Abstract

The global production of cassava was estimated at ca. 303 million tons. Due to this high production, the cassava processing industry (cassava flour and starch) generates approximately ca. 0.65 kg of solid residue and ca. 25.3 l of wastewater per kg of fresh processed cassava root. The composition of the liquid effluent varies according to its origin; for example, the effluent from cassava flour production, when compared to the wastewater from the starch processing, presents a higher organic load (ca. 12 times) and total cyanide (ca. 29 times). It is worthy to highlight the toxicity of cassava residues regarding cyanide presence, which could generate disorders with acute or chronic symptoms in humans and animals. In this sense, the development of simple and low-cost eco-friendly methods for the proper treatment or reuse of cassava wastewater is a challenging, but promising path. Cassava wastewater is rich in macro-nutrients (proteins, starch, sugars) and micro-nutrients (iron, magnesium), enabling its use as a low-cost culture medium for biotechnological processes, such as the production of biosurfactants. These compounds are amphipathic molecules synthesized by living cells and can be widely used in industries as pharmaceutical agents, for microbial-enhanced oil recovery, among others. Amongst these biosurfactants, surfactin, rhamnolipids, and mannosileritritol lipids show remarkable properties such as antimicrobial, biodegradability, demulsifying and emulsifying capacity. However, the high production cost restricts the massive biosurfactant applications. Therefore, this study aims to present the state of the art and challenges in the production of biosurfactants using cassava wastewater as an alternative culture medium.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Indigenous to South America, Cassava (Manihot esculenta Crantz) is a staple food in developing countries due to its rich nutritional composition (Lebot 2009). It is among the top five crops in the world in terms of produced per ton (FAO stat 2019). Cassava stands out for its use in the food, textile, alcohol, pharmaceutical, and paper industries and is widely used for human and animal consumption (de SouzaYes Fernandes et al. 2019; Acchar and da Silva 2021).

However, the cassava processing industry generates large amounts of waste (Fig. 1), such as solid residue (peels, bagasse, stem, and leaves) and cassava wastewater (Tumwesigye et al. 2016). Cassava wastewater is the residue from pressing the crushed mass of the cassava root that has already been washed and peeled (Chisté et al. 2006). Cassava wastewater can be considered an environmental problem since it represents about 30% of the weight of the raw material (Wosiacki and Cereda 2002).

The significant amount of agro-industrial residue is mostly composed of macro-nutrients (e.g., starch, sugars, and proteins) and micro-nutrients (e.g., phosphorus, potassium, calcium, magnesium, sulfur, iron, zinc, manganese, copper, and nitrate) (Maróstica and Pastore 2007). It has a potential environmental pollution factor due to the high concentrations of organic matter (composition) as well as the presence of cyanide-generating glycosides (Kuyucak and Akcil 2013; Tumwesigye et al. 2016). Cyanide is capable of complexing with metals (for example, the iron of hemoglobin, preventing oxygen transport to the cells and promoting individual suffocation). Due to this toxicity, for both humans and animals, the treatment of effluent before discharge requires even greater attention (Kuyucak and Akcil 2013).

Due to the large amounts of organic load in cassava wastewater, its discharge in aqueous environments can cause negative impacts (Patil and Paknikar 2000). In this perspective, residue management techniques have a high cost due to the requirement of appropriate infrastructure for physical–chemical treatments. This scenario hampers the correct treatment of cassava residues in small-scale industries (Peters and Ngai 2005). Therefore, an alternative to the cassava wastewater destination is its good and challenging use in biotechnological processes, contributing to the biorefinery concept. The main advantages are the low-cost, eco-friendly (green chemistry), simple methods, and potential carbon source (Nitschke and Pastore 2006; de Andrade et al. 2016).

As already reported in the literature, cassava wastewater has an adequate nutritional composition for cultivating microorganisms that produce biosurfactants. Its use for this purpose reduces the cost of treating the effluent, it is a cheap culture medium, and it produces a product with high added value (biosurfactants). In this way, it contributes to the circular economy and even builds an entirely environmentally friendly production chain, from the culture medium to the final product.

In this context, this review aims to explore the current state of the art and future trends in biosurfactant production using cassava wastewater as an alternative low-cost culture medium. Therefore, the paper addresses general aspects of cassava wastewater, including composition and treatment, the biorefinery to achieve the production of biosurfactants, as well as trends in the production of these surfactants.

Cassava wastewater

Composition

The liquid wastes generated by industrial processing of cassava are divided into cassava wastewater (pressing) and liquid residues (process water). Thus, this section will focus on the main characteristics related to cassava wastewater, such as composition, treatments related to its high level of pollution and applications of cassava wastewater that have industrial and commercial importance.

Cassava wastewater is a yellowish liquid waste generated by the pressing process in the manufacture of cassava flour. This residual liquid is composed of starch, glucose, cyanide, carbohydrates, proteins, lipids, and minerals. Its composition varies according to environmental factors (such as edaphic, climatic, and cassava variety) and the knowledge of these physicochemical characteristics is essential to determine its future applications (Neves et al., 2014). As shown in Table 1, the levels of nitrogen and potassium presented the highest concentration values, with a maximum of 3.3 and 5.9 g l−1, respectively. Magnesium, phosphorus, calcium, iron, and sodium were 0.62, 0.74, 0.38, 0.11 and 0.74 g l−1, respectively. Copper, manganese and zinc presented very low concentrations, not exceeding 0.02 g l−1.

The cyanide content varied considerably among the authors (values between 0.002 and 0.09 g l−1) (Table 2). Despite appearing to be a low value, free cyanide represents only 10% of all cyanide present in the residue (Cereda and Takahashi 1996). In studies such as Neves et al. (2014), the authors reported a cyanogenic potential of 257.5 mg l−1, while Cereda 2001 cited 364 mg l−1 with 50% free cyanide, and Cereda and Takahashi (1996) quantified 444 mg l−1 of cyanide, the highest value ever mentioned.

The COD of cassava wastewater varies between 15.7 and 141 g l−1, while the liquid residue has a maximum COD of 16 g l−1. This significant difference is because the second one – the wastewater from the cassava starch—is diluted with the starch extraction water, reducing its concentration. The BOD is very similar for both, with maximum of 8 and 12.21 g l−1, for the wastewater from the flour and the starch, respectively. Considering the organic load of this agro-industrial residue, it is possible to infer the high source of pollution that it represents, requiring treatment or proper use (Pinto 2008; Acchar and da Silva 2021).

From another perspective, it is possible to note that cassava wastewater has a rich composition of micro and macronutrients, and has the potential to be used in several biotechnological processes. An example is using this residue as a culture medium for microorganisms in fermentation processes, reducing operating costs, and optimizing the process. According to Zanotto et al. (2019), the high amount of starch present in cassava wastewater ensures greater productivity than supplemented synthetic media. Other examples of the use of cassava wastewater will be further discussed in next sections.

Wastewater treatment

Due to the composition and the characteristics of cassava wastewater, it can cause serious environmental problems if incorrectly discharged (Peres et al. 2019). The main challenge for the treatment of this effluent is the removal of the high COD, BOD, and high cyanide content (Potivichayanon et al. 2020). Usually, cassava wastewater is treated by the traditional anaerobic, facultative, and aerobic ponds, but can be used for the production of fermentation products (e.g., biohydrogen and biomethane) (de Carvalho et al. 2018).

The biodegradation of COD and cyanide was reported by several studies. Potivichayanon et al. (2020) achieved high levels of cyanide (78%) and COD (74%) removal from cassava wastewater by a fixed-film sequencing batch reactor, and 43 and 37% for a conventional sequencing batch reactor, respectively. Kaewkannetra et al. (2009) reported removing up to 90% of the cyanide using strains of Azotobactor vinelandii, a nitrogen-fixing bacteria. Other microorganisms such as Bacillus and Pseudomonas have also been reported as cyanide biodegraders (Akcil et al. 2003; Ebbs 2004; Kaewkannetra et al. 2009).

Anaerobic ponds are very efficient for the treatment of cassava wastewater, especially when this effluent is rich in suspended solids, which settle at the bottom of the ponds and are then digested by anaerobic microorganisms, reducing COD and TTS (total suspended solids) (Rajbhandari and Annachhatre 2004). Furthermore, anaerobic ponds can reduce cyanide concentrations, as reported by Rajbhandari and Annachhatre (2004), who investigated the removal of COD, TTS and cyanide of cassava wastewater by anaerobic ponds connected in series (three ponds), this system achieved a removal of COD and TSS of more than 90%, and 51% cyanide removal.

There are several efficient strategies for cassava wastewater treatment, and there is potential for the development of multi-product biorefineries on an industrial scale for integration into cassava processing, enhancing the economic exploitation of waste and industrial development (Padi and Chimphango 2021), which will be discussed in the next topic.

Valorization of cassava wastewater

Considering the composition and biochemical properties of cassava wastewater, it is clear that it requires several treatment processes before disposal since it can lead to an environmental imbalance, in case of incorrect disposal (Peres et al. 2019) The potential applications of cassava wastewater include the production of biogas, soil fertilizer, pesticide, and also as a culture medium for biotechnological products obtention (Pinto Zevallos et al. 2018), or even in civil construction, acting as a plasticizer in the production of ecological bricks (Ramos Filho 2021).

Since the 1980s, cassava wastewater has been studied for application as fertilizers and pesticides, mainly driven by the increased demand for more organic products and more sustainable technologies (Pinto Zevallos et al. 2018). Vieites (1998) evaluated the use of cassava wastewater as a fertilizer in the cultivation of tomatoes, while Lima and Valente (2017) tested it in the cultivation of bells peppers; in both works, when used in the proper proportion, this natural fertilizer provided an increase in productivity and size of the produced fruits. According to Costa et al. (2020), cassava wastewater can be used for partial or total replacement of mineral fertilizer—biquinho pepper (Capsicum chinense). The authors proved that a dose ca.of 150 m3 ha−1 was equivalent to mineral fertilizer (urea (40 kg ha−1); potassium sulfate (180 kg ha−1); single superphosphate (600 kg ha−1); boric acid (1 kg ha− 1); and zinc sulfate (30 kg ha−1). Bezerra et al. (2017) studied the use of cassava wastewater as a fertilizer in the production of 'Mandaru' grass pasture, and obtained an improvement in pasture characteristics, such as greater forage mass and chlorophyll content, in addition to the pesticide action of cassava wastewater, which decreased unwanted plants in the crop.

In addition, cassava wastewater anaerobic digestion is efficient in biogas production (Montoro et al. 2019; Mari et al. 2020). Jiraprasertwong et al. (2019) observed the generation of 328 ml of CH4 g−1 COD (92% COD reduction) by applying a three-stage UASB reactor. The biogas production was maximized by Andrade et al. (2020), who pre-treated the CW by alkalinization and photocatalysis to reduce the cyanide concentration; they obtained 27.6% more methane compared to AD from raw CW.

Researchers have reported the potential of H2 production by cassava wastewater. Wadjeam et al., (2019) indicated that the co-digestion of cassava wastewater with buffalo dung improved H2 production, once mixing these two substrates provided a balance of carbon, nitrogen, and other nutrients for indigenous hydrogen producers. Meier et al. (2020) obtained a 4.5-fold increase in H2 production when applying a process of co-digestion of cassava wastewater with 3% glycerol, co-digestion produced 1106.7 ml H2 while cassava wastewater digestion without glycerol produced only 243.5 ml H2. According to the authors, the increase in hydrogen production when glycerol is added is due to an alteration in the metabolic pathways of butyric acid production (Meier et al. 2020). Thanwised et al. (2012) revealed an optimized anaerobic baffled reactor for H2 production; they obtained 883 ml H2 (l d)−1, nevertheless, only about 29% of the COD was removed since a significant portion of COD was converted to liquid intermediate products (e.g., ethanol, butyrate, and propionate) and remained in the effluent. Therefore, the anaerobic digestion processes of cassava wastewaterares interesting from the point of view of the formation of a product with added value (H2), however, in some ca,ses it may require a subsequent complementary treatment of the effluent to increase the efficiency of COD removal (Rodrigues al., 2021).

Besides, cassava wastewater was already evaluated as a low-cost culture medium to produce carotenoids and fatty acids by Rhodotorula glutinis (Ribeiro et al. 2019), and, mainly biosurfactants. Nitschke and Pastore (2004) used cassava wastewater for the production of surfactin using two different strains of Bacillus subtilis. As a result, it was produced ca.3.0 g of crude surfactin.l−1. Recently, cassava wastewater was used to produce other biosurfactants such as mannosylerythritol lipids (ca. 1 g l−1) (Andrade et al. 2017).

According to de Oliveira Schmidt et al. (2021) biosurfactants have a wide range of chemical structures, even within sub-classes (homologues). The production of specific homologues is correlated with the culture medium, the biosurfactant-producing microorganism and the mode of operation, among others. Based on this, the next section has the main objective of discussing the focus and a more specific approach to the feasibility of using cassava wastewater as an alternative substrate in the production of biosurfactants.

Biosurfactants

Surfactants are synthetic (originated from petroleum) or bio-based (produced mainly by microorganisms) compounds, with a molecular structure that presents amphiphilic characteristics, which makes them capable of interacting with polar and non-polar compounds, reducing surface and interfacial tensions between immiscible fluids. Thus, surfactants have a wide range of industrial applications such as detergents, emulsifiers, defoamers, and biopesticides, among others (Jauregi and Kourmentza 2000; Joy et al. 2017).

The market of bio-based surfactants (biosurfactants) has been increasing yearly, very likely due to the consumer demand for eco-friendly products and processes. In addition, environmental laws favor the biosurfactants market (Vicente et al. 2021; Ahuja and Singh 2022).

Recently, with the coronavirus pandemic, there has been a drop in the production of biosurfactants due to shortages of raw material supplies, caused by travel prohibitions and manufacture unit closure impositions around the world. This fact can reduce its use in agricultural defensives, oil fields, or textile industries until everything stabilizes again. However, to contain the virus outbreak, the lockdown strategy was adopted. As a result, people were spending more time at home, increasing the use of hygiene and personal care, and household cleaning products. Therefore, the search for greener versions of products also increased considerably (Ahuja and Singh 2022).

Although biosurfactants are promising, the high production cost, compared to analogs of synthetic origin, still makes it difficult for this market to grow. As a strategy to reduce production costs, the use of residues as substrates to produce these natural surfactants has been investigated since these synthetic substrates usually represent approximately 30% of the total production costs (Tan and Li 2018; de Oliveira Schmidt et al. 2021; Mohanty et al. 2021). This strategy, in addition to transforming waste into a product with high added value, and reducing waste treatment and biosurfactant production costs, makes the product even more environmentally friendly (Mohanty et al. 2021).

Research involving the replacement of synthetic substrates by agro-industrial residues such as vegetable oils, lignocellulosic residues, residues from the dairy industry, or even residues rich in starch, as cassava wastewater in the production of biosurfactants have been frequent (Zanotto et al. 2019; Mohanty et al. 2021).

As well as their synthetic analogs, biosurfactants reduce surface and interfacial tension as their concentration is increased in the medium until the maximum possible reduction (variable according to the type of surfactant or even the producing strain) is obtained when reaching the critical micelle concentration (CMC). Above CMC, these surfactants form self-aggregating structures that can be micellar, hexagonal, cubic, or lamellar (diameter 2–3 orders of magnitude larger than the isolated molecule) (Jauregi and Kourmentza 2000; Zanotto et al. 2019; Vicente et al. 2021).

It is also important to point out that a wide range of microorganisms can produce biosurfactants (Ron and Rosenberg 2001). In addition, the same strain can produce more than one type of biosurfactant; for example, Bacillus subtilis can produce surfactin, iturine, fengycin, and subtilisin (Vicente et al. 2021). Natural surfactants can be classified into glycolipids, lipopeptides, lipoproteins, phospholipids, polymeric biosurfactants, and particulate surfactants. Among the classifications cited, glycolipids (mainly rhamnolipids, sophorolipids, and mannosylerythritol lipid) and lipopeptides (mainly surfactin) are the most known and studied due to their great efficiency in reducing surface and interfacial tension (Jauregi and Kourmentza 2000). Besides, lipopeptides are also highlighted due to their biological activities (Maier 2003; Vicente et al. 2021).

Surfactin

Surfactin is a lipopeptide-type biosurfactant and was identified as a secondary metabolism product of Bacillus subtilis in 1968. Surfactin was initially described as a lipopeptide composed of L-aspartic acid, L-glutamic acid, L-valine, L-leucine, D-leucine (1:1:1:2:2) and unidentified fatty acids with a long chain of hydrophobic fatty acid (Arima et al. 1968). Currently, the structure of surfactin and its four isomers (Surfactin A–D) is known (Fig. 2). Structural variation in the chain length of the fatty acid component or substitution of the amino acid components of the peptide ring may result in a change in the physicochemical properties of surfactin (Jahan et al. 2020).

Source: Chen et al. (2015)

Chemical structures of surfactins.

Surfactin is one of the most powerful biosurfactants, as it can reduce the surface tension of water from 72 to 27 mN m−1 (Farias et al. 2021). It is produced by various strains (e.g., Bacillus pumilus, Bacillus mojavensis, Bacillus licheniformis, Bacillus amyloliquefaciens), and mainly Bacillus subtilis (Chen et al. 2015). Metabolically, the production of surfactin is correlated to microbial sporulation, which can lead to low surfactin production yield. Thus, often the optimization of surfactin production is evaluated (Drakontis and Amin 2020; Markande et al. 2021).

Surfactin has potential applications in several areas, such as therapeutic, environmental, and agricultural. The therapeutic applications of surfactin are antibacterial, antiviral, antifungal and antimycoplasma, due to ion-conducting channel formation in bacterial lipid bi-layer membranes (Chen et al. 2015; Sałek and Euston 2019). It is worth noting that surfactin is a potent immunosuppressive agent and may serve as an alternative to immunosuppressive drugs used in autoimmune diseases (allergy, asthma, arthritis, and diabetes) and organ transplantation (Sajid et al. 2020). In addition, acts as an anti-inflammatory, one it inhibits the activity of phospholipase-A2 (Sajid et al. 2020). There are reports of the anticancer activity of surfactin, acting as an inhibitor of proliferation and inducing apoptosis of breast cancer cells (Cao et al. 2010) and lung carcinoma cells (Routhu et al. 2019).

The ability of surfactin to reduce surface tension makes it an interesting product for personal care and detergent formulations, as it has low toxicity and non-irritating properties (Markande et al. 2021). Moreover, surfactin has anti-aging, anti-photoaging, anti-wrinkle, anti-oxidation, and collagen inducer properties—skin restorative functions (Sałek and Euston 2019).

Regarding environmental applications, Mulligan (2009) highlighted the use of surfactin as a stimulating agent in bioremediation processes of soils contaminated with petroleum hydrocarbons; nevertheless, it was emphasized that high concentrations can inhibit the biological process, due to the antimicrobial characteristics of surfactin. Furthermore, surfactin is reported as a stabilizing agent for the production of nanoparticles (Mulligan 2009; Markande et al. 2021). In agriculture, surfactin has been reported to be effective against phytopathogens, including those that have already acquired resistance to other products (Sałek and Euston 2019).

A major challenge of large-scale surfactin production is the production cost. The culture medium can represent from 30 to 50% out of the total cost of production (de Oliveira Schmidt et al. 2021). The use of agro-industrial residues is an interesting alternative for culture medium. Several agro-industrial residues rich in carbon have been successfully tested as substrate for surfactin production (Barros et al. 2008), as potato waste (Fox and Bala 2000), whey powder (Cagri-Mehmetoglu et al. 2012), rice straw (Zhu et al. 2013), brewery waste (Paraszkiewicz et al. 2018; Nazareth et al. 2021). Cassava wastewater sanands out as a agro-industrial residue rich in carbon andfthe orssential nutrients to production of surfactin, in addition, it has advantages over other agro-industrial for being produced all year round and with low soil fertility requirements (de Oliveira Schmidt et al. 2021).

Surfactin purification is a stage in the production process that remains a challenge, mainly due to the subtle variations that occur in the surfactin molecules (isomers), as the similarities between these molecules make the separation and purification process difficult. The presence of isomers makes it difficult to purify the product when a single isomer is needed, as in the case of application in the pharmaceutical industry. On the other hand, it facilitates the separation of a family of molecules from the other impurities; thus, a partially purified surfactin mixture suitable for applications that require a lower degree of purity (e.g., environmental applications) can be obtained directly from the culture supernatant (Rangarajan and Clarke 2016). Several levels of purification can be achieved: a partial rification (when impurities such as proteins, amino acids, and unconsumed substrate remain); a purified product without the impurities, but with a mixture of isoforms; and an ultra-purified product containing only one isoform (Rangarajan and Clarke 2016).

Surfactin is an excellent alternative to chemical surfactants, and the characitsistics of surfactin make it highly interesting for industries related to human health, the environment, and agriculture (Sałek and Euston 2019). Nevertheless, studies are needed to enable its production on an industrial scale, especially in terms of reducing the costs of the process and purification technologies.

Rhamnolipids

Belonging to the glycolipids group, rhamnolipids (RLs) are anionic biosurfactants, mainly produced by Pseudomonas aeruginosa (Elakkiya et al. 2020). A RL molecule is composed of a lipophilic part (β-hydroxy fatty acids chains) and a hydrophilic part (rhamnoses), which can vary between mono-rhamnose and di-rhamnose, with one and two rhamnose residues in the molecule (Fig. 3) (Schmidt et al., 2021).

Adapted from de Oliveira Schmidt et al. (2021)

Chemical structure of a mono-rhamnolipid and b di-rhamnolipid.

Due to their physicochemical and biological properties such as surface-active, emulsifying capacity, antimicrobial activity, among others, rhamnolipids can be applied for bioremediation, advanced oil recovery, pharmacology and cosmetology, and food production (Liu et al. 2018)..

The main carbon sources for RLs production are glucose and glycerol (Ji et al. 2016). However, the characteristics of the carbon source directly affect the RL production yield (Varjani et al. 2021). Thus, hydrophobic carbon sources such as soy, olive, and sunflower oils, and petroleum-derived hydrocarbons such as kerosene and diesel have been evaluated for RL production (Wei et al. 2005; Ji et al. 2016; Radzuan et al. 2017).

Based on the potential application of RLs in several industrial sectors, it is essential to investigate the use of alternative substrates such as the cassava wastewater and the optimization of the production steps.

Mannosylerythriol lipids

The mannosylerythriol lipids (MELs) are one of the most promising classes of biosurfactants—glycolipids. The chemical structures of MELs vary according to the fatty acid chains and the degree of acetylation, named MEL-A, MEL-B, MEL-C, and MEL-D (Simiqueli et al. 2017; Coelho et al. 2020; Shu et al. 2020) as shown in Fig. 4.

Adapted from Coelho et al. (2020)

Variety of chemical structures of mannosylerythriol lipids according to acetyl substitution.

Due to the chemical structure variation, MELs have different properties that can be applied in several areas of interest, such as antimicrobial activity against Gram-positive bacteria and pathogens, antioxidant for cell protection in cosmetic products, other pharmaceutical and industrial products, as well as biological activity for medicinal purposes and human health (Arutchelvi et al. 2008; Morita et al. 2015; Nashida et al. 2018; Ceresa et al. 2020; Coelho et al. 2020).

Boothroyd et al. (1956) were the first to report MEL production. The author used a submerged fermentation system with the fungus Ustilado sp.. More recent studies have investigated the production of MELs using a wide range of microorganisms such as Schizonella melanogramma, Kurtzmanomyces sp., and Pseudozyma sp. (Simiqueli et al. 2017). In this sense, Pseudozyma tsukubaenis has gained great prominence for the production of MEL-B as a major component, since the species of Pseudozyma produce a mixture of different MEL molecules (Arutchelvi et al. 2008; Fukuoka et al. 2008; Andrade et al. 2017).

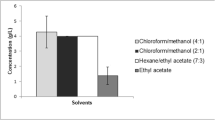

Fermentation processes for the production of MELs in general use a hydrophobic carbon source (e.g., soy oil). Nevertheless, the use of water-solubilized carbohydrates (cassava wastewater) has been drawing attention since it promotes an advantage on the purification process (Fukuoka et al. 2008; Konishi et al. 2008; Andrade et al. 2017; Simiqueli et al. 2017).

It is worth noting that the use of cassava wastewater as a cultivation medium for the production of MELs has been poorly investigated. Fai et al. (2015), described that the use of cassava wastewater for the production of MEL-B is a sustainable alternative. It was shown that the surface tension was reduced to 26.9 mN m−1, approaching the value of 33.8 mN m−1 found by Fukuoka et al (2008), in the critical micelle concentration (CMC). Fai et al. (2015) speculate that the production of mono-acetylated MEL (MEL-B) is more correlated with the strain and the culture medium than the microorganism species itself. Andrade et al. (2017), used the culture medium with cassava wastewater to scale the process in a bioreactor, for the production of MEL-B. After 84 h of fermentation, the bioprocess obtained a production of 1.26 g l−1 of MEL-B and the surface tension was in the range of 50 mN m−1.

Therefore, it is evident that the use of cassava wastewater is a sustainable alternative, with low cost and with a carbon source available in an aqueous medium for the production of MELs. It also may provide all essential nutrients to microbial biosurfactant producers. More research is needed to comprehend the specific characteristics of the use of cassava waswater as an alternative culture medium, as well as process scale-up, optimization and product specificities for application.

Operating conditions

Considering the range of applications of biosurfactants and taking into account that they can cost up to 12 times more to produce than synthetic surfactants, measures to make these biocompounds more economically competitive are necessary (de Oliveira Schmidt et al. 2021; Sun et al. 2021). The optimization of cultivation conditions emerges as a great alternative to reduce costs and increase the productivity of these biocomposites. For this, cultivation conditions close to ideal must be achieved, both in relation to nutritional factors (e.g., carbon and nitrogen) and cultivation conditions (e.g., aeration, temperature and agitation of the medium) (He et al. 2016; Lee et al. 2016; Jiang et al. 2020).

The literature presents some studies involving the use of cassava wastewater as a culture medium for the production of biosurfactants, these appear exemplified in Table 3, as well as the used cultivation conditions.

In this context, Nitschke and Pastore (2006) carried out a bench-batch with cassava wastewater as an alternative culture medium using Bacillus subtilis LB5a. The operating conditions were 150 rpm of agitation and temperature of 30 °C. At the end of the 72 h process, it was obtained a yield of 3 g l−1 of the biosurfactant classified as lipopeptide, as well as the surface tension was 26.6 mN m−1. Andrade et al. (2017) produced a glycolipid biosurfactant, mannosylerythritol lipids-B (MEL-B), by cassava wastewater fermentation with Pseudozyma tsukubaensis in a bioreactor. The operating conditions was 100 rpm agitation and aeration rate of 0.4 vvm (1 vessel volume per minute) in the first 24 h followed by 150 rpm and 0.8 vvm from 24 to 84 h. In 24 h of process, reduction of surface tension was from 50 to 26 mN m−1 and yield was 1.26 g l−1 of MEL-B at the end of the process.

In more recent studies, Bione et al. (2022) used 3.5% cassava wastewater (CW) as a culture medium supplemented with 6.5% waste soybean oil (WSO) and 6.5% corn steep liquor (CSL). Fermentation was made by bench-batch with Syncephalastrum racemosum UCP 1302 at 150 rpm agitation and 28 °C. After 72 h of process, 3.5 g l−1 of lipopeptide group biosurfactant was produced and the surface tension was 30 mN m−1.

Trends for biosurfactants production

Genetic modification

Recent years have seen a growing interest in genetic engineering and recombinant DNA technology as a means to produce biosurfactants (Ambaye et al. 2021). Methods for microbial genomes mutations and genetic recombination are being investigated to upgrade the main microbial strains for industrial purposes.

The main genes for the biosynthesis of the lipopeptides are related to non-ribosomal peptide synthetases (NRPSs)—modular multienzymatic complexes—and exhibit a linear array with similar structural organization (Das et al. 2008),although variations in length, branching of fatty acid chains and amino acids composition of polypeptide sequences are observed (Ongena and Jacques 2007; Luo et al. 2015). Details of these synthesis and their mechanism are explored in several studies, considering modifications in NRPSs by genetic engineering as the key to new biosurfactants (Weinrauch et al. 1989; Tosato et al. 1997; Doekel 2002; Dhali et al. 2017). The first described molecular aspects were about surfactin production (Nakano et al. 1988). Since then, editing technologies and genome sequencing for Bacillus spp. have helped to understanding the protein machinery involved in compound synthesis, such as lipopeptides (de Andrade et al. 2016) and explore new metabolic pathways in recent years (Dong and Zhang 2014).

Artificial promoters to improve surfactin production was developed by Jiao et al. (2017). The fusion of the PgroE and PsacB ribonucleic antiterminator generated the Pg1 promoter, which in the engineered strain of B. subtilis THY-7 generated a surfactin titer of 1.44 g l−1. From the PgroE-lacO fusion, the Pg2 (IPTG-inducible promoter) was originated and then substituted for the chromosomal PsrfA locus, and the surfactin titer increased to 5.98 g l−1. A novel promoter Pg3 was created by the inclusion of two-point mutations in the 35 and 10 regions of the Pg2. Its substitution in the strain produced up to 9.74 g l−1 surfactin.

Bacillus amyloliquefaciens HZ-12's iturin A synthetase cluster was replaced by P43, PbacA, PsrfA and Pylb promoters, which indicated that transcriptional levels of the ituD gene and iturin A titer had consistently changed, and that PbacA was the most effective promoter, with an iturin A titer reaching 950.08 ± 19.43 mg l−1 (Xu et al. 2020). Using a systematic engineering approach, Wu et al. (2019) improved surfactin biosynthesis. Using a metabolically engineered strain, they were able to produce sucrose at a concentration of 65.0 mmol mol−1 (42% of the theoretical yield) and surfactin at a level of 12.8 g l−1.

In addition to providing higher yields at lower costs, recombinant DNA technology can improve the microbial strain through the modification of their chemical properties, promoting more efficiency for the biomolecules (Sarubbo et al. 2022). In light of these findings, it may be possible to commercially produce surfactin in the near future.

Inducers

Carbon and nitrogen sources are of essential importance for biotechnological processes and although the cassava wastewater acts as a very complete carbon source, it can be supplemented with inducers to further enhance the process.

Inducers can be hydrophilic (such as metals) or hydrophobic (such as vegetable oils) and should be added at very low concentration levels (Ehrhardt et al. 2015). The addition of hydrophilic inducers is currently more common, as they act as cofactor molecules, aiding in cell growth and, consequently, in the generation of the product of interest. Hydrophobic inducers also help cell growth, acting as a secondary source of carbon, however, it has great importance in the synthesis of the fatty acid portion of biosurfactants, being responsible for the large rate of homologous molecules produced.

Recently, a study by Zhao et al. (2020) compared two culture media (hydrophilic and hydrophobic) to produce rhamnolipids by P. aeruginosa. The authors achieved 7.06 and 10.32 g l−1 of rhamnolipids using glucose and soybean oil. Furthermore, rhamnolipids produced from glucose showed higher surface activity (26.3 mN m−1) than rhamnolipids produced from soybean oil (28.1 mN m−1). On the other hand, rhamnolipids produced from soybean oil showed a higher index of petroleum emulsifying activity (76.1%) than rhamnolipids produced from glucose (65.5%). These results are most likely correlated with the rates of rhamnolipid homologues produced.

Other authors also report the production of biosurfactants and the possible formation of different homologues. The production of specific homologues is directly related to the substrate, microorganism and mode of operation (de Oliveira Schmidt et al. 2021). Usually, the literature presents soybean oil as an alternative co-substrate and/or hydrophobic inducer that is easy to assimilate (Zhao et al. 2020). Regarding the concentration of produced surfactin, the results were similar to Ghribi and Ellouze-Chaabouni (2011) The authors clearly showed that supplementation of the optimized medium with 2% of oils such as olive oil, sunflower oil, corn oil increased (1 g l−1) the production of biosurfactants by the strain B. subtilis SPB1. Similarly Pathania and Jana (2020) reported that rhamnolipid production by P. aeruginosa was enhanced using multiples carbon sources (glucose and fried soybean oil 2% w v−1). They obtained a production of biosurfactant ca. 3.3 g g−1 after 96 h of fermentation.

Meanwhile, studies are still needed to investigate its effects on productivity and the chemical structure of the molecules involved in the reaction (De Araujo et al. 2013; Niu et al. 2019; Pathania and Jana 2020; de Oliveira Schmidt et al. 2021).

Nanoparticles

Today, extensive research is conducted on the use of metallics to increase the amount of production and enhance the effects of biosurfactants. NPs have been used mainly to increase gene expression of genes linked to biosurfactant production (Yang et al. 2020; Ahsani Arani et al. 2022). induce oxidative stress in the cell membrane, and thus allow greater entry of nutrients into the cell and/or more efficient excretion of the biosurfactant (Sahebnazar et al. 2018; Yang et al. 2020); prevent biofilm formation during fermentatio (Ranmadugala et al. 2017); or even as a source of essential metals in the metabolism of biosurfactant production (Sahebnazar et al. 2018).

Bacillus subtilis is one of the most used microorganisms for the production of biosurfactants. The growth and biofilm formation of B. subtilis during the biosurfactant production process can lead to decreased metabolic activity, nutrient limitation, metabolite accumulation and high osmolarity, which can impair the performance of the fermentation process (Ranmadugala et al. 2017). Ranmadugala et al. (2017) tested the use of iron nanoparticles (naked NPs and NPs coated with APTES (3-aminopropyltriethoxysilane)) as a way to control the growth of B. subtilis biofilm. Naked NPs were toxic to cells, significantly affecting B. subtilis cell viability without significant reduction in biofilm biomass. On the other hand, the coated NPs proved to be effective in reducing the biofilm biomass without affecting the growth and cell viability of B. subtilis. The authors justify that the greater effect observed in the coated NPs is due to the attractive electrostatic interaction between the positively charged amine functional groups (present in the coating of the NPs) and the negatively charged cell surface of bacteria. Once bound to the bacterial cell surface, NPs can act as a physical barrier to bacterial cell adhesion. The coated NPs also promoted cell growth, the authors suggest that binding of coated NPs to B. subtilis altered the permeability of the B. subtilis membrane and facilitated mass transfer and nutrient uptake. Thus, the addition of coated iron NPs can be applied to enhance bacterial growth while inhibiting biofilm formation. (Ranmadugala et al. 2017).

Biosurfactants are extracellular metabolites, therefore, during their production, the secretion of the product through the cell membrane seems to be a key process to increase the production of biosurfactants (Sahebnazar et al. 2018; Yang et al. 2020). Yang et al. (2020) investigated the use of Fe NPs to increase surfactin production by Bacillus amyloliquefaciens MT45. The results showed that surfactin production increased from 5.94 to 9.18 g l−1 in a 7 l bioreactor when adding 5 g l−1 of Fe nanoparticles. The authors reported that the increase in surfactin production is due to changes in gene expression and cell membrane, caused by the addition of NPs. Electron microscopy analyzes showed that Fe NPs damaged the cell membrane to improve cell permeability, resulting in more efficient substrate ingestion and surfactin excretion, and the concentration of living cells was not changed (Yang et al. 2020). Transcriptomic analysis revealed that Fe NPs increased the expression of genes involved in the glycolysis and TCA cycle modules, amino acid metabolism, and surfactin modular enzymatic synthesis, which may divert energy and primary substrates for surfactin synthesis (Yang et al. 2020).

To investigate the role of iron NPs on gene expression during biosurfactant production, Ahsani Arani et al. (2022) evaluated the gene expression of rhamnolipid biosurfactant production genes by Pseudomonas aeruginosa in the presence of iron NPs coated with sodium dodecyl sulfate (SDS). The q-PCR results showed that the expression of rhlA, mvfR, lasR, rhlR genes (genes linked to biosurfactant production) was significantly increased in cells treated with Fe NPs coated with SDS, which indicates the significant positive effect (P < 0.05) of nanoparticles on the biosurfactant production of treated cells, while SDS and Fe alone were not able to significantly affect (> 0.05) the expression of these genes (Ahsani Arani et al. 2022).

Nanoparticles of different materials and different concentrations may have different effects on bacterial growth and biosurfactant production. Alamdar et al. (2018) investigated the effects of Fe nanoparticles coated with SDS and naked Au NPs on the growth and amnolipid biosurfactant production by Pseudomonas aeruginosa PBCC5. The concentrations of the nanoparticles used were 1, 500 and 1000 mg l−1. Test results showed that the effect of nanoparticles on bacterial growth and biosurfactant production varies according to the type and concentration of nanoparticles. Fe/SDS nanoparticles did not show bacterial toxicity when the concentration of nanoparticles was 1 mg ml−1 and increased growth and biosurfactant production, 23.21 and 20.73%, respectively (Alamdar et al. 2018). On the other hand, at higher concentrations (500, 1000 mg l−1), Fe/SDS NPS suppressed bacterial growth as well as biosurfactant production. Au NPs did not show bacterial toxicity at any concentration tested, but their effect on biomass growth and biosurfactant production was lower when compared to Fe NPs. The application of Au NPs increased biomass growth by 16% (500 mg l−1 of AuNP) and 5% (1000 mg l−1 of AuNP) and biosurfactant production by 14.63% (500 mg l−1 of AuNP) and 4.87% (1000 mg l−1 of AuNP) (Alamdar et al. 2018).

The concentration of added NPs and the time these NPs are added during fermentation can influence biomass growth and biosurfactant production. In this study, Sahebnazar et al. (2018) used Fe-Si nanoparticles to enhance biosurfactant production by P. aeruginosa. The results of the experiments showed that the concentration of nanoparticles and the time of addition of nanoparticles to the culture medium were effective parameters in increasing the growth and production of rhamnolipids. Maximum biosurfactant production was obtained at a concentration of 1 mg l−1 of nanoparticles and an addition time of 6 h (Sahebnazar et al. 2018).The increase in biosurfactant production at all nanoparticle concentrations can be attributed to the presence of the iron component, which is a significant element in biosurfactant production. The application of iron NPs to increase the production of biosurfactants is more efficient than the addition of iron salts because the speed of the biochemical reactions involved in the production process of biosurfactants using iron nanoparticles is much faster due to the high active surface available of nanoparticles (Sahebnazar et al. 2018).

Conclusions

This review aimed to explore the current state of the art and future trends for the production of biosurfactants from cassava wastewater. The liquid residue generated during the cassava processing stages has an adequate composition that can serve as a source of nutrients for the production of products with high added value, such as surfactin. Using a residue as an alternative culture medium in the production of biosurfactants, together with strategies to increase production (such as the use of inducers and/or genetic modification), contributes to the reduction of production costs in an attempt to make its production feasible on large scale. In this way, it would allow for a wide range of innovations in the area of food, medicine, and personal care products, among others with biological activity. Finally, the use of cassava wastewater as a culture medium, in addition to contributing to the circular economy, minimizes the environmental damage caused by waste that is not properly treated and enables the production of a product with high added value in a more environmentally friendly way.

Data availability

Not applicable.

References

Acchar W, da Silva V (2021) Ecological brick of mineral residues and cassava wastewater. In: Acchar W, da Silva V (eds) Use of cassava wastewater and scheelite residues in ceramic formulations. Springer International Publishing, Cham, pp 33–51

Agarry S, Oghenejobor K, Solomon B (2016) Bioelectricity production from cassava mill effluents using microbial fuel cell technology. Niger J Technol 35:329. https://doi.org/10.4314/njt.v35i2.13

Ahsani Arani Y, Noormohammadi Z, Rasekh B et al (2022) Evaluation of SDS-coated iron nanostructure on the gene expression of bio surfactant-producing genes by Pseudomonas aeruginosa. Eng Life Sci 22:584–593. https://doi.org/10.1002/elsc.202200002

Ahuja K, Singh S (2022) Biosurfactants market size by product. USA

Akcil A, Karahan AG, Ciftci H, Sagdic O (2003) Biological treatment of cyanide by natural isolated bacteria (Pseudomonas sp.). Miner Eng 16:643–649. https://doi.org/10.1016/S0892-6875(03)00101-8

Alamdar N, Rasekh B, Yazdian F (2018) Effects of Fe/SDS and Au nanoparticles on P. aeruginosa bacterial growth and biosurfactant production. IET Nanobiotechnol 12:520–525. https://doi.org/10.1049/iet-nbt.2016.0260

Ambaye TG, Vaccari M, Prasad S, Rtimi S (2021) Preparation, characterization and application of biosurfactant in various industries: a critical review on progress, challenges and perspectives. Environ Technol Innov 24:102090. https://doi.org/10.1016/j.eti.2021.102090

Andrade LRS, Cruz IA, de Melo L et al (2020) Oyster shell-based alkalinization and photocatalytic removal of cyanide as low-cost stabilization approaches for enhanced biogas production from cassava starch wastewater. Process Saf Environ Prot 139:47–59. https://doi.org/10.1016/j.psep.2020.04.008

Araújo NC, Costa TF, Oliveira SJC et al (2012) Avaliação do uso de efluente de casas de farinha como ferlitizante foliar na cultura do milho (Zea mays L). Rev Eng Na Agric—Reveng 20:340–349. https://doi.org/10.13083/reveng.v20i4.313

Arima K, Kakinuma A, Tamura G (1968) Surfactin, a crystalline peptidelipid surfactant produced by Bacillus subtilis: Isolation, characterization and its inhibition of fibrin clot formation. Biochem Biophys Res Commun 31:488–494. https://doi.org/10.1016/0006-291X(68)90503-2

Arutchelvi JI, Bhaduri S, Uppara PV, Doble M (2008) Mannosylerythritol lipids: a review. J Ind Microbiol Biotechnol 35:1559–1570. https://doi.org/10.1007/s10295-008-0460-4

Barreto M (2011) Efeito da manipueira na biomassa e nutrientes do Milho (Zea mays L.) hibrido para forragem e alterações noa atributos químicos do solo. 55

Barros FFC, Ponezi AN, Pastore GM (2008) Production of biosurfactant by Bacillus subtilis LB5a on a pilot scale using cassava wastewater as substrate. J Ind Microbiol Biotechnol 35:1071–1078. https://doi.org/10.1007/s10295-008-0385-y

Bezerra MGS, Silva GGC, Difante GS et al (2017) Cassava wastewater as organic fertilizer in ‘Marandu’ grass pasture. Rev. Bras. Eng. Agríc. Ambient. 21:404–409. https://doi.org/10.1590/1807-1929/agriambi.v21n6p404-409

Bione AP, Lins AB, Rodríguez DM et al (2022) Valorization of agro-industrial by-products for sustainable production of biosurfactant by Syncephalastrum racemosum UCP 1302. Res Soc Dev 11:e58011932372. https://doi.org/10.33448/rsd-v11i9.32372

Boothroyd B, Thorn JA, Haskins RH (1956) Characterization of extravellular glycolipids produced by Ustilago sp. Can J Biochem Physiol 34:10–14

Cagri-Mehmetoglu A, Kusakli S, van de Venter M (2012) Production of polysaccharide and surfactin by Bacillus subtilis ATCC 6633 using rehydrated whey powder as the fermentation medium. J Dairy Sci 95:3643–3649. https://doi.org/10.3168/jds.2012-5385

Cao X, hong, Wang A hua, Wang C ling, et al (2010) Surfactin induces apoptosis in human breast cancer MCF-7 cells through a ROS/JNK-mediated mitochondrial/caspase pathway. Chem Biol Interact 183:357–362. https://doi.org/10.1016/j.cbi.2009.11.027

Cardoso É, Cardoso DC, Cristiano MP et al (2009) Use of Manihot esculenta, Crantz Processing residue as biofertilizer in corn crops. Res J Agron 3:1–8

Cavalcante Fai AE, Resende Simiqueli AP, de Andrade CJ et al (2015) Optimized production of biosurfactant from Pseudozyma tsukubaensis using cassava wastewater and consecutive production of galactooligosaccharides: an integrated process. Biocatal Agric Biotechnol 4:535–542. https://doi.org/10.1016/j.bcab.2015.10.001

Ceresa C, Hutton S, Lajarin-Cuesta M et al (2020) Production of mannosylerythritol lipids (MELs) to be used as antimicrobial agents against S. aureus ATCC 6538. Curr Microbiol 77:1373–1380. https://doi.org/10.1007/s00284-020-01927-2

Chen WC, Juang RS, Wei YH (2015) Applications of a lipopeptide biosurfactant, surfactin, produced by microorganisms. Biochem Eng J 103:158–169. https://doi.org/10.1016/j.bej.2015.07.009

Chisté RC, Cohen K de O (2006) Efeito do Processo da fabricação da farinha de mandioca. Efeito do Process Fabr da Farinha Mandioca 75

Coelho ALS, Feuser PE, Carciofi BAM et al (2020) Mannosylerythritol lipids: antimicrobial and biomedical properties. Appl Microbiol Biotechnol 104:2297–2318. https://doi.org/10.1007/s00253-020-10354-z

Costa SGVAO, Lépine F, Milot S et al (2009) Cassava wastewater as a substrate for the simultaneous production of rhamnolipids and polyhydroxyalkanoates by Pseudomonas aeruginosa. J Ind Microbiol Biotechnol 36:1063–1072. https://doi.org/10.1007/s10295-009-0590-3

Costa AG, Watanabe Cova AM, Da L et al (2020) Use of cassava wastewater in Capsicum chinense production. Pesqui Agropecuária Trop 50:e64756. https://doi.org/10.1590/1983-40632020v5064756

Coutinho Rodrigues OH, Itokazu AG, Rörig L et al (2021) Evaluation of astaxanthin biosynthesis by Haematococcus pluvialis grown in culture medium added of cassava wastewater. Int Biodeterior Biodegradation 163:105269. https://doi.org/10.1016/j.ibiod.2021.105269

Das P, Mukherjee S, Sen R (2008) Antimicrobial potential of a lipopeptide biosurfactant derived from a marine Bacillus circulans. J Appl Microbiol 104:1675–1684. https://doi.org/10.1111/j.1365-2672.2007.03701.x

Daylin R-R, da Rosileide FSA, da Goretti SS et al (2017) Promising biosurfactant produced by a new Candida tropicalis UCP 1613 strain using substrates from renewable-resources. Afr J Microbiol Res 11:981–991. https://doi.org/10.5897/ajmr2017.8486

de Mesquita FL (2016) Manejo de Meloidogyne enterolobii em goiabeira com produtos biológicos e manipueira. Universidade de Brasília

de Andrade CJ, Barros FFC, de Andrade LM et al (2016) Ultrafiltration based purification strategies for surfactin produced by Bacillus subtilis LB5A using cassava wastewater as substrate. J Chem Technol Biotechnol 91:3018–3027. https://doi.org/10.1002/jctb.4928

de Andrade CJ, de Andrade LM, Rocco SA et al (2017) A novel approach for the production and purification of mannosylerythritol lipids (MEL) by Pseudozyma tsukubaensis using cassava wastewater as substrate. Sep Purif Technol 180:157–167. https://doi.org/10.1016/j.seppur.2017.02.045

de Carvalho JC, Borghetti IA, Cartas LC et al (2018) Biorefinery integration of microalgae production into cassava processing industry: potential and perspectives. Bioresour Technol 247:1165–1172. https://doi.org/10.1016/j.biortech.2017.09.213

de Duarte AS, Silva de ÊFFE, Rolim MM, et al (2012) Uso de diferentes doses de manipueira na cultura da alface em substituição à adubação mineral. Rev Bras Eng Agrícola e Ambient 16:262–267. https://doi.org/10.1590/s1415-43662012000300005

de Fonseca TCS, de Souza AF, dos Santos PN et al (2022) Sustainable production of biosurfactant by Issatchenkia orientalis UCP 1603 using renewable substrates. Res Soc Dev 11:e16111427174. https://doi.org/10.33448/rsd-v11i4.27174

de Maia PCVS, Rodríguez DM, de Souza AF et al (2022) Production of biosurfactant by Bacillus subtilis UCP 0999 using cassava wastewater (CWW) and waste frying oil (WFO) as renewable substrates. Res Soc Dev 11:e17011628805. https://doi.org/10.33448/rsd-v11i6.28805

de Oliveira Schmidt VK, de Souza CJ, de Oliveira D, de Andrade CJ (2021) Biosurfactant inducers for enhanced production of surfactin and rhamnolipids: an overview. World J Microbiol Biotechnol. https://doi.org/10.1007/s11274-020-02970-8

de SouzaYes FD, dos Santos TPR, Fernandes AM, Leonel M (2019) Harvest time optimization leads to the production of native cassava starches with different properties. Int J Biol Macromol 132:710–721. https://doi.org/10.1016/j.ijbiomac.2019.03.245

De Araujo LV, Freire DMG, Nitschke M (2013) Biossurfactantes: propriedades anticorrosivas, antibiofilmes e antimicrobianas. Quim Nova 36:848–858. https://doi.org/10.1590/S0100-40422013000600019

Dhali D, Coutte F, Arias AA et al (2017) Genetic engineering of the branched fatty acid metabolic pathway of Bacillus subtilis for the overproduction of surfactin C14 isoform. Biotechnol J 12:1–23. https://doi.org/10.1002/biot.201600574

Doekel S (2002) Heterologous expression of nonribosomal peptide synthetases in B. subtilis: construction of a bi-functional B. subtilis/E. coli shuttle vector system. FEMS Microbiol Lett 216:185–191

Dong H, Zhang D (2014) Current development in genetic engineering strategies of Bacillus species. Microb Cell Fact 13:1–11

Drakontis CE, Amin S (2020) Biosurfactants: formulations, properties, and applications. Curr Opin Colloid Interface Sci 48:77–90. https://doi.org/10.1016/j.cocis.2020.03.013

Ebbs S (2004) Biological degradation of cyanide compounds. Curr Opin Biotechnol 15:231–236. https://doi.org/10.1016/j.copbio.2004.03.006

Ehrhardt DD, Secato JFF, Tambourgi EB (2015) Produção de biossurfactante por Bacillus subtilis utilizando resíduo do processamento do abacaxi como substrato. Anais do XX Congresso Brasileiro de Engenharia Química. Editora Edgard Blücher, São Paulo, pp 1960–1965

Elakkiya VT, SureshKumar P, Alharbi NS et al (2020) Swift production of rhamnolipid biosurfactant, biopolymer and synthesis of biosurfactant-wrapped silver nanoparticles and its enhanced oil recovery. Saudi J Biol Sci 27:1892–1899. https://doi.org/10.1016/j.sjbs.2020.04.001

Farias CBB, Almeida FCG, Silva IA et al (2021) Production of green surfactants: market prospects. Electron J Biotechnol 51:28–39. https://doi.org/10.1016/j.ejbt.2021.02.002

Fox SL, Bala GA (2000) Production of surfactant from Bacillus subtilis ATCC 21332 using potato substrates. Bioresour Technol 75:235–240. https://doi.org/10.1016/S0960-8524(00)00059-6

Fukuoka T, Morita T, Konishi M et al (2008) A basidiomycetous yeast, Pseudozyma tsukubaensis, efficiently produces a novel glycolipid biosurfactant: the identification of a new diastereomer of mannosylerythritol lipid-B. Carbohydr Res 343:555–560. https://doi.org/10.1016/j.carres.2007.11.023

Ghribi D, Ellouze-Chaabouni S (2011) Enhancement of Bacillus subtilis lipopeptide biosurfactants production through optimization of medium composition and adequate control of aeration. Biotechnol Res Int 2011:1–6. https://doi.org/10.4061/2011/653654

He Z, Liu G, Yang X, Liu W (2016) A novel surfactant, N, N-diethyl-N’-cyclohexylthiourea: synthesis, flotation and adsorption on chalcopyrite. J Ind Eng Chem 37:107–114. https://doi.org/10.1016/j.jiec.2016.03.013

Jahan R, Bodratti AM, Tsianou M, Alexandridis P (2020) Biosurfactants, natural alternatives to synthetic surfactants: physicochemical properties and applications. Adv Colloid Interface Sci 275:102061. https://doi.org/10.1016/j.cis.2019.102061

Jauregi P, Kourmentza K (2000) A cross flow filtration apparatus. Filtr + Sep 37:29. https://doi.org/10.1016/S0015-1882(00)89238-1

Ji F, Li L, Ma S et al (2016) Production of rhamnolipids with a high specificity by Pseudomonas aeruginosa M408 isolated from petroleum-contaminated soil using olive oil as sole carbon source. Ann Microbiol 66:1145–1156. https://doi.org/10.1007/s13213-016-1203-9

Jiang J, Zu Y, Li X et al (2020) Recent progress towards industrial rhamnolipids fermentation: process optimization and foam control. Bioresour Technol 298:122394. https://doi.org/10.1016/j.biortech.2019.122394

Jiao S, Li X, Yu H et al (2017) In situ enhancement of surfactin biosynthesis in Bacillus subtilis using novel artificial inducible promoters. Biotechnol Bioeng 114:832–842. https://doi.org/10.1002/bit.26197

Jiraprasertwong A, Maitriwong K, Chavadej S (2019) Production of biogas from cassava wastewater using a three-stage upflow anaerobic sludge blanket (UASB) reactor. Renew Energy 130:191–205. https://doi.org/10.1016/j.renene.2018.06.034

Joy S, Rahman PKSM, Sharma S (2017) Biosurfactant production and concomitant hydrocarbon degradation potentials of bacteria isolated from extreme and hydrocarbon contaminated environments. Chem Eng J 317:232–241. https://doi.org/10.1016/j.cej.2017.02.054

Kaewkannetra P, Imai T, Garcia-Garcia FJ, Chiu TY (2009) Cyanide removal from cassava mill wastewater using Azotobactor vinelandii TISTR 1094 with mixed microorganisms in activated sludge treatment system. J Hazard Mater 172:224–228. https://doi.org/10.1016/j.jhazmat.2009.06.162

Konishi M, Morita T, Fukuoka T et al (2008) Efficient production of mannosylerythritol lipids with high hydrophilicity by Pseudozyma hubeiensis KM-59. Appl Microbiol Biotechnol 78:37–46. https://doi.org/10.1007/s00253-007-1292-2

Kuyucak N, Akcil A (2013) Cyanide and removal options from effluents in gold mining and metallurgical processes. Miner Eng 50–51:13–29. https://doi.org/10.1016/j.mineng.2013.05.027

Lebot V (2009) Tropical root and tuber crops. cassava, sweet potato. Yams and Aroids Exp Agric 45:382–382. https://doi.org/10.1017/S0014479709007832

Lee SM, Lee JY, Yu HP, Lim JC (2016) Synthesis of environment friendly nonionic surfactants from sugar base and characterization of interfacial properties for detergent application. J Ind Eng Chem 38:157–166. https://doi.org/10.1016/j.jiec.2016.04.019

Lied EB (2012) Tratamento de efluente industrial de fecularia utilizando macrófita aquática Eichhornia crassipes e coagulante natural. Universidade Estadual do Parana

Lima AST, Valente ECN (2017) Uso de manipueira na adubação do pimentão. Rev Craibeiras Agroecol 1:1–3

Liu G, Zhong H, Yang X et al (2018) Advances in applications of rhamnolipids biosurfactant in environmental remediation: a review. Biotechnol Bioeng 115:796–814. https://doi.org/10.1002/bit.26517

Luo C, Liu X, Zhou H et al (2015) Nonribosomal peptide synthase gene clusters for lipopeptide biosynthesis in Bacillus subtilis 916 and their phenotypic functions. Appl Environ Microbiol 81:422–431. https://doi.org/10.1128/AEM.02921-14

Magalhães AG, Rolim MM, de Duarte AS et al (2014) Desenvolvimento inicial do milho submetido à adubação com manipueira. Rev Bras Eng Agrícola e Ambient 18:675–681. https://doi.org/10.1590/s1415-43662014000700001

Maier RM (2003) Biosurfactants: evolution and diversity in bacteria. Adv Appl Microbiol 52:101–121. https://doi.org/10.1016/S0065-2164(03)01004-9

Mari AG, Andreani CL, Tonello TU et al (2020) Biohydrogen and biomethane production from cassava wastewater in a two-stage anaerobic sequencing batch biofilm reactor. Int J Hydrogen Energy 45:5165–5174. https://doi.org/10.1016/j.ijhydene.2019.07.054

Markande AR, Patel D, Varjani S (2021) A review on biosurfactants: properties, applications and current developments. Bioresour Technol 330:124963. https://doi.org/10.1016/j.biortech.2021.124963

Maróstica MR, Pastore GM (2007) Production of R-(+)-α-terpineol by the biotransformation of limonene from orange essential oil, using cassava waste water as medium. Food Chem 101:345–350. https://doi.org/10.1016/j.foodchem.2005.12.056

Meier TRW, Cremonez PA, Maniglia TC et al (2020) Production of biohydrogen by an anaerobic digestion process using the residual glycerol from biodiesel production as additive to cassava wastewater. J Clean Prod. https://doi.org/10.1016/j.jclepro.2020.120833

Mohanty SS, Koul Y, Varjani S et al (2021) A critical review on various feedstocks as sustainable substrates for biosurfactants production: a way towards cleaner production. Microb Cell Fact 20:1–13. https://doi.org/10.1186/s12934-021-01613-3

Montoro SB, Lucas J, Santos DFL, Costa MSSM (2019) Anaerobic co-digestion of sweet potato and dairy cattle manure: a technical and economic evaluation for energy and biofertilizer production. J Clean Prod 226:1082–1091. https://doi.org/10.1016/j.jclepro.2019.04.148

Morita T, Fukuoka T, Imura T, Kitamoto D (2015) Mannosylerythritol lipids: production and applications. J Oleo Sci 64:133–141. https://doi.org/10.5650/jos.ess14185

Mulligan CN (2009) Recent advances in the environmental applications of biosurfactants. Curr Opin Colloid Interface Sci 14:372–378. https://doi.org/10.1016/j.cocis.2009.06.005

Nakano MM, Marahiel MA, Zuber P (1988) Identification of a genetic locus required for biosynthesis of the lipopeptide antibiotic surfactin in Bacillus subtilis. J Bacteriol 170:5662–5668. https://doi.org/10.1128/jb.170.12.5662-5668.1988

Nashida J, Nishi N, Takahashi Y et al (2018) Systematic and stereoselective total synthesis of mannosylerythritol lipids and evaluation of their antibacterial activity. J Org Chem 83:7281–7289. https://doi.org/10.1021/acs.joc.8b00032

Nasu ÉGC, Pires E, Formentini HM, Furlanetto C (2010) Efeito de manipueira sobre Meloidogyne incognita em ensaios in vitro e em tomateiros em casa de vegetação. Trop Plant Pathol 35:032–036. https://doi.org/10.1590/s1982-56762010000100005

Nazareth TC, Zanutto CP, Maass D et al (2021) Impact of oxygen supply on surfactin biosynthesis using brewery waste as substrate. J Environ Chem Eng. https://doi.org/10.1016/j.jece.2021.105372

Nitschke M, Pastore GM (2004) Biosurfactant production by Bacillus subtilis using cassava-processing effluent. Appl Biochem Biotechnol 112:163–172. https://doi.org/10.1385/ABAB:112:3:163

Nitschke M, Pastore GM (2006) Production and properties of a surfactant obtained from Bacillus subtilis grown on cassava wastewater. Bioresour Technol 97:336–341. https://doi.org/10.1016/j.biortech.2005.02.044

Niu Y, Wu J, Wang W, Chen Q (2019) Production and characterization of a new glycolipid, mannosylerythritol lipid, from waste cooking oil biotransformation by Pseudozyma aphidis ZJUDM34. Food Sci Nutr 7:937–948. https://doi.org/10.1002/fsn3.880

Ongena M, Jacques P (2007) Bacillus lipopeptides: versatile weapons for plant disease biocontrol. Trends in Microbiol. https://doi.org/10.1016/j.tim.2007.12.009

Padi RK, Chimphango A (2021) Comparative sustainability assessments for integrated cassava starch wastes biorefineries. J Clean Prod 290:125171. https://doi.org/10.1016/j.jclepro.2020.125171

Paraszkiewicz K, Bernat P, Kuśmierska A et al (2018) Structural identification of lipopeptide biosurfactants produced by Bacillus subtilis strains grown on the media obtained from renewable natural resources. J Environ Manage 209:65–70. https://doi.org/10.1016/j.jenvman.2017.12.033

Pathania AS, Jana AK (2020) Utilization of waste frying oil for rhamnolipid production by indigenous Pseudomonas aeruginosa: Improvement through co-substrate optimization. J Environ Chem Eng 8:104304. https://doi.org/10.1016/j.jece.2020.104304

Patil YB, Paknikar KM (2000) Biodetoxification of silver-cyanide from electroplating industry wastewater. Lett Appl Microbiol 30:33–37. https://doi.org/10.1046/j.1472-765x.2000.00648.x

Peres S, Monteiro MR, Ferreira ML et al (2019) Anaerobic digestion process for the production of biogas from cassava and sewage treatment plant sludge in Brazil. Bioenergy Res 12:150–157. https://doi.org/10.1007/s12155-018-9942-z

Peters D, Ngai DD (2005) Agro-processing waste assessment and management in agro-processing waste assessment and management in peri-urban Hanoi, Vietnam. 37–41. https://doi.org/10.1300/J064v25n01

Pinto Zevallos DM, Pereira Querol M, Ambrogi BG (2018) Cassava wastewater as a natural pesticide: current knowledge and challenges for broader utilisation. Ann Appl Biol 173:191–201. https://doi.org/10.1111/aab.12464

Pinto P (2008) Tratamento de manipueira de fecularia em biodigestor anaeróbio para disposição em corpo receptor, rede pública ou uso em fertirrigação: Dissertação para obtenção do título de Mestre em Agronomia. Universidade Estadual Paulista “Júlio Mesquita Filho 9:87

Potivichayanon S, Toensakes R, Supromin N, Seaung K (2020) Removal of high levels of cyanide and COD from cassava industrial wastewater by a fixed-film sequencing batch reactor. Water Air Soil Pollut. https://doi.org/10.1007/s11270-020-04642-7

Radzuan MN, Banat IM, Winterburn J (2017) Production and characterization of rhamnolipid using palm oil agricultural refinery waste. Bioresour Technol 225:99–105. https://doi.org/10.1016/j.biortech.2016.11.052

Rajbhandari BK, Annachhatre AP (2004) Anaerobic ponds treatment of starch wastewater: case study in Thailand. Bioresour Technol 95:135–143. https://doi.org/10.1016/j.biortech.2004.01.017

RamosFilho REB (2021) Ecological brick of mineral residues and cassava wastewater. In: Acchar W, da Silva V (eds) Use of cassava wastewater and scheelite residues in ceramic formulations. Springer International Publishing, Cham, pp 33–51

Rangarajan V, Clarke KG (2016) Towards bacterial lipopeptide products for specific applications—a review of appropriate downstream processing schemes. Process Biochem 51:2176–2185. https://doi.org/10.1016/j.procbio.2016.08.026

Ranmadugala D, Ebrahiminezhad A, Manley-Harris M et al (2017) The effect of iron oxide nanoparticles on Bacillus subtilis biofilm, growth and viability. Process Biochem 62:231–240. https://doi.org/10.1016/j.procbio.2017.07.003

Ribeiro JSE, Sant’Ana da AMS, Martini M, et al (2019) Rhodotorula glutinis cultivation on cassava wastewater for carotenoids and fatty acids generation. Biocatal Agric Biotechnol. https://doi.org/10.1016/j.bcab.2019.101419

Ron EZ, Rosenberg E (2001) Natural roles of biosurfactants. Environ Microbiol 3:229–236. https://doi.org/10.1046/j.1462-2920.2001.00190.x

Routhu SR, Nagarjuna Chary R, Shaik AB et al (2019) Induction of apoptosis in lung carcinoma cells by antiproliferative cyclic lipopeptides from marine algicolous isolate Bacillus atrophaeus strain AKLSR1. Process Biochem 79:142–154. https://doi.org/10.1016/j.procbio.2018.12.010

Sahebnazar Z, Mowla D, Karimi G (2018) Enhancement of Pseudomonas aeruginosa growth and rhamnolipid production using iron-silica nanoparticles in low-cost medium. J Nanostruct 8:1–10. https://doi.org/10.22052/JNS.2018.01.001

Sajid M, Ahmad Khan MS, Singh Cameotra S, Safar Al-Thubiani A (2020) Biosurfactants: potential applications as immunomodulator drugs. Immunol Lett 223:71–77. https://doi.org/10.1016/j.imlet.2020.04.003

Sałek K, Euston SR (2019) Sustainable microbial biosurfactants and bioemulsifiers for commercial exploitation. Process Biochem 85:143–155. https://doi.org/10.1016/j.procbio.2019.06.027

Santos A (2014) Avaliação ambiental estratégica aplicada á cadeia produtiva da mandioca na Microrregião Sudoeste da Bahia

Sarubbo LA, da Silva MGC, Durval IJB et al (2022) Biosurfactants: production, properties, applications, trends, and general perspectives. Biochem Eng J. https://doi.org/10.1016/j.bej.2022.108377

Shu Q, Wei T, Lu H et al (2020) Mannosylerythritol lipids: dual inhibitory modes against Staphylococcus aureus through membrane-mediated apoptosis and biofilm disruption. Appl Microbiol Biotechnol 104:5053–5064. https://doi.org/10.1007/s00253-020-10561-8

Silva J (2009) Desempenho do Reator Anaeróbio Horizontal com Chicanas no tratamento da manipueira em fases separadas e estabilização do pH com conchas de sururu. Univ Fed Alagoas—UFAL 100

Simiqueli APR, De Andrade CJ, Fai AEC (2017) Current status and trends in mannosylerylthritol lipids: Production, purification and potential applications. Biosurfactants Occur Appl Res 149–171

Sun L, Wan S, Yu Z et al (2012) Anaerobic biological treatment of high strength cassava starch wastewater in a new type up-flow multistage anaerobic reactor. Bioresour Technol 104:280–288. https://doi.org/10.1016/j.biortech.2011.11.070

Sun W, Zhu B, Yang F et al (2021) Optimization of biosurfactant production from Pseudomonas sp CQ2 and its application for remediation of heavy metal contaminated soil. Elsevier Ltd

Tan YN, Li Q (2018) Microbial production of rhamnolipids using sugars as carbon sources. Microb Cell Fact 17:1–13. https://doi.org/10.1186/s12934-018-0938-3

Thanwised P, Wirojanagud W, Reungsang A (2012) Effect of hydraulic retention time on hydrogen production and chemical oxygen demand removal from tapioca wastewater using anaerobic mixed cultures in anaerobic baffled reactor (ABR). Int J Hydrogen Energy 37:15503–15510. https://doi.org/10.1016/j.ijhydene.2012.02.068

Tosato V, Albertini AM, Zotti M et al (1997) Sequence completion, identification and definition of the fengycin operon in Bacillus subtilis 168. Microbiology 143:3443–3450. https://doi.org/10.1099/00221287-143-11-3443

Trevisan AP, Lied EB, Fronza FL et al (2019) Cassava wastewater treatment by coagulation/flocculation using moringa oleifera seeds. Chem Eng Trans 74:367–372. https://doi.org/10.3303/CET1974062

Tumwesigye KS, Oliveira JC, Sousa-Gallagher MJ (2016) Integrated sustainable process design framework for cassava biobased packaging materials: critical review of current challenges, emerging trends and prospects. Trends Food Sci Technol 56:103–114. https://doi.org/10.1016/j.tifs.2016.08.001

Varjani S, Rakholiya P, Yong Ng H et al (2021) Bio-based rhamnolipids production and recovery from waste streams: status and perspectives. Bioresour Technol 319:124213. https://doi.org/10.1016/j.biortech.2020.124213

Vicente R, de Andrade CJ, de Oliveira D, Ambrosi A (2021) A prospection on membrane-based strategies for downstream processing of surfactin. Chem Eng J 415:129067. https://doi.org/10.1016/j.cej.2021.129067

Vieites RL (1998) Efeitos da adubação com manipueira sobre o rendimento e qualidade dos frutos de tomate. Pesqui Agropecu Bras 33:1239–1243

Wadjeam P, Reungsang A, Imai T, Plangklang P (2019) Co-digestion of cassava starch wastewater with buffalo dung for bio-hydrogen production. Int J Hydrogen Energy 44:14694–14706. https://doi.org/10.1016/j.ijhydene.2019.04.138

Wei YH, Chou CL, Chang JS (2005) Rhamnolipid production by indigenous Pseudomonas aeruginosa J4 originating from petrochemical wastewater. Biochem Eng J 27:146–154. https://doi.org/10.1016/j.bej.2005.08.028

Weinrauch Y, Guillen N, Dubnau DA (1989) Sequence and transcription mapping of Bacillus subtilis competence genes comB and comA, one of which is related to a family of bacterial regulatory determinants. J Bacteriol 171:5362–5375. https://doi.org/10.1128/jb.171.10.5362-5375.1989

Wosiacki G, Cereda MP (2002) Valorização De Resíduos Do Processamento De Mandioca. Publ UEPG—Ciencias Exatas e Da Terra, Agrar e Eng 8:27–43. https://doi.org/10.5212/publicatio.v8i01.762

Wu Q, Zhi Y, Xu Y (2019) Systematically engineering the biosynthesis of a green biosurfactant surfactin by Bacillus subtilis 168. Metab Eng 52:87–97. https://doi.org/10.1016/j.ymben.2018.11.004

Xu Y, Cai D, Zhang H et al (2020) Enhanced production of iturin A in Bacillus amyloliquefaciens by genetic engineering and medium optimization. Process Biochem 90:50–57. https://doi.org/10.1016/j.procbio.2019.11.017

Yang N, Wu Q, Xu Y (2020) Fe nanoparticles enhanced surfactin production in Bacillus amyloliquefaciens. ACS Omega 5:6321–6329. https://doi.org/10.1021/acsomega.9b03648

Zanotto AW, Valério A, de Andrade CJ, Pastore GM (2019) New sustainable alternatives to reduce the production costs for surfactin 50 years after the discovery. Appl Microbiol Biotechnol 103:8647–8656. https://doi.org/10.1007/s00253-019-10123-7

Zempulski DA (2013) Produção de ácidos graxos voláteis por fermentação anaeróbia de manipueira e de permeado de soro de queijo. Universidade Estadual do Oeste do Paraná

Zhao F, Han S, Zhang Y (2020) Comparative studies on the structural composition, surface/interface activity and application potential of rhamnolipids produced by Pseudomonas aeruginosa using hydrophobic or hydrophilic substrates. Bioresour Technol 295:122269. https://doi.org/10.1016/j.biortech.2019.122269

Zhu Z, Zhang F, Wei Z et al (2013) The usage of rice straw as a major substrate for the production of surfactin by Bacillus amyloliquefaciens XZ-173 in solid-state fermentation. J Environ Manage 127:96–102. https://doi.org/10.1016/j.jenvman.2013.04.017

Acknowledgements

The authors acknowledge CAPES-PRINT, project number 88887.310560/ 2018-00, and FAPESC (Fundação de Amparo à Pesquisa e Inovação do Estado de Santa Catarina) PRONEM (Programa de Apoio a Núcleos Emergentes) 2020TR731 for the financial support and CAPES-PROEX (Coordenação de Aperfeiçoamento Pessoal de Nível Superior—Programa de Excelência Acadêmica) for scholarship.

Funding

FAPESC (Fundação de Amparo à Pesquisa e Inovação do Estado de Santa Catarina) PRONEM (Programa de Apoio a Núcleos Emergentes) 2020TR731 for the financial support and CAPES-PROEX (Coordenação de Aperfeiçoamento Pessoal de Nível Superior—Programa de Excelência Acadêmica).

Author information

Authors and Affiliations

Contributions

Wrote the paper: VKO Schmidt, GMD Vasconscelos, R Vicente, IK Della-Flora, L Degang and JS Carvalho; performed manuscript editing and revised the language: CJ Andrade and D Oliveira.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Ethical approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

de Oliveira Schmidt, V.K., de Vasconscelos, G.M.D., Vicente, R. et al. Cassava wastewater valorization for the production of biosurfactants: surfactin, rhamnolipids, and mannosileritritol lipids. World J Microbiol Biotechnol 39, 65 (2023). https://doi.org/10.1007/s11274-022-03510-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11274-022-03510-2