Abstract

Sulfonated rice husk ash (RHA-SO3H), as a newly reported powerful solid acid catalyst, can be efficiently used for the promotion of the preparation of substituted quinoline derivatives via the condensation reaction between 2-aminoarylketones and α-methylene ketones. All reactions are performed under solvent-free conditions at 80 °C in high yields during short reaction times. Simple methodologies, easy work-up procedure, and easy preparation of the catalyst are other advantages of this work.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Quinolines and their derivatives are one of the most important classes of heterocyclic compounds that occur widely in natural products. They have a wide range of biological activities such as antimalarial [1], antibacterial [2], anti-inflammatory [3], antihypertensive [4], antimicrobial and antioxidant [5], anti-asthmatic [6, 7], and antiplatelet [8]. These compounds can also be used as tyrosine kinase PDGF-RTK inhibiting agents [9]. Poly-substituted quinolines have also been used for photonic and electronic applications in a variety of nano- and meso-structures due to their electroluminescence and photophysical properties [10–13]. Therefore, quinoline nucleus is frequently found in several drugs (Fig. 1).

Among various procedures that have been developed and documented for the synthesis of quinoline derivatives such as Friedländer, Meth-Cohn, Pfitzinger, Skraup, Doebner–Von Miller and Combes reactions [14–17], Friedlander annulation is one of the most simple and important approaches. This reaction involves a condensation reaction between 2-aminoarylketones and a ketone containing an active α-methylene group. For this purpose, many homogeneous and heterogeneous catalysts such as FeCl3·6H2O/[bmim][BF4] [18], sulfamic acid [19], CeCl3·7H2O [20], HCl [21], NaHSO4·SiO2 [22], amberlyst-15 [23], HClO4–SiO2 [24], SiO2/I2 [25], oxalic acid [26], silica sulfuric acid under microwave irradiation [27], dodecylphosphonic acid (DPA) [28], nano-Al2O3 [29], H3PW12O40 [30], FeCl2·2H2O‐RiHA [31], nano-flake ZnO [32], Yb(OTf)3 [33], and (BSPY)HSO4/MCM-41 [34] have been reported.

Although these procedures provide an improvement, many of these catalysts or activators suffer from disadvantages such as long reaction times, harsh reaction conditions, use of organic solvents and non-recoverability of the catalyst. Furthermore, the use of homogeneous catalysts has several serious problems, such as difficulty in the separation and recovery of the catalyst, and corrosion problems. Therefore, introducing simple, efficient, and mild procedures using easily separable and reusable solid catalysts to overcome these problems is still in demand.

Replacement of conventional, toxic and polluting Brönsted and Lewis acid catalysts with eco-friendly reusable heterogeneous catalysts is an area of current interest. In this context, there has been renewed interest in the use of solid acid catalysts for organic reactions [35]. Solid acid catalysts have many advantages compared to traditional liquid acids, such as their efficiency, operational simplicity, easy recyclability and recoverability, non-corrosive nature and environmental friendliness. Therefore, solid acid catalysts can play a significant role in the development of clean technologies.

Recently, utilization of waste materials has been found to be of increasing interest. Rice husk and rice husk ash could be a problem for farmers and societies, while they can be successfully used as natural sources of amorphous silica. Several papers have been published on the application of the modified amorphous silica obtained from rice husk ash as the catalyst [36–38]. Although useful, the reported method for the preparation of pure silica from rice husk ash needs various stages and a long time [39]. On the basis of these points and our investigations, we concluded that, under the same conditions, the use of RHA as a support for the preparation of the catalysts is better than the use of silica, which is prepared via the precipitation method during various stages and over a long time.

Experimental

Chemicals were purchased from Fluka, Merck, and Aldrich. All yields refer to the isolated products. Products were characterized by comparison of their physical constants, IR and NMR spectroscopy with authentic samples and those reported in the literature. The purity determination of the substrate and reaction monitoring were accompanied by TLC on silicagel polygram SILG/UV 254 plates.

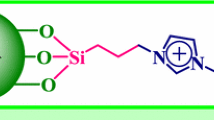

Catalyst preparation (RHA-SO3H) [36]: a 50-mL suction flask charged with 3.0 g of RHA and 10 mL CHCl3 was equipped with a constant-pressure dropping funnel containing chlorosulfonic acid (0.7 mL) and a gas inlet tube for conducting HCl gas into water as an adsorbing solution. Chlorosulfonic acid was added dropwise over a period of 20 min while the reaction mixture was stirred in an ice bath (0 °C). After addition was completed, the mixture was stirred for an additional 2 h at room temperature. Then, the mixture was filtered and the solid residue washed with methanol (20 mL) and dried at 70 °C for 1 h to afford RHA-SO3H (3.6 g) as an earthy powder.

General procedure for the synthesis of quinolines: a mixture of o-aminobenzophenone (1 mmol), ketone (1.2 mmol) and RHA-SO3H (80 mg) was heated at 80 °C under solvent-free conditions for the appropriate time. After completion of the reaction as monitored by TLC (n-hexane:EtOAc, 4:1), EtOH (10 mL) was added and the catalyst was separated. After addition of water, the product was precipitated with high purity.

Selected spectral data

(Table 1, entry 5): m.p. 157–159 °C. IR (KBr, cm−1): ν 3,045, 2,956, 1,695; 1H‐NMR (CDCl3, 400 MHz): δ 2.22 (m, 2H), 2.71 (t, J = 6.5 Hz, 2H), 3.29 (t, J = 6.20 Hz, 2H), 7.14 (m, 2H), 7.45 (m, 5H), 7.77 (m, 1H), 8.21 (d, J = 8.6 Hz, 1H); 13C‐NMR (CDCl3, 100 MHz): δ 22.4, 34.6, 42.7, 123.7, 126.2, 127.4, 127.8, 127.9, 128.0, 128.3, 131.5, 137.5, 148.5, 151.0, 162.0, 197.5.

(Table 1, entry 15): m.p. 161–163 °C. IR (KBr, cm−1): ν 3,060, 2,944, 1,604, 1,572, 1,481, 1,215, 703; 1H‐NMR(CDCl3, 400 MHz): δ 1.71–1.83 (m, 2H), 1.92–1.96 (m, 2H), 2.58 (t, J = 6.2 Hz, 2H), 3.30 (t, J = 6.2 Hz, 2H), 7.21–7.32 (m, 4H), 7.48–7.69 (m, 3H), 7.94 (d, J = 8.6 Hz, 1H); 13C‐NMR (CDCl3, 100 MHz): δ 22.6, 27.7, 35.6, 124.2, 126.9, 128.1, 128.8, 128.9, 129.0, 129.5, 130.4, 131.6, 136.8, 144.9, 145.9, 129.8.

Results and discussion

In recent years, introduction of new catalysts for the promotion of organic reactions has become an important part of our ongoing research program [40–42]. In 2013, and in continuation of these studies, we have reported the preparation and characterization of sulfonated rice husk ash (RHA-SO3H) in the reaction between rice husk ash (RHA) and chlorosulfonic acid (ClSO3H), and its applicability in the promotion of the chemoselective preparation and deprotection of 1,1-diacetates [40], synthesis of some of bis-heterocyclic compounds [43], synthesis of formamidines [44] and benzimidazole derivatives [45].

On the basis of the information obtained from studies on RHA-SO3H, we anticipated that RHA-SO3H can be used as an efficient catalyst for the acceleration of the reactions which need the use of an acidic catalyst to speed up. So, we were interested to investigate the applicability of RHA-SO3H in the Friedlander synthesis of quinolines. Our investigations clarified that this solid acid catalyst is very efficient in the requested reactions, and that all the products are obtained in good to high yields under mild reaction conditions.

For optimization of the reaction conditions, the reaction between 2-aminobenzophenone and ethyl acetoacetate to its corresponding quinoline was chosen as a model reaction and the various conditions including amount of the catalyst and ethyl acetoacetate, solvent, and temperature were examined. Finally, the best result was obtained using 80 mg of RHA-SO3H and 1.2 mmol ethyl acetoacetate at 80 °C under solvent-free condition (Scheme 1). The model reaction was also carried out in the absence of catalyst and in the presence of rice husk ash as the catalyst, but the reaction did not proceed. These results indicated that the catalyst is necessary to produce the products. Any further increase of the catalyst amount or temperature did not improve the reaction time or yield.

Furthermore, the X-ray fluorescence (XRF) analysis showed that RHA contains a high value of silica content (up to 80 %) and other compositions such as Al2O3, Fe2O3, K2O, Na2O and CaO [39]. For this purpose, and to prove the role of the covalently bounded –SO3H groups, we used various catalysts in the reaction of 2-aminobenzophenone and ethyl acetoacetate under optimal conditions. As can be seen in Table 1, CaCl2·2H2O, AlCl3 and FeCl3 can partly catalyze this type of reactions. So, the small available amounts of Ca, Fe and P in RHA can promote the reaction, therefore the reaction proceeding in the presence of RHA is more than SiO2. However, the completion of the reaction and reducing the reaction time using RHA-SO3H confirms the important role of the –SO3H group in the catalyst to obtain the best performance.

After optimization of the reaction conditions and in order to establish the effectiveness and the acceptability of the method, we explored the protocol with a variety of simple readily available substrates under the optimal conditions, and the results are presented in Table 2. Various carbonyl compounds bearing one activated α-methylene group, including 1,3-dicarbonyl compounds (ethyl acetoacetate, methyl acetoacetate, acetylacetone and benzoyl acetone), cyclic 1,3-diketones (5,5-dimethylcyclohexanedione (dimedone) and 1,3-cyclohexadione) and cyclic ketones (cyclopentanone and cyclohexanone), were used in order to synthesize quinolines. As can be seen, the reaction of 2-aminobenzophenone with cyclic diketones took place as good as open chain analogues and afforded the respective tricyclic quinolines (Table 2, entries 1–6). Furthermore, inactivated ketones, cyclohexanone and cyclopenthanone, afforded the desired products in good yields (Table 2, entries 7 and 8).

Under the optimized conditions, the above-mentioned carbonyl compounds also reacted satisfactorily with 5-chloro-2-aminobenzophenone to produce the desired quinolines in moderate to high yields (Table 2, entries 9–15).

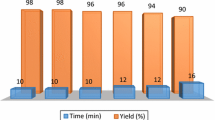

To check the reusability of the catalyst, the reaction of 2-aminobenzophenone and ethyl acetoacetate under the optimized reaction conditions was studied again. When the reaction was completed, ethanol was added and the catalyst was separated by filtration. The recovered catalyst was washed with dichloromethane, dried and reused for the same reaction. This process was carried out over three runs and all reactions ed to the desired products with high efficiency, which clearly demonstrates practical recyclability of RHA-SO3H. Further pH analysis of the recovered catalyst showed nearly the same loading of H+ as the freshly prepared catalyst. This result suggests that the nature of the catalyst remains intact after each run, and that leaching of the acid species did not occur during the course of the reaction.

In order to show the efficiency of the present method, we have compared our results obtained from the condensation of 2-aminobenzophenone with ethyl acetoacetate catalyzed by RHA-SO3H with other results reported in the literature. As can be seen in Table 3, this method avoids the disadvantages of other procedures such as long reaction times, excess reagents, organic solvents, reflux conditions and low yields of the products.

Conclusion

In conclusion, we have introduced a powerful Brönsted solid acid catalyst that shows remarkable catalytic activity in Friedlander synthesis of quinolines. The procedure has several advantages such as high reaction rates, no side reactions, ease of preparation and handling of the catalyst, simple experimental procedure, and the use of inexpensive and reusable catalyst. Furthermore, this process avoids problems associated with the use of organic solvents and liquid acids, which makes it a useful and attractive strategy in view of its economic and environmental advantages. It is also important to note that studies on some more practical applications of the RHA-SO3H catalyst in other organic reactions are currently underway in our laboratories.

References

P.M.S. Chauhan, S.K. Srivastava, Curr. Med. Chem. 8, 1535 (2001)

Y. Chen, K. Fang, J. Sheu, S. Hsu, C. Tzeng, J. Med. Chem. 44, 2374 (2001)

A. Baba, N. Kawamura, H. Makino, Y. Ohta, S. Taketomi, T. Sohda, J. Med. Chem. 39, 5176 (1996)

Y. Morizawa, T. Okazoe, S. Wang, J. Sasaki, H. Ebisu, M. Nishikawa, H. Shinyama, J. Fluor. Chem. 109, 83 (2001)

C. Praveen, P. DheenKumar, D. Muralidharan, P.T. Perumal, Bioorg. Med. Chem. Lett. 20, 7292 (2010)

D. Dubé, M. Blouin, C. Brideau, C. Chan, S. Desmarais, D. Ethier, J. Falgueyret, R.W. Friesen, M. Girard, Y. Girard, J. Guay, D. Riendeau, P. Tagari, R.N. Young, Bioorg. Med. Chem. Lett. 8, 1255 (1998)

P.R.D. Larsen, E.G. Corley, A.O. King, J.D. Carroll, P. Davis, T.R. Verhoeven, P.J. Reider, J. Org. Chem. 61, 3398 (1996)

T. Ko, M. Hour, J. Lien, C. Teng, K. Lee, S. Kou, L. Huang, Bioorg. Med. Chem. Lett. 11, 279 (2001)

M.P. Maguire, K.R. Sheets, K. McVety, A.P. Spada, A. Zilbersteint, J. Med. Chem. 37, 2129 (1994)

X. Zhang, A.S. Shetty, S.A. Jenekhe, Macromolecules 32, 7422 (1999)

R.X. Zhang, A. Jenekhe, Macromolecules 33, 2069 (2000)

S.A. Jenekhe, L. Lu, M.M. Alam, Macromolecules 34, 7315 (2001)

G. Jegou, S.A. Jenekhe, Macromolecules 34, 7926 (2001)

M. Theoclitou, L.A. Robinson, Tetrahedron Lett. 43, 3907 (2002)

S.A. Yamashkin, L.G. Yudin, A.N. Kost, Chem. Heterocycl. Compd. 28, 845 (1993)

J. Marco-Contelles, E. Perez-Mayoral, A. Samadi, M.D.C. Carreiras, E. Soriano, Chem. Rev. 109, 2652 (2009)

W. Luo, Q. Mu, W. Qiu, T. Liu, F. Yang, X. Liu, J. Tang, Tetrahedron 67, 7090 (2011)

J. Wang, X. Fan, X. Zhang, L. Han, Can. J. Chem. 82, 1192 (2004)

J.S. Yadav, P.P. Rao, D. Sreenu, R.S. Rao, V.N. Kumar, K. Nagaiah, A.R. Prasad, Tetrahedron Lett. 46, 7249 (2005)

D.S. Bose, R.K. Kumar, Tetrahedron Lett. 47, 813 (2006)

G. Wang, C. Jia, Y. Dong, Tetrahedron Lett. 47, 1059 (2006)

U.V. Desai, S.D. Mitragotri, T.S. Thopate, D.M. Pore, P.P. Wadgaonkar, ARKIVOC xv, 198 (2006)

B. Das, K. Damodar, N. Chowdhury, R.A. Kumar, J. Mol. Catal. A Chem. 274, 148 (2007)

M. Narasimhulu, T.S. Reddy, K.C. Mahesh, P. Prabhakar, C.B. Rao, Y. Venkateswarlu, J. Mol. Catal. A Chem. 266, 114 (2007)

M.A. Zolfigol, P. Salehi, A. Ghaderi, M. Shiri, J. Chin. Chem. Soc. 54, 267 (2007)

M. Dabiri, M. Baghbanzadeh, M.S. Nikcheh, Monatsh. Chem. 138, 1249 (2007)

M.A. Zolfigol, P. Salehi, M. Shiri, T.F. Rastegar, A. Ghaderi, J. Iran. Chem. Soc. 5, 490 (2008)

S. Ghassamipour, A.R. Sardarian, Tetrahedron Lett. 50, 514 (2009)

S. Sadjadi, S. Shiri, R. Hekmatshoar, Y.S. Beheshtiha, Monatsh. Chem. 140, 1343 (2009)

M. Dabiri, S. Bashiribod, Molecules 14, 1126 (2009)

F. Shirini, S. Akbari-Dadamahaleh, A. Mohammad-Khah, Chin. J. Catal. 34, 2200 (2013)

M. Hosseini-Sarvari, J. Iran. Chem. Soc. 8, 119 (2011)

S. Genovese, F. Epifano, M.C. Marcotullio, C. Pelucchini, M. Curini, Tetrahedron Lett. 52, 3474 (2011)

M. Abdollahi-Alibeik, M. Pouriayevali, Catal. Commun. 22, 13 (2012)

K. Wilson, J.H. Clark, Pure Appl. Chem. 72, 1313 (2000)

J. Davarpanah, A.R. Kiasat, Catal. Commun. 41, 6 (2013)

F. Adam, K.M. Hello, H. Osman, Appl. Catal. A 382, 115 (2010)

F. Adam, T. Chew, H. Mannyarasai, J.N. Appaturi, K.M. Hello, Microporous Mesoporous Mater. 167, 245 (2013)

D. An, Y. Guo, Y. Zhu, Z. Wang, Chem. Eng. J. 162, 509 (2010)

F. Shirini, M. Mamaghani, M. Seddighi, Catal. Commun. 36, 31 (2013)

F. Shirini, S. Akbari-Dadamahaleh, A. Mohammad-Khah, J. Mol. Catal. A Chem. 363–364, 10 (2012)

F. Shirini, N.G. Khaligh, O.G. Jolodar, Dyes Pigments 98, 290 (2013)

M. Seddighi, F. Shirini, M. Mamaghani, RSC Adv. 3, 24046 (2013)

M. Seddighi, F. Shirini, M. Mamaghani, J. Iran. Chem. Soc. (2014). doi:10.1007/s13738-014-0500-0

F. Shirini, M. Mamaghani, M. Seddighi, Res. Chem. Intermed. (2014). doi:10.1007/s11164-014-1685-7

Acknowledgment

We are grateful to the University of Guilan Research Council for the partial support of this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shirini, F., Seddighi, M. & Mamaghani, M. Sulfonated rice husk ash (RHA-SO3H) as an efficient and recyclable catalyst for the Friedlander synthesis of quinolines. Res Chem Intermed 41, 8673–8680 (2015). https://doi.org/10.1007/s11164-014-1919-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11164-014-1919-8