) was used. The content of total phenolic compounds was determined according to the Folin-Ciocalteu spectrophotometric method described in Singleton and Rossi (1965) and used by Turkyılmaz et al. (2013). Yogurt without the active compound was used as control, aiming to disregard the effects of interfering materials in quantifications.

Total Monomeric Anthocyanins

Total anthocyanins were determined by using the pH differential method, by AOAC (2006).

Antioxidant Capacity—DPPH

The antioxidant capacity by DPPH method was measured according to the Brand-Williams et al. (1995) methodology and applied in Arend et al. (2017).

Analysis of Color

Colorimetric evaluation of yogurt was conducted by analyzing the parameters L*, a*, b*, C*, and H*. Yogurt color reading was made with the samples in test tubes, in 10 different points of the sample.

Sensory Acceptability

Appearance Acceptability Test

It was conducted according to Meilgaard et al. (2015) and Ares et al. (2010). For this evaluation, 80 yogurt consumers were recruited among employees and trainees, with no restrictions for sex and age, from social classes A/B/C (high, intermediate, low) as per Brazilian Standard Economic Ranking Criteria 2015 (ABEP 2016).

The samples were evaluated for appearance acceptability by using the 9-point hedonic scale (9 = like extremely, 5 = neither like nor dislike and 1 = dislike extremely) and for purchase intention (5 = definitely would buy, 3 = maybe would buy it, maybe not, 1 = definitely would not buy). After the three samples were evaluated, the consumers were asked to put the samples in order of preference. In the end, a commercial red/purple sample (commercial light Greek yogurt, brand Nestlé, strawberry) was evaluated.

Samples were evaluated in one single monadic sequential session, as per an outline of complete balanced blocks and showed with random three-digit code number, each sample were placed in transparent acrylic square-shaped glasses and covered with plastic film. Test was conducted in individual cabins lightened by fluorescent lamps equipped with computed system Compusense Five version 5.6 for collection, and data analysis was made by using XLSTAT version 18.03.35937.

Data related to hedonic and purchase intention scales were presented with frequency distribution, separated into acceptance (values from 6 to 9, like a little to like extremely), indifference (value 5, neither like nor dislike) and rejection (values from 1 to 4, dislike extremely to dislike a little), and into positive attitude (values 4 and 5, probably would buy and definitely would buy), doubt (value 3, maybe would buy it, maybe not), and negative attitude (value 1 and 2, probably would not buy and definitely would not buy) for purchase intention scale.

Yogurt Stability Study

Recently processed yogurt samples were stored in polyethylene pots and stored at 5 ± 2 °C. The analyses were made during 36 days of storage and, after 62 days, pictures of the samples were taken.

Total Phenolic Compounds

The content of total phenolic compounds was determined according to the Folin-Ciocalteu spectrophotometric method described in Singleton and Rossi (1965) and used by Turkyılmaz et al. (2013).

Total Monomeric Anthocyanins

Total anthocyanins were determined by using the pH differential method, by AOAC (2006).

Analysis of Color

Yogurt colorimetric evaluation was conducted by analyzing the parameters L*, a*, b*, C*, and H*. The total color difference (∆E) of microparticles and fluids were calculated by Eq. (7).

pH

pH was measured in a potentiometer (Digimed, model DM 20, Brazil), according to the methodology described at Instituto Adolfo Lutz (Brasil 2005).

Titratable Acidity

AOAC acidimetric method no. 942.15 B (Official Methods of Analysis of the Association of Official Analytical Chemists—AOAC 2006) was used.

Syneresis

Whey released from yogurt formulations was quantified according to Aryana (2003), with adjustments. Reading of yogurt stored in 10-mL plastic tubes was made in triplicate, every 7 days, for a period of 30 days.

Statistical Methods

The results of the study were statistically evaluated using the analysis of variance (ANOVA) and Tukey’s test at the 5% level of significance, using the Statistica® software version 12 (StatSoft Inc., Tulsa, USA).

Results and Discussion

Content of Total Anthocyanins, Total Phenolic Compounds, and Antioxidant Capacity of Hibiscus Extract

Hibiscus extract has been examined in recent studies due to the possibility of extracting total phenolic compounds from different parts of the plant. The results of 279.14 mg/100 g total polyphenols for extract obtained from hibiscus calix are in compliance with values observed by Mohd-Esa et al. (2010) and Zhen et al. (2016) (Table 1).

Hibiscus calyx extract had higher anthocyanin and total phenolic compound contents than the values shown by Wilkowska et al. (2016) in a study with blueberry juice (38.0 mg/100 g of anthocyanins and 74.4 mg/100 g of total phenolic compounds); such fruit is known as a source of polyphenols and anthocyanins.

Hibiscus extract also had similar polyphenol content, higher antioxidant capacity, and lower total anthocyanin content than the values demonstrated by Colak et al. (2016), who studied total phenolic compounds content in blueberry extract. The values found by these authors were 288 mg/100 g of total polyphenols, 144 mg/100 g of total anthocyanins, and 12 μmol/g of antioxidant capacity by DPPH.

Studied hibiscus extract had moisture of 91.1%. The anthocyanin value found (1.13 g/100 g of dry extract) is slightly above the value shown by Sinela et al. (2017). These authors have performed quantification of anthocyanins present in Hibiscus sabdariffa L. extract, observing main anthocyanin contents of 0.46 and 0.30 g/100 g of dry extract. According to Sinela et al. (2017), total anthocyanin content may be affected by cultivation, year of production, soil, and climate conditions.

Anthocyanin content had values within the range shown by Juliani et al. (2009) for Hibiscus sabdariffa varieties of different origins and times of production (1 to 1.5 g/100 g of dry extract). With regard to polyphenol content, the value is also within the range (2 to 3 g/100 g of dry extract) demonstrated by Juliani et al. (2009).

Emulsion Stability Evaluation

In order to evaluate emulsion stability, sedimentation rate, interfacial tension, physicochemical properties, and microscopy follow-up assays were performed.

Sedimentation Rate

Sedimentation rate was reduced with increased PGPR percentage, and higher surfactant concentration (4%) has resulted in more stable emulsions (sedimentation rate of 0.09 ± 0.12%) after a 24-h follow-up period at room temperature.

PGPR has good emulsifying properties in A/O emulsions constituted by triglycerides in organic phase (Pawlik et al. 2010). PGPR hydrophilic portion is composed of polyglycerol moieties, which are relatively large molecules. Hydroxyl groups connected to water molecules by hydrogen bonds result in a structured interface. Good fixation of hydrophilic portion with emulsifier contributes for the stability of emulsions with higher water volume fractions (Ushikubo and Cunha 2014).

Microstructure

Microstructure of A/O emulsions after homogenization at surfactant concentrations of 1, 2, 3, and 4% (g/100 g) evaluated after 24 h of stabilization is shown in Fig. 1. The dilution used was 1:1 g/100 g with rapeseed oil. Magnification of 1000x was used.

Increased use of PGPR has caused the reduction of droplet size (Fig. 1), which results in higher emulsion stability.

Mean Diameter, Size Distribution, and Color

The D3,2 value found by applying PGPR 4% was similar to the value observed by Aditya et al. (2015) when evaluating the size of catechin emulsion droplets in olive oil at PGPR 6% (D3,2 = 0.53 ± 0.10 μm). Mean diameter of droplets was influenced by PGPR concentration (Table 2). Increased use of PGPR has resulted in significant reduction (p < 0.05) of droplets size (reduction of D50 and D3,2), in addition to reduced PDI (polydispersion index), which caused higher stability of emulsion when PGPR 4% was used. In a study described in Gomes et al. (2016), mean diameter of droplets has also diminished as PGPR increased, when concentration varied from 1 to 4% (g/100 g).

PDI values indicate polydispersity of droplet size distribution: the lower the value, the narrower the curve amplitude, indicating more uniform emulsions (Gomes et al. 2016). According to these authors, systems with PDI values lower than 2 can indicate narrow and uniform size distribution. Authors Ushikubo and Cunha (2014) reported high stability of A/O emulsions (60:40) with PGPR 4 (g/100 g) and low droplet polydispersity in emulsions, and results achieved in this study are in accordance with these authors.

The presence of acids causes a reduction in interfacial tension between aqueous phase and flexible interface formation, since acids act as cosurfactants and cosolvents (Fasolin et al. 2014). Therefore, the presence of acids, and also alcohol, in hibiscus extract may have promoted the formation of smaller droplets, due to their cosurfactant action.

Table 2 also shows the results of emulsion color parameters after 24 h of storage. Increased PGPR addition has resulted in increased L*, a trend of decrease in a* and decrease in b*, as well as increased C*. The hue value (H*) was very close to zero (red). The extract of hibiscus presented parameters of L* (19.36 ± 0.26), a* (1.44 ± 0.04), b*(0.19 ± 0.10), and C* (0.13 ± 0.07) significantly lower than those shown by emulsions, also presenting higher hue (H*) value (1.46 ± 0.05). The color of the extract is therefore less saturated and of a different shade of the emulsions.

Interfacial Tension

Interfacial tension diminished as the surfactant (PGPR) percentage was increased. For oil added with PGPR 1% (g/100 g), tension ranged from 2.3 to 0.7 mN/m in 17 s. For oil added with PGPR 2% (g/100 g), tension ranged from 1.25 to 0.7 mN/m in 4 s. For oil added with PGPR 3% (g/100 g), tension ranged from 1.05 to 0.7 mN/m in 3 s. For oil added with PGPR 4% (g/100 g), tension ranged from 0.9 to 0.7 mN/m in 3 s, with this amount of surfactant having the lowest range of tension in less time.

Formation and kinetics stability of emulsions depend on the properties of compounds with surface activity present in the systems (Dickinson 2001). During the emulsification process, an efficient surfactant should rapidly adsorb in the interface, in order to reduce interfacial tension as well as to promote the rupture and formation of a protection layer around droplets, aiming to avoid their flocculation (Jafari et al. 2012). Low molecular mass surfactants can rapidly and efficiently reduce interfacial tension, in order to promote the emulsification process (Bos and Van Vliet 2001).

Rheological Behavior

As described in Steffe (1996), food mixture and stirring processes usually involve strain rates between 10 and 1000 s−1. Apparent viscosity of emulsions remained practically constant after a strain rate of 100 s−1. Therefore, to elaborate Table 3, a strain rate of 100 s−1 was considered.

Regardless of surfactant concentration, emulsions had good adjustments to the power law model, with coefficient of determination (R2) values above 99%, both in ascending and descending curves (Table 3).

Increase in PGPR percentages has resulted in increased viscosity, both for flow behavior with ascending strain rate and for flow behavior with descending strain rate, showing no significant difference with an increase of 3 to 4% of PGPR surfactant application.

Consistency index (k) values found for adjustment to power law model are very similar to viscosity values shown by the rheometer. Since behavioral index (n) values for the power law model were close to 1, emulsions were considered as Newtonian fluids (R2 above 99%). For fluids with Newtonian behavior, n equals to 1, viscosity does not depend on the strain rate remaining constant.

Encapsulation of Anthocyanin Extract

Detailed results can be found in Moura et al. (2018).

Application of Microparticles in Yogurt Matrix

According to the Technical Regulation on the Identity and Quality of Fermented Milks (Brasil 2007), non-dairy optional ingredients, whether alone or combined, can be present at a maximum proportion of 30% (g/100 g) of final product. Yogurt formulation had 20% of particle addition, then being within the range allowed.

Microparticles initially had good resistance to pH of yogurt matrix (pH 4.75), remaining intact and with a typical color from the extract obtained (pink). Such characteristic is of great relevance from the technological point of view for bioactive compounds needing to be added to a product with different pH from the value required for its stability. The pH ideal value for anthocyanin stability is 3.0, which is lower than for yogurt.

Yogurt Sample Characterization

Figure 2 shows the final appearance of yogurt samples with free extract and with microparticles.

Yogurt with free extract—EY (Fig. 2a)—had uniform color (pink tone). For yogurt with particles obtained by atomization—APY (Fig. 2b)—the small size of particles resulted in better distribution of color. Due to the large size of particles obtained by dripping, dispersion of dye through yogurt was not regular (Fig. 2c).

Table 4 shows the characterization of yogurt samples containing free hibiscus extract, with microparticles obtained by dripping and with microparticles obtained by atomization.

Yogurt with particles had pH value significantly lower than yogurt with free extract. This fact is due to the addition of 20% of particles stored in acid solution (pH = 3), which caused slight increase yogurt acidification. EY had higher titratable acidity (p ≤ 0.05) than the other formulations and the results for titratable acidity ranged from 0.86 to 1.00 g of lactic acid/100 g of product, meeting the requirement established by the legislation in force (Brasil 2007), which defines that the yogurt products should have minimum acidity of 0.6 and maximum acidity of 1.5 g of lactic acid/100 g of product.

The presence of particles in yogurt contributed to higher values of total dry matter. As per the World Health Organization (FAO/WHO) rules, in whipped yogurt, the percentage of solids-non-fat should be within the range of 8.5 to 10%, while traditional product, which is firmer, should have 12% of solids-non-fat. Total solids have a strong effect in yogurt gel firmness. In general, the higher the percentage of solids, the firmer the product (Mantovani et al. 2012).

According to the Technical Regulation on the Identity and Quality of Fermented Milks (Brasil 2007), skim yogurt is the one containing up to 0.5 g/100 g of fat. Yogurt with extract (YE/IE) has a fat content that classifies it as a skimmed product, but yogurt with particles cannot be considered as skim yogurt, being classified as partially skimmed yogurt (0.6 to 2.9 g/100 g) instead. This was due to the presence of rapeseed oil during the preparation of emulsion used to elaborate the particles added to yogurt.

Protein content of yogurt with particles was significantly lower than yogurt with free extract, since fat and dry matter contents were higher. According to yogurt manufacturers, the protein content usually presented in yogurt is 3.0 g/100 g, at least. Formulations are in compliance with this condition (3.5 to 4.4 g/100 g).

Total phenolic compound content in yogurt with free extract was significantly higher (p ≤ 0.05) than yogurt with particles. This analysis may have been affected by interfering parts existing in yogurt, although the value of control sample (yogurt without active compound) was disregarded.

According to Oliveira et al. (2015), polyphenols have significant affinity for proteins, resulting in the formation of soluble complexes that may increase their size, even forming sediments. These authors observed reductions of 14% in total phenolics of yogurt 24 h after adding strawberry preparation. Among yogurt samples with particles, those with particles obtained by dripping had higher total phenolic values (R = 88.3%) than those with particles obtained by atomization (R = 64.2%). In general, larger microcapsules give better protection than smaller microcapsules; however, those show low dispersion in final food product (Zhao et al. 2008; Belscak-Cvitanovic et al. 2016). Results found in this study are in compliance with these authors.

Antioxidant capacity follows the same behavior as phenolic compounds, that is, the greatest maintenance of antioxidant capacity was observed in yogurt with extract, followed by yogurt with particles obtained by dripping, and the lowest value was noted for yogurt with particles obtained by atomization. Oliveira et al. (2015) observed total antioxidant capacity of strawberry-enriched yogurt had a reduction of 24% soon after 24 h of application of strawberry preparation to yogurt.

Anthocyanins are highly unstable and easily susceptible to degradation. In milk products, anthocyanins stability can be affected by pH and by the presence of proteins (Oliveira et al. 2015). Anthocyanins in yogurts may form complexes with macromolecules that protect anthocyanins from degradation (Jing and Giusti 2005), but such interaction can make anthocyanins less available and eventually result in their precipitation.

Anthocyanin contents found in yogurt samples when converted into dry base were 1.20 mg/100 g for yogurt with free extract, 2.74 mg/100 g for yogurt with particles obtained by atomization, and 2.88 mg/100 g for yogurt with particles obtained by dripping. Encapsulation has shown to be efficient in anthocyanin retention, since yogurt with free extract had anthocyanin retention of 19% only, which is quite below the values found in yogurt with microparticles (59–65%). Anthocyanin retention may have been impaired by pH of yogurt, which is higher than pH of hibiscus extract (pH = 3.0). The value of anthocyanin content from yogurt with free extract is similar to the value found by Colak et al. (2016) in a cocktail with cranberry juice (1.36 mg/100 g), while anthocyanin content from yogurt with particles is 43–45% of the value found by Colak et al. (2016) in strawberry juice (6.36 mg/100 g), which is a product acknowledged as a source of anthocyanins.

During the manufacturing process of yogurt with particles, the lowest retention was observed in total anthocyanin content (59–65%), while total phenolic content had the highest retention (64–88%). Yogurt with larger particles, that is, those generated by dripping, had better bioactive compound retention during the process.

The amount of extract and particles used in yogurt was determined therefore color parameters (L*, a*, b*, H*, and C*) could be quite similar. Differences in color were due to the fact the extract and particles were distinctly distributed on each yogurt type.

Among yogurt samples with particles, those with the most intense color (higher C*) were from yogurt with particles obtained by atomization, although color of particles used is similar for chroma and hue (chroma = 25.81 to 25.14 and hue 0.12 to 0.23). These results were shown in detail by Moura et al. (2018). The result is probably due to the particles obtained by atomization are smaller than particles obtained by dripping, which facilitated the dispersion in yogurt matrix.

The viability of anthocyanin microparticle application aiming at the distribution of pink color was according the results shown by Bilek et al. (2017). The a* value was also used to analyze the measurement of color of prepared yogurt samples, and authors concluded that yogurt samples with concentrate encapsulated in whey had a good color distribution, even at concentrations of 20%, in addition to stability during the manufacturing process.

According to the legislation (Brasil 2007), it is possible to increase the microparticle application rate by more 10% also elevating the a* value, which would result in a lower total color difference (ΔE) when compared to commercial yogurt.

Sensory Acceptability

A group of 80 yogurt consumers, composed of 8 men and 72 women, evaluated yogurt samples. The age group distribution was quite homogeneous, with the highest percentage (29.9%) being composed of consumers aged 26 to 35 and from social class B (58.8%). The highest percentage of consumers (32.4%) informed frequency of yogurt consumption of 2 to 3 times a week, preferring liquid yogurt, followed by Greek yogurt and strawberry yogurt, and then red berries flavor.

Mean results obtained in acceptability test of sample appearance using hedonic scale, as well as ranking test results are shown in Table 5.

With respect to appearance acceptability, the market sample was the most accepted (p ≤ 0.05) of all samples, with mean value close to “like extremely”; samples with free extract (EY) and those with particles obtained by atomization (APY) were not different among each other, with mean values from “like it” and “like a little,” being more accepted than samples with particles obtained by dripping (DPY), with mean value corresponding to “like a little.”

Regarding the acceptance, indifference, and rejection measured by frequency distribution relative to hedonic scale, the IE, market, and IPA samples had high acceptance, achieving over 80.0%. Although acceptance of IPG sample was 67.5% and rejection was 25.0%.

Concerning purchase intention, we verified 90.0% of consumers demonstrated positive attitude related to the purchase of market sample, while 57.5% and 58.8% for the purchase of samples with free extract (EY) and with particles obtained by atomization (APY), respectively, indicating “probably would buy it” or “certainly would buy it” in scale used. For purchase intention of sample with particles obtained by dripping (DPY), over 50% of consumers stated a negative attitude or doubt, with 31.3% of consumers indicating negative attitude and 23.8% doubt.

For ranking regarding preference, as the evaluation for appearance acceptability has classified the samples, EY and APY samples were not different among each other, being preferred (p ≤ 0.05) over the DPY sample.

Yogurt Stability Study

Table 6 shows pH and titratable acidity results evaluated for 36 days, as well as the count of lactic acid bacteria present in yogurt formulations after 1 and 30 days of storage at 5 °C.

Yogurt acidity increased during the storage period (lower pH values and higher titratable acidity values) regardless of microparticles addition. Increase in acidity is a result of post-acidification of products, related to continuation of the fermentation process by lactic acid bacteria during storage with the production of lactic acid (Aportela-Palacios et al. 2005). Mean value of pH/titratable acidity in natural yogurt matrix (with no addition of extract or particles) on the time point of 1 day was 4.75 ± 0.01 / 0.93 ± 0.01, and on the time point of 36 days was 4.58 ± 0.02 / 1.01 ± 0.01. Mean pH values of formulations were between 4.51 and 4.72 during storage, supporting literature papers (Pimentel et al. 2012; Silva and Ueno 2013; Yadav et al. 2018). Results achieved for titratable acidity were from 0.81 and 1.03% of lactic acid throughout storage and meet the requirements of the legislation in force, which is 0.6 to 1.5 g of lactic acid/100 g (Brasil 2007).

According to Technical Regulation on the Identity and Quality of Fermented Milks (Brasil 2007), total lactic bacteria count in yogurt samples should be of at least 107 CFU/g. Application of particles did not avoid the development of lactic acid bacteria in yogurt, not showing a significant difference among the samples (Table 6). Microorganisms of cultures used remained viable and active and at a higher concentration in comparison to the one established by legislation (minimum of 107 CFU/g) in final product and during yogurt shelf life. Also, a significant increase of 1 logarithmic cycle after 30 days was observed, indicating a positive effect of active compounds on the maintenance of bacteria viability, regardless of the form applied (free or encapsulated). These results are similar to those achieved by Yadav et al. (2018).

After 30 days of storage at 5 °C, yogurt syneresis values were as follows: yogurt with extract 1 mL/10 mL, yogurt with atomization particles 0.5 mL/10 mL, and yogurt with dripping microparticles 0.25 mL/10 mL, which are considered low values. Syneresis increased during storage in all formulations, which can be related to pH decrease during storage (Table 6); such decrease promotes casein micellar matrix contraction, elevating whey expulsion (Pimentel et al. 2012). As per Aportela-Palacios et al. (2005), syneresis values below 39% can be considered satisfactory. Mean values achieved in this study (2.5 to 10%) were below the value considered acceptable.

Total Phenolic Compounds and Total Anthocyanins

Figure 3 shows the results of total phenolic content and total anthocyanin content in yogurt with free hibiscus extract, with microparticles obtained by dripping and with microparticles obtained by atomization.

Yogurt samples showed a reduction in total phenolic content during 36 days of storage. Total polyphenol content of the samples was determined by the Folin-Ciocalteu method and as per Medina (2011); some components such as proteins have interfering effect in this analysis, producing blue color. Results of total polyphenol content by the Folin-Ciocalteu method can only be reliable after the removal of such interfering compounds, with such extraction being possible by sample purification only. With respect to yogurt with particles, separation of particles from yogurt mass was possible, thus enabling better quantification of total polyphenols arising from the hibiscus extract present in particles.

During 36 days of storage, yogurt with microparticles obtained by dripping always had polyphenol contents higher than yogurt with microparticles obtained by atomization, i.e., yogurt with larger particles had better retention of total phenolic compounds. Retention of phenolic compounds during storage was 62% for yogurt with particles generated by dripping, 58% for yogurt with particles generated by atomization, and 42% for yogurt with free extract. These results are consistent with those found by Martins et al. (2014) who, on a previous approach, evaluated microspheres containing Rubus ulmifolius flowers hydroalcoholic extract when incorporated to natural yogurt. The authors concluded that, when compared with the free form, microencapsulated formulation was able to preserve the antioxidant activity of extract in yogurt. This fact supports the protective effect of microencapsulation of polyphenol-rich active compounds.

Polyphenol reduction in yogurt with free extract had higher results than those observed by Trigueros et al. (2014) for yogurt with pomegranate juice. According to the authors, the stability of pigments and phenols in yogurt is affected by storage temperature, pH, content and type of phenolic compound, fat, and type of bacterial culture used. Authors also indicated that a protein-polyphenol interaction may occur, being reversible or irreversible depending on pH, temperature, and concentration of flavonoids.

A potential interaction between milk proteins and polyphenols was also reported by Yadav et al. (2018) on their evaluation of total phenolic content in yogurt when applied in encapsulated and non-encapsulated grape seed extract. With respect to non-encapsulated grape seed extract, a reduction of 46% in total polyphenol content was observed during the 21-day storage under refrigerated conditions (7–8 °C); such values were higher than those found in the present work. The results of this study are consistent with those authors, showing encapsulation promoted lower loss of polyphenols under refrigerated conditions.

After 29 days of storage, yogurt with extract (EY) had lower anthocyanin retention values (4%), indicating a potential degradation of the active compound when applied in yogurt. Another factor that may have contributed was the difficulty to extract anthocyanins from yogurt, as previously reported, resulting in lower anthocyanin values for IE yogurt in comparison with other samples from day 1 of storage on. At day 29 of storage, yogurt with microparticles obtained by dripping had higher anthocyanin retention (48%) than yogurt with microparticles obtained by atomization (21%), i.e., yogurt with larger particles had better total phenolic compound retention. At day 36 of storage, all three yogurt samples had a significant decrease in anthocyanin content, showing the yogurt shelf life related to this active compound had expired. The difficulty to extract anthocyanins from yogurt with smaller particles due to reduced visualization of particles may also have been resulted in lower quantification of the active compound. The low value of anthocyanin content in yogurt may also have been affected by uncertainty of analytical method used.

During storage, anthocyanin retention in yogurt with free extract was lower than in yogurt with particles. When anthocyanin retention after processing and storage is considered, values achieved 4% only for yogurt with free extract. Results prove that anthocyanin encapsulation enabled better retention of the active compound.

According to Robert et al. (2010), the stability of bioactive compounds followed a similar behavior to those compounds without encapsulation, showing the anthocyanin degradation rate can be affected by oxidation and consequently by polymerization of some phenolic compounds. In another study (Coısson et al. 2005), anthocyanin content could not be detected even before 7 days during the addition of açai (Euterpe oleracea) juice in yogurt (10 g/100 g), with anthocyanins remaining stable only for 2 days at 4 °C.

Analysis of Color

Table 7 shows the color results for yogurt with free extract, yogurt with particles obtained by atomization, and yogurt with particles obtained by dripping, respectively.

Yogurt with free extract had a* and C* decrease, but total color difference reduction (maximum ΔE 2.73). This yogurt sample also had L* and H* increase, in addition to b* decrease. The a* and C* decrease is probably due to anthocyanin content reduction during storage time.

Yogurt with particles obtained by atomization had a* and C* decrease, in addition to lower total color difference (2.52) than yogurt with extract. ΔE values below 3.5 cannot be easily detected by the naked eye (Hong et al. 2004). The a* value decrease is probably due to anthocyanin content reduction in such yogurt, which showed significant drop with storage time. We can also note the a* and C* decrease was higher on the first 8 days of storage, and such color difference was higher than the one observed in yogurt with free extract, probably due to particle adaptation to the new pH condition of the matrix. This yogurt sample also showed H* increase and did not have a clear behavior trend for L* and b*.

Yogurt with particles obtained by dripping also showed a* and C* decrease, in addition to higher total color difference (3.01) than yogurt with extract and yogurt with particles obtained by atomization, still lower than 3.50 when color difference is considered evident (Obon et al. 2009). Major standard deviations of readings caused by sample heterogeneity contributed to the biggest changes in color parameters. Yogurt also showed H* and L* increase, with no clear behavior trend for b*.

As per Wallace and Giusti (2008), the addition of seedless and dry berries of Berberis boliviana (rich in anthocyanins) to yogurt resulted in color characteristics similar to those of a commercial brand blueberry yogurt. Consistent with these authors, color compounds of yogurt samples with particles degraded faster during the first follow-up week and showed signs of stability during the second week. An adaptation of anthocyanin pigment to the new condition of medium (yogurt matrix) probably occurs during the first days of storage.

Conclusions

Emulsification of Hibiscus sabdariffa L. extract in rapeseed oil by using surfactant (PGPR) 4 g/100 g enabled good droplet distribution uniformity, low interfacial tension, and Newtonian rheological behavior.

The use of double emulsion followed by external ionic gelation provided 60% of mean retention of hibiscus extract anthocyanins after microparticles application in yogurt matrix, showing technical feasibility and providing color and functionality.

Application of microparticles in yogurt matrix did not negatively affect lactic acid bacteria viability; on the contrary, it promoted its maintenance.

Yogurt matrix with application of particles generated by atomization had higher appearance acceptability, with a mean grade of 6.5 for yogurt corresponding to values from “liked moderately” to “liked slightly.”

Color changes in yogurt matrix with particles were higher on the first 8 days of storage, probably due to particle adaptation to the new pH condition of the matrix.

During 29 days of storage, anthocyanin microparticles provided color to yogurt matrix, with 48 to 21% retention of anthocyanin content. Application of free extract when compared to microparticles showed anthocyanin retention of 14% only.

Yogurt matrix with addition of particles generated by ionic gelation with dripping technique had higher bioactive compound retention, although it has shown less homogeneous color distribution.

References

ABEP (2016). Brazilian Association of Research Companies. Economic Classification Criteria Brazil. Available in: www.abep.org/codigosguias/Criterio_Brasil_2008.pdf.

Aditya, N. P., Aditya, S., Yang, H., Kim, H. W., Park, S. O., & Ko, S. (2015). Co-delivery of hydrophobic curcumin and hydrophilic catechin by a water-in-oil-in-water double emulsion. Food Chemistry, 173, 7–13.

Alvim, I. D., Souza, F. S., Koury, I. P., Jurt, T. T., & Dantas, F. B. H. (2013). Use of the spray chilling method to deliver hydrophobic components: physical characterization of microparticles. Food Science and Technology, 33(1), 34–39.

AOAC. (2006). Official methods of analysis of AOAC International (18th ed.). Maryland: AOAC International Last revision in 2010.

Aportela-Palacios, A., Sosa-Morales, M. E., & Vélez-Ruiz, J. F. (2005). Rheological and physicochemical behavior of fortified yogurt, with fiber and calcium. Journal of Texture Studies, 36(3), 333–349.

Arend, G. D., Adorno, W. T., Rezzadori, K., Di Luccio, M., Chaves, V. C., Reginatto, F. H., & Petrus, J. C. C. (2017). Concentration of phenolic compounds from strawberry (Fragaria X ananassa Duch) juice by nanofiltration membrane. Journal of Food Engineering, 201, 36–41.

Ares, G., Barreiro, C., Deliza, R., Giménez, A., & Gámbaro, A. (2010). Application of a check-all-that-apply question to the development of chocolate milk desserts. Journal of Sensory Studies, 25, 67–86.

Arts, M. J. T. J., Haenen, G. R. M. M., Voss, H. P., & Bast, A. (2001). Masking of antioxidant capacity by the interaction of flavonoids with protein. Food and Chemical Toxicology, 39(8), 787–791.

Aryana, K. J. (2003). Folic acid fortified fat-free plain set yoghurt. International Journal of Dairy Technology, Huntingdon, 56(4), 219–222.

Belscak-Cvitanovic, A., Busic, A., Barisic, L., Vrsaljko, D., Karlovic, S., Spoljaric, I., Vojvodic, A., Mrsic, G., & Komes, D. (2016). Emulsion templated microencapsulation of dandelion (Taraxacum officinale L.) polyphenols and b-carotene by ionotropic gelation of alginate and pectin. Food Hydrocolloids, 57, 139–152.

Bilek, S. E., Yılmazb, F. M., & Özkan, G. (2017). The effects of industrial production on black carrot concentrate quality and encapsulation of anthocyanins in whey protein hydrogels. Food and Bioproducts Processing, 102, 72–80.

Bos, M., & Van Vliet, T. (2001). Interfacial rheological properties of adsorbed protein layer and surfactants: a review. Advances in Colloid and Interface Science, 91(3), 437–471.

Brand-Williams, W., Cuvelier, M. E., & Berset, C. (1995). Use of a free radical method to evaluate antioxidant activity. LWT – Food Science and Technology, 28(1), 25–31.

Brasil. (2005). Ministério da Saúde. Agência Nacional de Vigilância Sanitária. Physicochemical methods for food analysis (4th ed.). Brasília: Adolfo Lutz Institute. Ministry of Health 1018p. (Series A. Norms and Technical Manuals).

Brasil. (2007). Ministério da Agricultura. MAPA. Normative Instruction No. 46 of October 23, 2007. Approves the Technical Regulation on the Identity and Quality of Fermented Milks. Available in: http://www.agricultura.gov.br. Accessed: 12.4.2017.

Carvalho, A. G. S., Silva, V. M., & Hubinger, M. D. (2014). Microencapsulation by spray drying of emulsified green coffee oil with two-layered membranes. Food Research International, 61, 236–245.

Celli, G. B., Ghanem, A., & Brooks, M. S.-L. (2015). Bioactive encapsulated powders for functional foods—a review of methods and current limitations. Food and Bioprocess Technology, 8(9), 1825–1837. https://doi.org/10.1007/s11947-015-1559-z.

Coısson, J. D., Travaglia, F., Piana, G., Capasso, M., & Arlorio, M. (2005). Euterpe oleracea juice as a functional pigment for yogurt. Food Research International, 38(8-9), 893–897.

Colak, N., Torun, H., Gruz, J., Strnad, M., Hermosín-Gutiérrez, I., Hayirlioglu-Ayaz, S., & Ayaz, F. A. (2016). Bog bilberry phenolics, antioxidant capacity and nutrient profile. Food Chemistry, 201, 339–349.

Da-Costa-Rocha, I., Bonnlaender, B., Sievers, H., Pischel, I., & Heinrich, M. (2014). Hibiscus sabdariffa L.—a phytochemical and pharmacological review. Food Chemistry, 165, 424–443.

Dickinson, E. (2001). Milk protein interfacial layers and the relationship to emulsion stability and rheology. Colloids and Surfaces B: Biointerfaces, 20(3), 197–210.

Fasolin, L. H., Santana, R. C., & Cunha, R. L. (2014). Influence of organic acids on surfactant self-assemblies in surfactant/oil/water systems. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 459, 290–297.

Frank, J. F., & Yousef, A. E. (2004). Tests for groups of microorganisms. In H. M. Wehr, J. F. Frank, & R. T. Marshall (Eds.), Standard methods for the examination of dairy products, 17th. Chapter 8, 227–248. Washington, D.C.: American Public Health Association.

Frascareli, E. C., Silva, V. M., Tonon, R. V., & Hubinger, M. D. (2012). Effect of process conditions on the microencapsulation of coffee oil by spray drying. Food and Bioproducts Processing, 90(3), 413–424.

Ghaderi-Ghahfarokhi, M., Barzegar, M., Sahari, M. A., & Azizi, M. H. (2016). Nanoencapsulation approach to improve antimicrobial and antioxidant activity of thyme essential oil in beef burgers during refrigerated storage. Food and Bioprocess Technology, 9(7), 1187–1201. https://doi.org/10.1007/s11947-016-1708-z.

Gomes, A., Costa, L. R., Assis, F., & Cunha, R. L. (2016). Role of the phases composition on the incorporation of gallic acid in O/W and W/O emulsions. Journal of Food Engineering, 168, 205–214. https://doi.org/10.1016/j.jfoodeng.2015.07.041.

Gomez-Estaca, J., Comunian, T. A., Montero, P., & Favaro-Trindade, C. S. (2018). Physico-chemical properties, stability, and potential food applications of shrimp lipid extract encapsulated by complex coacervation. Food and Bioprocess Technology, 11(8), 1596–1604. https://doi.org/10.1007/s11947-018-2116-3.

Hong, S. I., Han, J. H., & Krochta, J. M. (2004). Optical and surface properties of whey protein isolate coatings on plastic films as influenced by substrate, protein concentration, and plasticizer type. Journal of Applied Polymer Science, 92(1), 335–343.

Hooi, R., Barbano, D. M., Bradley, R. L., Budde, D., Bulthaus, M., Chettiar, M., Lynch, J., & Reddy, R. (2004). Chemical and physical methods. In: Wehr, H. M., Frank, J. F. (ed.). Standard methods for the examination of dairy products. 17th ed. (pp. 385–391, 408–434, 442–460). Washington, DC: American Public Health Association.

Instituto Adolfo Lutz (2008). 494/IV Fermented milk—determination of volatile substances and total dry extract, 879, Chapter XXVII Milk and derivatives. In: Physical-chemical methods for food analysis, 1st digital edition, Coordinators: Odair Zenebon, Neus Sadocco Pascuet and Paulo Tiglea. 4th edition. São Paulo: Instituto Adolfo Lutz, 1020.

Jafari, S. M., He, Y., & Bhandari, B. (2007). Effectiveness of encapsulating biopolymers to produce sub-micron emulsions by high energy emulsification techniques. Food Research International, 40(7), 862–873.

Jafari, S. M., Beheshti, P., & Assadpoor, E. (2012). Rheological behavior and stability of d-limonene emulsions made by a novel hydrocolloid (Angum gum) compared with Arabic gum. Journal of Food Engineering, 109(1), 1–8.

Jansen-Alves, C., Fernandes, K. F., Crizel-Cardozo, M. M., Krumreich, F. D., Borges, C. D., & Zambiazi, R. C. (2018). Microencapsulation of propolis in protein matrix using spray drying for application in food systems. Food and Bioprocess Technology, 11(7), 1422–1436. https://doi.org/10.1007/s11947-018-2115-4.

Jing, P., & Giusti, M. M. (2005). Characterization of anthocyanin-rich waste from purple corncobs (Zea mays L.) and its application to color milk. Journal of Agricultural and Food Chemistry, 53(22), 8775–8781.

Juliani, H. R., Welch, C. R., Wu, Q., Diouf, B., Malainy, D., & Simon, J. E. (2009). Chemistry and quality of hibiscus (Hibiscus sabdariffa) for developing the natural-product industry in Senegal. Journal of Food Science, 74(2), S113–S121.

Lucey, J. A. (2016). Dairy innovations highlight exciting possibilities. Dairy foods. n. 15, August, 2016. Available in: http://www.dairyfoods.com/articles/91903-dairy- innovations-highlight- exciting-possibilities. Accessed on: 31. August, 2016.

Mantovani, D., Corazza, M. L., Cardozo Filho, L., & Da Costa, S. C. (2012). Elaboration of yoghurt with different concentrations of total solids, chemical-physical analysis and texture of profile. Revista Brasileira de Tecnologia Industrial, 6(1), 680–687.

Martins, A., Barros, L., Carvalho, A. M., Buelga, C. S., Fernandes, I. P., Barreiro, F., & Ferreira, I. C. F. R. (2014). Phenolic extracts of Rubus ulmifolius Schott flowers: characterization, microencapsulation and incorporation into yogurts as nutraceutical sources. Food & Function, 5(6), 1091–1100.

Mcclements, D. J. (2005). Food emulsions: principles, practices and techniques (2nd ed.). Boca Raton: CRC Press.

Medina, M. B. (2011). Determination of the total phenolics in juices and superfruits by a novel chemical method. Journal of Functional Foods, 3(2), 79–87.

Meilgaard, M., Civille, G. V., & Carr, B. T. (2015). Sensory evaluation techniques (5th ed.). Boca Raton: CRC Press 600p.

Mohd-Esa, N., Hern, F. S., Ismail, A., & Yee, C. L. (2010). Antioxidant activity in different parts of roselle (Hibiscus sabdariffa L.) extracts and potential exploitation of the seeds. Food Chemistry, 122(4), 1055–1060.

Moura, S. C. S. R., Berling, C. L., Germer, S. P. M., Alvim, I. D., & Hubinger, M. D. (2018). Encapsulating anthocyanins from Hibiscus sabdariffa L. calyces by ionic gelation: pigment stability during storage of microparticles. Food Chemistry, 241, 317–327.

Nachay, K. (2017). Ingredient development takes cues from research insights. Food Technology, 71(6), 83–98.

Obon, J. M., Castellar, M. R., Alacid, M., & Fernandez-Lopez, J. A. (2009). Production of a red food colorant from Opuntia stricta fruits by spray drying and its application in food model systems. Journal of Food Engineering, 90(4), 471–479.

Oliveira, A., Alexandre, E. M. C., Coelho, M., Lopes, C., Almeida, D. P. F., & Pintado, M. (2015). Incorporation of strawberries preparation in yoghurt: impact on phytochemicals and milk proteins. Food Chemistry, 171, 370–378.

Pawlik, A., Cox, P. W., & Norton, I. T. (2010). Food grade duplex emulsions designed and stabilized with different osmotic pressures. Journal of Colloid and Interface Science, 352(1), 59–67.

Pimentel, T. C., Garcia, S., & Prudencio, S. H. (2012). Probiotic yoghurt with inulin-type fructans of different degrees of polymerization: physicochemical and microbiological characteristics and storage stability. Ciências Agrárias Londrina, 33(3), 1059–1070.

Robert, P., Gorena, T., Romero, N., Sepulveda, E., Chavez, J., & Saenz, C. (2010). Encapsulation of polyphenols and anthocyanins from pomegranate (Punica granatum) by spray drying. International Journal of Food Science and Technology, 45(7), 1386–1394. https://doi.org/10.1111/j.1365-2621.2010.02270.x.

Silva, A. B. N., & Ueno, M. (2013). Evaluation of lactic acid bacteria viability and titratable acidity variation in fruit flavor yogurt. Revista do Instituto de Laticínios Cândido Tostes, 390(68), 20–25.

Sinela, A., Rawat, N., Mertz, C., Achir, N., Fulcrand, H., & Dornier, M. (2017). Anthocyanins degradation during storage of Hibiscus sabdariffa extract and evolution of its degradation products. Food Chemistry, 214, 234–241. https://doi.org/10.1016/j.foodchem.2016.07.071.

Singleton, V. L., & Rossi, J. A. (1965). Colorimetry of total phenolics with phosphomolybdic-phosphotungstic acid reagents. American Journal of Enology and Viticulture, 16(3), 144–158.

Steffe, J. F. (1996). Chapter 1 “Introduction to rheology”. In Rheological methods in food process engineering. 2nd ed. (pp. 1–91). East Lansing: Freeman Press.

Sun-Waterhouse, D., & Wadhwa, S. S. (2013). Industry-relevant approaches for minimising the bitterness of bioactive compounds in functional foods: a review. Food Bioprocess Technology, 6(3), 607–627. https://doi.org/10.1007/s11947-012-0829-2.

Trigueros, L., Wojdyło, A., & Sendra, E. (2014). Antioxidant activity and protein–polyphenol interactions in a pomegranate (Punica granatum L.) yogurt. Journal of Agricultural and Food Chemistry, 62(27), 6417–6425.

Turkyılmaz, M., Tağı, S., Dereli, U., & Ozkan, M. (2013). Effects of various pressing programs and yields on the antioxidant activity, antimicrobial activity, phenolic content and color of pomegranate juices. Food Chemistry, 138(2-3), 1810–1818.

Ushikubo, F. Y., & Cunha, R. L. (2014). Stability mechanisms of liquid water-in-oil emulsions. Food Hydrocolloids, 34, 145–153.

Wallace, T. C., & Giusti, M. M. (2008). Determination of color, pigment, and phenolic stability in yogurt systems colored with nonacylated anthocyanins from Berberis boliviana L. as compared to other natural/synthetic colorants. Journal of Food Science, 73(4), 241–248.

Wilkowska, A., Ambroziak, W., Czyżowska, A., & Adamiec, A. (2016). Effect of microencapsulation by spray-drying and freeze-drying technique on the antioxidant properties of blueberry (Vaccinium myrtillus) juice polyphenolic compounds. Polish Journal of Food and Nutrition Science, 66(1), 11–16. https://doi.org/10.1515/pjfns-2015-0015.

World Health Organization (2018). Vuori I. World Health Organization and physical activity. Progrevmed 2018, 3: e0012 Published online 12 March 2018 Doi: https://doi.org/10.1097/pp9.0000000000000012.

Yadav, K., Bajaj, R. K., Mandal, S., Saha, P., & Mann, B. (2018). Evaluation of total phenol content and antioxidant properties of encapsulated grape seed extract in yoghurt. International Journal of Dairy Technology., 71(1), 96–104.

Zacarchenco, P. B., Van Dender, A. G. F., & Rego, R. A. (2017). Brasil dairy trends 2020 (1ª ed.). Campinas: ITAL 343p.

Zhao, R., Sun, J., Torley, P., Wang, D., & Niu, S. (2008). Measurement of particle diameter of Lactobacillus acidophilus microcapsule by spray drying and analysis on its microstructure. World Journal of Microbiology Biotechnology and Biotechnology, 24(8), 1349–1354.

Zhen, J., Villani, T. E., Guo, Y., Qi, Y., Chin, K., Pan, M.-H., Ho, C.-T., Simon, J. E., & Wu, Q. (2016). Phytochemistry, antioxidant capacity, total phenolic content and anti-inflammatory activity of Hibiscus sabdariffa leaves. Food Chemistry, 190, 673–680.

Acknowledgments

The authors are grateful to the University of Campinas, Institute of Food Technology, FAPESP (2009/54137-1) and CNPq (PQ 304475/2013-0) for the financial support.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no competing interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

de Moura, S.C.S.R., Schettini, G.N., Garcia, A.O. et al. Stability of Hibiscus Extract Encapsulated by Ionic Gelation Incorporated in Yogurt. Food Bioprocess Technol 12, 1500–1515 (2019). https://doi.org/10.1007/s11947-019-02308-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-019-02308-9