Abstract

In this work, the thermal behavior of polymeric blends was prepared with the combination of post-consumer bottles of ethylene poly-terephthalate (recyclable RPET) and PHB (poly(3-hydroxybutyrate)), under several proportions. The PHB, RPET and PHB/RPET films were prepared from individual PHB and RPET solutions, obtained from controlled heating. X-ray diffractions, the absorption spectra in the infrared region (FTIR), thermogravimetry (TG), differential thermal analysis (DTA) techniques were used to examine the crystallinity, chemical interactions, thermal stability and melting point, respectively. In addition, the derivative thermogravimetry (DTG) curves under non-isothermal condition were also used to evaluate the behavior kinetics of the blends to see the possible alterations in thermal decomposition. The results of the X-ray analysis showed that the crystallinity in PHB/RPET had signals intense and also the lack of the diffraction related to PHB, while the FTIR analysis showed individual bands of the two polymers, indicating that there was little interaction between them. The TG/DTG and DTA curves had several reactions, shown that the blends are strongly dependent on the heating rates used. The thermal reactions also showed different events, which correspond to the decomposition of different components, of the blends. The kinetic parameters, such as activation energy (E) and the factor of Arrhenius (A), showed that two blends had a similar behavior in the initial development of the kinetic behavior, while the third sample had behavior differently of the others. Additionally, the kinetic compensation effect was determined and showed the probable direction of the thermal decomposition for individual PHB and RPET as for its respective blends.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Plastics originating from petroleum have some desirable mechanical properties and numerous applications. Conventional plastic materials have low degradation rates which can cause serious environmental problems. Alternatives to mitigate the effect of the various plastics have been made the chemical recycling these materials, with the purpose of reuse [1, 2]. Usually, ethylene poly-terephthalate accumulates in the garbage of Brazilian cities, originated mainly from post-consumption soft-drink PET bottles. These materials are considered and an important source of raw material for recycling (RPET). Moreover, the PET is a thermoplastic semicrystalline with excellent tensile and impact strength, and the polymer wastes can be recycled in many ways. It can be used for several applications, such as in packaging, textile and electronics compounds, and regardless to the end of the duty cycle also need to be recycled. Therefore, the production of eco-friendly biodegradable plastics is one such reality that can help to overcome the hazards of non-degradable plastics and avoid accumulation in the environment. As the disposal of manufactured products is still a constant problem, it is necessary to prepare and test new biodegradable materials, as, for example, the biodegradable aliphatics, such as poly (butyleneadipate-co-terephthalate) (PBAT), polycaprolactone (PCL), poly(lactic acid) (PLA), poly(butylenesuccinate) (PBS) and poly(3-hydroxybutyrate) (PHB) [3,4,5]. Vitorino et al. [6] have studied the biodegradable polymer produced with babassu palm (Attalea speciosa), which is new thermoplastic, formed with PHB matrix. Besides, the aim of manufacturing PHB is the biodegradability and also the biocompatibility environmental.

Thus, as an alternative to recycling PET, the use of blends with PHB can be an alternative, and much effort has been made by other researchers to overcome the problems of blending the PHB with various polymers. The PHB originates from renewable sources and biodegradable aliphatic polyester, and it also degrades entirely by aerobic microorganisms to CO2 and H2O conversion [2,3,4]. However, pure PHB has some disadvantages, such as its high degree of crystallinity, poor thermal stability and low mechanical properties [(7,8,9,10)]. Souza et al. [8] studied the PHB with structural modifications through reactions with hydroxy acids (HA), such as tartaric acid (TA) and malic acid (MA). The results showed that the introduction of tartaric acid and malic acid would significantly increase the activation energy values of PHB [7]. Taweel and Stoll [11] studied the effect of spherulitic growth rates of blends of polyhydroxybutyrate (PHB) with several oligomers, where the influence of the temperature in the mass increase in PHB in the blends was verified. According to Brebu et al. and also Sarker and Rashid, both authors have indicated that the plastic waste represents about 8 mass% of the municipal solid waste. The plastic wastes are a mixture of several polymers, which are not treated appropriately and are often incinerated by pyrolysis or low amounts of oxygen [12]. Czégény et al. indicated that the “pyrolysis is a promising alternative for plastic waste recycling since the process produces valuable chemicals or fuels.” These authors also indicate the use of thermal analysis, especially the evaluation by TG curves, as a technique to evaluate mixtures of different polymer, get interesting information about the steps of thermal decomposition [13]. Besides this, solid state reactions of many types of plastics include phase transitions such as melting, evaporation, sublimation and also decomposition stages, which can result in the production of different compounds [14,15,16]. Thus, thermal analysis can be used to monitor these reactions and determine the change of mass loss as well as others thermal behaviors.

There are studies concerning about PHB/PET polymers. Li et al. reported the polycondensation modification of PHB/PET polymers with eight monomers and each with different structural features. The authors showed that the compound with vanillic acid exhibits a lower melting point, and other characteristics properties [17]. Blends obtained with PET and PHB change the properties of the final product, improving the mechanical properties of the prepared compound [18,19,20].

Ioakeimidis et al. studied the PET bottles (ethylene poly-terephthalate) collected in the submarine environment. The samples were characterized by ATR-FTIR, and the authors indicate that after 15 years, there were the decreased functional groups or disappeared and even formed new groups [21]. The biodegradation of plastics by microorganisms and enzymes was studied by Nakkabi et al. [22]. These authors verified that this would be an interesting process for the effective process to fight against plastic waste. Japanese researchers also evaluated a bacterium that degrades and assimilates poly(ethylene terephthalate) and identified the decomposition mechanism [23].

In the present work, the aim was the preparation of PHB/RPET blends under heating of 50 °C and also in a room temperature with the purpose of comparison and evaluation of the thermal decomposition and kinetic behavior. Simultaneous TG–DTA curves have been used with a rising temperature program and specific rate constants to evaluate the thermal stability, while the DTG curves were used to determine the experimental data to evaluate the kinetic behavior. The kinetics parameters are estimated at temperatures corresponding to fixed values of conversion degree (α) and the activation energy (Ea/kJ mol−1). Thus, the data obtained from DTG curves (triplicate) were applied using the isoconversional method proposed by Flynn–Wall–Ozawa [1, 2, 24]. Furthermore, X-ray powder diffractometry evaluations were also carried out to verify the interaction between the polymers and the prepared blends. Preliminary tests carried out in the soil under different experimental conditions showed the possible degradation of PHB samples blends.

Experimental

The post-consumer soft-drink bottles (RPET) were washed, dried at room temperature, cut into pieces of approximately 2 mm2 and dissolved in a phenol/tetrachloromethane solution (~ 1:1 v/v) at 80 °C under stirring. After dissolving the RPET, trichloromethane was used as the stabilizing agent of the solution.

Samples of commercial PHB provided by PHB Industrial and medium MM 342,000 g mol−1 [25] were also prepared by dissolving in trichloromethane at 60 °C under stirring. Keeping the solutions on heating, add RPET slowly over the PHB, stirring continuously, thus obtaining the PHB/RPET solution. The films were obtained with the respective PHB, RPET and PHB/RPET solutions added in Petri dishes for drying at room temperature for 48 h (A) or drying by heating at 50 °C in an electric plate (B), as shown in Table 1.

The X-ray powder pattern of the samples was recorded by a Siemens D-5000 X-ray diffractometer, using CuKα radiation (λ = 1.544 Å) and settings of 40 kV and 20 mA.

The absorption spectra in the infrared region were obtained in an Impact 400 SX-FT “NICOLET” Spectrophotometer from 4000 to 400 cm−1 and resolution of 4 cm−1.

The thermal stability and kinetic studies were performed using a TA Instruments SDT 2960, from TA Instruments under dynamic nitrogen gas purge with a flow of 100 mL min−1. The heating rates of 5, 10 and 20 °C min−1 were used from 40 to 300 °C, with a sample mass around 9 mg in an α-alumina crucible. For the preliminary test in wet soil, a vessel of 10 L capacity was used, adding soil up to approximately 5 cm from the upper border. The sample was added in Eppendorf 2.0 mL with a plain cap and perforated at the thin end, and introduced into the soil with the tip down to facilitate mobility of moisture, keeping the soil constantly moist. The images used were obtained from a binocular optical microscope of the Bioval brand with the increase from 100x.

Results and discussion

Figure 1 shows the X-ray diffractions for samples of PHB, RPET, and PHB/RPET films in only one condition (A) because in condition B, the result was similar to that shown. The diffraction of PHB sample shows plans of diffraction in 2θ equal 13.9° and 16.9°, to RPET 14.1° and 16.9°. PHB/RPET 8/1 blends show plans of diffractions to 13.5°, 17.0° and 25.7°, and blend 1/1 and 8/1 shows plans of diffractions to 14.1°, 17.0° and 25.7°. It can be observed the crystallinity effect, with the increased mass ratio of RPET in blends, the signals are more intense and acute, and also the lack of the diffraction related to PHB. Thus, this result shows that the X-ray diffraction can be used as a technique for the evaluation of polymeric presence in the samples [26, 27].

Studies indicated surface erosion with the formation of holes and formation of layers and concluded that the degradation begins by the amorphous regions of the polymer extending into central crystalline regions and finally reaching the peripheral crystalline regions [28].

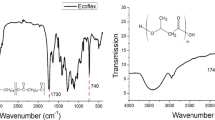

Samples of PHB, RPET, PHB and PHB/RPET (condition (A)) were evaluated by infrared spectroscopy from 4000 to 400 cm−1, as shown in Fig. 2.

The infrared spectra of PHB films have the main characteristic bands assigned as the axial deformations of carbonyl (C=O) at 1731 cm−1, OH at 3444 cm−1 and C–C at 980 cm−1 [29,30,31]. In addition, it possible to see the symmetrical and asymmetrical angular strain in the plane, of CH3 groups at 1375 and 1445 cm−1 and typical band of the helical conformation of the chains at 1126 cm−1. The 1135 and 1165 cm−1 bands are, respectively, assigned to symmetrical and asymmetrical stretches of C–O–C groups, and bands 2933 and 2982 cm−1 are attributed to symmetrical and asymmetric axial deformation, respectively, of the C–H bond.

The absorption spectrum in the infrared region for RPET films in also shows the characteristic bands [32], such as 1722 cm−1 relative to the stretching of the carbonyl esters (C=O), between 1024 and 1259 cm−1 relative to the stretching of the ester (CO) bond, at 731 cm−1, p-substitution of the aromatic ring conjugated with the carbonyl and at 2973 and 2908 cm−1, stretching of the CH bond. In 3436 cm−1 a band not reported in the literature is observed which must be of the OH group from the phenol.

From the results obtained by infrared spectra, all analyzed PHB/RPET samples show the characteristic bands contained in the individual PHB and RPET spectra. It is an indication that these polymers have low interaction since the chemical groups contained in the individual polymers are found in the blends in both. The only exception is the appearance of a band between 3433 and 3444 cm−1, which is more acute after heating and may be related to the chemical OH group of phenol, which should be promoting weak bonds with RPET.

Before performing the thermal evaluation of the blend, it is necessary to evaluate the two main materials (RPET and PHB) and both thermal behaviors. The evaluation of small reactions can shed light on understanding the thermal behavior observed. Besides this, the importance of these facts can be linked to the kinetic behavior in solid state [14, 33].

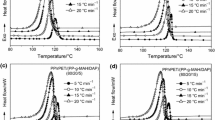

The effect of heating on the RPET and PHB can be seen in Figs. 3–6, where it is possible to observe the thermal parameters obtained by TG/DTG curves. Figure 3, for the RPET sample, shows that during the progress with the three heating rates (5, 10 and 20 °C min−1), several reactions took place, and that the thermal behavior is strongly dependent on the heating rate. For analysis under 20°Cmin−1, the compound has a mass gain of 1.36%, between initial temperature and 245 °C (not shown in Fig. 3). During the melting point (Fig. 6), there occurs a sudden mass loss of 0.63%, as seen in TG curve in Fig. 3. After melting, the compound had a mass gain of 0.63%, up to the temperature of 362 °C. The first stage of thermal decomposition occurs between 362 and 393 °C, and the second occurs between 393 and 500 °C with loss of 84.70%. For the analysis with a heating rate of 10°C min−1, the behavior is very similar to the rate of 20°C min−1, but with lower gain of mass and also of mass loss. The corresponding values of temperature and mass variation are: (1) Between the initial temperature and 244 °C, there was a mass gain of 0.70% (not shown in Fig. 3); (2) between 250 and 367 °C, there was a loss mass of 0.28% and after the 367 °C, there occurs the main thermal decomposition up to 500 °C, with mass loss of 84.72%. For the analysis with the rate of 5 °C min−1, between the initial temperature and 240 °C, there was a loss of 0.82%, and between 240 and 375 °C, there occurs a gain of 1.35%. The main thermal decomposition occurs with mass loss of 82.30%. The mass loss before the main thermal decomposition was not observed, as seen in the rates of 10 and 20 °C min−1, probably due to the lower speed rate of 5 °C min−1.

Concerning the PHB sample in Fig. 4, the thermal behavior shows that for heating rates used in this study, the sample also has small variations in mass. From the initial temperature, up to 140 ºC, was not seen mass variation with the samples. For rates of the 20 and 5 °C min−1, there were a mass gain between 147–228 °C (0.56%) and 169–230 °C (0.69%), respectively. The sample under 10 °C min−1 shows a mass loss of 0.16% between 156 and 180 °C and a mass gain of 0.80% between 222 and 245 °C.

As aforementioned, the masses variations observed can be attributed to the several sample sizes in the mass sample used for analysis, which causes a difference in the stages of mass variation. In addition, with samples not uniform, may cause variations in the behavior of the TG curves during the melting process, where the different particles size lose solvents in different times, and thus, the crucible vibrates. Other factors can also be considered, among which: (1) only the effect of the solvent present in the samples, due to the evaporation; (2) due to the melting point effect, which associated with the speed of the heating rate, can favor the loss or gain of mass the reaction with the purge gas [34, 35]; (3) factors related to the equipment, but in this case, the oscillation in balance should have a repetition pattern.

Figure 5 shows the TG/DTG curves for both samples (RPET and PHB), where it is possible to see the complete profile of both samples and that the mass loss occurs in one only stage. Moreover, these curves also were used for kinetic evaluation.

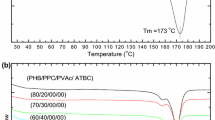

These previously observed changes may be better understood with the use of DTA curves of RPET and PHB samples, as shown in Fig. 6. Also, Santos et al. and Souza et al. have reported the behavior of RPET and PHB samples by DSC curves, as well as crystallization, vitreous transition and melting points, respectively [7, 8]. In the DTA curve of the RPET sample, we can see that the first endothermic peak is due to the melting point, which occurs at 248 °C. Furthermore, the DTA analysis under 20 °C min−1 shows an exothermic peak between 373 and 411 °C, which is followed by an endothermic peak, both during the thermal decomposition. This fact demonstrates that during the thermal decomposition, there occurs the alteration of heat, which is associated with the heating rate used. The curves are evaluated with heating rates of 5 and 10 °C min−1, and it is possible to see that both are in concordance. Concerning the PHB curves, we can see that the melting point of this compound occurs at 175 °C. The thermal decomposition occurs between 248 and 350 °C, as observed in TG/DTG curves. Also, it is possible to see the displacement of the curves, attributed to the inertia effect due to the several heating rates during the thermal decomposition.

The thermal stability of the prepared blends is summarized in Table 1, with the mass losses of these compounds. The same behavior of mass variation, as seen in PET and PHB samples, was not observed for all blends, which has more significant mass variations.

Figure 7 shows the TG/DTG curves of the A and B of the PHB/RPET films 8/1, 1/1 and 1/8, where it is possible to observe that for samples with the PHB/RPET with ratio of 1/8, the mass loss is more significant. It is also possible to verify that the samples with the presence of a higher mass of RPET had a higher amount of residue at the completion of analysis. For the second and third steps of thermal decomposition, the mass losses are proportional to the mass of PHB and RPET, respectively, contained in the mixtures in A and B [1, 2].

Figure 8 shows the DTA curves of the PHB/RPET samples with ratio of 1/1 and 8/1. For both blends investigated, there is a distinct endothermic peak, which was attributed to the fusion at 175 °C and another peak starting from 250 °C, which was attributed to the stage of decomposition of PHB. For samples regarding 1/8, also, we can see an endothermic peak around 242 °C which is attributed to the fusion of RPET, where the RPET prevails in the blend. This same event can also be noted in the proportion 1/1 but with less intensity. Nevertheless, the 8/1 blend shows no thermal event of RPET.

The kinetic parameters were determined for the thermal decomposition of the individual PHB and RPET films, according to Fig. 5. As well as this, the kinetic evaluation contained in PHB/RPET blends A and B was carried out on the first and second mass losses. The activation energy (Ea/kJ mol−1) and pre-exponential factor (A) were obtained by non-isothermal measures through the isoconversional method, which was determined from DTG curves. The experimental data of activation energy (Ea), ln A and coefficient of variation (CV) are summarized in Table 2.

Mathematically, the kinetic triplet (Ea, log A and f(α)) can be obtained by the general equation (Eq. 1) [1, 2, 7, 36]:

where α is a conversional fraction, T is the temperature, and β the heating rate. According to the isoconversional method, from the angular coefficient log β in function of 1/T, it is possible to calculate the activation energy.

Figure 9 shows the plots of activation energy versus conversion degree of thermal decomposition of the RPET and PHB samples. For the RPET sample, the behavior maintains the same feature on the extension of conversion degree (α), while the PHB sample shows a continual increase in the conversion degree. It is imperative to remember that the RPET and PHB samples were prepared with the dissolution in an appropriate solvent, as aforementioned. Santos et al. reported the thermal decomposition the PHB sample without dissolution, but only “in nature” condition. The result of this investigation under non-isothermal conditions shows that the kinetic evaluation shows a continual decrease in the activation energy (from around 160–145 kJ mol−1) [33]. The different results of PHB obtained by Santos et al. when compared with our results are attributed to the structural rearrangement of the molecules, which influences the kinetic behavior. Concerning the PET sample, Run et al. reported the kinetic behavior by isothermal condition and inert gas purge, with a variation of the values of activation energy from around 208–230 kJ mol−1. The results obtained by these authors are close to our results, as observed in Fig. 9 [37].

The behavior of the blends A and B is shown in Figs. 10 and 11, respectively, which were evaluated from the first stage of decomposition. It is possible to observe that the thermal decomposition of both blends (A and B) has a similar trend in the development of the kinetic behavior, which suggests the same reaction mechanism. Now, in blend B, the ratios of 1/8 and 8/1 had the same similarity, indicating the same reaction mechanism, which suggests that there was no change in kinetic behavior during the mass loss.

Also, the interpretation of kinetic results can be made using a mathematical artifice to verify the occurrence of similar reactions or to a reaction under several experimental conditions. This dependence is known as the kinetic compensation effect or isokinetic (activation energy (Ea) versus ln A) that is expressed mathematically using Eq. (2). A linear relationship has been verified between the ln A and the activation energy, and then, some alteration in one of the parameters is compensated by a corresponding variation in the other one.

where a and b are the characteristic constants of the system [38,39,40,41].

The dependence of activation energy on α and the kinetic compensation effect (KCE) have been observed for thermal decomposition of PHB, RPET and PHB/RPET samples obtained from A and B as aforementioned. Figure 12 shows the KCE to individual PHB and RPET and PHB and RPET in a mixture, respectively. Through the values shown, with the correlation coefficient next to 1, the KCE indicates that the thermal decomposition of the individual PHB and RPET and both of them in their respective blends occurs under the same mechanism.

The preliminary test in wet soil for RPET, PHB/RPET blends (1/8, 1/4, 1/2, 2/1 and 8/1) and PHB was evaluated for a period of 5 months to evaluate the degradability.

The wet soil showed a positive response to environmental degradation. The photomicrographs of Fig. 13 show films added in soil. The photomicrograph of the individual RPET film does not show a degraded surface, but with a gradual increase in PHB mass in the blends, dark regions occur on its surface indicating that it may have begun the degradative process at these points. These films are formed by small spheres agglutinated one on top of the other in the form of layers, and in the degradation process, these spheres are coming off the surface. The sample of the film containing individual PHB dissolved in the soil, not being possible to make the photograph.

Conclusions

The evaluation of polymer mixtures non-miscible is more complex than the degradation of mono polymers and, therefore, is of very high interest.

The results obtained with the FTIR shown that the PHB/PET-R samples analyzed have individual absorption bands PHB and PET-R. This is an indication that these polymers have low interaction between them. The X-ray analysis showed the crystallinity effect, with the mass increased of RPET in blends and the disappearance of some peaks, which may suggest small chemical and physical changes in the structure of the chains.

The thermal analytical study of PHB, RPET and PHB/RPET blends by thermogravimetry degradation under non-isothermal conditions allowed the determination of the main thermal events showed by the individual compounds and mixing. It was possible to observe the effect caused by the use of a different temperature of evaporation of the solvent and also the effect in thermal behavior on the performance of the blend curves. With the data of TG/DTG curves at different heating rates (5, 10 e 20 °C min−1), the kinetic parameters (E and log A) were calculated using several conversion degrees α (0.05 ≤ α ≤ 0.95). Through the average activation energy (Ea) and lnA, it was possible to observe the KCE effect for blends. This same behavior was observed for the RPET, although the latter has a small dispersion of points, indicating that the thermal decomposition of this polymer is more complex, but follows the same mechanism both individually and in blends.

It shows relevant points which contribute to the thermal degradation under high temperature, since PET bottles are removed from inappropriate locations where they are discarded, as well as the fact that the process can be economically viable, thus reducing the cost of the final product. Blends obtained with PET and PHB changed the properties of the final product improved the mechanical properties of PHB in addition to reuse of PET.

Preliminary tests indicate the degradability of PHB in the blends and the possible degradation of RPET, thus requiring further evaluation in the attempt to detect some physical and chemical changes in polyethylene terephthalate.

References

Dias DS, Crespi MS, Ribeiro CA. Non-isothermal decomposition kinetics of the interaction of poly(ethylene terephthalate) with alkyd varnish. J Therm Anal Calorim. 2008;94:539–43.

ElMejjatti A, Harit T, Riahi A, Khiari R, Bouabdallah I, Malek F. Chemical recycling of poly(ethylene terephthalate). Application to the synthesis of multiblock copolyesters. Express Polym Lett. 2014;8:544–53.

Mohanty AK, Misra M, Hinrichsen G. Biofibres, biodegradable polymers, and biocomposites: an overview. Macromol Mater Eng. 2000;276–277(1):1–24.

Levchik SV, Weil ED. A review on thermal decomposition and combustion of thermoplastic polyesters. Polym Adv Technol. 2004;15(12):691–700.

Pak YL, Ahmad MB, Shameli K, Yunus WMZW, Ibrahim NA, Zainuddin N. Preparation and characterization of poly-3-hydroxybutyrate/poly (butyleneadipate-coterephthalate)/layered double hydroxide nanocomposites. Dig J Nanomater Biostruct. 2013;8(4):1395–403.

Vitorino MBC, Cipriano PB, Wellen RMR, Canedo EL, Carvalho LH. Nonisothermal melt crystallization of PHB/babassu compounds: kinetics of crystallization. J Therm Anal Calorim. 2016;126:755–69.

Dias DS, Crespi MS, Kobelnik M, Ribeiro CA. Calorimetric and SEM studies of polymeric blends of PHB-PET. J Therm Anal Calorim. 2009;97:581–4.

Souza JL, Kobelnik M, Ribeiro CA, Capela JMV, Crespi MS. Kinetic study of crystallization of PHB in presence of hydroxy acids. J Therm Anal Calorim. 2009;97:525–8.

Nadia A, Mohamed NA, Salam HE, Sabaa MW, Saad GR. Synthesis and characterization of biodegradable copoly(etherester-urethane)s and their chitin whisker nanocomposites. J Therm Anal Calorim. 2016;125:163–73.

Hong SG, Hsu HW, Ye MT. Thermal properties and applications of low molecular weight polyhydroxybutyrate. J Therm Anal Calorim. 2013;111:1243–50.

El-Taweel SH, Stoll B. Spherulitic growth rate of blends of polyhydroxybutyrate (PHB) with oligomeric atactic PHB-diol. J. Macrom Sci Part B Phys. 2012;5:567–79.

Mihai B, Thallada B, Kazuya M, Akinori M, Yusaku S, Uddin MA. The effect of PVC and/or PET on thermal degradation of polymer mixtures containing brominated ABS. Fuel. 2004;83:2021–8.

Czégény ZS, Jakab E, Blazsó M, Bhaskar T, Sakata Y. Thermal decomposition of polymer mixtures of PVC, PET and ABS containing brominated flame retardant: formation of chlorinated and brominated organic compounds. J Anal Appl Pyrolys. 2012;96:69–77.

Liu H, Wang X, Liu W, Liu B, Zhou H, Wang W. Reactive modification of poly(ethylene terephthalate) and its foaming behavior. Cell Polym. 2014;33:189–212.

Moinuddin S, Mohammad MR. Thermal degradation of poly (ethylene terephthalate) waste soft drinks bottles and low-density polyethylene grocery bags. Int J Renew Energy Environ Eng. 2013;1:78–86.

Masek A, Diakowska K, Zaborski M. Physico-mechanical and thermal properties of epoxidized natural rubber/polylactide (ENR/PLA) composites reinforced with lignocellulose. J Therm Anal Calorim. 2016;125:1467–76.

Li XG, Huang MR, Guan GH, Sun T. Synthesis and characterization of liquid crystalline polymers from p-hydroxybenzoic acid, poly(ethylene terephthalate), and third monomers. J App Polym Sci. 1997;66:2129–38.

Ahumada O, Ezquerra TA, Nogales A, Balta-Calleja FJ, Zachmann HG. Influence of liquid crystalline order on the dielectric relaxation of random copolyesters of PET, PEN, and PHB. Macrom. 1996;29:5002–9.

Sridharbabu Y, Quamara YJK. TSDC behaviour of pristine and irradiated PET/0.8 PHB polymer liquid crystal samples. J Mater Sci. 2004;39:4651–3.

Bang YH, Lee SH, Kwon IH, Cho HH. Melt spinning and annealing of poly(ethyleneterephthalate)/p-hydroxybenzoate liquid crystalline polymer. J Appl Polym Sci. 2004;94:1265–78.

Ioakeimidis C, Fotopoulou KN, Karapanagioti HK, Geraga M, Zeri C, Papathanassiou E, Galgani F, Papatheodorou G. The degradation potential of PET bottles in the marine environment: an ATR-FTIR based approach. Sci Rep. 2016. https://doi.org/10.1038/srep23501.

Nakkabi A, ElmoualiJ N, Sadiki M, Ibnsouda S, Koraichi SI, Fahim M. Biodegradation of poly (ethylene terephthalate) by bacillus subtilis. Int J Recent Adv Multidiscip Res. 2015;2(12):1060–2.

Yoshida S, Hiraga K, Takehana T, Taniguchi I, Yamaji H, Maeda Y, Toyohara K, Miyamoto K, Kimura Y, Oda K. A bacterium that degrades and assimilates poly(ethylene terephthalate). Science. 2016;351:1196–9.

Galwey AK. Is the science of thermal analysis kinetics based on solid foundations? A literature appraisal. Therm Acta. 2004;413:139–83.

Paula EV, Campos TF, Mano V. Glicólise do poli(3-hidroxibutirato) por via enzimática. Quím Nova. 2003;37(3):487–91.

Vogelsanger N. Blendas biodegradáveis de poli(3-Hidroxibutirato)/poli(ε-caprolactona): obtenção e estudo da miscibilidade. Mater Res. 2003;6(3):359–65.

Rabello MS, Wellen MRM. Estudo da cristalização a frio do poli (tereftalato de etileno) (PET) para produção de embalagens. Rev Elet Mater Proc. 2008;3:01–9.

Costa CZ, Albuquerque MCC, Brum MC, Castro AM. Degradação microbiológica e enzimática de polímeros: uma revisão. Quím Nova. 2015;38(2):259–67.

Liang CY, Krimm S. Infrared spectra of high polymers. part IX. polyethylene terephthalate. J Mol Spectrosc. 1959;3:554–74.

Urbanová M, Galiková A, Subrt J, Pola J. IR laser ablative degradation of poly(ethylene terephthalate): formation of insoluble films with differently bonded C = O groups. Polym Degrad Stabil. 2016;91:2318–23.

Zhang GQ, Sun F, Gao LP, Wang LN, Shao M, Liu JQ. Thermodynamics properties and isothermal crystallization kinetics of carbon black/poly(ethylene terephthalate) composites. J Compos Mater. 2007;41(12):1459–75.

Mancini SD, Zanin M. Influência de meios reacionais na hidrólise de PET pós-consumo. Polímeros Ciência Tecnol. 2002;12(1):34–40.

Sirocic AP, Fijacko A, Hrnjak-Murgic Z. Chemical recycling of postconsumer poly(ethylene-terephthalate) bottles—depolymerization study. Chem Biochem Eng. 2013;27(1):65–71.

Kulkarini MG, Mashelkar RA. A unified approach to transport phenomena in polymeric media II. Diffusion in solid structured polymers. Chem Eng Sci. 1983;38:941–53.

Venkatachalam S, Nayak SG, Labde JV, Gharal PR, Rao K, Kelkar AK. Degradation and recyclability of poly (ethylene terephthalate), polyester. In: El-Din Saleh H (ed.) InTech, 2012. https://doi.org/10.5772/48612.

Santos AF, Polese L, Crespi MS, Ribeiro CA. Kinetic model of poly(3-hydroxybutyrate) thermal degradation from experimental non-isothermal data. J Therm Anal Calorim. 2009;96:287–91.

Mingtao R, Dayu Z, Sizhu W, Gang W. Thermal decomposition of poly(ethylene terephthalate)/mesoporous molecular sieve composites. Front Chem Eng China. 2007;1(1):50–4.

Budrugeac P, Segal E. On the apparent compensation effect found for two parallel reactions. Int J Chem Kinetics. 1998;30:673–81.

Brown ME, Galwey AK. The significance of “compensation effects” appearing in data published in “computational aspects of kinetic analysis”: ICTAC project, 2000. Therm Acta. 2002;387:173–83.

MacCallun JR, Munro MV. The kinetic compensation effect for the thermal decomposition of some polymers. Therm Acta. 1992;203:463–547.

Dias DS, Crespi MS, Ribeiro CA, Kobelnik M. Evaluation by thermogravimetry of the interaction of the poly(ethylene terephthalate) with oil-based paint. Eclet Quim. 2015;40:77–85.

Acknowledgements

The authors acknowledge CNPq financial support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Dias, D.S., Crespi, M.S., Ribeiro, C.A. et al. Evaluation of the thermal decomposition of blends prepared with poly(3-hydroxybutyrate) (PHB) and recyclable ethylene poly-terephthalate (RPET). J Therm Anal Calorim 143, 3447–3457 (2021). https://doi.org/10.1007/s10973-020-09885-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-020-09885-4