Abstract

Nineteen evaluation indicators in 15 yellow peach chips prepared by explosion puffing drying were analyzed, including color, rehydration ratio, texture, and so on. The analysis methods of principle component analysis (PCA), analytic hierarchy process (AHP), K-means cluster (KC) and Discriminate analysis (DA) were used to analyze the comprehensive quality of the yellow peach chips. The dispersed coefficient of variation of the 19 evaluation indicators varied from 3.58 to 852.89 %, suggesting significant differences among yellow peach cultivars. The characteristic evaluation indicators, namely, reducing sugar content, out-put ratio, water content, a value and L value were analyzed by PCA, and their weights 0.0429, 0.1140, 0.4816, 1.1807 and 0.1807 were obtained by AHP. The levels in 15 cultivars effectively were classified by discrimination functions which obtained by KC and DA. The results suggested that three levels of comprehensive quality for yellow peach chips were divided, and the highest synthesis scores was observed in “senggelin” (11.1037), while the lowest synthesis value was found in “goldbaby” (−3.7600).

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Peach (Prunus persica L. Batsch) is a climacteric stone fruit species originated from China, and it can provide high nutrition and a pleasant flavor. Peach is the fourth most important fruit in China, after orange, apple and pear. Peach fruit has a short shelf-life potential due to fast softening and overall ripening. Drying is one of the most used techniques to preserve peach and other agricultural products, which can prevent concurrent of undesirable changes induced by microbial activity. The use of artificial drying to preserve fruit products has been expanded widely, and increasing the requirement for more rapid drying techniques. New and /or innovative techniques that increase drying rates and enhance product quality have achieved considerable attention (Mongpraneet et al. 2002). There were several processing technology for peach chips, such as deep fat frying, freeze-drying and hot air drying. Despite quick rehydration and relatively good quality of final dried products, freeze-drying is only rarely used by the food industry because of its particularly high equipment and running costs. The use of freeze-drying is therefore limited to a few cases of high value products (Louka and Allaf 2002). Compared with hot air drying technologies and other traditional drying technologies, the product processed with EPD has viscoelastic behavior and porous structure. Among the peach chips processing technologies, explosion puffing drying (EPD) provides products that are less deformed, which can be more quickly rehydrated, with good preservation of flavor, for lower unit processing costs (Louka and Allaf 2004). As a rapid dying technology, EPD has been applied among vegetables and fruits such as apple (Bi et al. 2015), purple maize (Mard et al. 2014), jujube (Du et al. 2013), and mango (Zou et al. 2013).

Most previous studies on drying peaches were focused on drying characteristics (Wang and Sheng 2006; Kingsly et al. 2007), while no clear information was available about the evaluation quality of peach chips and the suitable clutivars for processing peach chips. The quality of chips includes sensory quality, physico-chemical nutritional quality and processing quality, which can be influenced by many complex factors (Bi et al. 2015). Principal Component Analysis (PCA), Analytic Hierarchy Process (AHP) and K-means Cluster (KC) and Discriminate analysis (DA) have been reported to evaluate the quality change of fruit and vegetable products, such as peaches (Wu et al. 2005), wines (Kallithraka et al. 2001), grapes (Fraige et al. 2014), and pineapples (Cárnara et al. 1995). PCA is a classical statistic analysis method, which can extract the common factor from abundant data, and its objective is to identify a reduced number of principal components (Versini et al. 2009). PCA has been used to discriminate the quality of peaches (Versari et al. 2002), carrot chips (Rosenfeld et al. 1997), mango (Liu et al. 2013), and display the changes in chemical constituents of pomegranate (Shwartz et al. 2009). The analysis method of DA is also a statistical analysis technique for producing score plots for the analyses (Stewart et al. 2014). DA has been used to discriminate sweet and bitter almonds (Borràs et al. 2014) and different Longjing tea (Jia et al. 2013). PCA and DA were used to identify exotic tropical fruits and classify 113 samples into three groups: the irradiated beverages, the non-irradiated beverages and the irradiated standard solutions (Gosetti et al. 2015). The analysis method of AHP can provide quick and automatic qualitative sample differentiation, in particular when quantification or characterization of specific components of matrix are not necessary (Cagliero et al. 2012).

In this work, the mathematical analytical methods were being proposed to allow discrimination of the comprehensive quality of yellow peach chips, based on the information of characteristic evaluation indicators. Therefore, the objective of this work was to develop mathematical analytical methods to evaluate the comprehensive quality of yellow peach chips prepared by EPD and select the appropriate cultivars used to process chips.

Materials and methods

Materials

A total of 15 yellow peach cultivars were picked from main peach producing areas in China, including Pinggu (Beijing City, 117°55ʹE, 40°12ʹN), Linyi (Shandong Province, 35°27ʺE, 118°37ʹN) and Dalian (Liaoning Province, 122°31ʺE, 39°10ʹN) (Table 1). The yellow peaches fruit with the similar size and maturity were collected from outside of the middle of trees from July to September in 2012.

Sample preparation and processing

Yellow peaches were cut into 9 mm thick slices by a Laboratory Slicer (model FA-200, Nanhai Defeng electrothermal equipment Co., Ltd., Guangdong China) after removing peel and core. The sliced peaches were placed in deep-frozen refrigerator at −40 °C for 12 h. The sliced fruits were steeped into malt syrup (25 %, v/v) for 4 h after thawing at room temperature. A treatment of 3.5 h hot-air drying was used to pre-drying for the samples which were wrapped with tissue paper to remove superficial water and sugar. After the above pre-treated procedure, chips were produced by using the experimental explosion puffing drying equipment system developed by Tianjin Qin-de New Material Scientific Development Co. Ltd. (Tianjing, China). Pre-treated peach slices were puffed at 85 °C for 20 min and dried in vacuum conditions with a lower temperature of 60 °C for 2.5 h. The procedure was optimized by previous studies. All the samples were stored in dryer until used.

Color

The surface color of yellow peach chips was analyzed by a colorimeter (D25LT, Hunter Lab, Virginia, Germany). The colorimeter was calibrated against a standard white plate before each actual color measurement. For each sample measured values were recorded (mean values of the three measurements). Three hunter color parameter, namely, L (lightness), a (redness/greenness), and b (yellowness/blueness) were measured (Nimmol et al. 2007).

Rehydration ratio (RR)

Three grams of dehydrated samples were placed in a baker with distilled water at room temperature on a 1:50 (m/v) basis. Then the samples were removed and allowed to drain over a mesh for 60s in order to eliminate the superficial water before weighing (Dadali et al. 2008). The degree of rehydration ration (RR) was expressed by the formula:

Where m 1, m 2 referred to weight of material (g) before and after rehydration, respectively.

Texture

Texture profile analysis was used to evaluate hardness and crispness of yellow peach chips by using a texture analyzer (TA.XT 2i/50, Stable Micro Systems Ltd., Godalming, UK) fitted with a spherical probe (p/2.5S). The maximum compression force and the number of peaks in the force-deformation curve of each sample were considered as an indication of hardness and crispness of sample, respectively .

The analysis parameters were as following: Mode: Measure Force Compression; Option: Return To Start; Pre-Test Speed: 1.0 mm/s; Test Speed: 1.0 mm/s; Post-Test Speed: 2.0 mm/s; Distance: 50.0 %; Trigger Force: 100 g; Trigger Type: Button; Data Acquisition Rate: 500 pps.

Moisture content

The moisture content of peach chips was determined by weight loss after drying 5 g samples in a forced air oven at 105 °C (AOAC 1986) for 24 h.

Expansion ratio

The bulk of samples were measured by a Volscan Profiler (Stable MicroSystem, England). The expansion ratio was calculated using the mean value of volume, and calculating equation was:

Where S2, Vt, V0 referred to expansion ratio, volume of the sample after and before puffing (cm3), respectively.

Soluble solid content (SSC)

Soluble solid content (SSC) was determined by a Digital Refractometer at 20 °C (dBX-55, Atago, Japan).

Other evaluation indicators

Reducing sugar content, titrable acidity content, ascorbic acid content, crude fiber content, crude protein content and crude fat content were determined according to standard AOAC Official Method 945.66 (1945), AOAC Official Method 942.15 (1942), AOAC Official Method 985.26 (1985), AOAC Official Method 992.16 (1992), AOAC Official Method 978.04 (1978), AOAC Official Method 2003.06(2006), respectively.

Statistical analysis

All experiments were performed in triplicated and the results were reported as mean values with standard deviations. All data were processed and analyzed on SPSS 21.0 (IBM, Chicago, USA) .

Results and discussion

In order to evaluate the comprehensive quality of yellow peach chips, the difference of evaluation indicators between cultivars was identified by coefficient of variation (CV), and the characteristic indicators were analyzed by PCA firstly. Then, the synthesis scores for yellow peach chips were obtained through the statistic methods of AHP. Finally, combining KC and DA, the discrimination functions were established and applied to quantitatively analyze the quality of yellow peach chips.

Quality evaluation indicators of yellow peach chips

Characteristics of 19 evaluation indicators of yellow peach chips were shown in Table 2. The range of variable coefficients varied from 3.58 to 852.89 % among products dried from 15 cultivars yellow peaches, signifying that variation degree were different, which closely related to fruit characteristics including color, firmness, sugar and acid (Génard and Bruchon 1992). The different genotypic variations and texture of fresh fruit might also result in the quality variability among yellow peach chips. Among all the evaluation indicators, CV of “explosion ratio” was the largest, which was 825.89 %. While soluble solid content of yellow peach chips showed the smallest CV value (3.58 %) indicating no significant difference for SCC among the 15 cultivars, and it could be excluded from further analysis data.

Principal component analysis (PCA)

PCA is a technique to both reduce the number of variables and give prominence to the relationship between the elements (Kara 2009). Based on Kaiser’s rule, choosing eigenvalues greater than one (>1), the dimensionality was reduced to five principal components (PC) which explained 85.84 % of the total variance (Table 3). And the eigenvalues of the five PCs were 5.660 3.310, 2.022, 1.673, and 1.069, respectively. The PC1 explained 35.376 % of total variability, and it was negatively connected with crude fat content and positively with reducing sugar content. For PC2 (explained 20.690 %), it was positively connected with rehydration ratio, and negatively connected with out-put ratio. For PC3 (explained 12.636 %), it was only positively connected with a value. For PC4 (explained 10.458 %), it was positively connected with L value and b value. PC5 (explained 6.681 %) was only positively connected with water content.

The characteristic evaluation indicators for yellow peach chips were selected from the connected indicators. For PC1, the weight of crude fat content was the highest, and the following was the weight of reducing sugar content. However, yellow peach chips produced by EPD were fried-free, and low fat content ranged from 0.75 to 5.08 %. Reducing sugar content was related to both browning degree and the taste of yellow peach chips, which could reflect the sweetness. As a substrate of Maillard reaction, reducing sugar was responsible to the browning reaction induced by the heat of drying technologies. Keenan et al. (2012) reported that reducing sugar was associated with high browning tendency during drying process, since Maillard reaction was occurred at higher temperatures. Therefore, reducing sugar content could be chosen to be the representative indicators for PC1, which could be on behalf of taste quality.

Both rehydration ratio and our-put ratio with the large values of weight were the main indicators for PC2. Rehydration ratio was considered as an indirect measurement of the damage to the material caused by drying and treatment preceding dehydration (Vega-Gáilvez et al. 2011). It was not only an indicator for evaluating process ability, but also an indicator for evaluating the texture of yellow peach chips. Compared with the indicator of out-put ratio, the indicator of rehydration ratio could better characterize the physical and chemical changes of yellow peach chips as influenced by processing conditions, sample pre-treatment (Xu et al. 2004). Thus, rehydration ratio was the representative for evaluating the structure of yellow peach chips, and chosen as the characteristic indicator for PC2.

For PC3 and PC4, both a value (0.928) and L value (0.963) got the largest weight respectively, which both could be defined as color indicators. Color was an extremely significant factor for the quality evaluation of dehydrated fruit (Xu et al. 2004). A value and L value were closely related to browning indicators that were induced by enzymatic or non-enzymatic browning. As reported by Ávila and Silva (1999), with the increasing heating temperature and time, peach puree became darker corresponding to the decrease of a value. Enzymatic browning was a serious problem when dealing with peaches because the oxidative enzymes might cause browning accompanied by changes in color. Therefore, a value and L value could be viewed as characteristic indicators for PC3 and PC4, respectively.

Water content was an important indicator for evaluating the safety of chips products. Water content of the product would affect microbial spoilage and quality deterioration due to undesirable biochemical reactions (Marques et al. 2009). Therefore, water content with the largest weight (0.903) could be regarded as the characteristic indicator for PC5.

In summary, five characteristic evaluation indicators of yellow peach chips were obtained by PCA. They were reducing sugar content, rehydration ratio, a value, L value and water content.

Analytic hierarchy process (AHP)

In order to eliminate the influence caused by the different dimensions and order of magnitudes of the evaluation indicators, the original data of evaluation indicators should be standardized. According to the procedure of AHP, three layers (Fig. 1) of the hierarchy model should be constructed based on the membership level among the chips, namely, the first layer was objective (O), meaning the comprehensive orders; the second layer was criterion (C), meaning four types of evaluation indicators, marked C = (c1,c2,c3,c4,) = (tasty quality, texture quality, safety quality, color quality); the third layer was project (P), meaning the five characteristic evaluation indicators, marked P = (P1, P2, P3,P4, P5) = (reducing sugar, rehydration ratio, water content, a value, L value). Secondly, an additive scale ranging from 1 to 9 was used to establish the quality evaluation judgment matrix of yellow peach chips (Table 4). Only the ratio of consistency (0.038) <0.10, the quality evaluation judgment for yellow peach chips could be viewed as reasonable and logical. The weights of characteristic evaluation indicators of yellow peach chips were 0.0429, 0.1140, 0.4816, 0.1807, and 0.1807, respectively.

The information of the synthesis scores for yellow peach chips was presented in Table 5, “sengelin” with the highest score had the best comprehensive quality, and “huangjinxiu” followed. “Goldbaby” with the lowest score had the worst quality.

In this study, AHP was applied to obtain the weights of five characteristic evaluation indicators and achieve the synthesis scores for comprehensive quality of yellow peach chips. However, the additive scale ranging from 1 to 9 was not the only scale used in the evaluation method. One of the most widely cited alternative scales was the geometric scale, which used the range (e0ɤ to e8ɤ) for the same semantic descriptions as the additive scale ranging from 1 to 9 (Ramanathan 2001). Hence, more additive scales could be applied in AHP, but a ratio characterization should be used for the purpose.

Evaluation of yellow peach chips was a complex multi-dimensional process, involving multiple criteria and factors. Multi-criteria methods could be served as useful aids for carrying out the quality evaluation. AHP has become a method used in solving various multi-criteria problems (Llamas et al. 2014), and also has been applied to numerous practical problems in the last decades.

K-means cluster (KC) and discriminate analysis (DA)

The comprehensive quality of 15 yellow peach chips were characterized as three different levels (excellent, medium and bad), according to the discrimination functions:

Where x1 was reducing sugar content, x 2 was rehydration ratio, x3 was water content, x4 was a value, x5 was L value.

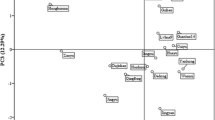

The evaluation of the yellow peach chips’ diversity within each group and their relationship was shown in Fig. 2. The group scatter plot represented the highest possible correlation between linear combination of comprehensive quality of yellow peach chips. Here, the score of the first characteristic vector (F1) and second characteristic vector (F2) for all the yellow peach chips were conducted the coordinate axis and ordinate axis, respectively. In the group scatter plot graph (Fig. 2), a wide discrimination between the comprehensive quality of yellow peach chips mainly divided by the characteristic evaluation indicators weight (Table 4).

The discriminant values of the comprehensive quality of yellow peach chips confirmed the influence of the characteristic evaluation indicators as the differentiating elements.

Montevecchi et al. (2012) proved that the quality of peach could be affected by the physico-chemical and sensory indicators, including color, sugars, weight and so on. For this reason, the method of PCA has been used to simplify the evaluation indicators. The characteristic evaluation indicators and their weights were analyzed to determine whether KC and DA could differentiate the comprehensive quality level of yellow peach chips from different cultivars. The results revealed that the characteristic evaluation indicators were able to forecast the key quality of yellow peach chips. It is important to note that, KC and DA could be used as an important analysis tool for evaluating and distinguishing the comprehensive quality of fruit or fruit products.

Conclusions

Fifteen different yellow peach cultivars were used to process chips by EPD. As expected, the evaluation indicators except SSC varied significantly among the different cultivars. PCA and AHP gave the performance of the five characteristic evaluation indicators from different yellow peach cultivars in the processed products. Based on the synthesis scores and the ranking, KC and DA was applied to establish the discrimination functions, which were used to divide three levels of comprehensive quality for yellow peach chips: The excellent cultivars for processing chips were Senggelin, Huangjinxiu and Delaifulaika; The medium cultivars were GNC 19, Goldbaby 8, Qiulu, Jinlu, Guangtao 5, Goldbaby 7, yellow fresh peach and Juhuang; the bad cultivars were Goldbaby 6, Huangguanwang, Goldbaby 5 and Goldbaby. PCA, AHP, KC and DA could be applied to simplify the quality evaluation process and improve the efficiency, which might be good analysis methods in food industry for quality control.

References

AOAC (1986) Method 986.21 Moisture in spices distillation methods. USA: offcial methods of analysis of AOAC international

Ávila IMLB, Silva CLM (1999) Modelling kinetics of thermal degradation of colour in peach puree. J Food Eng 39(2):161–166

Bi JF, Wang X, Chen QQ, Liu X, Wu XY, Wang Q, Lv J, Yang AJ (2015) Evaluation indicators of explosion puffing Fuji apple chips quality from different Chinese origins. LWT Food Sci Technol 60(2):1129–1135

Borràs E, Amigo MJ, Berg F, Boqué R, Busto O (2014) Fast and robust discrimination of almonds (Prunus amygdalus) with respect to their bitterness by using near infrared and partial least squares-discriminant analysis. Food Chem 153:15–19

Cagliero C, Bicchi C, Cordero C, Rubiolo P, Sgorbini B, Liberto E (2012) Fast headspace-enantioselective GC-mass spectrometric-multivariate statistical method for routine authentication of flavoured fruit food. Food Chem 132(2):1071–1079

Cárnara M, Díez C, Torija E (1995) Chemical characterization of pineapple juices and nectarines. Principal components analysis. Food Chem 54(1):93–100

Dadali G, Demirhan E, Özbek B (2008) Effect of drying conditions on dehydration kinetics of microwave dried spinach. Food Bioprod Process 86(4):238–241

Du LJ, Gao QH, Ji XL, Ma YJ, Xu FY, Wang M (2013) Comparison of flavonoids, phenolic acids, and antioxidant activity of explosion-puffed and sun-dried jujubes (Ziziphus jujuba Mill.). J Agric Food Chem 61(48):111840–111847

Fraige K, Pereira-Filho ER, Carrilho E (2014) Fingerprinting of anthocyanins from grapes produced in Brazil using HPLC-DAD-MS and exploratory analysis by principal component analysis. Food Chem 145(15):395–403

Génard M, Bruchon C (1992) Multivariate analysis of within-tree factors accounting for the variation of peach fruit quality. Sci Hortic 52(1–2):37–51

Gosetti F, Chiuminatto U, Mazzucco E, Mastroianni R, Marengo E (2015) Ultra-high-performance liquid chromatography/tandem high-resolution mass spectrometry analysis of sixteen red beverages containing caminic acid: identification of degradation products by using principal component analysis/discriminant analysis. Food Chem 167(15):454–462

Jia WS, Ma ZH, Lan YB, Wu WF, Wang D, Wang JH (2013) An identification of the growing area of longjing tea based on the fisher’s discriminant analysis with the combination of principal components analysis. Intell Autom Soft Co 19(4):545–553

Kallithraka S, Arvanitoyannis IS, Kefalas P, EI-Zajouli A, Soufleros E, Psarra E (2001) Instrumental and sensory analysis of Greek wines; implementation of principal component analysis (PCA) for classification according to geographical origin. Food Chem 73(4):501–514

Kara D (2009) Evaluation of trace metal concentrations in some herbs and herbal teas by principal component analysis. Food Chem 114(1):347–354

Keenan DF, Valverde J, Gormley R, Butler F, Brunto NP (2012) Selecting apple cultivars for use in ready-to-eat desserts based on multivariate analyses of physico-chemical properties. LWT-Food Sci Technol 48(2):308–315

Kingsly RP, Goyal RK, Manikantan MR, Ilyas SM (2007) Effect of pretreatments and drying air temperature on drying behaviour of peach slice. Int J Food Sci Technol 42(1):65–69

Liu FX, Fu SF, Bi XF, Chen F, Liao XJ, Hu XS, Wu JH (2013) Physico-chemical and antioxidant properties of four mango (Mangifera indica L.) cultivars in China. Food Chem 138(1):396–405

Llamas B, Mazadiego LF, Elío J, Ortega MF, Grandia F, Rincones M (2014) Systematic approach for the selection of monitoring technologies in CO2 geological storage projects. Application of multicriteria decision making. Global Nest J 16(1):36–42

Louka N, Allaf K (2002) New process for texturizing partially dehydrated biological products using controlled sudden decompression to the vacuum: application on potatoes. J Food Sci 67(8):3033–3038

Louka N, Allaf K (2004) Expansion ratio and color improvement of dried vegetables texturized by a new process “Controlled sudden decompression to the vacuum” application to potatoes, carrots and onions. J Food Eng 65(2):233–243

Louka N, Juhel F, Allaf K (2004) Quality studies on various type of partially dried vegetables texturized by Controlled sudden decompression general patterns for the variation of the expansion ratio. J Food Eng 65(2):245–253

Mard R, Debs E, Saliba R, Maroun RG, Louka N (2014) Multiple optimization of chemical and textural properties of roasted expanded purple maize using response surface methodology. J Cereal Sci 60(2):397–405

Marques LG, Prado MM, Freire JT (2009) Rehydration characteristics of freeze-dried tropical fruits. LWT-Food Sci Technol 42(7):1232–1237

Mongpraneet S, Abe T, Tsurusaki T (2002) Accelerated drying of welsh onion by far infrared radiation under vacuum conditions. J Food Eng 55(2):147–156

Montevecchi G, Simone GV, Masino F, Bignami C, Antonelli A (2012) Physical and chemical characterization of Pescabivona, a Sicilian white flesh peach cultivar [Prunus persica (L.) Batsch]. Food Res Int 45(1):123–131

Nimmol C, Devahastin S, Swasdisevi T, Sopon S (2007) Drying of banana slices using combined low-pressure superheated steam and far-infrared radiation. J Food Eng 81(3):624–633

Ramanathan R (2001) A note on the use of the analytic hierarchy process for environmental impact assessment. J Environ Manag 63(1):27–35

Rosenfeld HJ, Baardseth P, Skrede G (1997) Evaluation of carrot varieties for production of deep fried carrot chips –IV. The influence of growing environment on carrot raw material. Food Res Int 30(8):611–618

Shwartz E, Glazer I, Bar-Ya’akov I, Matityahu I, Bar-IIan I, Holland D, Amir R (2009) Changes in chemical constituents during the maturation and ripening of two commercially important pomegranate accessions. Food Chem 115(3):965–973

Stewart S, Ivy MA, Anslyn EV (2014) The use of principal component analysis and discriminant analysis in different sensing routines. R Soc Chem 43(1):70–84

Vega-Gáilvez A, Miranda M, Clavería R, Quispe I, Vergara J, Uribe E, Paez H, Di SK (2011) Effect of air temperature on drying kinetics and quality characteristics of osmo-treated jumbo squid (Dosidicus gigas). LWT-Food Sci Technol 44(1):16–23

Versari A, CAstellari M, Parpinello GP, Riponi C, Galassi S (2002) Characterisation of peach jucies obtained from cultivars Redhaven, Suncrest and Mariz Marta grown in Italy. Food Chem 76(2):181–185

Versini G, Franco MA, Moser S, Barchetti P, Manca G (2009) Characterisation of apple distillates from native varieties of Sardinia island and comparison with other Italian products. Food Chem 113(4):1176–1183

Wang J, Sheng KC (2006) Far-infrared and microwave drying of peach. LWT-Food Sci Technol 39(3):247–255

Wu BH, Quilot B, Génard M, Kervella J, Li SH (2005) Changes in sugar and organic acid concentrations during fruit maturation in peaches, P. davidiana and hybrids as analyzed by principal component analysis. Sci Hortic 103(4):429–439

Xu YY, Zhang M, Mujumdar AS, Zhou LQ, Sun JC (2004) Studies on hot air and microwave vacuum drying of wild cabbage. Dry Technol 22(9):2201–2209

Zou KJ, Teng JW, Li H, Dai XW, Wei BY (2013) Effect of osmotic pretreatment on quality of mango chips by explosion puffing drying. LWT-Food Sci Technol 55(1):253–259

Author information

Authors and Affiliations

Corresponding author

Additional information

Research highlights

• Yellow peach chips were prepared by explosion puffing drying technology.

• The characteristic indicators and the weights were obtain by PCA and AHP.

• Discrimination functions were established by KC and DA.

• The best cultivars for processing yellow peach chips were selected.

Rights and permissions

About this article

Cite this article

Lyu, J., Zhou, Ly., Bi, Jf. et al. Quality evaluation of yellow peach chips prepared by explosion puffing drying. J Food Sci Technol 52, 8204–8211 (2015). https://doi.org/10.1007/s13197-015-1906-0

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-015-1906-0