Abstract

All-solid-state quantum dot-sensitized TiO2 nanotube array solar cells have been drawing great attention to solar energy conversion, which break through restrictions in traditional solar cells, such as the high recombination at interfaces of porous TiO2 films/sensitizers/hole conductors/counter electrodes, instability of dyes, and leakage of solution electrolyte, and so the novel solar cells exhibit promising applications in the future. In this Minireview article, the assembling of solar cells including the preparation of TiO2 nanotube array photoanodes, quantum dot preparation and sensitization on photoanodes, filling of hole conductors in TiO2 nanotubes, and selection of counter electrodes are overviewed, and the development course of all-solid-state quantum dot-sensitized TiO2 nanotube array solar cells in recent years are summarized in detail. Moreover, the influences of TiO2 nanotube array photoanodes, quantum dots, solid electrolyte, and counter electrodes on photon-to-current efficiencies of solar cells are summarized. In addition, current problems of solid-state quantum dot-sensitized TiO2 nanotube array solar cells are analyzed, and the corresponding improvements, such as multisensitizers and passivation layers, are proposed to improve the photoelectric conversion efficiency. Finally, this Minireview provides a perspective for the future development of this novel solar cell.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

In recent years, because of the shortage of fossil fuels and the huge demand of energy, new energy has attracted intense attention due to its friendly environment and sustainability, and solar energy is no doubt the most dazzling one. As the third solar cell, quantum dot-sensitized solar cells show many advantages of low cost, simple fabrication progress, tunable band gap and multiple exciton generation effect for solar light harvesting, and excellent persistence compared with silicon-based solar cells and dye-sensitized solar cells (Kamat 2008; Lee and Lo 2009; Guan et al. 2011; Liu et al. 2012b; Speirs et al. 2015). TiO2 porous materials are mainly used as photoanode materials in quantum dot-sensitized solar cells due to their high BET for quantum dot adsorption; however, their inherent disadvantages limit the improvement of photon-to-current efficiencies. Firstly, porous materials are composed by TiO2 nanoparticles and mesoporous in a irregular arrangement way, and the defects and grain boundaries in porous materials cause the high resistance, which is unfavorable for the rapid transfer of photogenerated charge carriers. Secondly, the high recombination reduces the power conversion efficiency (PCE) of solar cells. Fortunately, the recent development of TiO2 nanotube arrays (TiO2 NTs) overcomes these restrictions, and the well-oriented tubular structures could provide excellent electron percolation pathways for vertical charge transfer. In addition, regular tubes in TiO2 NTs could effectively adsorb quantum dots (QDs), inhibit the recombination of electron–hole pairs, and then higher PCE could be obtained (Ruby and Sohrab 2011; Su and Zhou 2011; Yang et al. 2015). Ip et al. (2012) prepared quantum dot-sensitized TiO2 nanotube array solar cells (QDSTNASC), and PCE of the QDSTNASC achieved 7 %, which attracted immense attention of scientists. However, due to the volatilization, corrosion, leakage, and complex packaging process of liquid electrolyte, liquid-state solar cells show disadvantages of the short lifetime and instability. Based on the above restrictions, the preparation of solid-state QDSTNASC is required.

The composition and work mechanism of solid-state QDSTNASC are shown in Fig. 1. Generally, the solid-state QDSTNASC are composed by five parts. (1) Ti substrate or ITO glass; (2) TiO2 NTs serving as the backbone of photoelectrodes; (3) The QDs adsorbed on the surface of TiO2 NTs as sensitizers; (4) Hole conductor materials; (5) Counter electrodes. Figure 1b displays the mechanism of solid-state QDSTNASC. Under visible light irradiation, the excited electrons jump into the conduction band (CB) of QDs, leaving holes in the valance band (VB). The photoelectrons transfer rapidly to the CB of TiO2 nanotubes, and transfer along nanotube walls to Ti substrates. Otherwise, holes in the VB of QDs pass through hole conductor materials to the counter electrode.

In this paper, we focus on recent progresses in solid-state QDSTNASC, and summarized influences of TiO2 NT photoanodes, QDs, modification ways of QDs on TiO2 NTs, solid electrolyte, and counter electrodes on the photoelectrochemical (PEC) performance of the QDSTNASC. In addition, the current problem and prospect for future development of the novel solar cell are also proposed.

Preparation of QD-sensitized photoelectrodes

Photoelectrode materials are the hardcore part of solar cells, and they are composed of photoanodes and QDs sensitizers. The photoelectrode materials play significant roles in solar absorption and transfer of photogenerated electrons, which greatly influence the final PCE. Recently, many investigations on the novel QDSTNASC using TiO2 NTs as photoanodes and QDs as sensitizers were reported (Smith et al. 2012; Li et al. 2015; Liao et al. 2012), and the PCE were gradually improved.

Preparation of TiO2 NT photoanodes

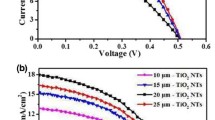

TiO2 NTs as photoanode materials caused people’s intense interest, and investigations about influences of preparation methods, nanotube lengths, and diameters on PCE of solar cells were studied in the previous report (Mor et al. 2006). In this paper, two photoanodes of TiO2 NTs aligned on Ti substrates or ITO glass were contrasted in detail, respectively.

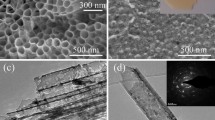

TiO2 NTs are prepared using the anodization of Ti foils, and the obtained samples could be used as a simple photoanode. The combination of TiO2 NTs and Ti substrates is tight, which effectively increases the transfer efficiency of electrons. Albu et al. (2010) summarized the formation mechanism of TiO2 NTs grown on Ti substrates, and investigated influences of anodization parameters, such as voltage, electrolyte composition, electrolyte pH and temperature on the morphology and PEC property of TiO2 NTs. TiO2 NTs with different lengths and diameters could be prepared by changing of experimental parameters. However, many disadvantages also exist in this kind of photoanode. Firstly, barrier layers are formed between TiO2 nanotubes and Ti substrates, and barrier layers inhibit the effective transfer of electrons, increase the recombination chance of electrons and holes, and decrease the PCE. Secondly, due to the light-tight trait of Ti substrates, solar cells only could be irradiated from top of TiO2 nanotubes which couldn’t utilize solar light from the opposed direction. On the contrary, TiO2 NTs on ITO glass could overcome this restriction, and two sides of the photoanode could be irradiated. Wang and Lin (2009) sputtered a thin layer of Ti on ITO glass, and then the Ti layer was anodized to prepare TiO2 NTs. The anodization time is hard to be controlled, and a thin barrier layer is still inevitable. Currently, the common method to prepare TiO2 NT photoanodes with top and back irradiation was described that the free-standing TiO2 NTs were transferred onto ITO glass, and combined with the substrate by TiO2 sol. The free-standing TiO2 NTs could be mainly prepared by four methods including mechanical or ultrasonic forced stripping, electrochemical extraction, chemical dissolution separation, and selective dissolution separation. The detailed stripping and through-hole methods were reported in the previous review (Liu et al. 2012a). The selective dissolution separation method was an effective way to prepare intact free-standing TiO2 NTs. The detailed progress is given as following: First, the TiO2 NTs with proper lengths were prepared by anodization of Ti foils. The TiO2 NTs were annealed at 250 °C for 2 h, and then anodized for 10 min. The samples were immersed into H2O2 solution for 5 min to prepare through-hole TiO2 NTs. At last, the combination of TiO2 NTs and ITO glass was carried out by the hydrolysis of TiCl4. The preparation progress of the through-hole TiO2 NT photoanode is displayed in Fig. 2 (Li et al. 2011b). Hsiao et al. (2011) investigated transfer kinetics of photogenerated electrons on the wall of the through-hole TiO2 NT solar cells irradiated from top and back surfaces, and the results indicated that electrons could be easily trapped from the back irradiation because of massive defects and crystal boundaries, and the PCE were also lower than that of top irradiation.

Schematic representation of the detachment and transfer of the ordered 1D nanotube arrays for front-illuminated TiO2 NT solar cells (Li et al. 2011b)

QDs-sensitized TiO2 NTs

Matchability of QDs with TiO2 NTs

Recently, various QDs including noble metals, TiO2 nanoparticles, and semiconductors with narrow band gaps, were explored to sensitize TiO2 NTs. Wet-chemical and electrochemical deposition methods were mainly applied to prepare noble-metal QDs, such as Au (Zhang et al. 2013), Ag (Chang et al. 2013b), and Pt (Wang et al. 2012d), on the surface of TiO2 NTs. The formed Schottky junction on the interface of metal QDs and TiO2 NTs plays significant roles in the following aspects: (1) The rapid transfer rate of photogenerated electrons on the surface of metals, (2) Visible light absorption of noble metals, such as the absorption peak of Ag nanoparticles at 410 nm, (3) Plasma resonance absorption produced by the interaction of metal nanoparticles and TiO2 nanotubes. In addition, the investigations indicated that the deposition of TiO2 nanoparticles on the surface of TiO2 NTs also significantly improved the PCE. TiO2 nanoparticle sensitizers were prepared by the hydrolysis of TiCl4 on the surface of TiO2 NTs, which increased the BET and PCE of solar cells. Prof. Roy et al. (2009) successfully prepared TiO2 nanoparticles with diameters of 3 nm on TiO2 NTs by the hydrolysis of TiCl4, and the prepared TiO2 nanoparticles were annealed to form mixed anatase and rutile phases, which increased the PCE from 1.9 to 3.8 %.

The visible light absorption intensities of TiO2 NT photoanodes sensitized by the above sensitizers are weak due to their inherent energy band structures. Fortunately, the sensitization by semiconductor QDs with narrow band gaps could overcome this restriction. The matchability of QDs with TiO2 NTs is mainly based on the following three aspects: (1) The band gaps should match well with solar spectrum, and 1.5 eV is the optimal band gap, which could cover the whole visible light region; (2) The CB bottom should be more negative than that of TiO2, and photogenerated electrons in QDs could transfer rapidly to that of TiO2; (3) The transform of electrons should be rapid and effective, which could reduce the recombination rate of photogenerated electron–hole pairs. Figure 3a shows band gaps and energy band structures of many semiconductors, and only a few ones match these criteria. As shown in Fig. 3b, CdS and CdSe QDs are suitable sensitizers, and the type-II band structure could be formed on the surface of QDs and TiO2 NTs. The stepwise energy band structures are favor to the transfer of charge carriers, and reduce recombination chances of electron–hole pairs. However, the band gaps and CB edges of QDs aren’t commonly immovable, which could be influenced by changing of QDs crystal sizes. Just as CdSe (Chu et al. 2012) and PbS (Ratanatawanate et al. 2008) QDs, decreasing crystal sizes, the influences of quantum confinement and small-size effects become intense, and band gaps and energy band structures of these QDs are correspondingly changed. As shown in Fig. 4, when sizes of CdSe QDs decreased from 4.2 to 2.8 nm, their visible light absorption regions also changed, the solution color changed from dark red to bright yellow, thus, the CB edge became more negative, and the band gap and energy band structure of QDs could be adjusted. This phenomenon could overcome the restrictions of the poor matchability of semiconductors with TiO2, just like the reported PbS QD-sensitized TiO2 NT solar cells (Kang et al. 2011a). Currently, CdS (Wang et al. 2012b), CdSe (Zhang et al. 2009), CdTe (Wang et al. 2013b), PbS (Chalita et al. 2009), PbSe ( Schaller and Klimov 2004), InP (Zeng et al. 2003), Bi2S3 (Li et al. 2012), and Sb2S3 (Xie et al. 2013) QDs were used as sensitizers in solar cells, and sizes of QDs were adjusted to optimize band gaps and energy band structures, which could achieve the optimal solar light absorption and electron transfer. Among these QDs, CdS and CdSe QDs were the most effective sensitizers. Baker and Kamat (2009) prepared CdS QDs with a diameter of 2 nm to sensitize TiO2 NTs by a successive ionic layer adsorption and reaction (SILAR) method, and the open voltage was 1.15 V, short photocurrent was 6.78 mA/cm2, quantum efficiency was 55 % at 517 nm, much higher than that of CdS QD-sensitized TiO2 porous layer photoelectrodes. Xie et al. (2010b) prepared CdS QDs with a diameter of 2 nm on inner walls of TiO2 NTs by a new ultrasonic-assisted chemical precipitation method, and the open voltage was 1.05 V, higher than 0.98 V of the photoelectrode prepared by a traditional wet-chemical method. The photocurrent density of the as-prepared photoelectrodes improved up to 2.06 mA/cm2 from 1.43 mA/cm2. Si et al. (2008) sensitized TiO2 NT photoelectrodes by physical adsorption of the prior prepared CdSe QDs, and the influences of QD sizes on the visible light response and photocurrent densities were investigated. The results indicated the photocurrent density of solar cells sensitized by CdSe QDs with diameters of 4.5 nm was 1.5 mA/cm2, however, the photocurrent of solar cells sensitized by CdSe QDs with diameters of 3 nm was improved to 1.8 mA/cm2.

a Band gaps and energy band structures of several semiconductors, b schematic diagram of excited electron transfer in the TiO2 NTs sensitized by CdSe QDs (Hagfeldtt and Grätzel 1995)

Diagram of the relative electronic band gaps and energy band structures of CdSe QDs with different size (Tvrdy et al. 2012)

The band gaps of these QDs such as CdS and CdSe nanoparticles are nearly changeless, therefore, the visible light response regions of QDs are limited in the scope of their energy bands. Although the visible light absorption region could be slightly adjusted by changing their sizes, the extension is extremely limited. To further extend the visible light response of these QD sensitizers, ternary direct band gap I–III–VI2 QDs such as CuInS2 (Chen et al. 2011a), CuInSe2 (Nguyen et al. 2012), ZnCdSe2 (Zheng et al. 2011), ZnCdSe2 (Kang et al. 2012), and CuAlS2 (Huang et al. 2010a) have many advantages of non-toxicity, low cost, stable properties, and regulatable band gaps and energy band structures by adjusting two metal element ratios. Prof. Chang et al. (2011) deposited CuS and In2S3 layers on the surface of TiO2 NTs by a SILAR method, and then CuInS2 QDs were formed by the post annealing treatment. The influences of Cu/In mole ratios on the visible light response and PCE were investigated in detail, and the transient photocurrent density achieved 300 μA/cm2.

Same QDs with various diameters were deposited on TiO2 NTs to maximally absorb solar light. The QDs with small diameters are distributed on the top of tubes to absorb UV and visible light with short wavelengths, and QDs with large diameters are distributed on bottom parts of nanotubes to absorb visible light with long wavelengths. The cap structures could absorb the maximum solar light, and the efficiency of solar cells is significantly improved. Moreover, different QDs with various band gaps on TiO2 NTs could form heterojunction, and synergistic effect could induce the visible light absorption and PCE. Taking CdS and CdSe QDs for example, the band gap of CdSe QDs is 1.74 eV, much narrower than that of CdS (2.4 eV), and visible light with long wavelengths could be absorbed and the utilization efficiency of solar light is high (Li et al. 2014). However, the electron transfer rate of CdSe QDs is much lower than that of CdS, and the electron injection rate and compatibility between CdSe and TiO2 NTs are also lower than that of CdS QDs. Therefore, combination of two QDs will obtain the synergistic enhancement in the visible light absorption and electron transfer efficiency (Shin et al. 2010). Prof. Cheng et al. (2012) and Wang et al. (2013a) prepared the co-sensitization of CdS and CdSe QDs on TiO2 NTs by a spray pyrolysis method and SILAR method, respectively. The heterojuctions were formed between CdS QDs and CdSe QDs, and the co-sensitization not only improved the visible light absorption, but also inhibited the recombination of electrons and holes, which greatly improved the PCE of solar cells.

The sensitization of TiO2 NTs by QDs with novel microstructures

The QDs with novel microstructures could further extend the response region to visible light or near-infrared light, accelerate the transfer rate of photogenerated electrons, improve the effective connection of QDs and TiO2 NTs, reduce the combination of electron–hole pairs, and finally improve the photon-to-current conversion efficiency of solar cells.

-

(1)

Heterojunction QDs In recent years, the PCE of single QD-sensitized TiO2 NT photoelectrodes has been limited by inherent photoelectrochemical performances of these QDs. Co-sensitization including two or multiple QDs was reported to sensitize TiO2 NTs for further synergistic enhancement of PEC performances ( Lee et al. 2009a; Lai et al. 2012). Therefore, material scientists are trying their best to improve the visible light response, electron transfer, and photocurrent density of the photoelectrodes co-sensitized by two or multiple QDs. However, high recombination is still observed in the simple hybrid of various sensitizers due to their poor interfaces, and electrons may be trapped by grain boundaries at the interface of sensitizers. Fortunately, the synergistic effect of co-sensitizer heterojunctions could effectively promote the transfer of the photogenerated electrons. For example, Chang et al. (2013a) successfully prepared solar cells composed of PbS/CdS colloidal QD heterojunctions, and the solar cell exhibited an average PCE of 3.5 %, which opened up the possibility of novel solar cells sensitized by heterojunction QDs.

-

(2)

QDs with core–shell structures The combination and separation are two contradictory progresses of electron transfer in solar cells. The introduction of core–shell structures into QDs provides a new way to optimize photoelectrodes via adjusting energy band structures and reducing the recombination of electrons and holes. The heterojunction is formed at the interface of core–shell QDs, and hierarchical energy bands of core–shell QDs could facilitate the transfer of charge carriers. Approaches for core–shell QDs synthesis can be broadly divided into two categories: “top-down” and “bottom-up”, and the bottom-up approach has proven more suitable (Chaudhuri and Paria 2012). The common preparation technology of core–shell QDs is deposition of shell materials on the pre-existing core materials by hydrolysis or wet-chemical deposition. This technology should be based on similar properties such as lattice matching in core and shell materials. LBL assembly technique also could be applied to deposit shell materials with negative charge on the surface of core materials, and the adjustment of the core–shell thickness and composition by reaction time and LBL cycle experimental parameters could optimize PEC properties of photoelectrodes. Our group (Wang et al. 2015) successfully prepared CdS@CdSe and CdS@CdTe core–shell QDs on TiO2 NTs by the ionic exchange method using CdS QDs as sacrificial templates. The new photoelectrodes significantly enhanced the visible light response, and the photocurrent densities of TiO2 NTs/CdS@CdSe and TiO2 NTs/CdS@CdTe solar cells achieved 22.6 and 14.7 mA/cm2, respectively. Apart from in situ deposition, the core–shell QDs could be deposited on the surface of TiO2 NTs by a coupling agent when the direct combination of QDs and TiO2 NTs is different due to the huge surface differences. Prof. Wang et al. (2013a) prepared CdTe QDs by an injecting method, and sensitized CdTe with CdSe layers to prepare CdTe@CdSe core–shell QDs with diameters of 4.9 nm via a SILAR method. Then the as-prepared core–shell QDs were deposited on the surface of TiO2 NTs by MPA coupling agents, and the PCE of this core–shell solar cell achieved 6.76 %.

-

(3)

Hierarchical QDs Hierarchically structured QDs with various morphologies have attracted immense attention, and the hierarchical structure could significantly improve optoelectronic performances of solar cells. The hierarchical branching frameworks are promising for designing high-performance PEC electrodes owing to their effective optical paths for the efficient light harvesting and high-quality conducting channels for the rapid carrier separation and transportation, as well as large surface areas for fast interfacial carrier transfer and electrochemical reactions. Zhou et al. (2011) prepared novel hierarchical Cu2ZnSnS4 particles by a solvothermal method, and investigated the influences of hierarchical structures on the performance of photoelectrodes. The results indicated that hierarchical sensitizers significantly promoted the absorption coefficient in the visible light region, electronic transmission, and photocurrent density. Prof. Bierman and Jin (2009) reviewed the investigation of hierarchical nanowire structures formed by branching nanowires for solar conversion devices, and the applications in solar energy harvesting and conversion are summarized in detail.

Sensitization methods of QDs on TiO2 NTs

Novel QDs attracted intense attention in applications of TiO2 NT photoelectrodes due to their high transfer efficiencies of photogenerated electrons, and the sensitization methods of QDs on TiO2 NTs also play significant roles in the final PCE. Taking Ag QDs for example, Ag QDs have been deposited on the surface of TiO2 NTs by many methods, such as UV reduction (Chen et al. 2013), electrochemical deposition (Huang et al. 2011b; Lai et al. 2010), and wet-chemical reduction (Macak et al. 2007). Among these methods, UV reduction and electrochemical deposition methods are popular ways to prepare well-distributed Ag nanoparticles with the uniform morphology and narrow size distribution. In the UV reduction progress, UV light with high energy could reduce the Ag+ ions adsorbed on TiO2 NTs into Ag QDs with the uniform distribution and small crystal size. Prof. Paramasivam et al. (2007) successfully prepared Ag QDs by a UV reduction method, and the detailed experimental progress are listed as following: The TiO2 NTs prepared by anodization of Ti foils were immersed into 1 M AgNO3 solution, and then UV irradiated for 0.5 h, so Ag QDs were adsorbed on top and inner surfaces of TiO2 nanotubes. Li et al. (2010) and Xie et al. (2010a) prepared TiO2 NTs sensitized by Ag QDs by constant voltage and pulse electrodeposition methods, respectively, and the sizes of Ag QDs could be adjusted by changing experimental parameters. In addition, chemical reducing agents were also used to prepare Ag QDs, but the violent reaction rate using strong reducing agents caused the agglomeration of Ag QDs. Prof. Liang et al. (2011) and Wang et al. (2012c) prepared Ag QDs on the surface of TiO2 NTs by chemical bath deposition and SILAR methods using NaBH4 as a reducing agent. The sensitization of noble-metal QDs on TiO2 NTs could significantly reduce the recombination of photogenerated electrons and holes, however, the visible light harvesting still showed at a low level. Therefore, compared with semiconductor sensitizers, the low PCE of noble-metal QDs-sensitized TiO2 NT photoelectrodes limit their potential applications.

Chalcogenide semiconductor QDs could be deposited on TiO2 NTs by the in situ growth and non-in situ growth. Electrochemical deposition, chemical bath deposition, and SILAR deposition are in situ growth styles. The in situ growth progress includes the progress of the nucleation and growth of QDs, and this style shows high coverage and tight combination of QDs and TiO2 NTs. The disadvantage of the in situ style is the uncontrollable growth of these QDs sensitizers. The external energy (voltage and current) in the electrochemical deposition progress drastically induces the nucleation and growth of QDs, and the rapid growth rate may cause the agglomeration on TiO2 NT surface, which blocks the inner sensitization (Liu et al. 2011; Huang et al. 2011a). Chemical bath deposition and SILAR methods are mainly used in the sensitization of chalcogenide semiconductor QDs on TiO2 NTs. The adsorbed S2− ions could react with metal ions to form chalcogenide semiconductor QDs on the inner surface of TiO2 NTs, and this method has been extended to the selenide and telluride. Sun et al. (2008) and Hossain et al. (2011) prepared CdS and CdSe QDs-sensitized TiO2 NTs by a chemical bath deposition method, and their PCE achieved 4.15 and 1.56 %, respectively. Prof. Cheng et al. (2011) and Kang et al. (2011b) prepared CdS and PbS QDs-sensitized TiO2 NT photoelectrodes by a SILAR method, respectively, and the solar cells showed high PCE. In addition, our group (Zhong et al. 2014) developed a novel photoreduction method to prepare chalcogenide QDs for the sensitization of TiO2 NTs. Photodeposition technique is recognized as an effective in situ growth method to achieve tight interfacial connection between semiconductor QDs and TiO2 NTs, and the TiO2 NTs/semiconductors heteronanojunction is formed by the photocatalytic redox property of TiO2 NTs. These metal sulfide QDs can be photodeposited not only on external surfaces but also on inner surfaces of mesopores. We successfully achieved TiO2 NTs sensitized by CdS (Zhong et al. 2014) and PbS (Qiao et al. 2014) QDs by this method, and their visible light photocurrent densities achieved 6.1 and 9.49 mA cm−2, respectively. Other binary and tribasic chalcogenide QDs such as Sb2S3 and CuInS2 are being investigated to further improve the PCE of solar cells.

The non-in situ growth styles including physical adsorption and chemical adsorption by organic coupling agents are also exploited to deposit QDs on TiO2 NTs. In the non-in situ growth, the pre-synthesized QDs were deposited on the surface of TiO2 NTs by Van der Waals forces or coupling agents. The lower QDs coverage of solar cells is the main disadvantage of physical adsorption, and the lower than 14 % coverage results in low PCE. Organic coupling agents in chemical adsorption could induce the top and inner sensitization of TiO2 NTs, and sizes of the adsorbed QDs could be accurately adjusted. However, the combination between QDs and TiO2 NTs is weak, and some organic molecules also inhibit the transport of photogenerated electrons. Two kinds of organic coupling agents are commonly applied to sensitize TiO2 NTs. Mercaptoacetic acid is a small molecule coupling agent with short molecule chains. The carboxyl group in one end of molecules could adsorb TiO2 NTs, and sulfhydryl group in the other end could adsorb these QDs (Gao et al. 2009). l-cysteine is another small molecule coupling agent that has carboxyl group and amidogen in two ends of molecule chains. Mercaptoacetic acid is extensively used in previous investigations, but the electron injection efficiency of QDs sensitized by l-cysteine is more promising. The adsorption mechanism of organic coupling agents is shown in Fig. 5 (Nevins et al. 2011). Prof. Nevins et al. (2011) investigated the adsorption efficiencies of l-cysteine, mercaptoacetic acid, and mercaptosuccinic acid on CdSe QDs, and the PCE of TiO2 NTs/CdSe photoelectrodes sensitized by l-cysteine is 1.2 and 6-fold higher than that of photoelectrodes sensitized by mercaptoacetic acid and mercaptosuccinic acid, respectively. The high PEC performance of solar cells sensitized by l-cysteine is attributed to the higher electron transfer rate and the low recombination rate of electron–hole pairs.

The incident photon-to-current efficiency of TiO2 NTs sensitized by CdSe using cysteinate, 3-mercaptopropionate, and mercaptosuccinate as coupling agents (Nevins et al. 2011)

Organic coupling agents in chemical adsorption are mainly used to deposit chalcogenide semiconductors on TiO2 NTs, but metallic oxide QDs with narrow band gaps are generally prepared by an electrochemical deposition method (Wen et al. 2011). Generally, metallic oxide QDs are prepared by annealing treatment of hydroxide precursors produced during the preparation progress of metal cations in alkaline environment. The hydroxide precursors are flocculent precipitates prepared by wet-chemical methods, which easily block nanotubes and few QDs could be deposited on the inner surface of TiO2 NTs. Compared with traditional wet-chemical methods, the electrochemical energy provided from an electrochemical workstation could induce crystal nucleations on inner walls of TiO2 NTs, and this method demonstrates tremendous advantages in the preparation of metallic oxide semiconductors. Li et al. (2011a) and Zhang et al. (2011) prepared Cu2O QDs with octahedron structures to sensitize TiO2 NTs by pulse electrodeposition and constant voltage methods, which greatly improved photocurrent densities of the QDSTNASC, and the detailed mechanism and PEC results are given in Fig. 6.

Selection of hole conductors

The overall PCE of most solid-state solar cells is much lower than that of liquid-state solar cells, and the further improvement is difficult to break through. The main obstacle is ascribed to hole conductors, especially the low filling ratio of these hole conductors in nanotubes. Contrary to liquid electrolyte, solid-state hole conductors show the low filling ratio and weak connection with QDs, the poor interface connection reversely inhibits the effective transfer of photogenerated charge carriers, and the low transfer efficiency correspondingly causes the intense recombination of electron/hole pairs. Therefore, the superior hole conductors and interface connections are the presupposition of outstanding solid-state solar cells with high PCE. There are four criteria for the selection of hole conductors: (1) VB edges of hole conductors should match well with that of QDs, which could be in favor of the hole flow on the interface of QDs/hole conductors; (2) Hole conductors should be amorphous solids, and the reason is that the crystal of hole conductors may inhibit the complete filling in TiO2 NTs; (3) The hole transfer rate in hole conductors should be high; (4) Hole conductors should show high stability and low absorption in the visible light region. The effective filling and interface connection between hole conductors and TiO2 NTs play key influences on the PEC of solar cells, and the transfer rate of hole conductors is just a secondary consideration. There are decades for investigations of the solid-state electrolyte, and all these hole conductors could be roughly classified into three kinds: (1) Inorganic salt electrolyte, such as CuI, CuBr, CuSCN, NiO, CsSnI3, and etc.; (2) Small organic molecule electrolyte, such as Spiro-OMeTAD; (3) Macromolecule electrolyte, such as polyaniline, polypyrrole, polythiophene, and etc. CuI and CuSCN are the most popular inorganic salt electrolyte. They have the advantage of rapid hole transport rates, but also have disadvantages of the crystallization and unstability which are main reasons for the low PCE of solid-state solar cells. Chen et al. (2011a) prepared CdSe QDs-sensitized TiO2 porous membrane as the photoelectrode, and CuSCN was selected as the hole conductor. The solid-state solar cells showed low PCE, and its photocurrent density was only 6.5 μA/cm2. The reason was attributed that the low transfer rate of holes and incompact interface connection with TiO2 nanoparticles caused low PEC properties. CsSnI3 is a new hole conductor prepared in recent years, and the PCE of solid-state solar cells using SnF2-doped CsSnI3 as the hole conductor achieved 10.2 %, which approached the level of liquid electrolyte (Chung et al. 2012a, b). In addition, the solid-state solar cell showed high stability of effective running for 25 years. Unfortunately, the super high cost limited investigations only in the level of theoretical research in laboratories. Spiro-OMeTAD is recognized as the optimal solid-state hole conductor, and it has advantages of high hole transfer rate, excellent wettability, no polymerization, and simple spin-coating performance in tubes, so solar cells using this organic electrolyte showed higher PCE than others. Using Spiro-OMeTAD as the hole conductor, Prof. Chi et al. (2011) prepared solid-state CdS/CdSe QDs-sensitized TiO2 solar cells, and the PCE achieved 0.88 %. However, the high cost similarly goes against the extensive applications. Due to the high hole transfer rate (550 S/cm), thermal stability, and low cost, polythiophene is recognized to be the most prospective hole conductor. As shown in Fig. 7, Shankar et al. (2007) prepared solid-state solar cells by physical spin coating of polythiophene on the surface of TiO2 NTs, but the filling ratio is still low. To improve the filling ratio, the in situ polymerization is explored to be complete filling by monomer polymerization in nanotubes. Chemical polymerization, electrochemistry polymerization, and UV light polymerization are the main in situ polymerization styles of polythiophene in TiO2 NTs. The investigations indicated that solar cells filled by polythiophene polymerized by UV light-assisted polymerization methods showed high PCE. Prof. Lim et al. (2012) prepared polythiophene hole conductors by UV polymerization methods. Polythiophene was then doped by I− ions, and PCE of solar cells improved 27.52 % more than that without doping treatment. The VB edges could be adjusted by the addition of Li+ ions and other small molecules, which could increase the filling efficiency and transfer rate of hole carriers, and it is an effective route to decrease the recombination of electrons/holes and improve the PCE of solid-state solar cells. Compared with chemical polymerization and UV light polymerization, the in situ electropolymerization could assist the orientated growth of hole conductors from the bottom of TiO2 nanotubular electrodes, and finally achieve the complete filling of mesoporous structures. For example, poly-3,4-ethylenedioxythiophene (PEDOT) conducting polymers were electrodeposited in TiO2 NTs, and electropolymerization typically leads to the deposition of PEDOT in tubes and spaces among tubes, which constructed compact PEDOT/TiO2 NTs interfaces for hole transfer (Kowalski et al. 2013).

Schematic diagram of TiO2 nanotube arrays coated with self-assembled carboxylated P3HT (Shankar et al. 2007)

Selection of counter electrodes

Counter electrodes (CE) are the key composition of solar cells, and they have significant roles to play in collecting holes in the circuit. In the early period of solar cells, PCE are so low that the influence of CE on the PCE is faint, and the investigation about the preparation and design of CE is scarce. However, with the improvement of PCE and commercial applications of solar cells, especially emergence of solid-state solar cells, the investigations of CE materials increased enormously, and so many papers reported investigations about the preparation and modification of various CE materials. The CE materials could be divided into the following four categories: (1) Pt and Au noble-metal counter electrodes; (2) Cu2S and its derivative counter electrodes; (3) Carbon counter electrodes; (4) Polymer and other organic counter electrodes.

Pt, Au noble-metal counter electrodes

Noble-metal counter electrodes mainly consist of Pt, Au, and Ag noble metals, and Pt layers are the most extensive and optimal CE materials. Several methods, such as magnetron sputtering (Dao et al. 2011) and thermal decomposition (Wang et al. 2005), were applied to prepare Pt CE on ITO/FTO glass with high electrochemical performances. However, the high cost and complex preparation technologies of Pt and Au CE materials greatly limited the large-scale application in solar cells. Therefore, people made great efforts to explore the substitutes with low cost and high efficiency.

Cu2S and its derivative counter electrodes

Pt and other noble metals like Au show low catalytic activities, which are generally applied in dye-sensitized solar cells, and they aren’t suitable for the QDSTNASC. Alternative CE materials, such as CoS, Cu2S, NiS, and PbS have been investigated in recent years. Cu2S has been demonstrated to be a promising CE material for solar cells owing to its low cost, simple fabrication, and broad variety of materials, as well as excellent catalytic activity. Based on Cu2S CE materials, Xu et al. (2012b) investigated the derivatives of Cu2S, and the new CE materials of monodisperse tetragonal Cu2SnS3 and rhombohedral Cu1.8S hierarchical microspheres were prepared via a simple solvothermal approach. The new CE promoted significant enhancement of PCE. The Cu2ZnSnS4 compound is another promising candidate for low-cost photovoltaic materials due to the abundances of constituting elements, low toxicity, suitable energy band gap (∼1.5 eV), and high absorption coefficient (∼104 cm−1). Xu et al. (2012a) prepared Cu2ZnSnS4 hierarchical microspheres as an effective CE material for QDSSC, and the PCE of this solar cell achieves 3.73 % under AM 1.5G illumination with an intensity of 100 mW cm−2, higher than that (2.27 %) of solar cells using noble-metal Pt-coated FTO glass substrates as CE. Moreover, other chalcogenide semiconductor CE materials also showed excellent electrochemical properties. Tachan et al. (2011) prepared PbS as CE materials to significantly improve the PCE.

C counter electrodes

Compared with other CE, carbon CE materials have advantages of excellent thermal stability, well corrosion resistance, high photocatalytic property and electroconductivity, as well as extensive sources and low cost. Carbon black, graphite, and porous carbon as traditional carbon CE materials have been intensely studied because of their high BET and electroconductivity to improve the PCE of solar cells. Therefore, the replacement of Pt with low-cost carbonaceous materials could facilitate the commercialization of solar cells. In recent years, the burgeoning CNT, carbon nanofibre, and grapheme as novel CE materials cause more and more attention. Because of their high BET and hole transfer properties, carbon CE materials greatly improve the PCE of solar cells. Screen painting is the main method to prepare carbon CE, but the complicated preparation progress and weak adhesive attraction are obvious drawbacks to limit their popularization. Electrospun carbon nanofibers have been explored as an electrocatalyst and low-cost alternative to Pt CE. The results indicated that solar cells using carbon nanofibers as CE showed high fill factor and PCE (Joshi et al. 2010). Graphene, which is an atomic planar sheet of hexagonally arrayed sp2 carbon atoms, has been demonstrated to be a promising CE material due to its outstanding conductivity and high electrocatalytic activity. The fabrication and performance of graphene-based CE were discussed and reviewed in previous paper (Wang and Hu 2012).

Polymer counter electrodes

Conductive polymers have been widely applied as CE materials in solar cells. The low cost and simple preparation technology of polymer electrodes are natural advantages as substitutes of Pt CE. In addition, the band gap and electroconductivity could be further adjusted by doping and modification of polymer CE materials. Polythiophene CE materials could be prepared by electrochemical polymerization on a FTO substrate, and the solar cells constructed by polythiophene CE showed a higher conversion efficiency (7.88 %) compared with that (7.77 %) of sputtered-Pt CE (Lee et al. 2009b).

Recently, people have paid more attention to the composite CE (Huang et al. 2010b), such as C/CoS (Lin et al. 2011), Pt/C (Li et al. 2009), C/conducting polymers (Sun et al. 2010), and so on. Taking advantage of the merit of single CE material, composite CE materials show higher photoelectrochemical performances than single CE materials, which is the development trend of CE materials in the further studies. Radich et al. (2011) prepared reduced graphene oxide (RGO)/Cu2S composite CE, and the sandwich-like CdSe QDSSC constructed by RGO-Cu2S composite CE exhibited PCE of 4.4 %, much higher than that of solar cells constructed by Pt CE.

Conclusions

This Minireview highlights the latest progress in constituent parts of the solid-state QDSTNASC, including the preparation of TiO2 NT photoanodes, matchability and modification methods of QDs on TiO2 NTs, and filling of hole conductors, as well as selection and exploitation of counter electrodes. TiO2 NTs attached on ITO glass as the photoanode showed higher PCE than that on Ti substrates, and these QDs prepared by chemical bath deposition and SILAR methods on the surface of TiO2 NTs showed rapid electron transfer rate, compact connection, and high PCE. The capillary force caused by small tube diameters is the main obstacle for the complete filling and effective connection between TiO2 NTs and hole conductors. The filling of hole conductors in TiO2 NTs using inorganic salt and macromolecules as hole conductors were reviewed. Various CE materials, including noble-metal CE, Cu2S CE, C CE, and polymer CE, were overviewed in detail to investigate the influences of CE materials on PCE.

Problems and perspective

Looking forward into the future of this exciting field, it is important to keep several questions in mind as well. In recent years, the PCE of QDSTNASC were gradually improved, but still showed extremely low efficiencies, and it was very difficult to achieve a great improvement. However, the PCE of dye-sensitized solar cells and perovskite solar cells exceed 12 and 20 %, respectively. To further improve the PCE of QDSTNASC, many efforts such as enhancing the visible light harvesting and reducing the recombination of electron–hole pairs should be taken. The photoelectrodes should be developed from weak visible light absorption of a single QD to combinatorial modification of multiple QDs or QDs/dyes, and the synergistic sensitization would achieve the broader visible light response until covering the whole solar spectrum. In addition, we should further investigate the kinetic of the carrier transfer and recombination, improve the energy band structure matchability of QDs and TiO2 NTs, enhance the effective filling and connection of solid electrolyte in the nanotubes, and inhibit the recombination of electrons and holes. For example, passivation layers, such as ZnS, Al2O3, and MgO films, could be covered on surfaces of QDs and TiO2 NTs, which would form buffer layers between electron conductors and hole conductors, significantly decrease the photocorrosion of QDs, increase the stability and connection of QDs and TiO2 NTs, and finally improve the PCE of the solid-state QDSTNASC. This Minireview is written to provide effective strategies for optimizing the solid-state QDSTNASC and to stimulate future research interests in the development of novel solid-state solar cells with new nanostructures for photoelectric conversion.

References

Albu SP, Roy P, Virtanen S, Schmuki P (2010) Self-organized TiO2 nanotube arrays: critical effects on morphology and growth. Isr J Chem 50:453–467

Baker DR, Kamat PV (2009) Photosensitization of TiO2 nanostructures with CdS quantum dots: particulate versus tubular support architectures. Adv Funct Mater 19:805–811

Bierman MJ, Jin S (2009) Potential applications of hierarchical branching nanowires in solar energy conversion. Energy Environ Sci 2:1050–1059

Chalita R, Yuan T Jr, Balkus KJ (2009) Photocatalytic activity of PbS quantum dot/TiO2 nanotube composites. J Phys Chem C 113:10755–10760

Chang H, Tzeng W, Lin C, Cheng S (2011) Ionic compounds lamination reaction and characteristics of photosensitive copper indium sulfide on titania nanotube arrays. J. Alloys Compd 509:8700–8706

Chang L, Lunt RR, Brown PR, Bulovic V, Bawendi MG (2013a) Low-temperature solution-processed solar cells based on PbS colloidal quantum dot/CdS heterojunctions. Nano Lett 13:994–999

Chang W, Hsueh Y, Huang S, Liu K, Kei C, Perng T (2013b) Fabrication of Ag-loadedmulti-walled TiO2 nanotube arrays and their photocatalytic activity. J Mater Chem A 1:1987–1991

Chaudhuri RG, Paria S (2012) Core/shell nanoparticles: classes, properties, synthesis mechanisms, characterization, and applications. Chem Rev 112:2373–2433

Chen C, Ali G, Yoo SH, Kuma JM, Cho SO (2011a) Improved conversion efficiency of CdS quantum dot-sensitized TiO2 nanotube-arrays using CuInS2 as a co-sensitizer and an energy barrier layer. J Mater Chem 21:16430–16435

Chen G, Wang L, Zou Y, Sheng X, Liu H, Pi X, Yang D (2011b) CdSe quantum dots sensitized mesoporous TiO2 solar cells with CuSCN as solid-state electrolyte. J Nanomater 2011:269591

Chen K, Feng X, Hu R, Li Y, Xie K, Li Y, Gu H (2013) Effect of Ag nanoparticle size on the photoelectrochemical properties of Ag decorated TiO2 nanotube arrays. J Alloys Compd 554:72–79

Cheng H, Zhao X, Sui X, Xiong Y, Zhao J (2011) Fabrication and characterization of CdS-sensitized TiO2 nanotube photoelectrode. J Nanopart Res 13:555–562

Cheng S, Fu W, Yang H, Zhang L, Ma J, Zhao H, Sun M, Yang L (2012) Photoelectrochemical performance of multiple semiconductors (CdS/CdSe/ZnS) co-sensitized TiO2 photoelectrodes. J Phys Chem C 116:2615–2621

Chi C, Chen P, Lee Y, Liu I, Chou S, Zhang X, Bach U (2011) Surface modifications of CdS/CdSe co-sensitized TiO2 photoelectrodes for solid-state quantum-dot-sensitized solar cells. J Mater Chem 21:17534–17540

Chu VH, Nghiem THL, Le TH, Vu DL, Tran HN, Vu TKL (2012) Synthesis and optical properties of water soluble CdSe/CdS quantum dots for biological applications. Adv Nat Sci 3:025017

Chung I, Lee B, He J, Chang RPH, Kanatzidis MG (2012a) All-solid-state dye-sensitized solar cells with high efficiency. Nature 485:486–489

Chung I, Song JH, Im J, Androulakis J, Malliakas CD, Li H, Freeman AJ, Kenney JT, Kanatzidis MG (2012b) CsSnI3: semiconductor or metal? High electrical conductivity and strong near-infrared photoluminescence from a single material. High hole mobility and phase-transitions. J Am Chem Soc 134:8579–8587

Dao VD, Kim SH, Choi HS, Kim JH, Park HO, Lee JK (2011) Efficiency enhancement of dye-sensitized solar cell using Pt hollow sphere counter electrode. J Phys Chem C 115:25529–25534

Gao X, Li H, Sun W, Chen Q, Tang F, Peng L (2009) CdTe quantum dots-sensitized TiO2 nanotube array photoelectrodes. J Phys Chem C 113:7531–7535

Guan X, Huang S, Zhang Q, Shen X, Sun H, Li D, Luo Y, Yu R, Meng Q (2011) Front-side illuminated CdS/CdSe quantum dots co-sensitized solar cells based on TiO2 nanotube arrays. Nanotechnology 22:465402

Hagfeldtt A, Grätzel M (1995) Light-induced redox reactions in nanocrys-talline systems. Chem Rev 95:49–68

Hossain MF, Biswas S, Zhang Z, Takahashi T (2011) Bubble-like CdSe nanoclusters sensitized TiO2 nanotube arrays for improvement in solar cell. J Photochem Photobiol A 217:68–75

Hsiao PT, Liou YJ, Teng H (2011) Electron transport patterns in TiO2 nanotube arrays based dye-sensitized solar cells under frontside and backside illuminations. J Phys Chem C 115:15018–15024

Huang D, Tian R, Zhao Y, Nie J, Cai X, Yao C (2010a) First-principles study of CuAlS2 for p-type transparent conductive materials. J Phys D Appl Phys 43:395405

Huang K, Wang Y, Dong R, Tsai W, Tsai K, Wang C, Chen Y, Vittal R, Lin J, Ho K (2010b) A high performance dye-sensitized solar cell with a novel nanocomposite film of PtNP/MWCNT on the counter electrode. J Mater Chem 20:4067–4073

Huang L, Peng F, Wang H, Yu H, Geng W, Yang J, Zhang S, Zhao H (2011a) Controlled synthesis of octahedral Cu2O on TiO2 nanotube arrays by lectrochemical deposition. Mater Chem Phys 130:316–322

Huang Y, Sun L, Xie K, Lai Y, Liu B, Ren B, Lin C (2011b) SERS study of Ag nanoparticles electrodeposited on patterned TiO2 nanotube films. J Raman Spectrosc 42:986–991

Ip AH, Thon SM, Hoogland S, Voznyy O, Zhitomirsky D, Debnath R, Levina L, Rollny LR, Carey GH, Fischer A, Kemp KW, Kramer IJ, Ning Z, Labelle AJ, Chou K, Amassian A, Sargent EH (2012) Hybrid passivated colloidal quantum dot solids. Nat Nanotechnol 7:577–582

Joshi P, Zhang L, Chen Q, Galipeau D, Fong H, Qiao Q (2010) Electrospun carbon nanofibers as low-cost counter electrode for dye-sensitized solar cells. ACS Appl Mater Interfaces 2:3572–3577

Kamat PV (2008) Semiconductor nanocrystals as light harvesters. J Phys Chem C 112:18737–18753

Kang Q, Liu S, Yang L, Cai Q, Grimes CA (2011a) Fabrication of PbS nanoparticle-sensitized TiO2 nanotube arrays and their photoelectrochemical properties. ACS Appl Mater Interfaces 3:746–749

Kang Q, Liu S, Yang L, Cai Q, Grimes CA (2011b) Fabrication of PbS nanoparticle-sensitized TiO2 nanotube arrays and their photoelectrochemical properties. ACS Appl Mater Interfaces 3:746–749

Kang Q, Cai Q, Yao S, Grimes CA, Ye J (2012) Fabrication of Zn x Cd1−x Se nanocrystal-sensitized TiO2 nanotube arrays and their photoelectrochemical properties. J Phys Chem C 116:16885–16892

Kowalski D, Albu SP, Schmuki P (2013) Current dependent formation of PEDOT inverse nanotube arrays. RSC Adv. 3:2154–2157

Lai Y, Zhuang H, Xie K, Gong D, Tang Y, Sun L, Lin C, Chen Z (2010) Fabrication of uniform Ag/TiO2 nanotube array structures with enhanced photoelectrochemical performance. New J Chem 34:1335–1340

Lai Y, Lin Z, Zheng D, Chi L, Du R, Lin C (2012) CdSe/CdS quantum dots co-sensitized TiO2 nanotube array photoelectrode for highly efficient solar cells. Electrochim Acta 79:175–181

Lee YL, Lo YS (2009) Highly efficient quantum-dot-sensitized solar cell based on co-sensitization of CdS/CdSe. Adv Funct Mater 19:604–609

Lee HJ, Leventis HC, Moon S, Chen P, Ito S, Haque SA, Torres T, Nüesch F, Geiger T, Zakeeruddin SM, Grätzel M, Nazeeruddin MK (2009a) PbS and CdS quantum dot-sensitized solid-state solar cells: old concepts, new results. Adv Funct Mater 19:2735–2742

Lee K, Chen P, Hsu C, Huang J, Ho W, Chen H, Ho K (2009b) A high-performance counter electrode based on poly (3, 4-alkylenedioxythiophene) for dye-sensitized solar cells. J Power Sources 188:313–318

Li P, Wu J, Lin J, Huang M, Huang Y, Li Q (2009) High-performance and low platinum loading Pt/Carbon black counter electrode for dye-sensitized solar cells. Sol Energy 83:845–849

Li J, Yang L, Luo S, Chen B, Li J, Lin H, Cai Q, Yao S (2010) Polycyclic aromatic hydrocarbon detection by electrochemiluminescence generating Ag/TiO2 nanotubes. Anal Chem 82:7357–7361

Li D, Chien C, Deora S, Chang P, Moulin E, Lu J (2011a) Prototype of a scalable core–shell Cu2O/TiO2 solar cell. Chem Phys Lett 501:446–450

Li L, Chen Y, Wu H, Wang NS, Diau Eric W (2011b) Detachment and transfer of ordered TiO2 nanotube arrays for front-illuminated dye-sensitized solar cells. Energy Environ Sci 4:3420–3425

Li X, Liu H, Luo D, Li J, Huang Y, Li H, Fang Y, Xu Y, Zhu L (2012) Adsorption of CO2 on heterostructure CdS(Bi2S3)/TiO2 nanotube photocatalysts and their photocatalytic activities in the reduction of CO2 to methanol under visible light irradiation. Chem Eng J 180:151–158

Li Z, Yu L, Liu Y, Sun S (2014) CdS/CdSe quantum dots co-sensitized TiO2 nanowire/nanotube solar cells with enhanced efficiency. Electrochim Acta 129:379–388

Li Z, Yu L, Liu Y, Sun S (2015) Efficient quantum dot-sensitized solar cell based on CdS x Se1−x /Mn–CdS/TiO2 nanotube array electrode. Electrochim Acta 153:200–209

Liang Y, Cui Z, Zhu S, Liu Y, Yang X (2011) Silver nanoparticles supported on TiO2 nanotubes as active catalysts for ethanol oxidation. J Catal 278:276–287

Liao J, Lin S, Li X, Li S, Cao X, Cao Y (2012) Fabrication of free-standing TiO2 nanotube membranes with through-hole morphology. Cryst Res Technol 47:731–737

Lim I, Yoon SJ, Lee W, Nah YC, Shrestha NK, Ahn H, Han SH (2012) Interfacially treated dye-sensitized solar cell with in situ photopolymerized iodine doped polythiophene. ACS Appl Mater Interfaces 4:838–841

Lin J, Liao J, Hung T (2011) A composite counter electrode of CoS/MWCNT with high electrocatalytic activity for dye-sensitized solar cells. Electrochem Commun 13:977–980

Liu Y, Zhang X, Liu R, Yang R, Liu C, Cai Q (2011) Fabrication and photocatalytic activity of high-efficiency visible-light-responsive photocatalyst ZnTe/TiO2 nanotube arrays. J Solid State Chem 184:684–689

Liu G, Wang K, Nils H, Henrik J (2012a) Progress on free-standing and flow-through TiO2 nanotube membranes. Sol Energy Mater Sol Cells 98:24–38

Liu X, Jiang Y, Lan X, Zhang Y, Liu C, Li J, Wang B, Yu Y, Wang W (2012b) Improved efficiency of hybrid solar cell based on thiols-passivated CdS quantum dots and poly(3-hexythiophene). Phys Status Solidi (a) 209:1583–1587

Macak JM, Schmidt-Stein F, Schmuki P (2007) Efficient oxygen reduction on layers of ordered TiO2 nanotubes loaded with Au nanoparticles. Electrochem Commun 9:1783–1787

Mor GK, Varghese OK, Paulose M, Shankar K, Grimes CA (2006) A review on highly ordered, vertically oriented TiO2 nanotube arrays: fabrication, material properties, and solar energy applications. Sol Energy Mater Sol Cells 90:2011–2075

Nevins JS, Coughlin KM, Watson DF (2011) Attachment of CdSe nanoparticles to TiO2 via aqueous linker-assisted assembly: influence of molecular linkers on electronic properties and interfacial electron transfer. ACS Appl Mater Interfaces 3:4242–4253

Nguyen D, Ito S, Inoue M, Yusa S (2012) Superstrate CuInSe2-printed solar cells on In2S3/TiO2/FTO/glass plates. Energy Sci Technol 3:10–17

Paramasivam I, Macak JM, Ghicov A, Schmuki P (2007) Enhanced photochromism of Ag loaded self-organized TiO2 nanotube layers. Chem Phys Lett 445:233–237

Qiao J, Wang Q, Xiao Y (2014) High-efficiency photoelectrochemical performance of PbS nanoparticles sensitized TiO2 nanotube arrays. J Appl Electrochem 44:1007–1011

Radich JG, Dwyer R, Kamat PV (2011) Cu2S reduced graphene oxide composite for high-efficiency quantum dot solar cells. Overcoming the redox limitations of S2−/S 2−n at the counter electrode. J Phys Chem Lett 2:2453–2460

Ratanatawanate C, Xiong C Jr, Balkus KJ (2008) Fabrication of PbS quantum dot doped TiO2 nanotubes. ACS Nano 2:1682–1688

Roy P, Kim D, Paramasivam I, Schmuki P (2009) Improved efficiency of TiO2 nanotubes in dye sensitized solar cells by decoration with TiO2 nanoparticles. Electrochem Commun 11:1001–1004

Ruby MAE, Sohrab R (2011) Modified TiO2 nanotube arrays (TNTAs): progressive strategies towards visible light responsive photoanode, a review. Energy Environ Sci 4:1065–1086

Schaller RD, Klimov VI (2004) High efficiency carrier multiplication in PbSe nanocrystals: implications for solar energy conversion. Phys Rev Lett 92:186601

Shankar K, Mor GK, Prakasam HE, Varghese OK, Grimes CA (2007) Self-assembled hybrid polymer-TiO2 nanotube array heterojunction solar cells. Langmuir 23:12445–12449

Shin K, Seok S, Im SH, Park JH (2010) CdS or CdSe decorated TiO2 nanotube arrays from spray pyrolysis deposition: use in photoelectrochemical cells. Chem Commun 46:2385–2387

Si H, Sun Z, Zhang H (2008) Photoelectrochemical response from CdSe-sensitized anodic oxidation TiO2 nanotubes. Colloids Surf 313:604–607

Smith YR, Sarma B, Mohanty SK, Misra M (2012) Light-assisted anodized TiO2 nanotube arrays. ACS Appl Mater Interfaces 4:5883–5890

Speirs MJ, Balazs DM, Fang HH, Lai LH, Protesescu L, Kovalenko MV, Loi MA (2015) Origin of the increased open circuit voltage in PbS–CdS core–shell quantum dot solar cells. J Mater Chem A 3:1450–1457

Su Z, Zhou W (2011) Formation, morphology control and applications of anodic TiO2 nanotube arrays. J Mater Chem 21:8955–8970

Sun W, Yu Y, Pan H, Gao X, Chen Q, Peng L (2008) CdS quantum dots sensitized TiO2 nanotube-array photoelectrodes. J Am Chem Soc 130:1124–1125

Sun H, Luo Y, Zhang Y, Li D, Yu Z, Li K, Meng Q (2010) In situ preparation of a flexible polyaniline/carbon composite counter electrode and its application in dye-sensitized solar cells. J Phys Chem C 114:11673–11679

Tachan Z, Shalom M, Hod I, Ruhle S, Tirosh S, Zaban A (2011) PbS as a highly catalytic counter electrode for polysulfide-based quantum dot solar cells. J Phys Chem C 115:6162–6166

Tvrdy K, Frantsuzov PA, Kamat PV (2012) Photoinduced electron transfer from semiconductor quantum dots to metal oxide nanoparticles. PNAS 108:29–34

Wang H, Hu Y (2012) Graphene as a counter electrode material for dye-sensitized solar cells. Energy Environ Sci 5:8182–8188

Wang J, Lin Z (2009) Anodic formation of ordered TiO2 nanotube arrays: effects of electrolyte temperature and anodization potential. J Phys Chem C 113:4026–4030

Wang G, Lin R, Lin Y, Li X, Zhou X, Xiao X (2005) A novel high-performance counter electrode for dye-sensitized solar cells. Electrochim Acta 50:5546–5552

Wang Q, Yang X, Liu D, Chi L, Hou J (2012a) Ag and CdS nanoparticles co-sensitized TiO2 nanotubes for enhancing visible photoelectrochemical performance. Electrochim Acta 83:140–145

Wang Q, Yang X, Liu D, Zhao J (2012b) Fabrication, characterization and photocatalytic properties of Ag nanoparticles modified TiO2 NTs. J Alloys Compd 527:106–111

Wang W, An W, Ramalingam B, Mukherjee S, Niedzwiedzki DM, Gangopadhyay S, Biswas P (2012c) Size and structure matter: enhanced CO2 photoreduction efficiency by size-resolved ultrafine Pt nanoparticles on TiO2 single crystals. J Am Chem Soc 134:11276–11281

Wang J, Mora-Sero I, Pan Z, Zhao K, Zhang H, Feng Y, Yang G, Zhong X, Bisquert J (2013a) Core/shell colloidal quantum dot exciplex states for the development of highly efficient quantum-dot-sensitized solar cells. J Am Chem Soc 135:15913–15922

Wang Q, Yang X, Chi L, Cui M (2013b) Photoelectrochemical performance of CdTe sensitized TiO2 nanotube array photoelectrodes. Electrochim Acta 91:330–336

Wang Q, Li S, Qiao J, Jin R, Yu Y, Gao S (2015) CdS-CdSe (CdTe) core-shell quantum dots sensitized TiO2 nanotube array solar cells. Sol Energy Mater Sol Cells 132:650–654

Wen H, Liu Z, Yang Q, Li Y, Yu J (2011) Synthesis and electrochemical properties of CeO2 nanoparticle modified TiO2 nanotube arrays. Electrochim Acta 56:2914–2918

Xie K, Sun L, Wang C, Lai Y, Wang M, Chen H, Lin C (2010a) Photoelectrocatalytic properties of Ag nanoparticles loaded TiO2 nanotube arrays prepared by pulse current deposition. Electrochim Acta 55:7211–7218

Xie Y, Ali G, Yoo SH, Cho SO (2010b) Sonication-assisted synthesis of CdS quantum-dot-sensitized TiO2 nanotube arrays with enhanced photoelectrochemical and photocatalytic activity. ACS Appl Mater Interfaces 2:2910–2914

Xie H, Que W, He Z, Zhong P, Liao Y, Wang G (2013) Preparation and photocatalytic activities of Sb2S3/TiO2 nanotube coaxial heterogeneous structure arrays via an ion exchange adsorption method. J Alloys Compd 550:314–319

Xu J, Yang X, Yang Q, Wong T, Lee C (2012a) Cu2ZnSnS4 hierarchical microspheres as an effective counter electrode material for quantum dot sensitized solar cells. J Phys Chem C 116:19718–19723

Xu J, Yang X, Wong T, Lee C (2012b) Large-scale synthesis of Cu2SnS3 and Cu1.8S hierarchical microspheres as efficient counter electrode materials for quantum dot sensitized solar cells. Nanoscale 4:6537–6542

Yang SY, Choi W, Park H (2015) TiO2 nanotube array photoelectrocatalyst and Ni–Sb–SnO2 electrocatalyst bifacial electrodes: a new type of bifunctional hybrid platform for water treatment. ACS Appl Mater Interfaces 7:1907–1914

Zeng T, Gladwin E, Claus RO (2003) Self-assembled InP quantum dot-TiO2 solid grätzel solar cell. MRS Proceedings 764

Zhang H, Quan X, Chen S, Yu H, Ma N (2009) “Mulberry-like” CdSe nanoclusters anchored on TiO2 nanotube arrays: a novel architecture with remarkable photoelectrochemical performance. Chem Mater 21:3090–3095

Zhang S, Zhang S, Peng F, Zhang H, Liu H, Zhao H (2011) Electrodeposition of polyhedral Cu2O on TiO2 nanotube arrays for enhancing visible light photocatalytic performance. Electrochem Commun 13:861–864

Zhang Z, Zhang L, Hedhili MN, Zhang H, Wang P (2013) Plasmonic gold nanocrystals coupled with photonic crystal seamlessly on TiO2 nanotube photoelectrodes for efficient visible light photoelectrochemical water splitting. Nano Lett 13:14–20

Zheng Q, Kang H, Yun J, Lee J, Park JH, Baik S (2011) Hierarchical construction of self-standing anodized titania nanotube arrays and nanoparticles for efficient and cost-effective front-illuminated dye-sensitized solar cells. ACS Nano 5:5088–5093

Zhong J, Wang Q, Xu X (2014) Photodeposition of CdS nanoparticles sensitized TiO2 nanotube arrays for enhanced photoelectrochemical performance. J Electrochem Soc 161:H656–H659

Zhou Y, Zhou W, Li M, Du Y, Wu S (2011) Hierarchical Cu2ZnSnS4 particles for a low-cost solar cell: morphology control and growth mechanism. J Phys Chem C 115:19632–19639

Acknowledgments

This work was financially supported by the National Natural Science Foundation of China (51402145), the Nanotechnology Special foundation of Shanghai (11nm0500700), and the Key Project of Natural Science Foundation of Shandong Province (ZR2013EMZ001).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Wang, Q., Chen, C., Liu, W. et al. Recent progress in all-solid-state quantum dot-sensitized TiO2 nanotube array solar cells. J Nanopart Res 18, 7 (2016). https://doi.org/10.1007/s11051-015-3314-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11051-015-3314-9