Abstract

Water-based lubricant is regarded as an important substitute for the oil-based lubricant when used in improving the tribological properties. Additives are urgent required in water-based lubricants as their disadvantages of poor lubricating properties. In the present work, a new additive containing S, P, Cl active element was synthesized, and the tribological properties were evaluated by using a four-ball tester. The impact of temperature on the tribological properties of water-soluble lubricant was also studied. The worn surfaces were analyzed by X-ray absorption near-edge structure (XANES) spectroscopy. The results show that the synthesized additive exhibit better tribological properties than oleate solution at higher load. XANES spectroscopy indicates that the compositions of tribofilms changed with the temperature. The different composition of the tribofilm has a great influence on tribological behavior.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

In the twenty-first century, environment and resources are two major issues that affect the development of human society, and tribology is closely related to them. With the increasing demands for environmental protection and energy saving, lubricating oil is also facing various new requirements and challenges [1]. The concept of traditional lubrication considering only adequate lubrication, reducing wear, and friction is outdated, and the modern viewpoint of lubrication has added requirements for energy saving, consumption reduction, pollution reduction and environmental friendliness [2]. Accordingly, the water-soluble lubricant becomes increasingly attractive because of its availability, good resistance to fire, ease of cleaning, and environmentally friendly properties [3, 4].

Compared with oil-based lubricants, water-based lubricant has some disadvantages such as poor lubricating properties. So additives are urgently required. Water-based lubricant additives are kinds of water-soluble compounds that can greatly improve the tribological properties [5]. Many studies have been done to explore an efficient additive to improve the tribological properties of water-based lubricant. Zhao et al. [6] synthesized water-soluble Cu nanoparticles of size approximately 3 nm, and found that the additive can significantly improve the tribological properties of distilled water. Su et al. [7] found that graphene oxide nanosheets exhibit superior friction-reducing and anti-wear abilities on applying heavy loads when used as lubricant additives in water. Ma et al. [8] synthesized an effective water-based lubricant additive, O,O-di-(AEO-3) phosphorodithioic acid, and found that the composition of tribofilms changed with duration and temperature.

Because of its high atom sensitivity, speediness, and accuracy, X-ray absorption near-edge structure (XANES) spectrocoscopy is an important tool which is widely used in tribological research works during recent years. It is widely used in oil-based lubricant, while water-based lubricant is rarely investigated by XANES [9]. In the present work, a new additive containing S, P, Cl active element was synthesized and the tribological properties were evaluated by using a four-ball tester. The worn surfaces at different temperatures were analysed by XANES. According to the tribofilms analysis, the mechanism of anti-wear and friction-reducing is proposed.

Experimental

Preparation of the additive

The additive, DEPTP, were prepared in laboratory as the following pathway: The blending of freshly distilled pyridine and 2-chloroethanol were heated to 120 °C, then the reaction was stirred for 24 h under the protection of nitrogen. After cooling, a solid crude product was obtained. After filtration, it was washed three times with anhydrous ether and calcium chloride was dried in vacuum for 4 h. Then it was dried at 60℃ under vacuum for 8 h. As a result, the white solid “HEpy+Cl−” was obtained with a melting point of 128–130℃.

The solid phosphorus pentasulfide was slowly added into the mixture of HEpy+Cl− and toluene, and then it was heated to 75–95 °C for 2 h. The hydrogen sulfide generated during the reaction was absorbed with 10% sodium hydroxide. After the reaction, toluene and hydrogen sulfide, which were not discharged from the reaction, were distilled off under reduced pressure to obtain a viscous liquid. After washing with ether 2–3 times, a white viscous liquid was obtained. The product “DEPTP” was titrated with an iodine solution. As the result, the content of thiophosphoric phosphinic acid was measured to be 90%, and the yield was about 80%. The theoretical reaction equations are shown in Fig. 1.

Tribological properties test

In the present work, in order to increase the solubility and the anti-corrosion capacity of base stock, 2.0 wt% triethanolamine aqueous solution were used as base stock. At 25 ± 5℃, the friction and wear properties of the DEPTP triethanolamine-containing lubricant were tested on a MMW-1 four-ball tester made in Jinan Testing Machine Factory of China. The same percentage of oleate triethanolamine in water was also tested at the same condition for reference. All the friction and wear tests were conducted at a rotating speed of 1450 r/min with test duration of 30 min.

The testing ball is made of GCrl5 bearing steel, with diameter 12.7 mm and hardness (HRC) in the range 59–61. The wear scar diameters on the three lower balls were measured using an optical microscope with an accuracy of ± 0.01 mm. Then, the average value of the three wear scar diameters was calculated and cited as wear scar diameter (WSD) reported in the results. The friction coefficients were measured under each applied load, and each test was repeated for three times [10, 11].

Worn surface analysis test

XANES data were obtained at the Institute of High Energy Physics (IHEP), Chinese Academy of Science. Phosphorus, sulfur and chlorine K-edge spectra were obtained on the double-crystal monochromator (DCM) covering an energy range of 1900–6000 eV with photon resolution of 0.8 eV. The photon absorption spectra for the model compounds and samples were recorded in the fluorescence yield (FY) mode for bulk sensitivity [12]. The assignment of the fine structure in XANES was obtained by using the spectra of model compounds.

Results and discussion

Characterization of the additive

FT-IR spectrum of DEPTP is presented in Fig. 2. The wide IR peak at 2930 cm−1 corresponds to the stretch of ––CH2. The peak at 1640 cm−1 is responsible for the stretch of Py–H from pyridine. Another peak at 685 cm−1 is also responsible for the stretch of CH2.

1H NMR spectra of DEPTP are depicted in Fig. 3 and Table 1. The multiplicities are designated as following abbreviations: s = singlet, d = doublet, t = triplet. Figure 3 and Table 1 show the 1H NMR spectrum of DEPTP: 8.75(d, 2H, pyridine, H-2, H-6), 8.47(t, 1H, pyridine, H-4), 7.98(t, 2H, pyridine, H-3, H-5), 4.62 (t, 2H,N–CH2), 3.96(s, 2H, O–CH2). The absence of –OH confirms that all the 2-chloroethanol is reacted. All above evidences from FT-IR and 1H NMR spectra prove the successful synthesis of DEPTP.

Friction properties at different concentration

As the concentration of additive is very important to its application, the performance of friction properties at different concentration were also investigated. The experiment was conducted at a load of 196 N. As we can see from Fig. 4, the friction coefficient decreases rapidly when the concentration increases from 1 to 5%. When the concentration increases from 5 to 7%, the rate of decline gradually slows down. This phenomenon indicates that 5.0 wt% DEPTP-containing lubricant is approximately a suitable concentration. So in the following experiment, the test was conducted at a concentration of 5.0 wt% DEPTP-containing lubricant.

Wear and friction properties at different loads

Influences of load on anti-wear and friction-reducing properties are shown in Fig. 5a and b, respectively. As a comparison, water containing 5.0 wt% oleate triethanolamine is tested. It is easy to conclude from Fig. 5 that the synthetic DEPTP possess better anti-wear and friction-reducing properties than oleate solution at higher loads, but worse at lower loads. Figure 5a indicates that the wear scar diameters of DEPTP-containing lubricant increase when the applied load increase from 98 to 392 N. When the applied load rises from 392 to 588 N, the wear scar diameters reduce from 0.72 to 0.6. As for oleate solution, the WSD increases with increasing loads. Figure 5b shows a trend similar to Fig. 5a. The friction coefficient value of DEPTP-containing lubricant is much smaller than that of oleate solution at high load. The reason may be due to the different lubricating manners. Without ‘‘active element’’, oleate can only form an adsorption layer on the friction pairs, while P, S and Cl in the synthetical additives form the tribofilms along with adsorption films to prevent rubbing. At lower load, adsorption film is dominant, but with increasing load, the adsorption layer is damaged and tribofilm forms quickly [13]. The phenomenon indicates that DEPTP is a better and stable additive when used in higher load.

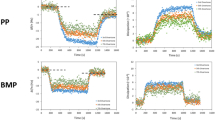

Wear and friction properties at different temperature

Since temperature has an important effect on the lubricating properties of additives, we studied the effect of different lubricating fluid temperatures on the lubricating properties of additives [14]. The experiment is also conducted at a rotating speed of 1450 r/min and load of 196 N with test duration of 30 min. The results are shown in Fig. 6a and b. As can be seen from the figure, as the temperature of the lubricating fluid increases, the WSD and friction coefficient produced by the additive decrease firstly and then rise. At the temperature of 40 ℃, the WSD and friction coefficient produced by the additive both reach the lowest value. When the temperature rises from 40 to 80 ℃, the lubricating properties of the additives will be greatly reduced.

Normally, the additive can be adsorbed on and react with the friction pair to form the tribofilms, which would have dominant influences on the lubricating process. A certain proportion of additive adsorption and tribochemical reactants in the tribofilms will result in good tribological properties. Lower temperature is favorable to physical adsorption, while higher temperature is beneficial to tribochemical reaction [15, 16]. In order to balance the adsorption and tribochemical reaction processes, an appropriate temperature should exist. In the present work, 40 ℃ is approximately the temperature which can balance the adsorption and tribochemical reaction to form a suitable tribofilm, which can result in good antiwear and friction-reducing properties.

XANES spectroscopy of tribofilms at different temperatures

Figure 7 shows P K-edge (a), S K-edge (b) and Cl K-edge (c) XANES of tribofilms generated by 5.0 wt% DEPTP at different temperatures along with the model compounds such as FePO4, Fe4P2O7, FeSO4, FeS, and FeCl3 (peaks situated at 2147.9, 2152.6, 2481.7, 2470.0 and 2823.3 eV, respectively). It can be seen from the spectra that the peak of P generated by DEPTP situating at 2152.7 eV is attributed to phosphate or polyphosphate. Another peak situated at 2147.8 eV is quite different when the temperature ranged from 20 to 80 ℃. As we can see from Fig. 7a, the intensity of peak a becomes weak with the increasing of temperature from 20 to 80℃. The phenomenon indicates that the amount of ferric iron bound to phosphate in the surface film decreases as the temperature rise. This may be one of the reasons why DEPTP possess better tribology properties in low temperature (20 and 40 ℃) than higher temperature.

S K-edge XANES spectra of tribofilms are shown in Fig. 7b. The main peak in this figure situates at 2470.0 eV corresponding to FeS. As the temperature rises, the peak position of FeS gradually shifts toward the direction of larger energy value. At the same time, we also find that there is a peak near the 2471.7 eV of the friction film formed by the additive at 40℃, which corresponds to the FeS2 peak. Combining the tribological data at different temperatures, this may be another reason that the tribological properties of additives at 40℃ are better than those at other temperatures.

Cl K-edge XANES spectra of tribofilms are shown in Fig. 7c. From the figure, we can conclude that the spectrum at different temperatures is not much different from that at room temperature, and is mainly composed of inorganic salts containing chlorine.

Conclusion

Based on the above results, the following conclusions can be drawn.

-

1.

DEPTP is a better water-based lubricant additive than oleate solution at higher loads

-

2.

Temperature has a great impact on the lubricating properties of DEPTP. At the temperature of 40 ℃, the WSD and friction coefficient produced by the additive both reach the lowest value.

-

3.

XANES results indicate that a high value of FePO4 and FeS2 in the tribofilm may result in better tribology properties.

References

R.B. Qiang, L.F. Hu, K.M. Hou, J.Q. Wang, S.R. Yang, Tribol. Lett. 67, 64 (2019)

C.L. Zhang, S.M. Zhang, S.Y. Song, G.B. Yang, L.G. Yu, Z.S. Wu, X.H. Li, P.Y. Zhang. Tribol Lett. 25 (2014).

E.M. Derun, A.S. Kipcak, F.T. Senberber, Res. Chem. Intermed. 41, 853 (2015)

A. Bernas, B. Peltopakka, P. Mäki-Arvela, K. Eränen, T. Salmi, DYu. Res, Chem. Intermed. 33, 645 (2007)

Q. Chen, X. Wang, Z.T. Wang, Y. Liu, T.Z. You, Nanoscale Res Lett. 8, 52 (2013)

J.H. Zhao, G.B. Yang, C.L. Zhang, Y.J. Zhang, S.M. Zhang, P.Y. Zhang, Friction 7(3), 246 (2019)

F.H. Su, G.F. Chen, P. Huang, Friction 8(1), 47 (2020)

H.B. Ma, J. Li, H. Chen, G.Z. Zuo, T.H. Ren, Y.D. Zhao. Tribol Int., 940 (2009).

H.B. Ma, R. Qiao, Y.L. Li, H. Chen, T.H. Ren. Surf. Interface Anal., 779 (2009).

Z.F. Jia, Y.Q. Xia, X.J. Pang, J.Y. Hao. Tribol Lett. 247 (2011).

B.G. Wang, W.W. Tang, X. Liu, Z.Y. Huang, Appl. Phys. A. 123, 680 (2017)

M.O. Asensio, M. Yildirim, F.T. Senberber, Res. Chem. Intermed. 42, 4859 (2016)

M. Gauvin, F. Dassenoy, M. Belin, C. Minfray, C. Guerret-Pie´court, S. Bec, J. M. Martin, G. Montagnac, B. Reynard. Tribol Lett. 139 (2008).

X. Xiong, J. Chen, P.P. Yao, S.P. Li, B.Y. Huang. Wear., 1182 (2007).

J. Guegan, M. Southby, H. Spikes, Tribol. Lett. 67, 83 (2019)

Y.G. Wang, N. Li, P. Liu, B. Dai, S. Han, Res. Chem. Intermed. 46, 2 (2019)

Acknowledgements

The work was supported by the Chinese Natural Science Foundation (No. 21203087).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wang, Y., Li, N., Liu, H. et al. Tribological properties generated by a S–P–Cl-containing additive in water-based lubricant. Res Chem Intermed 47, 1615–1623 (2021). https://doi.org/10.1007/s11164-020-04356-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11164-020-04356-9