Abstract

The dependence of sulfide capacity on the oxygen partial pressure for slags containing multivalent species was investigated experimentally using a slag containing vanadium oxide. Copper–slag equilibration experiments were carried out at 1873 K (1600 °C) in the approximate oxygen partial pressure range 10−15.4 to 10−9 atm. The sulfide capacity was found to be strongly dependent on the oxygen potential in this slag system, increasing with the oxygen partial pressure. The sulfide capacity changed by more than two orders of magnitude over the oxygen partial pressure range. The effect of changing oxygen partial pressure was found to be much greater than the effect of changing slag composition at a fixed oxygen partial pressure.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Sulfur removal has been an important research topic for metallurgists for many decades, since precise control of sulfur in steel is essential. A substantial amount of work has been carried out to understand the behavior of sulfur in slags in order to improve desulfurization. Richardson and Fincham introduced the sulfide capacity concept, which enabled the direct comparison of the desulfurization abilities of different slags.[1,2] They found that the sulfide capacity was only dependent on slag composition and temperature, but independent of oxygen and sulfur potentials over some ranges. Since its inception, the sulfide capacity concept has been widely adopted by both industry and academia. An impressive amount of work has been conducted measuring sulfide capacities for many different slag systems (it would be a huge task to include all references here). Recently Kang and Pelton compiled a database of sulfide capacities for systems including the oxides Al2O3, CaO, FeO, Fe2O3, MgO, MnO, SiO2, and TiO x .[3] Several models have also been developed based on the experimental data for the estimation of sulfide capacities.[4]

The sulfide capacity can be derived according to the following gas–ion exchange reaction between sulfur gas and free oxygen ions in the slag:

On the basis of reaction [1], the sulfide capacity is defined as

where (pct S) is the concentration of sulfur in the slag in mass pct, \( p_{{O_{2} }} \) and \( p_{{S_{2} }} \) the partial pressures of oxygen and sulfur, \( a_{{{\text{O}}^{2 - } }} \) the activity of oxygen ions, and \( f_{{{\text{S}}^{2 - } }} \) is the activity coefficient for sulfide ions, and K (1) is the equilibrium constant of reaction [1].

Two main techniques have historically been used to determine the sulfide capacities of slags, gas-slag equilibrium, and slag-metal equilibrium.[1,2,4–33] In both techniques, the oxygen and sulfur potentials are either controlled or measured.

Note that the precondition for using the sulfide capacity is the assumption that \( a_{{{\text{O}}^{ 2- } }} \) and \( f_{{{\text{S}}^{ 2- } }} \) are constant for a specific slag composition, meaning that the sulfide capacity is independent of oxygen and sulfur potentials. Richardson and Fincham found that the sulfide capacity was only a function of temperature and slag composition for some slags systems in the oxygen and sulfur potential ranges relevant to ironmaking and steelmaking.[1,2] It is reasonable that this would be the case as long as the oxide components in the slag does not react with the gas phase, viz. the structure of the slag does not vary with the oxygen and sulfur potentials.

A number of measurements have been performed for slags containing multivalent elements such as Cr and Fe[1,3,4,7–33] Even one of the present authors has made this kind of measurements for iron oxide-containing systems.[7,8] These elements can adopt different valence states in the slag depending on the oxygen potential in the system. It is common knowledge that different valences of the species can coexist in the slag.[34–54] For example the ratio of Fe2+/Fe3+ in a slag containing iron oxide is a function of oxygen potential.[40–43] The variation of Fe2+/Fe3+ in turn would have great impact on the slag structure, since the ionic oxide solution must keep electronic balance. In other words, \( a_{{{\text{O}}^{ 2- } }} \)in the slags containing multivalent species such as Cr and Fe would depend on the oxygen potential. Unfortunately, no study has been carried out to examine whether the effect of oxygen potential on the sulfide capacities in this type of slag is negligible. Since the laboratory measurements very often use oxygen partial pressures substantially different from the industrial conditions, an investigation to clarify this situation is needed.

The purpose of the present study is to investigate the effect of oxygen potential on the sulfide capacity when the slag contains multivalent species. Since preliminary efforts have revealed the difficulties in obtaining comparable slag compositions at different oxygen potentials for some slag systems, e.g., containing iron oxide, slags containing vanadium oxide is adopted.

Experimental

A detailed description of the experimental setup and method has already been given in an earlier publication.[5] Only a brief description of the experimental setup is given here. A schematic picture of the experimental setup is given in Figure 1. The setup consisted of a resistance furnace in combination with an alumina reaction tube directly connected to the water cooled quenching chamber. The furnace temperature was set and maintained by a PID controller using an optical pyrometer. A Type B (6 and 30 pct Rh) thermocouple was located internally of the reaction tube with the tip just below the samples, for precise control of the equilibration temperature. The gas mixture was precisely controlled by mixing pure gases of CO (99.999 pct) and CO2 (99.7 pct) at fixed ratios. The gases were thoroughly mixed in a gas mixer made of stainless steel containing small silica beads prior to entering the reaction tube.

Copper and slag were equilibrated in molybdenum crucibles under controlled oxygen potential. The Al2O3-CaO-SiO2-“V2O3” system was used for the study. The compositions were selected based on a previously published work on the vanadium solubility in slags, in order to ensure a completely liquid slag.[55,56] Three initial slag compositions were used, named as slag A, B, and C. The sulfur was added to the system by doping the copper phase with Cu2S. A complete list of the materials used is given in Table I. To investigate the effect of oxygen pressure on sulfide capacity a large range of oxygen pressures were used. The oxygen partial pressure was varied in the approximate range 10−15.4 to 10−9 atm. At the higher oxygen pressures, the CO-CO2 equilibrium can be employed according to the following reaction:[57]

The desired oxygen pressure was imposed on the system using a mixture of high-purity CO and CO2 gas. The upper limit of the oxygen pressure range was chosen in order to avoid oxidation of the Mo crucible.

At the experimental temperature, 1873 K (1600 °C), a very high ratio of CO/CO2 would be required in order to achieve very low oxygen pressure. This is not experimentally practical for precisely controlling the oxygen partial pressure. To avoid experimental uncertainties, the C-CO equilibrium was used to impose the lower oxygen pressure according to reaction [5].[57]

The oxygen partial pressure was controlled using a graphite sample container in combination with high-purity CO gas. The total gas flow rate was kept low, 0.1 l min−1, for all measurements.

Experimental Procedure

The samples were prepared in a similar manner. Copper and Cu2S were mixed thoroughly and put in the bottom of the molybdenum sample crucible. The slag was mixed from the individual oxides Al2O3, CaO, SiO2, and V2O3 and put on top. In each crucible, 5 g of Cu and 10 g of slag were used. The oxides were calcined prior to the mixing at 1173 K (900 °C) for 10 hours, except for V2O3. The samples were placed in a holding crucible of either molybdenum or graphite. When the graphite holding crucible was used, an Al2O3 spacer was placed in between the working crucible and the holding container. The container was placed in the furnace and lowered to the hot zone. The reaction chamber was completely sealed and evacuated for at least 30 min before refilling with CO gas or a CO-CO2 gas mixture. The furnace was ramped up with a heating rate of 1.5 to 2 K min−1 to the equilibration temperature, 1873 K (1600 °C), and held for 24 hours. The sample container was then quickly raised to the quenching chamber, and a high flow of quenching gas (Ar) was introduced directly under the sample container. This procedure took less than 3 seconds. Great care was taken to completely separate the copper and slag from each other and the crucible walls prior sending the samples for analysis.

Chemical Analysis

The copper and slag samples were analyzed for their sulfur contents by combustion method using a LECO CS–600. The relative uncertainty with this method was ±5 pct. The slag composition after equilibration was analyzed by X–ray fluorescence (XRF). The relative uncertainty of this method is ±5 pct.

Results

The results along with the experimental conditions are summarized in Table II. The compositions given are the analyzed values subsequent to the experiments. The slag compositions have been normalized. Slag was equilibrated with copper under different oxygen potentials at 1873 K (1600 °C). The samples were kept for 24 hours in molybdenum crucibles. An 93 pct CO-7 pct CO2 mixture was used to set the oxygen pressure at 9.7 × 10−10 atm, and an 99.5 pct CO-0.5 pct CO2 gas mixture was used to set the oxygen pressure at 4.3 × 10−12 atm. In these cases, a Mo sample holder was used. A graphite sample holder was used in combination with high-purity CO gas at 1 atm to set the oxygen partial pressure to 4.6 × 10−16 atm. Note that the vanadium content is expressed as V2O3 in Table II since this is the reference material used for the analysis. In the real case, it is likely that several valences of vanadium will coexist. No efforts were made to determine the different vanadium ions present, or their fractions in this work. The sulfur contents given for the copper and slag are the directly analyzed values. The calculated sulfide capacities based on the experimental results are also included in the table.

Discussion

The concept of sulfide capacity, C S, was introduced by Richardson and Fincham, which is a measurement of a slag’s ability to hold sulfur.[1,2] Because of its simplicity and practical importance in ironmaking and steelmaking, the concept of sulfide capacity has been widely used. A huge amount of measurements has been conducted for a large variety of slag systems.

As a pioneer work, Richardson and Fincham found that in the slag systems CaO-Al2O3, CaO-SiO2, and CaO-Al2O3-SiO2, C S did not depend on oxygen and sulfur partial pressures below approximately \( p_{{O_{2} }} = 10^{ - 6} \) atm (SO4 2− are formed at higher oxygen pressures).[1] This is of great convenience, especially for the experimentalist since it gives a large freedom when designing experiments. Additionally, measurements only have to be performed under one controlled atmosphere since C S can be used in calculations over a large range of oxygen partial pressures. The assumption that C S is independent of oxygen potential has been widely adopted. As a result, C S measurements have been performed over a wide range of oxygen pressures (approximately 10−14 to 10−6 atm.).[3,4,7–33] In the case of gas-slag equilibrium studies, very often an oxygen partial pressure of around 10−7 atm is employed.

As indicated by Eq. [2], the precondition for using the sulfide capacity is that the term \( a_{{{\text{O}}^{2 - } }} /f_{{{\text{S}}^{2 - } }} \) is independent of oxygen and sulfur potentials, for a specific slag at constant temperature. If the sulfur concentration in the slag is low, the activity coefficient\( f_{{{\text{S}}^{2 - } }} \) is expected to be nearly constant. Unless the sulfur potential is greatly increased, this assumption of constant \( f_{{{\text{S}}^{2 - } }} \) will hold. In the case of so called pseudo-binary (e.g., CaO-Al2O3, CaO-SiO2), pseudo-ternary (e.g., CaO-Al2O3-SiO2), and even other pseudo-higher order systems, where all the cations have only single valence, like Ca2+, Al3+, and Mg2+, the dependence of \( a_{{{\text{O}}^{2 - } }} \) on the oxygen potential could be considered negligible for a certain oxygen potential range. Below a certain oxygen partial pressure, one or several of the oxides would be reduced. Under such conditions, the sulfide capacity cannot be applied. Since most of the oxide components (like CaO, Al2O3, MgO, and SiO2) are stable under the oxygen potentials prevailing in the steelmaking reactors, the use of sulfide capacities is very successful, C S being constant over large ranges of oxygen and sulfur potentials.

However, the assumption of \( a_{{{\text{O}}^{2 - } }} /f_{{{\text{S}}^{2 - } }} \)being independent of oxygen potential may not be applicable for all slag systems. If a slag contains multivalent elements such as Fe, Cr, and V the situation is different. These elements can adopt several valence states in the slag, depending on the oxygen potential. For example, in the case of slags containing vanadium oxide, the presence of V2+, V3+, V4+, and V5+ have been reported.[34–39] Several of these valences can coexist in the slag.[34–39] Thus when a multivalent element is present in the slag, another degree of freedom is introduced to the system. This since the fraction of the valences will vary with the oxygen potential. It is very likely that this will also affect the \( a_{{{\text{O}}^{2 - } }} \) in the slag.

To elaborate this discussion, a silicate-slag containing vanadium oxide (e.g., the slag studied in the present work) is taken as an example. At a low oxygen pressure, the majority of vanadium is present at a low valence state, e.g., V2+. When the oxygen pressure is increased the vanadium will adopt higher valence states. If the oxygen pressure is increased substantially, the majority of vanadium will instead be present at higher valence states e.g., V5+. Consequently the slag structure will change to compensate for the higher charge of V ions, in order for the slag to retain electronic neutrality. This can happen either by the breakage of the Si-O bonds which increases the amount of non-bridging oxygen (O−), or by the dissolution of O2−. Both of these two mechanisms could occur, depending on the nature of the slag. This structural change will also affect the \( a_{{{\text{O}}^{2 - } }} \), especially if considerable amounts O2− are dissolved. When \( a_{{{\text{O}}^{2 - } }} \) varies, the assumption that \( f_{{{\text{S}}^{2 - } }} \) is constant may not be true anymore. It is thus very likely that the value of \( a_{{{\text{O}}^{2 - } }} /f_{{{\text{S}}^{2 - } }} \) in this case will be dependent on the oxygen potential. As seen in Eq. [2], this would also affect the C S. This means that the assumption that C S is independent of oxygen and sulfur potentials may not hold for slags containing multivalent species.

Experimental Observations

If the activity of sulfur in the metal is known, the corresponding sulfur partial pressure can be calculated.[57]

The equilibrium constant for reaction [8] can be expressed with the activity of sulfur in the infinitely dilute standard state and 1 mass pct as reference as

where \( a_{{\underline{\text{S}}_{\text{Cu}} }} \) is the activity of sulfur dissolved in copper, \( f_{{\underline{\text{S}}_{\text{Cu}} }} \) is the activity coefficient of sulfur, and \( \left[ {{\text{mass}}\,{\text{pct}}\,S} \right]_{\text{Cu}} \) is the concentration of sulfur in copper. The activity coefficient data for sulfur dissolved in liquid copper was calculated by extrapolating data from Sigworth and Elliott to the experimental temperature.[58]

The sulfide capacity was calculated by combining Eq. [2] with Eq. [9] which yields the following expression:

Prior to discussing the experimental findings, the authors would like to briefly discuss the conditions of the equilibrium with respect to reproducibility. Some crystals of vanadium sulfides were formed during the experiments and was found as a thin layer (<300 µm) in the copper near the copper-slag interface. The formation was found to increase with the vanadium content and with decreasing oxygen potential. Great care was taken to remove this layer before analyzing the copper. It is possible that a tiny fraction of sulfide was located in the bulk of the sample and could not be removed prior to the analysis. However, this would only affect the values of C S slightly and would not change the order of magnitude and therefore affect the present discussion. To check the reproducibility, a repeating run was made for one of the samples with identical conditions. It can be seen by comparing SV-9 and SV-10 that the results are satisfactorily reproducible. The difference in C S values could be due to the experimental uncertainties, involving the vanadium sulfides.

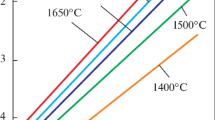

The experimental results shows a clear trend that C S changes with the oxygen partial pressure. When the pressure is increased from 4.6×10−16 to 9.7×10−10 atm, C S is increased by more than two orders of magnitude. This is the case for all the slag compositions. To help the discussion, the logC S is plotted against the log\( p_{{{\text{O}}_{2} }} \) in Figure 2. The substantial increase of C S with oxygen pressure is evidently seen. It can also be seen that the change of C S due to the change of oxygen partial pressure is much greater than the effect of slag composition at a fixed oxygen partial pressure. It is also worthwhile to point out that the sulfur concentration in the slag changes very little with the change of oxygen partial pressure (see Table II). If C S would be constant in this slag system, the concentration of sulfur would change much greater with the oxygen potential than seen in the present work.

The main purpose of the present study was not to report C S values for the present slag system, but to illustrate the effect of oxygen potential when the slag contain multivalent elements. Therefore, the valences of vanadium in the present slags were not analyzed as would be required for a more accurate study. In a previous work, the valences of vanadium was determined for a similar slag at \( p_{{{\text{O}}_{2} }} \approx \)10−12. The majority of vanadium presented as V3+ and V4+.[35] It is expected that in the present slags these species would be dominating as well. Since these species were not determined precisely, the sulfide capacity values reported in Table II need to be used with caution.

Theoretical Consideration

The principles discussed above would also apply for other multivalent elements in the slag. One would expect that C S of slags containing oxides of e.g., Cr, Fe, Ti, etc., would behave similarly. Slags containing these elements are more commonly found in steelmaking slags, especially Cr and Fe. Due to the experimental difficulties (see later discussion), it was impossible to get reliable experimental results for slags containing these elements for comparison. It is expected that the oxygen potential would have great impact on the fractions of e.g., Cr2+, Cr3+, Fe2+, and Fe3+, and consequently C S. Unfortunately, many of the publications[1,2,7–33] including the ones with one of the present authors did not take up such a discussion. It should be noted that in general there is a large difference in the oxygen potential between that is used in the laboratory studies and that is commonly involved in the industrial processes. The activity of dissolved oxygen in the ladle is typically 1-5 ppm [corresponding to \( p_{{{\text{O}}_{2} }} \) about 10−15 to 10−13.5 atm at 1873 K (1600 °C)], and around 1000 ppm in the converter (corresponding to \( p_{{O_{2} }} \) about 10−9 atm at 1873 K (1600 °C)). This can be compared to oxygen partial pressures about 10−11 to 10−5 atm that have been used in the C S measurements of these systems.[7–33]

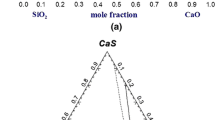

A thermodynamical calculation will help in elaborating the present discussion. A CaO (27 mass pct)-SiO2 (40 mass pct)-FeO-Fe2O3 slag containing 0.1 mass pct sulfur was chosen for the calculation. This slag composition remains liquid over the whole oxygen pressure range of interest and is related to some of the earlier data by one of the present authors for “FeO” containing systems.[8] The calculation was performed using the Thermo-Calc software[59] and the Fe-containing Slag Database.[60] The calculation was made at 1873 K (1600 °C), and the result is shown in Figure 3 where the fraction of Fe2+/Fe3+ is plotted against the oxygen partial pressure. It can be seen that the fraction of Fe2+/Fe3+ varies substantially with the oxygen partial pressure, especially at the lower oxygen pressure side. This indicates that C S in this slag would also be a function of the oxygen potential. This supports the present reasoning that the C S of slags containing multivalent elements cannot be assumed to be independent of oxygen potential.

As is revealed by the present study, C S is dependent on the oxygen partial pressure when the slag contains multivalent species. The extent of the variation with oxygen partial pressure will be dependent on the specific multivalent element and the overall nature of the slag. As seen in the experimental part, in the vanadium oxide-containing slag the variation of C S was substantial. The available data for systems containing chromium oxide, iron oxide, and titanium oxide needs to be used with great caution. The value of C S may only be true under the same conditions as were used in the laboratory measurements.

It should be mentioned that a serious attempt was made to study the iron oxide-containing slag. However, it was not possible to obtain reliable results. The experimental difficulties involved finding a suitable crucible material that could hold both slag and metal over a wide range of oxygen pressures, and the severe attack of iron oxide on the oxide crucibles. Instead, the vanadium oxide-containing system was found to be suitable for the present study, where reliable results could be obtained.

Summary

The dependence of the sulfide capacity on the oxygen potential was investigated experimentally for slags containing multivalent elements. Copper-slag equilibrium measurements were carried out with a slag containing vanadium oxide at 1873 K (1600 °C) over the approximate oxygen range 10−15.4 to 10−9 atm. It was found that the sulfide capacity was strongly dependent on the oxygen partial pressure in this slag system, increasing with the oxygen partial pressure. The capacity changed by more than two orders of magnitude over the oxygen pressure range. The change of C S with oxygen partial pressure was also found to be much greater than the effect of slag composition at a fixed oxygen partial pressure.

The dependence of the sulfide capacity on the oxygen potential is explained by the fact that multivalent elements can adopt several valence states in the slag. When the oxygen partial pressure is altered, the fraction of the valences will also change. Since the slag needs to retain electrical neutrality, the slag structure also needs to be altered. It is very likely that this will also affect \( a_{{{\text{O}}^{2 - } }} \). The general assumption regarding the sulfide capacity has been that it is independent of oxygen potential. The experimental results shows that this is not the case when the slag contains multivalent elements. The earlier data for systems containing multivalent elements must therefore be used with caution.

References

FD Richardson and CJB Fincham: J. Iron Steel Inst., 1954, 178: 4–15.

F.D. Richardson: Physical Chemistry of Melts in Metallurgy, vol 2, Academic Press, London, 1974 p. 293.

Y.-B. Kang and A.D. Pelton: Metall. Trans. B, 2009, vol. 40B, pp. 979-94.

H. Gaye and J. Lehmann: Slag Atlas 2nd Ed., Verlag Stahleisen GmbH, Düsseldorf, 1995, pp. 258-267.

C. Allertz and D. Sichen: Metall. Trans. B, 2015, vol. 46B, pp. 2609–15.

M. Ohta, T. Kubo and K. Morita: Tetsu–to–Hagané, 2003, 89: 742–49.

M.M. Nzotta, D. Sichen and S. Seetharaman: ISIJ Int., 1999, vol. 39, pp. 657–663.

M.M. Nzotta, D. Sichen and S. Seetharaman: Metall. Trans. B, 1999, vol. 30B, pp. 909–20.

S.D. Brown, R.J. Roxburgh, I. Ghita, H.B. Bell: Ironmak. Steelmak., 1982, vol. 9, pp. 163-67.

S. R. Simeonov, R. Sridhar, J.M. Toguri: Metall. Mater. Trans. B, 1995, vol. 26B, pp. 325-34.

K. Kärsrud: Scand. J. Metall., 1984, vol.13, pp. 173-75.

K. Kärsrud: Scand. J. Metall., 1984, vol.13, pp. 265-68.

A. Bronson and G.R. ST. Pierre, Metall. Trans. B, 1981, 12B: 729-731.

I. Ghita and H.B. Bell: Ironmak. Steelmak., 1982, vol. 9, pp.239-43.

T.P. Floridis: Metall. Trans. B, 1978, vol. 9B, pp.319-20.

J.-D. Seo and S.-H. Kim: Steel Res., 1999, vol. 70, pp. 203-08.

HSC O’Neill and J.A. Mavrogenes: J. Petrol., 2002, 43: 1049-87.

[18] E. Drakaliysky, N.S. Srinivasan and L.-I. Staffansson: Scand. J. Metall., 1991, vol. 20, pp. 251–55.

L. Wang and S. Seetharaman: Metall. Trans. B, 2010, vol. 41B, pp. 367–73.

M. Chapman, O. Ostrovski, G. Tranell, and S. Jahanshahi: Elektrometallurgiya, 2000, 3: 34-39.

M. Ito, K. Morita, and N. Sano: Metall. Trans. B, 1997, vol. 37B, pp. 839-43.

J.-D. Shim and S. Ban-Ya: Tetsu-to-Hagané, 1982, vol. 68, pp. 251-60

S. Ban-Ya, M. Hino, A. Sato, and O. Terayama: Tetsu-to-Hagané, 1991, vol. 77, pp. 361-80.

A. Shankar, M. Görnerup, S. Seetharaman, and A.K. Lahiri: Metall. Trans. B, 2006, vol. 37B, pp. 941-47.

T. Xin and X. Chushao: ISIJ Int., 1995, vol. 35, pp. 367-371.

[26] J. Zhang, X. Lv, Z. Yan, Y. Qin, and C. Bai: Ironmaking and Steelmaking, 2015, DOI: 10.1080/03019233.2015.1104070

K.D. Kim, W.W. Huh, and D.J. Min: Metall. Trans. B, 2014, vol. 45B, pp. 889-96.

C. Wang, Q. Lu, S. Zhang, and F. Li: J. Univ. Sci. Tehnol. Beijing, 2006, vol. 13, pp. 213-217.

T.G. Kim, W.K. Lee, J.H. Park, D.J. Min, H.S. Song: ISIJ Int., 2001, vol. 41, pp. 1460-64

M. Ito, K. Morita, and N. Sano: ISIJ Int., 1997, vol. 37, pp. 839-43.

M. Ohta and K. Morita: ISIJ Int., 1999, vol. 39, pp. 1231-38.

I.P. Rachev, F. Tsukihashi, and N. Sano: Metall. Trans. B, 1992, vol. 23, pp. 175-81.

R. Nagabayashi, M. Hino, S. Ban-Ya: Tetsu-to-Hagané, 1990, vol. 76, pp. 183-190.

B. Yan and J. Zhang: Steel Res. Int., 2010, vol. 81, pp. 742-48.

H. Wang, F. Li and D. Sichen: Metall. Mater. Trans. B, 42B: 9–12.

H. Farah, M.P. Brungs, D.J. Miller, G.R. Belton: Phy. Chem. Glasses, 1998, vol. 39, pp. 318-22.

H. Farah: J. Mater. Sci., 2003, vol. 38, pp. 727-37.

H. Farah and M. Brungs: J. Mater. Sci., 2003, vol. 38, pp. 1885–94.

R. Mittelstädt and K. Schwerdtfeger: Metall. Trans. B, 1990, vol. 21B, pp. 111–20.

L. Yang and G.R. Belton: Metall. Trans. B, 1998, vol. 29B, pp. 837–45.

S. Jahanshahi and S. Wright: ISIJ Int., 1993, vol. 33, pp. 195-203.

A.J. du Toit, P. Gaylard, S. Jahanshahi and J. Nell: Min. Eng., 2006, vol. 19, pp. 212-18.

B.O. Mysen, D. Virgo, E.-R. Neumann and F.A. Seifert: Am. Mineral, 1985, vol. 70, pp. 317-31.

A.-M. Mirzayousef-Jadid and K. Schwerdtfeger: Metall. Mater. Trans. B., 2009, vol. 40, pp. 533-43.

AJ Berry and HSC O’Neill: Am. Mineral., 2004, vol. 89, pp. 790-98.

AJ Berry, HSC O’Neill, DR Scott, GJ Foran and JMG Shelley: Am. Mineral., 2006, vol. 91, pp. 1901-08.

K. Morita, M. Mori, M. Guo, T. Ikagawa, and N. Sano: Steel Res. Int., 1999, vol. 70, pp. 319-24.

L. Wang and S. Seetharaman: Metall. Trans. B, 2010, vol. 41B, pp. 946-54.

S.M. Jung and R.J. Fruehan: ISIJ Int., 2001, vol. 41, pp. 1447-53.

C. Aryio, P. Gonzales and L. Holappa: Steel Res. Int., 2005, vol. 76, pp. 284-87.

G. Tranell, O. Ostrovski and S. Jahanshahi: Metall. Trans. B, 2002, vol. 33, pp. 61-67.

Y. Morizane, B. Ozturk and R.J. Fruehan: Metall. Trans. B, 1999, vol. 30, pp. 29-34.

A.-M. Mirzayousef-Jadid, K. Schwerdtfeger: Metall. Trans. B, 2010, vol. 41, pp. 1038-41.

F. Tsukihashi, A. Tagaya and N. Sano: Trans. ISIJ, 1998, vol. 28, pp. 164-71.

M. Lindwall, J. Gran and D. Sichen: CALPHAD, 2014, vol. 47, pp. 50–55.

M. Lindwall and D. Sichen: Metall. Trans. B, 2015, vol. 46B, pp. 733–40.

ET. Turkdogan: Physical Chemistry of High Temperature Technology, 7th ed., Academic Press, New York, 1980, pp. 7, 81.

G.K. Sigworth and J.F. Elliott: Can. Metall. Q., 1974, vol. 13, 99. 455–61.

J.O. Andersson, T. Helander, L. Höglund, P.F. Shi and B. Sundman. Calphad, 2002, vol. 26, pp. 273-312.

Thermo-Calc Software Database Fe-containing Slag Database v3.2 (accessed 17 Apr 2016). Thermo-Calc Software AB, Stockholm, Sweden.

Acknowledgments

The authors are thankful to Professor Mats Hillert for his comments and interest in this work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted February 23, 2016.

Rights and permissions

About this article

Cite this article

Allertz, C., Selleby, M. & Sichen, D. The Effect of Oxygen Potential on the Sulfide Capacity for Slags Containing Multivalent Species. Metall Mater Trans B 47, 3039–3045 (2016). https://doi.org/10.1007/s11663-016-0725-7

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-016-0725-7