Abstract

Biochar, the solid carbon product from the pyrolysis of biomass, has been gaining attention due to its many possible applications such as soil amendment and water or air purification. Several effects have been observed when biochar is applied to soil, including reduced greenhouse gas emissions, contaminant degradation and increased microbial activity. Recently, it has been demonstrated that some of these effects are a direct consequence of its electrochemical properties. Understanding the mechanisms that allow biochar to store and transfer electrons is essential to obtain a complete view on its role in biogeochemical redox reactions. This paper reviews the current knowledge on the electrochemical properties of biochar as well as the different techniques available to measure and modify these properties. Specific conditions (different feedstocks, additives, pyrolysis conditions) and treatments that influence biochar’s electrochemical properties are also discussed, with the aim of developing biochars with enhanced electrochemical properties for specific environmental applications.

Graphical Abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Environmental pollution and climate change are serious concerns that society is facing today. A significant amount of research has been made for the development of functional materials that could ameliorate these issues. Carbon materials, due to their environmentally friendly nature, stability and wide range of applications are excellent candidates for this task (Lithoxoos et al. 2010; Mauter and Elimelech 2008).

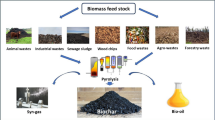

Worldwide, 2 × 1011 tons of lignocellulosic biomass are produced every year (Saini et al. 2015). Its abundance and low-cost make it ideal for the large scale production of functional carbon materials. One of these materials is biochar, a carbon-rich solid produced by the pyrolysis of biomass in an oxygen-limited environment. In recent years, biochar has attracted a great interest due to its many applications including soil amendment, soil and water remediation, carbon sequestration and reduction of greenhouse gas emissions (Cayuela et al. 2014; Lehmann et al. 2006; Mohan et al. 2014; Singh et al. 2010). Biochar beneficial effects have been traditionally attributed to its large surface area, complex pore structure and chemical composition. More recently, a new range of electrochemical properties have been discovered in biochar, i.e. electron transfer and storage capacity (Klüpfel et al. 2014; Sun et al. 2017). These properties have been proposed to play a role in some of its beneficial effects. Thus, when used as a soil amendment, biochar could be involved in some soil redox-mediated processes including nutrient cycling, contaminant degradation, free radical scavenging, microbial electron shuttling and direct interspecies electron transfer, among others (Chen et al. 2014; Fang et al. 2014; Joseph et al. 2015; Yu et al. 2015).

In this paper, the current knowledge on the electrochemical properties of biochar is reviewed and several modification methods for the production of biochars with altered electrochemical properties are discussed.

2 Origin of the electrochemical properties of biochar

Pyrolysis of lignocellulosic biomass is a thermochemical decomposition process that transforms its polymeric components into carbon-rich biochar (solid residue), bio-oil (liquid residue), and syngas (Kan et al. 2016). The solid fraction is a very heterogeneous material, generally comprised of an organic aromatic matrix with different levels of oxidation and inorganic constituents whose composition will vary depending on the original feedstock and temperature of pyrolysis (Lehmann and Joseph 2015).

The electrochemical properties of biochar arise both from the organic and mineral phases and include at least three different mechanisms:

(1) Pseudocapacitance (the ability to store electrical energy through faradaic reduction–oxidation reactions) (Zhang et al. 2009) related to the presence of redox-active functional groups, metals and radicals on the surface of biochar (Klüpfel et al. 2014). These moieties can be oxidized or reduced, some of them reversibly, giving biochar the ability to act as an electron storage material (Fig. 1a).

a Reduction and oxidation reactions of biochar; b Theoretical reduction–oxidation potential values (Eh) of different redox couples common in soil at 25 °C and pH 7. More positive values indicate an increased electron accepting nature, while more negative potentials indicate an increased electron donor nature.

Quinone/hydroquinone pair moieties have been identified as the main organic functional groups responsible for the redox properties of carbon materials (Fig. 2) (Hsieh and Teng 2002; Klüpfel et al. 2014; Raymundo-Piñero et al. 2006). The redox reaction involves protons and therefore the pseudocapacitance is pH dependent, usually with higher values at acidic pH (Lee et al. 2013b).

Apart from pyrolysis conditions, the amount of cellulose, hemicellulose and lignin in the original biomass determines to some degree the final concentration and type of these groups (Zhao et al. 2013). Biochar, being produced in an oxygen-limited atmosphere, is in a chemically reduced state compared with the initial feedstock. This is caused by the loss of oxygen atoms due to the elevated pyrolysis temperature and the high hydrogen − carbon ratio (H/C) of the original biomass, which can provide a reductive environment during pyrolysis (Liu et al. 2017). As a result, the electron donating capacity of biochar is typically greater than its capacity to accept electrons (Prévoteau et al. 2016). Hydroquinone and phenolic moieties make up for the majority of this electron donor capacity, while aromatic carbonyls (e.g. quinones) are the main electron acceptors (Klüpfel et al. 2014).

Radicals can also have a role in the redox properties of biochar, either as aryl radicals or as an intermediate of the quinone/hydroquinone system (semiquinone and phenoxyl radicals) (Bandosz and Ania 2006; Scott et al. 1998). The formation of persistent free radicals (PFRs) in biochar is favored by the presence of transition metals and the huge network of aromatic rings that stabilize by resonance the unpaired electrons (Yang et al. 2016a). The half-life of these PFRs can vary from a few hours to even months (Liao et al. 2014). Despite its importance, the specific role of PFRs in the redox properties of biochar remains to be elucidated and more research needs to be done.

The presence of redox active metals such as Fe and Mn, whether as minerals or attached as organometallic moieties to the carbon structure in biochar, is responsible for the redox mediation properties of the inorganic fraction (Klüpfel et al. 2014). Depending on the feedstock mineral content and pyrolysis conditions, these metals can exist in a wide range of oxidation states and therefore be oxidized or reduced by electron donors or acceptors. For example, minerals like magnetite (Fe3O4), which are known to be formed on the surface of biochar (Chen et al. 2011a), can act both as an electron donor and acceptor due to the presence of iron in two different oxidation states (Fe2+ and Fe3+) (Augustyn et al. 2014).

The electron storage ability of biochar arising from its pseudocapacitance properties allows biochar to act as an electron mediator between microorganisms and minerals in soil. Biochar can accept electrons from electron donors in soil such as certain microorganisms or minerals and transfer them either biotically or abiotically to different electron acceptors (e.g. NO3 −) when conditions change (Kappler et al. 2014). The specific electron donor and acceptor will mostly depend on the soil redox potential (Eh) (Fig. 1b), but also on the pH, microbiota, water content and organic and mineral composition (Tokarz and Urban 2015). This process of electron mediation between biochar and microorganisms, called “electron shuttling”, has been suggested to influence different processes of soil biogeochemistry such as methane and nitrous oxide emissions (Van Zwieten et al. 2015).

(2) Electron conductivity as a consequence of π-electron delocalization and the presence of graphite-like sheet structures (Saquing et al. 2016). Conductivity in biochar refers to the migration of electrons between energy bands with different electric potential (i.e. voltage). If the pyrolysis temperature is high enough, successive growth and condensation of the amorphous carbon sheets in biochar will produce graphite-like sheet structures with increased crystallinity and aromaticity (Keiluweit et al. 2010). The accumulation of these conjugated π-electron systems progressively increases the conductivity of the starting material, as electrons associated with π-bonds are delocalized and become available as charge carriers (Biniak et al. 2001; Pandolfo and Hollenkamp 2006). Thus, biochar is able to directly transfer electrons from an electron donor to an electron acceptor without storing them. Unlike mediation by surface functional groups, this electron transfer process does not require a chemical reaction and has been found to proceed much faster (Sun et al. 2017).

The conductive properties of biochar could play an important role in the biogeochemistry and microbial community of soil, for instance, promoting direct interspecies electron transfer (DIET), a mechanism for electron exchange between different species of microorganisms (Dubé and Guiot 2015). In this process, some microbial species can directly transfer electrons to biochar, transporting them beyond the reach of individual cells (Chen et al. 2014) and coupling the metabolic activities of two different microorganisms (Fig. 3) (Shi et al. 2016).

Adapted from Kouzuma et al. (2015)

An example of DIET with biochar as the conductive medium. After accepting electrons from an electron-donating microorganism, the conductive graphite like sheet structures allows electrons to migrate to electron-accepting microorganisms, linking both metabolisms.

(3) Double layer capacitance linked to the porous structure of biochar: Capacitance is the ability of a body to store energy electrostatically in the form of an electrical charge (Brousse et al. 2015). In double layer capacitance, the charge is stored electrostatically by reversible adsorption of ions onto the carbon surface, with no faradaic (redox) reaction involved (Simon and Gogotsi 2008). To increase the amount of charge stored, a high surface area material is needed. The high porosity and surface area of biochar, its low cost and low toxicity make it an ideal alternative to traditional carbon materials for the production of electrical energy storage devices with high capacitance (Jiang et al. 2013). Besides surface area, the conductivity of a material positively correlates with its double layer capacitance. In some cases, the presence of functional groups in the surface can also increase the double layer capacitance of the carbon material by improving its wettability to electrolyte ions (Bleda-Martínez et al. 2005; Fang and Binder 2007). This results in a higher usable surface area and could draw electrolyte ions closer to the surface, shrinking the thickness of the double layer and thus increasing its capacity (Wei et al. 2005; Shrestha et al. 2014).

Even though this mechanism probably has little effect on soil biogeochemical processes since it does not involve storage or transfer of electrons, the electrostatic adsorption of ions onto biochar can be exploited for different applications including the removal of contaminants (e.g. heavy metals) (Dehkhoda et al. 2014) and water desalination (Porada et al. 2012).

3 Measuring the electrochemical properties of biochar

The electrochemical properties of biochar and other carbon materials had been largely overlooked in the past due to the difficulty in measuring them. With the development of new techniques and methods, many studies have appeared in recent years to fill this void.

3.1 Pseudocapacitance

The measurable properties of biochars linked to their redox mediation and electron storage capacity are the electron donating capacity (EDC) and electron accepting capacity (EAC) (Aeschbacher et al. 2010; Klüpfel et al. 2014; Prévoteau et al. 2016). EDC is defined as the maximum number of electrons that a particular biochar can provide to a sufficiently oxidative solution, while the EAC is the maximum amount of electrons that a biochar can accept from a sufficiently reductive solution. The sum of the two is the electron exchange capacity (EEC), biochar’s total capacity to accept and donate electrons.

Traditionally, electrochemical analysis with a three-electrode system (Fig. 4a) has been used to measure the electron exchange capacities of materials like humic substances, that share many similarities with biochar (Aeschbacher et al. 2010; Peretyazhko and Sposito 2006). Its high sensitivity, precision and the capacity to measure the electron transfer in real time makes it an ideal technique for this task. However, the difficulty to solubilize biochar and the fact that many of its functional groups are hidden inside the complex pore structure makes it difficult to directly measure the electron exchange with an electrode. Klüpfel et al. (2014) overcame these issues using a technique called mediated electrochemical analysis (Fig. 4b). In this technique, a chemical mediator of known concentration is reduced/oxidized by a specific amount of biochar, transferring the electrons later to the electrode (or receiving the electrons from the electrode in the case of biochar reduction). Measuring the current that passes through the electrode, which is proportional to the amount of electrons that enter or exit the electrode, and knowing the mechanism of the reaction (e.g. how many electrons are involved) allows to calculate the number of electrons that biochar is able to accept or donate.

To reduce the noise of the signal, measurements should be taken away from electromagnetic fields (like those originating from the electrical grid) (Husson et al. 2016). One solution is to place the electrochemical cell inside a Faraday cage, which shields the apparatus and minimizes electromagnetic perturbations.

The selection of mediator is based on the redox potential (the tendency of a chemical species to acquire/donate electrons and be reduced/oxidized) of the main functional groups responsible for the donation/acceptance of electrons. A mediator with a more positive redox potential is used to measure the electron donating capacity and one with a more negative redox potential to measure the electron accepting capacity. If the redox potential of the mediator is very different to the redox potential biochar will encounter in the environment, the real amount of electrons donated/accepted by biochar in environmentally relevant conditions could significantly differ from the measured laboratory values. For this reason, for environmental applications it is advisable to use a mediator with a redox potential similar to the expected environmental conditions.

Klüpfel et al. (2014) used two different mediators, ABTS (2,2′-azino-bis(3-ethylbenzthiazoline-6-sulfonic acid)) for EDC and a synthesized zwitterionic viologen for EAC. They analyzed a total of 19 biochars produced at temperatures from 200 to 700 °C and found that for grass-based biochars, 1 g of biochar could accept a maximum of 0.90 mmol of electrons and donate up to 0.70 mmol of electrons.

The main disadvantage of electrochemical techniques is that the amount of electrons transferred depends on a wide range of variables like temperature, pH, the chemical mediator used, its concentration, etc. (Sander et al. 2015). Thus, two values can only be compared when measured in the same exact conditions. In a recent work, Prévoteau et al. (2016) performed electrochemical analysis on a similar wood-based biochar than the one Klüpfel et al. (2014) used, but with more stable mediators and longer incubation times (days instead of minutes). The methodology used by Klüpfel et al. (2014) allowed measuring the electron transfer between biochar and electrode (via mediator) in real time. However, due to the long incubation times in their study, Prévoteau et al. (2016) had to quantify the electron transfer indirectly by monitoring the extent of mediator reduction/oxidation caused by biochar at regular intervals. They achieved this using a rotating disk electrode, which induces a laminar flow of solution to the electrode and prevents diffusion issues. The continuous arrival of mediator molecules to the electrode caused by the rotation allows obtaining a steady-state limiting current proportional to the concentration of reduced/oxidized mediator. Once the amount of mediator reduced/oxidized by biochar reaches a plateau, it could be assumed that the electron transfer is over. Since the mechanism of the reaction and the initial concentration of mediator are known, the total number of electrons transferred can be calculated. After 60 days of incubation time, they reported a maximum EDC of 7 mmol of electrons per gram of biochar, while the EAC was similar to the values obtained by Klüpfel et al. (2014). This tenfold increase in EDC with respect to previous results was caused by a very slow electron donation, which could not be detected by ABTS due to its instability in solution after only a few hours. The authors attributed this sluggish donation to the slow kinetics of oxidation of recalcitrant compounds in biochar or to sequential irreversible oxidations of some chemical species.

Besides the use of mediators, there are other approaches to study materials that are difficult to solubilize or do not easily facilitate the electron transfer to the electrode. These non-mediated approaches rely on placing the material in direct physical contact with the electrode, for example through immobilization of the sample onto the electrode’s surface (Fig. 4c) (Sun et al. 2017) or by mixing the material with a conductive matrix which, after being compacted in a hydraulic press, serves as the working electrode (composite electrodes, Fig. 4d) (Joseph et al. 2015; Kalinke et al. 2016). The values obtained from non-mediated techniques, however, are sometimes much lower than those reported using mediated techniques. This is probably due to the redox-active moieties being hidden inside the bulk structure of the material and not in contact with the electrode, especially in very porous materials like biochar (Sander et al. 2015).

3.2 Double layer capacitance

The specific contributions of pseudocapacitance and double layer capacitance to the total current obtained from the electrochemical analysis are seldom differentiated. However, it could be important to discriminate between them considering that pseudocapacitance probably has a more dominant role in soil biogeochemical reactions.

To accomplish this, the total current has to be separated as a function of whether it’s been caused by faradaic and non-faradaic capacitative processes (Deen and Asselin 2016). This is achieved by analyzing the output current as a function of potential performed at different sweep rates. Since each process responds differently to varying sweep rates, their individual contributions to the total current can be calculated (Wang et al. 2007).

For instance, Sun et al. (2017) were able to measure the non-faradaic current of black walnut biochar produced at different temperatures. They found that the capacitance increased with higher temperatures, probably due to the formation of graphite-like sheet structures and the increased conductivity.

3.3 Conductivity

In order to determine the electrical conductivity of biochar, a two-probe technique is frequently used (Chen et al. 2014; Mochidzuki et al. 2003; Xu et al. 2013). A voltage is applied and a known current is forced to pass through the sample, which is placed between the two probes. The resulting voltage drop is measured by a potentiometer, and allows calculating the conductivity of biochar from its resistivity (how strongly biochar opposes the flow of electric current). In the work published by Chen et al. (2014), for example, the conductivity of several biochars produced at different temperatures and residence times were estimated using two gold electrodes as probes, separated by a 50 µm non-conductive gap. The biochar sample was placed between the electrodes as a connector, allowing current to pass and resistivity to be measured (Fig. 5).

When measuring the electrical conductivity of a material, a common problem is the electrical contact resistance between particles. Particulate carbons are especially sensitive to electrical contact resistance and it must be eliminated from the total measured resistance (Walker and Rusinko 1957). To overcome this issue, a pressure (or range of pressures) are typically applied to a packed bed of the carbon material, whose length and electrical resistivity decrease with increased pressure until a plateau is reached (when the contact electrical resistance is overcome) (Xu et al. 2013). After correcting for the empty bed values, the real electrical resistance of the material can be obtained and conductivity correctly evaluated. As an alternative, a graphite powder-based contact fluid can be applied to reduce the contact resistance substantially (Gabhi et al. 2017).

3.4 Kinetics of electron transfer

In addition to the amount of electrons that biochar can store and transfer, the kinetic of those processes is an important feature that can affect its role in soil biogeochemistry. For example, the direct reduction of Fe(III) minerals by Geobacter sulfurreducens proceeds at a much slower rate when the electron transfer is performed directly than when humic substances are used as electron shuttles (Jiang and Kappler 2008). This is due to the fast kinetics of electron transfer of the humic substances, which promotes the bacterial reduction of Fe(III) minerals.

In a recent article by Sun et al. (2017), the electron transfer kinetics of surface functional groups and graphitic carbon structures in pyrogenic carbon were determined using different electrochemical techniques. The assessment of the charging and discharging kinetics of surface functional groups were performed using a non-mediated electrochemical approach where the pyrogenic carbon was immobilized onto the surface of a graphite electrode. For the measurement of the kinetics of electron transfer in the graphitic structures, on the other hand, a composite electrode made of pyrogenic carbon particles was used, with a ferrocene derivative [dimethylaminomethyl ferrocene (FcDMAM)] as an electron donor. Results showed that direct electron transfer by the graphitic structures was three times faster than the charging and discharging behavior of surface functional groups. This is expected since in the functional group mechanism a chemical reaction is necessary. The kinetics of electron transfer due to functional groups were stable even at high pyrolysis temperatures, although its total electron contribution was lower as a result of the decreased number of groups.

4 Designing biochar for enhanced electrochemical properties

Since biochar can have a role in several biogeochemical redox reactions, modifying biochar electrochemical properties is an interesting approach to regulate its effect on different environments like soil and water. Furthermore, it could allow investigating their impact on soil under controlled conditions by comparing biochars produced from the same feedstock but with different electrochemical properties.

In order to adjust the electrochemical properties of biochar, the elements responsible for the desired properties have to be promoted. If a higher electron storage capacity is wanted, a biochar with an increased number of redox-active functional groups, radicals and/or metals must be produced. If conductivity is the desired trait, however, a biochar with a more aromatic and graphitic structure has to be made. Unfortunately, the combination of high electron storage capacity and conductivity is difficult to achieve. Oxygen-containing functional groups (OCFG) preferentially form at the edges of the graphite-like sheet structures, which increase the energy barrier for electrons to transfer from one sheet to the next (Barton and Koresh 1984; Polovina et al. 1997). Therefore, processes that increase the content of OCFG in biochar for an improved electron storage capacity can decrease its conductivity and vice versa.

In order to produce tailored biochars with the desired electrochemical properties, variables such as the starting material, the pyrolysis temperature and residence time, the presence of additives or the use of chemical treatments must be carefully chosen.

4.1 Selecting the original feedstock

Biochar can be produced from many kinds of feedstock including wood, grass, algae, manure, sewage sludge, etc., so a high variability is to be expected in the resulting properties among different biochars (Zhao et al. 2013). Some generalizations can be made about their characteristics depending on the initial feedstock. For example, wood-derived biochar consistently has a relatively high carbon and low ash content compared to non-wood-derived biochars (e.g. manure and grass biochars) (Mukome et al. 2013). Surface area, which is related to double layer capacitance and pseudocapacitance, is found to be higher in softwood and derived biochar then hardwood biochars. The less dense structure of softwoods makes them more susceptible to thermal decomposition, producing a biochar with a high amount of pores.

Biochar produced from animal wastes has a high nitrogen content and therefore an increased number of nitrogen-containing functional groups that could improve its pseudocapacitance (Zhao et al. 2010). Biochar from Sewage sludge has an even greater concentration of heavy metals than the original waste material (Lu et al. 2016), which is not recommended if it is going to be used as a soil amendment or for contaminant removal.

The abundance of lignocellulosic biomass makes plant-derived biochar the majority of commercially available biochar (Lehmann and Joseph 2015). The amount of cellulose, hemicellulose, lignin and inorganic components in these sources will determine to some degree the final structure and chemistry of the resulting biochar. Different studies have also shown that biochar with high mineral content can have a high redox activity, probably due to the presence of redox-active metals (Joseph et al. 2013; Quin et al. 2015). Biochars produced from biomass with high ash content (e.g. grass) have usually better electron storage capacity than biochars from low ash feedstocks like wood (Klüpfel et al. 2014). However, sometimes the presence of redox-active metals can only account for a fraction of this increase. It has been hypothesized that metal ions present in the biomass can influence the thermal degradation of lignocellulose and favor different depolymerization pathways, like cycloreversion-oxidation, that allows for a more efficient oxidation and a higher number of OCFGs (Harvey et al. 2012).

Although the nature of the original material used has an effect on the properties of biochar, other factors like pyrolysis conditions have large and more important effects on its electrochemical properties (Klüpfel et al. 2014; Zhao et al. 2013).

4.2 Adjusting pyrolysis conditions

In the production of biochar, the pyrolysis conditions are the most important variables since they determine the majority of its properties. The central roles of pyrolysis temperature, residence time and atmosphere are key to understand and control the thermally induced changes in the original material.

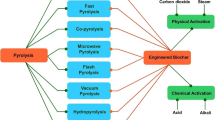

4.2.1 Type of pyrolysis

Fast and slow pyrolysis are the two most common types of pyrolysis. During fast pyrolysis there is a rapid heating of biomass with a small residence time of a few seconds, while slow pyrolysis has a gradual heating rate and a residence time of hours (Bruun et al. 2012). As a result, fast pyrolysis generates more liquid product, yielding only 10–25% of solid char with usually lower surface area than the slow pyrolysis method (Lehmann and Joseph 2015). The 25–35% yield for slow pyrolysis makes it the usual method of choice when the goal is the production of biochar (Mohan et al. 2006).

The different pyrolysis methods could also affect to some degree the functionalization and therefore the pseudocapacitance of biochar. Brewer et al. (2011) studied the composition of biochars produced from fast and slow pyrolysis. FTIR analysis showed large signals of oxygen-containing groups in fast pyrolysis biochars, being phenolic and carbonyl (C=O) groups the most prominent ones. In contrast, although slow pyrolysis biochar also presented these groups, their signals were much weaker than in fast pyrolysis biochars, suggesting a lower electron storage capacity.

The duration of the thermal treatment plays an essential role in the graphitization and therefore the conductivity of biochar (Gabhi et al. 2017). The electrical conductivity increases when the individual graphite-like sheets grow and become interconnected to form a conductive network (Pandolfo and Hollenkamp 2006). The randomly oriented sheets need to be properly aligned for conductivity to rise and the process is temperature and time-dependent (Nover et al. 2005). In the recent study by Gabhi et al. (2017), an extra 8-h heat treatment was performed on a commercial biochar, which resulted in a 600-fold increase in its conductivity. The X-ray diffraction (XRD) analysis showed a highly ordered crystal structure after the treatment, probably due to graphitization of the bulk material.

The concentration and type of radicals in biochar is also dependent on pyrolysis duration. At relatively low temperatures (300–400 °C) radicals gradually increase with increasing residence times, while at higher temperatures (500–600 °C) radicals decay with a longer residence time (Fang et al. 2015). Furthermore, as pyrolysis time increases the abundant oxygen-centered radicals (e.g. the semiquinone radical) decompose and convert to carbon-centered radicals (e.g. phenoxyl radical). This could have implications for the radical-related pseudocapacitance since oxygen-centered radicals are thought to be more reactive than carbon-centered radicals with an adjacent oxygen atom in biochar.

4.2.2 Temperature

Pyrolysis temperature is the most important parameter since it determines the structure and oxidation state of the organic phase (Al-Wabel et al. 2013; Crombie et al. 2013; Khanmohammadi et al. 2015; Klüpfel et al. 2014; Rafiq et al. 2016). As temperature rises, the crystalline structure of cellulose becomes amorphous and thermal depolymerization takes place (Keiluweit et al. 2010). Free monomeric phenols from lignin and other alcohols from cellulose and hemicellulose start to appear. Around the high treatment temperature (HTT) of 400 °C, all lignocellulose is in an amorphous state and is generally the temperature where biochar has a higher electron exchange capacity due to the high number of redox-active functional groups (mainly phenolic moieties).

Oxidation and condensation reactions at 500–550 °C increases the number of electron accepting moieties. The accumulation of quinones at this temperature (newly formed and from the oxidation of phenols and other alcohols) usually produces the biochar with the highest electron accepting capacity, although it varies between different feedstocks (Klüpfel et al. 2014; Prévoteau et al. 2016). The aromatization and loss of OCFGs, especially phenolic groups, via thermally induced dihydroxylation/dehydrogenation reactions can explain the sharp decrease in EDC at temperatures above 500 °C (Harvey et al. 2012).

At higher temperatures (> 600 °C) the EAC and EDC values drastically decrease due to the almost complete thermal degradation of functional groups and localized graphitic sheets start to grow and become aligned into small graphite-like micro-crystallites (Pandolfo and Hollenkamp 2006). The formation of these graphitic micro-crystallites and the loss of oxygen-containing functional groups result in higher electrical conductivity and lower pseudocapacitance (Prévoteau et al. 2016; Rafiq et al. 2016; Rhim et al. 2010).

The presence of radicals in biochar constantly increases with raising temperatures up to 600 °C and substantially drops at higher temperatures, becoming undetectable at 800 °C (Liu et al. 2015a). At relatively low to intermediate pyrolysis temperatures (300–550 °C) oxygen-centered radicals dominate, while at higher temperatures carbon-centered radicals are the predominant species (Fang et al. 2015).

Finally, higher temperatures during pyrolysis produces biochar with increased surface area and aromaticity (Gai et al. 2014), which facilitates the electrostatic adsorption of ions in the double layer capacitance mechanism.

4.2.3 Atmosphere

Although pyrolysis of biochar is usually performed in an oxygen-free atmosphere, the presence of little quantities of O2 during heating could increase the number of oxygen-containing functional groups. Chen et al. (2011b) thermally treated hydrothermal and activated carbon in air, creating a high number of these functional groups (including redox-active groups, like phenols and quinones, mainly responsible for the electron storage ability of biochar). The temperature used (100–300 °C) was sufficiently high to ensure that oxygen from air was reactive, adding new OCFGs to the biomass. In another study, Suliman et al. (2016) treated eighteen biochars from three feedstocks and six temperatures (350, 400, 450, 500, 550 and 600 °C) in a lab scale reactor at 250 °C. X‐ray photoemission spectra (XPS) analysis confirmed that greater quantities of carbonyl and carboxyl groups were formed on biochars.

The main problem with this approach is to prevent the oxidation process to reach combustion. Lee et al. (2013a) proposed several methods to achieve this, including oxygen plasma injection, the application of a quencher like water or the use of an artificial gas mixture. With these methods, the amount of oxygen used can be precisely monitored, preventing complete combustion and controlling the quantity and type of OCFGs formed in the surface of biochar. For example, Madej et al. (2016) produced Miscanthus biochar under a nitrogen atmosphere with different oxygen concentrations (0, 0.5, 1 and 2%). As mentioned before, if pyrolysis is performed with a highest treatment temperature > 500 °C, many OCFGs start to decompose. However, their analysis showed that the loss of oxygen content in biochars produced at > 500 °C was reduced with increasing concentration of oxygen in the artificial atmosphere.

4.3 Chemical and weathering treatments

Despite the fact that biochar has a greater concentration of functional groups than other carbon materials, a functionalization process is often a necessary step to achieve a biochar with the desired properties (Liu et al. 2015b). A wide range of chemical treatments have been tested for the production of modified biochar, generally post-pyrolysis. In carbon materials like graphene and graphite, some of these treatments were able to modify their electrochemical properties (Tang et al. 2009).

4.3.1 Oxidizing agents

For the chemical functionalization of biochar, oxidizing agents like hydrogen peroxide (H2O2), potassium permanganate (KMnO4) and ozone (O3) are commonly used (Lee et al. 2013a). These compounds are reactive enough to add oxygen atoms into organic materials producing a homogeneously oxygenated biochar. Huff and Lee (2016) produced pinewood biochar by pyrolysis at 400 °C, which then treated with H2O2 at different concentrations (from 1 to 30% w/w). FTIR-ATR analysis showed a higher concentration of oxygen-containing functional groups with increasing H2O2 concentration compared to the untreated biochar. In addition, the peak that correlates with the C=C stretching of the aromatic carbons (1585 cm−1) decreased with respect to the untreated sample. This suggests that some of the aromatic carbon of the sample was affected by the introduction of new oxygen atoms.

Even though biochar usually has a basic pH, oxidizing treatments can introduce a great number of acidic groups (e.g. carboxylic groups COOH), lowering its pH. Li et al. (2014) treated bamboo biochar with KMnO4 and HNO3 as oxidizing agents, after which the contents of carboxylic, phenol and lactone groups were substantially higher. The resulting acidity (especially for the HNO3 treatment) also led to increased hydrophilicity of the biochars, which improves wettability and thus the adsorption of ions onto its surface. This property, along with the increased number of redox-active functional groups produce biochar with unusually high capacitance, which has been exploited for the use of biochar as supercapacitor (Jiang et al. 2013).

Valdés et al. (2002) investigated the effect of ozone treatment to activated carbon. X-ray photoelectron analysis showed that short treatment times lead to a higher number of phenolic functional groups. With increasing ozonation times their concentration decreases and more oxidized groups such as lactones and carbonyls are generated, evolving finally to carboxylic groups that have low electrochemical reactivity.

4.3.2 Alkali and acid treatment

The modification of pseudocapacitance and double layer capacitance in biochar could be accomplished using strong bases such as NaOH and KOH, as several studies have proven their effect its functionalization and surface area. Yakout (2015) obtained a basic biochar after KOH treatment with an increased oxygen content, which they attributed to an abundance of phenolic groups. As reported by Li et al. (2014), NaOH treatment doubled the content of lactone groups compared to pristine biochar. However, the amount of carboxyl and phenolic groups were greatly reduced. As an additional effect, the concentration of alkali determines not only the number of functional groups, but also the pore structure and surface area of the treated biochar (Liu et al. 2015b).

A highly oxygenated and acidic biochar is produced when treated with H2SO4 (Yakout et al. 2015). Besides the addition of carboxyl and phenolic groups, sulfonation of the biochar’s surface can take place, which opens the possibility to use it as a catalyst for a wide range of applications (Yu et al. 2011).

Phosphoric acid treatment has been found to be an effective method for biochar modification both before and after the pyrolysis step. Taha et al. (2014) treated charcoal and two biochars from rice straw and corn stover with a solution of 1 M H3PO4, which significantly increased their aromatization and the number of surface functional groups. Jagtoyen et al. (1992), on the other hand, investigated the effect of phosphoric acid in lignocellulosic biomass before and during the pyrolysis process. At low temperatures H3PO4 causes and accelerates the hydrolysis of glycosidic bonds in holocellulose and β-O-4 aryl ether bonds in lignin, while also promoting crosslinking via cyclization and condensation. P-containing functional groups like phosphates or polyphosphates are introduced forming ester bonds with free –OH present in the biomass. These groups can form bridges that connect different polymer chains, creating a swelling effect on the lignocellulose that produces a biochar with an open pore structure. At higher temperatures (> 450 °C), the phosphate linkages become thermally unstable causing the contraction of the structure. Several studies have used phosphoric acid for the pretreatment of lignocellulosic biomass before the pyrolysis step. In a study by Uchimiya et al. (2011), pecan shells were ground, soaked overnight in 30 wt% phosphoric acid and pyrolyzed at 450 °C for 4 h. A higher Oxygen/Carbon molar ratio was obtained for phosphoric acid activated biochars than untreated biochar, which they attributed to an increased number of oxygen-containing functional groups.

4.3.3 Doping with heteroatoms

Another method to change the properties of biochar is to dope it with heteroatoms, which in carbon materials like graphene or graphite has proven to enhance their electrochemical properties (Shao et al. 2010). Doping the carbon matrix with heteroatoms (i.e. the graphitic carbon atoms are substituted by other atoms) can influence the conductivity of biochar by altering the electron density of the condensed π-electron network (Deng et al. 2015). In addition, many new functional groups can be attached which, if redox-active, can increase its pseudocapacitance.

The most common heteroatom used is the nitrogen atom. Nitrogen-modified biochar can be prepared treating the char with nitrogen reactive compounds like nitric acid, urea, nitrogen plasma or, more commonly, injecting ammonia at high temperatures during the pyrolysis of biomass (Liu et al. 2015b). At very high temperatures, ammonia breaks down into radicals and react with surface oxides and active sites at the edges of the polycondensed graphite-like sheets to form functional groups such as amines, pyridones, pyridine- and pyrrole-like functionalities (Fig. 6a) (Xiong et al. 2013). These groups add extra pseudocapacitance due to faradaic redox reactions where they can store and transfer electrons (Fig. 6b).

The addition of nitrogen-containing groups with chemical treatments is limited, since it can only introduce groups onto the surface of biochar, sometimes at the expense of oxygen-containing groups (Madej et al. 2016). Alternatively, the direct pyrolysis of nitrogen enriched biomass is usually cheaper, less time consuming and more efficient (Jassal et al. 2015; Purevsuren et al. 2003). Adding nitrogen precursors like chicken manure, urea or other nitrogen compounds to the biomass before pyrolysis can introduce nitrogen atoms into the carbon lattice of biochar forming nitrogen moieties such as pyridinic, pyrrolic and graphitic-N (also known as quaternary-N) (Zhao et al. 2010). Pyridinic and pyrrolic nitrogen species doped into the aromatic structure can enhance the electron-donor and storage capacity of biochar due to their redox properties (Uchimiya et al. 2011; Wang et al. 2014). Quaternary-N atoms increase the electronic density of the N-doped carbon, which improves the conductivity of the material (Liu et al. 2011).

Sulfur-doping has also been used to modify the electrochemical properties of many carbon materials, with similar effects on pseudocapacitance than nitrogen-doping (Seredych and Bandosz 2013). The introduction of the redox-active sulfones and sulfoxides in the carbon material are thought to be the main reason of this improvement in pseudocapacitance (Fig. 7).

In addition to doping carbon materials exclusively with one heteroatom, multi-heteroatom doping can provide a synergistic effect on the modification of the electrochemical properties (Hasegawa et al. 2015). For instance, Si et al. (2013) were able to produce activated hydrothermal carbons with both nitrogen and sulfur functionalities. The increased pseudocapacitance of the carbon material was higher when it contained both sulfur and nitrogen than when only one heteroatom was added.

4.3.4 Weathering processes

Biochar undergoes many chemical changes when added to soil related to complex chemical and biological interactions. Joseph et al. (2010) observed that the oxygen and radical content on the surface of biochar increase significantly after 1 year of application to soil, especially carbonyl functional groups. Biochars produced at elevated temperatures, with increased condensation of the aromatic carbon, showed a higher resistance against microbial oxidation (after which conductivity probably decreases). The rate of oxidation depends both on the type of soil (Rechberger et al. 2017) and biochar (Joseph et al. 2010).

A similar but much faster process of biochar weathering occurs during composting. The composting process can be described as the biological oxidative decomposition of organic wastes under controlled conditions (Sharma et al. 1997). In this context, it could be a suitable method to increase the oxygen-containing functional groups in biochar and therefore its electron storage capacity. Wiedner et al. (2015) added three types of biochar (beech biochar at ∼ 450 °C, wood chips biochar at ∼ 550 °C and green cutting biochar at ∼ 800 °C) to different mixtures of fresh organic material and composted them. At the end of the treatment, they recovered the modified biochars and analyzed them using Fourier transformation infrared microscopy (FTIM) mapping for carboxylic (1700–1725 cm−1), aromatic (1585–1725 cm−1) and phenolic groups (1190–1210 cm−1). In this technique, an infrared microscope allows to visualize the sample and measure the relative proportions of different functional groups before and after composting. Results showed signs of increased oxidation in composted biochars with respect to fresh biochar. The relative proportion of carboxylic groups increased for low temperature composted biochars (∼ 450 and ∼ 550 °C) in relation to fresh biochars, while phenolic groups had a higher contribution in the high temperature composted biochar (∼ 800 °C). Other studies have also reported an increased concentration of oxygen-containing functional groups on the surface of biochar after the composting process (Jindo et al. 2012). An alternative and complementary explanation to the oxidation of biochar is the adsorption of organic matter and/or microbial exudates from the composting mixture (Prost et al. 2012; Wiedner et al. 2015).

In addition to oxidation, aging in soil can modify its surface via mineral precipitation and the formation of mineral phases with a different electrochemical potential than the organic phase (Joseph et al. 2010; Lin et al. 2012). The organic phase has a nanoporous structure and can act as a semipermeable membrane, connecting mineral phases with different soluble metal concentrations (Joseph et al. 2013). A flow of electrons, protons, cations and anions can then occur between phases with different electrochemical potentials, in a similar way to galvanic cells. This potentially allows for complex redox reactions to take place, especially for phases having redox-active metals. These redox reactions can influence the environment around biochar, affecting microorganisms, plants, other minerals and even gases. One possible example of the electrochemical changes occurring during aging in soil can be seen in the work of Quin et al. (2015), where eucalypt biochar incubated in soil and sterilized was able to lower the emissions of injected N2O. XPS analysis showed that compared to the 100% biochar sample, in soil/biochar mixtures there was a considerable increment of nitrogen groups in the surface. This indicated the reaction of N2O with organic groups or mineral elements in the aged soil/biochar mixture that where not present in the original biochar (at least in the same amounts). Furthermore, the formation of a porous organomineral layer after injection and the presence of iron in both oxidation states (Fe2+ and Fe3+) suggested that redox reactions between N2O and Fe could have taken place.

4.4 Additives

The addition of metal ions can influence directly or indirectly the electrochemical properties of biochar. First, metal ions can influence the thermal degradation of lignocellulose and favor different depolymerization pathways, which control the final concentration and type of functional groups in biochar (Harvey et al. 2012). Second, mineral oxides can form in the surface of biochar with the metal in different oxidation states, which could also increase pseudocapacitance directly (Joseph et al. 2015; Klüpfel et al. 2014). This makes the presence of mineral additives during the biomass pyrolysis process an interesting, faster and possibly cheaper method than chemical treatments to produce electrochemically altered biochars.

4.4.1 Iron

Iron is the most common additive used for the production of modified biochar. Many Fe-enriched biochars has been developed in recent years for the removal of contaminants in soil and water due to their high surface area, increased functional group content and magnetic properties (Bandosz and Ania 2006; Rajapaksha et al. 2016; Saleh et al. 2016; Zhang et al. 2013; Zhou et al. 2014). Iron is usually added as FeCl3, although cheaper alternatives like hematite (α-Fe2O3) and Iron powder (Fe0) have also been used (Chandraiah 2016; Wang et al. 2015d). For the production of Fe-enriched biochar, biomass and FeCl3 are usually placed in solution and heated to facilitate impregnation. The solution is then filtered, dried and pyrolyzed. The sequence of reactions that takes place was investigated by Yang et al. (2016b) using X-ray diffraction (XRD). Based on XRD results, during the drying step the FeCl3 loaded on the biomass is hydrolyzed into Fe(OH)3 and FeO(OH), which then are reduced by volatiles released from the biomass during pyrolysis to different iron oxides. A magnetic mineral nano-phase is then formed in the surface of biochar, composed generally of maghemite (γ-Fe2O3) or magnetite (Fe3O4) nanoparticles. As a result of the influence of iron on the thermal degradation of lignocellulose, a greater concentration of carbonyl groups, phenols and aromatic carbon is found in these biochars. Their magnetic properties, which depends on the initial load of iron, appear usually at temperatures > 400 °C. However, Chen et al. (2011a) achieved the magnetization of biochar at a greater range of temperatures adding NaOH during impregnation, which increased iron coprecipitation.

As an alternative to a more functionalized biochar, Sun et al. (2013) obtained a biochar with an enhanced graphitic structure adding both FeCl3 and ZnCl2 as catalysts to biomass before pyrolysis. The higher graphitization of biochar resulted in an improved electrical conductivity, high surface area and pore volume.

Different metals, including iron, can participate in the formation of persistent free radicals in biochar. In the study carried by Fang et al. (2014), pine needles were loaded with different concentrations of iron (FeCl3), pyrolyzed at 400 °C for 2 h and analyzed by electron paramagnetic resonance spectroscopy (EPR). The concentration of oxygen-centered PFRs increased up to four times compared to the control biochar. In contrast, at concentrations of loaded iron higher than 10 mM the resulting biochar had a decreased abundance of PFRs, even lower than biochar without treatment. As a possible formation mechanism, they proposed that at low metal concentrations, transition metals like iron accept electrons from phenolic compounds, favoring the formation of radicals. However, at high concentrations the excess of metal would also accept electrons from radicals, consuming them in the process.

Not only can the high number of OCFGs and radicals in Fe-loaded biochar affect its electrochemical properties, but also the presence of iron in different oxidation states. Iron redox reactions can have a significant impact on the biogeochemistry of soil, including the carbon and nitrogen cycles (Li et al. 2012; Lindsay 1988; Lindsay and Schwab 1982; Roden 2012).

4.4.2 Manganese

The addition of manganese has a similar effect than iron in the pyrolysis of biomass in terms of functional groups and presence of the metal in different oxidation states (in the form manganese oxides for example). Wang et al. (2015a) reported a higher amount of OCFGs like phenolic, hydroxyl and carboxyl groups in a Mn-preloaded biochar compared to the unmodified biochar. They pyrolyzed hickory wood pretreated with potassium permanganate (KMnO4), obtaining a biochar covered with various forms of manganese oxide on its surface. XRD analysis identified these forms as Mn3O4 and α-MnO2. As with iron, not only the increased number of OCFGs but also the presence of Mn in different oxidation states can modify the redox properties of biochar. In a different study, Wang et al. (2015b) used MnCl2 as the precursor, obtaining a highly crystalline phase of manganosite (MnO) and higher oxygen content than pristine biochar. On the other hand, when they used potassium permanganate as the additive they obtained a poorly crystalline Mn-oxide but a much higher oxygen content than other treatments. Therefore, the high OCFG content on the surface of some Mn-modified biochars could be attributed to the high oxidant capacity of KMnO4.

Bimetal spinel nanocrystals, such as metal ferrites, have been successfully used lately in environmental pollutant removal. In this context, Wang et al. (2015c) developed in a different work a magnetic iron–manganese (Fe–Mn) biochar composite for arsenic adsorption. A mixture of Mn and Fe-oxides impregnated onto the surface of biochar was obtained when FeCl3 and MnCl2 were mixed with biomass in water, dried and pyrolyzed. Interestingly, when a coprecipitation step using NaOH was included, a ferrite (MnFe2O4) loaded biochar was produced. Oxygen content in the ferrite-loaded biochar was four times higher than in the mixture of metal oxides.

4.4.3 Clay

Clays can contain impurities such as F and Cl that are trapped in micropores or that are part of its lattice structure. For example, if present in certain amounts in soil, the fluoride ion can substitute the hydroxyl ion in many clay minerals (Chipera and Bish 2002). Due to the high temperatures reached during pyrolysis, clays can release small amounts of them as volatiles (Heller-Kallai and Miloslavski 1992). Although most of these volatiles are water vapor, very reactive volatiles like HF, HCl or PH3 are also liberated, which could affect the chemical surface of biochar (Heller-Kallai 1997). One example of this application can be found in the work of Chia et al. (2014), where biochar particles were coated in clay, manure and other minerals and heated at 200–240 °C. A higher number of oxygen containing functional groups was found in the surface of the treated biochar, as well as a thin mineral layer mainly composed of the redox active metals Fe and Mn between the organic and inorganic phases.

The study of Rawal et al. (2016) has shown the potential high redox activity of biochar-mineral complexes produced when biomass is pyrolyzed along with clay and other minerals. They developed biochar-mineral composites pyrolyzing bamboo cubes soaked in iron–sulfate–clay slurries and found that at temperatures of 350–550 °C, clay promoted biomass degradation and increased the concentration of phenolic, acidic and condensed aromatic groups. Scanning electron microscope images also revealed the incorporation of mineral phases into the biochar structure, including pores. The combination of increased surface organic functional groups and the formation of clay and metal oxide nanostructures inside the pores will probably promote redox reactions between biochar and different soil components when used as an amendment.

5 Future research prospects

Understanding the electrochemical properties of biochar and using the appropriate analytical techniques to measure them, will finally allow improving our knowledge on the effects and reactions that take place when biochar is added to soil or water. Among the most pressing research questions we can include:

-

The identification and quantification of the effects caused specifically by the electrochemical properties of biochar on the environment, in contrast to those derived from other properties like a high surface area. This can be achieved in laboratory and field studies comparing modified biochars produced from the same feedstock but with different electrochemical properties.

-

Changes in the soil microbiota caused by different electron storing and transfer properties. Electron shuttling and DIET processes facilitated by biochar could shift the microbial community structure of soil, altering different biogeochemical cycles.

-

Laboratory and field studies are needed to examine the interaction between plant roots and biochar and how the different electrochemical properties affect their development. Although not as known as pH, plants are affected by the redox potential (Eh) of soil (Husson 2013). The work of Joseph et al. (2015) showed the possibility of altering both the pH and redox potential of soil by adding biochar. Varying the application rates of biochar and representing the data in a modified Pourbaix diagram (with the pH-normalized redox potential), pH and Eh can be adjusted to values considered favorable for the growth of plants and beneficial microorganisms.

-

The Role of radicals in the electron storing and transfer properties of biochar. The contribution of radicals to the electrochemical properties compared to other functionalities and metals is poorly understood.

-

The specific changes in the electrochemical properties of biochar during aging in soil. After a long residence time in soil, changes in the functionality of biochar or the formation of organomineral phases at the surface and pores could modify its capacity to store and transfer electrons. New electrochemical studies are necessary to confirm and quantify the expected changes in these properties in order to know their evolution after biochar application to soil.

6 Conclusions

The electrochemical properties of biochar derive from the presence of certain functional groups, condensed aromatic structures, radicals, redox-active metals and high surface area. From the many biochar modification methods tested in the literature, those that have an effect on the concentration and structure of these components could be suitable for the purpose of tuning its electrochemical properties. These include changing pyrolysis conditions like temperature or atmosphere, chemical treatments, weathering processes or the use of different additives before the pyrolysis step.

The link between the electrochemical properties of biochar and their effect on soil has been ignored in the past due to the low amount of data gathered and the difficulty in measuring them. This knowledge gap is of critical importance because it is delaying the use of biochar as a soil amendment. The technical obstacles can now be overcome thanks to the recent development of novel electrochemical techniques. The production of biochar with different electron storage and transfer capacities could help to understand their role in the biogeochemistry of biochar amended soils. By comparing the changes in soil redox dynamics when unaltered and electrochemically modified biochar is added as an amendment, future laboratory and field trials could identify and quantify the specific effects of these properties.

Furthermore, tuning biochar electrochemical properties could allow designing tailored biochars for specific purposes and applications, like reducing greenhouse gas emissions, increasing crop yield and survival, reducing the use of fertilizers or water purification, among others.

References

Aeschbacher M, Sander M, Schwarzenbach RP (2010) Novel electrochemical approach to assess the redox properties of humic substances. Environ Sci Technol 44:87–93. https://doi.org/10.1021/es902627p

Al-Wabel MI, Al-Omran A, El-Naggar AH et al (2013) Pyrolysis temperature induced changes in characteristics and chemical composition of biochar produced from conocarpus wastes. Bioresour Technol 131:374–379. https://doi.org/10.1016/j.biortech.2012.12.165

Augustyn V, Simon P, Dunn B (2014) Pseudocapacitive oxide materials for high-rate electrochemical energy storage. Energy Environ Sci 7:1597. https://doi.org/10.1039/c3ee44164d

Bandosz TJ, Ania CO (2006) Surface chemistry of activated carbons and its characterization. In: Bandosz TJ (ed) Activated carbon surfaces in environmental remediation, vol 7. Elsevier, New York, pp 159–229. https://doi.org/10.1016/S1573-4285(06)80013-X

Barton SS, Koresh JE (1984) A study of the surface oxides on carbon cloth by electrical conductivity. Carbon 22:481–485. https://doi.org/10.1016/0008-6223(84)90079-4

Biniak S, Swiatkowski A, Pakula M, Radovic LR (2001) Electrochemical studies of phenomena at active carbon-electrolyte solution interfaces. In: Radovic LR (ed) Chemistry and physics of carbon, vol 27. Marcel Dekker Inc, New York, pp 125–225

Bleda-Martínez MJ, Maciá-Agulló JA, Lozano-Castelló D et al (2005) Role of surface chemistry on electric double layer capacitance of carbon materials. Carbon 43:2677–2684. https://doi.org/10.1016/j.carbon.2005.05.027

Brewer CE, Unger R, Schmidt-Rohr K, Brown RC (2011) Criteria to select biochars for field studies based on biochar chemical properties. Bioenergy Res 4:312–323. https://doi.org/10.1007/s12155-011-9133-7

Brousse T, Belanger D, Long JW (2015) To be or not to be pseudocapacitive? J Electrochem Soc 162:A5185–A5189. https://doi.org/10.1149/2.0201505jes

Bruun EW, Ambus P, Egsgaard H, Hauggaard-Nielsen H (2012) Effects of slow and fast pyrolysis biochar on soil C and N turnover dynamics. Soil Biol Biochem 46:73–79. https://doi.org/10.1016/j.soilbio.2011.11.019

Cayuela ML, van Zwieten L, Singh BP et al (2014) Biochar’s role in mitigating soil nitrous oxide emissions: a review and meta-analysis. Agric Ecosyst Environ 191:5–16. https://doi.org/10.1016/j.agee.2013.10.009

Chandraiah MR (2016) Facile synthesis of zero valent iron magnetic biochar composites for Pb(II) removal from the aqueous medium. Alex Eng J 55(1):619–625

Chen B, Chen Z, Lv S (2011a) A novel magnetic biochar efficiently sorbs organic pollutants and phosphate. Bioresour Technol 102:716–723. https://doi.org/10.1016/j.biortech.2010.08.067

Chen Z, Ma L, Li S et al (2011b) Simple approach to carboxyl-rich materials through low-temperature heat treatment of hydrothermal carbon in air. Appl Surf Sci 257:8686–8691. https://doi.org/10.1016/j.apsusc.2011.05.048

Chen S, Rotaru A-E, Shrestha PM et al (2014) Promoting interspecies electron transfer with biochar. Sci Rep 4:5019. https://doi.org/10.1038/srep05019

Chia CH, Singh BP, Joseph S, Graber ER, Munroe P (2014) Characterization of an enriched biochar. J Anal Appl Pyrol 108:26–34

Chipera SJ, Bish DL (2002) Thermal evolution of fluorine from smectite and kaolinite. Clays Clay Miner 50:38–46. https://doi.org/10.1346/000986002761002658

Crombie K, Mašek O, Sohi SP et al (2013) The effect of pyrolysis conditions on biochar stability as determined by three methods. GCB Bioenergy 5:122–131. https://doi.org/10.1111/gcbb.12030

Deen KM, Asselin E (2016) Differentiation of the non-faradaic and pseudocapacitive electrochemical response of graphite felt/CuFeS2 composite electrodes. Electrochim Acta 212:979–991. https://doi.org/10.1016/j.electacta.2016.07.083

Dehkhoda AM, Ellis N, Gyenge E (2014) Electrosorption on activated biochar: effect of thermo-chemical activation treatment on the electric double layer capacitance. J Appl Electrochem 44:141–157. https://doi.org/10.1007/s10800-013-0616-4

Deng Y, Xie Y, Zou K, Ji X (2015) Review on recent advances in nitrogen-doped carbons: preparations and applications in supercapacitors. J Mater Chem A 4:1144–1173. https://doi.org/10.1039/C5TA08620E

Dubé CD, Guiot SR (2015) Direct interspecies electron transfer in anaerobic digestion: a review. In: Guebitz G, Bauer A, Bochmann G, Gronauer A, Weiss S (eds) Biogas science and technology. Advances in biochemical engineering/biotechnology, vol 151. Springer, Cham, pp 101–115

Fang B, Binder L (2007) Influence of hydrophobisation of carbon surface on electrochemical capacitor performance. J Electroanal Chem 609:99–104. https://doi.org/10.1016/j.jelechem.2007.06.017

Fang G, Gao J, Liu C et al (2014) Key role of persistent free radicals in hydrogen peroxide activation by biochar: implications to organic contaminant degradation. Environ Sci Technol 48:1902–1910. https://doi.org/10.1021/es4048126

Fang G, Liu C, Gao J et al (2015) Manipulation of persistent free radicals in biochar to activate persulfate for contaminant degradation. Environ Sci Technol 49:5645–5653. https://doi.org/10.1021/es5061512

Gabhi RS, Kirk DW, Jia CQ (2017) Preliminary investigation of electrical conductivity of monolithic biochar. Carbon 116:435–442. https://doi.org/10.1016/j.carbon.2017.01.069

Gai X, Wang H, Liu J et al (2014) Effects of feedstock and pyrolysis temperature on biochar adsorption of ammonium and nitrate. PLoS ONE. https://doi.org/10.1371/journal.pone.0113888

Harvey OR, Herbert BE, Kuo LJ, Louchouarn P (2012) Generalized two-dimensional perturbation correlation infrared spectroscopy reveals mechanisms for the development of surface charge and recalcitrance in plant-derived biochars. Environ Sci Technol 46:10641–10650. https://doi.org/10.1021/es302971d

Hasegawa G, Deguchi T, Kanamori K et al (2015) High-level doping of nitrogen, phosphorus, and sulfur into activated carbon monoliths and their electrochemical capacitances. Chem Mater 27:4703–4712. https://doi.org/10.1021/acs.chemmater.5b01349

Heller-Kallai L (1997) The nature of clay volatiles and condensates and the effect on their environment—a review. J Therm Anal 50:145–156. https://doi.org/10.1007/bf01979557

Heller-Kallai L, Miloslavski I (1992) Reactions between clay volatiles and calcite reinvestigated. Clays Clay Miner 40:522–530. https://doi.org/10.1346/CCMN.1992.0400505

Hsieh CT, Teng H (2002) Influence of oxygen treatment on electric double-layer capacitance of activated carbon fabrics. Carbon 40:667–674. https://doi.org/10.1016/S0008-6223(01)00182-8

Huff MD, Lee JW (2016) Biochar-surface oxygenation with hydrogen peroxide. J Environ Manage 165:17–21. https://doi.org/10.1016/j.jenvman.2015.08.046

Husson O (2013) Redox potential (Eh) and pH as drivers of soil/plant/microorganism systems: a transdisciplinary overview pointing to integrative opportunities for agronomy. Plant Soil 362(1–2):389–417

Husson O, Husson B, Brunet A, Babre D, Alary K, Sarthou JP et al (2016) Practical improvements in soil redox potential (Eh) measurement for characterisation of soil properties. Application for comparison of conventional and conservation agriculture cropping systems. Anal Chim Acta 906:98–109

Jagtoyen M, Thwaites M, Stencel J et al (1992) Adsorbent carbon synthesis from coals by phosphoric acid activation. Carbon 30:1089–1096. https://doi.org/10.1016/0008-6223(92)90140-R

Jassal RS, Johnson MS, Molodovskaya M et al (2015) Nitrogen enrichment potential of biochar in relation to pyrolysis temperature and feedstock quality. J Environ Manage 152:140–144. https://doi.org/10.1016/j.jenvman.2015.01.021

Jiang J, Kappler A (2008) Kinetics of microbial and chemical reduction of humic substances: implications for electron shuttling. Environ Sci Technol 42:3563–3569. https://doi.org/10.1021/es7023803

Jiang J, Zhang L, Wang X et al (2013) Highly ordered macroporous woody biochar with ultra-high carbon content as supercapacitor electrodes. Electrochim Acta 113:481–489. https://doi.org/10.1016/j.electacta.2013.09.121

Jindo K, Suto K, Matsumoto K et al (2012) Chemical and biochemical characterisation of biochar-blended composts prepared from poultry manure. Bioresour Technol 110:396–404. https://doi.org/10.1016/j.biortech.2012.01.120

Joseph SD, Camps-Arbestain M, Lin Y et al (2010) An investigation into the reactions of biochar in soil. Aust J Soil Res 48(7):501–515

Joseph S, Graber ER, Chia C, Munroe P, Donne S, Thomas T et al (2013) Shifting paradigms: development of high-efficiency biochar fertilizers based on nano-structures and soluble components. Carbon Manag 4(3):323–343

Joseph S, Husson O, Graber ER et al (2015) The electrochemical properties of biochars and how they affect soil redox properties and processes. Agronomy 5:322–340. https://doi.org/10.3390/agronomy5030322

Kalinke C, Mangrich AS, Marcolino-Junior LH, Bergamini MF (2016) Carbon paste electrode modified with biochar for sensitive electrochemical determination of paraquat. Electroanalysis 28:764–769. https://doi.org/10.1002/elan.201500640

Kan T, Strezov V, Evans TJ (2016) Lignocellulosic biomass pyrolysis: a review of product properties and effects of pyrolysis parameters. Renew Sustain Energy Rev 57:126–1140

Kappler A, Wuestner ML, Ruecker A et al (2014) Biochar as an electron shuttle between bacteria and Fe(III) minerals. Environ Sci Technol Lett 1:339–344. https://doi.org/10.1021/ez5002209

Keiluweit M, Nico PS, Johnson M, Kleber M (2010) Dynamic molecular structure of plant biomass-derived black carbon (biochar). Environ Sci Technol 44:1247–1253. https://doi.org/10.1021/es9031419

Khanmohammadi Z, Afyuni M, Mosaddeghi MR (2015) Effect of pyrolysis temperature on chemical and physical properties of sewage sludge biochar. Waste Manag Res 33:275–283. https://doi.org/10.1177/0734242X14565210

Klüpfel L, Keiluweit M, Kleber M, Sander M (2014) Redox properties of plant biomass-derived black carbon (biochar). Environ Sci Technol 48:5601–5611. https://doi.org/10.1021/es500906d

Kouzuma A, Kato S, Watanabe K (2015) Microbial interspecies interactions: recent findings in syntrophic consortia. Front Microbiol 6:477

Lee JW, Buchanan AC, Evans BR, Kidder M (2013a) Oxygenation of biochar for enhanced cation exchange capacity. In: Lee J (ed) Advanced biofuels and bioproducts. Springer, New York, NY, pp 35–45

Lee YH, Chang KH, Hu CC (2013b) Differentiate the pseudocapacitance and double-layer capacitance contributions for nitrogen-doped reduced graphene oxide in acidic and alkaline electrolytes. J Power Sources 227:300–308. https://doi.org/10.1016/j.jpowsour.2012.11.026

Lehmann J, Joseph S (2015) Biochar for environmental management. Routledge, Abingdon

Lehmann J, Gaunt J, Rondon M (2006) Bio-char sequestration in terrestrial ecosystems—a review. Mitig Adapt Strateg Glob Change 11:403–427

Li Y, Yu S, Strong J, Wang H (2012) Are the biogeochemical cycles of carbon, nitrogen, sulfur, and phosphorus driven by the “FeIII–FeII redox wheel” in dynamic redox environments? J Soils Sediments 12:683–693. https://doi.org/10.1007/s11368-012-0507-z

Li Y, Shao J, Wang X et al (2014) Characterization of modified biochars derived from bamboo pyrolysis and their utilization for target component (furfural) adsorption. Energy Fuels 28:5119–5127. https://doi.org/10.1021/ef500725c

Liao S, Pan B, Li H et al (2014) Detecting free radicals in biochars and determining their ability to inhibit the germination and growth of corn, wheat and rice seedlings. Environ Sci Technol 48:8581–8587. https://doi.org/10.1021/es404250a

Lin Y, Munroe P, Joseph S, Kimber S, Van Zwieten L (2012) Nanoscale organo-mineral reactions of biochars in ferrosol: an investigation using microscopy. Plant Soil 357(1–2):369–380

Lindsay WL (1988) Solubility and redox equilibria of iron compounds in soils. In: Stucki JW, Goodman BA, Schwertmann U (eds) Iron in soils and clay minerals. NATO ASI Series (Series C: mathematical and physical sciences), vol 217. Springer, Dordrecht, pp 37–62

Lindsay WL, Schwab AP (1982) The chemistry of iron in soils and its availability to plants. J Plant Nutr 5:821–840. https://doi.org/10.1080/01904168209363012

Lithoxoos GP, Labropoulos A, Peristeras LD et al (2010) Adsorption of N2, CH4, CO and CO2 gases in single walled carbon nanotubes: a combined experimental and Monte Carlo molecular simulation study. J Supercrit Fluids 55:510–523. https://doi.org/10.1016/j.supflu.2010.09.017

Liu G, Li X, Lee J-W, Popov BN (2011) A review of the development of nitrogen-modified carbon-based catalysts for oxygen reduction at USC. Catal Sci Technol 1:207. https://doi.org/10.1039/c0cy00053a

Liu J, Jiang X, Shen J, Zhang H (2015a) Influences of particle size, ultraviolet irradiation and pyrolysis temperature on stable free radicals in coal. Powder Technol 272:64–74. https://doi.org/10.1016/j.powtec.2014.11.017

Liu WJ, Jiang H, Yu HQ (2015b) Development of biochar-based functional materials: toward a sustainable platform carbon material. Chem Rev 115:12251–12285

Liu WJ, Li WW, Jiang H, Yu HQ (2017) Fates of chemical elements in biomass during its pyrolysis. Chem Rev 117:6367–6398

Lu T, Yuan H, Wang Y et al (2016) Characteristic of heavy metals in biochar derived from sewage sludge. J Mater Cycles Waste Manag 18:725–733. https://doi.org/10.1007/s10163-015-0366-y

Madej J, Hilber I, Bucheli TD, Oleszczuk P (2016) Biochars with low polycyclic aromatic hydrocarbon concentrations achievable by pyrolysis under high carrier gas flows irrespective of oxygen content or feedstock. J Anal Appl Pyrolysis 122:365–369. https://doi.org/10.1016/j.jaap.2016.09.005

Mauter MS, Elimelech M (2008) Environmental applications of carbon-based nanomaterials. Environ Sci Technol 42:5843–5859

Mochidzuki K, Soutric F, Tadokoro K et al (2003) Electrical and physical properties of carbonized charcoals. Ind Eng Chem Res 42:5140–5151. https://doi.org/10.1021/ie030358e

Mohan D, Pittman CU, Steele PH (2006) Pyrolysis of wood/biomass for bio-oil: a critical review. Energy Fuels 20:848–889

Mohan D, Sarswat A, Ok YS, Pittman CU (2014) Organic and inorganic contaminants removal from water with biochar, a renewable, low cost and sustainable adsorbent—a critical review. Bioresour Technol 160:191–202. https://doi.org/10.1016/j.biortech.2014.01.120

Mukome FND, Zhang X, Silva LCR et al (2013) Use of chemical and physical characteristics to investigate trends in biochar feedstocks. J Agric Food Chem 61:2196–2204. https://doi.org/10.1021/jf3049142

Nover G, Stoll JB, von der Gönna J (2005) Promotion of graphite formation by tectonics stress—a laboratory experiment. Geophys J Int 160:1059–1067. https://doi.org/10.1111/j.1365-246X.2005.02395.x

Pandolfo AG, Hollenkamp AF (2006) Carbon properties and their role in supercapacitors. J Power Sources 157:11–27

Peretyazhko T, Sposito G (2006) Reducing capacity of terrestrial humic acids. Geoderma 137:140–146. https://doi.org/10.1016/j.geoderma.2006.08.004

Polovina M, Babić B, Kaluderović B, Dekanski A (1997) Surface characterization of oxidized activated carbon cloth. Carbon 35:1047–1052. https://doi.org/10.1016/S0008-6223(97)00057-2

Porada S, Weinstein L, Dash R et al (2012) Water desalination using capacitive deionization with microporous carbon electrodes. ACS Appl Mater Interfaces 4:1194–1199. https://doi.org/10.1021/am201683j

Prévoteau A, Ronsse F, Cid I et al (2016) The electron donating capacity of biochar is dramatically underestimated. Sci Rep 6:32870. https://doi.org/10.1038/srep32870

Prost K, Borchard N, Siemens J et al (2012) Biochar affected by composting with farmyard manure. J Environ Qual 42:164–172. https://doi.org/10.2134/jeq2012.0064

Purevsuren B, Avid B, Tesche B, Davaajav Y (2003) A biochar from casein and its properties. J Mater Sci 38:2347–2351. https://doi.org/10.1023/A:1023980429410

Quin P, Joseph S, Husson O, Donne S, Mitchell D, Munroe P et al (2015) Lowering N2O emissions from soils using eucalypt biochar: the importance of redox reactions. Sci Rep 5:16773

Rafiq MK, Bachmann RT, Rafiq MT et al (2016) Influence of pyrolysis temperature on physico-chemical properties of corn stover (Zea mays L.) biochar and feasibility for carbon capture and energy balance. PLoS ONE. https://doi.org/10.1371/journal.pone.0156894

Rajapaksha AU, Chen SS, Tsang DCW et al (2016) Engineered/designer biochar for contaminant removal/immobilization from soil and water: potential and implication of biochar modification. Chemosphere 148:276–291

Rawal A, Joseph SD, Hook JM et al (2016) Mineral-biochar composites: molecular structure and porosity. Environ Sci Technol 50:7706–7714. https://doi.org/10.1021/acs.est.6b00685

Raymundo-Piñero E, Leroux F, Béguin F (2006) A high-performance carbon for supercapacitors obtained by carbonization of a seaweed biopolymer. Adv Mater 18:1877–1882. https://doi.org/10.1002/adma.200501905

Rechberger MV, Kloss S, Rennhofer H et al (2017) Changes in biochar physical and chemical properties: accelerated biochar aging in an acidic soil. Carbon 115:209–219. https://doi.org/10.1016/j.carbon.2016.12.096

Rhim YR, Zhang D, Fairbrother DH et al (2010) Changes in electrical and microstructural properties of microcrystalline cellulose as function of carbonization temperature. Carbon 48:1012–1024. https://doi.org/10.1016/j.carbon.2009.11.020

Roden EE (2012) Microbial iron-redox cycling in subsurface environments. Biochem Soc Trans 40:1249–1256. https://doi.org/10.1042/BST20120202

Saini JK, Saini R, Tewari L (2015) Lignocellulosic agriculture wastes as biomass feedstocks for second-generation bioethanol production: concepts and recent developments. 3. Biotech 5:337–353

Saleh S, Kamarudin KB, Ghani WAWAK, Kheang LS (2016) Removal of organic contaminant from aqueous solution using magnetic biochar. Proc Eng 148:228–235

Sander M, Hofstetter TB, Gorski CA (2015) Electrochemical analyses of redox-active iron minerals: a review of nonmediated and mediated approaches. Environ Sci Technol 49:5862–5878. https://doi.org/10.1021/acs.est.5b00006

Saquing JM, Yu YH, Chiu PC (2016) Wood-derived black carbon (biochar) as a microbial electron donor and acceptor. Environ Sci Technol Lett 3:62–66. https://doi.org/10.1021/acs.estlett.5b00354

Scott DT, Mcknight DM, Blunt-Harris EL et al (1998) Quinone moieties act as electron acceptors in the reduction of humic substances by humics-reducing microorganisms. Environ Sci Technol 32:2984–2989. https://doi.org/10.1021/es980272q

Seredych M, Bandosz TJ (2013) S-doped micro/mesoporous carbon–graphene composites as efficient supercapacitors in alkaline media. J Mater Chem A 1:11717. https://doi.org/10.1039/c3ta12252b

Shao Y, Zhang S, Engelhard MH et al (2010) Nitrogen-doped graphene and its electrochemical applications. J Mater Chem 20:7491. https://doi.org/10.1039/c0jm00782j

Sharma VK, Canditelli M, Fortuna F, Cornacchia G (1997) Processing of urban and agro-industrial residues by aerobic composting: review. Energy Convers Manag 38:453–478. https://doi.org/10.1016/S0196-8904(96)00068-4

Shi L, Dong H, Reguera G et al (2016) Extracellular electron transfer mechanisms between microorganisms and minerals. Nat Rev Microbiol 14:651–662. https://doi.org/10.1038/nrmicro.2016.93

Shrestha S, Morse N, Mustain WE (2014) Effect of surface chemistry on the double layer capacitance of polypyrrole-derived ordered mesoporous carbon. RSC Adv 4:47039–47046. https://doi.org/10.1039/C4RA09119A

Si W, Zhou J, Zhang S et al (2013) Tunable N-doped or dual N, S-doped activated hydrothermal carbons derived from human hair and glucose for supercapacitor applications. Electrochim Acta 107:397–405. https://doi.org/10.1016/j.electacta.2013.06.065