Abstract

Novel processed whey cheese samples were prepared with the addition of different polysaccharides (0.8% w/w), namely, xanthan gum, guar gum, locust bean gum (LBG), and κ-carrageenan, used as stabilizers and added individually or in 1:1 mixtures. Chemical composition of samples was constant, as well as final pH (5.2). The effect of added stabilizers on rheological properties, fat globule size, and sensory attributes of samples was studied, where significant (P < 0.05) differences among samples were observed in all examined parameters. Rheological properties, as determined by squeezing flow viscometry, showed strong correlations among individual parameters, as well as to sensory attributes. During squeezing flow, all samples behaved as pseudoplastic fluids. Viscosity of samples, expressed as biaxial stress growth coefficient at 0.025 s−1, ranged from 390 to 1549 kPa·s. Samples containing xanthan gum, guar gum, LBG, and mixture of xanthan and guar gums were less consistent and solid, while they were rated as having increased spreadability and smoothness. The mixtures of LBG with xanthan gum or κ-carrageenan exhibited strong synergistic effects in samples, whereas they were rated as the firmest and least spreadable. The partial substitution of κ-carrageenan with xanthan or guar gums was found to produce samples of decreased firmness and increased spreadability and smoothness. Xanthan gum allowed the formation of the largest fat globules, while the mixture of κ-carrageenan with LBG gave the smallest ones. The interactions between polysaccharides and whey proteins may be exploited so as to produce spreadable processed whey cheeses with specific functional properties and improved sensory attributes.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The development of novel types of products is among the main goals of the processed cheese industry, which can be achieved by incorporation of various ingredients in formulations, such as whey proteins (WP) and polysaccharides.

WP are a low-cost by-product of the cheese making and casein industry, recovered by utilization of the resulting whey. The production of whey cheese is another means of utilization of whey, as in the case of Myzithra, a soft mild cheese produced in large quantities throughout Greece. Its preparation is based on denaturation and coagulation of WP present in whey [1]. WP represent 20% of total milk proteins and are composed of β-lactoglobulin, α-lactalbumin, serum albumin, immunoglobulin, and other minor proteins [2]. Due to excellent functional properties and very high digestibility and biological value, WP are considered as a valuable food constituent [3]. In processed cheeses, research on new product development has mainly focused on partial replacement of caseins with WP [4, 5], as has been extensively reviewed [6, 7].

Polysaccharides functioning as stabilizers are added to various foods, individually or combined. The most common polysaccharides used are galactomannans, such as guar gum and locust bean gum (LBG), as well as xanthan gum and carrageenans. Galactomannans are neutral, branched polysaccharides, and are capable of forming viscous solutions, whereas LBG has been reported to be more self-associating than guar gum [8, 9]. Xanthan gum, which is a high molecular-weight anionic polysaccharide, is mainly considered as a non-gelling polysaccharide [10, 11]. Carrageenans are a family of linear sulfated polysaccharides with a variable proportion of sulfate groups. The less sulfated fraction is κ-carrageenan, which is capable of forming gels on cooling [12].

Blending of polysaccharides can lead to the development of new textures, especially as interactions between them can improve or induce gelation. Xanthan gum showed strong synergistic interactions with galactomannans and has been found to form thermo-reversible weak or stronger and elastic gels with guar gum or LBG, respectively [13]. In addition, synergistic effects have been observed in mixed systems of κ-carrageenan and LBG [11, 12, 14]. Moderate-to-insignificant synergistic effects have also been reported between κ-carrageenan and guar gum [11]. Finally, no interactions between xanthan gum and κ-carrageenan have been observed [15].

In WP–polysaccharide systems, texture is a result of interactions between these constituents. Due to the nonionic character of galactomannans, segregative interactions between WP and guar gum or LBG, leading to phase separation, have been reported either to impede, not affect or slightly improve the structure of WP heat-set gels, depending on pH and concentration of biopolymers [9, 16]. Electrostatic attractions and complexation between WP and xanthan gum [17,18,19,20] or κ-carrageenan [21, 22] have been reported below or even around the isoelectric point (pI) of WP. The above have been attributed to the association of negatively charged groups of these anionic polysaccharides with positively charged patches on the WP’s surface near pI [21]. Thermodynamic incompatibility has also been observed between heat-denatured WP and xanthan gum [17, 23,24,25]. The above suggest that in complex food systems containing biopolymers and lipids, such as processed cheese, the properties of final products will be governed by the structures arising from the various interactions between different constituents.

In processed cheese research, polysaccharides have been mainly used as additives that could replace emulsifying salts [4, 5, 26,27,28]. Recent work involved the development of processed whey cheeses (PWC) of varying chemical composition, using guar gum as a stabilizer and a Myzithra-type whey cheese as the sole cheese base [6]. Results showed that the preparation of PWC was feasible and that the acceptability of these products was governed by chemical composition. Nonetheless, there is a lack of available literature focusing on the effects of various stabilizers on the properties of PWC. The aim of this work was to study the influence of different polysaccharides, such as xanthan gum, guar gum, LBG, and κ-carrageenan, added as stabilizers, individually or in 1:1 mixtures, on the rheological and sensory properties, as well as fat globule size of novel, semi-solid, spreadable PWC samples, prepared with whey cheese (Myzithra) as the sole cheese base.

Materials and methods

Materials

The cheese base for the preparation of novel spreadable PWC samples was a fresh Myzithra cheese (60.4% w/w moisture; 17.0% w/w fat; 16.9% w/w proteins, 1.21% w/w ash, pH 5.70), prepared exclusively from whey, without salt addition, and kindly provided by Mevgal Dairy S.A. (Thessaloniki, Greece). Pasteurized, homogenized full cream (47.7% w/w moisture; 48.0% w/w fat; 1.4% w/w proteins, 1.1% w/w ash, pH 6.70) was purchased from Neogal Dairy S.A. (Drama, Greece). Xanthan gum, guar gum, LBG, and κ-carrageenan, as well as NaCl, were obtained from Sigma-Aldrich (Saint-Louis, MO, USA). Freeze-dried starter culture of mixed mesophilic lactic strains (FD-DVS Flora-Danica) was purchased from Chr. Hansen’s Dairy Cultures (Hørsholm, Denmark). All reagents used for analyses were of analytical grade (Sigma-Aldrich, Saint-Louis, MO, USA).

Preparation of processed whey cheese samples

Nine (9) PWC samples were prepared using the Universal Machine UMC 5 jacketed mixer–cooker (Stephan Machinery GmbH, Hameln, Germany). All samples were obtained by mixing Myzithra cheese and cream at a ratio of 2.5:1 (w/w). The samples differed only in the type of stabilizer added (xanthan gum: X, guar gum: G, LBG: L, κ-carrageenan: C) or mixture (1:1 w/w) of two stabilizers added (xanthan gum/guar gum: X/G, xanthan gum/LBG: X/L, κ-carrageenan/xanthan gum: C/X, κ-carrageenan/guar gum: C/G, κ-carrageenan/LBG: C/L). The preparation procedure is described in detail elsewhere [6] and involved the addition of the starter culture to the mixture of Myzithra cheese and cream, which was kept at 30 °C with continuous monitoring of pH, until pH reached the value of 5.0. Stabilizers and NaCl were added at concentrations of 0.8 and 1.0% (w/w), respectively. Mixtures were heated up to 90 °C and held at this temperature for 5 min. An additional control sample was prepared without added stabilizer. The hot PWC samples were poured into glass jars with metal lids excluding any headspace, inverted and stored under refrigeration (4 °C) for analyses. For rheological measurements, portions of the hot PWC samples were immediately transferred into lubricated cylindrical molds, covered with saran cling wrap, and stored overnight at 4 °C. For reproducibility purposes, the nine samples were prepared in triplicate. All measurements that followed were conducted in all groups of triplicate samples within 4 days following preparation.

Chemical composition

Compositional analyses in raw materials and PWC samples involved the determination of moisture content (% w/w) [29], fat content (% w/w) [30], as well as ash and protein contents (% w/w) [31]. Total nitrogen (TN) and non-protein nitrogen (NPN), that is the fraction of TN soluble in 12% (w/v) trichloroacetic acid, were assayed by the Kjeldahl method. Protein content (% w/w) was calculated as 6.38 × (TN–NPN). The pH was measured using a pH-meter, model ΗΙ 8424 (Hanna Instruments Ltd, RI, USA), equipped with a glass, mass intrusion electrode (HI 1230B). All measurements of compositional parameters were performed in triplicate (one determination per triplicate sample).

Squeezing flow viscometry

Rheological properties of PWC samples were determined by squeezing flow viscometry [32], using TA.XTplus Texture Analyzer (Stable Micro Systems Ltd, Surrey, UK) equipped with a 300-N maximum load force cell. All samples were allowed to equilibrate at room temperature (23 ± 2 °C) for 2 h prior to testing. After removing the molds, lubricated squeezing flow tests were performed on the obtained cylindrical specimens of 10 mm height and 100 mm diameter. Specimen compression was applied between two parallel metal disks (Ø = 100 mm), previously lubricated with paraffin oil, with a speed of 6 mm/min, to 80% deformation. Immediately after compression, a stress relaxation test followed for 3 min. Six (6) measurements were made (two on each triplicate sample).

The following rheological parameters were determined: apparent stress at the end of compression, \(\sigma_{{{\text{app}}@2{\text{mm}}}}\), and apparent stress at the end of relaxation, \(\sigma_{{{\text{app}}@3{\text{mm}}}}\). The parameter \(\sigma_{{{\text{app}}@2{\text{mm}}}}\) is the compression stress at 2 mm specimen height (80% deformation). It is a measure of the sample’s consistency and is calculated as the force at 2 mm height divided by the cross-sectional area of specimen. The parameter \(\sigma_{{{\text{app}}@3{\text{mm}}}}\) is the unrelaxed residual stress after relaxation for 3 min at 80% deformation. It is a measure of the sample’s degree of solidity and is calculated as the force after relaxation for 3 min divided by the cross-sectional area of specimen [32].

Biaxial stress growth coefficient, \(\eta_{\rm E}^{ + }\) [33] and flow behavior index, n [34] were also calculated. The parameter \(\eta_{\rm E}^{ + }\) is the expression of elongational viscosity in the case that steady flow is not achieved. It is derived from force, \(F\left( t \right)\), versus displacement, \(H\left( t \right)\), data, as the stress, \(\sigma = F\left( t \right)/\pi r^{2}\), divided by the momentary strain rate, \(\dot{\varepsilon }_{b} = V_{z} /2 H\left( t \right)\), where r is the specimen’s radius and \(V_{z}\) is the normal velocity (compression speed). The parameter \(\eta_{\rm E}^{ + }\) was, thus, calculated using the following equation:

The flow behavior index, n, was calculated from the linear end parts of the derived log \(\eta_{\rm E}^{ + }\) versus log \(\dot{\varepsilon }_{b}\) curves, using simple linear regression, as the slope is equal to n − 1 [34].

In PWC samples that had distinguishable yield points during compression, the parameters fracture stress, \(\sigma_{f}\) (the stress at which a yield point is observed), as well as fracture strain, \(\varepsilon_{f}\) (the true strain at which a yield point is observed) [35], were determined from squeezing flow tests, as force versus displacement data were converted to stress, σ, versus true strain, ε, data. The lubricated squeezing flow test was chosen as an appropriate method for the study of rheological properties of semi-solids or semi-liquids and for the instrumental evaluation of spreadability, since the test conditions correspond to spreading of sample in a thin layer. That is, the lower the resistance force (or stress) of the sample, the higher its spreadability.

Fat globule size measurements

Fat globule size in PWC samples was measured using the MasterSizer 2000 particle size analyzer, equipped with a wet cell Hydro 2000 SM dispersion unit (Malvern Instruments Ltd, Worcestershire, UK). Measurements were carried out using procedures based on those described by Lee, Anema and Klostermeyer [36]. Sample preparation involved dispersion of 1 g of PWC sample in 100 mL of a dissociating solution containing EDTA (0.375% w/w) and Tween 20 (0.125% v/v). The pH was adjusted to 10 using NaOH. After dispersion for 1 h, samples were allowed to rest at refrigerated conditions (4 °C) overnight. Prior to measurements, samples were equilibrated at room temperature (23 ± 2 °C) for 1 h. Each sample was added to the dispersion unit until an obscuration between 10 and 20% was reached. Refractive index of the dispersed phase was 1.456, that of the dispersion medium was 1.330 and the absorbance value was 0.001. One measurement was conducted per triplicate sample, the following day after preparation of each sample. The average fat globule size was expressed as the volume-weighted mean diameter, d43 (μm). The size distribution width or dispersion index (span) was calculated as follows:

where d0.1, d0.5 and d0.9 are size values corresponding to the cumulative distribution at 10%, 50% and 90%, respectively.

Sensory evaluation

After equilibration at room temperature (23 ± 2 °C), the nine PWC samples were evaluated, using a descriptive intensity rating test, by a panel of 18 expert sensory assessors, comprising of members of the Department of Food Science and Technology, conforming to ISO 8586 [37]. Evaluations were conducted in a climate-controlled sensory analysis laboratory equipped with individual testing booths with neutral walls and a lighting system that represented illuminant D65. Panelists evaluated all samples, individually presented as cubic specimens and labelled with different and randomised three-digit codes. The PWC samples were distributed to the panelists according to a randomised, balanced for order and carry-over effects block design. A 9-point scale [38] was used for the sensory attributes: firmness (extremely soft–extremely firm), spreadability (not spreadable–extremely spreadable), and smoothness (extremely rough–extremely smooth). Each sample was evaluated six (6) times on each sensory attribute (two measurements per triplicate sample).

Statistical analysis

One-way analysis of variance (ANOVA) was employed on fat globule size, rheological, and sensory parameters of the PWC samples. When significant effects were detected (P < 0.05), the Student–Newman–Keuls’ (SNK) multiple range test was applied. Pearson’s correlation coefficients, r, were determined to reveal relationships between the properties of PWC samples. Statistical analyses were performed using the Statistica Software Package (version 10, StatSoft, Inc., Tulsa, OK).

Results and discussion

Chemical composition

Chemical composition of PWC samples was constant (moisture: 55.95 ± 0.45% w/w, protein: 12.31 ± 0.14% w/w, fat: 25.50 ± 0.32% w/w, ash: 1.62 ± 0.12% w/w), as well as pH (5.20 ± 0.04).

Characteristics of PWC samples

The preparation of a PWC control sample without the addition of polysaccharide resulted in a macroscopically phase separated sample, with a poorly emulsified and grainy texture, which was not further studied. Therefore, the presence of added polysaccharides played a crucial role in the formation of stable and smooth emulsions. As deduced from the preparation procedure, PWC samples can be described as heat-set emulsion gels, whose properties are governed by the interactions between proteins, polysaccharides, and fat globules. Specifically, pre-denatured and partially hydrolyzed WP, assisted by residual caseins, milk fat globule membrane materials, and polysaccharides, emulsified the liquefied fat globules [39]. At pH 5.0–5.2, which was the pH during heating and in final PWC samples, WP (pI ≈ 5.2) would further aggregate by reactions involving covalent, hydrophobic, or even electrostatic interactions [19]. The added polysaccharides functioned as stabilizers which immobilized the protein-coated fat globules in two ways: on the one hand, they modified the structure of the protein network due to interactions with WP, and on the other hand, they increased the viscosity of the aqueous phase or even formed gels [10], thus preventing the free movement of water and entrapping emulsified fat globules. Since this research aimed at the study of semi-solid spreadable PWC, a preliminary study has shown that the addition of at least 0.8% of stabilizer was indispensable, so that all nine PWC samples would be self-supporting gels.

Rheological properties

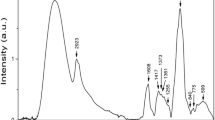

Figure 1 shows force–time curves of PWC samples obtained during the lubricated squeezing flow test. The first distinguished compression part of the curves has a duration of 80 s and corresponds up to 80% deformation (true strain = 1.61), while the following stress relaxation part of the curves has a duration of 180 s at 80% deformation.

Force–time curves of PWC samples (X, xanthan gum; G, guar gum; L, LBG; C, κ-carrageenan) during lubricated squeezing flow test: compression up to 80% deformation with a displacement rate of 6 mm/min and subsequent stress relaxation for 3 min. Curve values are means of six measurements per PWC sample

Compression curves of the PWC samples X, G, L, X/G, and C/X had smooth profiles with no clear yield point. Since these samples also showed lower force values, they did not have dense structural networks and could be described as weak gels. This behavior should be due to the fact that the aggregation of thermally denatured WP is promoted by phase separation effects, as well as by viscosity increase, due to the addition of stabilizers, without the presence of strong bonds. Polysaccharides used in the above PWC samples supported the protein matrix without forming a significant own network. In multi-component heat-set gels, phase separation between WP and xanthan gum or galactomannans has been reported to lead to a dispersed, compressed into spheres protein phase [16, 40].

On the contrary, PWC samples C, C/G, C/L, and X/L had higher force values and distinguishable yield points during compression, indicating signs of fracture or yielding. Compression profiles of these samples were characteristic of stronger and fracturable gels. As deformation further progressed, it led to a region of increasing stress, where squeezing flow was dominant. In the above samples, the parameters fracture stress, \(\sigma_{f}\), as well as fracture strain, \(\varepsilon_{f} ,\) were determined (Table 1).

Samples C and C/G, which had lower \(\sigma_{f}\) (20.40 and 15.07 kPa, respectively) and \(\varepsilon_{f}\) values (≈ 0.50), can be characterized as brittle. The structure of sample C is due to the ability of κ-carrageenan to produce strong gels on cooling, through self-association by formation of double helices between the coil regions of two adjacent molecules of the polysaccharide. The double helices then aggregate to form a three-dimensional network [12], but the rigid superstrands render the network brittle [41]. Also responsible for the structure of sample C is the associative phase separation between κ-carrageenan and WP, involving formation of electrostatic complexes. Sample C/G retained the fracture deformation behavior of κ-carrageenan, but had lower \(\sigma_{f}\) than sample C. This can be attributed to the high degree of galactose substitution of guar gum molecules [42], which presented a reduced ability to self-associate and cross-link with the κ-carrageenan molecules.

Samples C/L and X/L exhibiting high \(\sigma_{f}\) (37.62 and 34.47 kPa, respectively) and \(\varepsilon_{f}\) values (≈ 0.95) could be considered as tough. In sample C/L, due to the cross-linking between the double helices of the κ-carrageenan molecules and the unsubstituted (galactose-free) segments of the LBG chain [43], the polysaccharide mixture formed a denser and more homogeneous network that led to a more resistant and less brittle texture than κ-carrageenan alone (sample C). In agreement to the above results, Dunstan et al. [14] reported that the partial substitution of κ-carrageenan with LBG (1:1 ratio) in mixed polysaccharide gels (1% w/w total concentration) also increased fracture stress and deformation (from ≈ 25 to 45 kPa and ≈ 47–75%, respectively). In addition, the cross-linking between xanthan chains and unsubstituted regions of the LBG chain [44] produced a dense structural network in sample X/L, which fractured during compression.

The absence of a clear yield point in sample C/X could be attributed to the thermodynamic incompatibility between κ-carrageenan and xanthan gum resulting in segregative phase separation, due to electrostatic repulsions between the two anionic polysaccharides. In addition, associative interactions of the polysaccharides with WP by competitive adsorption, due to their difference in negative charges [45], could also be responsible for the resulting structure. Therefore, the network of sample C/X should involve two independent polysaccharide networks, produced by self-association, with simultaneous complex formation between the polysaccharides and WP. Such a system could be compressed without fracture. Similarly, in milk–polysaccharide gels, the contribution of κ-carrageenan to the gel-like behavior of xanthan gum was found to be insignificant, where xanthan gum exhibited a more independent behavior [15].

Profiles of compression curves similar to the PWC samples that fractured have also been shown during squeezing flow of WPI (13% w/w) emulsion gels containing high proportions of liquid fat (30% w/w), where samples failed under compression before reaching 80% deformation [46]. A study on model processed Edam cheese also reported that samples containing κ-carrageenan were harder and more fracturable, compared to those with LBG [27].

In PWC samples, values of apparent stress at the end of compression, \(\sigma_{\text{app@2mm}}\), were in the range of 9.84 for sample X to 39.10 kPa for sample C/L and values of apparent stress at the end of relaxation, \(\sigma_{\text{app@3min}}\), ranged from 4.78 for sample X to 20.45 kPa for sample C/L (Table 1). That is, at large deformation (80%), xanthan gum gave the least consistent and solid PWC, while the mixture of κ-carrageenan and LBG produced the most consistent and solid PWC. In other words, sample X was the most spreadable, while sample C/L the least spreadable. The reduced rheological properties of sample X should be due to a weak electrostatic complexation of WP with xanthan gum, which has been found to reduce the ability of WP aggregates to interact and build a rigid network at pH ≈ 5.5 [17, 24, 47]. This is supported by the fact that, in the absence of added whey proteins, xanthan gum gave suspensions and emulsions with a higher consistency coefficient than those produced by guar gum and LBG [48].

Segregative interactions of galactomannans with WP produced more consistent and solid samples (G, L) than sample X. Sample G was more consistent and solid than sample L, because guar gum increased the viscosity of the continuous phase more than LBG, due to its higher molecular weight [8] and density of hydrophilic groups, which resulted in better water binding. Blending of xanthan and guar gums exhibited a marginal synergistic effect at 80% deformation, since both apparent stress values of sample X/G were higher than those predicted by the additivity law, i.e., higher than the means calculated from the corresponding values of samples X and G. This synergism has been attributed to the association of unsubstituted or lightly substituted stretches of mannan backbone with xanthan rods [49]. Blending of κ-carrageenan with xanthan and guar gums produced less consistent and solid PWC samples (samples C/X and C/G, respectively) than sample C. In addition, samples C/X and C/G showed slight antagonism between κ-carrageenan and xanthan and guar gums, respectively, as their rheological properties had lower values than those predicted by the additivity law. Finally, the synergistic interactions of LBG with xanthan gum, as well as κ-carrageenan, were clearly manifested at 80% deformation (samples X/L and C/L, respectively), where, in particular, sample X/L gave \(\sigma_{\text{app@2mm}}\) and \(\sigma_{\text{app@3min}}\)values more than three times higher than the means calculated from the corresponding values of samples X and L.

In analogy to the above results, as determined by squeezing flow tests, \(\sigma_{\text{app@2mm}}\)values of ≈ 40 kPa have been reported for WP emulsion gels [50]. Comparable results have been reported for processed cheese analogs containing WPI and polysaccharides (0.2% w/w), where samples containing xanthan gum and LBG were soft, while samples containing carrageenan were harder [4].

Figure 2 shows the variation of biaxial stress growth coefficient, \(\eta_{\rm E}^{ + }\), of PWC samples, up to 80% deformation, in relation to the biaxial extensional strain rate, \(\dot{\varepsilon }_{b}\), on logarithmic scales. In all curves, an initial sharp increase in \(\eta_{\rm E}^{ + }\) was evident, which corresponds to the transient flow regime. The curves ended with a slightly or more pronounced decreasing linear part corresponding to the squeezing flow regime, the slope of which is n − 1, where n is the flow behavior index [34]. All PWC samples presented values of n lower than unity (Table 1), therefore, were considered pseudoplastic fluids. Samples X, G, L, X/G, and C/X had values of n from 0.69 to 0.81, while for samples C/L, X/L, C, and C/G that clearly fractured, n values ranged from 0.43 to 0.67. The shear-thinning behavior of samples C/L and X/L was especially pronounced. The pseudoplastic character was increased in the PWC samples, where the galactomannans partially substituted xanthan gum and κ-carrageenan (X/G, X/L, and C/G, C/L, respectively). A study on processed cheese spreads containing WP (20% of total proteins) also reported that all samples were typically pseudoplastic, where n values varied from 0.15 to 0.68, depending on the pH during cooking [7]. Similar profiles of variation of \(\eta_{\rm E}^{ + }\) with \(\dot{\varepsilon }_{b}\) have been reported for PWC [6], processed cheese spreads [51] and set kefir samples [52].

For comparison of PWC samples, values of \(\eta_{\rm E}^{ + }\) were selected at the \(\dot{\varepsilon }_{b}\) value of 0.025 s−1. They ranged from 389.85 for sample X to 1548.54 kPa·s for sample C/L (Table 1). Since \(\eta_{\rm E}^{ + }\) expresses the biaxial extensional (elongational) viscosity, the samples X/L, C, and C/L were shown to be more viscous than the other PWC samples.

Results from lubricated squeezing flow tests showed correlations among them. Specifically, \(\sigma_{f}\) strongly correlated with \(\varepsilon_{f}\) (r = 0.959), \(\sigma_{\text{app@2mm}}\) (r = 0.825) and \(\sigma_{\text{app@3min}}\) (r = 0.870), while \(\sigma_{\text{app@2mm}}\) correlated highly positively with \(\sigma_{\text{app@3min}}\) (r = 0.976), showing that PWC samples which had increased consistency had a more solid character and increased fracture stress and strain. On the contrary, n correlated highly negatively with \(\eta_{\rm E}^{ + }\) (r = – 0.785), \(\sigma_{\text{app@2mm}}\) (r = – 0.788) and \(\sigma_{\text{app@3min}}\) (r = – 0.801), as well as with \(\sigma_{f}\) (r = – 0.754) and \(\varepsilon_{f}\) (r = – 0.875). The above show that, regardless of the type of stabilizer added, as the viscosity, the consistency, and the solid character increased, PWC samples were more pseudoplastic and that the more consistent and deformable PWC samples of those that fractured had a more pronounced shear-thinning behavior.

Fat globule size

Size distribution of fat globules in PWC samples is shown in Fig. 3. All PWC samples had similar bimodal fat globule size distribution, with two group sizes of mean values: a major size class of large fat globules (≈ 8–15 μm) and a minor size class of small fat globules (≈ 1 μm). During emulsification, the rates of fat globule breakage and coalescence or aggregation would govern the fat globule size distribution. Since the type of added stabilizer did not markedly affect fat globule size distribution, the formed fat globules were produced by comparable conditions during heating under shear. In this respect, it has been shown that the gelling temperature or time of WP heat-set gels at pH 5.0–5.5 is not affected by added stabilizers, such as xanthan gum [17], LBG [9], or κ-carrageenan [53]. The small size class of fat globules in PWC samples corresponds to individual fat globules, whereas the higher size class corresponds either to partially coalesced fat globules or to aggregated ones formed through proteins adsorbed onto different fat globules [54].

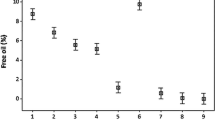

The mean fat globule size of PWC samples, d43 (μm), is shown in Fig. 4, whereas d0.1, d0.5, d0.9 and span values are given in Table 2. The majority of PWC samples exhibited similar span values, ranging from 1.38 to 1.50, whereas samples L, C, and X/L had increased and non-significantly different span values, ranging from 1.69 to 1.75 (P > 0.05). The type of added stabilizer had significant effects on mean fat globule size, d43, where values ranged from 9.35 μm in sample C/L to 16.48 μm in sample X (P < 0.05). The remainder PWC samples had intermediate and non-significantly different d0.5, d0.9 and d43 values (P > 0.05); thus, large fat globules of similar size were present in the majority of PWC samples.

In sample X, which had the largest d43 value, both the small and large size classes of fat globules were clearly shifted to larger diameters (as observed in d0.1 and d0.9 values, respectively), which reveal that fat globules were indeed larger than all other PWC samples. This can be attributed to the fact that xanthan gum, as a non-adsorbing polysaccharide [10], is expected to show no surface activity. Furthermore, xanthan gum has been known to cause depletion flocculation, due to its high hydrodynamic volume which tends to be excluded from interparticle gaps [55], thereby possibly allowing for aggregation and coalescence of neighboring fat globules. It also appeared that the low viscosity of sample X, expressed as \(\eta_{\rm E}^{ + }\) (Table 1), as a result of poor support of the protein matrix by the xanthan molecules, allowed the formation of large fat globules, during cooling.

Regarding the samples with intermediate fat globule sizes (d43 = 11.05–13.54 μm, Fig. 4), LBG and guar gum, which are both neutral polysaccharides, would not adsorb to proteins at the interface but have been reported to exhibit some weak and reversible surface activity [56, 57] and to stabilize emulsions through a steric stabilization mechanism [57,58,59]. On the other hand, the anionic κ-carrageenan is considered non-adsorbing at the oil–water interface [10], but could associatively interact with the adsorbed proteins on the surface of fat globules, since more positive patches of WP could be exposed as they unfold after adsorption. At pH around 5.0, electrostatic interactions at the interface between κ-carrageenan and milk proteins have been reported to occur [21, 60,61,62] and are expected to be more prominent than those between xanthan gum, because κ-carrageenan has a higher charge density [45]. This could have provided an increased repulsion between adsorbed layers or even produced thicker stabilizing layers around fat globules [21], both of which should enhance the protection of fat globules against aggregation and coalescence.

Finally, in sample C/L, which had the lowest d43 value, both the small and large size classes of fat globules were reduced, whereas they were more narrowly distributed. This shows that the interactions between κ-carrageenan and LBG, as well as between both polysaccharides and adsorbed milk proteins provided a better protection to the fat globules from aggregation and coalescence. In this sample, which presented the highest \(\eta_{\rm E}^{ + }\) (Table 1), the fat globules were immobilized in a highly viscous gelled phase between κ-carrageenan and LBG, which apparently provided the most competent steric stabilization of fat globules.

Analogous bimodal distribution has been observed in emulsions (20% w/w oil) stabilized by pre-heated (at 80 °C for 30 min) WP (12% w/w) [63], in emulsions (20% w/w oil, 4% w/w proteins) prepared at 55 °C, stabilized by aggregated proteins from milk protein concentrate and skim milk powder [64] and in heated (at 90 °C for 30 min) WP (3% w/w) stabilized emulsions (30% w/w oil) [65]. Bimodal size distribution has also been reported for processed cheese of 55% moisture [36], for pasteurized emulsions (9% oil) stabilized by 3% w/w WPI [66], and for heated (at 121 °C for 16 min) emulsions (4% oil) stabilized by 4% w/w hydrolyzed WP containing xanthan gum and guar gum (0.8% w/w) [67]. Values of d43 in model processed cheeses containing starch were reported ranging from 1 to 10 μm [68], whereas in emulsions stabilized by heated-treated WP, d43 was equal to 20 μm [63].

Sensory attributes

Significant differences were observed (P < 0.05) among the mean scores of PWC samples’ sensory attributes (Table 3). The firmest and least spreadable PWC samples were samples C, C/L and X/L, while the least firm and more spreadable PWC samples were samples G, L and X/G. Samples C and X/L were perceived as the least smooth PWC samples, while samples X, G and X/G were rated as very smooth. The partial substitution of κ-carrageenan with xanthan gum or guar gum was found to produce PWC samples (C/X and C/G, respectively) of decreased firmness and increased spreadability and smoothness.

Results of sensory attributes showed strong correlations among them (P < 0.05). Firmness correlated strongly negatively with spreadability (r = – 0.858) and smoothness (r = – 0.782), revealing that panelists rated the perceived less firm PWC samples as more spreadable and smoother. In a study on sensory and breakdown properties of WPI gels containing different polysaccharides, spreadability, a property related to gel breakdown after fracture, was also found to correlate strongly negatively with firmness [69]. Sensory evaluation of emulsifying salt-free processed cheese spreads has also shown that κ-carrageenan addition (0.8% w/w) produced samples which were assessed as very firm [27].

Correlations between instrumental and sensory parameters

Sensory firmness showed strong positive correlations with \(\sigma_{f}\) (r = 0.716), \(\sigma_{\text{app@2mm}}\) (r = 0.963) and \(\sigma_{\text{app@3min}}\) (r = 0.949), while it correlated strongly negatively with n (r = – 0.771). These correlations suggest that the PWC samples perceived as firmer were those with increased instrumentally determined consistency, resistance to fracture, as well as solid and pseudoplastic character. The sensory firmness has been previously found to correlate positively to fracture stress of emulsion-filled gels [70] and mixed WP/polysaccharide gels [69] and it was also shown to highly positively correlate with \(\sigma_{\text{app@2mm}}\) and \(\sigma_{\text{app@3min}}\) in similar PWC samples of variable chemical composition [6]. Smoothness correlated strongly negatively with \(\sigma_{\text{app@2mm}}\) (r = – 0.729) and \(\sigma_{\text{app@3min}}\) (r = – 0.707), revealing that the more consistent and solid PWC samples were perceived as less smooth. Analogous correlations have been reported by Melito et al. [71], where WPI/κ-carrageenan gels with increased nonlinear behavior were found to have a chalky texture. Spreadability correlated highly positively with n (r = 0.734), but strongly negatively with \(\sigma_{\text{app@2mm}}\) (r = – 0.862), \(\sigma_{\text{app@3min}}\) (r = – 0.826) and \(\eta_{\rm E}^{ + }\) (r = – 0.847). Thus, the less pseudoplastic, consistent, solid, and viscous PWC samples were rated as more spreadable.

Conclusions

The type of polysaccharides added as stabilizers, individually or in mixtures, greatly influenced rheological properties, fat globule size, and sensory attributes of the novel spreadable PWC samples prepared. Samples had differing structures as a result of phase separation involving segregative or partially associative interactions between polysaccharides and WP, as well as gelation of these biopolymers. However, similarities in rheological and sensory properties were observed between PWC samples containing xanthan gum, guar gum, and LBG alone and mixtures of xanthan gum with guar gum or κ-carrageenan, as well as between PWC samples containing κ-carrageenan alone, mixtures of LBG with κ-carrageenan or xanthan gum and mixture of κ-carrageenan with guar gum. The first group included samples that did not present fracture during compression, had low consistency, viscosity, and solid character, while exhibiting high spreadability. On the contrary, the second group included samples that showed fracture during compression, had high consistency, viscosity, and solid character while exhibiting low spreadability.

Nevertheless, the properties of each of the nine developed and studied PWC samples have been interpreted as a result of the already known specific interactions between their constituents, as follows: Xanthan gum alone produced the least consistent and the most spreadable sample, due to its weak electrostatic complexation with WP. In addition, xanthan gum, with its non-adsorbing character and its low viscosity in solution, allowed the formation of the largest fat globules. The segregative interactions of WP with the neutral galactomannans (guar gum and LBG) promoted WP aggregation, leading to more consistent samples with smaller fat globules than the sample with xanthan gum. Blending of xanthan and guar gums showed a marginal synergistic effect, due to their cross-linking. κ-carrageenan produced an even more consistent sample because of self-association and aggregation, as well as its electrostatic complexation with WP. Blending of κ-carrageenan with xanthan and guar gums gave less consistent samples than that with κ-carrageenan alone. This could be attributed to the impeding of κ-carrageenan gelation by the electrostatic repulsions, in the case of xanthan gum, or by the high degree of galactose substitution, in the case of guar gum. The strong synergistic interactions of xanthan gum with LBG, by cross-linking, produced a very consistent sample. Finally, the most consistent and least spreadable PWC sample was obtained by the synergism of the cross-linked κ-carrageenan and LBG. In this sample, the strong interactions between the two polysaccharides and adsorbed milk proteins, as well as the high viscosity led to the formation of the smallest fat globules.

The interactions between polysaccharides, as well as those with WP can be exploited so as to produce spreadable PWC with specific functional properties and improved sensory attributes.

References

Dermiki M, Ntzimani A, Badeka A, Savvaidis IN, Kontominas MG (2008) Shelf-life extension and quality attributes of the whey cheese “Myzithra Kalathaki” using modified atmosphere packaging. LWT Food Sci Technol 41:284–294

Fox PF, McSweeney PLH (1998) In: Fox PF, McSweeney PLH (eds) Dairy chemistry and biochemistry. Blackie Academic and Professional, London

Smithers GW (2008) Whey and whey proteins—from ‘gutter-to-gold’. Review. Int Dairy J 18:695–704

Gustaw W, Mleko S (2007) The effect of polysaccharides and sodium chloride on physical properties of processed cheese analogs containing whey proteins. Milchwissenschaft 62(1):59–62

Schäffer B, Szakály S, Lõrinczy D, Schäffer B (2001) Processed cheeses made with and without peptization. Submicroscopic structure and thermodynamic characteristics. J Therm Anal Calorim 64:671–679

Chatziantoniou SE, Thomareis AS, Kontominas MG (2015) Effect of chemical composition on physico-chemical, rheological and sensory properties of spreadable processed whey cheese. Eur Food Res Technol 241:737–748

Lee SK, Anema SG (2009) The effect of the pH at cooking on the properties of processed cheese spreads containing whey proteins. Food Chem 115:373–380

Kök MS, Hill SE, Mitchell JR (1999) Viscosity of galactomannans during high temperature processing: influence of degradation and solubilisation. Food Hydrocoll 13:535–542

Tavares C, da Silva JAL (2003) Rheology of galactomannan–whey protein mixed systems. Int Dairy J 13:699–706

Bouyer E, Mekhloufi G, Rosilio V, Grossiord J-L, Agnely F (2012) Proteins, polysaccharides, and their complexes used as stabilizers for emulsions: alternatives to synthetic surfactants in the pharmaceutical field? Review. Int J Pharm 436:359–378

Pinheiro AC, Bourbon AI, Rocha C, Ribeiro C, Maia JM, Gonçalves MP, Teixeira JA, Vicente AA (2011) Rheological characterization of κ-carrageenan/galactomannan and xanthan/galactomannan gels: comparison of galactomannans from non-traditional sources with conventional galactomannans. Carbohydr Polym 83:392–399

Arda E, Kara S, Pekcan O (2009) Synergistic effect of the locust bean gum on the thermal phase transitions of κ-carrageenan gels. Food Hydrocoll 23:451–459

Saha D, Bhattacharya S (2010) Hydrocolloids as thickening and gelling agents in food: a critical review. J Food Sci Technol 47(6):587–597

Dunstan DE, Chen Y, Liao M-L, Salvatore R, Boger DV, Prica M (2001) Structure and rheology of the κ-carrageenan/locust bean gum gels. Food Hydrocoll 15:475–484

Thaiudom S, Goff HD (2003) Effect of κ-carrageenan on milk protein polysaccharide mixtures. Int Dairy J 13:763–771

Rocha C, Teixeira JA, Hilliou L, Sampaio P, Gonçalves MP (2009) Rheological and structural characterization of gels from whey protein hydrolysates/locust bean gum mixed systems. Food Hydrocoll 23:1734–1745

Bertrand ME, Turgeon SL (2007) Improved gelling properties of whey protein isolate by addition of xanthan gum. Food Hydrocoll 21:159–166

Benichou A, Aserin A, Garti N (2007) W/O/W double emulsions stabilized with WPI–polysaccharide complexes. Coll Surf A Physicochem Eng Aspects 294:20–32

Cavallieri ALF, Cunha RL (2009) Cold-set whey protein gels with addition of polysaccharides. Food Biophys 4:94–105

Le XT, Turgeon SL (2015) Textural and waterbinding behaviors of β-lactoglobulin-xanthan gum electrostatic hydrogels in relation to their microstructure. Food Hydrocoll 49:216–223

Stone AK, Nickerson MT (2012) Formation and functionality of whey protein isolate- (kappa-, iota-, and lambda-type) carrageenan electrostatic complexes. Food Hydrocoll 27:271–277

Heilig A, Göggerle A, Hinrichs J (2009) Multiphase visualisation of fat containing β-lactoglobulin–κ-carrageenan gels by confocal scanning laser microscopy, using a novel dye, V03-01136, for fat staining. LWT Food Sci Technol 42:46–653

Li J, Eleya MMO, Gunasekaran S (2006) Gelation of whey protein and xanthan mixture: effect of heating rate on rheological properties. Food Hydrocoll 20:678–686

Sanchez C, Schmitt C, Babak VG, Hardy J (1997) Rheology of whey protein isolate-xanthan mixed solutions and gels. Effect of pH and xanthan concentration. Nahrung 41(6):336–343

Bryant CM, McClements DJ (2000) Influence of xanthan gum on physical characteristics of heat-denatured whey protein solutions and gels. Food Hydrocoll 14:383–390

Ahmad S, Butt MS, Pasha I, Sameen A (2015) Quality of processed Cheddar cheese as a function of emulsifying salt replaced by κ-carrageenan. Int J Food Prop 19(8):1874–1883

Černíková M, Buňka F, Pospiech M, Tremlová B, Hladká K, Pavlínek K, Březina P (2010) Replacement of traditional emulsifying salts by selected hydrocolloids in processed cheese production. Int Dairy J 20(5):336–343

Swenson BJ, Wendorff WL, Lindsay RC (2000) Effects of ingredients on the functionality of fat-free process cheese spreads. J Food Sci 65(5):822–825

IDF (2004) Cheese and processed cheese—determination of total solid content (reference method). Int Dairy Fed, Brussels

ISO (2008) Cheese—Determination of fat content—Van Gulik method. ISO, Geneva

AOAC (2005) Official methods of analysis, 17th edn. Association of Official Analytical Chemists, Washington

Corradini MG, Peleg M (2005) Consistency of dispersed food systems and its evaluation by squeezing flow viscometry. J Texture Stud 36:605–629

Shukla A, Rizvi SSH, Bartsch JA (1995) Rheological characterization of butter using lubricated squeezing flow. J Texture Stud 26:313–323

Campanella OH, Peleg M (2002) Squeezing flow viscometry for nonelastic semiliquid foods-Theory and applications. Crit Rev Food Sci Nutr 42(3):241–264

Oliver L, Scholten E, van Aken GA (2015) Effect of fat hardness on large deformation rheology of emulsion-filled gels. Food Hydrocoll 43:299–310

Lee SK, Anema SG, Klostermeyer H (2004) The influence of moisture content on the rheological properties of processed cheese spreads. Int J Food Sci Tech 39:763–771

ISO (2012) Sensory analysis—general guidelines for the selection, training and monitoring of selected assessors and expert sensory assessors. ISO, Geneva

Rousseau B (2004) Sensory evaluation techniques. In: Nollet LML (ed) Handbook of food analysis: physical characterization and nutrient analysis, vol 1, 2nd edn. Marcel Dekker Inc., New York

Guinee TP, Carić M, Kaláb M (2004) Pasteurized processed cheese and substitute/imitation cheese products. In: Fox PF, McSweeney PLH, Cogan TM, Guinee TP (eds) Cheese chemistry, physics and microbiology, vol 2, 3rd edn. Elsevier Academic Press, London

Tavares C, Monteiro SR, Moreno N, da Silva JAL (2005) Does the branching degree of galactomannans influence their effect on whey protein gelation? Coll Surf A Physicochem Eng Aspects 270–271:213–219

Stading M, Hermansson A-M (1993) Rheological behaviour of mixed gels of κ-carrageenan-locust bean gum. Carbohydr Polym 22:49–56

Murayama A, Ichikawa Y, Kawabata A (1995) Rheological properties of mixed gels of κ-carrageenan with galactomannans. Biosci Biotech Biochem 59(1):5–10

Dea ICM, McKinnon AA, Rees DA (1972) Tertiary and quaternary structure in aqueous polysaccharide systems which model cell wall cohesion: reversible changes in conformation and association of agarose, carrageenan and galactomannan. J Mol Biol 68:153–172

Renou F, Petibon O, Malhiac C, Grisel M (2013) Effect of xanthan structure on its interaction with locust bean gum: Toward prediction of rheological properties. Food Hydrocoll 32:331–340

de Jong S, van de Velde F (2007) Charge density of polysaccharide controls microstructure and large deformation properties of mixed gels. Food Hydrocoll 21:1172–1187

Mor-Rosenberg Y, Shoemaker CF, Rosenberg M (2004) Mechanical properties of composite gels consisting of fractionated whey proteins and fractionated milk fat. Food Hydrocoll 18:153–166

Walkenström P, Nielsen M, Windhab E, Hermansson A-M (1999) Effects of flow behaviour on the aggregation of whey protein suspensions, pure or mixed with xanthan. J Food Eng 42:15–26

Chatziantoniou S, Katopodis S, Thomareis AS (2013) Rheological behavior of suspensions and emulsions produced with different stabilizers. In: International Conference on Food and Biosystems Engineering (FaBE), Skiathos Island, Greece, pp 293–301

Morris ER, Rees DA, Robinson G, Young GA (1980) Competitive inhibition of interchain interactions in polysaccharide systems. J Mol Biol 138:363–374

Boutin C, Giroux HJ, Paquin P, Britten M (2007) Characterization and acid-induced gelation of butter oil emulsions produced from heated whey protein dispersions. Int Dairy J 17:696–703

Casiraghi EM, Bagley EB, Christianson DD (1985) Behavior of Mozzarella, Cheddar and processed cheese spread in lubricated and bonded uniaxial compression. J Texture Stud 16:281–301

Yovanoudi M, Dimitreli G, Raphaelides SN, Antoniou KD (2013) Flow behaviour studies of kefir type systems. J Food Eng 118:41–48

Eleya MMO, Turgeon SL (2000) The effects of pH on the rheology of β-lactoglobulin/κ-carrageenan mixed gels. Food Hydrocoll 14:245–251

Sourdet S, Relkin P, César B (2003) Effects of milk protein type and pre-heating on physical stability of whipped and frozen emulsions. Colloids Surf B Biointerfaces 31:55–64

Euston SR, Finnigan SR, Hirst RL (2002) Kinetics of droplet aggregation in heated whey protein-stabilized emulsions: effect of polysaccharides. Food Hydrocoll 16:499–505

Dickinson E (2003) Hydrocolloids at interfaces and the influence on the properties of dispersed systems. Food Hydrocoll 17:25–40

Garti N, Reichman D (1993) Hydrocolloids as food emulsifiers and stabilizers. Food Struct 12:411–426

Wu Y, Cui YW, Eskin NAM, Goff HD (2009) An investigation of four commercial galactomannans on their emulsion and rheological properties. Food Res Int 42:1141–1146

Nor Hayati I, Che Man YB, Tan CP, Nor Aini I (2009) Droplet characterization and stability of soybean oil/palm kernel olein O/W emulsions with the presence of selected polysaccharides. Food Hydrocoll 23:233–243

Gu YS, Decker EA, McClements DJ (2005) Influence of pH and carrageenan type on properties of β-lactoglobulin stabilized oil-in-water emulsions. Food Hydrocoll 19(1):83–91

Cho YH, Decker EA, McClements DJ (2009) Competitive adsorption of mixed anionic polysaccharides at the surfaces of protein-coated lipid droplets. Langmuir 25:2654–2660

Dalgleish DG (2006) Food emulsions—their structures and structure-forming properties. Food Hydrocoll 20:415–422

Ruffin E, Schmit T, Lafitte G, Dollat J-M, Chambin O (2014) The impact of whey protein preheating on the properties of emulsion gel bead. Food Chem 151:324–332

Euston SR, Hirst RL (1999) Comparison of the concentration-dependent emulsifying properties of protein products containing aggregated and non-aggregated milk protein. Int Dairy J 9:693–701

Ye A, Taylor S (2009) Characterization of cold-set gels produced from heated emulsions stabilized by whey protein. Int Dairy J 19:721–727

Sourdet S, Relkin P, Fosseux P-Y, Aubry V (2002) Composition of fat protein layer in complex food emulsions at various weight ratios of casein-to-whey proteins. Lait 82:567–578

Ye A, Singh H (2006) Heat stability of oil-in-water emulsions formed with intact or hydrolysed whey proteins: influence of polysaccharides. Food Hydrocoll 20:269–276

Trivedi D, Bennett RJ, Hemar Y, Reid DCW, Lee SK, Illingworth D (2008) Effect of different starches on rheological and micro-structural properties of (I) model processed cheese. Int J Food Sci Tech 43:2191–2196

van den Berg L, van Vliet T, van der Linden E, van Boekel MAJS, van de Velde F (2007) Breakdown properties and sensory perception of whey proteins/polysaccharide mixed gels as a function of microstructure. Food Hydrocoll 21:961–976

Devezeaux de Lavergne MD, Strijbosch VMG, van den Broek AWM, van de Velde F, Stieger M (2016) Uncoupling the impact of fracture properties and composition on sensory perception of emulsion-filled gels. J Texture Stud 47:92–111

Melito HS, Daubert CR, Foegeding EA (2013) Relating large amplitude oscillatory shear and food behavior: correlation of nonlinear viscoelastic, rheological, sensory and oral processing behavior of whey protein isolate/κ-carrageenan gels. J Food Process Eng 36(4):521–534

Acknowledgements

The preparation and provision of Myzithra cheese by Mevgal Dairy S.A. (Thessaloniki, Greece) are gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no competing interests.

Compliance with ethics requirements

This article does not contain any studies with human or animal subjects.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chatziantoniou, S.E., Thomareis, A.S. & Kontominas, M.G. Effect of different stabilizers on rheological properties, fat globule size and sensory attributes of novel spreadable processed whey cheese. Eur Food Res Technol 245, 2401–2412 (2019). https://doi.org/10.1007/s00217-019-03360-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-019-03360-7