Abstract

The agro-industrial processing of mango generates high amounts of by-products, like peels and paste, that are commonly discarded. These are potential sources of bioactive ingredients, such as phenolic compounds and carotenoids, that can be used to supplement other edible products to increase their nutritional value. In order to be successful in this regard, the processing methods used must avoid losses of the compounds of interest. The objective of this study was to identify the effects of freeze-drying (frozen 24 h at − 80 °C, freeze dried 48 h at − 50 °C, 4.00 Pa) and hot air-drying (convective hot air at 60 °C) on the profile and concentration of phenolic compounds and carotenoids, using sensitive chromatographic analyses. Our data showed that the total phenolic concentration, and that of the most abundant compounds (mangiferin and valoneic acid dilactone), were unaffected by drying method. Conversely, freeze-dried paste had greater carotenoid concentration than peel, while hot air-dried peel had greater carotenoid concentration than paste (main carotenoids: all-trans-β-carotene, 9-cis-β-carotene, all-trans-lutein, and 13-cis-β-cryptoxanthin). We concluded that carotenoids from mango peel and paste were more sensitive to drying method than phenolic compounds, and the effects on each by-product were in function of the food matrix and method used. By choosing the most adequate drying method, mango by-products can be sources of bioactive compounds to produce functional foods or beverages.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The agro-industrial processing of fruits generates by-products that retain high levels of underutilised bioactive compounds. By-products can be further processed to extract compounds of interest, and use them as ingredients to produce functional foods, nutraceuticals, or beverages with added value. Mango (Mangifera indica L.) cv Ataulfo is a tropical fruit that is consumed as juices, concentrates, jams, etc., generating peels and paste as by-products. This popular variety is cultivated in southern Mexico, and is highly consumed locally and exported to international markets. The pulp has been extensively analysed, for example, it contains the highest amount of vitamin C as compared to other cultivars, it also contains carotenoids, and its phenolic composition is comprised of different phenolic acids [1], gallic acid being the most abundant and bioactive [2].

Mango by-products have also gained attention in recent years. The peels are rich sources of hydrolysable tannins with high antioxidant potential [3], while others have shown that the dietary fibre obtained from mango peels is of good quality, and contains high amounts of bioactive compounds that can be incorporated into edible products [4]. Mango by-products contain compounds such as xanthones, tannins, gallates, and flavonoids, whose synergistic in vitro antioxidant and antiproliferative activities have been reported [5].

Because the by-products still contain high water content, drying is one of the first steps that have to be performed in order to concentrate the bioactive compounds. Dry samples have the advantage of being easier to manipulate, and proliferation of microorganisms is halted due to low water activity. Two drying methods frequently used on fruits are freeze-drying (also known as lyophilisation) and hot air-drying [6, 7], each relying on different physicochemical ways to remove the water. Hot air-drying is very common because of its simplicity, speed, and low-cost [7, 8]. Hot air-drying evaporates water, which induces various chemical (pH and redox potential), physical (shrinkage, less rehydration ability and higher exposure to oxygen), and biological effects (enzymatic and non-enzymatic reactions), resulting in a product of less quality than the original [9], and may decrease the content of heat-labile bioactives [10].

Freeze-drying removes water by sublimation, passing directly from ice into the gas phase with the aid of low pressure. Freeze-dried products have slight shrinkage, good rehydration ability, very high retention of flavours, nutrients, bioactive compounds, texture, and appearance [11, 12]. Because of the low temperatures and pressures used during freeze-drying, contact with oxygen and enzymatic activity is minimal, inhibiting oxidation processes that may degrade susceptible nutrients. However, the final product has a porous texture, which increases the surface area exposed to oxygen once the drying process has concluded, requiring optimal handing to minimise oxidation. In contrast to the advantages of freeze-drying, some disadvantages include longer treatment times, expensive equipment, and higher operational costs that are difficult to implement for practical purposes, due to the tons of by-products that have to be treated. Therefore, in order to maintain bioactivity of these compounds, other alternatives have been suggested, such as vacuum drying and others [13].

The aim of this study was to evaluate the effects of freeze-drying and hot air-drying, on the phenolic and carotenoid profile of mango cv Ataulfo by-products. The obtained information will identify the most appropriate drying method for each by-product, and subsequently use them as potential sources of bioactive compounds to be incorporated into other edible products.

Materials and methods

Sample drying

Mango cv Ataulfo by-products (peel and paste) were kindly provided by MexiFrutas®, in the state of Nayarit, Mexico (21.75° N, 104.84° W), during June 2015. The peels were cut into strips of 2 cm in width, while the paste was spread into a thin sheet. Both by-products were laid on top of aluminium trays in a single layer, and were freeze-dried or hot air-dried until their weight became constant.

A set of samples were initially frozen at − 80 °C for 24 h, and then freeze-dried for 48 h (Labconco Corporation, Kansas City, MO, USA), with a condenser temperature of − 50 °C, and chamber vacuum pressure of 4.00 Pa (0.03 Torr). Another set of samples were placed in a cabinet with convective hot air (60 ± 2 °C), with constant air circulation until water was completely removed. Each drying trial was performed in triplicate. Dry samples were ground, sieved (0.5 µm), and stored in sealed bags at − 20 °C until further analysis. The samples are referred to as freeze-dried peel (FPE), freeze-dried paste (FPA), hot air-dried peel (HPE), and hot air-dried paste (HPA).

Extraction of bioactive compounds

The extraction protocols for mango by-products have been previously published [14,15,16], and exert maximum extraction of phenolics. Briefly, 0.5 g of samples were placed in a 100 mL amber flask fitted with a refrigerant, fluxed with nitrogen, and extracted with 25 mL of ethanol:water (1:1 v/v, 75 °C, 3 h). After each extraction, the supernatants were separated by centrifugation (7000×g, 4 °C, 15 min) (Sorvall Evolution RC, Thermo Scientific, Waltham, MA, USA), and the pellets were re-extracted using the same conditions during 2 h. The two supernatants were combined, and the total volume was reduced by evaporation under vacuum at 30 °C. The aqueous solution was transferred into a volumetric flask and made up to 25 mL with milli-Q water. An aliquot of the aqueous extract (2 mL) was loaded into a Sep-Pack cartridge (300 mg, silica-based C18 sorbent, 55–105 µm particle size) (Waters, Milford, MA, USA), that had been previously equilibrated with 5 mL of methanol, followed by 5 mL of water. After sample loading, the column was washed with 4 mL of deionised water, and the phenolic compounds were eluted and recovered from the column with 4 mL of methanol. 200 µL of this solution were combined with 1800 µL of formic acid in water (10 mL/L), filtered through a 0.45 µm syringe filter, and stored at − 80 °C until HPLC analysis.

Identification and quantification of phenolic compounds by HPLC-DAD

The liquid chromatography (LC) analyses were performed as previously described [14], in an Agilent 1200 series LC apparatus (Agilent Technologies, Waldbronn, Germany), equipped with a quaternary pump, solvent degasser, auto-sampler, temperature-controlled column compartment, diode array detector (DAD), and a reversed-phase C18 Hypersil ODS column (250 mm × 4.6 mm, 5 µm) (Teknokroma, Barcelona, Spain) maintained at 25 °C. The mobile phases were (A) formic acid in milli-Q water (10 mL/L), and (B) formic acid in acetonitrile (10 mL/L). Separation was carried out during 70 min, using the following mobile phase gradient: 0 min, 100% A; 15 min, 75% A; 30 min, 70% A; 60 min, 20% A; 65 min, 0% A; 70 min, 100% A. The column was equilibrated for 5 min prior to analysis. The mobile phase flow rate was 1 mL/min, and the injection volume was 10 µL. Detection was carried out at 280 nm (gallic acid), 320 nm (xanthones and benzophenones), 360 nm (flavonoids), and 255 nm (ellagic acid). The identity of each peak was confirmed by comparing its retention time and absorption spectrum to those of commercial standards of gallic acid (gallates), ellagic acid (ellagic acid and derivatives), mangiferin (xanthones), and maclurin (benzophenones). To quantify each compound, peak area (automatically calculated by the instrument’s software) was used to calculate the concentration of each compound, based on a previously prepared standard curve using the above-mentioned commercial standards in the range of 5–100 µg/mL.

Identification of phenolic compounds by HPLC-ESI-QTOF-MS

The HPLC-MS analyses were performed with the same system described for HPLC-DAD, coupled in series to a hybrid mass spectrometer quadrupole-time of flight (QTOF) detector (Agilent Accurate Mass QTOF LC-MS) via an electrospray ionisation source (ESI) with Jet Stream technology. Mass spectra were recorded in the negative ionisation mode over m/z range of 100–1000. Nitrogen was used as collision gas (ultrahigh-purity) and nebulising gas (high-purity). Capillary voltage was 3.5 kV and fragmentor voltage was 100 V. The ESI Jet Stream parameters were: nitrogen pressure and flow-rate of the nebuliser at 310 kPa (45 psi) and 10 L/min, respectively; drying gas temperature of 350 °C; sheath gas temperature of 250 °C; sheath gas flow of 6 L/min; and MS/MS collision energies of 20 V. The MS and MS/MS data were processed on the Mass Hunter Workstation software (version B.04.00, Agilent Technologies), which provides a list of possible elemental molecular formulas by using the Generate Molecular Formula editor, according to the accurate masses and isotopic pattern. The molecular formula generated with the highest score percentage would indicate a closer similarity between the formula generated by the software and the real formula of the compound. Two other factors impacting the overall correlation score are the mass accuracy of the observed fragment ions, and the overall percentage of fragment ion intensity. The observed MS and MS/MS spectra and data obtained by QTOF-MS analysis were interpreted by comparing them with those found in the literature and several online databases, and by comparing chromatographic behaviour and mass spectral data generated by authentic standards or related structural compounds when possible.

Identification and quantification of carotenoids by HPLC-DAD

Extraction, identification, and quantification of carotenoids was performed as previously described [17]. Briefly, carotenoids were extracted from 250 mg of dried samples, and were identified and quantified on the previously described HPLC-DAD apparatus. A C30 carotenoid column (250 mm × 4.6 mm, 5 µm) coupled with a C30 guard column (20 mm × 4.0 mm, 5 µm) (YMC, Europe GMBH, Germany) was used. Carotenoids were identified by their retention time and fine spectra (250–540 nm) as previously reported [18, 19]. The carotenoid peaks were integrated at their individual maximum wavelength, and their concentrations were calculated using standard calibration curves, using a similar procedure to that described for phenolic compounds.

Statistical analyses

Analyses were performed in triplicate. The results were analysed using Student’s T test to compare drying methods in the statistical software Minitab v. 17 (Minitab, State College, PA, USA). Differences were considered significant when p < 0.05.

Results and discussion

Figure 1 shows the total ion chromatograms (TICs) of freeze-dried and hot air-dried peel (FPE and HPE). The drying method seems to have minimal effects on the qualitative phenolic composition of mango peel. Figure 2 shows the TICs of freeze-dried and hot air-dried paste (FPA and HPA), where a similar behaviour was observed, as described for peels. An overview of the phenolic profile from both mango by-products is given in Table 1 and is further discussed by molecular family in the following sections. The molecular structures of the identified phenolic compounds are presented in Fig. 3 (xanthones and benzophenones) and Fig. 4 (gallates, ellagic acid and derivatives, and flavonoids).

Xanthones

Peak 9 was identified as mangiferin and was the main phenolic compound in all samples. It gave an [M-HR]− ion of m/z 421.0789 with the molecular formula C19H18O11. Mangiferin is a xanthone C-glycoside previously described in several studies as a representative compound of mango peel [20,21,22]. The molecular ion of m/z 421.0776 appeared in the MS/MS mode, the typical fragmentation of C-glycosides with ions of m/z 301 [M-HR-120]− and m/z 331 [M-HR-90]−, further confirming its identity.

Other related xanthones were identified, specifically, peak 12 and peak 13 gave an [M-HR]− ion of m/z 573.0900 and an MS/MS fragmentation pattern very similar to that of peak 9 (mangiferin), with main fragments of m/z 421 [M-HR-152]− and 403 [M-HR-170]−, indicating the loss of a galloyl and gallic acid moiety, respectively. This information allowed us to identify peak 12 and peak 13 as mangiferin-6′-O-gallate and isomangiferin-6′-O-gallate, respectively. Mangiferin-6′-O-gallate is a galloylated derivative of mangiferin, and isomangiferin-6′-O-gallate is its structural isomer, differing by the attachment position of the monosaccharide and galloyl moieties to the main xanthone skeleton. Both have been previously identified in mango peels [20, 22].

Peak 14 was tentatively identified as mangiferin-3-C-(2,3-di-O-galloyl)-β-d-glucoside, according to the [M-HR]− ion of m/z 725.1015 and molecular formula C33H26O19, that showed two hydrogen atoms less that the molecular formula of maclurin-3-C-(2,3-di-O-galloyl)-β-d-glucoside (C33H28O19) (peak 8), and are also consistent with peak 12 (mangiferin-6′-O-gallate) with an additional galloyl moiety. Others have reported related digalloylated compounds in mango [23, 24], but to our knowledge, mangiferin-3-C-(2,3-di-O-galloyl)-β-d-glucoside has not been previously reported in mango peel.

Mangiferin (peak 9) was the main compound found in the peel and paste of mango cv Ataulfo, independently of drying process. Mangiferin-6′-O-gallate (peak 12), was detected in the peel, independently of drying process, but it was only found in the paste when it was freeze-dried. Isomangiferin-6′-O-gallate (peak 13) and mangiferin-3-C-(2,3-di-O-galloyl)-β-d-glucoside (peak 14) were only identified in peel samples that were freeze-dried (FPE). The absence of a compound from the hot air-dried samples may indicate that exposure to heat and/or oxygen cleaved the monosaccharide or galloyl substituents from the main mangiferin skeleton. Mangiferin and related xanthones have been reported as susceptible to thermal degradation at temperatures in the range of 30–80 °C [25, 26]. This is one of the disadvantages of heat treatments when applied to fruits rich in bioactive compounds, such as vitamin C, phenolics, and carotenoids.

Benzophenones

Benzophenones are major intermediates of the xanthone biosynthetic pathway, as evidenced by their similar molecular structure. Four benzophenones (peaks 4, 5, 8, and 10) were identified in peel and paste, showing [M-HR]− ions of m/z 423.0934 (peak 4), 575.1058 (peak 5), 727.1162 (peak 8), and 543.1147 (peak 10) [20, 21, 24].

Peak 4, with an [M-HR]− ion of m/z 423.0934, gave fragment ions of m/z 303 and 333 that were probably related to the loss of 120 and 90 Da, that correspond to fragments from a glucose moiety, representing the characteristic fragmentation of C-glycosides. Two main fragments lost 110 Da, and generated product ions of m/z 193 and 223. The molecular formula C19H20O11 and fragmentation pattern are consisted with maclurin-3-C-β-d-glucoside.

Peak 5, with an [M-HR]− ion of m/z 575.1058 and C26H24O15 molecular formula, was identified as maclurin-3-C-(2-O-galloyl)-β-d-glucoside. The major fragment ions were of m/z 423 [M-HR-152]−, indicating the loss of a galloyl moiety, and 303 [M-HR-120-152]−. The loss of 272 Da, [M-HR-120-152]−, indicated the presence of a galloylated benzophenone, as reported in previous studies of different mango cultivars [20, 24].

Peak 8 showed an [M-HR]− ion of m/z 727.1162 and molecular formula C33H28O19, which was identified as maclurin-3-C-(2,3-di-O-galloyl)-β-d-glucoside, a digalloylated benzophenone derivative. The major fragment detected was of m/z 575, caused by the loss of 152 Da, likely indicating the presence of a galloyl group [M-HR-152]−. The resulting fragments of m/z 575 provided a product ion of m/z 405 [M-HR-152-170]−, indicating the presence of a further galloyl moiety.

Peak 10 gave an [M-HR]− ion of m/z 543.1147, and the p-hydroxybenzoic acid moiety was evident due to the fragment ion of m/z 405 caused by the loss of 138 Da. The fragment ion of m/z 285 corresponds to the loss of p-hydroxybenzoic and glucose moieties [M-HR-138-120]−. The C26H24O13 molecular formula and fragmentation pattern are consistent with maclurin-3-C-(6″-p-hydroxybenzoyl-glucoside).

Peak 4 (maclurin-3-C-β-d-glucoside) and peak 5 (maclurin-3-C-(2-O-galloyl)-β-d-glucoside) were found in all samples, independently of drying method, suggesting that they are stable at both, low and high temperatures used. Peak 8 (maclurin-3-C-(2,3-di-O-galloyl)-β-d-glucoside) and peak 10 (maclurin-3-C-(6″-p-hydroxybenzoyl-glucoside)) were only found in the peel, independently of drying method, suggesting that these benzophenones are only synthesised in sufficient amounts in the peel, or were fully extracted from the paste during the industrial treatment of mango pulp.

Ellagic acid and derivatives

The identity of peak 17 (m/z 300.9990) was confirmed as ellagic acid. The MS/MS spectrum of a deprotonated molecule [M-HR]− of m/z 301, showed the loss of a carboxyl group (–CO2) [M-HR-44]−, yielding a fragment ion of m/z 257, while the loss of two carboxyl groups and two hydroxyl groups (–OH) [M-HR-44-44-17-17]− gave fragment ions of m/z 179 and m/z 145. Also, ellagic acid was detected using HPLC-DAD, due to its characteristic absorption at 255 nm, and by comparison with the commercial standard. Ellagic acid is abundant in mangoes of commercial maturity [27], and its absence in our paste samples indicates that it may have been fully extracted during its processing previous to our study and was barely linked to fibre.

Peak 15 was detected in all samples. It gave an [M-HR]− ion of m/z 469.0514, and fragment ions of m/z 301 and 169, which are typical of ellagic acid and gallic acid moieties, respectively. Peak 15 was tentatively identified as valoneic acid dilactone [28], which has been previously reported in mango peel and seed [14]. Valoneic acid dilactone is a hydrolysable tannin, formed by a gallate moiety bound to ellagic acid through an ether bond. It has been reported as a non-extractable compound that may be part of a more complex polymeric structure, requiring an initial acid hydrolysis to be fully released and detectable [29, 30]. Its presence indicates that it apparently withstands the conditions of the processing methods used in this study.

Gallates

The presence of different gallates (derived from gallic acid) were identified as galloyl glucose, gallic acid, methyl gallate, m-digallic acid, ethyl gallate, m-digallic acid methyl ester, and ethyl 2,4-dihydroxy-3-((3,4,5-trihydroxybenzoyl)oxy)-benzoate [20, 21].

Peak 1 gave an [M-HR]− ion of m/z 331.0690 and a major fragment ion of m/z 169, which correspond to a gallic acid moiety. The molecular formula C13H16O10 and fragmentation pattern are consisted with galloyl glucose [21].

Peak 2 was identified as gallic acid, showing an [M-HR]− ion of m/z 169.0149 and a major fragment ion of m/z 125, produced after the loss of a carboxyl group.

Peak 6 gave an [M-HR]− ion of m/z 183.0309 and a major fragment ion of m/z 124 [M-HR-59]−, due to the loss of a -CO2CH3 group, and was identified as methyl gallate [20, 21].

Peak 7 gave an [M-HR]− ion of m/z 321.0269 and fragments of m/z 169 and m/z 125, which correspond to a gallic acid moiety. The molecular formula C14H10O9 and fragmentation pattern are consistent with m-digallic acid [20, 21].

Peak 11 showed an [M-HR]− ion of m/z 197.0465 and main fragment ions of m/z 124 and 169, the typical fragments that determine the presence of gallic acid. The molecular formula C9H10O5 and fragmentation pattern are consistent with ethyl gallate [14].

Peak 18 gave an [M-HR]− ion of m/z 335.0421 with major fragment ions of m/z 183 and 169, suggesting the presence of a methyl gallate and gallic acid moieties. According to the molecular formula C15H12O9 and fragmentation pattern, peak 18 was identified as m-digallic acid methyl ester [21].

Peaks 20 and 21 showed [M-HR]− ions of m/z 349.0588 and 349.0592, respectively, and a fragment ion of m/z 197. This fragment indicated the presence of an ethyl gallate moiety. These compounds were tentatively identified as two isomers of ethyl 2,4-dihydroxy-3-((3,4,5-trihydroxybenzoyl)oxy)-benzoate, and were found in all samples. These compounds have been previously identified in mango peels [14, 21].

Gallates were minimally affected by drying method, since most were present in all samples independently of drying method, except for m-digallic acid methyl ester, which was not found in the HPA samples. This suggests it may have been cleaved by the increased temperature into gallic acid and methyl gallate. However, more detailed work must be performed in order to confirm this statement.

Flavonoids

Peaks 16 and 19 were identified as quercetin derivatives. Peak 16 gave an [M-HR]− ion of m/z 463.0514, and molecular formula C21H20O12, while also showing the typical fragmentation of quercetin glycosides with fragment ions of m/z 301, characteristic of quercetin with loss of a hexose moiety [M-HR-162]−. The extracted ion chromatograms (EICs) of m/z 463.0514, showed two peaks that were identified as quercetin-3-O-glucoside and quercetin-3-O-galactoside; both have been previously identified in mango peels [21].

Peak 19 was identified as a quercetin pentoside (C20H18O11), which gave an [M-HR]− ion of m/z 433.0794 and a fragment ion of m/z 301, corresponding with the radical anion of quercetin aglycone. The EICs of m/z 433.0749 produced three different peaks, tentatively characterised as quercetin xyloside, quercetin arabinopyranoside, and quercetin arabinofuranoside [20, 21]. Peak 16 (quercetin hexosides) and peak 19 (quercetin pentosides) were present in all evaluated samples.

Quantification of phenolic compounds

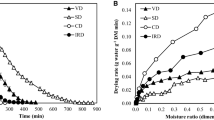

Table 2 shows the concentration of the phenolic compounds found in dried peel and paste of mango cv Ataulfo. The major compounds were mangiferin (peak 9), a xanthone, and valoneic acid dilactone (peak 15), an ellagic acid derivative. Concentration of phenolic compounds grouped by molecular family and the total phenolic compound concentration are shown in Fig. 5a, b. Xanthones and gallates were the most abundant compounds present. Total phenolic compounds found in mango peel were higher than those found in paste, as previously reported by other authors [20, 31].

Total phenolic compound content of freeze-dried peel (FPE), hot air-dried peel (HPE), freeze-dried paste (FPA), and hot air-dried paste (HPA) of mango cv Ataulfo by-products. a Grouped by molecular family and b as total compounds. Gall gallates; Xan xanthones; Ella ellagic acid and derivatives; BP benzophenones; Fla flavonoids. Significant differences (p < 0.05) between drying methods are indicated by an asterisk (*)

The concentration of two xanthones decreased in the HPE samples as compared to the FPE samples, mangiferin-6′-O-gallate and mangiferin-3-C-(2,3-di-O-galloyl)-β-d-glucoside, while isomangiferin-6′-O-gallate was not detected in the HPE samples. The changes in these three compounds were reflected on a significantly lower xanthone concentration in HPE, as compared to FPE. Similarly, the concentration of flavonoids (quercetin hexosides and pentosides) decreased significantly in HPE, as compared to FPE. From these results we can argue that xanthones and flavonoids were sensitive to hot air-drying in the peel, but not in the paste, suggesting that the food matrix plays an important role in their stability.

In HPA, the concentration of ethyl gallate was the only one that significantly decreased, without significant changes on any molecular family of mango paste. The changes in concentration of individual compounds or molecular families in paste, were inconsequential to the total phenolic content, because no significant changes were found between drying methods.

Other authors have analysed the effects of drying on mango pulp and by-products. For example, Sogi et al. [32] compared the effects of freeze-drying against thermal methods, when drying the peel of mango cv Tommy Atkins. It was found that freeze-dried peel had higher phenolic content, as compared to thermal methods. Furthermore, the antioxidant capacity values (analysed with four different assays) changed accordingly and were consistently higher in freeze-dried samples. These results are comparable with the ones documented herein, where freeze-dried samples had higher phenolic content than hot air-dried samples. Another study by Sogi et al. [33] showed that freeze-drying also preserved the phenolic content and antioxidant capacity of mango pulp cv Tommy Atkins, which indicates that, in general, phenolic compounds are more sensitive to thermal drying methods than to freeze-drying. Freeze-drying has been shown to preserve the phenolic content of other fruits, such as citrus fruits and muscadine pomace [34, 35], while thermal drying methods negatively affect their concentration.

When mango by-products are used as sources of functional ingredients, preserving the concentration and bioactivity of phenolic compounds is essential because of their many reported health benefits. Our results suggest that particular compounds are more sensitive to thermal drying, but the overall concentration of phenolics was not affected by drying method used in this study.

Carotenoids

Carotenoids are another important class of bioactive compounds found in mangoes and other tropical fruits. They are responsible for the yellow, orange, and red hues of numerous plants, including the characteristic yellow of ripe Ataulfo mangoes [36].

The carotenoid profile found in the peel and paste of mango cv Ataulfo is presented in Table 3. All-trans-β-carotene, 9-cis-β-carotene, all-trans-lutein, and 13-cis-β-cryptoxanthin were identified in all samples. Other carotenoids were also present, but only in some samples, specifically: β-carotene 5,6 epoxide, β-xanthophylls, apocarotenoids, all-trans-zeaxanthin, 9-cis-zeaxanthin, 9-cis-β-cryptoxanthin, and 15-cis-β-cryptoxanthin.

Drying method barely changed the concentration of all-trans-β-carotene in the peel. In contrast, its concentration varied significantly in the paste, where hot air-drying decreased its value, as compared to freeze-drying. 9-cis-β-carotene was present in all samples, but its concentration was not significantly affected (p > 0.05) by drying method.

Although cis and trans isomers of β-carotene were found, there is a possibility that the cis isomers were not initially present in the samples, and were instead formed during industrial processing, preparation, and storage [37], because carotenoids are predominantly found in the all-trans configuration [38]. Under preparation and storage conditions (particularly during thermal processing of foods), trans bonds are susceptible to conformational isomerisation, transforming some to a cis configuration [38, 39]. All-trans-α-carotene was not found in any sample, indicating that β-carotene predominated over α-carotene. The extraction of β-carotene from mango by-products could contribute to adding value to subsequently enriched products, because of its role as vitamin A, and potent antioxidant effects. Apparently, the thermal treatment enhanced the degradation of β-carotene in mango paste, but not in peel. Suggesting that the food matrix protects in some extent against carotenoid degradation.

The carotenoid 13-cis-β-cryptoxanthin was found in all samples, and its concentration varied significantly according to drying method. HPE samples had a significantly higher 13-cis-β-cryptoxanthin concentration, as compared to FPE. In contrast, the opposite trend was observed in paste, since FPA had higher 13-cis-β-cryptoxanthin concentration than HPA. This indicates that the concentration of 13-cis-β-cryptoxanthin is dependent on the sample’s matrix and drying method. Others authors have reported that the carotenoid concentration (including 13-cis-β-cryptoxanthin) of various tropical fruits is dependent on the processing methods, especially when high temperature is used [40].

The concentration of all-trans-lutein was approximately twice as high in peel than in paste, but drying method did not significantly affect its concentration. Lutein is a highly bioactive carotenoid, and its health benefits have been well-documented. For example, its consumption from fruits and vegetables can prevent various eye disorders and maintain visual health [41]. Mango by-products that contain β-carotene, β-cryptoxanthin, and lutein can serve as functional ingredients to enrich other edible products that lack them.

Other carotenoids were also found in some samples. For example, β-carotene 5,6 epoxide, β-xanthophylls, and apocarotenoids were quantified in both paste samples, but only in peel when air-drying was used. Hot air-drying significantly decreased their concentration in paste, as compared to freeze-drying. Apocarotenoids are formed by enzyme-mediated hydrolysis of carotenoids, such as α- or β-carotene [42]. They have been reported as highly bioactive in animal (including human) cells, because of their effects as modulators of gene expression [43], making their presence in mango by-products of high interest. Mango by-products that contain carotenoids can serve as functional ingredients to enrich other edible products, as determined in this study.

Finally, the total carotenoid content (TCC), as the sum of all quantified carotenoids and their isomers, varied significantly in response to drying method. HPE samples had higher TCC than FPE, and the opposite behaviour was documented in paste (higher TCC in FPA, than in HPA). These trends correspond with the significant changes reported for individual carotenoids in peel (13-cis-β-cryptoxanthin) and paste (β-carotene 5,6 epoxide/β-xanthophylls/apocarotenoids, 13-cis-β-cryptoxanthin, and all-trans-β-carotene). In other words, significant changes on individual carotenoids accrued onto TCC. According to these data, freeze-drying appears to be the best method to preserve mango paste carotenoids, but hot air-drying may be more suitable for mango peels.

Freeze-drying has been shown to preserve carotenoids in the peel [32] and pulp [33] of mangoes cv Tommy Atkins, which was attributed to the thermal lability of carotenoids. It has been reported that freeze-drying can be the most adequate carotenoid-preserving method [44], while others have found few or no differences among methods [45]. These contrasting results, as well as our data, suggest that the food matrix that contains them is important, and determines the impact that a drying method will have on its carotenoid profile and concentration. Therefore, experimental data on the samples of interest is required before extrapolating results from one food matrix to another.

Conclusions

The major phenolic compounds found in mango peel and paste were mangiferin and valoneic acid dilactone, the major carotenoids were all-trans-β-carotene, 9-cis-β-carotene, all-trans-lutein, and 13-cis-β-cryptoxanthin.

The drying method (frozen 24 h at − 80 °C, freeze dried 48 h at − 50 °C, 4.00 Pa; or 60 °C convective hot air-dried) showed no significant effects on the total concentration of phenolic compounds of mango peel and paste, with minor changes detected on some compound families (xanthones and flavonoids). In contrast, freeze-drying was better suited to dry mango paste, and hot air-drying was better suited for mango peels, as determined by their effects on the carotenoid profile.

Mango peel and paste can be useful sources of bioactive polyphenols and carotenoids that can be added to edible products, in order to generate a functional food or beverage. In order to gain the most benefit from these by-products, they must be treated with methods that induce the least undesired effects to the compounds of interest. In vivo effects of these individual compounds after thermal and freeze-drying must be evaluated, in order to establish the method that best preserves the bioactivity of phenolics and carotenoids.

References

H. Palafox-Carlos, E.M. Yahia, G.A. Gonzalez-Aguilar, Food Chem. 135(1), 105–111 (2012)

H. Palafox-Carlos, J. Gil-Chavez, R.R. Sotelo-Mundo, J. Namiesnik, S. Gorinstein, G.A. Gonzalez-Aguilar, Molecules 17(11), 12657–12664 (2012)

S.G. Sayago-Ayerdi, C.L. Moreno-Hernandez, E. Montalvo-Gonzalez, M.L. Garcia-Magana, M.M.M. de Oca, J.L. Torres, J. Perez-Jimenez, Food Res. Int. 51(1), 188–194 (2013)

M.D. Garcia-Magana, H.S. Garcia, L.A. Bello-Perez, S.G. Sayago-Ayerdi, M.M.M. de Oca, Plant Food Hum. Nutr. 68(3), 254–258 (2013)

A.M. Abbasi, F.Y. Liu, X.B. Guo, X. Fu, T. Li, R.H. Liu, Int. J. Food Sci. Technol. 52(3), 817–826 (2017)

E. Dorta, M.G. Lobo, M. Gonzalez, LWT-Food Sci. Technol. 45(2), 261–268 (2012)

C. Henriquez, A. Cordova, S. Almonacid, J. Saavedra, J. Food Eng. 143, 146–153 (2014)

M.L. Chen, D.J. Yang, S.C. Liu, Int. J. Food Sci. Technol. 46(6), 1179–1185 (2011)

P.P. Lewicki, Trends Food Sci. Technol. 17(4), 153–163 (2006)

P. Chantaro, S. Devahastin, N. Chiewchan, LWT-Food Sci. Technol. 41(10), 1987–1994 (2008)

A. Ciurzyńska, A. Lenart, Pol. J. Food Nutr. Sci. 61(3), 165–171 (2011)

X. Duan, X.T. Yang, G.Y. Ren, Y.Q. Pang, L.L. Liu, Y.H. Liu, Dry Technol. 34(11), 1271–1285 (2016)

C. Ratti, J. Food Eng. 49(4), 311–319 (2001)

E. Dorta, M. Gonzalez, M.G. Lobo, C. Sanchez-Moreno, B. de Ancos, Food Res. Int. 57, 51–60 (2014)

E. Dorta, M.G. Lobo, M. Gonzalez, Plant Food Hum. Nutr. 68(2), 190–199 (2013)

E. Dorta, M.G. Lobo, M. Gonzalez, Food Bioprocess. Technol. 6(4), 1067–1081 (2013)

L. Carmona, L. Zacarias, M.J. Rodrigo, Postharvest Biol. Technol. 74, 108–117 (2012)

A.J. Melendez-Martinez, C.M. Stinco, C. Liu, X.D. Wang, Food Chem. 138(2–3), 1341–1350 (2013)

M.J. Rodrigo, J.F. Marcos, F. Alférez, M.D. Mallent, L. Zacarías, J. Exp. Bot. 54(383), 727–738 (2003)

J.C. Barreto, M.T.S. Trevisan, W.E. Hull, G. Erben, E.S. de Brito, B. Pfundstein, G. Wurtele, B. Spiegelhalder, R.W. Owen, J. Agric. Food Chem. 56(14), 5599–5610 (2008)

A.M. Gomez-Caravaca, A. Lopez-Cobo, V. Verardo, A. Segura-Carretero, A. Fernandez-Gutierrez, Electrophoresis 37(7–8), 1072–1084 (2016)

A. Schieber, N. Berardini, R. Carle, J. Agric. Food Chem. 51(17), 5006–5011 (2003)

C.M. Ajila, L.J. Rao, U.J.S.P. Rao, Food Chem. Toxicol. 48(12), 3406–3411 (2010)

N. Berardini, R. Carle, A. Schieber, Rapid Commun. Mass Spectrom. 18(19), 2208–2216 (2004)

T. Beelders, D. de Beer, E. Joubert, J. Agric. Food Chem. 63(22), 5518–5527 (2015)

H. Ichiki, O. Takeda, I. Sakakibara, S. Terabayashi, S. Takeda, H. Sasaki, J. Nat. Med. 61(2), 146–153 (2007)

B.G. Oliveira, H.B. Costa, J.A. Ventura, T.P. Kondratyuk, M.E.S. Barroso, R.M. Correia, E.F. Pimentel, F.E. Pinto, D.C. Endringer, W. Romao, Food Chem. 204, 37–45 (2016)

K.J. Meyers, T.J. Swiecki, A.E. Mitchell, J. Agric. Food Chem. 54(20), 7686–7691 (2006)

R. Garcia-Villalba, J.C. Espin, K. Aaby, C. Alasalvar, M. Heinonen, G. Jacobs, S. Voorspoels, T. Koivumaki, P.A. Kroon, E. Pelvan, S. Saha, F.A. Tomas-Barberan, J. Agric. Food Chem. 63(29), 6555–6566 (2015)

J. Perez-Jimenez, J.L. Torres, J. Agric. Food Chem. 59(24), 12713–12724 (2011)

A. López-Cobo, V. Verardo, E. Diaz-de-Cerio, A. Segura-Carretero, A. Fernández-Gutiérrez, A.M. Gómez-Caravaca, Food Res. Int. (2017)

D.S. Sogi, M. Siddiq, I. Greiby, K.D. Dolan, Food Chem. 141(3), 2649–2655 (2013)

D.S. Sogi, M. Siddiq, K.D. Dolan, LWT-Food Sci. Technol. 62(1), 564–568 (2015)

Y.J. Sun, Y. Shen, D.H. Liu, X.Q. Ye, LWT-Food Sci. Technol. 60(2), 1269–1275 (2015)

T. Vashisth, R.K. Singh, R.B. Pegg, LWT-Food Sci. Technol. 44(7), 1649–1657 (2011)

J.D. Ornelas-Paz, E.M. Yahia, A.A. Gardea, Postharvest Biol. Technol. 50(2–3), 145–152 (2008)

A.L. Vasquez-Caicedo, P. Sruamsiri, R. Carle, S. Neidhart, J. Agric. Food Chem. 53(12), 4827–4835 (2005)

X.W. Sui, P.D. Kiser, T. Che, P.R. Carey, M. Golczak, W.X. Shi, J. von Lintig, K. Palczewski, J. Biol. Chem. 289(18), 12286–12299 (2014)

J. von Lintig, Annu. Rev. Nutr. 30, 35–56 (2010)

C. Hernandez-Brenes, P.A. Ramos-Parra, D.A. Jacobo-Velazquez, R. Villarreal-Lara, R.I. Diaz-De la Garza, Tropical and Subtropical Fruits: Flavors, Color, and Health Benefits, In: G.K.J.B.S. Patil, C.O. Roa, K. Mahattanatawee, Editors. (ACS, Washington, D.C., 2013) pp. 29–42

J. Mares, Annu. Rev. Nutr. 36, 571–602 (2016)

X. Hou, J. Rivers, P. Leon, R.P. McQuinn, B.J. Pogson, Trends Plant Sci. 21(9), 792–803 (2016)

Y. Sharoni, K. Linnewiel-Hermoni, M. Khanin, H. Salman, A. Veprik, M. Danilenko, J. Levy, Mol. Nutr. Food Res. 56(2), 259–269 (2012)

D. Albanese, G. Adiletta, M. D’Acunto, L. Cinquanta, M. Di Matteo, Int. J. Food Sci. Technol. 49(11), 2458–2463 (2014)

E. Ryckebosch, K. Muylaert, M. Eeckhout, T. Ruyssen, I. Foubert, J. Agric. Food Chem. 59(20), 11063–11069 (2011)

Acknowledgements

This work was funded by Consejo Nacional de Ciencia y Tecnología (CONACYT), through project number 563: “Un Enfoque Multidisciplinario de la Farmacocinética de Polifenoles de Mango Ataulfo: Interacciones Moleculares, Estudios Preclínicos y Clínicos”.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

de Ancos, B., Sánchez-Moreno, C., Zacarías, L. et al. Effects of two different drying methods (freeze-drying and hot air-drying) on the phenolic and carotenoid profile of ‘Ataulfo’ mango by-products. Food Measure 12, 2145–2157 (2018). https://doi.org/10.1007/s11694-018-9830-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-018-9830-4