Abstract

Contemporary society is increasingly interested in topics related to healthy eating. Cases of poisoning, allergies, and adverse reactions related to the consumption of synthetic dyes have driven the development of new technologies for the use of natural dyes. In this context, the objective of this research is to evaluate the stability of jambolan extract (Syzygium cumini (L.) Skeels) microencapsulated by atomization and stored at two temperatures (5 °C and 28 °C), for 90 days, and without lighting. Analyses of total phenolic content, total anthocyanins, and instrumental color were carried out every 15 days. The microencapsulated extract was used to color gelatin powder as an alternative to synthetic dyes. Jambolan extract microcapsules showed high solubility (90%) and had average diameters ranging from 16.75 to 23.35 μm and considerable levels of phenolic compounds (522 mg GAE/100 g) and anthocyanins (128.90 mg/100 g). It also showed high encapsulation efficiency of phenolic compounds (89.23%) and anthocyanins (94.56%). At the end of the storage time, the total phenolic and total anthocyanin contents of the gelatin produced were significantly reduced, from 350.45 mg EAG/100 g and 481.48 mg/100 g to 194.39 mg EAG/100 g and 217.70 mg EAG/100 g, respectively. Even with the decrease, the final product presented a visible shadow at the end of the storage time. Although there was a decrease in ΔE in gelatin powder during storage, the addition of 7% natural coloring to the powder from microencapsulated jambolan extract resulted in an intense and bright color and a high concentration of anthocyanins.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Jambolan [Syzygium cumini (L.) Skeels] is popularly known as jambolan, black plum, Indian blackberry, or jamelan (Ayyanar & Subash-Babu, 2012). Jambolan is an arboreal, perennial species, belonging to the genus Myrtaceae, native to India and which can reach up to 20 m high (Santiago et al., 2016). Its fruit is native to tropical Asia, but has wide geographic dispersion due to the success of introductions of the species in tropical and subtropical America. Its fruits are small, ovoid, juicy, with white pulp and dark colored skin, when ripe, due to the presence of anthocyanins, which makes it a cheaper source of natural dyes for industrial use (Faria et al., 2011; Santiago et al., 2016). Jambolan fruit contains high amounts of phenolic compounds, such as anthocyanins, which are antioxidant pigments found mainly in the peel, with several functional characteristics, such as antioxidant, antimutagenic, antimicrobial, antiglycemic, anticarcinogenic, and antiviral activities (Freitas-Sá et al., 2018; Paul & Das, 2019; Seraglio et al., 2018; Emam & El-Nashar, 2022). One way to add value to the jambolan fruit, promoting a food with high biological potential that does not yet have consolidated marketing potential, is the application of technologies to improve its conservation (Albuquerque, 2019).

Anthocyanins are water-soluble, glycosylated polyphenolic compounds belonging to the flavonoid family that produce colors ranging from red to blue and are found mainly in flowers and fruits (Iacobucci & Sweeny, 1983). Anthocyanins differ according to the degree and pattern of hydroxylation and methoxylation; number, position, and type of sugar in the molecule; and number and nature of aromatic or aliphatic acids linked to the sugar. The presence of hydroxylations or methylations influences the stability of these molecules in solution. Increased glycosylation provides greater stability; however, the type of sugar in the medium also influences this parameter (Schwartz et al., 2010). The stability of these molecules is dependent on physical, chemical, and environmental factors related to pH, temperature, light (UV/visible), copigmentation, oxygen, ascorbic acid, relative humidity, presence of sugars, sulfur dioxide or sulfites, enzymes, and metal ions (Sharma et al., 2016).

In the perception and evaluation of the overall appearance of food, color is the most important quality attribute that affects consumer acceptance, and an unpleasant color will lead to low acceptance and reduce its market value. Consumers associate the color of food with safety and quality and as an indicator of good processing (Freitas-Sá et al., 2018; Gaibor et al., 2022). The dyes most used in the food industry are generally synthetic dyes whose application has raised legal and health issues in recent years, such as cases of allergies, poisoning, and adverse reactions that can cause harm to the consumer’s health (Lao & Giusti, 2018). The search for natural dyes comes as a response to contemporary society’s search for more sources of healthy food. Including plant extracts as natural colorings has received a boost in the food industry and already has recognition in several countries (Freita et al., 2021). The jambolan fruit has been studied and applied with the aim of increasing the quality and appearance of processed foods, without interfering with their organoleptic properties as in Emam and El-Nashar (2022) who applied it to yogurt.

One of the challenges in the production of natural dyes is the development of processes that reduce losses of extracted compounds to obtain a more stable and desirable product for consumers. Various technologies have been used to increase the stability of anthocyanins during product development, storage, and consumption, reducing nutritional losses. Microencapsulation by spray drying is one of the most used processes in the food industry and has advantages such as preventing biochemical deterioration of the product (degradation of anthocyanins), limiting enzymatic activity and microbial growth (Machado et al., 2022). This process has gained prominence for protecting phenolic compounds from adverse environmental conditions, such as oxygen, humidity, light, and temperature, thus increasing color stability, in addition to facilitating the controlled release of materials from the encapsulation matrix (Kuck et al., 2017; Mar et al., 2020). In this way, the product’s shelf life can be increased.

Taking these factors into consideration, the objective of this work was to evaluate the stability of phenolic compounds, more specifically the anthocyanins present in the aqueous extract of jambolan microencapsulated by spray drying, during storage and when applied as a powder for colorless and flavorless gelatin. An aqueous extract was made with the edible parts of the fruit, in contrast to several studies in the literature that use organic solvents (mainly acetone and methanol), which can leave toxic residues, for phenolic extraction from jambolan. To the best of our knowledge, it is the first time that a microencapsulated jambolan aqueous extract was applied as a natural food coloring.

2. Materials and Methods

2.1. Jambolan Processing

Jambolan (Syzygium cumini (L.) Skeels) fruits were collected on Gaibu beach, located in the city of Cabo de Santo Agostinho, metropolitan region of Pernambuco (latitude: 8°17′15″ S, longitude: 35°2′7″ W), between the months of February and March 2021. Exsiccates of this plant material were produced at the Professor Vasconcelos Sobrinho Herbarium (UFRPE), located in the Dois Irmãos, metropolitan region of Recife at Pernambuco, Brazil, with registration number 55,893. The fruits were washed and sanitized in a sodium hypochlorite solution (2.5%) for 15 min, rinsed (Romualdo et al., 2021), and pulped (Bonina Compacta, Itabuna/BA). The pulp was packed in low-density polyethylene bags, immediately frozen, and stored at − 18 °C. To obtain the freeze-dried pulp, the frozen pulp was transferred to a freeze-dryer (model Alpha 1-4 LD Plus; Martin Christ, Osterode am Harz, Germany) at − 80 °C for 48 h using a chamber pressure of 0.28 mbar. The freeze-dried material was crushed in a blender (ARNO, Arno Power Max 700, Groupe SEB Ltda.), packaged in low-density polyethylene bags and stored at −18 °C, protected from light.

2.2. Characterization of the Edible Part of Fresh and Freeze-Dried Jambolan

2.2.1. Chemical and Physical-Chemical Characterization

The edible part of fresh and freeze-dried jambolan was characterized; for moisture content, it was determined using an infrared balance (model ID50, Marte Científica, Marconi, Brazil) at 105 °C for 30 min, proteins and total sugars. For the physical-chemical characterization, water activity was measured using an instrumental water activity meter (AQUA LAB®, model 4TE), pH using a calibrated potentiometer (TECNAL® TEC-3MP, Piracicaba/SP), and titratable acidity by means of potentiometric titration, neutralizing with sodium hydroxide solution (0.1 M). All measurements were done according to AOAC (2016), in triplicate.

2.2.2. Determination of Chromatic Parameters

Instrumental color determination was performed with a colorimeter (CR400/410, Minolta Co. Ltd., Osaka, Japan) calibrated with a calibration plate (Y = 92.78; x = 0.3139; y = 0.3200). The values of L, a*, and b* were determined. The color variation during storage time and in the food matrix was calculated by ΔE (Eq. 1) (Yekdane et al., 2019).

where ΔE is the color variation, “i” refers to the analyses carried out on day 1, and “f” refers to the last analysis carried out.

2.2.3. Determination of Total Phenolic Compounds and Total Monomeric Anthocyanin Content

Total phenolic compounds were determined by reaction, in the absence of light, with the phenolic reagent Folin–Ciocalteu (Sigma Aldrich®, St. Louis, MO, USA), stabilized with saturated sodium carbonate solution, according to the methodology described by Wettasinghe and Shahidi (1999). Absorbances were read at 725 nm on a UV-visible spectrophotometer (SHIMADZU®, UV-1650pc, Japan), and the content of TPC was determined by interpolating the absorbance of the samples against a standard curve prepared from aqueous solutions of gallic acid (0.1–1 mg mL−1) (R2 = 0.995), and the results were expressed in mg of gallic acid equivalent (GAE) g−1 microcapsules (powder) (mg GAE g−1). Results were expressed as mg of gallic acid equivalent (GAE)/g−1 of dry matter.

The determination of total monomeric anthocyanins was carried out using the differential pH method described by Wrolstad et al. (2005). A diluted aliquot of the extract reacted with two buffer solutions, 0.025 M potassium chloride (pH = 1) and 0.4 M sodium acetate (pH = 4.5), for 50 min at room temperature. The absorbances were measured at 520 nm and 700 nm, and the concentration of total anthocyanins was determined using Eq. 2, with the results expressed as mg of cyanidin 3-glucoside per 100 g of dry matter.

where A is the absorbance at certain wavelengths, Mω is the molecular weight of cyanidin 3-glysoside (449.2 g/mol), DF is the dilution factor, ε is the molar absorption coefficient (29,600 L/(cm·mol)), and L is the optical path (1 cm).

2.3. Production of Jambolan Aqueous Extract

The aqueous extract of jambolan was obtained following the methodology of Merz et al. (2020). One gram of the edible part of the freeze-dried fruit was mixed with 200 mL of an acidified aqueous solution (99:1 v/v, H2O:HCl 37%) for 80 min, protected from light, at 35 °C and under constant stirring (100 rpm). The extract was filtered through qualitative filter paper (black band, reference model REF. 41) and stored at 5 °C.

2.4. Microencapsulation of Jambolan Aqueous Extract

Microencapsulation was performed according to the methodology proposed by Santhalakshmy et al. (2015) with some modifications. A solution was prepared with aqueous jambolan extract and 30% (m/v) maltodextrin 20DE and stirred with a magnetic stirrer until (TECNAL®, TE-102 Turratec, Piracicaba/SP) complete solubilization. A mini spray dryer (MSD® 1.0 LM, LABMAQ do Brasil LTDA) was used to obtain microparticles (Fig S1, Supplementary Material) under the following conditions: drying inlet air temperature of 150 °C, feed flow rate of 10 mL/min, air flow rate of 35 L/min, and outlet air temperature of 80 °C. The microparticles were kept in a metallized stand-up pouch bag (80 mL, 8 × 12.5 cm) and stored at −18 °C, being characterized for water activity and moisture content, according to item 2.2.

2.4.1. Encapsulation Efficiency of Phenolic Compounds

To determine the total phenolic content (TCF) according to the methodology described by Saénz et al. (2009), 100 mg of microencapsules was dispersed in 1.0 mL of a 50:8:42 (v/v/v) ethanol to acetic acid to distilled water solution. The mixture was vortexed for 1 min, filtered through a microfilter with 0.45-µm pore diameter (Syringe Filters K-18; Kasvi, São José dos Pinhais, PR, Brazil), and analyzed after reaction with the Folin–Ciocalteu reagent as described above.

The surface phenolic compound content (TSF) was determined according to the methodology described by Saénz et al. (2009). 100 mg of microcapsules was dispersed in 1.0 mL of 1:1 (v/v) ethanol to methanol solution, gently stirred for 5 min to avoid their rupture and microfiltered as described above. The phenolic content was assessed in the filtrate using the Folin–Ciocalteu reagent and a gallic acid standard curve. The encapsulation efficiency (EE) was calculated considering the equation described by Rocha et al. (2019).

where EE is the encapsulation efficiency, TCF is the total phenolic compounds content, and TSF is the surface phenolic compound content.

2.4.2 Anthocyanin Encapsulation Efficiency

The determination of the encapsulation efficiency (EE) of anthocyanins followed the methodology described by Kanha et al. (2021). The total anthocyanin content in the microcapsules (TACm) and on the surface of the microcapsules (TACs) was determined by spectrophotometry, using the differential pH method previously described in item 2.2. The microencapsulation efficiency was calculated by the equation shown in Mahdavi et al. (2016a).

where EE is the encapsulation efficiency, TACt is the total anthocyanin content, and TACs is the surface anthocyanin content.

2.5. Particle Characterization

2.5.1 Identification and Quantification of Phenolic and Anthocyanin by HPLC-DAD

External standards of hesperidin, procyanidin B1, catechin, procyanidin B2, trans-caftaric acid, chlorogenic acid, caffeic acid, and p-coumaric acid were purchased from Sigma-Aldrich, whereas epigallocatechin gallate, epicatechin, epicatechin gallate, procyanidin A2, quercetin 3-glucoside, rutin, myricetin, kaempferol 3-glucoside, and petunidin 3-glucoside from Extrasynthese (Genay, France). Trans-resveratrol was obtained from Cayman Chemical Company (Ann Arbor, MI, USA).

The phenolic and anthocyanin profile of the aqueous extract of jambolan and the microparticles (Figs. S2–S7, Supplementary Material) was determined according to the methodology validated by Padilha et al. (2017), with adaptations from Dutra et al. (2018). A 1 g aliquot of the sample was mixed with methanol acidified with hydrochloric acid (6.0 mol/L) and placed in ultrasound at 40 kHz for 30 min at 25 °C (UNIQUE, model USC-1800, Brazil). The extract was centrifuged at 3000×g for 20 min (SL-701 centrifuge; Solab, São Paulo, Brazil), and the supernatant was collected, diluted to 10% with 0.52 mol/L phosphoric acid solution (pH = 2.0), and filtered at 0.45 μm (PTFE) (Millex Millipore, Barueri, SP, Brazil).

The analysis was performed on an Agilent 1260 Infinity LC System liquid chromatograph (Agilent Technologies, Santa Clara, USA) coupled to a diode array detector (DAD) (model G1315D), using the Zorbax Eclipse Plus RP-C18 column as the stationary phase (100 × 4.6 mm, 3.5 μm), coupled to the Zorbax C18 pre-column (12.6 × 4.6 mm, 5 μm), and solvents A (0.52 mol phosphoric acid solution, pH = 2.0) and B (methanol acidified with 0.5% phosphoric acid). The mobile phase flow rate was 0.8 mL/min and the injection volume was 20 µL and the column temperature was 35 °C. Detection of compounds was carried out at 220, 280, 320, 360, and 520 nm, and identification and quantification were made by comparison with external standards. The results were expressed in mg/100 g of dry mass sample. Data collection and analysis were performed using the Open LAB CDS ChemStation Edition software (Agilent Technologies, Santa Clara, USA).

2.5.2 Hygroscopicity and Solubility

A sample of the microencapsulated aqueous extract (2 g) was placed in an airtight container containing a saturated NaCl solution (relative humidity of 75.1%). Hygroscopicity was expressed by the mass of water absorbed per 100 g of sample after 7 days (Tonon et al., 2008).

Solubility was determined according to Shittu and Lawal (2007), with modifications. One gram of the sample was added to 10 mL of distilled water and kept under magnetic stirring for 30 min. The mixture was centrifuged at 6000 rpm for 5 min. The supernatant was collected and dried at 105 °C for 24 h. The relationship between the mass of the dry solid, coming from the supernatant, and the initial mass of the sample resulted in the percentage of solubility.

2.5.3 Average Diameter and Morphology of the Microencapsulated Aqueous Extract

The average diameter was determined on a laser diffraction analyzer (model S3500, Microtrac, Largo, FL, USA) coupled to a common bench ultrasound device to increase sample dispersibility. A small amount of sample was dispersed in isopropyl alcohol as a carrying fluid and subjected to particle size distribution readings. The average diameter was determined based on the average diameter of a sphere of the same volume (Brouckere diameter, D [4.3]), which is generally used to characterize powder particles.

Particle morphology was observed using scanning electron microscopy (SEM). The samples were fixed in metallic specimen holders (stubs) and then metallized with gold (Leica metalizer, model EM SCD500), at a coating rate of 15 nm thick, for 80 s, and current of 40 mA and observed in a scanning electron microscope (FEI, model Quanta 200 FEG), operating with 30 kV at 25 °C. Image acquisition was performed using the XT microscope software (Utpott et al., 2020).

2.6 Stability of Phenolic Compounds and Anthocyanins in the Microencapsulated Extract

Aliquots of the microcapsules (5 g) were transferred to metallized stand-up pouch bags (80 mL, 8 × 12.5 cm), protected from exposure to light. The samples were stored under refrigeration and at room temperature (5 °C and 28 °C, respectively), for 90 days, being periodically evaluated in relation to color, content of phenolic compounds, and total monomeric anthocyanins.

2.7 Application and Stability of the Extract Microencapsulated in Gelatin

The microencapsulated jambolan extract was applied in a colorless, flavorless gelatin powder, following the methodology proposed by Mahdavi et al. (2016b). The tests carried out to monitor the stability of microcapsules in gelatin were the instrumental determination of color, total phenolic content, and total monomeric anthocyanins.

2.8 Statistical Analysis

All analyses were performed in triplicate and experimental data were presented as mean ± standard deviation. Results were subjected to analysis of variance, and post hoc comparison of the means was performed by Tukey’s test at p < 0.05 using the Statistica, version 12.0 (StatSoft. Inc., Tulsa, OK, USA) software package.

3. Results and Discussion

3.1 Characterization of Fresh and Freeze-Dried Jambolana

Table 1 presents the chemical and physicochemical parameters and the content of bioactive compounds in the peel and pulp of in natura and freeze-dried jambolan (Syzygium cumini (L.) Skeels). The values found for the edible part of fresh jambolan are close to those presented by Silva and Sá and Sabaa-Srur (2012), and those obtained for freeze-dried jambolan are similar to those reported by Santiago et al. (2016). Barcia et al. (2012) report, in their studies with fresh jambolão collected in three different cities (Pelotas, Capão do Leão, and Santa Vitória do Palmar), similar results for moisture (81.7% ± 3.6–83.9% ± 1.5), ash (0.35% ± 0.1–0.42% ± 0.1), proteins (0.73% ± 0.0–0.91% ± 0.3), and fibers (0.40% ± 0.4–0.57% ± 0.3). The water activity (aw) of freeze-dried jambolan (0.264 ± 0.002) was much lower than that of in natura jambolan (0.982 ± 0.001), which indicates that it can be considered microbiologically safe (Leong et al., 2011). Determining water activity reveals the amount of free water in the food responsible for all biochemical, microbiological, and spoilage reactions. Low water activity values are considered safer and promote greater dust stability (Wadibhasme et al., 2020a).

In relation to bioactive compounds, jambolan presented levels of phenolic compounds above those reported by Singh et al. (2019) (450 g GAE/100 g) and close to the anthocyanin content (198 mg/100 g), for the fresh fruit. Brito et al. (2017) found a higher value for anthocyanins of 296.00 ± 16.00 mg/100 g in fresh fruit. Some factors must be taken into consideration to explain such divergences in values, such as differences in soil or climate.

3.2 Characterization of Microencapsulated Jambolan Extract

Table 2 presents the physical and physicochemical characterization and the content of bioactive compounds of the microencapsulated jambolan extract. The water activity of the jambolan extract microcapsules was 0.304, a value considered very suitable for the stability of the extract, as it represents a low amount of water available for chemical reactions and microbiological growth. Determining the moisture content of microcapsules is important as it is related to the drying efficiency and consequently the microbiological safety of the product, in addition to characteristics such as adhesion and crystallization. Wadibhasme et al. (2020a) presented values of water activity, moisture content, and total acidity (0.333 ± 0.002; 3.90% ±0.02; 0.65 g/100 g malic acid ± 0.05, respectively) close to those found in the present study; however, the pH value was slightly higher (3.45 ± 0.04). The moisture content was similar to those commonly observed for powder products obtained by spray drying (Singh et al., 2019; Gaibor et al., 2022).

The chromatic parameters L*, a*, and b* (Table 2) reveal that the microencapsulated jambolan extract presented high luminosity, due to the color (white) of the encapsulating agent used in microencapsulation by atomization and greater intensity of the red color, due to the high content of anthocyanins in the extract. The values of total phenolic compounds were lower than those reported by Tavares et al. (2020) for the jambolan powder produced by foam mat drying. The anthocyanin content found in the microencapsulated jambolan extract was higher than the value reported by Singh et al. (2019) and Raman et al. (2020) in jambolan juice powder and lower than that reported by Tavares et al. (2020).

Solubility is one of the properties that informs how microcapsules will behave in an aqueous solution, fundamental for their reconstitution and definition of possible applications. The microencapsulated extract showed a solubility above 90% (Table 2); similar values were observed by Singh et al. (2019), Wadibhasme et al. (2020a) for the solubility of jambolan microcapsules, and by Santhalakshmy et al. (2015) for the powder of the aqueous extract of microencapsulated jambolan.

The hygroscopicity value for microencapsulated jambolan extract reported by Santhalakshmy et al. (2015), also using maltodextrin as wall material, was higher (22.33 ± 1.52 g H2O/100 g) than that obtained in the present study, which can be explained by a difference in the amount of wall material applied.

The encapsulation efficiency (EE) of phenolic compounds from microencapsulated jambolan extract was 89.23% (Table 2), a value close to that found by Rocha et al. (2019) in a mixture of microencapsulated extracts of jussara, jabuticaba, and blueberry (94.21%) and lower than that reported by Rezende et al. (2018) in an extract of microencapsulated acerola pulp (69.75%).

Regarding the EE of anthocyanins from microencapsulated jambolan extract (94.56%), lower EE values were reported by Ahmad et al. (2018) in the study with microencapsulated saffron extracts (45% and 63.25%). Mahdavi et al. (2016b) obtained EE in their barberry extracts for anthocyanins close to those found in this study (between 91.5 and 93%). In research carried out with microencapsulated Chagalapoli extract, Antonio-Gómez et al. (2021) present a higher EE value for anthocyanins than the present study (99.40%).

The difference in EE values may be attributed to some factors, such as the microencapsulation conditions, type, and concentration of wall material. Furthermore, the EE for total phenolic compounds did not follow the same behavior as anthocyanins. In their study with pomegranate juice microencapsulated with maltodextrin, Robert et al. (2010) found behavior similar to this work, where the EE of anthocyanins was 80%, but only 70% for total phenolics. The authors attributed these differences to the charges present in the bioactive compounds, taking into account that anthocyanins contain a positive charge, having greater affinity for maltodextrin in relation to other phenols, which have a negative charge, with lower affinity for maltodextrin.

3.3 Phenolic Profile of Liquid and Microencapsulated Aqueous Extract

In the aqueous extract of jambolan and in the microencapsulated extract, 6 phenolic compounds were quantified, including 2 flavanols, 1 condensed tannin, and 3 anthocyanins (Table 3). These results show the variety and richness of phenolic compounds present in the fruit and its derivatives. Some phenolic compounds such as catechin and the anthocyanin cyanidin 3-glucoside were also reported by Azima et al. (2017) in the aqueous extract of jambolan.

Catechin was quantified in jambolan extract in quantities greater than procyanidin A2 and epicatechin gallate (Table 3), which presented significant concentrations only in the microcapsules of the extract. Studies report that catechin has long been attributed to its antioxidant and anti-inflammatory effects, increasing its therapeutic potential as interventions for numerous clinical disorders, being used as an alternative therapy in the treatment of HIV infection, in addition to being one of the most abundant phenolic compounds after simulation of gastrointestinal digestion in vitro, showing greater bioaccessibility in aqueous extracts (Andrade et al., 2022). The condensed tannin (procyanidin A2), found in jambolan, has a high molecular size, as indicated by the high mDP value (average degree of polymerization), in addition to contributing to the high astringency characteristic of this fruit (Tavares et al., 2016).

Observing the anthocyanin profile (Table 3), two diglycosylated anthocyanins (cyanidin 3,5-diglycoside and pelargonidin 3,5-diglycoside) and one monoglycosylated (cyanidin 3-glucoside) were quantified. Pelargonidin in the diglucoside version was the largest source of contribution to the total anthocyanins quantified by liquid chromatography in the present study.

Carvalho et al. (2017) quantified nine anthocyanins in samples of jambolan juice dehydrated in a foam bed, among which they found cyanidin in mono- and diglycosylated versions, however, in concentrations lower than those found in the present study (3.59 ± 0.21 mg/L and 0.10 ± 0.04 mg/L, for cyanidin 3,5-diglucoside and cyanidin 3-diglucoside in jambolan juice, respectively). Cyanidin in mono- and diglycosylated versions are widely reported by other authors (Lestario et al., 2017; Romualdo et al., 2021; Santiago et al., 2016); however, none of the studies reported pelargonidin 3,5-diglycoside. The difference between the results presented in this study and those of the authors consulted may be caused by different environmental conditions of development, varietal differences in the species, and different extraction and analysis methods. The compounds identified but not quantified were below the limit of quantification.

3.4 Average Diameter and Morphology of Microparticles

The particle size of powder extracts has been associated with important characteristics such as susceptibility to deterioration, fluidity, appearance, and dispersibility (Botrel et al., 2014). Jambolan extract microcapsules had average diameters ranging from 16.75 to 23.35 μm. The jambolan extract microparticles had a spherical shape and varied in size, characteristics typical of those produced by microencapsulation by spray drying, in addition to a surface without cracks (Fig. 1); this effect is due to the rapid evaporation of water forming a smooth and hard crust (Tonon et al., 2008). However, it can be noted that some parts of the surface of the microcapsules became rough, possibly due to shrinkage of the encapsulating agent in the initial stages of drying (Mar et al., 2020). These characteristics were also observed by other authors (Nunes et al., 2015; Daza et al., 2016; Tolun et al., 2020).

3.5 Stability of Bioactive Compounds in the Microencapsulated Jambolan Extract

Regarding the stability of total phenolic and total anthocyanin content (Figs. 2 and 3), all samples showed a decrease in these compounds over time. It is important to highlight that the microencapsulated jambolan extract stored at 28 °C presented a higher content of phenolic compounds (437.07 mg GAE/100 g ± 0.33) at the final storage time (90 days), in relation to the extract stored at 5 °C (403. 17 mg GAE/100 g ± 0.54), representing a retention of 83.61% for the microencapsulated extract stored at 28 °C, compared to 77.12% for that stored at 5 °C.

The anthocyanins present in the microencapsulated jambolan extract also reduced during storage for 90 days at 5 °C and 28 °C. The microencapsulated jambolan extract stored at 5 °C presented a higher final content of total anthocyanins (117.18 mg/100 g ± 0.47) than that stored at 28 °C (105.72 mg/100 g ± 4.63), representing a stability of 90.91% for the microencapsulated extract stored at 5 °C, compared to 82.02% for that stored at 28 °C.

Taking into account that anthocyanins degrade at high temperatures, a greater decrease is expected during storage at 28 °C compared to those stored at 5 °C (Sharma et al., 2016); however, the group of phenolic compounds is much larger and has a wide variety of subgroups, each with different behaviors across temperature ranges, requiring a more in-depth study to precisely justify the behavior of the phenolic compounds present in the jambolan extract microcapsules.

These results were reflected in the color variation at the end of 90 days, where the microencapsulated jambolan extract stored at 5 °C presented a ΔE of 5.29 ± 0.39, while at 28 °C the difference was greater (ΔE = 10.16 ± 0. 73), due to greater degradation of anthocyanins.

Changes in total anthocyanin content in microencapsulated jambolan extracts stored at 5 °C and 28 °C. Means followed by the same lowercase letter in the lines in each of the analyses do not differ significantly (p < 0.05), using the Tukey test. Means followed by the same capital letter between the lines in each of the analyses do not differ significantly (p < 0.05), using the Tukey test

In the study carried out by Tavares et al. (2020) with jambolan juice powder obtained by drying on a foam bed and in a hot air circulation dryer, the content of phenolic compounds showed a stability of 96% and anthocyanins of 84.99%, after a period of storage for 150 days at 35 °C.

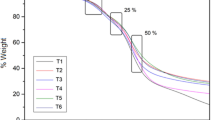

3.6 Stability of the Microencapsulated Extract Added to Gelatin

The results for the colorless gelatin powder sample mixed with microencapsulated jambolan extract followed the same trend, with a drop in the total phenolic content after 30 days (194.39 mg GAE/100 g ± 3.44), which represents a stability of 55.46% (Fig. 4).

The total phenolic content decreased and these differences were statistically significant along time. The reason for the decrease may be the phenolic compounds present on the surface of the sample, which are more susceptible to interaction with oxygen and humidity in the environment, leaving them more prone to degradation than those present inside the sample. A similar result was obtained by Tolun et al. (2020) in their study with microencapsulated grape pulp extract. The authors also highlight that phenolic compounds are a large group of substances that have different sensitivity levels that can be affected by various conditions during storage.

The results for the colorless gelatin powder sample mixed with microencapsulated jambolan extract follow the same trend. At the end of 30 days, the total anthocyanin content was 217.70 mg/100 g ± 5.67, representing retention of 45.21% (Fig. 5).

Analyzing the anthocyanin content in all cases, a decreasing trend was observed; similar behavior was found in the study carried out by Bednarska et al. (2020) with anthocyanins in microencapsulated aronia juice. The authors argue that during storage, chemical interaction may occur between the components of the food matrix, such as proteins or polyuronic acids, and the anthocyanins of the natural dye, causing degradation or exposure to oxidation of the anthocyanins. Thus, the stability of phenolic compounds and anthocyanins is strongly dependent on the characteristics of the food matrix.

The L value (luminosity) dropped probably due to the degradation of anthocyanins, which caused changes in the color of the gelatin powder, due to the original products of anthocyanin degradation, and which also contributed to the increase in the b coordinate (yellow intensity). In both cases, the decrease in anthocyanin values results in a statistically significant color variation (Table 4) confirmed by the ΔE for the colorless gelatin mixed with the microencapsulated jambolan extract (20.72 ± 0.91). Although the decrease values were high at the end of storage, the powders prepared for gelatin still showed bright color.

Based on the observed data, the addition of 7% of natural coloring in the powder for colorless gelatin from microencapsulated jambolan extract resulted in intense coloring and concentration of anthocyanins.

Conclusions

Jambolan extract (Syzygium cumini (L.) Skeels) microencapsulated by spray drying is considered a sustainable source of natural antioxidants and phenolic compounds, in addition to being used to color gelatin powder as an alternative to synthetic dyes. At the end of 90 days of storage, the microencapsulated jambolan extract showed a decrease in phenolic compounds and anthocyanins, but still with significant amounts of these compounds, indicating its potential as a functional ingredient and natural pigment for the food industry. Gelatin powder formulations made with 7% natural coloring, despite greater anthocyanin losses after 30 days of storage, showed visible coloration.

The final decision on the best option to add to the food must be based on additional criteria, such as the type of food you want to dye and the final cost. Finally, there is a need for further studies on ways to optimize the microencapsulation process to reduce losses of anthocyanins, in addition to more research on the stability of the application of freeze-dried jambolan fruit and microencapsulated jambolan extract in foods.

Data Availability

No datasets were generated or analysed during the current study.

References

Ahmad, M., Ashraf, B., Gani, A., & Gani, A. (2018). Microencapsulation of saffron anthocyanins using β glucan and β cyclodextrin: Microcapsule characterization, release behavior & antioxidant potential during in-vitro digestion. International Journal of Biological Macromolecules, 109, 435–442. https://doi.org/10.1016/j.ijbiomac.2017.11.122.

Albuquerque, G. A., Carvalho, A. V., Faria, L. J. G., De, Chisté, R. C., Martins, L. H., Da, S., & Lopes, A. S. (2019). Effects of thermal pasteurization on jambolan tropical juice bioactive compounds. British Food Journal, 121, 2821–2834. https://doi.org/10.1108/BFJ-03-2019-0191.

Andrade, J. K. S., Barros, R. G. C., Pereira, U. C., Nogueira, J. P., Gualberto, N. C., De Oliveira, C. S., Oliveira, C. S., Shanmugan, S., & Narain, N. (2022). Bioaccessibility of bioactive compounds after in vitro gastrointestinal digestion and probiotics fermentation of Brazilian fruits residues with antioxidant and antidiabetic potential. LWT - Food Science and Technology, 153, 112469. https://doi.org/10.1016/j.lwt.2021.112469.

Antonio-Gómez, M. V., Salinas-Moreno, Y., Hernández-Rosas, F., Martínez-Bustos, F., Andrade-González, I., & Herrera-Corredor, J. A. (2021). Optimized extraction, Microencapsulation, and Stability of Anthocyanins from Ardisiacompressa K Fruit. Polish Journal of Food and Nutrition Sciences, 71(3), 299–310. https://doi.org/10.31883/pjfns/140404.

AOAC, Association of Official Analytical Chemists (2016). Official methods of analysis of the Association Analytical Chemists. 20 ed. Maryland.

Ayyanar, M., & Subash-Babu, P. (2012). Syzygium cumini (L.) Skeels: A review of its phytochemical constituents and traditional uses. Asian Pacific Journal of Tropical Biomedicine, 2, 240–246. https://doi.org/10.1016%2FS2221-1691(12)60050-1.

Azima, A. M. S., Noriham, A., & Manshoor, N. (2017). Phenolics, antioxidants and color properties of aqueous pigmented plant extracts: Ardisiacolorata var. Elliptica, clitoriaternatea, garciniamangostana and Syzygiumcumini. Journal of Functional Foods, 38(Part A), 232–241. https://doi.org/10.1016/j.jff.2017.09.018.

Barcia, M. T., Pertuzatti, P. B., Jacques, A. C., Godoy, H. T., & Zambiazi, R. (2012). Bioactive compounds, antioxidant activity and percent composition of jambolão fruits (Syzygium cumini). The Natural Products Journal, 2, 129–138. https://doi.org/10.2174/2210315511202020129.

Bednarska, M. A., & Janiszewska-Turak, E. (2020). The influence of spray drying parameters and carrier material on the physico-chemical properties and quality of chokeberry juice powder. Journal of Food Science and Technology, 57(2), 564–577. https://doi.org/10.1007/s13197-019-04088-8.

Botrel, D. A., Borges, S. V., Barros, R. V., De, & Do Carmo, E. L. (2014). Optimization of fish oil spray drying using a protein: Inulin system optimization of fish oil spray drying using a protein: Inulin system. Drying Technology, 32(3), 279–290. https://doi.org/10.1080/07373937.2013.823621.

Brito, B. D. N. do, Pena, C., Da, R., Lopes, S., A. S., & Chisté, R. C. (2017). Anthocyanins of jambolan (Syzygium cumini): Extraction and pH dependent color changes. Journal of Food Science, 82, 2286–2290. https://doi.org/10.1111/1750-3841.13847.

Carvalho, T. I. M., De, Nogueira, T. Y. K., Mauro, M. A., Gomez-Alonso, S., Gomes, E., Da-Silva, R., Hermosín-Gutiérrez, I., & Lago-Vanzela, E. S. (2017). Dehydration of jambolan [Syzygium cumini (L.)] juice during foam mat drying: Quantitative and qualitative changes of the phenolic compounds. Food Research International, 102, 32–42. https://doi.org/10.1016/j.foodres.2017.09.068.

Daza, L. D., Fujita, A., Fávaro-Trindade, C. S., Rodrigues-Ract, J. N., Granato, D., & Genovese, M. I. (2016). Effect of spray drying conditions on the physical properties of Cagaita (Eugenia Dysenterica DC.) Fruit extracts. Food and Bioproducts Processing, 97, 20–29. https://doi.org/10.1016/j.fbp.2015.10.001.

Dutra, M. C. P., Rodrigues, L. L., Oliveira, D., Pereira, G. E., & Lima, M. S. (2018). Integrated analyses of phenolic compounds and minerals of Brazilian organic and conventional grape juices and wines: Validation of a method for determination of Cu, Fe and Mn. Food Chesmitry, 269, 157–165. https://doi.org/10.1016/j.foodchem.2018.07.014.

Emam, A. O., & El-Nashar, H. A. (2022). Technological and nutritional aspects of incorporating jamun (Syzygiumcumini (L.) skeels) fruit extract into yoghurt. Journal of Food Research, 11(1), 1–28. https://doi.org/10.5539/jfr.v11n1p28.

Faria, A. F., Marques, M. C., & Mercadante, A. Z. (2011). Identification of bioactive compounds from jambolão (Syzygium cumini) and antioxidant capacity evaluation in different pH conditions. Food Chemistry, 126, 1571–1578. https://doi.org/10.1016/j.foodchem.2010.12.007.

Freita, B. F. D., Magalhães, G. L., Júnior, M. S. S., & Caliari, M. (2021). Production of natural dye extracted from jambolan (Syzygium cumini). Research Society and Development, 10(2), e27410212600. https://doi.org/10.33448/rsd-v10i2.12600.

Freitas-Sá, D. D. G. C., Souza, R. C., De., Araujo, M. C. P., De., Borguini, R. G., Mattos, L. D. S., De., Pacheco, S., Godoy, R. L., & De, O. (2018). Effect of jabuticaba (Myrciaria jaboticaba (Vell) O. Berg) and jamelão (Syzygium cumini (L.) Skeels) peel powders as colorants on color-flavor congruence and acceptability of yogurts. LWT - Food Science and Technology, 96, 215–221. https://doi.org/10.1016/j.lwt.2018.05.024.

Gaibor, F. M., Rodríguez, D., García, M. A., Peraza, C. M., Vidal, D., Nogueira, A., & Casariego, A. (2022). Development of a food colorant from Syzygium cumini L.(Skeels) by spray drying. Journal of Food Science and Technology, 59(10), 4045–4055. https://doi.org/10.1007/s13197-022-05454-9.

Iacobucci, G. A., & Sweeny, J. G. (1983). The chemistry of anthocyanins, anthocyanidins and related flavylium salts. Tetrahedron, 39(19), 3005–3038. https://doi.org/10.1016/S0040-4020(01)91542-X.

Kanha, N., Regenstein, J. M., Surawang, S., Pitchakarn, P., & Laokuldilok, T. (2021). Properties and kinetics of the in vitro release of anthocyanin-rich microcapsules produced through spray and freeze-drying complex coacervated double emulsions. Food Chemistry, 340, 127950. https://doi.org/10.1016/j.foodchem.2020.127950.

Kuck, L. S., Wesolowski, J. L., & Noreña, C. P. Z. (2017). Effect of temperature and relative humidity on stability following simulated gastro-intestinal digestion of microcapsules of Bordo grape skin phenolic extract produced with different carrier agents. Food Chemistry, 230, 257–264. https://doi.org/10.1016/j.foodchem.2017.03.038.

Lao, F., & Giusti, M. M. (2018). Extraction of purple corn (Zea mays L) cob pigments and phenolic compounds using food-friendly solvents. Journal of Cereal Science, 80, 87–93. https://doi.org/10.1016/j.jcs.2018.01.001.

Leong, S. L., Pettersson, O. V., Rice, T., Hocking, A. D., & Schnürer, J. (2011). The extreme xerophilic mould xeromyces bisporus — growth and competition at various water activities. International Journal of Food Microbiology, 145, 57–63. https://doi.org/10.1016/j.ijfoodmicro.2010.11.025.

Lestario, L. N., Howard, L. R., Brownmiller, C., Stebbins, N. B., Liyanage, R., & Lay, J. O. (2017). Changes in polyphenolics during maturation of Java plum (Syzygium cumini Lam). Food Research International, 100(3), 385–391. https://doi.org/10.1016/j.foodres.2017.04.023.

Machado, M. H., Rosa Almeida, D., Maciel, A., Vitorino, M. V. D. O. B., Bazzo, V. B., Rosa, G. C. D., Sganzerla, C. G., Mendes, W. G., C., & Barreto, P. L. M. (2022). Microencapsulation by spray drying of red cabbage anthocyanin-rich extract for the production of a natural food colorant. Biocatalysis and Agricultural Biotechnology, 39, 102287. https://doi.org/10.1016/j.bcab.2022.102287.

Mahdavi, S. A., Jafari, S. M., Assadpoor, E., & Dehnad, D. (2016a). Microencapsulation optimization of natural anthocyanins with maltodextrin, gum arabic and gelatin. International Journal of Biological Macromolecules, 85, 379–385. https://doi.org/10.1016/j.ijbiomac.2016.01.011.

Mahdavi, S. A., Jafari, S. M., Assadpour, E., & Ghorbani, M. (2016b). Storage stability of encapsulated barberry’s anthocyanin and its application in jelly formulation. Journal of food Engineering, 181, 59–66. https://doi.org/10.1016/j.jfoodeng.2016.03.003.

Mar, J. M., Silva, L. S., Da, Lira, A. C., Kinupp, V. F., Yoshida, M. I., Moreira, W. P., Bruginski, E., Campos, F. R., Machado, M. B., Souza, T. P., De, Campelo, P. H., Bezerra, J., De, A., & Sanches, E. A. (2020). Bioactive compounds-rich powders: Influence of different carriers and drying techniques on the chemical stability of the Hibiscus acetosella extract. Powder Technology, 360, 383–391. https://doi.org/10.1016/j.powtec.2019.10.062.

Merz, B., Capello, C., Leandro, G. C., Moritz, D. E., Monteiro, A. R., & Valencia, G. A. (2020). A novel colorimetric indicator film based on chitosan, polyvinyl alcohol and anthocyanins from jambolan (Syzygium cumini) fruit for monitoring shrimp freshness. International Journal of Biological Macromolecules, 153, 625–632. https://doi.org/10.1016/j.ijbiomac.2020.03.048.

Nunes, G. L., Boaventura, B. C. B., Pinto, S. S., Verruck, S., Murakami, F. S., Prudêncio, E. S., & Amboni, R. D. M. C. (2015). Microencapsulation of freeze concentrated Ilex paraguariensis extract by spray drying. Journal of Food Engineering, 151, 60–68. https://doi.org/10.1016/j.jfoodeng.2014.10.031.

Padilha, C. V. S., Miskinis, G. A., Souza, M. E. A. O., Pereira, G. E., Oliveira, D., Bordignon-Luiz, M. T., & Lima, M. S. (2017). Rapid determination of flavonoids and phenolic acids in grape juices and wines by RP-HPLC/DAD: Method validation and characterization of commercial products of the new Brazilian varieties of grape. Food Chesmistry, 228, 106–115. https://doi.org/10.1016/j.foodchem.2017.01.137.

Paul, I. D., & Das, M. (2019). Microwave convective hot airdriedjamun (Syzygium cumini L) pulp powder: Optimization of drying aids. Journal of Food Process Engineering, 42, e13166. https://doi.org/10.1111/jfpe.13166.

Raman, R. K., Santhalakshmy, S., Bosco, S. J. D., & Ganguly, S. (2020). Phytochemical properties of spray dried jamun juice powder as affected by encapsulating agents. Journal of Pharmacognosy and Phytochemistry, 9(3), 599–602.

Rezende, Y. R. R. S., Nogueira, J. P., & Narain, N. (2018). Microencapsulation of extracts of bioactive compounds obtained from acerola (Malpighiaemarginata DC) pulp and residue by spray and freeze drying: Chemical, morphological and chemometric characterization. Food Chemistry, 254, 281–291. https://doi.org/10.1016/j.foodchem.2018.02.026.

Robert, P., Gorena, T., Romero, N., Sepulveda, E., Chavez, J., & Saenz, C. (2010). Encapsulation of polyphenols and anthocyanins from pomegranate (Punicagranatum) by spray drying. International Journal of Food Science & Technology, 45, 1386–1394. https://doi.org/10.1111/j.1365-2621.2010.02270.x.

Rocha, J. D. C. G., Barros, F. A. R., De, Perrone, Í. T., Viana, K. W. C., Tavares, G. M., Stephani, R., & Stringheta, P. C. (2019). Microencapsulation by atomization of the mixture of phenolic extracts. Powder Technology, 343, 317–325. https://doi.org/10.1016/j.powtec.2018.11.040.

Romualdo, G. R., Souza, I. P., De., Souza, L. V., De., Prata, G. B., Fraga-Silva, T. F., De, C., Sartori, A., Borguini, R. G., Santiago, M. C. P., De, A., Fernandes, A. A. H., & Cogliati, B. (2021). Beneficial effects of anthocyanin-rich peels of Myrtaceae fruits on chemically-induced liver fibrosis and carcinogenesis in mice. Food Research International, 139, 109964. https://doi.org/10.1016/j.foodres.2020.109964.

Saénz, C., Tapia, S., Chávez, J., & Robert, P. (2009). Microencapsulation by spray drying of bioactive compounds from cactus pear (Opuntia ficus-indica). Food Chemistry, 114(2), 616–622. https://doi.org/10.1016/j.foodchem.2008.09.095.

Santhalakshmy, S., Bosco, S. J. D., Francis, S., & Sabeena, M. (2015). Effect of inlet temperature on physicochemical properties of spray-dried jamun fruit juice powder. Powder Technology, 274, 37–43. https://doi.org/10.1016/j.powtec.2015.01.016.

Santiago, M. C. P. A., Gouvêa, A. C. M. S., Peixoto, F. M., Borguini, R. G., Godoy, R. L. O., Pacheco, S., Nascimento, L. S. M., & Nogueira, R. I. (2016). Characterization of jamelão (Syzygium cumini (L.) Skeels) fruit peel powder for use as natural colorant. Fruits, 71(1), 3–8. https://doi.org/10.1051/fruits/2015041.

Schwartz, S. J., Von Elbe, J. H., & Giusti, M. M. (2010). Dyes. In O. R. Fennema, S. Damodaran, & K. L. Park (Eds.), Fennema food chemistry (4th ed., pp. 445–495). Artmed.

Seraglio, S. K. T., Schulz, M., Nehring, P., Betta, F. D., Valese, A. C., Daguer, H., Gonzaga, L. V., Fett, R., & Costa, A. C. O (2018). Nutritional and bioactive potential of Myrtaceae fruits during ripening. Food Chemistry, 239, 649–656. https://doi.org/10.1016/j.foodchem.2017.06.118.

Sharma, R. J., Gupta, R. C., Singh, S., Bansal, A. K., & Singh, I. P. (2016). Stability of anthocyanins- and anthocyanidins-enriched extracts, and formulations of fruit pulp of Eugenia jambolana (‘jamun’). Food Chemistry, 190, 808–817. https://doi.org/10.1016/j.foodchem.2015.06.029.

Shittu, T. A., & Lawal, M. O. (2007). Factors affecting instant properties of powdered cocoa beverages. Food Chemistry, 100(1), 91–98. https://doi.org/10.1016/j.foodchem.2005.09.013.

Silva, Sá, A. P. C., Da, & Sabaa-Srur, A. U. O. (2012). Chemical and physical aspects of the edible fractions and seeds of Jamelão (Syzygium cumini, L. Skeels). The Natural Products Journal, 2(2), 123–128. https://doi.org/10.2174/2210315511202020123.

Singh, C. S., Paswan, V. K., & Rai, D. C. (2019). Process optimization of spray dried Jamun (Syzygium cumini L) pulp powder. LWT - Food Science and Technology, 109, 1–6. https://doi.org/10.1016/j.lwt.2019.04.011.

Tavares, I. M., De, C., Lago-Vanzela, E. S., Rebello, L. P. G., Ramos, A. M., Gómez-Alonso, S., García-Romero, E., Da-Silva, R., & Hermosín-Gutiérrez, I. (2016). Comprehensive study of the phenolic composition of the edible parts of jambolan fruit (Syzygium cumini (L.) Skeels). Food Research International, 82, 1–13. https://doi.org/10.1016/j.foodres.2016.01.014.

Tavares, I. M., De, C., Sumere, B. R., Gómez-Alonso, S., Gomes, E., Hermosín-Gutiérrez, I., Da-Silva, R., & Lago-Vanzela, E. S. (2020). Storage stability of the phenolic compounds, color and antioxidant activity of jambolan juice powder obtained by foam mat drying. Food Research International, 128, 108750. https://doi.org/10.1016/j.foodres.2019.108750.

Tolun, A., Artik, N., & Altintas, Z. (2020). Effect of different microencapsulating materials and relative humidities on storage stability of microencapsulated grape pomace extract. Food Chemistry, 302, 125347. https://doi.org/10.1016/j.foodchem.2019.125347.

Tonon, R. V., Brabet, C., & Hubinger, M. D. (2008). Influence of process conditions on the physicochemical properties of açai (Euterpe Oleraceae Mart) powder produced by spray drying. Journal of Food Engineering, 88(3), 411–418. https://doi.org/10.1016/j.jfoodeng.2008.02.029.

Utpott, M., Assis, R. Q., Pagno, C. H., Krigger, S. P., Rodrigues, E., Rios, A., De, O., & Flôres, S. H. (2020). Evaluation of the Use of Industrial Wastes on the encapsulation of Betalains extracted from red pitaya pulp (Hylocereus polyrhizus) by spray drying: Powder stability and application. Food and Bioprocess Technology, 13(11), 1940–1953. https://doi.org/10.1007/s11947-020-02529-3. https://springerlink.bibliotecabuap.elogim.com/article/.

Wadibhasme, U., Athmaselvi, K. A., Hemke, J., & Kalkote, S. (2020). Development and evaluation of Jamun (Syzygium cumini) fortified instant drink mix by utilizing the spray drying technique. The Pharma Innovation, 9(4), 103–110.

Wadibhasme, U., Athmaselvi, K. A., Hemke, J., & Kalkote, S. (2020a). Development and evaluation of Jamun (Syzygium cumini) fortified instant drink mix by utilizing the spray drying technique. The Pharma Innovation Journal, 9(4), 103–110.

Wettasinghe, M., & Shahidi, F. (1999). Evening primrose meal: A source of natural antioxidants and scavenger of hydrogen peroxide and oxygen-derived free radicals. Journal of Agricultural and Food Chemistry, 47(5), 1801–1812. https://doi.org/10.1021/jf9810416.

Wrolstad, R. E., Durst, R. W., & Lee, J. (2005). Tracking color and pigment changes in anthocyanin products. Trends in Food Science & Technology, 16(9), 423–428. https://doi.org/10.1016/j.tifs.2005.03.019.

Yekdane, N., & Goli, S. A. H. (2019). Effect of Pomegranate Juice on characteristics and oxidative Stability of Microencapsulated Pomegranate seed oil using spray drying. Food and Bioprocess Technology, 12, 1614–1625. https://doi.org/10.1007/s11947-019-02325-84.

Funding

This study was financed in part by the Coordenação de Aperfeiçoamento de Pessoal de Nível Superior-Brasil (CAPES)-Finance Code 001. The authors also acknowledge the National Institute of Science and Technology of Tropical Fruits and CNPq for the financial support.

Author information

Authors and Affiliations

Contributions

P. N. A. S.: conceptualization, methodology, writing and investigation. M.E.S.J.: writing and investigation. D.S.R: writing—review. M.S.L.: investigation. R.V.T.: wwriting—review and editing. M.I.S.M.: supervision, writing—review and editing.

Corresponding author

Ethics declarations

Competing Interests

The authors declare no competing interests.

Authors and Affiliations

Postgraduate Program in Food Science and Technology, Universidade Federal Rural De Pernambuco, 52171-900, Recife, Brazil

Panait Abu Nidal Alves dos Santos; Marcony Edson da Silva Júnior; Renata Valeriano Tonon & Maria Inês Sucupira Maciel

Department of Food Engineering, Universidade Federal Do Agreste De Pernambuco, 55292-278, Garanhuns, Brazil

Daniele Silva Ribeiro

Federal Institute of Sertão Pernambucano, Department of Food Technology, Petrolina Campus, Rod. BR 407 km 08, S/N, Jardim São Paulo, 56314-520, Petrolina, PE, Brazil

Marcos dos Santos Lima

Embrapa Food Agroindustry, Av. Das Américas, 29501, 23020-470. Rio De Janeiro, Brazil

Renata Valeriano Tonon

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic Supplementary Material

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

dos Santos, P.A.N.A., da Silva Júnior, M.E., Ribeiro, D.S. et al. Stability of Phenolic Compounds Present in Aqueous Jambolan Extract Microencapsulated by Spray Drying and Application as a Natural Food Coloring. Food Bioprocess Technol (2024). https://doi.org/10.1007/s11947-024-03464-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11947-024-03464-3