Abstract

This work investigated the effects of the addition of different concentrations (0–3.0 wt%) of β-cyclodextrin (β-CD) on the properties of wheat dough and prebaked bread. Dough tensile test results and scanning electron microscopy revealed that the addition of 0.5–1.5 wt% β-CD enhanced dough tensile strength and promoted gluten formation. The addition of 2.0–3.0 wt% β-CD, however, failed to improve gluten network formation. Fourier transform infrared spectroscopy showed that the α-helix-to-β-sheet ratios of dough samples increased as β-CD content increased. This result indicated that the protein secondary structure of the dough had changed. Fermentation rheometry illustrated that dough fermentation height, gas production volume, and gas-holding capacity increased with the addition of 0–1.5 wt% β-CD. Dough fermentation capacity decreased when the addition of β-CD exceeded 2.0 wt%. The effect of β-CD on the quality of prebaked frozen bread was also studied. The results of texture profile analysis indicated that the addition of 1.5 wt% β-CD could reduce bread hardness and increase bread crumb elasticity and resilience. The results of the C-cell test further demonstrated that the addition of 1.5 wt% β-CD could increase stomatal number and decrease pore number and pore wall thickness. These characteristics suggested that the addition of β-CD improved bread structure.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Baked goods, such as bread, are important products of the food industry. Traditional bread factories produce and transport large quantities of baked bread to stores for sale. During transport, however, bread aging causes bread quality to deteriorate and prevents bread from being consumed fresh [1]. The development of freezing technology has enabled the production of prebaked frozen bread, which could meet the increasing consumer demand for freshly baked products. The main processes of prebaked bread preparation include flour blending, fermentation, par-baking, frozen storage, thawing, and rebaking [2]. In contrast to dough freezing, prebaking improves the volume and quality of prebaked frozen bread by preventing yeast populations in the dough from declining during postfreezing fermentation [1]. Nevertheless, the quality markers of prebaked bread, such as specific volume and hardness, are worse than those of fresh bread given the complexity of prebaked bread production.

Researchers have begun to explore related methods for improving prebaked bread quality. Some have attempted to improve prebaked bread quality by optimizing process parameters, including baking time, frozen storage time, frozen storage temperature, and steam volume. These researchers, however, provided differing results because they investigated different products [2, 3]. Studies have also focused on the use of additives to improve the quality of prebaked bread. For example, the addition of glucolipase, hemicellulase, and hexose oxidase influenced the proofing time, crumb firmness, oven spring, shape, cut opening, and cut height of frozen prebaked French bread [4]. Bread antiaging is a perennial hot topic in food technology research. Bárcenas [5] found that the addition of ɑ-amylase, sourdough, κ-carrageenan, and hydroxypropyl methyl cellulose could retard the staling of prebaked frozen bread by decreasing the retrogradation enthalpy of amylopectin. Bread additives, particularly additives based on enzyme preparations, are highly unstable during high-temperature baking processes. Prebaked bread processing involves two high-temperature baking stages and frozen storage. Thus, identifying a thermostable additive that can improve the quality of prebaked bread remains challenging.

β-cyclodextrin (β-CD), a cyclic oligosaccharide that contains seven α-1,4-linked glycopyranose units, is synthesized through the action of cyclodextrin glucosyltransferase on starch [6, 7]. Its special physical and chemical properties can be attributed to its unique structure, which comprises a hydrophobic cavity and an external hydrophilic shell [8, 9]. β-CD and its inclusion complexes are widely used in the food industry given their antiheight, antioxidant, antilight, and antithermal decomposition activities [10, 11]. For example, β-CD has been used to remove polyphenol oxidase from fruit juice, to retain aroma-related compounds in food matrices during thermal processing, and to improve the taste of milk casein hydrolysate [10, 11]. The antiaging effect of β-CD extends the storage period of traditional baked bread and may originate from the formation of a helical amylose–lipid–β-CD/ complex [12]. Nevertheless, the effects of different β-CD concentrations on dough rheological properties and gluten formation during prebaked bread production remain unknown.

Prebaked bread quality is mainly determined by dough quality. Previous works have mainly focused on observing the effect of additives on the quality of common bread products, and few have investigated the effects of β-CD on the dough quality and structures of prebaked bread. In this study, the effects of β-CD on dough tensile properties, gluten network formation, protein secondary structure, dough fermentation ability, bread texture, specific volume, and slice structure were investigated. This study aimed to determine the optimal β-CD content for improving prebaked bread quality and the specific mechanism underlying the effect of β-CD on dough quality.

Materials and Methods

Materials

Durum wheat flour (Xinmai-26, Henan Province, China) with a moisture content, protein content, and flour yield of 11.5%, 11.88%, and 68.6% (wet basis), respectively, were used to prepare dough samples. High-activity dry bread yeast was purchased from Angel Yeast Co., Ltd., and β-CD was procured from Seebio Biochemical, Inc., Shanghai, China.

Dough Tensile Test

Dough tensile resistance and elongation were measured by using a Brabender farinograph and extensograph (Brabender GmbH & Co. KG, Germany). Durum wheat flour was mixed evenly with different concentrations (0–3.0 wt%) of β-CD. Flour with a moisture content of 11.5% (wet basis) and mass of 291.5 g was added to the Brabender farinograph. The amount of flour added to the Brabender farinograph was determined on the basis of the moisture content of the flour–β-CD mixture. Then, the flour–β-CD mixture containing 6 g of salt was mixed for 5 min with water until the flour consistency was 500 Brabender units. Data at the time of 135 min were taken as the final test result. Each group was tested three times in parallel. Data were presented as the average of three tests.

Scanning Electron Microscopy

Samples were prepared for scanning electron microscopy (SEM) observation through a previously reported method with slight modifications [13]. Dough samples were fixed for 24 h with 3.5% glutaraldehyde; eluted with 30%, 50%, 70%, and 100% acetone for 20 min per elution; and volatilized at room temperature. The samples were sliced after freeze-drying. The morphological characteristics of the samples were then observed under SEM (S-3000 N) under 500 × magnification.

Protein Secondary Structure Determination

Protein secondary structures were determined through Fourier transform infrared spectroscopy (FTIR). The FTIR procedure used in this study was based on a previously used procedure with slight modifications [14]. Dough samples containing different concentrations (0–3.0 wt%) of β-CD were subject to the tensile test. Freeze-dried dough samples were crushed into powder by a crusher, passed through a 160 mesh screen, and mixed with KBr at the ratio of 100:1 w/w. The samples were then pressed and subjected to FTIR over the spectral range of 400–4000 cm−1 with 32 scanning times. Spectral data were analyzed using Peakfit software.

Fermentation Rheometer Test

A fermentation rheometer (Chopin Technologies, France) was used to test the effects of different β-CD contents on dough fermentation height, gas production, and gas volume retention. Durum wheat flour was first evenly mixed with different concentrations (0–3.0 wt%) of β-CD. Then, 250 g of the flour–β-CD mixtures, 5 g of yeast, and 6 g of salt were added to ALVEO (Chopin Technologies, France). The dry ingredients were then mixed with water for 8 min. The amount of water added to the mixture was selected in accordance with the results provided by a Chopin fermentation rheometer. Finally, 315 g of dough was placed in the fermentation rheometer and fermented for 180 min at 28.5 °C [15].

Prebaked Bread Preparation

The breadmaking procedure was optimized in reference to a previous study [16]. The basic bread formula consisted of 1000 g of wheat flour, 0.5% w/w dry yeast, 1.6% w/w salt, 8% w/w butter, and 6% w/w sugar. Sufficient water was added to the dry ingredients to achieve the maximum dough consistency of 500 Brabender units. Ice was used to maintain the initial water temperature at 8 °C–9 °C. Flour, yeast, and sugar were first mixed evenly in a flour mixer. Water was then added to the dry ingredients. The dough was subsequently stirred for 5 min prior to the addition of different β-CD concentrations. Butter was added to the dough after 2 min of mixing. The dough was stirred until the gluten network had formed. Finally, salt was added to the dough after the complete formation of the gluten network. The dough was divided into pieces with weights of 80 g, rested for 20 min at room temperature, and kneaded. The dough was fermented for 60 min at 30 °C under 85% RH and subjected to another cycle of resting and reshaping. Next, the dough was allowed to ferment for 60 min. The fermented dough was baked for 10 min at the top temperature of 210 °C and bottom temperature of 180 °C with vapor injection during the first 5 s. The bread samples were removed from the oven after baking and cooled for 1 h at room temperature, placed in a freezer for 40 min (−35 °C), transferred to a refrigerator for 3 days at −18 °C, and removed from the refrigerator and thawed for 20 min at 30 °C under 85% RH. Frozen bread samples were rebaked for 10 min at the top temperature of 210 °C and bottom temperature of 180 °C.

Texture Profile Analysis

Rebaked bread samples were cut into 20 mm × 20 mm × 20 mm pieces and placed under a P/100 probe (TA. XT plus, Stable Micro Systems). Texture profile analysis was conducted with the pretest rate of 1.0 mm/s, test rate of 3.0 mm/s, trigger force of 5 g, compression degree of 50%, and two-compression intervals of 5 s. Each sample was tested three times, and the average of three measurements was taken. Each group of samples was tested six times in parallel [12].

Specific Volume Test

The weight and specific volume of bread were measured with a food volume analyzer (BVW-L370, Perten). Each sample was tested three times, and the average of three measurements was taken. Each group of samples was tested six times in parallel.

C-Cell Test

Prebaked bread samples were cooled for 2 h after rebaking. Slices with thicknesses of 12 mm were collected from the centers of the bread samples. Each slice was placed in a sample box for image acquisition. An image analysis software was used to analyze the images of the bread slices (Calibre Control International Ltd., England).

Statistical Analysis

Data were expressed as the means of triplicate determinations. Statistical significance was assessed through one-way analysis of variance using ORIGIN 7.5 (OriginLab Inc., USA) for Windows. Treatment means were considered significantly different at P ≤ 0.05.

Results and Discussion

Extensograph Measurements

Dough samples were subjected to the tensile test after 135 min of fermentation, which approximates dough fermentation time under actual production conditions. The test results are shown in Fig. 1. The dough tensile resistance of the samples containing 0.5–1.5 wt% β-CD was superior to that of the control group. The sample with the addition of 1.5 wt% β-CD exhibited the maximum dough tensile resistance. Dough tensile resistance decreased when the addition of β-CD exceeded 2.0 wt%. The dough extensibility of the samples containing 0.5 and 1.0 wt% β-CD was slightly greater than that of the control group. Dough tensile resistance negligibly changed when the addition of β-CD exceeded 1.5 wt%.

Tensile deformation occurs during dough fermentation and baking. Tensile properties are important indices of dough baking quality and reflect gluten strength and dough gas-holding capacity [17]. Tensile curves reflect dough strength and extensibility, which are conferred by glutenin [18], and dough extensibility and cohesion, which are provided by gliadin. The tensile properties of wheat dough are mainly related to gluten network formation. The formation of the gluten network, in turn, is mainly dependent on the content and proportion of gluten and network fillers, such as starch granules [19]. The addition of 0.5–1.5 wt% β-CD enhanced dough tensile resistance. This result indicates that β-CD promoted the formation of the gluten network. The addition of 2.0–3.0 wt% β-CD, however, decreased dough tensile resistance. This result suggests that the addition of high concentrations of β-CD adversely affected gluten network formation. The results of the dough tensile resistance test collectively suggest that the effect of β-CD on gluten network structure may be caused by multiple factors. Wheat flour contains a small amount of V-type starch, a complex that is formed by natural amylose and lipids [20]. β-CD can be used to encapsulate hydrophobic substances, such as lipids, to fabricate stable complexes with extensive applications in food and medicine [9]. β-CD may form a new stable complex with V-type starch. This complex fills in the gluten network structure and strengthens the gluten network. Therefore, the addition of 0.5–1.5 wt% β-CD enhanced the tensile resistance of the dough. In this Brabender experiment, high amounts of water must be added to ensure that the consistency of dough samples containing 2.0–3.0 wt% β-CD reached 500 BU. The addition of excess water reduced tensile resistance and increased dough extensibility [21, 22].

SEM Analysis

Dough formation is the first step in baking and determines the quality of the final product. SEM has been widely used to observe dough microstructures because of its high resolution and ability to visualize three-dimensional structures [23, 24]. The effects of different concentrations of β-CD on dough microstructure were observed through SEM. As shown in the figure, starch granules with uneven sizes were embedded in the protein network structure. The control group exhibited a starch granule protein network with pronounced holes and gaps and a rough surface. In contrast to that of the control group, the dough gluten network of the samples containing 0.5–1.5 wt% β-CD appeared complete and lacked cracks. Dough containing 2.0–3.0 wt% β-CD presented numerous crushed white gluten molecules. Pronounced voids and cracks are observed in Figure e-g. The similar appearances of Figures e–g may be attributed to the adverse effects of 2.0 wt% β-CD on gluten formation. Further increasing β-CD content did not further exacerbate the adverse effects of β-CD on gluten (Fig. 2).

Dough contains a continuous gluten network that is incorporated with starch granules and air bubbles [25, 26]. β-CD exerted a protective effect on the gluten network when it was present at low amounts. As inferred from the figure, the protective effect of β-CD may be attributed to its ability to promote the inclusion of starch granules and gluten networks. This result is consistent with the results of the dough tensile test and may be ascribed to the firm embedment of starch–lipid–β-CD complexes in the protein network when the addition of β-CD was less than 1.5 wt%. Gluten network formation was hindered when the addition of β-CD exceeded 2.0 wt%. β-CD has good water holding capacity [27], the enhancement in the competition between β-CD and protein for water as β-CD content increased resulted in the insufficient water absorption of the proteins and prevented the formation of the gluten network in dough. The gluten network failed to encapsulate starch granules completely. Thus, the rough dough surface showed a disrupted gluten network.

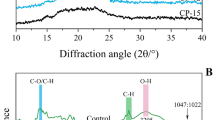

Protein Secondary Structure

The FTIR spectra of dried dough powders with different concentrations(0–3.0 wt%) of β-CD are shown in Fig. 3a. Visible infrared absorption peaks can be observed in the 1600–1700 cm−1 region. Secondary structure proportions were calculated using Peakfit on the basis of the subpeak areas in the 1600–1700 cm−1 wave region. As shown in Fig. 3b, major peaks were observed at 1625, 1644, 1652, 1657, 1664, 1669, 1680, and 1685 cm−1. The data provided in Table 1 indicated that the protein secondary structures present in the samples were mainly composed of α-helixes and β-sheets. The β-sheets ratio of samples containing β-CD gradually decreased relative to that of the control group. The β-sheets ratio decreased by 1.67% when the addition of β-CD reached 3.0 wt%. In contrast to that of β-sheets, the proportion of α-helixes gradually increased. This increase, however, was not observed in the group containing 0.5 wt% β-CD. When the addition of β-CD was 3.0 wt%, the proportion of α-helixes increased by 1.18%. The β-turn ratio of the group containing 2.0–3.0 wt% β-CD was higher than that of the control group. In addition, the irregular curl ratio fluctuated with the addition of β-CD. These results showed that β-CD changed protein secondary structures during dough formation and affected the α-helix-to-β-sheet ratio of the dough samples.

a FTIR curves of samples with different concentrations (0–3.0 wt%) of β-CD. Spectra were collected over the wavelength range of 400–4000 cm−1 with the scanning time of 32. b Analysis of the 1600–1700 cm−1 wave region through Peakfit revealed major peaks at 1625, 1644, 1652, 1657, 1664, 1669, 1680 and 1685 cm−1

The amide-I band (1600–1700 cm−1) is valuable for the FTIR analysis of protein secondary structures [28]. Peaks in the 1600–1640, 1640–1650, 1650–1670, and 1680–1685 cm−1 wave regions could be attributed to β-sheets, irregular curls, α-helixes, and β-turns, respectively [29, 30]. Cyclodextrins could interact with amino acids and protein side chains [31]. The interaction between β-CD and protein is driven by hydrogen bond formation and van Edward forces [32, 33]. β-CD could alter the secondary structure of α-amylase in a dose-dependent manner [34]. These observations are consistent with the present findings, which showed that protein secondary structure changed through the complexation of β-CD with dough protein. These results indicate that the β-sheet-to-α-helix ratio drastically decreased when the addition of β-CD exceeded 1.5 wt%, and the irregular curl ratio decreased when the addition of β-CD reached 3.0 wt%. These results may be attributed to weakening of hydrogen bonds between protein and water molecules and the strengthening of hydrogen bonds between polypeptide chains through the interaction of β-CD with protein side chains or amino acids. The partial conversion of β-sheets and irregular curls into α-helixes stabilized peptide chains may be related to the changes in gluten strength and structure observed through tensile testing and SEM.

Dough Fermentation Parameters

Dough fermentation height, total gas production, and gas maintain capacity were measured by using a fermentation rheometer. The effects of β-CD on dough height after 135 min of fermentation are shown in Fig. 4. As inferred from the curve, the increase in dough fermentation height followed the increasing order of 0 wt% < 3.0 wt% < 2.5 wt% < 0.5 wt% < 1.0 wt% < 2.0 wt% < 1.5 wt%. That is, fermentation height increased when the addition of β-CD fell in the range of 0.5–1.5 wt% and then decreased when the addition of β-CD fell in the range of 2.0–3.0 wt%. Overall, the fermentation heights of the experimental groups were higher than those of the control group. The effects of β-CD on dough gas production and gas maintaining capacity were shown in Table 2. The addition of 0.5–1.5 wt% β-CD increased total gas production and maintain gas volume. Both of these parameters, however, decreased when the addition of β-CD was 2.0–3.0 wt%. The total gas production of the sample containing 3.0 wt% β-CD was even lower than that of the control group. The dough fermentation curves of the control group and 1.5 wt% β-CD group are shown in Fig. 5.

Fermentation rheometers can be used to observe dough fermentation visually [35]. Dough fermentation height is related to gas production, dough toughness, and gluten network formation [36]. The combined results of the tensile test, SEM, and gas production test confirm that the addition of 0.5–1.5 wt% β-CD increased dough formation and gas production. Thus, the fermentation height of the 0.5–1.5 wt% β-CD groups increased. The addition of β-CD exceeded 2.0 wt%, however, dough fermentation height decreased because dough gas production and gluten formation decreased. Given that dough temperature was held constant in the fermentation apparatus, the main factors that likely affected gas production are the number of yeast cells and the amount of yeast-available sugar. These factors are indirectly related to the number of air bubbles trapped in the dough and the activity of α-amylase. The numerous tiny bubbles that were trapped in the dough during dough formation provided the oxygen needed for yeast proliferation and aerobic respiration [37]. SEM revealed that the addition of 0.5–1.5 wt% β-CD enhanced the smoothness and completeness of the gluten network. This result suggests that bubbles became evenly distributed in dough. The even distribution of bubbles in dough, in turn, promoted yeast proliferation and gas production. The results may also be related to the interaction between β-CD and amylase. Low concentrations of β-CD increased α-amylase activity, whereas high concentrations of β-CD could inhibit α-amylase activity [34]. The increase or decrease in amylase activity can determine the amount of sugar available for yeast fermentation in dough and thus affected the gas production capacity of yeast. Dough gas maintain capacity is mainly related to dough strength [38, 39]. This relationship could be demonstrated by the results of the tensile test.

Prebaked Bread Textural Properties

As shown in Fig. 6, the addition of 0.5–1.5 wt% β-CD decreased bread hardness but increased bread elasticity and resilience. When β-CD content exceeded 2.0 wt%, bread hardness increased, and bread elasticity and resilience decreased. In general, the addition of β-CD improved bread textural properties. The elasticity and resilience of prebaked bread are related to flour protein content, dough formation, and gas production when all other processing parameters are held constant [4]. The improvement in bread elasticity and resilience with the addition of 0.5–1.5 wt% β-CD may be attributed to the promotion of gluten network formation. Meanwhile, the addition of 2.0–3.0 wt% β-CD destroyed gluten structure and reduced bread elasticity and resilience.

Effects of different concentrations (0–3.0 wt%) of β-CD on the hardness, resilience, and recovery of prebaked frozen bread. Bread was cut into 20 × 20 × 20 pieces and placed under the P/100 probe. Samples were tested three times. The average of three measurements was calculated. Each group was tested six times in parallel

The addition of enzymes to increase dough sugar levels can promote gas production by yeast and ultimately improve bread texture [40]. Low or high concentrations of β-CD could promote or inhibit the activity of α-amylase, respectively [34]. Given this effect, the addition of 0.5–1.5 wt% or 2.0–3.0 wt% β-CD may indirectly increase or decrease bread elasticity and resilience by promoting or inhibiting the activity of α-amylase in wheat flour. Bread hardness is associated with water migration and starch retrogradation [41]. The β-CD cavity is prone to forming stable hydrates with water molecules [27] . This effect may decelerate the migration of moisture in bread and thus delay bread aging and reduce hardness. Moreover, β-CD added to bread can bind to V-type starch and consequently inhibit starch retrogradation and reduce bread firmness. These findings may account for the reduced hardness of the bread samples prepared with 0.5–1.5 wt% β-CD. The increased hardness of the bread samples containing 2.0–3.0 wt% β-CD may be more related to the adverse effect of β-CD on dough quality.

Bread Specific Volume and Tissue Structure

As shown in Fig. 7, the specific volume of the 1.5 wt% β-CD group slightly increased relative to that of the blank group. The specific volumes of the 0.5 wt%, 1 wt%, and 2 wt% β-CD groups were close to those of the blank group. The specific volumes of the 2.5 wt% and 3.0 wt% β-CD groups were significantly lower than those of the control group. The final bread weight increased with the addition of β-CD. In this work, stomatal and hole numbers and hole wall thickness were used as indices of bread microstructure. The results are shown in Table 3.The addition of β-CD increased stomatal number, and the most stomatal number was observed in samples containing 1.5 wt% β-CD. Hole wall thickness decreased with the addition of β-CD, particularly at the concentration of 1.5 wt%. The microstructures of the 1.5% β-CD and control groups were compared as shown in Fig. 8.

The C-Cell evaluation system is more accurate than sensory evaluation, which may provide inaccurate evaluation results that stem from evaluator error. The addition of 1.5 wt% β-CD decreased hole number and promoted uniform hole distribution. Microstructure considerably affects the physical, textural, and sensory properties of baked goods [42]. Stomatal and hole number can reflect the completeness of dough fermentation, which has an important effect on bread specific volume [43]. In this study, although the addition of 1.5 wt% β-CD increased bread stomatal number and reduced stomatal wall thickness, the specific volume of the bread did not considerably increase. The increase in stomatal number may be attributed to the conversion of original holes into stomata with the addition of 1.5 wt% β-CD. The increase in stomatal number does not translate to an increase in bread volume. Moreover, β-CD can retain moisture [12, 27]. Moisture retention reduces moisture loss during prebaked bread processing and increases bread weight, which may also account for the negligible increase in the specific volume (volume/mass) of bread.

Stomatal and hole formation is associated with dough bubble generation, which is partly affected by the ability of the dough to generate and retain carbon dioxide [44]. The trend followed by the effects of β-CD on dough fermentation is consistent with that followed by the effects of β-CD on stomatal number. That is, the increase in gas production coincided with the increase in dough stomatal number. The decrease in hole number implies that β-CD promoted the uniform distribution of stomata and the transformation of large holes into stomata. These changes can be observed in Fig. 8. Scanlon et al. showed that hole wall thickness is negatively correlated with bread fineness and reported that the addition of the appropriate amounts of β-CD decreased hole wall thickness and improved prebaked bread fineness [45].

Conclusion

This study demonstrated that β-CD altered bread quality by affecting dough properties. The results of this study indicate that the addition of 0.5–1.5 wt% β-CD can enhance tensile resistance and promote gluten network formation. These effects may be related to the enhancement of the secondary structures of dough protein as observed through FTIR. The addition of 0.5–1.5 wt% β-CD can reduce bread firmness and improve bread tissue structure, which are of positive effect on quality of bread. These results are related to the increase in gas production during dough fermentation upon β-CD addition. In summary, the results of this study show that the addition of 0.5–1.5 wt% β-CD to flour can improve the quality of the prebaked bread. The recommended optimal amount is 1.5 wt%.

References

A. Le-Bail, D. Gabric, Breadmaking, 661–686 (2012)

M. Fik, K. Surowka, J. Sci. Food Agric. 82(11), 1268–1275 (2002)

E. Debonne, F.V. Bockstaele, E. Philipps, I.D. Leyn, M. Eecjhout, LWT Food Sci. Technol. 78, 16–22 (2017)

E.L. Almeida, Y.K. Chang, LWT Food Sci. Technol. 49(1), 56–61 (2012)

M.E. Bárcenas, M. Haros, C.M. Rosell, Eur. Food Res. Technol. 218(1), 56–61 (2003)

G. Shikhar, G.C. Soni, S.K. Jain, Int. J. Pharmaceut. 3(10) (2012)

V.J. Stella, Q. He, Toxicol. Pathol. 36(1), 30–42 (2008)

J. Zhan, Y. Tian, Q. Tong, Carbohydr. Polym. 91(2), 609–612 (2013)

N. Qiu, X. Li, J. Liu, J. Incl. Phenom. Macrocycl. Chem. 89(2), 1–18 (2017)

C. Jouquand, V. Ducruet, P. Giampaoli, Food Chem. 85(3), 467–474 (2004)

Chen, Q., Chemical Industry Times, (2007)

Y.Q. Tian, Y. Li, Z.Y. Jin, X.M. Xu, J.P. Wang, A.Q. Jiao, B. Yu, T. Talba, Thermochim. Acta 489(1), 22–26 (2009)

N.R. Ponzio, C. Ferrero, M.C. Puppo, Int. J. Food Prop. 16(1), 33–44 (2013)

S. Meziani, J. Jasniewski, C. Gaiani, I. Ioannou, J.M. Muller, M. Ghoul, S. Desobry, J. Food Eng. 107(3-4), 358–365 (2011)

C. Verheyen, A. Albrecht, D. Elgeti, M. Jekle, T. Becker, Food Res. Int. 76(Pt 3), 860–866 (2015)

E.L. Almeida, Y.K. Chang, LWT Food Sci. Technol. 49(1), 64–72 (2012)

T.H. Mccann, M.L. Gall, D. Li, J. Cereal Sci. 69, 228–237 (2016)

F.I. Yue, X.A. Guo, K.U. Zhu, Cereal Chem. 94(5), 881–886 (2017)

F. Macritchie, Adv. Food Nutr. Res. 36, 1–87 (1992)

C.G. Biliaderis, G. Galloway, Carbohydr. Res. 189(12), 31–48 (1989)

N.W. Tschoegl, J.A. Rinde, T.L. Smith, Rheol. Acta 9(2), 223–238 (1970)

A.H. Bloksma, Cereal Foods World 35 (1990)

T. Amend, H.D. Belitz, Z. Lebensm. Unters. Forsch. 190(5), 401–409 (1990)

O. Paredeslopez, W. Bushuk, Cereal Chem. 60(1), 24–27 (1983)

B. Schiedt, A. Baumann, B. Conde-Petit, T.A. Vilgis, J. Texture Stud. 44(4), 317–332 (2013)

M. Kokawa, K. Fujita, J. Sugiyama, M. Tsuta, M. Shibata, T. Araki, H. Nabetani, J. Cereal Sci. 55(1), 15–21 (2012)

D. Duchene, A. Bochot, Int. J. Pharm. 514(1), 58–72 (2016)

B.R. Singh, M.P. Fuller, G. Schiavo, Biophys. Chem. 36(2), 155–166 (1990)

K.G. Duodu, H. Tang, A. Grant, N. Wellner, P.S. Belton, J.R.N. Taylor, J. Cereal Sci. 33(3), 261–269 (2001)

Q. Zhang, Y. Shen, A. Xie, B. Xia, Spectrosc. Spectr. Anal. 20(6), 781–784 (2002)

P.R. Santagapita, L.G. Brizuela, M.F. Mazzobre, H.L. Ramírez, H.R. Corti, R.V. Santana, M. Pilarbuer, Carbohydr. Polym. 83(1), 203–209 (2011)

S.B. Larson, A. Greenwood, D. Cascio, J. Day, A. Mcpherson, J. Mol. Biol. 235(5), 1560–1584 (1994)

B. Mikami, E.J. Hehre, M. Sato, Y. Katsube, M. Hirose, Y. Morita, J.C. Sacchettini, Biochemistry 32(27), 6836–6845 (1993)

M. Wang, Z. Jin, L.Y. Liu, Z. Wang, F. Li, W. Sun, H.Y. Cai, X. Chen, W.Y. Shen, Z.Z. Zhu, F.J. Barba, W. Zhang, J. Incl. Phenom. Macrocycl. Chem. 90(1), 1–6 (2018)

Z. Czuchajowska, Y. Pomerana, Cereal Foods World 38(7), 499–503 (1993)

M. Gómez, S. Jiménez, E. Ruiz, B. Oliete, LWT-Food Sci. Technol. 44(10), 2231–2237 (2011)

M.N. Rezaei, V.B. Jayaram, K.J. Verstrepen, C.M. Courtin, J. Sci. Food Agric. 96(11), 3741–3748 (2016)

J. Hargreaves, Y. Popineau, M.L. Meste, M.A. Hemminga, FEBS Lett. 372(1), 103–107 (1995)

T. Vanvliet, A.M. Janssen, A.H. Bloksma, P. Walstra, J. Texture Stud. 23(4), 439–460 (2010)

A.R. Shah, R.K. Shah, D. Madamwar, Bioresour. Technol. 97(16), 2047–2053 (2006)

J.K. Purhagen, M.E. Sjöö, A.C. Eliasson, Food Hydrocoll 25(7), 1656–1666 (2011)

V. Lampignano, J. Laverse, M. Mastromatteo, M.A.D. Nobile, Food Res. Int. 50(1), 369–376 (2013)

S.M. He, D.S. Chen, Y. Zhan, Z.H. He, Sci. Agric. Sin. (2007)

P. Shah, G.M. Campbell, S.L. Mckee, C.D. Rielly, Food Bioprod. Process. 76(2), 73–79 (1998)

M. G. Scanlon, H. D. Saoirstein, in Elucidation: The Bushuk legacy supply chain (2002)

Acknowledgements

This work is funded by the Open Project Fund of the Key Laboratory for Processing and Transformation of Agricultural Products (Wuhan Polytechnic University) and Science and Technology Support Program of Hubei Province, China (2015BBA167). The authors would also like to express their appreciation for the support provided by the Hubei Key Laboratory for Processing and Transformation of Agricultural Products (Wuhan Polytechnic University).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhou, J., Yang, H., Qin, X. et al. Effect of β-Cyclodextrin on the Quality of Wheat Flour Dough and Prebaked Bread. Food Biophysics 14, 173–181 (2019). https://doi.org/10.1007/s11483-019-09566-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11483-019-09566-2