Abstract

The thermal stabilization effect of copper complexes on ethylene-propylene-diene terpolymer (EPDM) is studied during an accelerated degradation of polymer samples by their exposure to γ(137Cs)-radiation. These complexes of Cu(II) with two Schiff base ligands provided an efficient improvement in the stabilization of basic polymer. For the evaluation of improvement action of inorganic additive on thermal behavior of EPDM, the calculation of carbonyl and hydroxyl indexes and the radiochemical yields of corresponding radiolysis products prove the long-term stability of EPDM. Isothermal and nonisothermal chemiluminescence investigations were also accomplished, and the protection proficiencies of studied additives are compared by means of kinetic features of degradation. The activation energies required by the oxidation of polymer substrate were calculated, and their values are significant higher in comparison with the similar value found for pristine EPDM. The stabilized polymer is assisted by the interaction between mobile protons of ligands and hydrocarbon free radicals.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The long-term service of materials is always dependent on the contribution on the stabilizer added in the formulation [1–3] having the defined extension of material durability on application ranges. The ageing protection of polymers is generally provided by organic compounds with antioxidant features [4–6] by blocking the reactions of free radical with molecular oxygen. In fact, the basic process is the coupling of unpaired electron belonging to radical with other available electron from antioxidant molecules. The efficiency in the breaking chain of oxidation depends directly on the molecular configuration, which provides more or less available positions [7, 8].

The electronic configuration of molecules plays a determinant role in the oxidation protection of polymers. Titania is a good example for the delaying degradation of epoxy resins [9], even though its presence in polyolefins promotes photooxidation under peculiar conditions [10]. For the blocking oxidation of aldehydes (one of the main products formed during the degradation polymers), nickel (II) complexes with tetraazomacrocyclic ligands were proposed [11]. The proposed mechanism is explained by the trapping activity of Ni(II) complex structures on the intermediate acylperoxy radicals.

The investigation on efficient antioxidant activity provided by metal complexes was scarcely reported. The metal (II) complexes with isocoumarin derivatives have extended application ranges in agriculture, pharmacy and industrial chemistry [12]. Chromone-derived thiosemicarbazones represents an interesting class of organic ligands due to their structural chemistry. Similarly, metal complexes obtained with thiosemicarbazones exhibit antioxidant activity [13].

Previous studies have showed that transitional metal complexes with chromone thiosemicarbazone possess significant antioxidant activity against superoxide and hydroxyl radicals and the scavenging effects of Cu(II) complex are stronger than Zn(II), Ni(II) complexes or some standard antioxidants, such as mannitol and vitamin C [14].

The effects of thiosemicarbazide complexes of several divalent metallic ions (Ni(II), Cu(II), Zn(II), Cd(II)) on the thermal stabilization of polypropylene were previously reported [15], whose oxidation protection is equivalent to the performances of commercial Irganox 1076.

An foreseen decrease in the peroxidation rate of poly(ethylene oxide) was found in the thermal degradation of this polymer modified with inorganic salt complexes [16]. The explanation on the influence of metal ion on the progress of oxidation is based on the interaction between cation Mn+ and the π component of C=O bonds from oxygenated structures. The opposite conclusions were presented on the photodegradation [17] and thermodegradation [18] of polyethylenes in an intimate contact with uncomplexed metals.

This paper proves the successful protection activity in the oxidation prevention in ethylene propylene substrates by inorganic complexes during the exposure to accelerated degradation in the field of high-energy radiation. The improvement effect of inorganic phase in the thermal stabilization presented by studied complexes in degrading EPDM is an opposite result relative to the other reported papers on polymer/inorganic filler (EPDM/BaSO4 [19] or EPDM phosphate-alumina pigments [20]).

The antioxidant activities of present Cu(II) complexes are complementary choices for the protection of polymers in respect with organic compounds [21–23].

Experimental

Materials and sample preparation

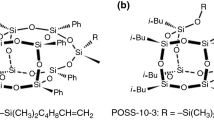

Basic material, ethylene-propylene-diene terpolymer (EPDM), TERPIT C, was provided by ARPECHIM Piteşti (Romania). It had initially the ratio ethylene/propylene as 3/2, unsaturation (5-ethylidene-2-norbornene) of 3.5 phr, number of CH3 for 100 C atoms was 0.983, gravimetric average molecular weight 155,500 Da. The synthesis and characterization of the Schiff base Cu(II) complexes was previously reported [24]. The molecular structures are presented in Fig. 1. The molecular formulas of complexes are listed in Table 1.

All samples were prepared by casting method from chloroform EPDM solutions. The concentration of each added Cu complex was 0.5 phr. Each polymer/complex blend was prepared by mixing of CH3Cl solutions of pristine polymer with proper additive. Sonicated homogenous polymer/inorganic additive solutions were previously prepared, because our complexes are not soluble in chloroform. Thin films for spectroscopic (FTIR) investigations had similar thickness (100 μm) after the evaporation of solvent at room temperature from stainless steel trays.

The samples destined to chemiluminescence (CL) determinations were obtained by chloroform evaporation at room temperature from small aluminum pans.

Measurements

γ-Exposures were accomplished in an irradiator (Gammator M-38 provided with 137Cs source) in air at room temperature. Four doses were selected (0, 50, 100 and 150 kGy received at a dose rate of 0.4 kGy h−1). For suggestive comparison of stabilization activities, the exposure to 200 kGy was added. The dosimetry of source was accomplished with Fricke method.

Spectral records on polymer samples were carried out with JASCO 4000 spectrometer (Japan) at 40 scans. The structural modifications occurred in inorganic filler were studied by infrared spectroscopy on a Bruker Vertex 70 spectrophotometer (USA) using a PIKE MIRacle™ ATR (4400–600 cm−1). The molar extinction coefficients 310 l and 90 l mol−1 cm−1 [25] were used for the calculation of the radiochemical yields of carbonyl- and hydroxyl-containing products.

The CL evidence for polymer degradation is the decay of carbonyl from its excited state onto fundamental level. For the evaluation of thermal stability of radiolyzed samples, CL spectra were recorded on LUMIPOL 3 (Institute of Polymers, SAS, Bratislava). Two CL procedures were applied: nonisothermal regime at a heating rate of 5 °C min−1 and isothermal measurements over the temperature range starting from 170 to 190 °C. The error of temperature measurement was ±0.5 °C.

The analytical evaluation was performed immediately after the end of irradiations preventing the alteration of results by the decay of medium and long-life radicals.

Results and discussion

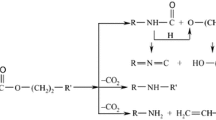

The start of polymer degradation involves an energetic transfer onto macromolecules presenting weaker bonds available for scission. In the case of EPDM, the unsaturation from diene component and the tertiary and quaternary carbon atoms from propylene moieties are the main reactive places from where the oxidation chain starts by the formation of RO ·2 initiators [26]. Pragmatically, the course of degradation depends strongly on the propagation rate of oxidation; meanwhile, the accumulation of oxygenated products can be constrained by the preventive action of antioxidants. Once oxidation becomes significant, the free radicals are decayed by oxidation with specific rates directly related to the polymer structure. The selection of degradation inhibitor allows the proper limitation of material damage on time. The antioxidant activity of these types of ligands can be ascribed to the presence of an N–H group in the thiosemicarbazone and thiocarbonohydrazone moieties, due to the fact that both ligands may exist in two tautomeric forms [27]. The tautomerism thiol-thione (Fig. 1) is manifested especially in solution [28, 29] and may result in complexes in which the ligand coordinates in the thiol form [24].

FT-IR investigations

The protection effects of Cu(II) complexes with present Schiff bases can be described by the evolution of FT-IR spectra recorded on two modified EPDM films (Fig. 2), whose efficiencies are described by the evolution of the main vibration bands, 1715 and 3350 cm−1. The accumulation of carbonyl- and hydroxyl-containing degradation products takes place slowly at low irradiation doses, because the concentrations of free radicals are low and the efficiency of stabilizers is not significantly different from each to other. At degradation doses exceeding 100 kGy, when the oxidizing free radicals attain substantial amounts, the protection activities become unlike.

The shape of carbonyl band (1715–1740 cm−1) does not describe the selective route in the formation of different carbonyl compounds (Fig. 2). Its complex structure is evident at higher degradation doses exceeding 100 kGy, when the carbonyl band starts to become centered on 1715 cm−1. The dimensions of ligand and the free space around organic fragment of complexes made differences between the distribution of C=O compounds.

According with generally accepted mechanism of radiochemical degradation of EPDM [30, 31], the splitting of C–C bonds joining methyl groups to backbone from propylene moieties and the breaking π bonds from unsaturation from diene fragments are the primary acts through which radicals appear. The breaking modification in C–C bonds where methyl groups are linked was demonstrated by labeled carbon measurements [31]. An opposite situation happens with the decay of double bond at 808 cm−1 ascribed to the unsaturation of ethylidene norbornene units [3]. Figure 3 illustrates the consumption of double bonds during γ-irradiation of EPDM/D3 sample, an aleatory choice. The consumption of double bonds and the scissions of C–C bonds of tertiary or quaternary carbon atoms are the processes which create the further protected radicals. The primary intermediates of structural damage may follow two ways: jointing to antioxidant molecules hindering the progress of degradation or oxidation to peroxyl radicals, the initiators of degradation chain. The propagation rate of oxidation is characterized by the scavenging potential of additive by which stabilizer confirms its capability for efficient interaction with radicals against their reactions with oxygen molecules. During γ-irradiation, an accelerated degradative process, the rising in the concentrations of radiolysis final products can be expressed by radiochemical yields (Fig. 4). They can be calculated by Lambert–Beer law followed between by the application of the conversion of product concentration into number of functions existing at certain doses:

where G is radiochemical yield (events/100 eV), ε is extinction coefficient for each spectral band (l mol−1 cm−1), ρ is material density (g cm−3), l is the film thickness (cm), A is the difference between actual and initial absorbance values, D is exposure dose (kGy). The constant value 9.63 × 103 is the result of the conversions of units for concentration, dose and density.

Evolution of radiochemical yields for carbonyl- and hydroxyl-containing products in irradiated samples of EPDM modified with different Cu (II) complexes. (red square) pristine EPDM, (dark green square) EPDM/D1, (dark blue square) EPDM/D2, (light blue square) EPDM/D3, (pink square) EPDM/D4, (yellow square) EPDM/D5, (light green square) EPDM/D6. (Color figure online)

The antioxidant action of Cu(II) complexes takes place after the scission of bonds when the oxidation of hydrocarbon radicals is prevented. They influence the ratios between the formation and decay rates being illustrate by the evolution of radiochemical yields (Fig. 4). In the samples containing this kind of radiation-resistant compound, the formation of peroxyl radicals as chain degradation initiator is slowed down and the propagation step of oxidation has consequently lower contribution to the buildup of stable oxygenated products. Over this effect, the studied complexes do not overlap any effect of their radiation decomposition, being known that benzene rings can be efficient energetic depositors due to the delocalization of π electrons. Radiochemical yields are dependent on the efficiency of additive, but the differences between the antioxidant capabilities are rather small. The overall view on the stabilization effect of this class of complexes describes a promising protection activity, which is important for the long-term stability of degrading organic substrates.

CL investigations

The irradiated samples consisting of EPDM modified with Cu(II) complexes contain oxidation intermediates, long-life radicals and peroxyl radicals which are the initiators of oxidative degradation. The detailed aspects of oxidative degradation can be analyzed by the modification of temperature (nonisothermal CL), when the stability of polymer is related to the influence of energetic conditions or by the accumulation of emissive intermediates (isothermal CL), when the resistance of polymer is described by oxidation induction time [32].

The nonisothermal determinations of oxidizability illustrated by their values of onset oxidation temperatures, OOT (Table 2), develop the initiation and the acceleration of thermal degradation over a large temperature range. The different interaction levels between polymer and additive molecules are conceived by the different values of onset oxidation temperatures. The further evolution of emission CL intensities is influenced by the capability of complex to withdraw free radicals from their oxidation site. The scavenging radicals would be possible on chain-branching stage, when the conversion of hydroperoxides into alcohols and new radicals closes the degradation loop [33].

The nonisothermal CL spectra recorded on raw EPDM samples at different degradation levels by their exposure to various γ-doses (Fig. 5) demand the addition of a protection compound for the slowing down the degradation rates on the earlier start of stability demoting. The contribution of Cu(II) complexes to the modification of oxidation resistance measured on nonirradiated samples is qualified as stabilizer effect (compounds D2–D6, Fig. 6). The onset oxidation temperatures (Table 2) decrease with irradiation dose, but they are placed on the range between the highest values obtained for EPDM/D3 formulation and the lowest figures obtained for EPDM/D4 compound. The activation energies were calculated using Kissinger method [34]. From the examination of Table 3, it can be state that the modification of ligand structure induces different level of interaction between free radicals and the molecules of Cu(II) complexes. It must be revealed that the degradation of polymer substrate does not happen at temperatures below 150 °C. While the degradation state of polymer advances due to the radiolysis of EPDM, the stabilization efficiency of complex additive becomes more relevant (Fig. 7). Some features can be remarked from the dependencies of CL intensities, the measure of degradation level, and the degradation temperatures:

-

the maximum intensity measured on neat EPDM is 3.5 times higher than the recorded intensity for the most unstable EPDM/D6 system,

-

the oxidation of pristine EPDM starts very early, at the temperature around 100 °C,

-

D3 complex offers the largest temperature range, where the oxidative degradation does not occur,

-

even though the nonisothermal CL spectra present a maximum intensity at 195 °C, the protection effect is evident, because the emission intensities decrease, while the neat polymer continues to be oxidized.

The nonisothermal CL study sustains the contribution of some Cu(II) complexes to the oxidative of EPDM even in the irradiated polymer, which is always susceptible to easy degradation.

The clear image on the stabilization effect of Cu (II) complexes with Schiff base ligands was obtained by isothermal CL (Fig. 8). The unirradiated neat EPDM is oxidized softly at 170 °C, while stabilized polymer maintains its thermal stability over a long period after which oxidation occurs sharply. The temperature on the progress of degradation makes differences between the oxidation rates of differently modified EPDM substrate (Fig. 9), and the decrease of ageing temperatures emphasizes the antioxidant property of studied complexes. The addition of D6 compound brings about the most efficient protection, and D1 molecules present a moderate effect in the delay of oxidation when it is present in EPDM samples (Fig. 9). The protection effect can be judged not only by the duration of oxidation induction time, whose length is proportional with the antioxidant efficiency, but also by the emission intensity, which is higher at the lower activity. The activation energies required for the thermal oxidation of EPDM are presented in Table 3. The addition of Cu(II) complexes with Schiff base ligands increases the stability of EPDM against oxidation and the differences that exist between these values can be explained by the deprotonation activities. In addition, the electronic interaction between the ligands and free orbitals of Cu influences the availability of complex molecules to allow the coupling of unpaired electron of free radicals to them.

As the nonisothermal CL spectra suggest, the maximum CL intensities are shifted toward lower temperatures as γ-irradiation dose increases (Fig. 5). This modifying behavior proves that ligands are not radiochemically stable under the action of high-energy radiation. Consequently, the antioxidant efficiency is diminished and the availability of complexes to the radical scavenging becomes weaker. The isothermal CL measurements (Fig. 9) provide additional proofs for the modification of antioxidant efficiency, while an energetic transfer occurs, even in the case of thermal treatment. The variation in the electronic densities due to the thermal decomposition of complexes induces sharp decrease in the antioxidant efficiency. FTIR spectra (Fig. 10) recorded on the irradiated compounds at 150 kGy. The evolution of oxidation in the polymer phase is controlled by the stability of inorganic additives, which delay differently the oxidative ageing according to the alteration of protection capacity.

The structural changes characterized by the modifications occurred in FTIR spectra may explain the progressive failure of stabilization activities. By overlapping the infrared spectra for the two ligands, changes in the intensity of all absorption bands were observed after irradiation. For complexes D1, D4 and D5 were observed a significant decreases in the intensity of the absorption bands assigned to ν(C=S), [ν(C=S) + ν(C=N)], and ν(C–C), δ(C–C) and γ(CH). Besides these bands, in the IR spectrum of complex D2 is observed the disappearance of absorption bands assigned to sulfate ion (Figures—supplementary figures). The same behavior is observed for the complex D6. In the case of complex D3, no significant changes have been observed, because two molecules of ligand HL1 are coordinated to the copper ion. Also, a new absorption band appears at 1702 cm−1 in the IR spectra of complexes D1, D2, D4 and D5.

The industrial implementation of these results can provide successfully processing by γ-irradiation of several polymer materials. [35, 36].

Conclusions

The purpose of this study is the emphasizing excellent antioxidant activities of Cu(II) complexes with two Schiff bases, inorganic stabilizer, in the ageing protection of ethylene-propylene-diene monomer. The stability measurements pointed out the high efficiency improvement in long-term stability by delaying polymer oxidation. The isothermal CL results prove the large extent in retarding action of studied Cu(II) complexes. The higher activation energies required for the oxidation of EPDM substrate are the relevant proofs for the antioxidant feature of these complex compounds. The significant changes in the kinetic parameters support the protection action of our complexes even at temperature around 150 °C or during a minute transfer of energy similar to slight γ-irradiation exposure.

References

Cibulková Z, Česná A, Šimon P, Uhlár J, Kosár K, Lehocký P. Stabilization effect of potential antioxidants on the thermooxidation stability of styrene-butadiene rubber. J Therm Anal Calorim. 2011;105(2):607–13.

Navarro R, Audouin L, Verdu J. Reactions of antioxidants with molecular oxygen. Part III. Influence of phenolic stabilizer structures on their oxidation in an inert matrix. Polym Degrad Stab. 2011;96(7):1389–96.

Rivaton A, Cambon S, Gardette J-L. Radiochemical ageing of ethylene-propylene-diene elastomers. 4. Evaluation of some anti-oxidants. Polym Degrad Stab. 2006;91(1):136–43.

Mei XL, Jiao SL, Li XY, Li YC, Cheng Y. Effect of the antioxidants on the stability of poly(vinyl butyral) and kinetic analysis. J Therm Anal Calorim. 2014;116(3):1345–9.

Chao MR, Li WM, Wang XB. Thermal decomposition kinetics and anti-oxidant performance of commercial antioxidants. J Therm Anal Calorim. 2015. doi:10.1007/10973-015-4525-0.

Ahmed FA, Shafy M, Abd El-Megeed AA, Hegazi EM. The effect of γ-irradiation on acrylonitrile—butadiene rubber NBR seal materials with different antioxidants. Mater Des. 2012;36:823–8.

Peltzer M, Wagner JR, Jiménez A. Thermal characterization of UHMWPE stabilized with natural antioxidants. J Therm Anal Calorim. 2007;87(2):493–7.

Koutný M, Václavková T, Matisová-Rychlá L, Rychlý J. Characterization of oxidation process by chemiluminescence: a study of polyethylene with prooxidant additives. Polym Degrad Stab. 2008;93(8):1515–9.

Crăciun E, Zaharescu T, Jipa S, Mantsch A. Radiation effects on the stability of epoxy resin modified with titania nanoparticles. Mater Plast. 2011;48(4):426–31 (Bucharest).

Zapata PA, Rabagliati FM, Lieberwirth I, Catalina F, Corrales F. Study on the photodegradation of nanocomposites containing TiO2 nanoparticles dispersed in polyethylene and in poly(ethylene-cooctadecane). Polym Degrad Stab. 2014;109:106–14.

Nam WW, Baek SJ, Lee KA, Ahn BT, Muller JG, Burrows CJ, Selverstone VJ. Nickel complexes as antioxidants. Inhibition of aldehyde autoxidation by nickel (II) tetraazamacrocycles. Inorg Chem. 1996;35(23):6632–3.

Rajeshirke M, Shah R, Yadav P, Purohit NV. Synthesis and antioxidant activity of metal (II) complexes of isocoumarin derivatives. Der Pharm Sin. 2012;3(2):239–48.

Li Y, Yang Z-Y, Wu J-C. Synthesis, crystal structures, biological activities and fluorescence studies of transition metal complexes with 3-carbaldehyde chromone thiosemicarbazone. Eur J Med Chem. 2010;45(12):5692–701.

Wang B-D, Yang Z-Y, Lu M-H, Hai J, Wang Q, Chen Z-N. Synthesis, characterization, cytotoxic activity and DNA binding Ni(II) complex with the 6-hydroxy chromone-3-carbaldehyde thiosemicarbazone. J Organomet Chem. 2009;694(25):4069–75.

Setnescu R, Bărcuţan C, Jipa S, Setnescu T, Negoiu M, Mihalcea I, Dumitru M, Zaharescu T. The effect of some thiosemicarbazide compounds on thermal oxidation of polypropylene. Polym Degrad Stab. 2004;85(3):997–1001.

Costa L, Gad AM, Camino G, Cameron GG, Qureshi MY. Thermal and thermooxidative degradation of poly(ethylene oxide)—metal salt complexes. Macromolecules. 1992;25(20):5512–8.

Osawa Z, Kurisu N, Nagashima K, Nakano K. The effects of transitional metal stearates on the photodegradation of polyethylene. J Appl Polym Sci. 1979;23(12):3583–90.

Gorghiu LM, Jipa S, Zaharescu T, Setnescu R, Mihalcea I. The effect of metals on thermal degradation of polyethylenes. Polym Degrad Stab. 2004;85(1):7–11.

Nandakumar N, Kurian P. Effect of chemical degradation on the mechanical properties of ethylene-propylene-diene (5-ethylene-2-norbornene) terpolymer-BaSO4 nano composites. Mat Des. 2013;43(1):118–24.

Ahmed NM, El-Sabbagh SH. The influence of hybrid phosphate-alumina pigments on properties of ethylene-propylene-diene rubber composites. Mat Des. 2011;32(1):303–21.

Cibulková Z, Šimon P, Lehocký P, Kosár K, Chochulová A. DSC study on antioxidant activity of selected p-phenylenediamines in styrene-butadiene rubber. J Therm Anal Calorim. 2009;97(2):535–40.

Parra DF, do Rosário Matos J. Some synergetic effects of antioxidants in natural rubber. J Therm Anal Calorim. 2002;67(2):287–94.

Bessmann S, Reissinger M, Grabmayer K, Wallner G, Nitsche D, Brechberger W. Analytical evaluation of the performances of stabilization system for polyolefin materials. Part I. interaction between hindered amine light stabilizers and phenolic antioxidants. Polym Degrad Stab. 2014;110:489–508.

Ilies D-C, Pahontu E, Shova S, Georgescu R, Stanica N, Olar R, Gulea A, Rosu T. Synthesis, characterization, crystal structure and antimicrobial activity of copper(II) complexes with a thiosemicarbazone derived from 3-formyl-6-methylchromone. Polyhedron. 2014;81:123–31.

Allen NS, Hoang E, Liauw CM, Edge M, Fontan E. Influence of processing aids on the thermal and photostabilisation of HDPE with antioxidant blends. Polym Degrad Stab. 2001;72(1):367–76.

Zaharescu T, Jipa S. Radiochemical modifications in polymers. In: Polymer solids and polymer melts. Arndt K.-F, Lechner MD, editors Landolt-Börnstein series, vol. VIII/6 C2, ch. II. Heidelberg: Springer; 2013. p. 93–184.

Nguyen DT, Le TH, Bui TTT. Antioxidant activities of thiosemicarbazones from substituted benzaldehydes and N-(tetra-O-acetyl-b-d-galactopyranosyl) thiosemicarbazide. Eur J Med Chem. 2013;60:199–207.

Lobana TS, Sharma R, Bawa G, Khanna S. Bonding and structure trends of thiosemicarbazone derivatives of metals—an overview. Coord Chem Rev. 2009;253(7–8):977–1055.

Kuzer F, Wilkinson M. The chemistry of carbohydrazide and thiocarbohydrazide. Chem Rev. 1970;70(1):111–49.

Zaharescu T, Giurginca M, Jipa S. Radiochemical oxidation of ethylene-propylene elastomers in the presence of some phenolic antioxidants. Polym Degrad Stab. 1999;63(2):245–51.

Assink RA, Celina M, Gillen KT, Clough RL, Alam TM. Morphology changes during radiation-thermal degradation of polyethylene and an EPDM copolymer by 13C NMR spectroscopy. Polym Degrad Stab. 2001;73(2):355–62.

Rychlý J, Matisová-Rychlá A, Tiemblo P, Gomez-Elvira J. The effect of physical parameters of isotactic polypropylene on its oxidisability measured by CL method. Contribution to the spreading phenomenon. Polym Degrad Stab. 2001;71(2):253–60.

Gijsman P, Hennekens J. The mechanism of the low-temperature oxidation of polypropylene. Polym Degrad Stab. 1993;42(1):95–105.

Kissinger HE. Reaction kinetics in differential thermal analysis. Anal Chem. 1957;59(11):1702–6.

Jung C-H, Kim D-K, Suh D-H, Nho Y-C, Kang PH, Ganesan R. Preparation of polymer/POSS nanocomposites by radiation processing. Radiat Phys Chem. 2009;78(7–8):517–20.

Stelescu MD, Manaila E, Craciun G. Vulcanization of ethylene-propylene-terpolymer-based rubber mixtures by radiation processes. J Appl Polym Sci. 2013;128(4):2325–36.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Zaharescu, T., Ilies, DC. & Roşu, T. Thermal and spectroscopic analysis of stabilization effect of copper complexes in EPDM. J Therm Anal Calorim 123, 231–239 (2016). https://doi.org/10.1007/s10973-015-4893-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-015-4893-5