Abstract

Dairy custard is a dessert of semisolid consistency, whose main ingredients are milk, sugar and a gelling component. The aim of this work was to study the influence of the addition of xanthan gum on the rheological behavior and the structure of low-fat custard, which was prepared with the addition of inulin as a fat replacer. The results indicated that the magnitudes of the storage modulus and the loss modulus increased with the measurement frequency. A skimmed milk sample without xanthan and inulin exhibited fluid-like behavior characteristics. All other samples exhibited mechanical spectra that were typical of weak gels, suggesting that both xanthan and inulin can increase the elastic characteristics of the samples. The rheological properties of the custards also changed during storage. An ANOVA study suggested significant interactions among the variables (inulin, xanthan, type of milk and time of storage) on the viscoelastic properties. To substitute for the high fat content typically observed in dairy custard, a dendrogram of similarity and a microscopic analysis indicated that a formulation of skimmed milk containing both inulin and xanthan gum (0.25 %) could prevent increases in the rates of inulin aggregation.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The presence of fat in dairy products has considerable impact on both rheological and textural properties and influences multiple characteristics, such as handling, stability, appearance, flavor and mouthfeel [1]. With consumer preferences for these types of products containing less fat and cholesterol, a reduction in the fat content can be achieved by a replacement with water and several ingredients. Dairy-based custards are very popular in multiple countries around the world, representing a model food for the study of fat replacement.

Among the fat replacers, carbohydrate-based substances (starch, cellulose, pectin, inulin, xanthan gum or carrageenan) have generated increased interest with favorable physicochemical properties and health-friendly characteristics [2]. Starch and non-starch hydrocolloids have been used in many foods to improve both texture and stability, facilitate processing and improve the overall quality [3]. Starch is a polysaccharide of major importance with many functional properties, such as gelatinization, which consists of a continuous phase enriched in amylose and a dispersed phase (more or less ruptured starch granules containing mainly amylopectin) [3].

At various solids levels, inulin can affect the characteristics of aqueous solutions and has therefore been used primarily as a texturizer. At levels above 25 %, the solutions can form particle gels with fat-like characteristics. At levels exceeding 50 % concentrations, the gels retain a fat-like texture, with increased firmness [4]. The presence of other hydrocolloids and processing of the mixtures using multiple conditions (various temperature profiles and mixing shear rates) can affect the formation of the gel characteristics [5]. Inulin gels are formed by a network of small crystallites, whose properties closely resemble those observed with a network of fat crystals in oil [6]. The formation of small insoluble inulin particles can induce a gel-like texture [7]. These small particles can be produced by controlling the heating and the cooling of the dissolved inulin, inducing nucleation and the formation of small insoluble crystals [8]. Under these conditions, soluble inulin can become insoluble, forming a network with an association of polymer molecules in the polymer solution [9]. With a high degree of polymerization (22–25), long-chain inulin has improved thermal stability, reduced solubility and increased viscosity, compared with the other inulin polymers [10]. Several authors have reported that this polymer has been used as a fat substitute in multiple dairy products [11].

Selective non-digestible carbohydrate, such inulin and oligosaccharides, that promote the proliferation of bifidobacteria and lactobacilli have been defined as prebiotics [12]. Prebiotics are selectively fermented ingredients that allow specific changes, both in the composition and/or activity in the gastrointestinal microbiota that confers benefits upon host well-being and health [13]. Functioning as a prebiotic, inulin has been associated with enhancing the gastrointestinal system and immune system [14].

Xanthan gum is a polysaccharide used as a thickener, increasing the low shear-rate viscosity in fluid foods without affecting the viscosity of the food at high shear rates [15]. Xanthan gum is a unique hydrocolloid that exhibits significant yield stress values even at low concentrations, which explains the ability of xanthan solutions to stabilize emulsions or suspensions with the formation of microgel particles or aggregates of the xanthan polymer chains [16].

The addition of xanthan gum can increase the viscosity of starch, influencing the gelatinization and retrogradation characteristics of the starch mixtures. Both the physical properties and the storage stability of tapioca starch can be modified using hydrocolloids, such as xanthan gum [17]. According to Abdulmola et al. [18], increases in the viscosities of starch–xanthan gum mixtures may result from the interactions between the gelatinized granules that are enhanced by the xanthan gum. In addition, xanthan gum molecules have the ability to engage in non-electrostatic interactions with other polysaccharides, such as the starch polymers present at the periphery of the swollen granules [19]. Kruger et al. [20] suggested that in the presence of gums, granule swelling was restricted, resulting in more rigid granules which break up less easily. Some of these mechanisms may be responsible for increasing the viscosity of starch. Gum can also affect both gelatinization and retrogradation of starch through strong associations of amylose with the gum, resulting in a decrease in the retrogradation of the starch [21].

The effects of inulin additions on the rheological properties of fat-free dairy desserts containing various starch concentrations were compared with the properties of full fat milk samples [22]. Using inulin as a fat replacer with fixed amounts of skimmed milk and starch, Arcia et al. [23] determined the rheological properties of starch-based low fat dairy dessert samples, suggesting that an ideal thickness (viscosity) can be achieved with formulations containing inulin in the range from 3.5 to 6 %. González-Tomás et al. [24] suggested that the effects of multiple types of inulin on the viscoelastic properties of the semisolid dairy systems formulated with either skimmed or whole milk were greatly dependent on the starch concentration, the type of milk and the amounts of inulin. Tárrega et al. [11] studied the rheological and sensory properties of long-chain inulin and short-chain inulin combined in various proportions and subsequently added (7.5 g/100 g) to low-fat custards. Using a 50:50 blend of the long-chain and short-chain inulins, this mixture combined with carrageenan produced thick, creamy custard samples, which were preferred over the full-fat custard.

The aim of this work was to study the influence of the addition of xanthan gum on the rheological behavior and the structure of low-fat custard, which was prepared with the addition of inulin as a fat replacer.

Materials and Methods

Materials

Samples were prepared with long chain length inulin (≥23 monomers) (Frutafit® TEX!), provided by Sensus (Brenntag Química, Barcelona, Spain), commercial whole (25 % w/w protein, 39 % w/w carbohydrate, 26 % w/w fat and 1.2 % w/w calcium) and skimmed (34 % w/w protein, 52 % w/w carbohydrate, 1 % w/w fat and 1.2 %w/w calcium) milk powder (Central Lechera Asturiana, Siero, Spain), hydroxypropylated tapioca di-starch phosphate (C* Creamtex 75720; Cerestar Ibérica, Spain), mineral water (Font Vella, Spain), potassium sorbate and potassium benzoate (Panreac, Quimica SA, Spain), xanthan gum (Kalys, Bernin, France) and commercial sucrose.

Sample Preparation

Four skimmed-milk samples (S) and four whole milk samples (W) varying in inulin and in xanthan gum content were prepared. Two more samples, one prepared with skimmed milk and the other with whole milk without added inulin or xanthan gum were used as control. The amounts of the rehydrated milk (80 % w/w), sugar (6 % w/w), potassium sorbate (0.05 % w/w) and potassium benzoate (0.05 % w/w) and starch (3 % w/w, corrected for moisture content) were fixed. Starch moisture content was determined with a LJ16 moisture analyzer (Mettler Toledo GmbHB, Greifensee, Switzerland). Mineral water was added up to 100 % w/w. Sample identification and composition was in Table 1.

Skimmed and whole milk were prepared with the same protein content (2.7 % w/w) by dissolving skimmed (7.95 % w/w) and whole milk(10.8 % w/w) powders in mineral water. Milk powder was dispersed at 250 rpm and 85 °C for 10 min, with the help of a magnetic stirrer and a hot plate (Ared, Velp Scientifica, Usmate, Italy) and stored at 4 ± 1 °C overnight to ensure complete hydration of milk proteins.

Custard samples were prepared as described previously by González-Tomás et al. [25]. Ingredients (starch, sugar, inulin and/or xanthan gum) were weighted in a flask and rehydrated milk was added at room temperature and then they were mixed by magnetic stirring for 10 min. The flask was placed in a water bath at 97 ± 1 °C and stirred at around 200 rpm constantly with a propeller stirrer (Heidolph RZR 1, Schwabach, Germany). When the product temperature reached 85 ± 1 °C, it was held for a further 15 min and then cooled in a water bath at 10 ± 1 °C. Finally, the evaporated water was replaced gravimetrically and the samples were stirred, transferred to closed flasks and stored under refrigeration (4 ± 1 °C) prior measurements. Rheological, particle size and microscopy analyses were realized after 1, 3, and 6 days of storage.

Viscoelastic Properties

The rheological measurements were carried out with a controlled stress rheometer (RheoStress 1, Haake, Karslruhe, Germany), using a sensor based on parallel-plates geometry (6 cm diameter and 1 mm gap). A temperature of 10 ± 1 °C was kept constant during measurements by means of a Phoenix P1 Circulator device (Thermo Haake, Karlsruhe, Germany).

First, to determine the linear viscoelasticity range (LVR), stress sweeps were run at 1 Hz. After that, the frequency sweeps were performed within LVR, over the range from 0.1 at 10 Hz and the values of the storage modulus (G′) and the loss modulus (G″) were registered as a function of frequency using the Rheowin Job software (v. 2.93, Haake) [26].

To characterise the viscoelastic behaviour of samples the plot of the G′ and G″ values versus angular frequency (ω, in Hz) was fitted to the Power law equation [27]:

k′and k″ were the intercepts and n′and n″ were the slopes.

Particle-size Distribution

Particle size distributions were measured using a laser diffraction particle size analyzer (Mastersizer 2000, Malvern Instruments Ltd., England). Measurements were made in the range from 0.1 to 1,000 μm, with the following conditions: refractive index value of 1.53 [28] particle absorption coefficient of 0.1 and refractive index value of water of 1.33. Volume mean diameter values (D[3, 4]) and the diameters D 10 , D 50 and D 90 were calculated using the software Mastersizer 2000, V. 5.40. Three measurements in cycles of 10 s were performed for each sample.

Microstructure

The microstructure of the different samples was examined using an optical microscope (Nikon Eclipse 90i) coupled to a digital camera (Nikon DS-5MC). Samples were placed in glass slides with a cover slip and observed using 20× magnification.

Statistical Analysis

The effects of inulin and xanthan gum contents and the storage times on viscoelastic properties for custard samples were studied through analyses of variance, using two ways ANOVA. Hierarchical cluster analysis was used to search the natural groupings among the samples. The sample similarities were calculated on the basis of the squared Euclidean distance, and the Ward method was used in order to establish clusters. Analyses and calculus were realized using statistical software SAS version 9.3.

Results and Discussion

Influence of Sample Compositions and Storage Times on the Viscoelastic Properties

Influence of Either Inulin or Xanthan Gum Additions

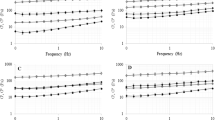

The storage modulus (G′) and the loss modulus (G″) as a function of the frequency were determined at 10 °C for custard containing either xanthan gum or an inulin mixture, as well as a control without either polymer (Fig. 1). The magnitudes of G′ and G″ increased with increasing frequencies. According to Mezger [29], the G′ value is a measure of the deformation energy stored in the sample during the oscillation process, representing the elastic behavior of a sample. The G″ value is a measure of the deformation energy used up in the sample during the oscillation and lost to the sample afterwards, representing the viscous behavior of a sample.

Mechanical spectra for the custard dessert samples: (Sa), (Sb), (Sc), (Wa), (Wb) and (Wc). G′ (filled symbols) and G″ (open symbols). ● ○ day 1; ▼ ∇ day 3; ■ □ day 6. Identification of samples in Table 1

For samples of custard mixtures containing skimmed milk without either inulin or xanthan gum (Sa), the G″ values were larger than the G′ values over the entire frequency range. The two values converged at high frequencies, which is a characteristic of non-gelling, liquid-like systems. Zimeri & Kokini [30] found this non-gelling behavior in samples with total polymer concentrations of 2 % and 5 % using an inulin to waxy maize starch (ratio 50:50) mixture over the entire frequency range, with both G′ and G″ parameters exhibiting strong frequency dependence with convergence at high frequencies. An addition of either xanthan (Sb) or inulin (Sc) resulted in a change in behavior, where G′ exceeded G″ and both were frequency-dependent, the characteristic of weak gel-like structure. For the samples containing xanthan gum, the values of G′ were higher than the samples containing inulin. For rice starch–xanthan gum mixtures (5 %w/w), it was reported that the magnitudes of G′ and G″ increased with increasing concentrations of xanthan gum, with the mixtures exhibiting weak gel-like behaviors [31]. Similar trends were observed by Viturawong et al. [32]. Based on the macroscopic behavior of gelled systems, true gels are a consequence of the development of the three dimensional networks, with weak gels characterized by a tenuous gel-like network that can be easily broken with enough applied stress [33].

The mechanical spectra for custards containing whole milk are shown in Fig. 1. For all these samples (Wa, Wb, Wc), the G′ values were larger than the G″ values, with both moduli dependent upon the frequency, exhibiting behaviors that are characteristic of weak gels. The values of these parameters for the samples with either xanthan (Wb) or inulin (Wc) were much greater (10-fold) than the values for the Wa sample. For the two samples (Wb, Wc), the values of G′ were higher with the addition of the xanthan gum. That is, for samples containing xanthan as the gum, larger values of G′ were obtained than for the samples containing inulin. The different gelling mechanism found among xanthan gum (Wb) and inulin (Wc) was explained by several authors. Abdulmola et al. [18] mention that in the case of the granules remain intact, the swollen starch granules are surrounded by the continuous watery phase containing the dissolved xanthan gum. On the other hand, whether long-chain inulin is used at high concentrations can interact with each other forming small aggregates, which occlude a great amount of water [11] and there are the competition between inulin and starch for water [22]. Different molecular weight of the employed hydrocolloids could also have influenced in this behavior. Dan et al. [34] reported that the weight average molar mass of inulin monomer and its aggregate was 4,468 and 1.03 × 106 g/mol, respectively, in aqueous solution, meanwhile the molecular weight of commercial xanthan gum is usually in the range of 106 g/mol [35].

In the figure is also observed different gelling mechanism among Wa and Sa, which is influenced by the higher presence of fat globules that can affect their structure [25], and to the possible interaction between this component and starch. In addition, the more fluid-like behaviour in skimmed-milk samples may be attributed to a possible release of water from starch granules in the continuous phase during storage, and this phenomenon did not seem to affect the whole-milk sample structure [36].

Clark & Ross-Murphy [37] classified two types of gelled systems based on a determination of the gel with mechanical spectroscopy, designating strong gels as those networks that have finite energy and weak gels as those systems that are transient in time and exhibit several properties usually attributed to the presence of hyperentanglements. This effect of time was also observed in these samples, as shown in the figure. In these formulations of custard, the values of G′ and G″ increased with time, with the strength of the structure increasing during storage. Similar observations were reported by Torres et al. [36] for dairy desserts containing long chain inulin, with the seven-day mechanical spectra obtained for the samples containing long-chain inulin suggesting high viscoelastic moduli values, indicating more structured systems. On the other hand, Sb was not influenced by the storage time and it may be due to presence of xanthan gum in the continuous phase, which protects the starch granules from breaking and swelling is also restricted, resulting in more rigid granules which break up less easily by preserving their structure [19]. In addition, granule integrity is a prerequisite for synergistic rheological effects between xanthan and starch [38], and this way, this interaction improves the stability during storage.

Other reports in the literature also found that the addition of long-chain inulin at concentrations of 6 and 7.5 g / 100 g to custard desserts can significantly change the rheological behaviors by increasing the consistency, viscosity and elasticity of the systems [24]. Torres et al. [36] suggested that long-chain inulin has the ability to crystallize and form aggregates, creating a new structure (without the occlusion of water) within the continuous phase that is responsible for increasing the elastic response of the system. In addition, Tárrega et al. [39] indicated that the increase in the starch granule rigidity combined with several milk components (casein or fat) may affect the entire system structure, altering the rheological properties. In a study on the effects of skimmed milk components on the rheological properties of highly cross-linked waxy maize starch suspensions, Matser & Steeneken [40] found that lactose increased the system storage modulus values, attributing this increase to an increase in the rigidity of the starch granules. The addition of casein micelles also increased the G′ values of starch–skimmed milk systems, possibly resulting from the exclusion of the casein micelles from the swollen starch granules and the consequential increase of the milk protein concentrations in the voids between the starch granules. Kip et al. [41] suggested that there are interactions between the inulin and the dairy components, such as whey proteins and caseinate.

To characterize the viscoelastic behavior of both skimmed and whole milk custard dessert systems, the plots of the G′ and G″ values versus frequency were fitted to the Power law equation (Eqs. 1 and 2). The model parameters and the regression coefficients are listed in Table 2, indicating that both the storage modulus and the loss modulus versus frequency data were fitted adequately (R2 ≥ 0.90) for all the dairy custard samples.

According to Bayarri et al. [42], both k′ and k″ are parameters providing information on the structure of sample, with the n′ and n″ values providing information on the variation of the moduli with frequency. The viscoelastic behavior can be classified as fluid-like (k″ > k′), concentrated solution (k′ = k″) and gel-like (k′ > k″) structures. For values of the parameter k′ exceeding the values of k″, G′ at a particular frequency predominates.

For the skimmed-milk sample (Sa) that did not contain either inulin or xanthan, the n′ value was close to 1 with k″ > k′, confirming the predominantly viscous character of this sample. The addition of either xanthan gum or inulin caused dramatic increases in the elastic characteristics, with samples containing whole milk exceeding the values measured for skimmed milk. Among the samples, these increases in the elastic properties were highest in the custard samples containing xanthan gum. The intercepts (k′and k″) were clearly lower for the skimmed milk samples than for the whole milk samples. In all samples except Sb, the values for k′ and k″ increased with time. In Table 2 also is showed than skimmed milk has intercept values of k′ and k″ lower than whole milk. This behavior indicated that skimmed-milk has characteristic more viscous than elastic and that the whole-milk showed a more pronounced gel-like characteristic than skimmed-milk. In the table is also observed that those values for Sb sample was not changed with storage time, this way, it was confirmed that xanthan gum improves the stability of this sample. It is also showed the influence of the addition of xanthan on desserts enriched with inulin, which drastically increased those parameters.

The Sa sample had a high value of n′, suggesting that G′ increases dramatically with frequency. Dynamic rheological data for all samples except for Sa showed that the n′ values (0.12–0.51 Pa.sn′) were lower than the n″ values (0.13–0.64 Pa.sn″), indicating that the storage modulus and the loss modulus were slightly dependent on frequency and exhibited weak gel behavior characteristics. For the n″ values exceeding the n′ values, G″ increased faster than G′ with increasing frequency values.

Influence of the Addition of Xanthan on Desserts Enriched with Inulin

The changes in the storage modulus (G′) and the loss modulus (G″) values for skimmed milk (Sd and Se) and whole milk (Wd and We) as a function of the frequency for custards containing both xanthan gum and an inulin (7.5 % w/w) mixture at 10 °C were determined and shown in Fig. 2. The magnitudes of G′ and G″ increased with increasing frequency values.

Mechanical spectra for the custard dessert samples: (Sd), (Se), (Wd) and (We). G′ (filled symbols) and G″ (open symbols). ● ○ day 1; ▼ ∇ day 3; ■ □ day 6. Identification of samples in Table 1

For custard samples containing either whole or skimmed milk, the mixtures of inulin and xanthan resulted, in general, in an increase of these two properties, with increased values observed at 0.5 % of xanthan gum. For these samples, the values of G′ were larger than G″, characteristic of weak gels with a slight dependence on the frequency for the dynamic moduli. These results suggest the existence of relaxation processes, occurring even at short time scales with decreased differences between the moduli values, indicating that a low percentage of the stored energy was recovered [33]. The G′ and G″ values also increased with time.

In a model of the mechanical spectra using a structural perspective, true gels are characterized by zero value for the parameters n′ or n″, with either weak gels or highly concentrated dispersions having positive values and G′ exceeding G″ over a wide range of ω [37]. As shown in Table 2, the values of k′ were higher than k″ over most of the frequency range, indicating that all samples had behavior that was gel-like characteristic. For all samples, the results indicated that the storage and loss modulus were slightly dependent on frequency and exhibited weak gel behavior characteristics. These results suggest that these samples were more predominantly elastic than viscous, and the samples were more elastic at increased xanthan gum concentrations. These increases in the constants were further amplified with the addition of inulin, indicating that the presence of xanthan may lead to the promotion of inulin aggregation.

For all samples, the exponent values n″ were higher than n′, indicating that, with increases in the frequency, G″ increased at a higher rate than the increases in G′, as shown in Table 2. In addition, the values of n′ and n″ decreased with increasing xanthan concentration. Heyman et al. [35] mention that xanthan generally engages in strong intermolecular associations with starch, and they demonstrated that the network synergy between gums and starches is not purely additive and depends strongly on the concentration of both. These decreases in the exponent values n″ and n′ indicated a reduction in the increasing rates of both G″ and G′.

The k′ and k″ values increased with increasing xanthan concentration (at 7.5 % of inulin) and storage times (days). In general, on the third day of storage, both n′ and n″ values had slightly decreased.

These behaviors can be explained by the associations of ordered chain segments of proteins and globules of fat in the milk powder, starch, inulin and xanthan gum mixtures, generating a weak three dimensional network, as suggested by Choi & Yoo [43] for starch xanthan-gum mixtures. The addition of xanthan gum and inulin appeared to contribute synergistically to the rheological properties of the custard samples. The synergistic interactions were related to the formation of continuous networks. Hébette et al. [8] mention that the property of long-chain inulin to act as fat replacer is based on its capacity to form microcrystals, which interact with each other thereby forming small aggregates that ultimately may agglomerate into a gel network. Meyer [44] suggested that improvements in homogeneity were observed with the addition of both xanthan gum and inulin in beverage systems. The synergistic interactions between heat-denatured whey proteins and xanthan gum at low concentrations were also related to the formation of two continuous networks that resulted from the segregated phase separation prior to gelation [45]. Compared with the interactions of starch and water, the increased affinity of water towards inulin can influence the viscosity of starch and inulin aqueous systems [44]. Christianson et al. [21] reported synergistic interactions between wheat starch and xanthan gum, as measured by the viscosity. Gelation arises either from chemical cross-linking with covalent reactions or from physical cross-linking through polymer-polymer interactions [46].

In conclusion, the increases in G′ were more pronounced for the whole milk samples than for the skimmed-milk samples. With an inulin and xanthan gum (0.5 % content) mixture, increased values of G′ were obtained, exhibiting an improved elastic response.

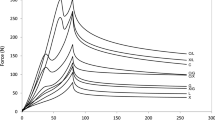

To compare the effects of storage times on the samples, the values of G′ and G″ at 1 Hz were evaluated in Fig. 3. For the storage modulus and the loss modulus, an analysis of variance indicated that the effects of inulin, xanthan gum and storage time had significant interactions (p < 0.05), suggesting that variations in the viscoelastic properties of the custard samples during storage were dependent on these two components. The type of milk also contributed to the viscoelastic properties of the studied dispersions (p < 0.05).

Average values of G′ (a, c) and G″ (b, d) for skimmed and whole milk custard desserts at various times, as measured at 1 Hz. (Different superscript letters denote significant differences between the samples, α < 0.05). 1d, 3d and 6d indicate the first, the third and the sixth day of storage. Identification of samples in Table 1

Among the samples studied, the G′ values had increased values for the Wb and Sb samples, with reduced values for the Wa and Sa samples. The samples Sc and Wc had G′ values that increased significantly (p < 0.05) with time (Fig. 3a). As shown in Fig. 3b, similar behaviors were observed in the G″ values of the samples. As shown in Fig. 3c, the G′ values were high for We. For all samples, the G′ values increased significantly with time (p < 0.05). Similar behaviors were observed with the G″ values (Fig. 3d).

Particle-size Distributions

As shown in Table 3, the size distributions were monomodal for samples without either inulin or xanthan gum (Sa and Wa), with values ranging from 36.5 to 40.1 μm (D[3, 4]). These distributions represent the particles found in a basic custard system and should correspond to the dispersed swollen starch granules [28, 36]. The skimmed-milk contains only xanthan (Sb) had also monomodal distribuition. The other samples had bimodal distributions, corresponding to a second population of particles. These second populations may have resulted from the presence of either fat globules in the whole milk sample (Wb) or particles of inulin (Sc, Sd, Se) that may have crystallized. Changes in the particle-size distributions were observed during storage for samples Wc, Wd and We, changing to trimodal distributions with time. According to Torres et al. [36], these populations of particles could be both fat globules and inulin aggregates. These aggregates were formed after 3 days of storage. However, a possible explanation to distribution profiles were changed upon storage, as seen from the development of bimodal or trimodal distributions in several systems, is as consequence that Sc, Wc, Wd and We samples were unstable upon storage.

Samples that contained both inulin and xanthan gum mixtures had small diameters D[3, 4], ranging from 34.2 to 37.7 μm. Furthermore, addition of xanthan on desserts enriched with inulin contributed to reduce significantly (p < 0.05) volume mean diameter values (D[3, 4]) of the population of particles.

In order to express the degree of uniformity, the relative span of a particle size distribution was also used. The particle span slightly increased from 0.939 to 1.724 and the uniformity of distribution of the samples differed significantly. When mass relative span is greater than 1 indicate a wide distribution of particle sizes. The span increased when was added either inulin or xanthan gum and both polymers, and in the sixth day the span also increased significantly.

Meyer et al. [47] reported that custard desserts made with either whole-milk or skimmed-milk had inulin particles less than 10 μm, a size range that is similar to the values observed with fat globules.

Structure Microscopic Analysis

As shown in Fig. 4, light microscopy images were obtained for custard samples formulated with either whole-milk or skimmed-milk. For all samples, particles of gelatinized starch granules were observed. Aggregated particles (Sc and Wc) were also observed, indicating that the aggregation of inulin crystals occurred in the continuous phase. The inulin aggregation also increased the effective fraction volume, providing an explanation for the important rheological and sensory changes observed in the low-fat starch-based dairy desserts formed with long-chain inulin [47]. In inulin-enriched desserts, Arcia et al. [48] observed spontaneous nucleation of inulin with two different steps, with the first step leading to large particles and the second step generating small ones. These crystallites can act like seeding crystals [49]. Torres et al. [36] showed that inulin particles with a sizes ranging from 0.1 to 10 μm were formed and progressively increased in number during the first 7 days of storage. As a consequence of the inulin aggregation, the rheological properties of the custard changed, showing important increases in the consistency, thixotropy and elasticity characteristics. Tárrega et al. [11] indicated that the consistency, the elasticity and the abundance of inulin aggregates in the product increased with the proportion of long chain molecules (DP > 20).

Light micrograph images (×20) for the skimmed and whole milk custard dessert samples: (Sc), (Sd), (Se), (Wc), (Wd) and (We), obtained on the third day of storage. Identification of samples in Table 1

Meyer [44] suggested that the submicron-sized crystals can form aggregates that are interlinked into a network, with the rate of either precipitation or crystallization (and consequently the size of the inulin particles) depending on the temperature, the concentrations of the components and the cooling process characteristics. Within a few hours, the free water can be captured in the network of crystallized inulin particles, resulting in a gel structure.

In formulations containing inulin and xanthan gum at 0.25 % (Sd and Wd) and 0.5 % (Se and We), micrograph images displayed abundant inulin particles, with decreased sizes of the inulin aggregates, as compared with the formulations without xanthan gum. Sworn [50] suggested that the xanthan molecules in solution form intermolecular aggregates through hydrogen bonding and polymer entanglements. As previously observed, the diameters D[3, 4] were less with the addition of a xanthan and inulin mixture. With a high number of hydroxyl groups, inulin may play a role in the hydrogen bonding in food systems by influencing the solubility of other water-binding ingredients, such as xanthan gum and starch, and competing for the available water as the solvent [44]. The presence of xanthan gum may have decreased the growth rates of the inulin aggregates. Torres et al. [36] mention that the exclusion effect of the starch, would lead to the formation of aggregates containing inulin crystals and a progressive aggregation of inulin crystals took place in the continuous phase, thereby increasing the effective fraction volume. When xanthan gum is also present in the continuous phase may affect the formation of aggregates containing of inulin crystals. Upon heating above the transition temperature, xanthan loses its helical conformation and converts to a random coil and after that, when the denatured xanthan molecules are cooled, the helical conformation is restored [35]. Xanthan gum molecules have the ability to engage in non-electrostatic interactions with other polysaccharides during cooling and it was proven that these interactions are suppressed by the helical conformation [51, 52]. Our results of particle-size distributions and microscopy indicated that in formulations containing inulin and xanthan gum at 0.25 % and 0.5 % displayed abundant inulin particles, with decreased sizes of the inulin aggregates, as compared with the formulations contain inulin without xanthan gum. This way, xanthan gum assisted the retardation of inulin aggregate.

Cluster Analysis

A cluster analysis of the custards analyzed at various days of storage is presented as a dendrogram in Fig. 5. As shown in the figure, clear clusters were found to be present. The formation of groups based in the measurement of the Euclidean distance among the samples and the similarity level of each sample were determined by the distance of the horizontal line in the dendrogram, with short distances indicating strong relationships. Considering a distance of 80, the samples at various days of storage were segmented into three clusters, which can be identified as follows: the first cluster (1) was composed of 14 samples (Sb, Sd, Wb and Wd); the second cluster (2) contained 10 samples (Sa, Sc and Wa); and the third cluster (3) included 6 samples (Se and We). With respect to sample Wa, the first day of analysis was within the second cluster. With increased storage time, these values accumulated in the first cluster.

Dendrogram of similarity among the custards dessert samples. 1d, 3d and 6d indicate the first, the third and the sixth day of storage. Identification of samples in Table 1

From a rheology perspective, the skimmed milk system with only 0.5 % xanthan addition yielded elastic (gel-like) behavior and was very stable upon the storage condition studied. Inulin was needed to improve taste and texture properties, and increase health benefits to the prepared low-fat custard. As a replacement of the fat content in dairy custard with the formulation Sd may also be advantageous, as Sd contained less concentrations of xanthan gum using inulin as a prebiotic, producing a formulation that may prevent the rate of inulin aggregation.

Conclusions

The results indicated that the magnitudes of the storage modulus and the loss modulus increased with frequency. Skimmed milk samples without xanthan and inulin exhibited fluid-like behaviors, with values of G″ exceeding G′. For all the other samples, the mechanical spectra were generally typical of weak gels, with values of G′ exceeding G″, suggesting that xanthan and inulin led to increases in the elastic characteristics of the samples. The rheological properties of the skimmed milk custard dessert contains only xanthan was not influenced by the storage time. A dendrogram of similarity and a microscopic analysis indicated that the fat content in dairy custard could be replaced with a formulation of skimmed milk containing both inulin and xanthan gum (0.25 %), which would prevent the growth rate of the inulin aggregates.

References

C.S. Brennan, C.M. Tudorica, Carbohydrate-based fat replacers in the modification of the rheological, textural and sensory quality of yoghurt: comparative study of the utilisation of barley beta-glucan, guar gum and inulin. Int. J. Food Sci. Technol. 43, 824–833 (2008)

J. Warrand, Healthy polysaccharides. The next chapter in food products. Food Technol. Biotech. 44, 355–370 (2006)

I. Mandala, C. Michon, B. Launay, Phase and rheological behaviors of xanthan/amylose and xanthan/starch mixed systems. Carbohydr. Polym. 58, 285–292 (2004)

J.E. Zimeri, J.L. Kokini, The effect of moisture content on the cristallinity and glass transition temperature of inulin. Carbohydr. Polym. 48, 299–304 (2002)

D. Pszczola, Curdlan differs from other gelling agents. Food Technol. 51, 30–33 (1997)

A. Bot, U. Erle, R. Vreeker, W.G.M. Agterof, Influence of crystallisation conditions on the large deformation rheology of inulin gels. Food Hydrocoll. 18, 547–556 (2004)

Y. Kim, M.N. Faqih, S.S. Wang, Factors affecting gel formation of inulin. Carbohydr. Polym. 46, 135–145 (2001)

C.L.M. Hébette, J.A. Delcour, M.H.J. Koch, K. Booten, R. Kleppinger, N. Mischenko, H. Reynaers, Complex melting of semi-crystalline chicory (Cichorium intybus L.) root inulin. Carbohydr. Res. 310, 65–75 (1998)

S.N. Ronkart, M. Paquot, C. Deroanne, C. Fougnies, S. Besbes, C.S. Blecker, Development of gelling properties of inulin by microfluidization. Food Hydrocoll. 24, 318–324 (2010)

T. Wada, J.N. Sugatani, E. Terada, M. Ohguchi, M. Miwa, Physicochemical characterization and biological effects of inulin enzymatically synthesized from sucrose. J. Agric. Food Chem. 53, 1246–1253 (2005)

A. Tárrega, A. Rocafull, E. Costell, Effect of blends of short and long-chain inulin on the rheological and sensory properties of prebiotic low-fat custards. LWT Food Sci. Technol. 43, 556–562 (2010)

G.R. Gibson, M.R. Roberfroid, Dietary modulation of the human colonic microbiota: introducing the concept of prebiotics. J. Nutr. 125, 1401–1412 (1995)

Y. Wang, Review Prebiotics: Present and future in food science and technology. Food Res. Int. 42, 8–12 (2009)

D. López-Molina, M.D. Navarro-Martínez, F.R. Melgarejo, A.N.P. Hiner, S. Chazarra, J.N. Rodríguez-López, Molecular properties and prebiotic effect of inulin obtained from artichoke (Cynara scolymus L.). Phytochemistry 66, 1476–1484 (2005)

R.A. Speers, M.A. Tung, Concentration and temperature dependence of flow behavior of xanthan gum dispersions. J. Food Sci. 51, 96–98 (1986)

V.J. Morris, Gelation of Polysaccharides, in Functional Properties of Food Macromolecules, ed. by S.E. Hill, D.A. Ledward, J.R. Mitchell, 2nd edn. (Aspen Publ, MD, 1998), pp. 143–226

R. Pongsawatmanit, S. Srijunthongsiri, Influence of xanthan gum on rheological properties and freeze–thaw stability of tapioca starch. J. Food Eng. 88, 137–143 (2008)

N.A. Abdulmola, W.N. Hember, R.K. Richardson, E.R. Morris, Effect of xanthan on the small-deformation rheology of crosslinked and uncrosslinked waxy maize starch. Carbohydr. Polym. 31, 65–78 (1996)

B. Heyman, W.H. De Vos, F. Depypere, P. Van der Meeren, K. Dewettinck, Guar and xanthan gum differentially affect shear induced breakdown of native waxy maize starch. Food Hydrocoll. 35, 546–556 (2014)

A. Kruger, C. Ferrero, N.E. Zaritzky, Modelling corn starch swelling in batch systems: effect of sucrose and hydrocolloids. J. Food Eng. 58, 125–133 (2003)

D.D. Christianson, J.E. Hodge, D. Osborne, R.W. Detroy, Gelatinization of wheat starch as modified by xanthan gum, guar gum, and cellulose gum. Cereal Chem. 58, 513–517 (1981)

A. Tárrega, A.E. Costell, Effect of composition on the rheological behaviour and sensory properties of semisolid dairy dessert. Food Hydrocoll. 20, 914–922 (2006)

P.L. Arcia, E. Costell, A. Tárrega, Thickness suitability of prebiotic dairy desserts: Relationship with rheological properties. Food Res. Int. 43, 2409–2416 (2010)

L. González-Tomás, J. Coll-Marqués, E. Costell, Viscoelasticity of inulin-starch-based dairy systems. Influence of inulin average chain length. Food Hydrocoll. 22, 1372–1380 (2008)

L. González-Tomás, S. Bayarri, J. Coll-Marqués, E. Costell, Flow behaviour of inulin-enriched dairy desserts: influence of inulin average chain length. Int. J. Food Sci. Technol. 44, 1214–1222 (2009)

S. Bayarri, I. Chuliá, E. Costell, Comparing l-carrageenan and an inulin blend as fat replacers in carboxymethyl cellulose dairy desserts. Rheological and sensory aspects. Food Hydrocoll. 24, 578–587 (2010)

M.S. Lizarraga, D.D.P. Vicin, R. González, A. Rubiolo, L.G. Santiago, Rheological behaviour of whey protein concentrate and λ-carrageenan aqueous mixtures. Food Hydrocoll. 20, 740–748 (2006)

A. Tárrega, J.D. Torres, E. Costell, Influence of the chain-length distribution of inulin on the rheology and microstructure of prebiotic dairy desserts. J. Food Eng. 104, 356–363 (2011)

T.G. Mezger, The Rheology Handbook – For Users of Rotational and Oscillatory Rheometers (Vincentz Verlag, Hannover, 2002)

J.E. Zimeri, J.L. Kokini, Rheological properties of inulin–waxy maize starch systems. Carbohydr. Polym. 52(1), 67–85 (2003)

C. Kim, B. Yoo, Rheological properties of rice starch–xanthan gum mixtures. J. Food Eng. 75, 120–128 (2006)

Y. Viturawong, P. Achayuthakan, M. Suphantharika, Gelatinization and rheological properties of rice starch/xanthan mixtures: Effects of molecular weight of xanthan and different salts. Food Chem. 111, 106–114 (2008)

J.A. da Silva Lopes, M.A. Rao, Rheological Behavior of Food Gel Systems, in Rheology of Fluid and Semisolid Foods: Principles and Applications, ed. by M.A. Rao (Springer, New York, 2007), pp. 339–401

A. Dan, S. Ghosh, S.P. Moulik, Physicochemical studies on the biopolymer inulin: a critical evaluation of its self-aggregation, aggregate-morphology, interaction with water, and thermal stability. Biopolymers 91, 687–699 (2009)

B. Heyman, W.H. De Vos, P. Van der Meeren, K. Dewettinck, Gums tuning the rheological properties of modified maize starch pastes: Differences between guar and xanthan. Food Hydrocoll. 39, 85–94 (2014)

J.D. Torres, A. Tárrega, E. Costell, Storage stability of starch-based dairy desserts containing long-chain inulin: Rheology and particle size distribution. Int. Dairy J. 20, 46–52 (2010)

A.H. Clark, S.B. Ross-Murphy, Structural and mechanical properties of biopolymer gels. Adv. Polym. Sci. 83, 57–192 (1987)

B. Heyman, F. Depypere, P. Van der Meeren, K. Dewettinck, Processing of waxy starch/xanthan gum mixtures within the gelatinization temperature range. Carbohydr. Polym. 96, 560–567 (2013)

A. Tárrega, J.F. Velez-Ruiz, E. Costell, Influence of milk on the rheological behaviour of cross-linked waxy maize and tapioca starch dispersions. Food Res. Int. 38, 759–768 (2005)

A.M. Matser, P.A.M. Steeneken, Rheological properties of highly cross-linked waxy maize starch in aqueous suspensions of skim milk components. Effects of the concentration of starch and skim milk components. Carbohydr. Polym. 32(297–305) (1997)

P. Kip, D. Meyer, R.H. Jellema, Inulins improve sensoric and textural properties of low-fat yoghurts. Int. Dairy J. 16, 1098–1103 (2006)

S. Bayarri, L. González-Tomás, E. Costell, Viscoelastic properties of aqueous and milk systems with carboxymethyl cellulose. Food Hydrocoll. 23, 441–450 (2009)

H.M. Choi, B. Yoo, Steady and dynamic shear rheology of sweet potato starch–xanthan gum mixtures. Food Chem. 116, 638–643 (2009)

D. Meyer, Inulin, in Handbook of Hydrocolloids, ed. by G.O. Phillips, P.A. Williams (CRC Press, Boca Raton, 2009), pp. 829–848

C.M. Bryant, D.J. McClements, Influence of xanthan gum on physical characteristics of heat-denatured whey protein solutions and gels. Food Hydrocoll. 14, 383–390 (2000)

G. Tabilo-Munizaga, G.V. Barbosa-Cánovas, Rheology for the food industry. J. Food Eng. 67, 147–156 (2005)

D. Meyer, S. Bayarri, A. Tárrega, E. Costell, Inulin as texture modifier in dairy products. Food Hydrocoll. 25, 1881–1890 (2011)

P.L. Arcia, S. Navarro, E. Costell, A. Tárrega, Effect of inulin seeding on rheology and microstructure of prebiotic dairy desserts. Food Biophys. 6, 440–449 (2011)

P. Glibowski, A. Wasko, Effect of thermochemical treatment on the structure of inulin and its gelling properties. Int. J. Food Sci. 43, 2075–2082 (2008)

G. Sworn, Xanthan Gum, in Handbook of Hydrocolloids, ed. by G.O. Phillips, P.A. Williams (CRC Press, Woodhead Publishing Ltd, Cambridge, 2009), p. 186

C.F. Mao, W. Klinthong, Y.C. Zeng, C.H. Chen, On the interaction between konjac glucomannan and xanthan in mixed gels: an analysis based on the cascade model. Carbohydr. Polym. 89, 98–103 (2012)

F. Renou, O. Petibon, C. Malhiac, M. Grisel, Effect of xanthan structure on its interaction with locust bean gum: toward prediction of rheological properties. Food Hydrocoll. 32, 331–340 (2013)

Acknowledgments

We would like to express our appreciation to The Carolina Foundation of Spain for a scholarship awarded to one of the authors (Noreña).

Author information

Authors and Affiliations

Corresponding author

Additional information

Headings

Rheological properties of the custard samples changed during the storage time.

There were interactions among inulin, xanthan, type of milk and the time of storage.

Inulin and xanthan gum may be used as a replacement for the fat in dairy custards.

Xanthan gum may prevent the growth rates of inulin aggregation.

Rights and permissions

About this article

Cite this article

Zapata Noreña, C.P., Bayarri, S. & Costell, E. Effects of Xanthan Gum Additions on the Viscoelasticity, Structure and Storage Stability Characteristics of Prebiotic Custard Desserts. Food Biophysics 10, 116–128 (2015). https://doi.org/10.1007/s11483-014-9371-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11483-014-9371-2