Abstract

Magnesium borates are one of the major groups of boron minerals that have high heat and corrosion resistance and high coefficients of elasticity. In this study, magnesium borate minerals are hydrothermally synthesised using boric acid and magnesium oxide and are characterised by various analysis techniques. A drying temperature of 40 °C was used. From the results obtained, admontite mineral is synthesised purely at a reaction temperature of 100 °C and reaction times of both 120 and 240 min. Characterisations of the products are determined with the techniques of X-ray diffraction, Fourier transform infrared spectroscopy, Raman spectroscopy, scanning electron microscopy, differential thermal analysis and thermal gravimetry analysis. Additionally, overall admontite yields were calculated and varied between 89.98 ± 3.05 and 89.07 ± 1.28 %. Moreover, a kinetic study using the Ozawa, Kissenger, and Doyle methods was performed in the stage of decomposition of admontite that had been synthesised at a reaction time of 240 min.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Magnesium borates, which are a class of boron minerals, can be used as sources of both magnesium and boron. The percentage of boron trioxide (B2O3) is an important index for boron minerals and products. These borates have excellent mechanical and thermal properties, such as corrosion resistance, high coefficients of elasticity and high heat resistance, which increase with increasing boron trioxide content. The B2O3 content varies between 36.5 and 62.2 % in magnesium borates. In admontite, the B2O3 content is 55.6 %. Magnesium borates can be used in the ceramic industry, in detergent formulations, in the production of superconducting materials, and as catalysts for the conversion of hydrocarbons, due to the content of boron in the friction-reducing additives in oils and insulating coating compositions [1–3].

Magnesium borates can be synthesised by either natural or artificial means. Artificial methods can be classified as hydrothermal and solid state (thermal) techniques. While magnesium borate is formed by a solid–solid reaction in the solid state method [4], raw materials are usually in an aqueous solution in the hydrothermal method. Suanite (Mg2B2O5) and kotoite (Mg3B2O6 or Mg3(BO3)2) can be synthesised by the solid state method. In the hydrothermal method, the hydrated magnesium borates can be produced as Mg(BO2)2·3H2O, MgB8O13·4H2O, Mg2B6O11·15H2O, and 2MgO·3B2O3·17H2O [5]. Zhihong and Mancheng [6], produced MgO·3B2O3·3.5H2O at the boiling point of the solution. Zhihong et al. [7] synthesised magnesium borate with the formula of 2MgO·B2O3·H2O at 180 °C, and Zhihong and Mancheng [8] obtained Mg2[B2O4(OH)2]·H2O at 120 °C. Moreover, the reaction yields have not been studied in any of the studies carried out. However, according to the study of Jun et al. [9], the equation of the hydrothermal production is given as follows:

The main advantage of the hydrothermal method in powder preparation is that it can be used to directly and easily synthesise homogeneous, producing extremely fine and narrowly dispersed particles with good uniformity of composition [10]. Hydrothermal treatment has reportedly been used for powder synthesis [11, 12].

Knowledge of the decomposition kinetics of boron minerals is extremely important in the production of boron compounds, where dehydration of the boron minerals, which has been investigated mostly with thermogravimetric methods, is highly significant [13–16]. To the best of our knowledge, there have been few studies done on kinetics of boron minerals while there have been no studies done on the thermal decomposition kinetics of magnesium borate hydrate minerals under non-isothermal conditions.

In the magnesium borate synthesis studies conducted by Zhihong et al. [7] and Zhihong and Mancheng [8] at the temperatures of 180 and 120 °C, respectively, the reaction time for both was 3 days. The novelty of the current study is that magnesium borate hydrate was successfully synthesised at low temperatures (≤100 °C) and in a short time (≤4 h). In this study, magnesium oxide (MgO) and boric acid (H3BO3) were used as reactants, and a batch-type reactor was used at different reaction temperatures and at reaction times of 30, 60, 120, and 240 min. Pre-synthesis of magnesium borates was also investigated in this study. In our previous study, only a reaction temperature of 80 °C was used, and the synthesised magnesium borates were dried at a temperature of 80 °C. However, the synthesised magnesium borates were not as expected due to the evaporation of the crystal water at the selected drying temperature [17]. In this study, two other reaction temperatures, 90 and 100 °C, in addition to the reaction temperature of 80 °C, were studied, and the drying temperature was reduced to 40 °C. The difference of our study was to investigate the thermal decomposition kinetics of hydrated magnesium borate minerals which were synthesised at lower temperatures and reaction times than previous experiments. Another originality of the paper is that the reaction yields of the products are calculated.

The synthesised products of magnesium borate hydrates were investigated and characterised by the methods of X-ray diffraction (XRD), Fourier transform infrared spectroscopy (FT-IR), Raman spectroscopy and scanning electron microscopy (SEM), and their B2O3 contents were determined experimentally. In addition, thermal decomposition and the dehydration kinetics under non-isothermal conditions using Ozawa, Kissenger, and Doyle methods of material obtained under the condition of 240 min reaction time were studied using thermal analysis techniques.

Experimental

Preparation of the reactants

H3BO3 was supplied by Kirka Boron Management Plant in Eskisehir, Turkey, and MgO was supplied from Merck Chemicals. H3BO3 was crushed, ground and sieved to +200 mesh with an agate mortar. MgO was used as supplied. Then, these reactants were taken for identification analysis, which was performed with PAN analytical XRD. X-rays were produced from a Cu-Kα tube at 45 kV and 40 mA.

Hydrothermal synthesis of magnesium borate hydrates

A molar ratio of 1:6 MgO:H3BO3 was selected. Ultrapure water (18.3 mΩ cm) used in the experiments was supplied from a Human Power I+ Water Purification System. All reactions were conducted in a closed vessel with a temperature control unit. After the reaction, the slurry residue was dried in an Ecocell oven at 40 °C. The dried content was washed and filtered with pure alcohol (96 %), to remove excess boric acid content. Then, the filtered content was again dried in an oven, at 40 °C. This procedure was performed at temperatures of 80, 90 and 100 °C and for reaction times of 30, 60, 120 and 240 min. The reaction parameters of these experiments are shown in Table 1.

Reaction yields

In the case of reaction yields based on molar flow rates, the overall yield, Y D, is defined as the ratio of moles of product formed at the end of the reaction, N D is to the number of moles of the key reactant, A, that have been consumed, and N A0 and N A are the initial and final moles of consumed reactant, respectively. For a batch system [18]:

Using magnesium oxide as the key reactant, five parallel experiments were conducted. Because the pure admontite was synthesised at 100 °C and reaction times of both 120 and 240 min, the reaction yields were calculated under these two conditions using Eq. (2).

Characterization of the synthesised products

To identify and characterise the synthesised products, XRD measurements were taken. Then, the synthesised minerals were subjected to a Perkin Elmer FT-IR spectrometer equipped with the Universal ATR sampling accessory (ZnSe cell) with a diamond window. A measurement range of 2,000–650 cm−1 was selected, with a scan number of 4 and resolution of 4 cm−1. Additionally, a Perkin Elmer RamanStation 400F was used to obtain Raman spectra for comparison with the FT-IR spectra. For Raman spectroscopy, the exposure time (seconds) and number of exposures were both set to 4. A measurement range of 1,400–250 cm−1 was elected, and the data interval used was 2 cm−1. Full (100 %) laser power and the “auto baseline” option were used.

For the B2O3 experiments, 1 g of synthesised mineral was dissolved in 3 ml of 37 % HCl and then diluted to 100 ml. Pure H3BO3 prepared in the same manner was used as the reference material. Then, B2O3 amounts were determined through acid–base titration with a METTLER DL-25 titrator [19].

SEM analysis was conducted to view the surface morphology. A CamScan Apollo 300 field-emission SEM was used, and experiments were conducted at 20 kV. A backscattering electron detector was used with magnification set at ×1,000 and ×5,000.

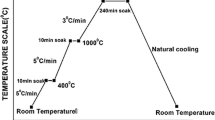

The non-isothermal thermogravimetric experiments of magnesium borate were carried out with a Perkin Elmer Pyris Diamond DTA-TG instrument. Analyses were performed under nitrogen atmosphere within a temperature range of 30–700 °C, at heating rates of 2, 5, 10, 15 and 20 °C/min.

Kinetics study

Many theoretical methods for kinetic analysis have been reported. These methods help us to understand the following reaction type: solid → solid + gas.

In this study, data from the TG curve in the decomposition range were used to determine the kinetic parameters of decomposition process, and kinetic calculations were performed using the Ozawa, Kissenger, and Doyle kinetic models.

The Ozawa method is shown in Eq. (3):

where g(α) is the degree of conversion, β is the heating rate, k o is the pre-exponential factor, E a is the activation energy, R is the gas constant, and T is the thermodynamic temperature. α values were determined from TG/DTG data at intervals of 0.1 in the range of 0.1–0.9, and the temperature values at different heating rates are recorded in the graph. The plot of log β versus 1/T is a line and the slope is 0.4567 (E a/R) [20].

The Kissinger method allows us to obtain the E a from a plot of log (β/T 2m ) against 1/T m for different heating rates, where T m is the temperature at the maximum of the DTG curve [21]. The equation is as follows:

The Doyle method can be represented by the following expression:

A plot of log β versus 1/T m gives a slope of 0.4567 E a/R for evaluating the activation energy most appropriately [22].

Results and discussion

X-ray diffraction results

The reactants used in the experiments were analysed and found to be “Periclase [MgO]” and “Sassolite [H3BO3]” with reference codes of 01-087-0651 and 01-073-2158, respectively. XRD results of the synthesised products are shown in Table 2. The admontite mineral code is 01-076-0540, and it has a formula of MgO(B2O3)3·7(H2O). The mcallisterite mineral code and formula are 01-070-1902 and Mg2(B6O7(OH)6)2·9(H2O), respectively. The mineral codes and formulas for the two types of magnesium borate hydrates (MgB1 and MgB2) are 01-073-0638, MgB6O7(OH)6·3(H2O) and 01-076-0539, MgO(B2O3)3·6(H2O), respectively.

As seen from the XRD results at a reaction temperature of 80 °C, admontite, mcallisterite and two types of magnesium borate hydrates were formed. The XRD scores of admontite minerals increase with increasing reaction times except for the reaction time of 240 min. This result indicates that the crystallisation decreased after a reaction time of 120 min. At 90 °C, admontite, mcallisterite and 01-073-0638-coded magnesium borate hydrates were formed. The results show that admontite and mcallisterite minerals were synthesised at reaction times of both 30 and 60 min. After 60 min of reaction time, mcallisterite minerals were changed to admontite minerals and magnesium borate hydrate (coded 01-073-0638) was formed in very small amounts. At 100 °C and 30 min of reaction time, admontite and magnesium borate hydrate (coded 01-073-0638) were formed. After 30 min of reaction time, some admontite and magnesium borate hydrate minerals transformed into mcallisterite, and, after 60 min, mcallisterite and magnesium borate hydrate minerals transformed to admontite mineral. The formation of admontite was seen in each trial, but the pure and complete formation was seen at a reaction temperature of 100 °C and after a reaction time of 120 min. XRD scores and patterns of synthesised magnesium borate minerals are listed in Table 2, and XRD patterns of the synthesised admontite minerals are shown in Fig. 1.

A three-dimensional model graph of admontite formation was obtained from the XRD data and drawn using Statistica (Fig. 2). In this graph, the z, y and x axes represent the XRD score, the reaction temperature in °C and the reaction time in minutes, respectively. From this graph, it is seen that admontite mineral crystallisation increased with increasing temperature and reaction time from 30 to 150 min and that admontite minerals can be synthesised at 100 °C with reaction times >120 min.

FT-IR, Raman, SEM and overall yield results

FT-IR and Raman spectroscopic data for the synthesised magnesium borates are presented in Figs. 3 and 4, respectively. B2O3 results and SEM morphology photos are also given in Table 3 and Fig. 6, respectively.

According to the FT-IR results; the peak values around 1660 cm−1, represents the H2O zone. The peak values of 1,419.41 and 1,418.78 cm−1 represent the asymmetric and stretching of the three coordinate boron (B(3)–O). The peaks between 1,348.89 and 1,235.08 cm−1 represent the in-plane OH−1 bending. Asymmetric and symmetric stretching of four-coordinate boron (B(4)–O) occurred at the peak values between 1,095.91–956.05 and 898.37–860.32 cm−1, respectively. Out-of plane OH−1 bending is seen between the peak values of 810.67 and 809.49 cm−1. Lastly, bending of B(3)–O occurred at the peak values of 675.06 and 647.33 cm−1.

From the Raman results, asymmetric stretching of B(4)–O is seen at the peak values of 1,091.62 and 1,085.87 cm−1. Symmetric stretching of B(3)–O is seen at the peak at 962.82 cm−1. Symmetric stretching of B(4)–O is only observed in the 240 min synthesis, with the peak value of 881.28 cm−1. The characteristic peaks of magnesium borates, which are Vp[B6O7(OH)6]2−/Vp[[B3O3(OH)4]−, are seen between the peak values of 637.16 and 636.80 cm−1. Lastly, bending of B(3)–O and B(4)–O can be seen at the peak values between 525.92–523.30 and 499.76–319.91 cm−1.

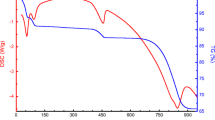

Figure 5 shows the TG/DTG curves in air at different heating rates for admontite that was synthesised at a reaction time of 240 min. The TG/DTG curves show that the thermal decomposition of admontite at temperatures below 570 °C occurs in two well-defined steps. The first weight loss, amounting to ~11.19 wt% and occurring in the temperature range from 40 to 125 °C, is caused by the dehydration of admontite; whereas the second weight loss, amounting to ~24.53 wt% and occurring in the temperature range from 125 to 570 °C, is caused by the dehydration of admontite.

In accord with the B2O3 results, it is seen that for all the synthesised products, B2O3 contents are nearly the same. As a constant molar ratio of MgO to H3BO3 (1:6) was used in the experiments, these results are expected. The B2O3 content of admontite and mcallisterite minerals have been reported to be 55.66 and 54.35 %, respectively [1, 2]. This small difference between the experimental and theoretical values can be explained by the purity of the H3BO3 used. The maximum and minimum B2O3 content are found in products coded 80-40-120 (with the value of 50.89 ± 0.26 %) and 80-80-60 (with the value of 48.04 ± 0.53 %), respectively.

In Fig. 6, minerals produced at reaction times of 120 and 240 min are shown at a magnification of ×5,000; here, admontite minerals are crystallised in rectangular shapes, and the crystals are nearly transparent. The particle sizes of the minerals produced at a reaction time of 240 min are smaller, between 2.37–9.23 μm, than those produced at a reaction time of 120 min, between 6.61–12.44 μm. The crystals produced at both reaction times are also shown at a magnification of ×1,000.

Overall admontite yields were calculated to be 89.98 ± 3.05 and 89.07 ± 1.28 % at reaction times of 120 and 240 min, respectively; the standard deviation likely occurred due to experimental errors during the filtration processes. It is seen that the reaction time did not affect the overall yield; however, the small decrease in the overall yield between reaction times of 120 and 240 min may be explained as being due to the adherence of the formed admontite mineral to the inner walls of the reaction vessel.

Kinetic analysis results

Figure 7 shows the isoconversional determination of the kinetic parameters for admontite by the Ozawa method. This method also gives the activation energy according to the degree of conversion. The average E a values for the first and second dehydration stages were 107.72 and 165.42 kJ/mol, respectively. The apparent activation energies for the first and second dehydration stages were calculated from the Kissinger method (Fig. 8) to be 88.79 and 129.78 kJ/mol, respectively. The pre-exponential factors for the first and second dehydration stages were calculated using the same method and were determined to be 5.98 × 1011 and 1.98 × 1013 min−1, respectively. With the Doyle method (Fig. 9), the obtained values of the apparent activation energies for the first and second dehydration stages were calculated 90.48 and 131.24 kJ/mol. The pre-exponential factors were calculated for the first and second dehydration stages were calculated using the same method and were determined to be 4.01 × 1014 and 1.44 × 1016 min−1, respectively (Table 4).

Conclusions

In this study, the reactants of magnesium oxide and boric acid were used to produce magnesium borate hydrate by the hydrothermal method at different reaction temperatures and reaction times. The synthesised minerals were characterised, and the results show that the properties of the synthesised minerals are in good agreement with those in the literature. The major result from this study, obtained from XRD analysis, is that the admontite minerals can be easily synthesised at a temperature of 100 °C for reaction times of 120 min or more. FT-IR and Raman results show that the synthesised minerals had the characteristic peaks of magnesium borates. Identified peaks were found to be compatible with previous studies [1, 7, 8]. This shows that, in the low-temperature syntheses, the structure does not change the characteristic bond stresses. Additionally, the synthesised minerals had B2O3 contents between the values of 48.04 ± 0.53 and 50.89 ± 0.26 %, which compares to the reported B2O3 content of 55.66 % in admontite. Additionally, it is seen from the SEM images that the particle sizes of the minerals decreased with an increase in the reaction times.

The thermal decomposition of admontite mineral occurred in two dehydration stages. In these stages, the dehydration reactions are took place according to the following mechanism:

The apparent activation energy of admontite decomposition for the first and second dehydration stages varied from 89 to 107 kJ/mol and from 130 to 165 kJ/mol, respectively. The results of kinetic analysis show that E a values were in good agreement with each other, indicating that the selection of the thermal decomposition kinetics of admontite was reasonable.

References

S. Li, X. Fang, J. Leng, H. Shen, Y. Fan, D. Xu, Mater. Lett. 64, 151 (2010)

E.M. Elssfah, A. Elsanousi, J. Zhang, H.S. Song, C. Tang, Mater. Lett. 61, 4358 (2007)

T. R. Prime Ministry SPO. Chemical Industry Private Expertise Commission. Boron Operations Group report: Ninth development plan (2007–2013) (2006)

S.H. Kim, K.H. Lee, B.S. Seong, G. Kim, J.S. Kim, Y.S. Yoon, Korean J. Chem. Eng. 23, 961 (2006)

U. Dosler, M.M. Krzmanc, D.J. Suvorov, Eur. Ceram. Soc. 30, 413 (2010)

L. Zhihong, H. Mancheng, Thermochim. Acta 403, 181 (2003)

L. Zhihong, H. Mancheng, G. Shiyang, J. Therm. Anal. Calorim. 75, 73 (2004)

L. Zhihong, H. Mancheng, Thermochim. Acta 411, 27 (2004)

L. Jun, G. Shiyang, X. Shuping, L. Bing, H. Rongzu, Chem. Thermodyn. 29, 491 (1997)

Y.S. Cho, K.W. Seo, Korean J. Chem. Eng. 19, 688 (2002)

A. Kanturk, M. Sari, S. Piskin, Korean J. Chem. Eng. 25, 1331 (2008)

D.Y. Kim, S. Kim, M. Yoo, I. Jung, M. Kang, Korean J. Chem. Eng. 26, 261 (2009)

S. Piskin, Ph.D. Thesis, Istanbul Technical University, 1983 [in Turkish]

M. Tunc, H. Ersahan, S. Yapici, S. Colak, J. Therm. Anal. 48, 403 (1997)

A. Kantürk, M. Sari Yilmaz, S. Piskin, Mater. Charact. 6, 640–647 (2010)

M. Sari Yilmaz, S. Piskin, J. Chem. Soc. Pak. 34(3), 526–532 (2012)

A.S. Kipcak, F.T. Senberber, E.M. Derun, S. Piskin, Research Bulletin of the Australian Institute of High Energetic Materials 1, 47 (2011)

H.S. Fogler, Element of Chemical Reaction Engineering, 3rd edn. (Prentice-Hall, New Jersey, 1999)

A. S. Kipcak, M.Sc. Thesis, Yildiz Technical University, 2009

T. Ozawa, Bull. Chem. Soc. Jpn. 38, 1881 (1965)

S. Wang, Z. Tan, Y. Li, Q. Shi, B. Tong, Thermochim. Acta 463, 21 (2007)

C.D. Doyle, J. Appl. Polym. Sci. 639, 6 (1962)

Acknowledgments

This research has been supported by Yildiz Technical University Scientific Research Projects Coordination Department. Project Number: 2012-07-01-KAP03.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Derun, E.M., Kipcak, A.S., Senberber, F.T. et al. Characterization and thermal dehydration kinetics of admontite mineral hydrothermally synthesized from magnesium oxide and boric acid precursor. Res Chem Intermed 41, 853–866 (2015). https://doi.org/10.1007/s11164-013-1237-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11164-013-1237-6