Abstract

In this work, the isothermal decomposition kinetics of a promising high-energy dense nitrated cellulose carbamate (NCC) was investigated, for the first time, using vacuum stability test (VST) at different isothermal temperatures. The kinetic triplet of NCC was calculated by model-fitting and model-free methods, and compared to that of the conventional nitrocellulose (NC). VST results showed that the gas pressure of the studied energetic cellulose-rich materials (NCC and NC) increased with the increase in time test, which is found more pronounced for NCC compared to NC. Furthermore, thermo-kinetic findings demonstrated that the Arrhenius parameters determined by the two performed kinetic approaches are in good concordance. Indeed, the apparent activation energy of NCC is found to be around 141 kJ/mol, which is lower than that of the common NC (Eα = 152 kJ/mol). The model-fitting approach revealed that the mechanism of isothermal decomposition of NCC and NC is controlled by a chemical process. Besides, a strong linear relationship between the activation energy and the logarithm of the pre-exponential factor is observed. This work provides valuable guidance for the isothermal decomposition kinetics of energetic cellulose-rich materials and further supports and complements their kinetic database.

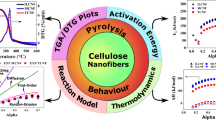

Graphical abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

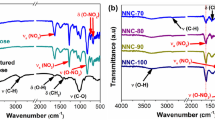

The new trend in the area of energetic materials is to explore natural polymers as candidates for the development of new high-energy dense polysaccharides [1,2,3]. Cellulose, among numerous biopolymers, is the most abundant carbohydrate polymer found in the Earth [4, 5]. The chemical structure of cellulose consists of a linear chain composed of repeated anhydro-D-glucose moieties functionalized with three hydroxyls (OH) groups positioned on the ring sites C2, C3, and C6. These reactive OH functions can be substituted by energetic functional groups such as nitrate ester, nitrocarbamate, nitramine, azide, and nitrogen-containing heterocycles (triazole, tetrazole, etc.) to design advanced cellulose-based energetic materials [6, 7]. As the first energetic cellulose-rich material, nitrocellulose (NC) still finds widespread practical applications in both civilian and military areas owing to its desirable mechanical properties, energetic performance, and ability to interact with other materials [8]. Nevertheless, despite nearly two centuries of research on NC, some serious problems of this important material including elevated shock sensitivity and suboptimal combustion performance have prompted researchers to investigate alternative energy-rich cellulosic polymers with desired mechanical sensitivities, thermal stability, and energy levels. In this context, our research group has recently designed and investigated several new cellulose-rich polymers with outstanding features [9,10,11]. Among those of interest, nitrated cellulose carbamate (NCC), as an emerging high-energy dense cellulosic polymer, has been shown to possess improved density (1.698–1.716 g/cm3), nitrogen content (15.14–15.67%, w/w), heat of combustion (− 2365 cal/g), and impact sensitivity (40 J) compared to those of traditional NC [12]. These attractive characteristics make it suitable for multiple energetic applications such as rocket propellants, gun propellants, explosives, and others [6]. However, cellulose-based energetic materials suffer from a high risk of thermal runaway during decomposition which can limit their storage and application [13, 14]. Therefore, studying the thermo-kinetic behavior of such energetic materials is a necessary and important aspect for understanding their thermal runaway, and for facilitating the prevention and mitigation of related accidents. In previous studies, researchers delved into thermo-kinetic analysis of nitrated cellulosic polymers and summarized some useful conclusions [15, 16]. In one study, Luo et al. [17], computed the Arrhenius parameters of NC by conducting isothermal decomposition dynamics research using a specific instrument. They reported an average activation energy (Eα) of 144.7 kJ/mol and a pre-exponential factor (lnA) of 27.39. Wei and coworkers conducted comprehensive kinetic analyses on the stable decomposition and combustion of cellulose nitrate, with the conclusion that the Eα for combustion (89.5–97.5 kJ/mol) is lower than that for stable decomposition (123.3–145.8 kJ/mol) [14]. Recently, Gao et al. [13], determined the kinetic parameters for the isothermal and non-isothermal decomposition of NC using model-free and model-fitting methods. The authors mentioned that NC is more susceptible to decomposition under non-isothermal conditions, and its pyrolysis mechanism under heating rates is controlled by the third-order reaction model. In another recent work, Tarchoun et al. analyzed the non-isothermal decomposition kinetics of nitrated carbamate-functionalized cellulose using isoconversional kinetic approaches [12]. Their research revealed that nitrated cellulose carbamate exhibits smaller Arrhenius parameter values when compared to conventional nitrocellulose (160–163 kJ/mol vs. 172–173 kJ/mol), and its decomposition mechanism can be described with the Avrami–Erofeev autocatalytic nucleation process. In summary, the kinetic data of energetic cellulose-rich materials and their reaction mechanisms can be affected by the experimental conditions, analytical techniques, and the used kinetic approaches. In addition, to the best knowledge of the authors, there is no report on the isothermal decomposition kinetics of emergent NCC. Therefore, it is seen of interest to investigate the thermal decomposition kinetics of this energetic polymer by employing diverse research methods and test conditions for effective hazard control.

Typically, thermal analysis techniques are regarded as the most effective methods for elucidating the decomposition kinetic features of energetic materials [18, 19]. Compared to non-isothermal research methods, isothermal kinetics can more effectively and precisely depict slow chemical reactions due to the relatively low-temperature testing [20, 21]. Herein, vacuum stability test (VST), which is based on measuring the pressure of the gas released from the sample over time, was used to elucidate the isothermal decomposition kinetics of the designed NCC. At present, VST has been sucssufuly applied to compute the isothermal decomposition kinetics of stabilized NC [22, 23], double base rocket propellants [24], and some plastic bonded explosives [25, 26].

In this study, we investigate the isothermal decomposition kinetics of a high-energy dense cellulosic polymer called nitrated cellulose carbamate. The obtained kinetic results are then compared with those of traditional nitrocellulose. Based on the conducted VST experiments at different temperatures (60, 70, 80, 90, and 100 °C), the Arrhenius parameters and the most probable reaction model of NCC and NC were determined using model-fitting and model-free methods. The results of this study can further deepen the understanding of the thermochemical kinetics of cellulose-based energetic materials.

Experimental section

Materials

NC and NCC with nitrogen contents of 12.70% and 15.21%, respectively, were previously synthesized by our research group according to the procedures reported elsewhere [12]. Before analysis, samples were dried in a vacuum oven at 60 °C for 2 h, and then stored in a desiccator for testing.

Experimental technique

The vacuum stability test was performed in a STABIL apparatus (OZM Research, Pardubice, Czech Republic), as shown in Fig. S1. During this test, a dried sample mass of 2.000 ± 0.001 g was introduced into a glass tube, after which the internal pressure of the tube was reduced to 0.250 kPa using a vacuum pump. Next, the sealed reaction tube was placed into the heating block and heated isothermally at different test temperatures of 60, 70, 80, 90, and 100 °C for 48 h. Each isothermal experiment was repeated three times, and the obtained data were found to be highly reproducible. Pressure transducers and a computer are used to record the relationship of the gas pressure evolved by the sample versus heating time. It is worth noting that before conducting the VST measurements, the heating block was calibrated using silicon oil provided by the manufacturer, OZM Research. This calibration step ensured accurate and reliable temperature control throughout the measurements.

Kinetic analysis

Investigating thermally stimulated reactions in a condensed phase typically involves representing the reaction rate as a function of the Arrhenius rate constant (k(T)), which varies only with temperature (T), and the differential form the reaction model that depends on the extent of conversion (α) [27].

The integral rate law can be determined by integrating Eq. (1):

Here \(g\left(\alpha \right)\) is the integral form of the reaction model, \(A\) is the pre-exponential factor, Ea is the activation energy, R is the gas constant, and t is the time to reach a certain degree of conversion.

In the case of VST data, the extent of conversion (0 ≤ α ≤ 1) is defined as follows [23]:

Here P is the pressure of the gas generated at a certain time, P0 refers to the initial pressure (P0 = 0.250 kPa), and PT denotes the total gas pressure. It is essential to highlight that the raw data from the VST underwent a smoothing process through a nonlinear curve fit before computing the values of the extent of conversion. This preprocessing step is crucial to prevent potential fluctuations in the extent of conversion values caused by noise in the VST signal [22].

Based on these rate laws, kinetic parameters can be derived from isothermal data using model-fitting or model-free (isoconversional) approaches. In the model-fitting method, the mechanism is postulated from 41 types of kinetic models at the beginning of the data treatment [28]. By applying Eq. (2), 41 distinct curves of \(g\left(\alpha \right)\) versus time are generated. The optimal form of \(g\left(\alpha \right)\) is then determined by selecting the fitting curve with the highest correlation coefficient and the lowest intercept. The Arrhenius rate constant at each VST temperature is determined by analyzing the slope of each selected g(α) vs. t plot. The Arrhenius parameters (Ea and A) are then assessed using the logarithmic form of the Arrhenius equation [20]:

The model-free approach is based on the isoconversional principle, which states that the reaction rate at a constant extent of conversion is only a function of temperature [19]. Consequently, the Arrhenius parameters can be obtained without making any assumptions about the reaction model. Under isothermal conditions, the logarithmic form of Eq. (2) is applied as follows:

At each conversion α, Ea is obtained from the slope of a plot of \(-ln{ t}_{\alpha ,i}\) vs. Ti−1. After that, the A values are evaluated using the kinetic compensation effect, which has been broadly discussed in the literature [29,30,31,32]. This approach suggests that the Arrhenius parameters show a mutual dependence between Ea and A as follows:

Here a and b are constants, and the subscript i denotes the selected integral model to compute \(\text{ln}{A}_{i}\) and \({E}_{i}\) pairs using Eq. 2. Therefore, for a set of 41 gi(α) models reported elsewhere [28], 41 pairs of \(\text{ln}{A}_{i}\) and \({E}_{i}\) are determined and fitted to Eq. 6 to obtain the parameters a and b [33]. The resulting correlation coefficients r2 were higher than 0.998. Once the correlation parameters a and b have been evaluated, the Ea values, derived from Eq. 5, are substituted for \({E}_{i}\) in Eq. 6 to estimate the corresponding \(\text{ln}A\) values. Simulations by Vyazovkin have outlined the excellent accuracy of this approach [34]. It is important to note that all kinetic calculations were performed using a graphical user interface (GUI) compiled under MATLAB software as reported in our previous work [22].

Results and discussion

Gases pressure evolution process

The evolution of the pressure of the evolved gases during the isothermal decomposition of the investigated cellulose-rich polymers within the temperature range of 60–100 °C is illustrated in Fig. 1. The foremost observation is that an elevation in the temperature test results in an increased release of gases, emphasizing the impact of temperature on accelerating the thermolysis process of the studied nitrated cellulosic materials. Similar findings about the effect of temperature tests on the gas evolution of energetic materials are reported elsewhere [25, 35]. It can be also inferred from Fig. 1 that the evolved pressure for both NC and NCC increases with prolonged reaction time. This consistent behavior is evident in all isothermal temperature tests, suggesting a similarity in the mechanism governing the proceeding reaction across the various applied isothermal temperatures [36, 37]. At the beginning of the test, NC and NCC display a very fast pressure evolution trend, which is mainly due to the evaporation of moisture accompanied by the partial thermolytic split-off of explosophoric and thermally unstable O–NO2 and N–NO2 groups within the condensed phase of NC and NCC [16, 38]. Subsequently, a gradual evolution of pressure over test time is observed, with this phenomenon being more pronounced for NCC compared to NC. This behavior is attributed to the main decomposition stage characterized by the total scission of intramolecular chemical bonds and the thermo-oxidative decomposition of molecular chains through autocatalytic reaction pathways, resulting in the formation of a wider variety of gases [16, 39]. Furthermore, the higher pressure evolution rate of NCC in comparison to NC is attributed to the presence of nitrogen-rich O–NO2 and nitrocarbamate (CO–NH–NO2) groups, leading to more thorough and rapid decomposition. These findings are consistent and supported by evidence from previous research papers, which highlighted that the combination of multiple explosophoric nitrogen-rich functions on the same cellulosic backbone could ultimately accelerate the degradation process [11, 12].

Determination of the isothermal kinetic parameters

The obtained isothermal VST data for the investigated energetic NC and NCC polymers were used to compute their kinetic triplet, involving, the activation energy Ea, the frequency factor \(\text{ln}A\), and and the best fitting reaction model g(α) [22, 24]. It is important to note that the Ea is defined as the minor amount of energy required to initiate the decomposition reaction of the reactants; while the \(\text{ln}A\) reflects the rate of molecular collisions at a certain temperature upon the thermolysis reaction, and a higher frequency factor indicates a higher reactivity.

For the model-fitting approach, Table 1 provides the best-fitting kinetic parameters obtained from the isothermal decomposition of both NC and NCC, along with their corresponding uncertainties. As explained earlier, the maximum correlation coefficient (r2) is used as a parameter for selecting the best model fitting. The corresponding r2 values are also given in Table 1. By using the different g(α) models (among the available 41 models), it is found that the best model that fits the data of NC and NCC is a chemical process (G2 and G3). The high accuracy of the obtained kinetic parameters is validated by the strong regression coefficient exceeding 0.997 [34]. Furthermore, the plot of average conversion as a function of a reduced time variable t/t0.9, where t0.9 is the time required to reach a specified conversion of 0.9, is widely used in solid-state kinetics to check the accordance of the chosen model with the experimental data [37, 40]. The reduced time plots for the thermal decomposition of NC and NCC are shown in Fig. 2. The experimental data, which are the average of five isothermal experiments performed at 60, 70, 80, 90, and 100 °C, are used in this analysis. As revealed in Fig. 2, the data computed from kinetic modeling are in good agreement with the experimental data, corroborating the consistency of the obtained kinetic triplet.

Besides that, the calculated Arrhenius parameters for NC are determined to be Ea (kJ/mol) = 151.4 and \(\text{ln}(A/{s}^{-1})\)= 35.34, while for NCC, the corresponding values are Ea (kJ/mol) = 140.3 kJ/mol and \(\text{ln}(A/{s}^{-1})\)= 31.70. This expected decrease in the Arrhenius parameters of NCC with respect to NC is caused by the coexistence of unstable nitrate esters and nitrocarbamate groups on the same cellulosic backbone. The homolytic splitting of these groups generates more heat and a higher number of radicals and oxidizing species, thereby accelerating the beginning of the degradation process.

In the case of the model-free method, which is based on the isoconversional theory, the Arrhenius parameters are calculated within a conversion range of 0.05–0.95, with a step size of 0.05. Fig. 3 depicts the evolution of Ea and \(\text{ln}A\) as a function of the conversion, while the average values of these parameters, along with their corresponding confidence intervals, are listed in Table 1. The main observation from Table 1 is that the Arrhenius parameters calculated using the two kinetic approaches (fitting and free models) are in good agreement with each other. This is reflected by a maximum relative deviation of less than 10%, affirming the reliability and consistency of the implemented computations. This result supports the conclusions reported by Vyazovkin et al. [37], who stipulated that utilizing the fitting model with isothermal data yields unambiguous values for the Arrhenius parameters. Furthermore, it is interesting to point out that the uncertainties in evaluating the Ea and \(\text{ln}A\) fall within the limits recommended by the International Confederation for Thermal Analysis and Calorimetry (ICTAC) (≤ ± 10%) [41]. Another important observation from Fig. 3 is that evaluating the pre-exponential factor as a function of conversion presents the same behavior as the activation energy, which is mainly explained by the compensation effect since the employed model-free method is based on this principle. According to ICTAC instructions, it is recommended to consider the dependency of Ea with α when the difference between the highest and the lowest values of the activation energy surpasses 20% of the mean activation energy value [41]. In our case, this deviation has been found to reach the value of 61% for NC and 60% for NCC supporting the fact that their thermolysis follows a multi-step decomposition process. In fact, it is obvious from Fig. 3 that the dependence of Ea versus α for both NC and NCC reveals two distinct stages, aligning with the observed variations in the rate of gas release. In the initial stage of decomposition, the Ea increased with different rates until reaching a maximum value of around Ea = 187.1 kJ/mol at α = 0.65 for NC and Ea = 173.6 kJ/mol at α = 0.55 for NCC. In the subsequent decomposition stage, the activation energy for thermolysis gradually decreased to approximately Ea = 119.8 kJ/mol for NC and Ea = 102.3 kJ/mol for NCC when α = 0.95. The obtained outcomes demonstrate that the rate of the isothermal decomposition of the investigated energetic cellulose-rich materials (NC and NCC) is much faster at the initial conversion. This behavior is mainly related to the cleavage of energetic O-NO2 groups and N-NO2 of nitrocarbamate moieties, followed by the breaking of intramolecular chemical bonds in the condensed phase of NC and NCC. This initial decomposition generates a high amount of highly reactive radicals and oxidizing species [16]. However, the downtrends in Ea, in the second stage, mainly corresponded to the thermo-oxidative destruction of the polymeric framework through autocatalytic reaction pathways, accompanied by the generation of multiple gases. It is important to note that during the thermolysis of NC and NCC, the activation complex is formed as the material undergoes a series of bond-breaking and radical-forming reactions [42, 43]. Initially, the thermolytic splitting of explosophoric and thermally unstable nitrate ester and nitrocarbamate groups occurs, leading to the formation of nitrogen oxides and alkoxyl radicals. These reactive intermediates play a critical role in further decomposition by promoting the cleavage of intermolecular chemical bonds within the NC and NCC matrices [44, 45]. This process leads to the thermo-oxidative decomposition of nitrated cellulosic chains through autocatalytic reaction pathways to form various gases such as NO, NO2, CO2, H2O, CH4, HCN, CH2O, and HCOOH [16, 43]. For comparison purposes, the mean Ea and \(\text{ln}A\) values could be considered for discussion, and such an approach has been found to be highly consistent [46, 47]. Hence, the Arrhenius parameters obtained in this study are compared with those derived from other methods found in the literature, as presented in Table 2. Unfortunately, it should be noted that there are no existing studies in the literature on the thermolysis of nitrated cellulose carbamate, and the only available data has recently been reported by our research group [12]. It is evident from the data presented in Table 2 that the thermal decomposition activation energies of the investigated NC and NCC are consistent with the most of the reported range of thermolysis energy found for nitrated cellulose (140–190 kJ/mol). Moreover, the activation energy of NCC, computed in this study using isothermal VST data, is found to be slightly lower than that determined through non-isothermal DSC experiments [12]. Herein, the main factors contributing to the recorded differences in the kinetic parameters include sample characteristics, cellulose sources, nitration conditions, variations in nitrogen content, the analytical technique employed, experimental conditions, and the kinetic modeling approach used. Taking NC as a reference, it is evident that the thermal reactivity could be further promoted by incorporating energy-rich nitrocarbamate, resulting in a reduction in the thermolysis activation energy of approximately 10 kJ/mol. This finding can be also explained by the effect of nitrogen content in which its increase promotes the beginning of the thermolysis process as shown in previous reports [48, 49].

On the other hand, the compensation effect could be effectively emphasized by investigating the isokinetic relationship, a method extensively utilized for the study of physical and chemical processes [54,55,56]. This relationship is established when different lines on the Arrhenius plot intersect at a single point, typically identified as the isokinetic temperature (Tiso). Therefore, Tiso represents the specific temperature at which the chemical reaction rates of NC and NCC should proceed at the same rate constant (Kiso). As can be seen from the plot of the rate constants as a function of temperature, depicted in Fig. 4, the Arrhenius plots for NC and NCC exhibit a common intersection point at Tiso = 91.9 °C (365.1 K). This finding serves as an indication that the reported kinetic compensation effect is genuine and not merely an experimental artifact, as the determined isokinetic temperature falls within the range of experimental temperatures [29, 57]. It can also be inferred from Fig. 4 that there is an increase in the decomposition reaction rates of NCC below the isokinetic temperature compared to those of NC. This behavior provides further evidence that NCC is more reactive than NC, and its isothermal reaction involves more activated molecules with a lower energy transition state [58, 59]. Therefore, the findings of this study can additionally reinforce and supplement the kinetic database of cellulose-based energetic materials.

Arrhenius plots of the reaction rate constants ln(k) at various test temperatures of 60, 70, 80, 90, and 100 °C for the thermal decomposition of NC and NCC, as determined by the Arrhenius equation (Eq. 4)

Conclusions

In summary, the present work investigates the isothermal decomposition kinetics of a promising energetic NCC for the first time using a vacuum stability test. Analysis of the recorded VST data reveals that NCC produces a higher gas-evolved pressure than conventional NC. Furthermore, it is revealed that the total pressures of both NCC and NC increase with testing temperatures, emphasizing the impact of temperature on accelerating the thermolysis process of nitrated cellulosic materials. The Arrhenius parameters and the best-fitting reaction model are computed based on isothermal VST experiments using both model-fitting and model-free methods. Computational results highlight that the average Arrhenius parameters, computed through both model-fitting and isoconversional methods, are consistent.

The apparent activation energy of emergent NCC (Ea = 141.1 kJ/mol) is found to be lower than the common thermolysis activation energy of traditional nitrocellulose, demonstrating its improved thermal reactivity. Moreover, both NC and NCC display an isothermal decomposition behavior predominantly governed by chemical reaction mechanisms. Additionally, the determination of the isokinetic behavior confirms the kinetic compensation effect between the activation energy values and those of the pre-exponential factors, corroborating the reliability of the predicted isothermal kinetic parameters. The knowledge gained in this study paves the way for the potential exploitation of VST to study the isothermal decomposition kinetics of energetic materials and offers a kinetic perspective on the safety of NCC for future research and applications.

Data availability

All data supporting the findings of this study are available within the article.

References

Kashcheyeva EI, Korchagina AA, Gismatulina YA, Gladysheva EK, Budaeva VV, Sakovich GV (2023) Simultaneous production of cellulose nitrates and bacterial cellulose from lignocellulose of energy crop. Polymers 16(1):42

Tarchoun AF, Trache D, Hamouche MA, Abdelaziz A, Boukeciat H, Chentir I, Touidjine S, Klapötke TM (2023) Elucidating the characteristics of a promising nitrate ester polysaccharide derived from shrimp shells and its blends with cellulose nitrate. Cellulose 30(8):4941–4955

Sahnoun N, Abdelaziz A, Trache D, Tarchoun AF, Bessa W, Mahdjoub AS, Thakur S (2023) Unrevealing the role of the sulfonitric media composition on the design and properties of potato starch-based nitrogen-rich biopolymer. Ind Crops Prod 205:117536

Etale A, Onyianta AJ, Turner SR, Eichhorn SJ (2023) Cellulose: a review of water interactions, applications in composites, and water treatment. Chem Rev 123(5):2016–2048

Tarchoun AF, Trache D, Hamouche MA, Abdelaziz A, Bessa W (2024) Extraction of nanocellulose—mechanical and chemical approaches. Elastomeric nanocellulose composites. Elsevier, Amsterdam, pp 15–40

Dou J, Xu M, Tan B, Lu X, Mo H, Wang B, Liu N (2022) Research progress of nitrate ester binders. FirePhysChem 3(1):54–77

Tarchoun AF, Trache D, Klapötke TM, Krumm B, Mezroua A, Derradji M, Bessa W (2021) Design and characterization of new advanced energetic biopolymers based on surface functionalized cellulosic materials. Cellulose 28(10):6107–6123

Morris E, Pulham CR, Morrison CA (2023) Structure and properties of nitrocellulose: approaching 200 years of research. RSC Adv 13(46):32321–32333

Tarchoun AF, Trache D, Klapötke TM, Khimeche K (2020) Tetrazole-functionalized microcrystalline cellulose: a promising biopolymer for advanced energetic materials. Chem Eng J 400:125960

Tarchoun AF, Trache D, Klapötke TM, Krumm B (2020) New insensitive nitrogen-rich energetic polymers based on amino-functionalized cellulose and microcrystalline cellulose: synthesis and characterization. Fuel 277:118258

Tarchoun AF, Trache D, Klapötke TM, Krumm B, Kofen M (2021) Synthesis and characterization of new insensitive and high-energy dense cellulosic biopolymers. Fuel 292:120347

Tarchoun AF, Trache D, Klapötke TM, Selmani A, Saada M, Chelouche S, Mezroua A, Abdelaziz A (2021) New insensitive high-energy dense biopolymers from giant reed cellulosic fibers: their synthesis, characterization, and non-isothermal decomposition kinetics. New J Chem 45(11):5099–5113

Gao X, Jiang L, Xu Q, Wu W-Q, Mensah RA (2020) Thermal kinetics and reactive mechanism of cellulose nitrate decomposition by traditional multi kinetics and modeling calculation under isothermal and non-isothermal conditions. Ind Crops Prod 145:112085

Wei R, Huang S, Weng J, Wang J, Wang C (2021) Comparative analysis of stable decomposition and combustion kinetics of nitrated cellulose. Cellulose 28(15):9613–9632

Tang Y, Li Z-P, Zhou H-L, Miao C-F, Jiang J-C, Huang A-C (2023) Thermal stability assessment of nitrocellulose by using multiple calorimetric techniques and advanced thermokinetics. J Thermal Anal Calorim 148(11):5029–5038

Chai H, Duan Q, Cao H, Li M, Sun J (2020) Effects of nitrogen content on pyrolysis behavior of nitrocellulose. Fuel 264:116853

Luo L, Jin B, Xiao Y, Zhang Q, Chai Z, Huang Q, Chu S, Peng R (2019) Study on the isothermal decomposition kinetics and mechanism of nitrocellulose. Polym Testing 75:337–343

Koga N, Vyazovkin S, Burnham AK, Favergeon L, Muravyev NV, Pérez-Maqueda LA, Saggese C, Sánchez-Jiménez PE (2023) ICTAC Kinetics Committee recommendations for analysis of thermal decomposition kinetics. Thermochim Acta 719:179384

Vyazovkin S, Burnham AK, Criado JM, Pérez-Maqueda LA, Popescu C, Sbirrazzuoli N (2011) ICTAC Kinetics Committee recommendations for performing kinetic computations on thermal analysis data. Thermochim Acta 520(1–2):1–19

Vyazovkin S, Wight CA (1998) Isothermal and non-isothermal kinetics of thermally stimulated reactions of solids. Int Rev Phys Chem 17(3):407–433

Luo L, Jin B, Chai Z, Huang Q, Chu S, Peng R (2019) Interaction and mechanism of nitrocellulose and N-methyl-4-nitroaniline by isothermal decomposition method. Cellulose 26:9021–9033

Chelouche S, Trache D, Tarchoun AF, Khimeche K (2019) Effect of organic eutectic on nitrocellulose stability during artificial aging. J Energ Mater 37(4):387–406

Trache D, Tarchoun AF, Chelouche S, Khimeche K (2019) New insights on the compatibility of nitrocellulose with aniline-based compounds. Propellants Exp Pyrotech 44(8):970–979

Chelouche S, Trache D, Tarchoun AF, Khimeche K, Mezroua A (2021) Stability assessment for double base rocket propellant during long natural/artificial aging using various methods and kinetic modeling. Materials research applications: select papers from JCH8-. Springer, Algeria

Elbeih A, Abd-Elghany M, Elshenawy T (2017) Application of vacuum stability test to determine thermal decomposition kinetics of nitramines bonded by polyurethane matrix. Acta Astronaut 132:124–130

Elbeih A, Abd-Elghany M, Klapötke TM (2017) Kinetic parameters of PBX based on Cis-1, 3, 4, 6-tetranitroocta-hydroimidazo-[4, 5-d] imidazole obtained by isoconversional methods using different thermal analysis techniques. Propellants Explos Pyrotech 42(5):468–476

Vyazovkin S, Sbirrazzuoli N (2006) Isoconversional kinetic analysis of thermally stimulated processes in polymers. Macromol Rapid Commun 27(18):1515–1532

Trache D, Abdelaziz A, Siouani B (2017) A simple and linear isoconversional method to determine the pre-exponential factors and the mathematical reaction mechanism functions. J Therm Anal Calorim 128(1):335–348

Koga N (1994) A review of the mutual dependence of Arrhenius parameters evaluated by the thermoanalytical study of solid-state reactions: the kinetic compensation effect. Thermochim Acta 244:1–20

Vyazovkin S (2021) Determining preexponential factor in model-free kinetic methods: how and why? Molecules 26(11):3077

Hotta M, Koga N (2024) Extended kinetic approach to reversible thermal decomposition of solids: a universal description considering the effect of the gaseous product and the kinetic compensation effect. Thermochim Acta 733:179699

Çılgı GK, Ak M (2020) Thermal degradation kinetics and thermodynamics of maleimide-sytrene based alternating copolymer: a comparative investigation of monomer and polymer structures. J Mol Struct 1221:128879

Sbirrazzuoli N (2020) Determination of pre-exponential factor and reaction mechanism in a model-free way. Thermochim Acta 691:178707

Vyazovkin S (2015) Isoconversional kinetics of thermally stimulated processes. Springer, Cham

Luo L, Guo P, Jin B, Xiao Y, Zhang Q, Chu S, Peng R (2020) An isothermal decomposition dynamics research instrument and its application in HMX/TNT/Al composite explosive. J Thermal Anal Calorim 139:2265–2272

Khawam A, Flanagan DR (2006) Solid-state kinetic models: basics and mathematical fundamentals. J Phys Chem B 110(35):17315–17328

Vyazovkin S, Wight CA (1999) Model-free and model-fitting approaches to kinetic analysis of isothermal and nonisothermal data. Thermochim Acta 340:53–68

Benhammada A, Trache D (2020) Thermal decomposition of energetic materials using TG-FTIR and TG-MS: a state-of-the-art review. Appl Spectrosc Rev 55(8):724–777

Boumaza L, Tarchoun AF, Trache D, Abdelaziz A, Hamouche MA (2023) Insights into decomposition mechanism and gas evolution characteristics of energy-rich nitrochitosan by hyphenated TGA-FTIR analysis. Thermochim Acta 728:179590

Tanaka H (2005) The theory and practice of thermoanalytical kinetics of solid-state reactions. J Thermal Anal Calorim 80(3):795–797

Vyazovkin S, Burnham AK, Favergeon L, Koga N, Moukhina E, Pérez-Maqueda LA, Sbirrazzuoli N (2020) ICTAC Kinetics Committee recommendations for analysis of multi-step kinetics. Thermochim Acta. https://doi.org/10.1016/j.tca.2020.178597

Trache D, Tarchoun AF (2018) Stabilizers for nitrate ester-based energetic materials and their mechanism of action: a state-of-the-art review. J Mater Sci 53(1):100–123

Boukeciat H, Tarchoun AF, Trache D, Abdelaziz A, Belmehdi D, Meziani R, Boumaza L, Klapötke TM (2024) Pyrolysis mechanism and evolved gas analysis of a promising energetic carbamate-functionalized microcrystalline cellulose nitrate. FirePhysChem 4(4):327–332

Boumaza L, Tarchoun AF, Trache D, Abdelaziz A, Boukeciat H, Thakur S, Klapötke TM (2024) Unraveling the characteristics and pyrolysis mechanism of diethylene glycol dinitrate plasticized nitrocellulose supplemented with organic stabilizers. J Anal Appl Pyrol 180:106564

El-Sayed SA (2022) Review of thermal decomposition, kinetics parameters and evolved gases during pyrolysis of energetic materials using different techniques. J Anal Appl Pyrol 161:105364

Matmat N, Abdelaziz A, Trache D, Tarchoun AF, Boukeciat H, Rahal A (2023) Elaboration, spectroscopic characterization, and study of the thermal decomposition process of energetic composites based on ammonium perchlorate and dual-biopolymers. FirePhysChem. https://doi.org/10.1016/j.fpc.2023.10.003

Šimon P, Dubaj T, Cibulková Z (2022) Frequent flaws encountered in the manuscripts of kinetic papers. J Therm Anal Calorim 147(18):10083–10088

Tarchoun AF, Sayah ZBD, Trache D, Klapötke TM, Belmerabt M, Abdelaziz A, Bekhouche S (2022) Towards investigating the characteristics and thermal kinetic behavior of emergent nanostructured nitrocellulose prepared using various sulfonitric media. J Nanostruct Chem. https://doi.org/10.1007/s40097-021-00466-x

Cieślak K, Gańczyk-Specjalska K, Drożdżewska-Szymańska K, Uszyński M (2021) Effect of stabilizers and nitrogen content on thermal properties of nitrocellulose granules. J Thermal Anal Calorim 143(5):3459–3470

Chai H, Duan Q, Cao H, Li M, Qi K, Sun J, Yang X (2020) Experimental study on the effect of storage conditions on thermal stability of nitrocellulose. Appl Therm Eng 180:115871

Zhao Y, Jin B, Zheng T, Peng R (2022) Structure–activity relationship of thermal interaction between arylmalonamide [70] fullerocyclopropane stabilizer and nitrocellulose. Cellulose 29(12):6579–6593

Tarchoun AF, Trache D, Klapötke TM, Abdelaziz A, Bekhouche S, Boukeciat H, Sahnoun N (2022) Making progress towards promising energetic cellulosic microcrystals developed from alternative lignocellulosic biomasses. J Energetic Materials. https://doi.org/10.1080/07370652.2022.2032484

Pourmortazavi S, Hosseini S, Rahimi-Nasrabadi M, Hajimirsadeghi S, Momenian H (2009) Effect of nitrate content on thermal decomposition of nitrocellulose. J Hazard Mater 162(2–3):1141–1144

Vyazovkin S, Linert W (1995) The application of isoconversional methods for analyzing isokinetic relationships occurring at thermal decomposition of solids. J Solid State Chem 114(2):392–398

Lyon RE (2023) A physical basis for kinetic compensation. J Phys Chem A 127(10):2399–2406

Lyon RE (2019) Isokinetics. J Phys Chem A 123(12):2462–2469

Agrawal RK (1989) The compensation effect: a fact or a fiction. J Therm Anal 35:909–917

Chelouche S, Trache D, Tarchoun AF, Khimeche K, Mezroua A (2020) Compatibility of nitrocellulose with aniline-based compounds and their eutectic mixtures. J Therm Anal Calorim 141(2):941–955

Liu R, Yu W, Zhang T, Yang L, Zhou Z (2013) Nanoscale effect on thermal decomposition kinetics of organic particles: dynamic vacuum stability test of 1, 3, 5-triamino-2, 4, 6-trinitrobenzene. Phys Chem Chem Phys 15(20):7889–7895

Acknowledgements

Financial support of this research by the Ecole Militaire Polytechnique is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no potential conflicts of interest with respect to the research, authorship, and/or publication of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Tarchoun, A.F., Trache, D., Abdelaziz, A. et al. A study on the isothermal decomposition kinetics of energetic cellulose-rich materials using a vacuum stability test. Reac Kinet Mech Cat (2024). https://doi.org/10.1007/s11144-024-02706-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11144-024-02706-x