Abstract

An international group of laboratories participating in CMX-4 subjected three samples to comparative nuclear forensic analysis using uranium assay and trace element analysis techniques to determine if the samples had similar or different origins. Uranium assay indicated that two pellet samples (ES-2 and ES-3) were nearly pure UO2 while the black powder sample ES-1 was primarily UO2 with UO3 and/or U3O8 forms present as impurities. Trace element analysis by five of the six participating laboratories reported molybdenum concentrations below 10 µg/g U in all of the exercise samples, suggesting the same likely facility of origin for all three samples.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Recently, an international group of nuclear laboratories participated in the 4th Collaborative materials exercise (CMX-4) during which they tested samples hypothetically confiscated by police, and designated ES-1 (black powder), ES-2 (a deep gray pellet), and ES-3 (similar to ES-2 in appearance). The samples were believed to have originated from one of the following hypothetical enrichment facilities—EA Fuel Products, LN Enrichment International, and ATOMic Power Services [1]. The participating laboratories were requested to determine if a connection could be established between ES-1 and/or ES-2 and ES-3 production processes. Special interest was given to the measurement of molybdenum because the laboratories were given the process information that the EA Fuel Products pellets are designed to contain approximately 10 µg/gU or less of natural molybdenum, which is nearly 10 times less when compared to the typical molybdenum content in fuel generated from the other two facilities [1]. These samples were subjected to comparative nuclear forensic analyses using Davies-Gray titration for uranium assay and inductively coupled plasma mass spectrometry/optical emission spectroscopy ICP-MS/OES techniques to determine the uranium oxidation phase and to establish if materials correspond with the specifications given for the EA Fuel Products or contain some other common impurities to suggest similar or related origins.

Uranium titration can occur under a large variety of conditions using many different reagents; however, the most commonly used and accepted technique is based on a method developed by Davies and Gray in 1964 [2]. This method can determine precise uranium assay values with minimum interferences and without requiring separations prior to the assay of uranium materials. The uranium is reduced to U(IV) by excess Fe(II) in strong phosphoric-sulfamic acid, and excess Fe(II) is selectively oxidized by nitric acid in the presence of a Mo(VI) catalyst. Then the U(IV) is titrated by a dichromate solution or by cerium sulphate solution with a potentiometric titration using vanadyl as electrochemical enhancer.

The Davies-Gray titration method used for uranium assay has been reviewed and improved by many authors since its first introduction [3,4,5,6,7]. Experience with titrations indicates either automated or manual titrations can perform equally well and the choice of either is based on the frequency of the analysis, and available funding and space [8]. The special aim of this coverage, apart from giving the contributing laboratories the opportunity to compare their results and express the trace elements in units of µg/gU, was the general assessment of the precision and accuracy of this analytical method. The Davies-Gray titration is very useful if the laboratory does not have the ability to measure oxygen directly or perform X-ray diffraction analyses.

The impurity spectrum in the uranium material differs from sample to sample among the stages of uranium production and among production sites and can provide decisive information for origin characterization. It is also common for impurities to enter the sample during different stages of the sample processing and analysis [9]. Inductively coupled plasma mass spectrometry has excellent sensitivity, precision, and good accuracy for trace elements measurements [10,11,12,13,14,15]. Ultra-trace elements levels can generally be measured by ICP-MS techniques, such as multi-collector (MC-ICP-MS), quadrupole (ICP-qMS) or sector-field (ICP-SFMS). The principle of ICP-MS is that a stream of sample is heated to 5000–8000 K during which the sample is evaporated, atomized, and ionized. The ions separate according to their mass-to-charge ratio. Quadrupoles or sectors are used for mass separation.

This paper presents a comparative view of the approaches and methodologies used for the trace element analysis in the three samples, along with the laboratory data interpretation against the set CMX-4 exercise objectives. The authors also address aspects of the determination of the uranium assay and oxidation state based on the use of the Davies-Gray method. The laboratories that contributed to this paper are South Africa Nuclear Energy Corporation Nuclear Forensics Laboratory, Los Alamos National Laboratory (United States of America), Swedish Defense Research Agency, Defense Science Organization National Laboratories (Singapore), Lawrence Livermore National Laboratory (United States of America) and European Commission’s Joint Research Centre (Germany).

Experimental

Instruments and equipment used

Mass spectrometric measurements of the metal impurities and uranium assay analysis in ES-1, ES-2 and ES-3 samples were performed. The participating laboratories were code-named Cezanne, Buonarroti, Gauguin, Monet, Van Gogh, and Vermeer. The instruments these laboratories used are listed in Table 1.

Mass spectrometry is among the analytical techniques that are frequently used for nuclear forensic analysis [1, 16]. Out of the six laboratories, four used quadrupole ICP-MS for the impurities measurements, while two used a sector-field ICP-MS. ICP-MS instruments’ operating parameters such as the carrier gas flow, nebulizer pump speed, and peak patterns were used for sensitivity optimization and to suppress/eliminate interferences. Monet made use of two other different types of ICP-OES instruments. These are a Thermo Scientific IRIS ICP-OES and a Horiba Jobin–Yvon Ultima 2 ICP-OES instruments.

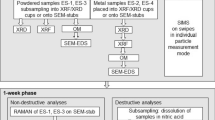

Sample preparations

High-purity trace element analysis grade mineral acids (nitric and hydrofluoric acids), high-purity water (18.2 M cm resistivity at 25 °C) were used for all the sample and standard preparations. Standards were purchased as traceable single/multi-element, calibration standard solutions, or uranium based certified references.

Prevention against contamination

Sample contamination prevention measures undertaken by the respective laboratories are summarized in Table 2.

Analyte solutions and calibration standards

The ES-1 (black powder) samples were dissolved as received by all participating laboratories, except for Gauguin, without drying prior to weighing and dissolving the required amounts. Gauguin dried the sample at 140 °C for 17 h. The measured percent moisture in wt% was 0.022 ± 0.003. The dissolved masses varied between 100 and 600 mg in about 5–30 ml of nitric acid solution. Nominal masses of the ES-2 and ES-3 samples were each dissolved in concentrated (7–10 M) HNO3 and then diluted to yield low uranium concentrations in the final analyte solutions. Monet used 15.9 M HNO3 (plus trace HF) for dissolution to give about 40 mgU/g solution for aliquoting. ICP-MS aliquots were then reduced in volume and brought up in 8 M HNO3. Gauguin’s ES-2 and ES-3 sample digestion began with a sequential leach procedure to remove any surface contamination from sampling. The cleaning involved the steps of ultrasonification in high-purity water for 5 min, rinsing in 1 M HNO3 and then high-purity water, rinsing in 2 M HNO3 and high-purity water, and then finally rinsing with 4 M HNO3 and high-purity water. The masses of the “cleaned” samples were approximately 600 mg. All three Gauguin samples were digested in 8 M HNO3 and subsequently diluted so that the final solutions contained approximately 20 mg U/g solution in 3.2 M HNO3 and 0.05 M HF. HF was used to stabilize the high-field-strength elements. These primary solutions were used to prepare subsequent dilutions for both trace element and U assay analysis. Different laboratory setups were used to dissolve the samples. These included the use of an ANALAB Evapo-clean hot block (Hoenheim, France) with screw-top Teflon Savillex (Eden Prairie, MN, USA) used by Cezanne; Teflon beakers with Teflon watch glasses on hotplate (used by Monet); quartz vials on a hotplate (used by Gauguin) and heating on a hotplate (used by Vermeer and Van Gogh). The temperature and time taken by the different laboratories to completely dissolve these solid samples was depended on the setup used. Buonarroti etched the pellets with dilute HNO3, and then crushed them with a iron tool covered with PE plastic to avoid contamination. All laboratories easily dissolved the samples (pellets and black powder) in hot nitric acid solution.

High-purity nitric acid, high-purity HF (Gauguin), and high-purity water (of 18.2 MΩ cm resistivity) were used for sample and instrument calibration standard solution preparations. Multi-element and single-elements calibration standards and check element solutions, including internal standards were prepared from certified stock solutions supplied by ISO/IEC 17025 accredited agents of Spex CertiPrep, Inorganic Ventures, and the National Institute of Standards and Technology (NIST). Dilutions for ICP-MS using dilute HNO3, and in the case of Gauguin trace HF to stabilize the high-field-strength elements, were commonly performed gravimetrically using high-precision balances.

Molybdenum and a different number of other impurities were targeted for analyses by the contributing laboratories. Four laboratories—Monet, Cezanne, Gauguin, and Buonarroti—included the analysis of rare-earth elements (REE).

Trace element/impurity analysis

Different approaches were used to deal with ICP-MS interferences, such as the removal of uranium prior to analysis and the suppression or corrections of known problematic transition elements. The different methods used by the contributing laboratories to eliminate or reduce interferences are summarized in Table 3.

Vermeer used UTEVA resin (Triskem, France) to remove the uranium from the trace elements. The method is aimed at retaining the uranium on the resin while rinsing out the trace elements using a modified method [17]. Nitric acid was used to condition the cartridges. The solutions were collected in Teflon beakers followed by heating to dryness, and then dissolving in nitric acid.

Validation of methods and procedures used

The contributing laboratories used different approaches to verify the accuracy of methods and to complete the trace elements analysis. These included the use of spiking, certified reference materials, check solutions, and digested blank solutions. The different means used are summarized in Table 4.

Laboratories chose their own internal standards, certified reference materials (CRM), and check elements for use in methods verifications. Among the isotopes used as internal standards were 6Li, 45Sc, 73Ge, 103Rh, 115In, and 169Tm. CANMET Cup-2 uranium oxide (certified for uranium isotopes content), NBL CRM 124 uranium oxide (certified for trace elements content), NIST SRM 950 uranium oxide standard (certified for U3O8 content), and CRM 112A uranium metal standard (certified for U %wt) were used for method validations. A list of the internal standards and CRMs used by the different laboratories is provided in Table 5.

Davies-Gray experimental approach used by Cezanne

The method used by Cezanne is the modified Davies-Gray method for uranium determination by iron(II) reduction in phosphoric acid followed by chromium(VI) titration in the presence of vanadium. This is essentially a three-step procedure wherein [5].

-

Uranium is reduced quantitatively from + 6 valence to + 4 valence by excess of iron(II) in strong phosphoric acid in the absence of nitrite. Prior to the uranium reduction, nitrite is destroyed by addition of sulfamic acid.

-

Iron(II) is selectively oxidized to iron(III) by nitric acid in the presence of a molybdenum(VI) catalyst.

-

After dilution to reduce phosphate concentration, the uranium is titrated to uranium(VI) by standard dichromate.

A potentiometric titration was performed on the 888 Titrando with a metal electrode (platinum). The addition of vanadium(IV) just prior to titration sufficiently improved the reaction rate and simplified the potentiometric endpoint determination. To establish a relation between K2Cr2O7 concentration and the uranium in the sample, this concentration is expressed in titer, which is the ratio between equivalent uranium mass content and the weight of K2Cr2O7 standard solution (i.e., mgU/g K2Cr2O7 solution). By using this solution, aliquots containing ES-1, ES-2, or ES-3 samples were titrated to determine the uranium concentrations. In addition, uranium standard reference materials (CRM 112A obtained from New Brunswick Laboratory) were used for calibration of the system.

Cezanne made a single mass dissolution of approximately 800 mg uranium oxide for each of the as-received ES-1, ES-2 and ES-3 samples. The aliquots were divided into three fractions each for triplicate titrations. The uranium levels titrated ranged between 30 and 50 mg as detailed in [5]. Titration calibration for the uranium determination was performed using certified reference material CRM 112A to check on the material handling of the K2Cr2O7 solution. All work was carried out in the dedicated clean area using labware cleaned in accordance with the specifications of References [5, 6].

Davies-Gray experimental approach used by Monet

Uranium assay at Monet was performed using a modified Davies-Gray titration method with cerium sulfate as the titrant in a manner similar to using the ISO 7097-2 [6]. Cezanne uranium assay was based on the use of potassium dichromate as the titrant. The two approaches are expected to yield equivalent accuracy and uncertainty [7, 8]. The biggest difference between the potassium dichromate and cerium sulfate titrations has been the sharpness of the end point with the cerium sulfate having a sharper endpoint. Care by the analyst must be taken not to over-titrate when using cerium sulfate. Although one can automate this method, Monet has not done so because of low sample load. This method is performed manually at Monet with a weighing burette and balance instead of automatic volumetric titrators.

For each sample, two solid portions (cuts 1 and 2) of ~ 500 mg were prepared, dissolved, and distributed for analysis. Because uranium is ubiquitous in the local area dust, samples were handled in gloved tents inside cleaned enclosures. All new, clean glassware and labware were used as well and all acids and reagents were analytical grade or better. Sample dissolutions were performed in Teflon beakers with Teflon watch glasses covering the opening to prevent any environmental dust from settling within the beaker. Solution bottles were capped at all times with new dispenser tops used each time the storage cap was removed. Pellet samples were snipped apart with new, ethanol-cleaned diagonal cutting pliers to provide the 440–500 mg used for each dissolution. Multiple aliquots were dispensed from each dissolution into glass beakers, each containing nominally 25 mg of sample. Titrimetric calibration for uranium assay sample measurements was performed each day using SRM 960 (still available from New Brunswick Laboratory as CRM 112A). An in-house working reference uranium metal sample and a SRM uranium oxide (SRM 950b, U3O8) were run as control samples each day to effectively bracket the concentration range of sample assays. Sample replicates were analyzed on two separate days to provide additional confidence in the reported numbers.

Isotope-dilution thermal ionization mass spectrometry approach used by Buonarroti

Uranium assay by Buonarroti was performed using isotope dilution thermal ionization mass spectrometry (TIMS) method with 233U spike. Buonarroti made a single mass dissolution of approximately 500 mg uranium oxide for each of the as-received ES-1, ES-2, and ES-3 samples with and without spike. The unspiked aliquots were used after as a base solution for all the forthcoming analysis. Sample dissolutions were performed overnight in Teflon Erlenmeyer covered with PE to avoid evaporation. All the samplings were performed gravimetrically. The uranium content of the samples was calculated by the isotopic composition of the unspiked sample and the n(238U)/n(233U) of the spiked sample with the isotope dilution rules [18].

Isotope-dilution MC-ICP-MS approach used by Gauguin

Uranium assay by Gauguin was performed using a standard isotope dilution mass spectrometry technique. Gravimetric dilutions of each of the primary sample dissolutions described in section entitled “Analyte solutions and calibration standards,” were made to adjust the uranium concentration to approximately 10 ng/g. Multiple aliquots of these dilutions were taken and spiked with a well-calibrated 233U spike in order to obtain a sample to spike ratio (235U/233U) of approximately one. Unspiked aliquots for each sample were analysed using MC-ICP-MS to determine the isotopic composition of each sample. Uranium assay was determined using the isotopic ratios measured on unspiked samples combined with the 238U/233U ratio measured on the spiked samples using typical IDMS calculations [19].

Results

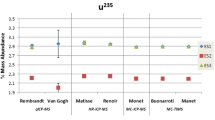

Results of uranium assay analysis

The Davies-Gray uranium assay results presented in Table 6. Cezanne results are from triplicate analysis of three separate dissolutions of each sample. According to the Monet Davies-Gray procedure, duplicate dissolutions were assayed in triplicate over two separate days and results were compared to assess agreement prior to reporting. The Buonarroti and Gauguin’s uranium assay results obtained using isotope dilution analysis on Thermo Fischer Triton TIMS and Nu Instrument’s NuPlasma HR MC-ICP-MS, respectively are included in Table 6. Uncertainties are reported as total combined uncertainty at the 95 percent confidence interval (corresponding to coverage factor of k = 2) [20].

Results of ICP-MS/OES trace elements analysis

Trace elements abundances were independently determined by the participating laboratories using each laboratory dissolved samples. All six laboratories reported on the amounts of Mo because only Mo was given as the significant signature. There is a great deal of variability in the sets and number of other elements measured. Five out of six laboratories included trace element analysis and four included REE in their list of impurities.

Measurements verifications

Cezanne completed laboratory method validation studies based on inter-laboratory results of Cup-2 certified reference materials (with recommended values for some elements). Samples were independently analysed by both Cezanne and Gauguin, and the measured values from the two laboratories corresponded well and with most of the reference materials certified values [21]. Gauguin and Buonarroti have together participated in international round robins of trace element analysis of impurities in uranium material, which demonstrated good agreement between the two laboratories [22].

Vermeer measured the concentration of a spiked dilution in the calibration solution at regular interval and used this to check against the accuracy of the measurements. Van Gogh used the isotopic ratio of 95Mo and 96Mo to check if these were consistent with its natural abundance and both internal and external standardization means to ensure accuracy of quantifications. Gauguin performed a matrix spike on selected elements above detection to assess accuracy of quantification. Buonarroti used matrix-matched standards prepared from hydrolysed high-purity UF6. The accuracy was checked with a uranyl solution spiked with multi-elemental standard, which was different from the calibration. Monet, Cezanne, and Gauguin used the addition of an internal standard to both the calibration solutions and to the samples as additional means to compensate for measurement signal drift.

Molybdenum concentrations measured by ICP-MS

All six contributing laboratories measured and reported molybdenum concentrations in the three exercise samples. The results are summarized in Table 7.

Other trace elements measured using ICP-MS

Some contributing laboratories measured several impurities other than molybdenum, to fully compare the characteristic concentrations of the ES-1, ES-2, and ES-3 samples. The averaged elemental results for the three samples analysed are given in Table 8.

Trace elements measured using ICP-OES

Monet conducted a simultaneous multi-element determination analysis of 10 elements using the ICP-OES after the removal of uranium matrix. The results are presented in Table 9. These were assessed for day-to-day variation as well as homogeneity of the sample prior to reporting. Elements such as B, Ca, Fe, Li, Mg, Si, and Zn were determined by the IRIS ICP-OES instrument, whereas K, Na, and P were analysed by the Horiba Jobin–Yvon Ultima 2 ICP-OES for an improved sensitivity. The reported uncertainties are ISO/IEC Guide 98-3:2008 compliant at a coverage factor of k = 2 [20]. Only above method detection level (MDL) results are included in the calculations.

Rare-earth elements measured

Four contributing laboratories reported the measurements of rare-earth elements to provide a full complementary assessment of possible similarities in the origins of ES-1, ES-2, and ES-3 samples. The results are given in Table 10.

Discussion

Interpretations and discussions of uranium assay results

By comparing the reported values (Table 6) to these estimations, one can expect the ES-2 and ES-3 materials to be nearly pure UO2 materials with fairly low enrichment. ES-1 also appears to be predominately UO2, but the heterogeneity and the lower assay values indicate that the material either has other forms of uranium oxide or larger impurity concentrations.

Uncertainty of ≤ 0.2 percent [23] would normally be expected for titration of pure uranium oxide materials. Cezanne’s high uncertainties values (in Table 6) are attributable to the uncertainty of the titration itself. The Davies-Gray method is not certified and the laboratory had no reliable means for the uranium assay quality assurance. Factors such as the aging electrode in that it was used more often and not stored appropriately; no addition of potassium dichromate solution to pre-oxidize phosphoric acid delaying the reaction; uncertainty of burette of the titer; uncertainty of weighed masses; and inhomogeneous samples (also confirmed for ES-1 by other workers using other analytical techniques)—have all contributed to the uncertainties. There is very little difference in the replicates for ES-2 and ES-3 for Monet’s data, even though replicate analyses of both dissolutions were completed on two separate days. All Monet uranium content measurements in the two dissolutions averages plotted in Fig. 1 show a difference between the two dissolutions in ES-1 data where the error bars (uncertainty) do not overlap. Combined, these observations support the earlier suggestion that uranium concentration may not be homogenous throughout the ES-1 powder at the level sampled. The Buonarroti and Gauguin uranium assay measurements performed using isotope dilution technique are in good agreement with the Davies-Gray results.

Interpretations and discussions of trace elements analysis results

The mass spectrometer instruments were all calibrated for use according to manufacturer recommendations prior to sample analysis. Different laboratories used the instruments listed in Table 1 with or without modifications. Monet specifically indicated that their Thermo Scientific instrument is modified so that the vacuum chamber and quadrupole are interfaced with a glove box at the service panel. Further details as to the adaptations and related modifications are obtainable from the respective laboratories.

The instruments listed in Table 1 are similar in a number of respects. However, the detection limits, precision, and long-term stability are different and depend on the mass spectrometer design features. All contributing laboratories took measures to prevent common causes of sample contamination. The precaution taken during the dissolution of samples and the preparations of calibration standards ranged from handling the materials in dedicated clean areas, use of plastic labware as containers, use of high-purity certified reference standards, use of high-purity acids and high-purity water with 18.2 M cm resistivity. Sample container materials can introduce errors in measurement particularly at low or ultra-trace levels, by contributing contaminants through leaching or surface desorption, or by depleting concentrations through adsorption [9]. Good attention was given to the selection and cleaning of sample containers. The inclusion of the blank and check samples, processed the same way as the analyte samples, provided the data used to ascertain that results were generally free from contamination, memory effects, and common spectral interferences.

Clean laboratory practices were used by all the contributing laboratories. Preference is shown for Teflon, low-density polyethylene (LDPE) and polypropylene (PP) labware because these materials are inert to attack by corrosive acids. PP and Teflon vials used for dissolution were first cleaned using high-purity HNO3 acid followed by 18.2 M cm high-purity water and dried beforehand. The approach generally involved soaking the labware in nitric acid solution overnight followed by washing and rinsing with high-purity water. Preparation of analyte standard and blank solutions was performed following different procedures based on the analysis approaches chosen [14, 15]. Quality control samples such as blanks, replicates, spiked samples and certified reference material were included in the analyses as tools for validation and/or means of confirming the measurements. All laboratories used both a quality check (1 ng/g) and digested blank solution run (except Van Gogh and Gauguin) before and after each sample to control the calibration curve and the contamination of the instrument. Analyte measures were bracketed by blank sample or calibration verification standard measurements to monitor for memory effects.

Certified reference materials such as New Brunswick Laboratory CRM 112A, New Brunswick Laboratory CRM 124 series and CANMET Cup-2 (reference values only) were used for method validation and to check against accuracy of the laboratories results. The certified reference materials and detailed approaches differ. Cezanne used CUP-2 for inter-laboratory based method validation. Buonarroti used a spiked uranium sample with multi-elemental standard, which is from a different manufacturer than the calibration solutions. The measured values agree well with each other and also with the reference values. The CANMET Cup-2 analysis generally agreed with recommended values. Two other laboratories used spiking and check solutions and these confirmed that the methods employed are capable of delivering reliable results. Internal standards were used by all the laboratories to monitor and to help with the correction of instrument drift and physical interferences.

Dominant problems in ICP-MS-based trace element analysis are caused by matrix effect, instrument drift and interferences [24,25,26,27]. Spectral and non-spectral interferences are recognized [28]. Spectral interferences are caused by

-

The combination of two or more atomic ions to give same nominal mass–to-charge ratio as the isotope of interest normally formed in the plasma or the interface system from vector gases or constituents of the sample (polyatomic or molecular interferences).

-

Isotopes of different elements that form singly or doubly charged ions with the same normal mass-to-charge ratio (isobaric interferences).

Non-spectral, often called matrix effects, originate from three different processes or locations: the nebulization process, the plasma, or the zone of the interface and the lens. They also include clogging of the nebulizer, the injector tube of the torch and the cones (sampler and skimmer) due to high concentrations of dissolved salts. Participating laboratories used various combinations of methods to eliminate, suppress, or correct for known ICP-MS interferences and other problems. Vermeer and Monet used the chemical separation method based on the use of commercially available UTEVA resin to remove uranium matrix from trace elements prior to mass spectroscopic measurements of uranium-free analyte solution [17]. Monet uranium matrix removal was for ICP-OES only, and not for ICP-MS. Cezanne and Van Gogh used the availability of the reaction collision cell to suppress interferences.

Mathematical correction for interfering ions was used by Cezanne, Monet, and Gauguin to handle interferences from known troublesome isotopes [28, 29]. Some other isotopes that are free of interferences were also chosen for use in case of multi-isotopic elements. It is logical to imagine that the removal of the uranium matrix (allowing the analyst to introduce more impurities from the sample into the mass spectrometer) and/or the use of the more sensitive ICP-SFMS would produce lower detection limits and lower uncertainties. However, the reported results indicate that there are likely other contributing factors to the detection limits and uncertainties in this report. At first look it appeared as though the use of a reaction collision cell by Cezanne might be the other contributing factor to the reduced uncertainties in the impurity values that are generally lower than those reported by Monet for molybdenum (Table 7) and the same trace elements (Table 8). The latter suggestion is however unlikely because Gauguin and Buonarroti did not use the uranium matrix removal nor a reaction collision cell but the uncertainties are comparable to those by Vermeer and Cezanne. This is with the exception of Ba values where it has been confirmed that purple vial caps used to close the ICP-MS centrifuge tubes are well known sources of Ba [21]. Van Gogh reported higher Mo values with the highest uncertainty values in (Table 7) than the other laboratories, and it is apparent that no suitable internal standard and means of quality checks was used to aid the ICP-MS data manipulation to allow for an appropriate calibration fit.

The CMX-4 main goal of the impurity analysis was to evaluate the similarity of the three samples, ES-1, ES-2, and ES-3; and to determine if they may have same possible origin. The impurities of the three samples were analysed to extract their signatures. Low Mo concentration is an important characteristic of the materials used in one of the three facilities of interest, EA Fuel Products. The measured amounts of Mo in ES-1 and ES-3 compared favorably and suggested that the three could be from same or related feed material. Molybdenum in ES-2 is also not much different from that found in the other two samples. All of the six laboratories reported Mo concentrations below or slightly above 10 µg/gU within all of the exercise samples, which was consistent with manufacturer declarations, and suggested that the most likely facility of positive origin for all three samples was EA Fuel Products. The concentrations of most ICP-MS/OES-based impurities in ES-1, ES-2, and ES-3 were different in all the three samples. The powder sample had one or two elements at much higher concentration levels in relation to their concentrations in the two pellet samples. Two such elements were W and Co, where laboratories found their concentrations to be significantly higher in the powder (ES-1) sample. In this case, W and Co were likely introduced to ES-1 as contaminants when pulverizing the sample with a tungsten ball mill.

The concentrations of large, but different collections of elements in Tables 8 and 10 were determined on each of the three samples by the contributing laboratories. The different elements measured make it problematic to compare the results across all the different laboratory approaches. It is however noteworthy that the concentrations of Cd, Co, Cr, Ga, Mn, Th, V, and W measured by either four contributing laboratories or just three of them were comparable. The rest of the concentration values were significantly different for most elements and most laboratories. An interesting observation made here is that the reported data by Gauguin showed a much higher Mo in ES-2 compared to the other laboratories (in Table 7), but Mo/Cr ratio of 0.34 compares well with the values estimated from the Mo and Cr values reported by the other laboratories. This discrepancy in the absolute concentrations of these elements may represent sample inhomogeneity. With the only exception of W, Cu, and Al in ES-1 samples, measured concentrations in Table 8 are all well below 10 µg/gU. Tungsten concentrations in ES-1 samples are approximately 10 times higher than in the other two samples. Monet reported the results of impurities measured by the ICP-OES technique in Table 9. All the reported data averages in Table 9 are within 3 × of the method detectable level for all ten elements. For Monet results in Table 9 the ES-1 powder sample, sub-sample 1 and sub-sample 2 measurements did not show agreement for Cu and W. Cu and W appeared in the second sub-sample at much higher concentration than that in the first sub-sample: 21.50 ± 1.50 versus 2.20 ± 0.30 for Cu, and 21.10 ± 1.30 versus 5.70 ± 1.00 for W. The same disagreement was also verified by the ICP-OES measurement. This may be taken to support the Davies-Gray suggestion that the ES-1 sample may not be homogenous.

The concentration of the rare earth elements in the three samples are reported by four laboratories in Table 10. Variations in these values are most likely attributed to the detection limits of the different instrumentation. The PQ-2 is not as modern as the iCAP-Q, and the Element XR by design has a greater signal/noise ratio than quadrupole ICP-MS. Normalization and representing the values relative to a standard reference material of known composition has been suggested in the literature [30, 31], but is not considered an option here because participating laboratories were given only Mo as the significant signature. Also, there is a lack of certified reference materials for trace element analysis that meet the current scope of demands in terms of elemental composition and uncertainty. The overall very low levels of impurities measured supports the assumption that the variability from Davies-Gray is most likely due to form and not trace elements present in the CMX-4 samples.

Conclusions

It is evident that analyzing laboratories should reduce the uncertainties on their Davies-Gray method or risk missing important information about the uranium oxidation phases. Also, further analyses by other methods would be required to ascertain the UO2 phase for ES-2 and ES-3, and also help distinguish which (of the UO2, UO3, U3O8, and U3O7) is the predominate compound for the ES-1 black powder.

Higher confidence can be obtained from the ICP-MS/OES technique if few aspects of the technique were to be standardized. This includes quality assurance using validated methods, certified reference materials, and uncertainty calculations. Low uncertainty associated with uranium removal prior to analysis, or the use of a reaction collision cell suggests the two as better approaches for the ICP-MS impurity analysis. Further studies are needed to confirm this view, to look at the homogeneity of the CMX-4 samples, and to look at the acceptability of existing certified reference materials such as CRM 124 (with certified uncertainties and others for ICP-MS trace elements analysis method verification in nuclear forensics [32, 33]. The CANMET Cup-2 standards may not be very useful when used to represent materials with low impurities or to test the lower detection limits of modern ICP-MS methods [34, 35]. CUP-2 is not certified for trace elements, it is reference values only with no reported uncertainties and it is thus important to obtain consensus values. There is also a need for new reference materials for trace element analysis in nuclear forensics, that meet the current demands on composition and uncertainty. Another possibility to ensure measurement quality is to arrange and participate in inter-comparison exercises for trace element analysis.

An obvious advantage was that data were available, from Buonarroti and Gauguin to compare the results obtained using the Davies-Gray uranium assay method with the determination of uranium assay made using the additional techniques of isotope dilution TIMS and isotope dilution MC-ICP-MS. The uranium assay results obtained using the two isotope dilution techniques were in good agreement with the Davies-Gray results, except for the noted discrepancies which were accounted for in terms of the compromised experimental conditions. Both the Mo analysis and the uranium assay results are indicative of similar origin for the ES-2 and ES-3 pellets. The ES-1 black powder sample also shows much in common with the two pellet samples. The values obtained for Mo were well below 10 µg/gU for most laboratories, which suggested that the ES-1, ES-2, and ES-3 samples may have originated from the same EA Fuel Products facility. The trace elements concentrations reported were not entirely consistent across all laboratories, however the results among a few laboratories were in good agreement for analytes above detection. Overall, these were challenging analyses with the presence of analytes of interest at very low concentrations that were close to detection limits of the ICP-MS instruments employed, potential inhomogeneity in the exercise samples (confirmed for ES-1 powder using other techniques), inconsistency in the measurement procedures, and experimental errors/conditions. Methods validations that include certified reference materials should improve the accuracy of the measurements. Another possibility to ensure measurement quality is to arrange and participate in inter-comparison exercises for trace element analysis. Efforts to standardize the analytical techniques, including a closer look at detection limits, process blanks, replicates, and uncertainty calculations should provide more confidence in identifying signatures in uranium materials.

References

Schwantes JM, Marsden O, Pellegrini KL (2017) State of practice and emerging application of analytical techniques of nuclear forensic analysis: highlights from the 4th collaborative materials exercise of the nuclear forensics International technical working group (ITWG). J Radioanal Nucl Chem 311(2):1441–1452. https://doi.org/10.1007/s10967-016-5037-5

Davies W, Gray W (1964) A rapid and specific titrimetric method for the precise determination of uranium using iron(II) sulphate as reductant. Talanta 11(1964):1203–1211. https://doi.org/10.1016/0039-9140(64)80171-5

Bickel M (1997) The Davies-Gray titration for the assay of uranium in nuclear materials: a performance study. J Nucl Mater 246(1):30–36. https://doi.org/10.1016/S0022-3115(97)00040-8

Mathew KJ, Bürger S, Vogt S, Mason P, Morales-Arteaga ME, Narayanan UI (2009) Uranium assay determination using Davies and Gray titration: an overview and implementation of GUM for uncertainty evaluation. J Radioanal Nucl Chem 282:939–944

ASTM International (2017) Standard Test Method for Uranium by Iron (II) Reduction in Phosphoric Acid Followed by Chromium (VI) Titration in the Presence of Vanadium, ASTM C1267-06. https://www.astm.org/DATABASE.CART/HISTORICAL/C1267-06.htm

ISO (2017) ISO 7097-2:2004(en) Nuclear fuel technology—Determination of uranium in solutions, uranium hexafluoride and solids—Part 2: Iron(II) reduction/cerium(IV) oxidation titrimetric method—First Edition. https://www.iso.org/obp/ui/#iso:std:iso:7097:-2:ed-1:v1:en

Zebrowski JP, Orlowicz GJ, Johnson KD, Smith MM, Soriano MD (1995) Evaluation on the Use of Cerium in the NBL Titrimetric method, NBL-332. New Brunswick Laboratory, Argonne

Slanina J, Bakker F, Groen AJP, Lingerak WA, Fresenius Z (1978) Accurate and precise determination of 2–25 mg amounts of uranium by means of a special automatic potentiometric titration. Anal Chem 289(2):102–105. https://doi.org/10.1007/BF00443954

Moody JK, Grant PM, Hutcheon ID (2015) Nuclear Forensics Analysis, 2nd edn. CRC Press, Boca Raton

Jenner GA, Longerich HP, Jackson SE, Fryer BJ (1990) ICP-MS—A powerful tool for high-precision trace-element analysis in Earth sciences: evidence from analysis of selected U.S.G.S. reference samples. Chem Geol 83(1–2):133–148

Mayer K, Wallenius M, Ray I (2005) Isotopic analysis: fundamentals and applications using ICP-MS. Analyst 130:433–441

Brown RJC, Milton MJT (2005) Analytical techniques for trace element analysis: an overview. TrAC Trends Anal Chem 24(3):266–274

Krachler M, Alvarez-Sarandes R, Van Winckel S (2015) Challenges in the quality assurance of elemental and isotopic analyses in the nuclear domain benefitting from high resolution ICP-OES and sector field ICP-MS. J Radioanal Nucl Chem 304(3):1201–1209

Oliviera OP Jr, Sarkis JES (2002) Determination of impurities in uranium oxide by inductively coupled plasma mass spectrometry (ICPMS) by the matrix matching method. J Radioanal Nucl Chem 254(3):515–526

Golik VM, Golik SV, Trepachev SA, Kuz’mina NV (2010) Determination of B, Si, P, S, Cl, and Br in uranium materials by inductively coupled plasma mass spectrometry. J Anal Chem 65(14):1511–1516

IAEA (2006) Nuclear Forensics Support, IAEA Nuclear Security Series No. 2. International Atomic Energy Agency, Vienna, Austria

Nygren U, Ramebäck H, Nilsson C (2007) Age determination of plutonium using inductively coupled plasma mass spectrometry. J Radioanal Nucl Chem 272(1):45–51

Vanhaecke F, Balcaen L, Taylor P (2007) In: Hill SJ (ed) Inductively coupled Plasma spectrometry and Its applications, 2nd edn. Wiley, Hoboken, New Jersey

Smith DH (2000) In: Barshick CM, Duckworth DC, Smith DH (eds) Inorganic mass spectrometry: fundamentals and applications. Marcel Dekker Inc., New York

ISO/IEC (2008) Uncertainty of Measurement – Part 3: Guide to the Expression of Uncertainty in Measurement (GUM:1995), ISO/IEC Guide 98-3:2008 https://www.iso.org/standard/50461.html

Nelwamondo AN (2015) The fourth collaborative materials exercise (CMX-4) Data Review Meeting of the International Technical Working Group (ITWG) in Nuclear Forensics, 17–19 March (2015), Institute for Transuranium Elements (ITU), Joint Research Centre (JRC). Karlsruhe, Germany

Bürger S, Boulyga SF, Pénkin MV, Bostick D, Jovanovic S, Lindvall R, Rasmussen G, Riciputi L (2014) Quantifying multiple trace elements in uranium ore concentrates: an interlaboratory comparison. J Radioanal Nucl Chem 301:711–729

IAEA (2010) International target values 2010 for measurement uncertainties in safeguarding nuclear materials, STR-368. International Atomic Energy Agency, Vienna

Gueguen F, Nonell A, Granet M, Favre G, Isnard H, Chartier F (2010) Eu isotopic measurements with in situ Eu/Gd/Sm separation using O2 as a reactant gas in collision/reaction cell based MC-ICP-MS. J Anal At Spectrom 25:201–205

Varga Z, Wallenius M, Mayer K (2010) Origin assessment of uranium ore concentrates based on their rare-earth elemental impurity pattern. Radiochim Acta 98:771–778

Ammann AA (2007) Inductively coupled plasma mass spectrometry (ICP MS): a versatile tool. J Mass Spectrom 42(4):419–427

Heumann KG, Gallus SM, Rädlinger G, Vogl J (1998) Precision and accuracy in isotope ratio measurements by plasma source mass spectrometry. J Anal At Spectrom 13:1001–1008

Bürger S, Riciputi LR, Bostick DA (2007) Determination of impurities in uranium matrices by time-of-flight ICP-MS using matrix-matched method. J Radioanal Nucl Chem 274(3):491–505

Zimmer E, Mertz E (1984) Dissolution of thorium-uranium mixed oxides in concentrated nitric acid. J Nucl Mater 124:64–67

Mercadier J, Cuney M, Lach P, Boiron M-C, Bonhoure J, Richard A, Leisen M, Kister P (2011) Origin of uranium deposits revealed by their rare earth element signature. Terra Nova 23(4):264–269

Mayer K, Wallenius M, Varga Z (2013) Nuclear forensic science: correlating measurable material parameters to the history of nuclear material. Chem Rev 113(2):884–900

Leggitt J, Inn K, Goldberg S, Essex R, LaMont S, Chase S (2009) Nuclear forensics—metrological basis for legal defensibility. J Radioanal Nucl Chem 282:997–1001

Inn KGW, Johnson CM Jr, Oldham W, Jerome S, Tandon L, Schaaf T, Jones R, Mackney D, MacKill P, Palmer B, Smith D, LaMont S, Griggs J (2013) The urgent requirement for new radioanalytical certified reference materials for nuclear safeguards, forensics, and consequence management. J Radioanal Nucl Chem 296(1):5–22

Bürger S, Mathew KJ, Mason P, Narayanan U (2009) Reference materials characterized for impurities in uranium matrices: an overview and re-evaluation of the NBL CRM 124 series. J Radioanl Nucl Chem 279:659–673

New Brunswick Laboratory (2008) Certificate of analysis CRM No 124. New Brunswick Laboratory, Argonne

Acknowledgements

The South Africa Nuclear Energy Corporation gratefully acknowledges the U.S. Department of Energy national laboratories for hands-on training in general aspects of nuclear forensics and the advanced training in the ICP-MS trace elements analysis for nuclear forensics purposes. Lawrence Livermore National Laboratory contributions were performed under the auspices of the U.S. Department of Energy under Contract DE-AC52-07NA27344.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nelwamondo, A.N., Colletti, L.P., Lindvall, R.E. et al. Uranium assay and trace element analysis of the fourth collaborative material exercise samples by the modified Davies-Gray method and the ICP-MS/OES techniques. J Radioanal Nucl Chem 315, 379–394 (2018). https://doi.org/10.1007/s10967-018-5708-5

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10967-018-5708-5