Abstract

The aim of this study was to investigate the addition of oleiferous powders to the pasta formulation by replacing a percentage of the wheat flour and semolina blends. In addition, the effect of oleiferous powders on the physicochemical and sensorial properties, and cooking quality of the pasta samples was also determined in this study. The oleiferous powders were added to the pasta formulations at the replacement ratio of 20% (10% of the wheat flour and 10% of the semolina blends) of the total weight of the wheat flour and semolina blends. The results showed that the addition of different oleiferous powders to the pasta formulation resulted in a significant increase in the browning and yellowness index values, ash, fat, protein and phenolic contents, total energy, antioxidant activity, and optimal cooking time, whereas, the addition of the oleiferous powders, resulted in a significant decrease in the moisture and total carbohydrate contents, swelling volume, and weight gain (p < 0.05). The main polyunsaturated fatty acid was linoleic acid in all the samples. The highest overall acceptability rating was obtained for the pasta enriched with hazelnut powder (p < 0.05).

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The consumption of pasta and pasta like products, particularly in the Middle Eastern region, is very common due to preparation being easy and quick, low cost and nutritional value (low glycemic index, sodium and total fat, and high carbohydrates, B vitamins, and iron), and for being suitable for long term storage, healthy, and tasty [1]. With the consumers' increasing demand for highly nutritious food products and the interest to achieve a healthier lifestyle, the enrichment or fortification of staple food products such as bread, pasta, etc. has been a major concern both in the food industry and scientific researches. Pasta and pasta products mainly consist of durum wheat flour and water [2]. Although pasta products include high amounts of carbohydrates due to the wheat flour, they lack of protein, fiber, vitamins, essential oils, phenolic compounds, or antioxidants, etc. This lack of nutrients in food causes malnutrition [2, 3]. For this reason, the enrichment of pasta and pasta like products is an important way to combat malnutrition. The incorporation of oleiferous powders, which are rich in protein, essential oils, vitamin, mineral, phenolic and antioxidant compounds, etc., into the pasta formulation can enhance their nutritional value thus increasing the beneficial health effects, and generate substantial income for the manufactures. Nuts are very important for a healthy diet due to their beneficial health effects (hypertension, obesity, diabetes, etc.) and their contents of vitamins, mineral, protein, fiber, lipids etc.[4]. Nuts (peanut, hazelnut, walnut, almond, etc.) which are rich in fiber, vitamin E, minerals, fatty acids, and phytosterols, also contain a high amount of protein [5]. The pumpkin seed (seed content of a pumpkin 3.52–4.27%) which is generally discarded during processing or used as animal feed, fertilizer, etc. is very nutritious and provides the best quality oil and is an excellent source of protein [6, 7].

There are a few studies in literature about the enrichment of pasta products for example: the addition of peanut powder [8], and flaxseed [9]. From the author’s knowledge, there is a paucity in the literature on the enrichment of the pasta product with several oleiferous powders which are rich in essential fatty acids, protein, phenolic compounds, etc. The scope of this study was to fortify the pasta using several oleiferous powders which are generally served with the pasta (as a decoration or sauce etc.) and rich in protein, fatty acids, etc. and to investigate the effect of various oleiferous powders on the physicochemical and sensorial properties, and cooking quality of the enriched pasta.

Materials and methods

Material

Hazelnut, peanut, walnut, almond, and pumpkin seed were purchased from a local supermarket (Demirciler Gıda San. A.Ş, Turkey) as well as the wheat flour (Söke Değirmencilik Sanayi ve Ticaret A.Ş., Turkey), semolina (Pasta DAlfredo, Gümüştaş Gıda San. Tic. Ltd., Turkey), olive oil (Kristal Yağları, Ticaret ve Sanayi Kontuvarı T.A.Ş., Turkey), and salt (Billur Tuz San. A.Ş., Turkey). The oleiferous seeds were milled using a Sinbo grinder (1000 W power, SHB 3107, Sinbo, Turkey). The powders were kept in the packaging material at room temperature.

Methods

Preparation of enriched pasta

All the ingredients (145 g wheat flour, 145 g semolina, 170 g whole egg, 6 g olive oil, 2 g salt, and the oleiferous powders in the percentage of 20% of the total weight of wheat flour and semolina blends) were mixed using a dough making machine (Electrolux 602,037 E-Mix 5 L Planetary Mixer, Sweden, 3 min) and kneaded by hand (3 min). Then, the obtained homogenous dough was rested at 20–25 ºC for 30 min. The pasta dough was then flattened cut into a regular shape (30 cm height and 0.65 cm width) with a pasta making machine (Fackelmann, Germany). Furthermore, a convective oven (Memmert, UF 110, Germany) was used to dry the long pasta strips for 4 h at 80 ± 2 °C. The pasta samples were then stored in a desiccator at 20–25 ºC until further analysis.

Analysis

Determination of physicochemical composition

The moisture, ash, protein, and fat content analysis were performed according to the methods of the American Association of Cereal Chemists ( [10] No. 44–01, No:08–01, No: 46–12, and No: 30–25, respectively). The total carbohydrate content and total energy value of the pasta samples were calculated according to the formula (Total Carbohydrate (%) = 100-(Moisture + Ash + Protein + Fat); Total Energy = cal/100 g) = 4x (Carbohydrate (%) + Protein (%)) + 9x (Fat (%)) given by Gibson [11]. The total phenolic compounds (mg of gallic acid equivalents (GAE)/ kg pasta) and antioxidant capacity (the ability to scavenge 2,2-diphenyl-1-picrylhydrazyl (DPPH) radicals) analysis were performed according to the modified methods of Singleton and Rossi [12], Kim et al. [13], and Lima et al. [14], respectively. The water activity, color (CIE Lab. System), and pH values of the oleiferous powders and pasta samples were measured using a LabStart Swiss (Sweden) water activity measurement device, a Minolta CR-400 Colorimeter (Japan), and a Seven Excellence Mettler TOLEDO AG (China), respectively. Chroma, Hue angle (º), total color change (ΔE*), browning index (BI), and the yellowness index (YI) values were calculated according to Pathare et al. [15].

Fatty acid composition

The extracted oils were methylated according to AOAC [16]. The gas chromatography (GC, Agilent 7890A, Santa Clara, CA, DB23 fused silica capillary column (100 m × 250 mm i.d. × 0.25 µm film thickness; JandW Scientific C., Folsom, CA)) was used for the determination of fatty acid methyl esters (FAMEs) after methylation. The GC was equipped with a flame ionization detector (FID). The column was operated at 100 °C for 5 min, followed by a 5 °C/min increase to 165 °C, held for 5 min, then increased to 210 °C, at a rate of 2 °C/min, held for 5 min and finally the temperature was increased from 210 °C to 240 °C, at a rate of 3 °C/min and maintained at 240 °C for 5 min. The injection temperature and transfer line were set at 250 °C. The injection volume and carrier gas were 1 µl nitrogen (constant flow of 1 mL/min), respectively. The fatty acid methyl esters were identified by comparing the retention times with established retention times for fatty acid methyl esters.

Determination of the water (WHC) and oil (OHC) holding capacities

The WHC and OHC values of the oleiferous powders and pasta samples were determined according to Stone et al. [17].

Cooking quality

The optimal cooking time, cooking loss, water absorption, and volume expansion analysis were performed according to the method described by AACC [18] and Yalçın and Basman [19].

Sensory evaluation

The pasta samples were prepared by boiling the pasta samples in distilled water for their specific optimal cooking times. The cooking water was drained, and the pasta samples were not rinsed.

A descriptive rating sensory tests (5-point scale (ranging from 1 as being “poor” to 5 as being “excellent”)) was used to measure the rating of consumer acceptance. The sensory panel was conducted with 20 panelists, aged between 20 and 40 years, from among the students of the Department of Gastronomy and Culinary Arts (AHEP University, Antalya, Turkey). The panelists were invited to participate as a sensory panel and were informed that samples contain different oleiferous powders. The panelists consent to join the sensory panel and were asked to evaluate the color, odor, flavor, taste, firmness, elasticity, smoothness, stickiness, and the overall acceptability of the samples.

Mathematical modeling and statistical analysis

In order to determine the effect of the chemical composition, WHC, and OHC values on the cooking quality, the linear (y = ax + b, a: slope and b: intercept), power (y = axb, a: proportionality consta0nt and b: power), logarithmic (y = aln(x) + b, a and b: model parameters), and quadratic (y = ax2 + bx + c, a: indicates the direction of parabola and c: intercept) functions were fitted to experimental data using SPSS 20.0 (SPSS Inc., Chicago, IL, U.S.A). The goodness of fit was determined using the coefficient of correlation (R2, Erbay and Icier [20]).

Data analysis was performed using the one-way ANOVA procedures using SPSS Statistical Software (SPSS 20.0, SPSS Inc., Chicago, IL, U.S.A.) All analyses were carried out in triplicate. The data was presented as a mean ± standard deviation. The Duncan test was used for comparison of the means with a level significance of 0.05.

Results and discussion

Physicochemical properties, and the WHC and OHC values of oleiferous powders

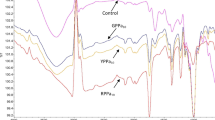

The physicochemical properties and the WHC and OHC values of the oleiferous powders are shown in Table 1. When comparing the oleiferous powders, it can be stated that the walnut powder has superior properties in moisture content and OHC values, whereas, the pumpkin seed powder has superior properties in the ash and protein content values when compared to the other powders. The peanut powder has the highest WHC value which is important for bakery products. The significantly lowest and highest pH values were observed for the almond and pumpkin seed powders, respectively (p < 0.05). In addition, the YI values of the powders ranged between 39.68 and 112.19. The moisture, ash, total fat, and protein contents of the seventeen different hazelnut varieties which were grown in the Black Sea Region of Turkey ranged between 2.49% and 5.25%, 1.87% and 2.72%, 56.07%, and 68.52%, and 11.70% and 20.80%, respectively [21]. Similar results were also obtained in this study for the hazelnut powders. Sze-Tao and Sathe [22] reported that walnuts contained 3.62 ± 0.04% moisture, 1.81 ± 0.03% ash, 66.90 ± 0.25% lipids, and 16.66 ± 0.51% protein (dry basis) which are consistent with the results of this study. Oliete et al. [4] reported that the ash, protein, and fat content of the following oleiferous powders as: almond 2.5%, 21%, and 56.7%, hazelnut 2.5%, 14%, and 65%, peanut 2.5%, 28%, and 50%, and walnut 2.3%, 16.7%, and 68.5%, respectively. The results of this study are consistent with the results of Oliete et al. [4]. The small differences between the values may be due to different varieties of nuts, or growing conditions, etc. The color values of the oleiferous powders are shown in Fig. 1a. The highest L*, a*, and b* values were obtained for almond, walnut, and pumpkin seed powders, respectively (p < 0.05). The green color of the pumpkin seed powder may be the reason for the lowest L* and a* values (p < 0.05). The brown color of walnut also resulted in a significantly lower L* value compared to other oleiferous powders except for the pumpkin seed powder (p < 0.05).

Physicochemical properties of the pasta samples

The moisture content, water activity, pH, BI, YI, and ΔE* values of the pasta samples enriched with different oleiferous powders are shown in Table 2. The moisture content of the pastas was lower than 13.00% which is in the acceptable limits according to the Turkish Food Codex Pasta Communiqué [23]. Significantly lower moisture content values were observed for the enriched samples compared to the control (p < 0.05). The different moisture content values may be due to lower moisture content values of oleiferous powders compared to wheat flour (12.20 ± 0.26%), different moisture content and WHC values of the oleiferous powders. The water activity values of the samples were lower than 0.45 which is important for safe storage. Since the water activity values of the pasta samples were lower than 0.6, they can be considered as microbiologically stable [24]. There is no statistical differences between the pH values (p ≥ 0.05) except for the pasta with almond powder (p < 0.05). Higher BI and YI values were observed for the enriched pasta samples compared to the control (p < 0.05). The highest YI value of pumpkin seed powder resulted in the highest YI value of the pasta with pumpkin seed powder (p < 0.05). The lowest and highest ΔE* values were observed for pasta with pumpkin seed and almond powders, respectively.

Color is an important parameter on the acceptability of food products by a consumer [25]. The results of the color measurements are shown in Fig. 1b. The L* value, which was found as 82.51 in the control sample, decreased after the addition of the oleiferous powders. The color values of the pasta samples were significantly affected using the oleiferous powders (p<0.05). The color of the enriched pasta samples with the hazelnut and peanut powders were lighter than that of the pasta samples with the walnut and pumpkin seed powder (p < 0.05). Guiné et al. [26] reported than the color of the almonds were brighter than the walnut and hazelnut. According to the results, it was observed that the pasta with pumpkin seed powder had the highest yellowness value. The a* values of the pasta samples with walnut and hazelnut powders were not found to be statistically different (p ≥ 0.05). Pasta with pumpkin seed powder had the highest b* value among all samples. There were no significant differences (p ≥ 0.05) between the redness value of the pasta with almond and peanut powders. On the other hand, the control sample had the lowest b* value among all the samples. As reported by Bilgiçli [27] noodles produced with a different type of flours (buckwheat, rice, and corn) had lower L* and higher a* and b* values compared to the control. Mirhosseini et al. [28] also observed the same results for the gluten-free pasta samples containing durian seed and pumpkin powders.

The chemical composition, WHC, and OHC values of the pasta samples enriched with different oleiferous powders are given in Table 3. The ash content of the control and the pasta samples ranged between 1.13% and 1.48% which were in line with the Turkish Food Codex Pasta Communiqué [23], which reported that the ash content of the pasta sample can be a maximum of 2% in a dry basis, however, there is no limitation for the pasta samples. The ash contents of the pasta samples were generally found higher than the control except for the pasta samples with hazelnut and peanut powders. Higher ash content values were observed for the enriched pasta samples with almond and pumpkin seed powders (p < 0.05). The higher ash content of the almond and pumpkin seed powders than other oleiferous powders may be the reason for this (Table 1, p < 0.05). The fat contents of the enriched samples significantly increased when compared to the control (p < 0.05). These increases were found as 108.97%, 97.73%, 95.22, 75.48%, and 118.42% for pasta enriched with hazelnut, peanut, walnut, almond, and pumpkin seed powders, respectively. The differences between the fat content of the enriched pastas were found insignificant (p ≥ 0.05). Depending on the Turkish Food Codex Pasta Communiqué [23], the minimum value for the protein content of plain and the pasta samples are 15.5% on a dry basis. Our findings are consistent with the Turkish Food Codex Pasta Communiqué [23]. Similar to the results of the fat content, the protein contents of the enriched samples were found higher than the control. The higher protein content of the oleiferous powders compared to wheat flour and semolina may be the reason for this. The addition of oleiferous powders to the pasta formulation resulted in a significant decrease (around 10.88–18.55%) in the total carbohydrate value of the control sample (p < 0.05). The total energy of the pasta samples was also calculated and the results showed that the enriched pasta samples with hazelnut and pumpkin seed powder have a higher calorie value compared to the other samples (p < 0.05). The higher calorie values were observed for the enriched pasta samples compared to control (p < 0.05). The higher fat content of the oleiferous powders may be the reason for this (p < 0.05). The total phenolic compounds and antioxidant capacity of the enriched pasta samples were found significantly higher compared to the control (p < 0.05). The higher total phenolic compounds and antioxidant capacity of oleiferous powders when compared to wheat flour and semolina may be the reason for this situation. The highest total phenolic compounds and antioxidant capacity values were obtained from the pasta containing walnut powder (p < 0.05). In addition, different total phenolic compounds and the antioxidant capacity of the oleiferous powders may have resulted in different values in the pasta samples.

The WHC values of the enriched pastas were found generally lower than the control sample except for the pasta with the hazelnut and peanut powders. The differences between the WHC values of the control and the pasta with hazelnut and peanut powders were found insignificant (p ≥ 0.05). Generally, the moisture content and WHC values of the samples have an inverse relationship, however, no trends were observed between the moisture content and WHC values of the pasta samples. The OHC values of the pasta samples ranged between 23.75% (pasta with pumpkin seed powder) and 41.25% (pasta with peanut powder). No relationship was observed between the fat content and OHC values of the pasta samples. A different chemical composition such as starch and protein contents, surface area and properties, and the energy of the pasta may be the reason for the different water and OHC values.

Fatty acid composition

The fatty acid composition and oil content of the pasta samples with different oleiferous powders are presented in Table 4. Palmitic, palmitoleic, and linoleic acids were detected as the main fatty acids in the pasta samples. Similar results were also obtained by Villeneuve et al. [9] and Prabhasankar et al. [29]. The oil of the control sample contained a higher percentage of palmitic acid compared to the others that are produced from different flours. In contrast, the lowest octadecenoic acid content was observed in the control sample oil. The oil of the pasta with peanut powder had higher levels of palmitic acid than the oil of the pasta with almond, walnut, and hazelnut powders. Similar to this result, Maguire et al. [30] determined that peanuts had higher levels of palmitic acid than the almond, walnut, and hazelnut. For the linoleic acid content, the highest value was obtained from the pasta with hazelnut powder. Tetradecanoic acid and pentadecylic acid were only detected in the control sample oil. The oil of the pasta with pumpkin seed powder had the highest percentage of myristic acid. In a previous study, similar to our results, the average percentage of myristic acid in pumpkin seed oil was found as 0.25 [31]. Margaric and heptadecenoic acids were not detected in the oil of the pasta with hazelnut, peanut, and pumpkin seed powders. The oil of the pasta with peanut powder only contained behenic acid.

The oil yield of the pasta samples ranged from 7.68 to 17.04% (by weight) (Table 4). Addition of different oleiferous powders increased the oil content of the pasta due to the higher oil content of the oleiferous powders. Pasta with pumpkin seed powder had the highest oil yield. In contrast, the pasta with almond powder had the lowest oil yield. Similar results were also obtained by Maguire et al. [30]. The researchers reported that the oil content of the almond is lower than the hazelnut, walnut, and peanut. Any significant difference was observed between oil yield of pasta with hazelnut and pumpkin seed powders (p ≥ 0.05).

Cooking quality

The results of the cooking quality analysis are shown in Table 5. The optimal cooking time of the pasta samples ranged between 12 and 17 min. It can be stated that the enrichment of pasta samples with different oleiferous powders had a significant effect on the cooking time of the samples (p < 0.05). While the control sample has the lowest cooking time, the addition of different oleiferous powders resulted in a significant increase (p < 0.05). The increase was found around 2–5 min longer than the control. This increase may be due to the hydrophobic structure of the pasta with different oleiferous powders (Table 3). In addition, the higher amount of fiber and lower amount of starch content of the different oleiferous powders may have resulted in a slower rate of water diffusion and consequently raised the optimal cooking times. The differences between the cooking time of the pasta with peanut, almond, and pumpkin seed powders were not found to be significant (p ≥ 0.05). Del Nobile et al. [32] claimed that the spaghetti samples which have the highest protein contents are the most resistant to overcooking. In this study, the enriched pasta samples with almond and pumpkin seed powders have a higher protein content (Table 3) and a longer cooking time.

Soluble parts of pasta such as starch, non-starch polysaccharides, etc. leach into the boiling water during cooking [33]. The pasta quality is generally determined according to the amount of soluble solid content in the cooking water. The lowest amount of soluble parts in the boiling water shows that pasta has a high quality [34]. The cooking loss of the pasta samples ranged between 5.89% (pasta with hazelnut powder) and 7.63% (pasta with peanut powder) which are in the acceptable limits (lower than 10%) according to Turkish Food Codex Pasta Communiqué [23]. In addition, the cooking loss values of all the enriched pastas were found to be lower than the technologically acceptable limit which is lower than 8% [35]. Our results for the pasta with peanut powder were also in line with those obtained by Howard et al. [8]. The researchers claimed that the cooking loss values of the pasta with peanut powder (30–50% peanut enrichment, 2.4–2.9% carrageenan concentration, and 60–88 ºC drying temperature) ranged between 5.4 and 7.8%. The higher cooking loss values of the samples compared to the control may be because of a lower protein (gluten) content (p < 0.05, except for the pasta with hazelnut powder). Wheat gluten proteins form a strong gluten network due to the molecular disulfide bonds formation during processing. Ajila et al. [33] reported that a higher amount of mango peel powder addition resulted in a higher amount of residue in the boiling water. The disruption of the protein-starch matrix by the fiber and nonhomogeneous water distribution within the macaroni matrix may be the reason for this. In addition, the higher fiber content of the pasta with different oleiferous powders may be the reason for the higher amount of residue in the boiling water. Lower swelling volume and weight gain values were observed for pasta samples with different oleiferous powders compared to the control (p < 0.05). Howard et al. [8] claimed that when the hydrophilic compounds are tightly bound together in the pasta, they have less surface area available to absorb water during boiling. Therefore, the hydrophobic structure of the pasta with different oleiferous powders may be the reason for lower water absorption which resulted in lower weight gain and swelling volume (Table 3). The higher protein and fat content, and lower starch content of the enriched pasta samples with different oleiferous powders which resulted in a lower water absorption may also be the reason for the lower swelling volume and weight gain values. In addition, the differences between the swelling volume values of the pasta samples enriched with different oleiferous powders were not found statistically significant except for the pasta with walnut powder (p ≥ 0.05). Although, the differences between the weight gain values of the pasta samples enriched with different oleiferous powders (p < 0.05), and the differences between the pasta samples with hazelnut and pumpkin seed powder were not found to be significant (p ≥ 0.05).

The effect of chemical composition, WHC, and OHC values on the cooking quality were also determined in this study. The correlation coefficient (R2) which was higher than 0.8 was accepted for explaining the relationship between the parameters. The effect of fat content (y = -0.7132x2 + 22.213x-156.15, R2 = 0.8959), swelling volume (y = 2.8261x2-99.865x + 1076.6, R2 = 0.8855), and weight gain (y = 5.2102x2-174.22x + 1674.3, R2 = 0.8377) on the optimal cooking time followed a quadratic trend. Only the effect of WHC on the cooking loss was found to be important (p ≥ 0.05), and it also followed the quadratic trend (y = 14.434x2-194.95x + 691.27, R2 = 0.8723). The relationship between the swelling volume and weight gain were found to be linear (y = 1.2996x–39.202, R2 = 0.9641). The relationship between the fat content and weight gain of the pasta samples also followed a quadratic trend (y = -0.005x2 + 0.196x-3.5275, R2 = 0.83388).

Sensory evaluation

The sensory research was conducted at the AHEP University of Gastronomy and Culinary Arts Department where the aim was examining the sensory properties of the enriched pasta samples with different oleiferous powders and their consumer acceptance. Mercier et al. [36] reported that the enrichment levels lower than 10% generally do not affect consumer acceptability. Similar to the findings of Mercier et al. [36], depending on the preliminary tests (5%, 10%, and 20% enrichment percentage (data was not given)), the addition of 5% and 10% of oleiferous powders did not affect the sensory characteristics of the pasta products significantly. Therefore, the oleiferous powder concentration was chosen as 20%. The ratings for the pasta samples enriched with different oleiferous powders are shown in Fig. 1. The significantly highest color rating (3.82) was obtained for the pasta with pumpkin seed flour which has a green color (p < 0.05). According to this result, it can be stated that green color is acceptable for pasta and pasta like products. For this reason, the pasta products can be enriched with different kind of vegetables such as spinach, mint, parsley, etc. which have a green color. The lowest color rating (3.05) was obtained for the pasta with peanut flour which has dark yellow color (p < 0.05). According to this finding, it can be stated that the bright yellow color is the desired color for the pasta and pasta products. In spite of the lowest color rating of the pasta with peanut flour, the highest odor rating was obtained for the pasta with walnut and peanut flour (p < 0.05). It may be due to the specific odor of walnut and peanut flours. Oleiferous powders had also the greatest impact on the firmness and elasticity ratings. The pasta samples with different oleiferous powders have generally lower firmness and elasticity ratings compared to the control sample (p < 0.05). It can be concluded that the enriched pasta samples are easily chewable as is the control sample. Similar to the findings of this study, Howard et al. [8] reported that the non-gluten protein enrichment of pasta generally resulted in lower firmness and brightness values compared to the traditional pasta. Depending on the homogeneity and stickiness ratings, it can be stated that there are no significant differences between the samples (p ≥ 0.05). Del Nobile et al. [32] claimed that there is an inverse relationship between the spaghetti stickiness and protein content. Similarly, in this study, the lowest stickiness rating (3) was obtained for the pasta with pumpkin seed flour. As expected, the oleiferous nuts were ground to fine particles and homogeneously mixed with the pasta dough and as a result, a homogeneous pasta structure was obtained. The flavor ratings of the pasta samples were found higher than 2.50 and the significantly highest ratings were obtained for the pasta with the almond and peanut powders (p < 0.05). An off-flavor was not detected. Depending on the overall acceptance ratings it can be stated that all the pasta samples were accepted by the panelists, however, a higher rating was obtained for the pasta with the hazelnut powder (p < 0.05).

Conclusions

In this study, the addition of hazelnut, peanut, walnut, almond, and pumpkin seed powders to the pasta formulation replacing the wheat flour and semolina blends and the effect of additional powders on the chemical composition, cooking quality, and sensorial evaluation of the pasta samples were studied. In order to the increase the nutritional value of the pasta and pasta like products, oleiferous powders which are rich in protein, and essential fatty acids can be used. The pasta samples can be stored safely because of their low moisture content (< 14%) and water activity (< 0.6) values. The cooking loss values of all the pasta samples were found lower than 8% which is in the technologically acceptable limit. This study also indicates some differences in the total oil content and fatty acid composition between pasta samples which were produced with different oleiferous powders. The pasta enriched with hazelnut powder had the highest overall acceptability score compared to other samples. The effect of the addition of a different amount of oleiferous powders to the pasta formulation and the different storage conditions on the chemical composition of the pasta samples can be investigated in further studies.

References

M. Alireza Sadeghi and S. Bhagya (2008) J. Food Sci. 73, 229

A. Marti, M.A. Pagani, Trends Food Sci. Technol. 31, 63 (2013)

S.N. Dirim and G. Çalışkan Koç, Croat. J. Food Sci. Technol. 11, 88 (2019).

B. Oliete, M. Gómez, V. Pando, E. Fernández-Fernández, P.A. Caballero, F. Ronda, Food Sci. Technol. Int. 14, 259 (2008)

J. Vinson, Y. Cai, Food Funct. 3, 134 (2011)

R.H. Glew, R.S. Glew, L.T. Chuang, Y.S. Huang, M. Millson, D. Constans, D.J. Vanderjagt, Plant Food Hum Nutr 61, 51–56 (2006)

N. Manda Devi, R. V Prasad, and P. Gaibimei, Int. J. Chem. Stud., 5, 828 (2018).

B.M. Howard, Y.-C. Hung, K. McWatters, J. Food Sci. 76, E40 (2011)

S. Villeneuve, L.-P. Des Marchais, V. Gauvreau, S. Mercier, C. B. Do, and Y. Arcand, Food Bioprod. Process. 91, 183 (2013).

AACC, Assoc. St Paul, MN (1990).

R.S. Gibson, Principles of Nutritional Assessment, 2nd edn. (Oxford University Press Inc., New York, 2005)

V. L. Singleton and J. A. Rossi, Am. J. Enol. Vitic. 16, 144 LP (1965).

Y.K. Kim, Q. Guo, L. Packer, Toxicology 172, 149 (2002)

S. Lima, C. Prudêncio, I. Maia, L. Claudio, G. Elias, D. De Oliveira, M.T. Bordignon-luiz, J. Luiz, Food Chem. 188, 384 (2015)

P.B. Pathare, U.L. Opara, F.A.-J. Al-Said, Food Bioprocess Technol. 6, 36 (2013)

AOAC, Arlington. (1997).

A.K. Stone, A. Karalash, R.T. Tyler, T.D. Warkentin, M.T. Nickerson, FRIN 76, 31 (2015)

AACC, Assoc St Paul (2000).

S. Yalçın, A. Basman, J. Food Qual. 31, 465 (2008)

Z. Erbay, F. Icier, Crit Rev Food Sci Nutr 50, 441–464 (2009)

A.İ. Köksal, N. Artik, A. Şimşek, N. Güneş, Food Chem. 99, 509 (2006)

K.W.C. Sze-Tao, S.K. Sathe, J. Sci. Food Agric. 80, 1393 (2000)

Turkish Food Codex Pasta Communiqué, (2002).

S.Y. Quek, N.K. Chok, P. Swedlund, Chem. Eng. Process. Process Intensif. 46, 386 (2007)

Y. Tekgül and T. Baysal, J. Food Process Eng. 0, e13080 (n.d.).

R.P.F. Guiné, C.F.F. Almeida, P.M.R. Correia, M. Mendes, Food Bioprocess Technol. 8, 1113 (2015)

N. Bilgiçli, J. Food, Agric. Environ. 6, (2008).

H. Mirhosseini, N. F. Abdul Rashid, B. Tabatabaee Amid, K. W. Cheong, M. Kazemi, and M. Zulkurnain, LWT - Food Sci. Technol. 63, 184 (2015).

P. Prabhasankar, P. Ganesan, N. Bhaskar, A. Hirose, N. Stephen, L.R. Gowda, M. Hosokawa, K. Miyashita, Food Chem. 115, 501 (2009)

L.S. Maguire, S.M. O’Sullivan, K. Galvin, T.P. O’Connor, N.M. O’Brien, Int. J. Food Sci. Nutr. 55, 171 (2004)

D.G. Stevenson, F.J. Eller, L. Wang, J.-L. Jane, T. Wang, G.E. Inglett, J. Agric. Food Chem. 55, 4005 (2007)

M.A. Del Nobile, A. Baiano, A. Conte, G. Mocci, J. Cereal Sci. 41, 347 (2005)

C.M. Ajila, M. Aalami, K. Leelavathi, U.J.S.P. Rao, Innov. Food Sci. Emerg. Technol. 11, 219 (2010)

A. Baiano, A. Conte, M.A. Del Nobile, J. Food Eng. 76, 341 (2006)

Y. V. Dick JW, Durum Wheat Chem. Technol. (G. Fabriani C. Lintas, Eds.), Am. Assoc. Cereal Chem. Inc., St. Paul, MN. 237 (1998).

S. Mercier, C. Moresoli, M. Mondor, S. Villeneuve, B. Marcos, Compr. Rev. Food Sci. Food Saf. 15, 685 (2016)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Çalışkan Koç, G., Tekgül, Y. & Çoban, S. Physicochemical properties, fatty acid composition, cooking quality, and sensory evaluation of pasta enriched with different oleiferous powders. Food Measure 14, 3048–3057 (2020). https://doi.org/10.1007/s11694-020-00540-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-020-00540-y