Abstract

Ionic liquids have been found abroad application as lubricant additives due to their unique physic properties, as well as the powerful friction-reducing and anti-wear performances. In this work, four examples of 1,8-diazabicyclo[5.4.0]undecane-7-ene–organophosphoric acid-based protic ionic liquids were synthesized via simple neutralization and valuated as lubricant additives in PAO-10. These unique ionic liquids with dianionic and dicationic structure in one molecular could achieve maximum decreases by 60% in the friction coefficient and 83% in wear volume. After a series of tests including contact angle, ECR, SEM, EDS, and XPS, it was confirmed that the physical adsorption film and chemical reaction film generated during the friction process were responsible for the excellent tribiological performances. Besides the simple synthesis and exceptional tribological abilities, convenient purification procedure and low cost together make this powerful type of ionic liquid additives great potential to be employed in the industrial field.

Graphical Abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Useful lubricant additives have been proved as an indispensable component in the mechanical systems [1,2,3,4], which have played a crucial role to enhance the performances of lubricants, reduce the energy loses, and improve the energy efficiency. In this respect, ionic liquids (ILs) lubricant additives have attracted considerable attention for their unique properties including high thermal stability, negligible volatility, non-flammability, and strong attachment to surface [5,6,7,8,9,10]. Furthermore, good structure designability of ILs can produce versatile features such as the excellent solubility in different base oils, good corrosion resistance, friction-reducing, and anti-wear performances. For example, Qu and co-workers presented a urea-functionalized imidazolium-organophosphate ionic liquid as additive for glycerol [11], which not only improved the friction reducing and anti-wear properties of glycerol system dramatically, but also displayed high corrosion inhibiting properties. Ma et al. reported two oil-soluble ammonium-phosphate type ILs as additives in PAO-10 [12], which exhibited excellent copper corrosion inhibition behaviors and anti-rust properties, as well as good friction-reducing, anti-wear, and load-carrying capacity performances. The Khatri group developed a series of tetrabutylammonium-fatty acid ILs as additives in polyol ester lube [13], showing remarkably friction-reducing, anti-wear performances for the steel tribopairs. Despite these achievements, the challenges in the purification, complex synthesis method of ILs and expensive starting reagents still hinder the abroad application in the field of lubrication.

In recent years, the methods for the synthesis of ILs via neutralization reactions have been well established [14,15,16]. As a consequence, the synthesis and purification efficiency of ILs have been greatly improved. Zhu et al. synthesized the amino acids-based ILs via neutralization reaction at ambient temperature [17], which could be easily purified by removing water under reduced pressure in a rotary evaporator. Moreover, the synthesized ILs used as additives in PAO40 displayed glorious lubrication ability for diverse contacts. The Fan group reported an in situ preparation of ammonium-benzotriazole-based lubricant additives in aqueous solution [18]. The method featured easy-handling operations and the target ILs were not required further purification. In addition, this lubricant system showed significant improvement on the tribological performances and corrosion-resistant abilities. Organic bases such as tertiary amines, guanidines, and amidines could also be neutralized with acids to prepare proton-type ILs [19,20,21]. Dong and co-workers designed a series of alcoholamine-phosphate protic ionic liquids (PILs) based on the neutralization reactions and found that these PILs additives had good tribological performances and excellent anticorrosion functions in water [22]. Sadanandan et. al. evaluated the tribological abilities of a series of IL additives derived from 1,1,3,3-tetramethylguanidine (TMG) and amino acids [23]. The results suggested that 2 wt% concentration of these PILs additives in PEG200 could exhibit good performance in terms of reduction in friction and wear along with the non-corrosive nature. However, dicationic PILs for tribology applications were seldom reported in the past two decades, which might have exceptional lubrication effects.

1,8-Diazabicyclo[5.4.0]undecane-7-ene (DBU) is a common organic base along with useful catalysis, which finds wide applications in organic synthesis [24,25,26,27]. As known, the alkalinity of DBU is determined by the conjugated two nitrogen atoms in the structure, which can react with acids to offer chances for the design and synthesis of a novel type of PILs with potential powerful tribological abilities. However, only a few reports mentioned the traditional DBU-related PILs and investigated their tribologial performances. For example, Hatsuda’s team prepared a thermally stable 1,8-diazabicyclo[5.4.0] undecane-7-ene (DBU)-based PIL additive used in mPAO (molecular weight 5400), which possessed good tribological performances at high temperature, even 300 °C [28]. However, in the present work, four examples of PILs with unique dianionic and dicationic structure were synthesized from DBU and phosphonic acids bearing different lengths of carbon chains via simple neutralization. Besides the simple synthesis and purification procedure, low cost and excellent tribological performances make this useful type of ionic liquid additives great potential to be employed in the industrial field.

2 Materials and Methods

2.1 Materials

1,8-Diazabicyclo[5.4.0]undecane-7-ene (purity > 99.0%), n-hexylphosphonic acid (purity > 98.0%), n-octylphosphonic acid (purity > 97.0%), n-dodecylphosphonic acid (purity > 97.0%), and n-tetradecylphosphonic acid (purity > 98.0%) were purchased from Energy Chemical Scientific Ltd. All chemicals were used without further purification.

2.2 Preparation

All of the PILs were synthesized through mixing equimolar phosphonic acid with different chain lengths and DBU together in ethanol, which was then stirred overnight at 80 °C. After removal of ethanol by a rotary evaporator under reduced pressure, the target PILs were obtained and then dried under vacuum at 60 °C for 24 h. The molecular structures of the four PILs are plotted in Fig. 1.

2.3 Structural Characterization

The fourier transform infrared (FTIR, PerkinElmer, Frontier) spectra of the above four PILs were collected and are shown in Fig. 2. The characteristic peaks at 3100–3500 cm−1 are attributed to the stretching vibrations of N–H bonds; those at 2810–2990 cm−1 are assigned to the asymmetric stretch of saturated C–H bonds; those at 1590–1650 cm−1 are related to the asymmetric stretch of C=N structure; those at 1360–1465 cm−1 correspond to C–P bonds stretching vibration; those at 1120–1220 cm−1 are assigned to P–O bonds stretching vibration; and finally the ranges of 900–1100 cm−1 are attributed to P=O bonds stretching vibration, indicating the formation of the PTILs [29], respectively.

2.4 Thermal Stability

Thermal stability of these ionic liquids was tested on a thermal analyzer (STA449C TGADSC(NETZSCH)). The temperature was programmed from 25 to 600 °C with thermal rate of 10 °C/min under N2 environment.

2.5 Tribological Tests and Surface Analysis

The tribological performances of PAO-10 with PIL additives were recorded on an optimal (SRV-V, Germany) reciprocation friction tester under the condition of 100 N, 25 Hz, 25 °C, 1 mm, 30 min, and 20–40% comparative humidity. Then the wear volumes of the baseplates were estimated on a MicroXAM 3D noncontact surface-mapping microscope profiler (BRUKER-NPFLEX). Above tests should be repeated at least three times to avoid casual. The load and frequency ramp tests were also conducted. During the tests, the load was monitored to increase from 50 to 350 N (50 N, 100 N, 150 N, 200 N, 250 N, 300 N, and 350 N) and the frequencies from 10–50 Hz (10 Hz, 20 Hz, 30 Hz, 40 Hz, 50 Hz). The upper ball (diameter = 10 mm, hardness = 700–800 HV, GCr15 steel, AISI 52100) was served to move against to the lower stainless steel baseplates (ø 24 mm × 7.9 mm, hardness = 700–800 HV, AISI 40300). The morphological features of worn surfaces baseplates were evaluated by a SEM (Quanta 250 EFG) produced by United States of FEI company, and the chemical composition of worn surfaces was analyzed by XPS produced by Kratos analysis company in the UK.

3 Results and Discussion

3.1 Solubility

Poor solubility of ILs in nonpolar base oils is an essential issue for their practical application. To our satisfaction, the synthesized PILs exhibited good solubility in PAO-10. As seen in Fig. 3a, all of the mixtures were homogeneous and clear without any cloud or separation phase. Except C6PDBU, the other mixtures still kept the initial state even after stewing two weeks (room temperature, Fig. 3b), demonstrating the superior solubility of these PILs. Although two pairs of anions and cations existed in the molecular, the hydrocarbon chains of DBU and phosphonic acids could strengthen the compatibility of PILs with PAO-10 and decrease the interaction between cations and anions via steric hindrance effect [8], both of which led to the excellent solubility. The lower of solubility of C6PDBU might be due to the short hydrocarbon chains in the structure, which cannot decrease the effect between the anions and cations effectively.

3.2 Thermal Stability

TGA was employed to evaluate the thermal decomposition properties of all PILs. As illustrated in Fig. 4 and Table 1, all of the ILs are thermally decomposed by 20% of total mass in the range of 280–360 °C, 30% in 330–420 °C, and 50% in 420–470 °C, indicating that the synthesized PILs exhibited good thermal stability. Furthermore, C14PDBU displayed higher thermal stability than other PILs and PAO-10. Based on the unique structure of the PILs, it was considered that molecular interactions of the long alkyl chains entwined with coulombs led to the special results [30,31,32].

3.3 Tribological Properties

3.3.1 Friction Test

The friction-reducing and anti-wear properties of PAO-10 with different concentrations of the synthesized C14PDBU on steel/steel contacts are shown in Fig. 5. The curves in Fig. 5a demonstrated the friction coefficients with addition of different concentrations of C14PDBU in PAO-10 and the corresponding wear volumes of the lower baseplates after friction test are shown in Fig. 5b. As seen, the mean friction coefficients could be lowered to about 0.1 and kept stable during the test period no matter how much C14PDBU was added. In comparison to pure PAO-10, the friction coefficient decreased by about 60% in maximum, suggesting that C14PDBU played an important role in the friction-reducing procedure. Moreover, the wear volumes also decreased when C14PDBU was employed. With an addition of 0.5–3 wt% C14PDBU into PAO-10, the curve of wear volumes showed a trend from decline to rise with the increase of concentration. In particular, 1 wt% C14PDBU gave the lowest wear volume, which realized a sharp 83% decrease in maximum.

With the optimized concentration in hand, the tribology abilities of PIL additives were further tested. As shown in Fig. 6a, addition of a PIL additive into PAO-10 could significantly reduce the friction coefficients to about 0.1–0.12. Among the tested samples, C8PDBU, C12PDBU, and C14PDBU exhibited relatively lower friction coefficients and maintained stable on the level. Meanwhile, the corresponding wear volumes are illustrated in Fig. 6b. The wear volumes of PAO-10 with additives realized different degree decreases and the best outcome was still the C14PDBU/PAO-10 lubricant system. Then, the cross-section areas of wear traces on the baseplates were tested and the results are plotted in Fig. 7. The worn surface with PAO-10 was much rougher than PAO-10 with PIL additives. With 1 wt% of PIL additive, the depth and width of worn surface were significantly reduced and the best result was produced by C14PDBU, which was highly in consistent with the previous tests.

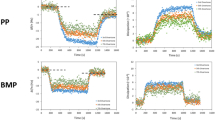

Besides the tribology abilities tested above, the carrying capacity of these PIL additives was further investigated [33]. As presented in Fig. 8a, PAO-10 could cause the failure of lubrication when the applied load reached to 150 N. By contrast, addition of 1 wt% of PIL additives into PAO-10 could improve the seizure load to 250 N or 350 N. Subsequently, the changed-frequency test was also carried out (Fig. 8b). The results illustrated that the friction coefficients of PAO-10 rose sharply at relative lower frequencies in a short test time; however, the curves of PAO-10 with additives kept stable in the whole test time, respectively, even at 50 Hz. Thus, the results suggested that these synthesized PIL additives possessed perfect properties to dramatically improve the carrying capacity of PAO-10.

Contact angle is a key parameter to reflect the wettability of ILs on the surface of contact pairs [34]. Consequently, the contact angles of the PAO-10 and PAO-10 with PIL additives on the steel surfaces were measured. As shown in Fig. 9, the contact angle of PAO-10 was 30.27°, which was the largest one among the samples. PAO-10 with PIL additives produced relative lower contact angles, revealing that the anions in the PIL molecules could influence the surface tension of PAO-10. As a result, the addition of these ILs into PAO-10 improved the spreadability of the lubricating oil system on surface of contact pair [35], which was further profited to the formation of aphysical-adsorption tribofilm and might lead to the excellent tribological performances in part.

Electrical contact resistance (ECR) is an effective pathway to detect the generation of tribochemical reaction films between the friction interfaces [36]. As known, an effective tribochemical reaction film can prevent direct contact between the metal pairs, which enhances the tribological performances of the lubricating oil system. As clearly displayed in Fig. 10, with pure PAO-10 as lubricant, the ECR value was about 0.18. A slight decrease was observed while PAO-10 with C6PDBU or C8PDBU was employed, revealing that the two PILs could not strengthen the formation of tribochemical reaction films. On the contrary, an addition of 1 wt% C12PDBU or C14PDBU into PAO-10 greatly improved the ECR value up to 1.18, demonstrating that a much thicker insulating tribochemical reaction film was formed.

3.4 Wear Spots Surface Analysis

3.4.1 SEM and EDS Analysis

To further clarify the lubrication mechanism, SEM and EDS were employed to analyze the topography and element composition of the worn surface. Figure 11a and a1 shows that the worn surface lubricated by PAO-10 was full of the clear wear traces and deep-grinding spots, suggesting that heavy abrasive and adhesive wear were caused during the friction process [37]. While employing PAO-10 with PIL additives as lubricant, much smaller worn spots were observed, as well as the wear dramatically reduced (Fig. 11b–e, b1–e1). In particular, the worn traces lubricated by PAO-10 with C14PDBU were quite shallow and only slight quantity of furrows was detected, which also confirmed the above excellent tribological properties of PAO-10 with C14PDBU-lubricating system.

The element distribution and composition of the tribochemical reaction films were then tested by EDS spectra. As shown in Fig. 11a2–e2, the element compositions of the baseplate surface were listed. Only C and Fe elements were detected in the surface lubricated by pure PAO-10. Moreover, certain contents of N, O, and P elements were detected in the samples of PAO-10 with PIL additives. Notably, the content of O element was much higher than N and P, which might mean that the anion of PILs played a crucial role in the generation of the tribochemical reaction films [38]. The above results indicated that the tribochemical reactions really took place between the steel pair and these PIL additives during the friction process, which led to the formation of the tribochemical reaction films.

3.4.2 XPS Analysis

The XPS elemental analysis was further performed to gain a deep insight of the chemical valence state of the active elements on the worn surface. As seen in Fig. 12, the spectrum of C1s, N1s, P2p, O1s, and Fe2p of the worn surface lubricated by PAO with 1 wt% C14PDBU was conducted. The peaks located at 284.8 and 286.5 eV are assigned to organic C–C and C–N structure [29], respectively. N1s signal at 398.8 eV corresponds to the C–N, which is good fit with the C1s spectrum. Combining P2p peak at 133.8 eV, O1s at 530.5–532.7 eV with Fe2p at 711.8 and 724.8 eV, it can be implied that Fe2O3 and FePO4 exist in the tribofilm [11].

3.5 Lubrication Mechanism

Based on the above discussions and literature reports [39,40,41,42,43], a possible lubrication mechanism was proposed (Fig. 13). The escape of electrons during the friction process leads to the formation of positive charges on the surface of contact pair. Further, the anionic n-tetradecyl phosphate in C14PDBU is adsorbed on the surface via electrostatic action to form a stable anion adsorption layer. The cation of C14PDBU combines with the anionic n-tetradecyl phosphate to generate the cationic shielding layer via electrostatic interaction, which forms the physical adsorption film. Moreover, the alkyl chains of ILs guarantee the good solubility in PAO-10. At the same time, the decomposion of these PILs under high pressure, frictional heat, and mechanical energy during the friction procedure makes the active elements such as N, O, C, and P react with the steel surface, producing Fe2O3 and FePO4 to generate the effective tribochemical reaction film. It is worthy noted that the long alkyl chains combined with the unique dianionic and dicationic structure of ILs not only favor for the formation of a much denser and more stable physical adsorption film, but also make the reaction probability of active elements with steel surface increased in certain area [41, 44]. Finally, the physical adsorption film together with the chemical reaction film endows the C14PDBU/PAO-10 system with outstanding tribological performances, provides good excellent lubrication for the contact of steel/steel pair, and thus, prevents the steel surface from being further worn.

4 Conclusion

In summary, the tribological properties of the synthesized DBU-derived PILs as lubricant additives in PAO-10 were evaluated. Among the samples tested, C14PDBU displayed the best friction-reducing and anti-wear ability, which could achieve maximum decreases by 60% in the friction coefficient and 83% in wear volume. In addition, C14PDBU could also improve the carrying capacity of PAO-10. Furthermore, after a series of tests including contact angle, ECR, SEM, EDS, and XPS, the physical adsorption film and chemical reaction film were identified to be existed on the contact surface, which were responsible for the excellent tribiological performances of the C14PDBU/PAO-10 system. This unique PIL with dianionic and dicationic structure in one molecular features simple synthesis and purification procedure, low cost, and excellent tribological functions, which is a promising high-performance lubricant additive applied in industrial field.

Data Availability

All the data in this paper are obtained from experiments. Data will be made available on reasonable request.

References

Tang, W., Zhang, Z., Li, Y.: Applications of carbon quantum dots in lubricant additives: a review. J. Mater. Sci. 56, 12061–12092 (2021)

Cai, M., Yu, Q., Liu, W., Zhou, F.: Ionic liquid lubricants: when chemistry meets tribology. Chem. Soc. Rev. 49, 7753–7818 (2020)

Wang, B., Qiu, F., Barber, G.C., Zou, Q., Wang, J., Guo, S., Yuan, Y., Jiang, Q.: Role of nano-sized materials as lubricant additives in friction and wear reduction: a review. Wear 490–491, 204206 (2022)

Zhao, J., Ga, T., Li, Y., He, Y., Shi, Y.: Two-dimensional (2D) graphene nanosheets as advanced lubricant additives: a critical review and prospect. Mater. Today Commun. 29, 102755 (2021)

Donato, M.T., Colaço, R., Branco, L.C., Saramago, B.: A review on alternative lubricants: ionic liquids as additives and deep eutectic solvents. J. Mol. Liq. 333, 116004 (2021)

Zhou, Y., Qu, J.: Ionic liquids as lubricant additives: a review. ACS Appl. Mater. Interfaces 9, 3209–3222 (2017)

Xiao, H.: Ionic liquid lubricants: basics and applications. Tribol. Trans. 60, 20–30 (2017)

Ma, R., Li, W., Zhao, Q., Zheng, D., Wang, X.: In situ synthesized phosphate-based ionic liquids as high-performance lubricant additives. Tribol. Lett. 60, 67 (2019)

Jiang, C., Wang, Y., Su, H., Li, W., Lou, W., Wang, X.: Synthesis and evaluation of a protic ionic liquid as a multifunctional lubricant additive. Friction 8, 568–576 (2019)

Monge, R., González, R., Battez, A.H., Fernández-González, A., Viesca, J.L., Hadfield, G.A.M.: Ionic liquids as an additive in fully formulated wind turbine gearbox oils. Wear 328–329, 50–63 (2015)

Qu, M., Yang, Z., Zhang, C., Yu, Q., Cai, M., Zhou, F.: Significantly enhancing lubricity and anti-wear performances of glycerol lubricant with urea-functionalized imidazolium-organophosphate ionic liquid as additive. Tribol. Int. 153, 106602 (2021)

Ma, R., Zhao, Q., Zhang, E., Zheng, D., Li, W., Wang, X.: Synthesis and evaluation of oil-soluble ionic liquids as multifunctional lubricant additives. Tribol. Int. 151, 106446 (2020)

Gusain, R., Dhingra, S., Khatri, O.P.: Fatty acids constituted halogen-free ionic liquids as renewable, environmentally friendly and high-performance lubricant additives. Ind. Eng. Chem. Res. 55, 856–865 (2016)

Khatri, P.K., Sadanandan, A.M., Thakre, G.D., Jain, S.L., Singh, R., Gupta, P.: Tribo-performance of the ionic liquids derived from dicarboxylic acids as lubricant additives for reducing wear and friction. J. Mol. Liq. 364, 119941 (2022)

Dong, R., Wen, P., Zhang, S., Zhang, C., Sun, W., Fan, M., Yang, D., Zhou, F., Liu, W.: The synthesis and tribological properties of dicarboxylic acid ionic liquids. Tribol. Int. 114, 132–140 (2017)

Song, Z., Liang, Y., Fan, M., Zhou, F., Liu, W.: Ionic liquids from amino acids: fully green fluid lubricants for various surface contacts. RSC Adv. 4, 19396–19402 (2014)

Zhu, L., Dong, J., Zeng, Q., Chao, M., Gong, K., Li, W., Wang, X.: A comprehensive study of amino acids based ionic liquids as green lubricants for various contacts. Tribol. Int. 162, 107163 (2021)

Fan, M., Du, X., Ma, L., Wen, P., Zhang, S., Dong, R., Sun, W., Yang, D., Zhou, F., Liu, W.: In situ preparation of multifunctional additives in water. Tribol. Int. 130, 317–323 (2019)

Kreivaitis, R., Kupčinskas, A., Žunda, A., Ta, T.N., Horng, J.H.: Effect of temperature on the lubrication ability of two ammonium ionic liquids. Wear 492–493, 204217 (2022)

Chen, G., Zhang, C., Huang, Q., Yu, Q., Yang, Z., Zhou, C., Yan, X., Wang, R., Yu, B., Cai, M.: Novel phosphate organic guanidine salt water-based additive with integrated anti-friction, anti-wear and anti-corrosion properties. Tribol. Lett. 70, 33 (2022)

Wu, L., Song, J., Zhang, B., Zhou, B., Zhou, H., Fan, H., Yang, Y., Han, B.: Very efficient conversion of glucose to 5-hydroxymethylfurfural in DBU-based ionic liquids with benzenesulfonate anion. Green Chem. 16, 3935–3941 (2014)

Dong, R., Yu, Q., Bai, Y., Wu, Y., Ma, Z., Zhang, J., Zhang, C., Yu, B., Zhou, F., Liu, W., Cai, M.: Towards superior lubricity and anticorrosion performances of proton-type ionic liquids additives for water-based lubricating fluids. Chem. Eng. J. 383, 123201 (2020)

Sadanandan, A.M., Khatri, P.K., Saxena, R.C., Jain, S.L.: Guanidine based amino acid derived task specific ionic liquids as noncorrosive lubricant additives for tribological performance. J. Mol. Liq. 313, 113527 (2020)

Muzart, J.: DBU: a reaction product component. ChemistrySelect 5, 11608–11620 (2020)

Boddu, S.K., Rehman, N.U., Mohanta, T.K., Majhi, A., Avula, S.K., Al-Harrasi, A.: A review on DBU-mediated organic transformations. Green Chem. Lett. Rev. 15, 765–795 (2022)

Zhu, X., Song, M., Xu, Y.: DBU-based protic ionic liquids for CO2 capture. ACS Sust. Chem. Eng. 5, 8192–8198 (2017)

Wang, S., Luo, N., Li, Y., Wang, C.: DBU-Mediated cyclization of acylcyclopropane-carboxylates with amidines: access to polysubstituted pyrimidines. Org. Lett. 21, 4544–4548 (2019)

Hatsuda, K., Kondo, H., Murakami, T.: Effect of a long alkyl chain in protic ionic liquids molecules on tribological properties at high temperature. Tribol Online 15, 356–364 (2020)

Zhao, L.N., Cai, T., Zhang, Y.X., Ye, M.T., Shang, W.J., Liu, D., Tong, D.Y., Liu, G.S.: Synthesis, characterization and tribological evaluation of novel 1,4-diazabicyclo[2.2.2]octane based dicationic ionic liquids as efficient antiwear lubricant additives. Sci. China. Tech. Sci. 62, 252–262 (2019)

Kawada, S., Watanabe, S., Tadokoro, C., Sasaki, S.: Effects of alkyl chain length of sulfate and phosphate anion-based ionic liquids on tribochemical reactions. Tribol. Lett. 66, 8 (2018)

Xu, C., Cheng, Z.: Thermal stability of ionic liquids: current status and prospects for future development. Processes 9, 31–36 (2021)

Patil, R.A., Talebi, M., Berthod, A., Armstrong, D.W.: Dicationic ionic liquid thermal decomposition pathways. Anal. Bioanal. Chem. 410, 4645–4655 (2018)

Cui, J., Tang, Q., Chen, C., Xu, H., Liu, L., Dong, J.: High-viscosity polyalkylphenanthrene oils: synthesis and evaluation of lubricating properties. Lubr. Sci. 34, 527–536 (2022)

Siddiqui, M.A.Q., Ali, S., Fei, H., Roshan, H.: Current understanding of shale wettability: a review on contact angle measurements. Earth-Sci. Rev. 181, 1–11 (2018)

Edachery, V., Shashank, R., Kailas, S.V.: Influence of surface texture directionality and roughness on wettability, sliding angle, contact angle hysteresis, and lubricant entrapment capability. Tribol. Int. 158, 106932 (2021)

Clarke, A., Weeks, I.J.J., Evans, H.P., Snidle, R.W.: An investigation into mixed lubrication conditions using electrical contact resistance techniques. Tribol. Int. 93, 709–716 (2016)

Yu, Q., Zhang, C., Wang, J., Fan, F., Yang, Z., Zhou, X., Tang, Z., Cai, M., Zhou, F.: Tribological performance and lubrication mechanism of new gemini quaternary phosphonium ionic liquid lubricants. J. Mol. Liq. 322, 114522 (2021)

Li, X., Li, Y., Tong, Z., Ma, Q., Ni, Y., Dong, G.: Enhanced lubrication effect of gallium-based liquid metal with laser textured surface. Tribol. Int. 129, 407–415 (2019)

Rahman, M.H., Khajeh, A., Panwar, P., Patel, M., Martini, A., Menezes, P.L.: Recent progress on phosphonium-based room temperature ionic liquids: synthesis, properties, tribological performances and applications. Tribol. Int. 167, 107331 (2022)

Li, Z., Dolocan, A., Morales-Collazo, O., Sadowski, J.T., Celio, H., Chrostowski, R., Brennecke, J.F., Mangolini, F.: Lubrication mechanism of phosphonium phosphate ionic liquid in nanoscale single-asperity sliding contacts. Adv. Mater. Interfaces 7, 2000426 (2020)

Huang, G., Fan, S., Ba, Z., Cai, M., Qiao, D.: Insight into the lubricating mechanism for alkylimidazolium phosphate ionic liquids with different alkyl chain length. Tribol. Int. 140, 105886 (2019)

Khanmohammadi, H., Wijanarko, W., Espallargas, N.: Ionic liquids as additives in water-based lubricants: from surface adsorption to tribofilm formation. Tribol. Lett. 68, 130 (2020)

González, R., Viesca, J.L., Hernández, A., Hadfield, B.M., Fernández-González, A., Bartolomé, M.: Two phosphonium cation-based ionic liquids as lubricant additive to a polyalphaolefin base oil. J. Mol. Liq. 293, 111536 (2019)

Xiao, H., Guo, D., Liu, S., Pan, G., Lu, X.: Film thickness of ionic liquids under high contact pressures as a function of alkyl chain length. Tribol. Lett. 41, 471–477 (2011)

Acknowledgements

This work was supported by the National Natural Science Foundation (Grant No.51575454) and the Fundamental Research Funds for the Central Universities (Grant No. 3102019JC002). We also thank Prof. Mingjin Fan (Baoji University of Arts and Sciences) for collaboration.

Funding

National Natural Science Foundation (Grant No.51575454) and the Fundamental Research Funds for the Central Universities (Grant No. 3102019JC002).

Author information

Authors and Affiliations

Contributions

ZB contributed toward investigation, data curation, and writing the original draft. JQ, DZ, and PG contributed toward investigation and data curation. ZJ contributed toward resources, supervision, funding acquisition, writing, review, and editing.

Corresponding author

Ethics declarations

Competing interests

The authors have not disclosed any competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Bai, Z., Qiu, J., Zhang, D. et al. Tribological Behavior of 1,8-Diazabicyclo[5.4.0]Undecane-7-Ene–Organophosphoric Acid-Based Protic Ionic Liquids as Lubricant Additives. Tribol Lett 71, 105 (2023). https://doi.org/10.1007/s11249-023-01775-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11249-023-01775-8