Abstract

1,1,1,5,5,5-Hexaethoxy-3,3-dimethyltrisiloxane (QDQ), consisting of di- (D) and quadra-functional (Q) siloxane units, and its polymer (pQDQ) were synthesized. As the comparison, co-hydrolysis of diethoxy(dimethyl)silane (DEDMS) and two equivalents of tetraethoxysilane (TEOS) yielded a copolymer of DEDMS and TEOS (pDEDMS1-TEOS2). The polymer structure and film properties using two types of polymers with an average molecular weight of approximately 10,000 were investigated. The polymer structure was investigated using 29Si NMR and MS. The two films were characterized by thermogravimetric and differential thermal analyses, ultraviolet and visible spectroscopy, and tensile strength and swelling tests. The films from pQDQ and pDEDMS1-TEOS2 exhibited similar chemical structures and physical properties, except for the tensile strength test. The pQDQ film exhibited higher Young’s modulus and breaking stress (455 and 3.7 MPa, respectively) than those of the pDEDMS1-TEOS2 film (55 and 1.1 MPa, respectively), suggesting that the arrangement of the D and Q units affects the mechanical strength of the gel film. Consequently, the mechanical properties of polysiloxane-based materials can be controlled by modifying the sequence of siloxane units.

Two DQ polymer gel films were prepared. They were colorless, transparent, thermally stable, and exhibited different tensile strengths.

Highlights

-

Di- (D) and quadra-functional (Q) siloxane-containing alkoxytrisiloxanes (QDQ) were polymerized.

-

Didiethoxy(dimethyl)silane (DEDMS) and tetraethoxysilane (TEOS) were copolymerized.

-

Thermally stable, transparent, and flexible films were prepared from polysiloxanes.

-

The film from QDQ polymer showed harder mechanical strength than that from DEDMS-TEOS copolymer.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Colorless, transparent, and thermally stable films have attracted significant attention owing to the rapid emergence of flexible/wearable electronic devices, such as roll-up displays, conformable displays, and portable devices [1, 2]. Although polyimides are mainly used as substrates for utility applications, they have poor processability owing to their limited solubility in organic solvents and strong absorption in the yellow to brown region of the visible spectrum. Therefore, molecularly modified polyamides have been developed [3, 4]. Polysiloxanes, including silicones [R2SiO]n and silsesquioxanes [RSiO1.5]n, are used as optical films because of their colorless, transparent, and thermally stable properties [5,6,7,8]. Polysiloxanes with the R(4-n)Si(O0.5)n chemical structure are classified into M (n = 1), D (n = 2), T (n = 3), and Q (n = 4) structures. Di-functional siloxane (D unit) produces flexible polymers owing to its linear structure, whereas tri-functional (T unit) and quadra-functional (Q unit) siloxanes exhibit rigid properties owing to the formation of crosslinked polymer structures. In addition, film properties can be altered by the chemical and physical properties of organic groups such as methyl, phenyl, and vinyl groups; for example, methyl groups are preferred for optical films because the methylsilyl group absorbs no visible light and little ultraviolet (UV) light, resulting in less discoloration [9].

The mechanical rigidity and flexibility of polysiloxanes with D and Q heterogeneous components (DQ polysiloxanes) can be manipulated by proportion of D and Q units. For example, Li et al. reported that polymers consisting of cyclotetrasiloxane with D and Q units give transparent silicone elastomers, which show thermal stability and flexibility owing to the high proportion of D units [10]. In general, DQ polysiloxanes can be prepared via the hydrolytic polycondensation of D and Q precursors. However, heterogeneous component polymers tend to undergo phase separation because of their different reactivities and low compatibility. In addition, polydimethylsiloxane (PDMS) prepared from diethoxy(dimethyl)silane (DEDMS) contains low-molecular-weight cyclic oligomers, including Dx (x = number of siloxanes), such as D3, D4, D5, and D6. These volatile siloxanes often adversely affect electrical devices because they cover conductive sites and block electrical current [11].

In a previous study, we reported several types of DQ polysiloxanes [12]. The reaction of PDMS end groups with tetraethoxysilane (TEOS) in the presence of water resulted in the formation of a DQ polymer with an average molecular weight (Mw) of approximately 600,000. Random copolymers pDEDMSx-TEOSy synthesized from DEDMS and TEOS of molar ratios, DEDMS: TEOS = x: y = 3:1, 1:1, and 1:3 were also prepared. Depending on their composition ratio, they showed different thermal stabilities and solvent uptake properties. From these results, we assumed that the pre-synthesized monomer consisting of D and Q units would exhibit high dispersity of the D and Q components. In this study, we prepared a polymer pQDQ from 1,1,1,5,5,5-hexaethoxy-3,3-dimethyltrisiloxane (QDQ), as illustrated in Scheme 1. The QDQ is expected to be polymerized by the sol–gel reaction while maintaining the Q–D–Q unit. Because no D–D bond is formed, QDQ does not form a cyclic siloxane (Dx), and a homogeneous polymer is formed. To investigate the effectiveness of the QDQ monomer, a random copolymer, pDEDMS1-TEOS2, consisting of one equivalent of DEDMS and two equivalents of TEOS, is prepared. We prepared these polymers by focusing on their color, thermal stability, and transparency, and investigated their chemical structure and film formation ability. This is the first systematic study dealing with the comparison of polymer and film properties of structurally designed trisiloxane QDQ and random copolymer pDEDMS1-TEOS2.

2 Experimental

2.1 Materials

Ammonium carbonate ((NH4)2CO3), hexane, pyridine, potassium hydroxide (KOH), tetrahydrofuran (THF), and molecular sieves (MS) (3A, 4A, and 5A) were purchased from Kanto Chemical Co., Inc. Ethanol, N,N-dimethylformamide (DMF), and 6 M hydrochloric acid (HCl) were purchased from FUJIFILM Wako Pure Chemical Corporation. Dichlorodimethylsilane (DCDMS), DEDMS, TEOS, thionyl chloride (SOCl2), and chromium(III) acetylacetonate (Cr(acac)3) were purchased from Tokyo Chemical Industry Co. Ltd. Hexane was dried over MS 4A. THF was distilled and dried over MS 5A. Ethanol was dried over MS 3A. Pyridine was distilled and dried over KOH. Ultrapure water from ELGA PURELAB flex3 was used. All other reagents were used as received, without further purification.

2.2 Measurements

Gel permeation chromatography (GPC) was performed using a Shimadzu LC-6AD HPLC system attached to a 5-μm PLgel Mixed-D column with THF as the eluent. The molecular weights were calculated based on polystyrene standards. Nuclear magnetic resonance (NMR) spectra were recorded using JEOL Resonance JNM-ECZ 500, JNM-ECZ 400, and JNM-ECP 300 spectrometers. For the 29Si NMR spectra, Cr(acac)3 was added to the samples as a paramagnetic relaxation agent. Solid-state NMR spectra were recorded using a Varian 600PS spectrometer. Measurements were performed using a 6-mm ϕ spinner at a 119.18-MHz resonance frequency with dipolar decoupling. Fourier transform infrared (FT-IR) spectra were recorded on a JASCO FT-IR spectrophotometer using the liquid film and KBr disk methods. Thermogravimetric-differential thermal analysis (TG-DTA) was performed using a Netzsch Japan Sirius 2000SE-TR25 TG-DTA analyzer. The samples were heated to 1000 °C at a rate of 10 °C·min−1 under air flow. UV-Vis transmittance spectra were recorded using a JASCO V-670 instrument with an integrating sphere (ISN-470 type). The tensile strength was measured at a tensile speed of 10 mm/min using an A&D MCT-2150 tabletop universal testing machine (0.01 N of load mean resolution) with the MSAT-Lite software. The samples, cut to a size of 40 mm × 5 mm with a thickness of 80–115 µm, were set to an attachment. A swelling test was conducted by increasing the weight of the film after immersion. The weights of the samples before immersion were measured, and the films were immersed in THF for 24 h. After pulling, the swollen films were weighed. The degree of swelling of the films was calculated using the following equation:

where DS(%) is the degree of swelling, Wa is the weight after film immersion, and Wb is the weight before film immersion.

2.3 Synthesis

2.3.1 Synthesis of chloro(triethoxy)silane (CTES)

CTES was synthesized as previously described by Kazakova et al. [13]. SOCl2 (59.8 g, 0.50 mol) and DMF (0.5 mL) were added to a 500-mL two-neck flask and stirred until a homogeneous solution was formed. The solution was then cooled in an ice bath, and TEOS (104 g, 0.50 mol) was slowly added dropwise to the solution and stirred for 1 h in the ice bath and then for 4 h at room temperature. Subsequently, the volatiles were evaporated under reduced pressure, followed by distillation under reduced pressure (33–35 °C, 3 Torr) to give 89.3 g (92% yield) of CTES as a colorless liquid. 1H NMR (400 MHz, CDCl3): δ (ppm) 1.26 (t, 9H, J = 7.0 Hz, CH3), 3.90 (q, 6H, J = 7.0 Hz, CH2). 29Si NMR (60 MHz, CDCl3): δ (ppm) −70.3.

2.3.2 Synthesis of triethoxysilanol (TESOL)

TESOL was synthesized as previously described by Kazakova et al. [13]. THF (250 mL), (NH4)2CO3 (24.22 g, 0.25 mol), and water (0.90 g, 0.05 mol) were added to a 500-mL two-neck flask and stirred until a homogeneous solution was obtained. Then, CTES (9.98 g, 0.05 mol) dissolved in THF (100 mL) was added dropwise to the solution in an ice bath. The mixture was then stirred for 1 h at room temperature. The solution was then dried over Na2SO4 to remove unreacted water. After filtration, the volatiles were removed under reduced pressure, followed by vacuum distillation (b.p. 59–60 °C, 3 Torr) to give 5.6 g (62% yield) of TESOL as a colorless liquid. 1H NMR (500 MHz, C6D6): δ (ppm) 1.21 (t, 9H, J = 7.0 Hz, CH3), 3.83 (q, 6H, J = 7.0 Hz, CH2), 4.50 (s, 1H, OH). 13C NMR (125 MHz, CDCl3): δ (ppm) 18.0 (CH3), 59.4 (CH2). 29Si NMR (100 MHz, CDCl3): δ (ppm) −78.7. FT-IR (neat, cm−1): 905 (νSi-O-H), 966, 1080, 1103, 1170 (νSi-O-C), 2895, 2929, 2976 (νC-H), 3403 (νO-H).

2.3.3 Synthesis of dimethylsilanediol (DMSDOL)

DMSDOL was synthesized as previously described by Cella and Carpenter [14]. DCDMS (10.0 g, 0.077 mol) in diethyl ether (100 mL) was added dropwise to a mixture of triethylamine (15.8 g, 0.16 mol), water (3.0 g, 0.17 mol), diethyl ether (200 mL), and acetone (20 mL) in an ice bath and stirred for 30 min. After filtration, the solution was evaporated and washed with hexane. The volatiles were removed under reduced pressure to give 3.6 g (72% yield) of DMSDOL as a white solid. 1H NMR (500 MHz, CDCl3) δ (ppm) 0.020 (s, 3H, CH3), 4.89 (s, 1H, OH). 29Si NMR (100 MHz, CDCl3): δ (ppm) −6.14.

2.3.4 Synthesis of 1,1,1,5,5,5-hexaethoxy-3,3-dimethyltrisiloxane (QDQ) via routes A and B

1,1,1,5,5,5-Hexaethoxy-3,3-dimethyltrisiloxane (QDQ) was synthesized by two methods: route A and route B.

Route A: pyridine (11.34 g, 0.14 mol) was cooled in an ice bath and a cold mixture of DCDMS (4.7 g, 0.036 mol) and hexane (150 mL) followed by a mixture of TESOL (10.82 g, 0.060 mol) and hexane (100 mL) were added dropwise to the solution. The mixture was stirred for 1 h at room temperature then for 1 h under gentle heating (60 °C). The residue was removed by filtration under reduced pressure. The solution was distilled under reduced pressure (b.p. 120–123 °C, 3 Torr) to give 3.8 g (36% yield) of QDQ as a colorless liquid. B.p. 99 °C (1 Torr). 1H NMR (500 MHz, CDCl3): δ (ppm) 0.16 (s, 6H, CH3), 1.18 (t, 18H, J = 7.0 Hz, CH3), 3.79 (q, 12H, J = 7.0 Hz, CH2). 13C NMR (125 MHz, CDCl3): δ (ppm) 0.5 (SiCH3), 18.1 (CH2CH3), 59.1 (CH2CH3). 29Si NMR (100 MHz, CDCl3): δ (ppm) −88.1 (OSi(OEt)3), −18.5 (Me2SiO2). FT-IR (neat, cm−1): 801 (νSi-C), 967 (νSi-O-C), 1054 (νSi-O-Si), 1083, 1170 (νSi-O-C), 1262 (νSi-C), 2889 (νC-H), 2928 (νC-H), 2976 (νC-H). The MS (ESI-HR, m/z) was calculated for C14H36Na1O8Si3: 439.16010 [M+Na]+, Found: 439.16157.

Route B: a solution of pyridine (7.91 g, 0.10 mol) in THF (10 mL) was cooled in an ice bath. CTES (19.9 g, 0.10 mol) in THF (100 mL) followed by DMSDOL (4.61 g, 0.05 mol) in THF (100 mL) were added to the solution. The mixture was stirred for 1 h at room temperature then for 1 h at 60 °C. After stirring, hexane was added to the solution and the precipitate was filtered. The solution was distilled under reduced pressure (120–123 °C, 3 Torr) to give 9.38 g (45% yield) of QDQ as a colorless liquid.

2.4 Preparation of polymers

2.4.1 Preparation of pQDQ

QDQ (2.08 g, 5 mmol) and ethanol (2.30 g, 50 mmol) were placed in a 100-mL four-neck flask equipped with a gas inlet and outlet and cooled in an ice bath for 10 min while being stirred at 150 rpm. Subsequently, 6 M HCl(aq) (0.096 g, 0.505 mmol of HCl) and various amounts of water were added to the mixture, which was then stirred at room temperature for 10 min then heated for 3 h at 80 °C under a flow of dry nitrogen gas at a rate of 360 mL/min to produce pQDQ.

2.4.2 Preparation of pDEDMS1-TEOS2

DEDMS (4.94 g, 33.3 mmol), TEOS (13.9 g, 66.7 mmol), and ethanol (9.54 g, 207 mmol) were placed in a 100-mL four-neck flask equipped with a gas inlet and outlet and cooled in an ice bath for 10 min while being stirred at 150 rpm. Afterward, 6 M HCl(aq) (1.91 g, 10.5 mmol of HCl) and various amounts of water were added to the mixture, which was then stirred at room temperature for 10 min then heated for 3 h at 80 °C under a flow of dry nitrogen gas at a rate of 360 mL/min to give pDEDMS1-TEOS2.

2.5 Preparation of films

The pQDQ and pDEDMS1-TEOS2 polymers as viscous liquid were dissolved in EtOH/acetone (1:1 v/v) to form a 20 wt% solution. The solution was poured into a 90.5-mm polymethylpentene (PMP) Petri dish and dried for 24 h at 25 °C then for 7 days at 120 °C. After cooling, the films were peeled from the Petri dish to obtain a gel film. The thickness of the films was 80–115 µm.

3 Results and discussion

3.1 Monomer synthesis

QDQ was synthesized via two routes to establish a synthetic process for the reaction of silanol with chlorosilane. While Muzanof et al. reported a reaction using sodium silanolate [15], we found an easier route to synthesize QDQ, as shown in Scheme 2. In route A, TEOS was chlorinated by SOCl2 to produce CTES in high yield (92%), and then hydrolyzed in the presence of (NH4)2CO3 to obtain TESOL in moderate yield (62%). The reaction of DCDMS with TESOL afforded a 36% yield of QDQ. The total yield for route A was calculated to be 21%. In route B, DCDMS was hydrolyzed to give DMSDOL, which reacted with CTES to form QDQ. The DCDMS-based total yield of route B was 32%, which was higher than that of route A. Bottom-up synthesis allowed us to process silanol, although silanols are generally known to be unstable and afford self-condensation. The synthesis of silanol compounds, TESOL and DMSDOL, was achieved by the careful treatment in terms of molar ratio and temperature control of the reaction according to the literature [13, 14]. The reaction of stable silanols with chlorosilanes is an effective route for the preparation of hetero-oligosilanes.

3.2 Preparation of pQDQ and pDEDMS1-TEOS2

The pQDQ polymer was prepared via a sol–gel reaction under nitrogen flow, and the results are shown in Table 1. The sol–gel process was carried out in an open system where dry nitrogen gas was introduced and volatiles (HCl, solvent, and water) were evaporated to obtain polymer sols with high molecular weight and solubility in organic solvents [16,17,18]. The molecular weight of the polymer sol was controlled by varying the molar ratio of water. As the ratio of water to alkoxysilane monomer (H2O/Si) increased, Mw and polydispersity (Mw/Mn) increased. When H2O/Si increased, the viscosity of pQDQ increased, resulting in a viscous liquid. When H2O/Si reached 1.45, an insoluble gel was obtained, which was attributed to the highly crosslinked pQDQ. As the molar amount of water increased, the pQDQ yield decreased and the number of hydrolyzed ethoxy groups increased, indicating that hydrolysis and polycondensation proceeded. The reaction ratio was estimated from the intensity of the signals originating from the ethoxy groups in the 1H NMR spectra. Because the reproducibility was low when H2O/Si was greater than 1.40, the optimal molar amount of water for the preparation of pQDQ films was determined to be 1.35.

To determine how pQDQ differs from a comonomer with the same composition [DQ2]n, pDEDMS1-TEOS2 was prepared via the copolymerization of one equivalent of DEDMS and two equivalents of TEOS under the same sol–gel reaction conditions, as shown in Table 2. As the water content increased, the yield decreased, the hydrolysis ratio of the ethoxy group increased, and Mw and Mw/Mn increased. An insoluble gel was obtained when the water molar ratio was 1.40. Therefore, a water molar ratio of 1.35 was set as the optimal condition for the preparation of pDEDMS1-TEOS2.

To investigate the initial stage of polymerization, ESI-MS of pQDQ (Mw = 1,900) was performed, as shown in Fig. 1. As no signals attributed to molecular weights lower than the that of QDQ (m/z = 439) were detected in the m/z region, cleavage of the D–Q bond or formation of a cyclic monomer were excluded. Observed peaks were corresponding to the monomer, dimer, cyclic dimer, trimer, and cyclic trimer, respectively. This result suggests that QDQ was polymerized with maintaining QDQ backbone such as [QDQ]n (n = 1–3).

The polymer structure was analyzed based on 29Si NMR spectra that are shown in Figs. 2 and 3. To investigate polymerization behavior, pQDQ and pDEDMS1-TEOS2 with low and high molecular weight were analyzed as shown in Figs. 2b, c, e, f and 3b, c, e, f. As a comparison, spectra of QDQ monomer and DEDMS1-TEOS2 comonomer were also shown in Figs. 2a, d, and 3a, d. In 29Si NMR spectra, signals ascribed to D unit at –25 to 0 ppm and Q unit at −115 to −80 ppm were observed, respectively [19]. The low-molar-ratio pQDQ (Fig. 2b) exhibits a signal at −18.4 ppm due to unreacted monomers, which corresponds to the monomer peak (m/z = 439) observed in ESI-MS presented in Fig. 1. The signal at −11.1 ppm is attributed to the D1 structure (SiOSiMe2OH) or to the D2 unit of cyclotrisiloxane. However, the peaks could not be precisely assigned. Although MS results suggested that the QDQ unit was maintained in polymerization, the Q-D bonds might be partially cleaved to form D1 unit. Cyclic dimethylsiloxanes such as D3 and D4 are generally found in −9.1 and −19.4 ppm [19]. No signal for D3 was observed and a signal at –20 ppm, possibly D4, was observed in both polymers (pQDQ and pDEDMS1-TEOS2). Absence of the signal at –9 ppm is likely due to too little D3 product to be detected by 29Si NMR. Low-molecular-weight pDEDMS1-TEOS2 (Fig. 2e) exhibits more signals than pQDQ, implying the existence of multiple components, including the D-D bond. A broad signal due to the D region in the high-molecular-weight pQDQ spectrum (Fig. 2c) indicates that further polymerization occurred. Compared to the high-molecular-weight pDEDMS1-TEOS2 polymer (Fig. 2f), the half-width of pQDQ was smaller, indicating that pDEDMS1-TEOS2 has a complicated polymer structure.

The 29Si NMR spectra of the Q region are shown in Fig. 3. No signals for Q0 units (approximately −82 ppm) were observed in the low-molecular-weight pQDQ spectrum (Fig. 3b), indicating no cleavage of QDQ units. The polymer contains a Q region (Q1–Q4), indicating that polymerization occurred via condensation reactions [19, 20]. The spectra of high-molecular-weight pQDQ and pDEDMS1-TEOS2 (Fig. 3c, f) mainly consisted of Q3 signals (ca. −100 to −105 ppm), which indicated that these polymers were highly crosslinked. These results indicate that, although the spectra of pQDQ and pDEDMS1-TEOS2 were similar, the pDEDMS1-TEOS2 polymer contains a DD unit. The structure of pQDQ would be the same as that of pDEDMS1-TEOS2, but the sequence of the Q and D units are different.

From MS and 29Si NMR spectra, we concluded that pQDQ retained QDQ arrangement such as (QDQ)n, and that the possibility of D-D bond formation by the rearrangement of Q-D bond could not be completely ruled out. In contrast, pDEDMS1-TEOS2 includes D-D bond. This result showed that pQDQ has highly regulated structure compared to pDEDMS1-TEOS2. Thus, polymerization of oligosiloxanes is effective in preparing homogenous polymers with multiple siloxane units.

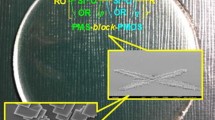

3.3 Preparation of gel films and their properties

Gel films were prepared by casting polymer solutions onto PMP Petri dishes. As the resultant film can be peeled off from Petri dishes, a Petri dish is a suitable substrate for the preparation of polysiloxane films as opposed to glass substrates, to which polysiloxane films tend to adhere. A transparent film was obtained, as shown in Fig. 4a. The film was flexible and bent, as shown in Fig. 4b, although it broke when bending stress with a strong force was applied. A pDEDMS1-TEOS2 film with similar appearance and flexibility was also obtained.

The FT-IR spectra of the gel films are shown in Fig. 5. Absorption bands were observed at 2976 cm−1 (νasC-H), 2928 cm−1 (νasC-H of CH2), 2889 cm−1 (νsC-H of CH3), 1391 cm−1 (δas(in-plane) of CH3), 1262 cm−1 (νasSi-CH3), 1170 cm−1 (δas(in-plane)C-H of CH3), 1105 cm−1 (νasSi-O-C), 1083 cm−1 (νsSi-O-Si), 1055 (νSi-O-Si) cm−1, 960 cm−1 (δas(in-plane)Si-OC), and 801 cm−1 (νsSi-CH3) [21,22,23]. Compared to the half value of the broad band at approximately 1000–1200 cm−1 ascribed to Si–O–Si, the half value of pQDQ was sharper than that of pDEDMS1-TEOS2, indicating that pDEDMS1-TEOS2 is a complicated Si–O–Si network, most likely because of the existence of D–D bonds. The band ascribed to Si–OH at approximately 3400 cm−1 (νsOH) for each film was small, which indicates that this polymer has few Si–OH groups.

To investigate the structure of siloxane in the gel films, solid-state DD MAS 29Si NMR spectra were obtained (Fig. 6). The spectra of these two films were similar to each other and to the solution-state NMR spectra shown in Figs. 2 and 3. Signals attributed to the D2 (−16 ppm) and Q1, Q2, Q3, and Q4 (−89, −95, −101, and −109 ppm, respectively) units were observed. The peak areas were calculated as shown in Table 3. The D:Q area ratio was approximately 1:2, which corresponds to the molar ratio of D and Q in the feed. The degree of condensation (DC) was calculated using the peak area ratio of the silicon units, as follows: (Qn is the peak area of the Qn unit (n = 1, 2, 3, 4) and Q is the sum of the peak area of the Qn unit (n = 1, 2, 3, 4)):

The DCs of pDEDMS and pQDQ were calculated to be 68% and 74%, respectively. This indicates that approximately 70% of the Si–O–R bonds are present as Si–O–Si to enable crosslinking, and the remaining 30% are Si–O–Et or Si–O–H. These similar structures may exhibit similar material properties while having different mechanical strengths, as described below.

The films were characterized by tensile strength, TG-DTA, UV-Vis spectroscopy, and swelling tests, and the results are shown in Table 4. Tensile strength tests were conducted to determine the flexibility of the gel films. Figure 7 shows the results of the tensile strength tests. The pQDQ film showed higher Young’s modulus and breaking stress (455 and 3.7 MPa, respectively) than the pDEDMS1-TEOS2 film (55 and 1.1 MPa, respectively), suggesting that the arrangement of the Q and D units affects the mechanical strength of the gel films.

TG-DTA was performed to investigate the thermal properties of the films, and the results are shown in Fig. 8a. The decomposition temperature at 5% weight loss (Td5) and ceramic yield were almost identical for the pQDQ and pDEDMS1-TEOS2 gel films, which reflects the same ratio of units as D:Q = 2:1. The initial weight loss with a sharp exothermic peak at 250–300 °C was due to the thermal decomposition of the residual ethoxy group. The gradual weight loss at 300–600 °C was due to the thermal decomposition of the methyl group [24].

Both films were colorless and transparent based on the UV-Vis spectra, as shown in Fig. 8b. The transmittances of pQDQ and pDEDMS1-TEOS2 in the visible region of the spectrum (400–700 nm) were 94% and 93%, respectively, indicating that almost all visible light was transmitted through the films. This high transparency is expected to be utilized for opto-electric applications.

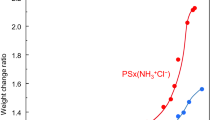

Solvent swelling tests were conducted to investigate the solvent capture ability of the gel films, which is related to the density of the polymer network. Both films absorbed THF and swelled after being immersed in the solvent for 24 h. The swelling weight ratios of pQDQ and pDEDMS1-TEOS2 were 18% and 20%, respectively, which reflected the formation of a highly homogeneous dense siloxane network for pQDQ by preventing phase separation between the D and Q domains.

4 Conclusions

DQ hybrid polysiloxanes, pQDQ and pDEDMS1-TEOS2, were prepared via a sol–gel reaction. The polymer structure was investigated using 29Si NMR and MS. The gel films were colorless, transparent, and thermally stable. The structures of the gel films were analyzed by FT-IR and NMR to show that the sequences of the D and Q units were almost identical. The pQDQ film exhibited harder mechanical properties than the pDEDMS1-TEOS2 film. This dissimilarity may be due to the difference in the sequence of the Q and D units; pQDQ was continuously combined with the QDQ unit with high dispersity, whereas pDEDMS1-TEOS2 included a DD unit and a cyclic D unit because of its reactivity. These results highlight the importance of the homogeneity between siloxane units. Oligosiloxane, a precursor for sol–gel polymerization, is an effective approach for the production of homogenous component polymers.

References

Kim SH, Choi KH, Cho SJ, Choi S, Park S, Lee SY (2015) Printable solid-state lithium-ion batteries: A new route toward shape-conformable power sources with aesthetic versatility for flexible electronics. Nano Lett 15:5168–5177. https://doi.org/10.1021/acs.nanolett.5b01394

Ni H, Liu J, Wang Z, Yang S (2015) A review on colorless and optically transparent polyimide films: Chemistry, process and engineering applications. J Ind Eng Chem 28:16–27. https://doi.org/10.1016/j.jiec.2015.03.013

Yu H-C, Kumar SV, Lee JH, Oh SY, Chung C-M (2015) Preparation of robust, flexible, transparent films from partially aliphatic copolyimides. Macromol Res 23:566–573. https://doi.org/10.1007/s13233-015-3073-6

Lan Z, Chen X, Zhang X, Zhu C, Yu Y, Wei J (2019) Transparent, high glass-transition temperature, shape memory hybrid polyimides based on polyhedral oligomeric Silsesquioxane. Polymers 11:1058. https://doi.org/10.3390/polym11061058

Ahmed N, Fan H, Dubois P, Zhang X, Fahad S, Aziz T, Wan J (2019) Nano-engineering and micromolecular science of polysilsesquioxane materials and their emerging applications. J Mater Chem A 7:21577–21604. https://doi.org/10.1039/C9TA04575A

Koh K, Sohn H (2021) Fast curable polysiloxane-Silphenylene Hybrimer with high transparency and refractive index for optical applications. Polymers 13:515. https://doi.org/10.3390/polym13040515

Hamada T, Nakanishi Y, Okada K, Ohshita J (2021) Crack- and shrinkage-free ethylene-bridged polysilsesquioxane film prepared by a Hydrosilylation reaction. ACS Omega 6:8430–8437. https://doi.org/10.1021/acsomega.1c00183

Yoshimatsu M, Komori K, Ohnagamitsu Y, Sueyoshi N, Kawashima N, Chinen S, Murakami Y, Izumi J, Inoki D, Sakai K, Matsuo T, Watanabe K, Kunitake M (2012) Necklace-shaped dimethylsiloxane polymers bearing a polyhedral oligomeric Silsesquioxane cage prepared by polycondensation and ring-opening polymerization. Chem Lett 41:622–624. https://doi.org/10.1246/cl.2012.622

Bae JY, Kim Y, Kim H, Kim Y, Jin J, Bae BS (2015) Ultraviolet light stable and transparent sol–gel methyl siloxane hybrid material for UV light-emitting diode (UV LED) encapsulant. ACS Appl Mater Interfaces 7:1035–1039. https://doi.org/10.1021/am507132a

Li G, Liu Y (2020) Cyclosiloxane-containing polymers and the formation of highly stable elastomer. Chem Lett 49:299–302. https://doi.org/10.1246/cl.190915

Urasaki N, Wong CP (1999) Separation of low molecular siloxanes for electronic application by liquid–liquid extraction. IEEE Trans Electron Packag Manufact 22:295–298. https://doi.org/10.1109/6104.816097

Hayami R, Nishikawa I, Hisa T, Nakashima H, Sato Y, Ideno Y, Sagawa T, Tsukada S, Yamamoto K, Gunji T (2018) Preparation and characterization of stable DQ silicone polymer sols. J Sol-Gel Sci Technol 88:660–670. https://doi.org/10.1007/s10971-018-4839-z

Kazakova VV, Gorbatsevich OB, Skvortsova SA, Demchenko NV, Muzafarov AM (2005) Synthesis of triethoxysilanol. Russ Chem Bull 54:1350–1351. https://doi.org/10.1007/s11172-005-0409-y

Cella JA, Carpenter JC (1994) Procedures for the preparation of silanols. J Organomet Chem 480:23–26. https://doi.org/10.1016/0022-328X(94)87098-5

Rebrov EA, Muzafarov AM (2006) Monosodiumoxyorganoalkoxysilanes: Synthesis and properties. Heteroat Chem 17:514–541. https://doi.org/10.1002/hc.20280

Hayami R, Ideno Y, Sato Y, Tsukagoshi H, Yamamoto K, Gunji T (2020) Soluble ethane-bridged silsesquioxane polymer by hydrolysis–condensation of bis(trimethoxysilyl)ethane: Characterization and mixing in organic polymers. J Polym Res 27:316. https://doi.org/10.1007/s10965-020-02294-z

Sato Y, Hayami R, Miyase Y, Ideno Y, Yamamoto K, Gunji T (2020) Preparation and properties of methyl- and cyclohexylsilsesquioxane oligomers as organic–inorganic fillers. J Sol-Gel Sci Technol 95:474–481. https://doi.org/10.1007/s10971-020-05291-2

Gunji T, Tozune T, Kaburaki H, Arimitsu K, Abe Y (2013) Preparation of co -polymethyl(alkoxy)siloxanes by acid-catalyzed controlled hydrolytic copolycondensation of methyl(trialkoxy)silane and tetraalkoxysilane. J Polym Sci Part A: Polym Chem 51:4732–4741. https://doi.org/10.1002/pola.26904

Brus J, Dybal J (1999) Copolymerization of tetraethoxysilane and dimethyl(diethoxy)silane studied by 29Si NMR and ab initio calculations of 29Si NMR chemical shifts. Polymer 40:6933–6945. https://doi.org/10.1016/S0032-3861(99)00095-6

Babonneau F, Thorne K, Mackenzie JD (1989) Dimethyldiethoxysilane/tetraethoxysilane copolymers: Precursors for the silicon–carbon–oxygen system. Chem Mater 1:554–558. https://doi.org/10.1021/cm00005a017

Yoshino H, Kamiya K, Nasu H (1990) IR study on the structural evolution of sol–gel derived SiO2 gels in the early stage of conversion to glasses. J Non-Crystalline Solids 126:68–78. https://doi.org/10.1016/0022-3093(90)91024-L

Olejniczak Z, Łęczka M, Cholewa-Kowalska K, Wojtach K, Rokita M, Mozgawa W (2005) 29Si MAS NMR and FTIR study of inorganic–organic hybrid gels. J Mol Struct 744–747:465–471. https://doi.org/10.1016/j.molstruc.2004.11.069

Roche V, Perrin FX, Gigmes D, Vacandio F, Ziarelli F, Bertin D (2010) Tracking the fate of γ-aminopropyltriethoxysilane from the sol state to the dried film state. Thin Solid Films 518:3640–3645. https://doi.org/10.1016/j.tsf.2009.09.085

Yamamoto K, Ohshita J, Mizumo T, Tsuru T (2014) Polymerization behavior and gel properties of ethane, ethylene and acetylene-bridged polysilsesquioxanes. J Sol-Gel Sci Technol 71:24–30. https://doi.org/10.1007/s10971-014-3322-8

Funding

This study was supported by JSPS KAKENHI (Grant number JP19K05636).

Author information

Authors and Affiliations

Contributions

KY: conceptualization and writing—original draft. TS, YS and TN: data curation. JO: writing—reviewing and editing. TG: supervision and writing—reviewing and editing.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yamamoto, K., Shimoda, T., Sato, Y. et al. Preparation and film properties of polysiloxanes consisting of di- and quadra-functional hybrid units. J Sol-Gel Sci Technol 104, 724–734 (2022). https://doi.org/10.1007/s10971-022-05806-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-022-05806-z