Abstract

The impact of cooking, drying and grinding on essential oil content, curcuminoid contents and their bioaccessibility and sensorial quality of Curcuma longa L. was assessed. Sliced fresh turmeric rhizomes (5 mm thick) were air-dried at 60 °C, 40% RH directly or pre-cooked (95 °C/3 min) before drying at different conditions (50, 60 or 80 °C; 40% RH). Dried slices, at 0.11 kg kg−1 db water content, were ground to obtain two powders of different particle sizes (i.e. fine < 500 µm and coarse < 750 µm). Cooking had no impact on essential oil content, curcuminoid contents and their bioaccessibility but reduced drying time. Drying decreased essential oil content (− 22.5%), curcuminoid contents (− 11.0%) and their bioaccessibility (− 28.6%). Surprisingly, grinding had no impact on curcuminoid contents and their bioaccessibility. The combination of the tested unit operations produced final products with the same quality in terms of total curcuminoid contents (12.1 g/100 g db) and bioaccessible curcuminoids (1.0 g/100 g db). However, consumers detected significant differences in colour, texture and overall liking between processed turmeric powders (dried and cooked-dried). Our results demonstrate that smooth cooking (95 °C/3 min) followed by drying (60 °C, 40% RH) is the most appropriate process to produce a curcuminoid-rich powder and improve consumer acceptance.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Turmeric (Curcuma longa L.) has been used for years all over the world to prepare a large number of recipes and improve their aroma and colour. Consumers are also increasingly attracted to its anti-inflammatory potential and health properties. As a spice, turmeric is used fresh or processed in the formulation of sauces, soups, seasonings and marinades to enhance the sensory profile of many foods, particularly meat products. Rhizomes of dried Curcuma longa L. contain carbohydrates (60–70%), protein (6–8%), fibre (2–7%), minerals (3–7%), fat (5–10%), essential oil (3–7%) and curcuminoid pigments (2–6%). The essential oil and the curcuminoid pigments are active components of turmeric. The essential oil is composed mainly of sesquiterpenes i.e. α- (30–32%), β- (15–18%) and ar-turmerone (17–26%). Curcuminoids are a mixture of curcumin (52–63%) and its two derivatives demethoxycurcumin (19–27%) and bisdemethoxycurcumin (18–28%) [1]. These are considered bioactive polyphenols with beneficial health properties and are responsible for the yellow-orange colouration of turmeric powder [2]. Although turmeric has been used as a food colourant and functional ingredient, these uses have remained challenging due to its low solubility in water, which limits its dispersion in food matrices and its bioaccessibility [3, 4].

After harvest, fresh turmeric rhizome undergoes continuous physical, chemical and microbiological changes. These changes are particularly influenced by the moisture content of the material, relative humidity of ambient air and storage conditions [5]. To preserve its quality and make it available throughout the year, it must be subjected to specific technological treatment such as drying. Depending on the geographical area of production, turmeric is either dried directly or bleached and then dried; depending on local consumer preferences, it may also be ground more or less finely. Air drying is an alternative to sun drying, not only to increase the drying rate and reduce drying time but also to better preserve the quality of the product [5, 6]. However, it is recognised that it is time- and energy-consuming when whole rhizomes are dried directly or pre-cooked for a long time at a high temperature (≥ 100 °C) and then dried [7, 8]. Heat applied to turmeric may inactivate enzymes and soften the tissue to prevent phytochemical degradation and improve their release from plant matrix and therefore, turmeric powder functionality (i.e. curcuminoids bioaccessibility).

This study aimed to assess the impact of unit operations and their combinations on the essential oil content, curcuminoid contents and their bioaccessibility and sensorial quality of Curcuma longa L. In order to determine optimum transformation conditions, the impact of cooking, drying and grinding was studied through different process conditions on sliced rhizomes. The impact of cooking and drying on drying kinetics was also studied.

Materials and methods

Materials

Fresh turmeric rhizome (Curcuma longa L.) was purchased from a farmer in Kampong Cham (Cambodia) in November 2020. It was packed and transported to Montpellier (France) by airplane in the next 2 days. Turmeric rhizomes were stored at 4 °C before processing. About 60 g of fresh turmeric rhizome was cleaned and sliced to a thickness of 5 mm. Next, it was frozen by using liquid nitrogen and ground for 10 s at 10,000 rpm in a mill (Retsch Grindomix GM200, Retsch Gmbh, Germany) prior to immediate analyses of water content, essential oil content, curcuminoids and their bioaccessibility. About 360 g of fresh turmeric rhizome was cleaned and sliced then frozen at − 80 °C overnight before being freeze-dried in a vacuum freeze-dryer (Cryonext, France) for 48 h. It was ground following the same method as for the fresh turmeric. The commercial turmeric powder (Ducros) was purchased from a supermarket in Montpellier (France) in February 2021. It was packed in glass bottle with a net content of 45 g. HPLC standards curcumin (C), demethoxycurcumin (DMC), bisdemethoxycurcumin (BDMC), α-amylase from human saliva (5 units/mg protein), pepsin from porcine gastric mucosa (3200–4500 units/mg protein) and pancreatin from porcine pancreas (8 × USP specifications) were purchased from Sigma-Aldrich (Saint Quentin Fallavier, France).

Processing experiments

The fresh turmeric rhizomes were cleaned and washed thoroughly under running water to remove adhering soil and mud and other foreign materials. Then, the excess water was drained and the cleaned turmeric rhizomes were sliced manually to a thickness of 5 mm. The sliced turmerics (420 g) were cooked at 95 °C/3 min by immersion in a nylon net in hot water at a ratio of 1:10 w/w material to water. The cooked turmerics were immediately soaked in an ice water bath for 1 min to stop the heat exposure, before being drained. Then, the cooked turmerics were dried in a hot air dryer, developed in our laboratory at three conditions (D1: 60 °C, 40% RH; D2: 50 °C, 40% RH; D3: 80 °C/1 h + 50 °C, 40% RH) until reaching a water content of 0.11 kg kg−1 db [9]. In the vertical drying chamber, the sliced turmerics were spread on a grid sieve (0.25 m × 0.25 m × 0.06 m). Hot air was circulated downwards through the layer of sliced turmerics by a high-capacity fan. Airspeed was measured thanks to an anemometer (ALMEMO® 2690-8A, Ahlborn Mess, Germany). The air velocity was set to 2.1 ± 0.1 m s−1 to have no significant effect on temperature when passing through the layer of sliced turmerics. Monitoring by weighing was carried out continuously during the drying process, every 10 min for the first hour and then every 15 min. The water content, which was expressed on a dry basis (noted X) as a function of time, was estimated in line, using the mass reading of the sieve. Water content kinetics X(t) were fitted with a cubic smoothing spline (Matlab® Version 5.2, The Mathworks Inc., USA). The drying rate (dX/dt) was calculated as the direct analytical derivative of the cubic smoothing spline function on X(t). Next, the dried turmerics were ground at 10,000 rpm for 10 s by using an ultra-centrifugal mill (Retsch ZM 200, Retsch Gmbh, Germany) with two different sieves (500 µm and 750 µm) in order to produce two different particle size powders (P1: < 500 µm; P2: < 750 µm) (Fig. 1). For essential oil content determination, the dried turmerics were ground following the same method as for the fresh turmeric (“Materials” section). The samples were put in glass bottles and frozen at − 80 °C for further analysis.

Analytical methods

Dry matter and water contents

The dry matter content (means ‘‘dry matter free of essential oil”) was obtained by drying 1 g of ground turmeric in an aluminium cup in an oven (Gefran 800, Italy) at 105 °C for 30 h (i.e. until constant weight). The mean relative deviation of repeatability was ± 1.9% (n = 4). Water content, expressed on a dry basis, was deduced from essential oil and dry matter contents.

Essential oil content

The essential oil content, expressed in ml/100 g on a dry weight basis (ml/100 g db), was determined using a method adapted from the international official standard method ISO 6571:2008 [10]. The only modification in the method we applied was the elimination of xylene. About 20 g of fresh turmeric or 5 g of dried turmeric was weighed and transferred to 1 l round bottom flask, then 250 ml of distilled water was added with 10 pieces of pumice stones to homogenize boiling. It was heated at medium heat for 4 h and the condensed vapour was separated. The essential oil present in the uppermost layers was measured. The mean relative deviation of repeatability was ± 3.8% (n = 4).

Particle characterisation

A laser granulometry instrument (Mastersizer 3000, Malvern Instruments Ltd., Malvern, Worcestershire, UK) was used to measure the particle diameter and particle size distribution of the turmeric powders. The particle size was reported as the surface mean diameter (D3,2). The mean relative deviation of repeatability was ± 15.9% (n = 6).

Curcuminoid contents

Approximately 0.3 g of turmeric sample was mixed with 30 ml of 60 °C ethanol (99.8%) and homogenized for 2 min at 30,000 rpm (IKA T10 basic Ultra-Turrax, Prolabo, France). The samples were heated for 30 min at 60 °C [11]. After cooling, the extracts were diluted 1/10 with ethanol and filtered on 0.45 µm PTFE Minisart SRP4 membrane (Sartorius, Palaiseau, France). Curcuminoids were analysed by high-performance liquid chromatography (Agilent System 1200 series, Massy, France). The column was a polymeric ACE C18 (250 × 4.6 mm, 5 µm particle size, Inc Wilmington NC) and the injection volume was 5 µl. The quantification of curcuminoids was carried out according to the method of Sepahpour et al. [12] with small modifications. The elution was done isocratically with a mixture of acetonitrile and 0.1% acetic acid (40:60) at a flow rate of 1.0 ml/min. The temperature of the column was set at 25 °C. Chromatograms were recorded over 30 min period with a UV–visible photodiode array detector (Agilent Technologies 1200 series) at 425 nm, the wavelength of maximum absorption of the curcuminoids in the mobile phase. The curcuminoids were identified by their retention time and spectrum. External calibration was realized weekly with standard solutions of the pure chemicals in ethanol in the range of 1 to 50 mg/l. The curcuminoid contents were expressed in g/100 g on a dry weight basis (g/100 g db). The mean relative deviation of repeatability was 2.5%, 3.6%, 4.2% and 3.5%, respectively for C, DMC, BDMC and total curcuminoid contents (n = 4).

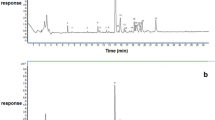

Assessment of bioaccessible curcuminoids

A static in vitro gastrointestinal tract model was used to study the potential gastrointestinal fate and bioaccessibility of curcuminoids in turmeric powders. The simulated gastrointestinal tract used in our study was based on one described previously [13, 14] with some slight modifications. The stock solutions were prepared before the experiments while the enzymatic solutions were prepared at the last moment. About 1.0 g of fresh turmeric or 0.3 g of dried turmeric was weighed and distilled water was added into the sample to get the total weight about 5.0 g that was left at room temperature for 15 min. Then, 5 ml of salivary solution was added and the sample was incubated for 2 min at 37 °C with gentle stirring (Oral phase). Next, 10 ml of gastric phase was added and incubated for 2 h at 37 °C with gentle stirring (Gastric phase). The solution was adjusted to pH 5.0 with sodium hydroxide at 2 M and then 20 ml of intestinal phase was added. The sample was incubated for 2 h at 37 °C with gentle stirring (Intestinal phase). After that, the digest phases were separated from the solid residue by centrifugation at 10,000×g for 30 min at 15 °C (Avanti™ J-E, Beckman Coulter®). The liquid phase was weighed accurately. To extract the bioaccessible curcuminoids, 10 ml of the digesta was mixed with 10 ml of chloroform (≥ 99.8%) and vortexed for 10 s (Fisherbrand™ Classic Vortex Mixer). Next, the samples were centrifuged at 10,000×g for 10 min at 15 °C. After that, 5 ml of yellow phase was evaporated at 50 °C for 3 min using a rotary evaporator (Heidolph Laborota 4000, Schwabach, Germany). Then, the residue was solubilized in 10 ml ethanol (≥ 99.8%) and filtered on a 0.45 µm PTFE Minisart SRP4 membrane. Finally, the bioaccessible curcuminoids were analysed by HPLC following the same method as the curcuminoids analysis (“Curcuminoid contents” section). The chromatogram figure of curcuminoids separated in the total extract and after digestion was shown in the supplementary information (Fig. SI). The bioaccessible curcuminoids were expressed in g/100 g on a dry weight basis (g/100 g db) by using the total content in the sample. The mean relative deviation of repeatability was 10.4%, 6.4%, 5.6% and 7.5%, respectively for C, DMC, BDMC and total curcuminoids (n = 4).

Sample preparation for the focus group, consumer acceptance and quantitative descriptive analysis

As turmeric is not consumed alone, the consumer evaluation was carried out by mixing the powders with cooked rice. For this purpose, plain rice was cooked in a pressure cooker with a ratio of rice/water equal to 1/1.5 (w/w). Then, it was mixed (in bowls) with the processed turmerics in a w/w ratio of 1.5% (kept warm by covering). About 20 g of sample per tasting glass was prepared for each panellist. The “turmeric rice samples” were kept warm (between 60 and 70 °C) in a heated cabinet and tested by using a teaspoon. The panellists were recommended to rinse their mouths with white rice and/or water between the samples, to minimise any residual effect.

Focus group and consumer acceptance

The focus group and consumer acceptance tests were conducted at the Institut de Technologie du Cambodge (Phnom Penh, Cambodia). The consumers were informed prior to the study that their participation was entirely voluntary, that they could stop the interview at any point/time and that their responses would remain anonymous. A focus group discussion was performed to collect the perceptions and attitudes of consumers towards turmeric powders. Six volunteers (three females and three males) of different ages (20 to 60-year-old) were invited to evaluate two turmeric powders and to taste two turmeric rice samples. We asked them to give their impressions about the samples, main product attributes and their motivations to buy and to consume turmeric powders. The results from the focus group discussion were used to develop a survey for the consumer acceptance test. The consumer acceptance test was carried out with 120 non-trained consumers. Since there were eight samples, two sessions were held on four consecutive days. The samples were presented in random order and labelled with three-digit numbers. We asked the participants to provide information on their gender, age, occupation, marital status, turmeric consumption pattern and frequency. For each sample, the consumers were asked to score their appreciation of each attribute (colour, texture, odour, taste and overall liking) on a structured nine-point hedonic scale (1: dislike extremely, 5: neither like nor dislike, 9: like extremely). After tasting, we asked them to provide their appreciation of turmeric powder: general appreciation, purposes of buy/use, ways of consuming and occasion of consumption.

Quantitative descriptive analysis

A quantitative descriptive analysis was carried out to characterize four turmeric rice samples. The panellists were recruited and selected in compliance with ISO Standard 8586:2012 [15] and panel performance was evaluated in compliance with ISO Standard 11132:2012 [16]. Twelve trained panellists (seven females and five males) were selected from researchers and staff in the UMR—Qualisud of CIRAD (Montpellier, France). We provided two training sessions to the panellists in order to determine the consensus list of quality attributes. In the first session, the panellists were specifically asked to identify and describe the quality attributes perceived and to memorize the perception and trained how to use the scale. After the individual assessment, an open discussion was held to assess the evaluation results. From this discussion, the terms were selected and the mean of each attribute was calculated for the second training session. The list of descriptors, their definitions and the assessment protocols were developed (Table 1). In the second session, the panellists were trained to assess warm-up samples using the same sensory sheets to be used in the main sensory evaluation. All panellists were asked to compare their results with the previous ones and the mean scale. We made sure that all the panellists were able to identify each attribute and score them in accordance with the entire panel. Sensory evaluation was performed in random order and the samples were coded with three alphabets. We asked the panellists to evaluate the samples in monadic service and to participate in two sessions with a 15 min break after the 1st session. The intensity of each attribute was scaled from 0 to 10 on which 0 corresponded to “low intensity” and 10 to “high intensity”. The laboratory met the requirements of the international norm ISO 8589 [17] i.e. it was air-conditioned with a controlled temperature (22 °C ± 1 °C) and humidity (75% ± 10%). The panellists tasted in individual tasting booths.

Statistical analysis

The results were expressed as means ± standard deviations. The significance of differences was determined by analysis of variance (ANOVA) and Duncan’s test using SPSS version 26.0 (SPSS Inc., Chicago, IL, USA). The level of significance was set at p < 0.05.

Results and discussion

Essential oil content

The essential oil content of our fresh turmeric was 13.25 ml/100 g db (equal to 1.51 ml/100 g wb). This value was higher than the value of 10.72 ml/100 g db (equal to 1.32 ml/100 g wb) found in our previous study [18], on fresh turmeric from Thailand. However, the value was in agreement with Garg et al. [19] who found that the essential oil content of turmerics collected from the sub-Himalayan Tarai region of India ranged from 0.16 to 1.94 ml/100 g wb. The difference may be due to turmeric variety, planting period, environmental conditions, plant development stage, and harvesting season [20, 21]. Cooking had no impact on essential oil content but drying significantly decreased it with a relative loss of 22.5%. This result was in agreement with Ararsa [22] who found a loss of essential oil up to 25% by evaporation and destruction of some light-sensitive oil constituents. The essential oil contents of freeze-dried and hot air-dried turmerics were not significantly different (p < 0.05) and the average value (10.30 ml/100 g db) was much higher than that of commercial turmeric powder (2.44 ml/100 g db). The essential oil content was quite stable during the tested unit operations.

Particle characterization

Different drying conditions had no impact on the particle size of turmeric powders obtained by grinding (Table 2). Our turmeric powders (both fine and coarse particle size groups) had bimodal distribution (data not shown). The average of D3,2 of fine and coarse particle size groups was 425 ± 49 µm and 711 ± 54 µm, respectively. The particle size distribution is dependent on the mill used for the grinding [23]. Here, the results were relevant with the use of two different sieves (< 500 µm for fine and < 750 µm for coarse). Different drying conditions, but with the same final water content (0.11 ± 0.01 kg kg−1 db), had no impact on the particle size distribution and surface mean diameter of turmeric powders. We can notice that the freeze-dried powder with low water content (0.06 kg kg−1 db) has a very low D3,2 (63 µm).

Impact of cooking and drying on drying curves

The water content of our fresh turmeric was 86.9 ± 0.5 g/100 g wb (equal to 6.7 ± 0.3 kg kg−1 db). The drying time required to reach a water content of 0.11 kg kg−1 db for FD1, FCD1, FCD2 and FCD3 was 8 h 19 min, 5 h 37 min, 7 h 48 min and 6 h 17 min, respectively. The use of a pre-cooking step saved 32.4% of drying time; increasing drying temperature reduced drying time (Fig. 2). Drying the cooked turmeric at 60 °C (FCD1) saved 11.8% and 38.7% as compared to drying at 80 °C/1 h + 50 °C (FCD3) and 50 °C (FCD2), respectively. The initial drying rate of FCD3 (9.0 ± 0.3 kg kg−1 h−1) was much higher than FCD2 (5.7 ± 0.1 kg kg−1 h−1), FCD1 (5.2 ± 0.2 kg kg−1 h−1) and FD1 (5.8 ± 0.7 kg kg−1 h−1). The drying rate increased with the drying temperature. This behaviour is due to higher temperature increasing the system’s enthalpy, which increases the transfer of mass and energy, accelerating the migration of the water [24]. Llano et al. [25] evaluated different temperatures (between 50 and 80 °C) in a fluidized bed dryer on turmeric, finding that the efficiency of dehydration was better at a higher temperature (80 °C) which can reduce drying time up to 37.5% as compared to drying at 50 °C. Drying kinetics presented a classical behaviour with an intense water loss during the initial stage and a lower one at a later stage. This can be attributed to the fact that water on the surface of the food evaporates easily at the beginning of the drying process, whereas it takes longer to remove the water inside the product.

Drying curves of fresh and cooked turmerics. a water content (X) on a dry basis as a function of time (t) and b drying rate (dX/dt) as a function of X. Drying curves recorded by an air dryer at different temperatures with an air velocity at 2.1 ± 0.1 m s−1. The different dash types on curves correspond to different trials

Impacts of unit operations on curcuminoid contents and their bioaccessibility

The C, DMC, BDMC and total curcuminoid contents of fresh turmeric were 5.29, 3.50, 4.77 and 13.56 g/100 g, respectively on a dry weight basis (Table 2). Cooking had no significant impact on curcuminoid contents; the average contents of C, DMC, BDMC and total curcuminoid contents of final products were 5.40, 2.46, 4.21 and 12.07 g/100 g db respectively. Among all the samples, the freeze-dried had the highest curcuminoid contents. Air drying (≥ 50 °C) decreased DMC, BDMC and total curcuminoid contents while grinding had no impact. At the end, the combination of the distinct unit operations produced final products with the same quality in terms of curcuminoid profiles. The curcuminoids were rather stable during the tested unit operations. Indeed, they are known to resist at high temperatures (above 100 °C) and in acidic conditions; however, they can be degraded by reactions in alkaline conditions and by light [26]. Our previous study [18] showed that the turmeric starchy matrix could preserve the curcuminoids and essential oil during cooking. Prathapan et al. [6] found no significant differences in curcuminoid content when comparing fresh and heat-treated material (between 50 and 100 °C for 30 min). Heat treatment of turmeric immersed in water produced good-quality turmeric with respect to curcuminoid; cooked turmeric showed higher uniformity or better pigment distribution [5]. Llano et al. [25] found no significant differences in the C, DMC and BDMC concentrations between the dried turmerics obtained under different drying conditions (between 50 and 80 °C). The total curcuminoid content of a commercial turmeric powder was assessed and it reached 1.94 g/100 g db, a value greatly lower than ours. The differences may be due to different turmeric crop origins, seasonal variation, environmental conditions and the post-harvest process operations [27].

The bioaccessible C, DMC, BDMC and total curcuminoids of fresh turmeric were 0.87, 0.51, 0.35 and 1.72 g/100 g db, respectively which correspond to an average bioaccessibility equal to 12.7% (Table 2). Regardless of the treatment applied, cooking had no impact on the average contents of bioaccessible curcuminoids. Only fresh turmeric differs from other products with a higher bioaccessibility of curcuminoids. Drying decreased the contents of C, DMC and total bioaccessible curcuminoids while grinding had no impact. The bioaccessible curcuminoids of the commercial turmeric powder was 0.42 g/100 g db, a value greatly lower than ours. The average relative bioaccessibility of curcuminoids in the final products (9.1%) and in the freeze-dried turmeric (9.2%) was identical although their particle sizes were very different (ranging from 63 to 711 µm). Our previous results [18] showed that starch could be completely gelatinized when the sliced turmeric (thickness of 5 mm) was cooked at 95 °C for 3 min. Here, even though starch was gelatinised or not, we observed that the bioaccessibility of the curcuminoids was not significantly different. We also observed that after drying, the texture of turmeric was hard. Our hypothesis is that the biological fluids from in vitro digestion did not diffuse well into the powder particles. As a result, their constituents were less well solubilised in the digestive tract than the ones of fresh turmeric.

Impacts of unit operations on sensorial quality

Focus group

The participants observed both turmeric powders and turmeric rice samples and made some considerations and reactions as follows:

-

Local consumers use turmeric in a fresh form as it is easy to grow and available throughout the year.

-

Turmeric is mixed with other spices or herbs to make Kroeung for traditional Cambodian foods (Machu Kroeung, Korko, Kari…) to enhance their aroma and colour and to marinate meat by mixing it with other seasonings or spices to boost the flavour of the meat.

-

Turmeric is also used in cosmetic products (body lotion and scrap to whiten the skin) and medicine.

Consumer study

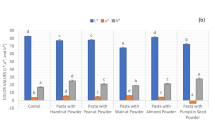

The consumer panel was constituted by 73.3% women, 91.7% young adults aged between 18 and 35 years old, 65.0% university students and 91.7% single. Almost all of them (96.7%) ate turmeric and mainly in fresh form (76.1%). About 25.9% ate turmeric once a week, 24.1% ate several times a month, 22.4% ate several times a week and 13.8% ate once a month and rarely. The results of the consumer acceptance showed that cooking improved colour, texture and overall liking while drying and grinding had no impact. The score of the sensory attributes was 6.2 on a 1–9 scale (Table 3). The samples that looked more like the ones they usually consumed were direct-dried samples (FD1P1: 16.3% and FD1P2: 14.0%). Surprisingly, both of them were also the most disliked (FD1P1: 27.1% and FD1P2: 23.7%). In contrast, they liked the most the samples that were cooked-dried at 60 °C and 40% RH (FCD1P2: 19.0% and FCD1P1: 14.9%) (Fig. 3a). The reasons for disliking direct-dried samples (FD1P1 and FD1P2) that appear most frequently are the perception of a strong bitterness (25.9–33.3%), strong odour (33.3–34.6%) and dark/brown colour (12.5–29.6%) (Fig. 3b). Approximately 47.5% of consumers would use this type of dried turmeric for cooking purposes (to enhance colour and odour), followed by 30.3% for health and 22.2% for cosmetics. Moreover, about 28.9% of them preferred to use this dried turmeric in soup or Khmer foods and 24.3% and 22.5% preferred to use it to prepare marinade and paste, respectively and 34.7% of them preferred to eat the turmeric at lunch and dinner (Fig. 3c). Madhusankha et al. [28] reported that once the curcuminoid contents decreased, yellowness and redness also decreased. The curcuminoid contents of our final products were not significantly different, however, the consumers detected a significant difference in colour, texture and overall liking between dried and cooked-dried samples. Heat treatment of the rhizome before dehydration can inactivate oxidative enzymes, avoid unpleasant odours and limit enzymatic browning reactions [29]. Boiling comprises the removal of boiled water after cooking so as to reduce the bitterness of some species [30]. These might be reasons why the consumers could detect higher intensity of bitter taste, odour and colour in direct-dried samples. Cooking the turmeric followed by drying at 60 °C and 40% RH (FCD1) improved the consumer's perception of taste by reducing bitterness, odour and dark colour. Based on these data, four samples (i.e. FD1P1, FD1P2, FCD1P1 and FCD1P2) were selected for quantitative descriptive analysis to see if trained panellists detected differences in sensory profile.

The appreciation of consumers on turmeric powder. a general appreciation, b reasons of dislike and c purposes of buy/use, ways of consuming and occasion of consumption. F: fresh; C: cooking (95 °C/3 min); D: drying (D1: 60 °C, 40% RH; D2: 50 °C, 40% RH; D3: 80 °C/1 h + 50 °C, 40% RH); P: particle size (P1: < 500 µm; P2: < 750 µm)

Descriptive attributes

The results of the descriptive test indicated that cooking decreased yellowness, turmeric odour and bitterness while it increased brightness and pungency mouthfeel; grinding had no impact on all descriptive attributes (Table 3). However, all the tested unit operations had no impact on earthy odour, aroma (turmeric, earthy, woody, green, minty and floral) and fresh mouthfeel. From consumer acceptance and quantitative descriptive analysis, the overall quality of turmeric powder is linked to low yellowness, turmeric odour, bitterness and high brightness and pungency mouthfeel.

Conclusion

Our findings clearly indicate that cooking saved drying time and improved overall liking with no impact on the essential oil, curcuminoid contents and their bioaccessibility. Drying decreased essential oil, curcuminoid contents and their bioaccessibility while grinding had no impact at all. Although starch was gelatinised or not, the bioaccessibility of the curcuminoids was not significantly different. The combination of the tested unit operations produced identical final products in terms of curcuminoid contents and their bioaccessibility. However, the consumers detected significant differences in colour, texture and overall liking between dried and cooked-dried samples. The overall quality of turmeric powder is correlated to low yellowness, turmeric odour, bitterness and high brightness and pungency mouthfeel. Therefore, it is necessary to process turmeric with a smooth cooking (95 °C/3 min) followed by drying at 60 °C and 40% RH (FCD1) to reduce drying time and improve consumer liking. This study shows that it is possible to master turmeric processing to preserve bioactive compounds and improve consumer acceptability. The technological conditions identified in this work allow the production of interesting turmeric powders in terms of sensorial and nutritional qualities for consumers. However, as Cambodian consumers prefer fresh turmeric, this processing could be used for export to the international market, and thus contribute to the improvement of the income of local producers and processors.

Data availability

The data supporting this study’s findings are available from the corresponding author upon reasonable request.

References

P.N. Ravindran, K. NirmalBabu, K. Sivaraman, Turmeric: The Genus Curcuma, 1st edn. (CRC Press Taylor & Francis Group, New York, 2007)

T. Jiang, W. Liao, C. Charcosset, Food Res. Int. 132, 109035 (2020)

S. Calligaris, M. Alongi, P. Lucci, M. Anese, Food Chem. 314, 126146 (2020)

J. Gómez-Estaca, R. Gavara, P. Hernández-Muñoz, Innov. Food Sci. Emerg. Technol. 29, 302 (2015)

M.L.A. Bambirra, R.G. Junqueira, M.B.A. Glória, Braz. Arch. Biol. Technol. 45, 423 (2002)

A. Prathapan, M. Lukhman, C. Arumughan, A. Sundaresan, K.G. Raghu, Int. J. Food Sci. Technol. 44, 1438 (2009)

R. Pethkar, A. Ujwal, K. Siddhesh, K. Avadhoot, K. Shrikant, Int. J. Innov. Eng. Res. Technol. 4, 128 (2017)

D. Suresh, H. Manjunatha, K. Srinivasan, J. Food Compos. Anal. 20, 346 (2007)

International Organization for Standardization, Turmeric, Whole or Ground (Powdered)—Specification (ISO Standard No. 5562:1983) (1983)

International Organization for Standardization, Spices, Condiments and Herbs—Determination of Volatile Oil Content (Hydrodistillation Method) (ISO Standard No. 6571:1984) (1984)

D.S. Sogi, S. Sharma, D.P.S. Oberoi, I.A. Wani, J. Food Sci. Technol. 47, 300 (2010)

S. Sepahpour, J. Selamat, M.Y.A. Manap, A. Khatib, A.F.A. Razis, Molecules 23, 1 (2018)

M. Minekus, M. Alminger, P. Alvito, S. Ballance, T. Bohn, C. Bourlieu, F. Carrière, R. Boutrou, M. Corredig, D. Dupont, C. Dufour, L. Egger, M. Golding, S. Karakaya, B. Kirkhus, S. Le Feunteun, U. Lesmes, A. Macierzanka, A. Mackie, S. Marze, D.J. McClements, O. Ménard, I. Recio, C.N. Santos, R.P. Singh, G.E. Vegarud, M.S.J. Wickham, W. Weitschies, A. Brodkorb, Food Funct 5, 1113 (2014)

M. Yerramilli, N. Longmore, S. Ghosh, J. Am. Oil Chem. Soc. 95, 1013 (2018)

International Organization for Standardization, Sensory Analysis. General Guidelines for the Selection, Training and Monitoring of Selected Assessors and Expert Sensory Assessors (ISO Standard No. 8586:2012) (2012)

International Organization for Standardization, Sensory Analysis. Methodology. Guidelines for Monitoring the Performance of a Quantitative Sensory Panel (ISO Standard No. ISO 11132:2012) (2012)

International Organization for Standardization, Sensory Analysis. General Guidance for the Design of Test Rooms (ISO Standard No. 8589:2007) (2007)

M. Yin, M. Weil, S. Avallone, M. Lebrun, G. Conejero, S. In, P. Bohuon, J. Food Process. Preserv. 46(5), e16643 (2022)

S.N. Garg, R.P. Bansal, M.M. Gupta, S. Kumar, Flavour Fragr. J. 14, 315 (1999)

S. Hirun, N. Utama-ang, P.D. Roach, J. Food Sci. Technol. 51, 2127 (2014)

C. Monton, C. Luprasong, L. Charoenchai, J. Food Process. Preserv. 43, 1 (2019)

B.H. Ararsa, Effect of Processing Methods on Quality of Turmeric (Curcuma Longa L.) Finger Rhizome Grown in Teppi, Sheka Zone (Haramaya University, Ethiopia, 2018)

E. de la Hera, M. Gomez, C.M. Rosell, Carbohydr. Polym. 98, 421 (2013)

J. Osorio-Arias, S. Delgado-Arias, L. Cano, S. Zapata, M. Quintero, H. Nuñez, C. Ramírez, R. Simpson, O. Vega-Castro, Waste Biomass Valoriz. 11, 5015 (2020)

S.M. Llano, A.M. Gómez, Y. Duarte-Correa, Processes 10, 702 (2022)

W.-H. Lee, C.-Y. Loo, M. Bebawy, F. Luk, R. Mason, R. Rohanizadeh, Curr. Neuropharmacol. 11, 338 (2013)

C. Monton, L. Charoenchai, J. Suksaeree, L. Sueree, J. Food Drug Anal. 24, 493 (2016)

G. Madhusankha, R. Thilakarathna, T. Liyanage, S. Navaratne, Int. J. Food Sci. Nutr. 3, 3 (2018)

E. Jayashree, T.J. Zachariah, R. Rakhi, J. Spices Aromat. Crops 27, 138 (2018)

M. Faber, A. Oelofse, P. Van Jaarsveld, F. Wenhold, W. Jansen van Rensburg, S. Afr. J. Clin. Nutr. 23, 30 (2010)

Acknowledgements

We would like to thank researchers and staff of UMR—Qualisud of CIRAD and lecturers/researchers, staff and students of Institut de Technologie du Cambodge for their participation in the sensory test.

Funding

This work was supported by the French Government Scholarships Cofounded by the Ministry of Education, Youth and Sports of Cambodia, CIRAD—UMR Qualisud, Cambodia Higher Education Improvement Project (Credit No. 6221-KH), Erasmus Camfoodtech Project and Agence Universitaire de la Francophonie.

Author information

Authors and Affiliations

Contributions

MY: Formal analysis; methodology; writing—original draft; writing—review and editing. MW: Funding acquisition; project administration; supervision; writing—review and editing. SA: Conceptualization; methodology; validation; writing—review and editing. IM: Formal analysis; methodology. NF-C: Formal analysis; methodology. AS: Formal analysis; methodology. SI: Project administration; supervision. PB: Conceptualization; supervision; validation; writing—review and editing.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Ethical approval

The studies involving human participants did not require approval, in line with national guidelines. The participants provided their written informed consent to take part in this study. This study does not need to be supported by IRB approval.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Yin, M., Weil, M., Avallone, S. et al. Impact of cooking, drying and grinding operations on chemical content, functional and sensorial qualities of Curcuma longa L.. Food Measure 17, 998–1008 (2023). https://doi.org/10.1007/s11694-022-01683-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-022-01683-w