Abstract

A multi-agency workshop was held from 25 to 27 August 2009, at the National Institute of Standards and Technology (NIST), to identify and prioritize the development of radioanalytical Certified Reference Materials (CRMs, generally provided by National Metrology Institutes; Standard Reference Materials, a CRM issued by NIST) for field and laboratory nuclear measurement methods to be used to assess the consequences of a domestic or international nuclear event. Without these CRMs, policy makers concerned with detecting proliferation and trafficking of nuclear materials, attribution and retribution following a nuclear event, and public health consequences of a nuclear event would have difficulty making decisions based on analytical data that would stand up to scientific, public, and judicial scrutiny. The workshop concentrated on three areas: post-incident Improvised Nuclear Device (IND) nuclear forensics, safeguard materials characterization, and consequence management for an IND or a Radiological Dispersion Device detonation scenario. The workshop identified specific CRM requirements to fulfill the needs for these three measurement communities. Of highest priority are: (1) isotope dilution mass spectrometry standards, specifically 233U, 236gNp, 244Pu, and 243Am, used for quantitative analysis of the respective elements that are in critically short supply and in urgent need of replenishment and certification; (2) CRMs that are urgently needed for post-detonation debris analysis of actinides and fission fragments, and (3) CRMs used for destructive and nondestructive analyses for safeguards measurements, and radioisotopes of interest in environmental matrices.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Preamble

In preparing the report of this workshop, it is instructive to consider the baseline for any terrorist event. The magnitude of the social, economic and political impact are such that inaction cannot be considered and it is thus self-evident that it is essential, and urgently so, that action must be taken to counter any terrorist threat. This set the baseline for the workshop.

Furthermore, we consider where any CRMs that may be produced are of use. This was most forcefully stated that matters prior, as well as subsequent to a terrorist event must be considered. The workshop, therefore, took these two basic assumptions as the basis for all subsequent discussion:

-

Inaction is not an option, and

-

Any CRMs produced must address pre- and post-event scenarios.

Introduction

One of the pre-eminent threats to the United States is a domestic nuclear explosive event. Nuclear safeguards measures exist in order to protect nuclear material and prevent the illicit construction or transport of a nuclear explosive device. These safeguards measures are a key part of a global nuclear non-proliferation security strategy designed to prevent proliferation and thwart the spread of weapons (international partnering on illicit trafficking and threat reduction by finding diverted materials, reaction conversions and undisclosed enrichment activities).

A mistake in calibration could have severe consequences if the instrument is involved in the defense against the asymmetric threat of nuclear terrorism. Furthermore, the recent nuclear weapon programs in the Democratic People’s Republic of Korea and the Islamic Republic of Iran are situations that need high measurement scrutiny supported by a variety of different but compatible certified reference materials and quality systems that assure undeniable certainty and confidence. There are a number of analytical measurement programs within the U.S. Government and abroad to safeguard nuclear material, detect the unauthorized production or trafficking of nuclear material, and in the catastrophic event of a terrorist nuclear attack, collect and analyze debris to aid in forensically assessing the source of the attack and ensure the extent of contamination is known and affected persons are properly identified and treated. The assessment of such events would require the highest quality measurement scrutiny supported by a variety of CRMs and quality systems to assure undeniable certainty and confidence given the potentially dire consequences associated with an incorrect result. Certified reference materials provide the foundation for accurate and precise measurements which provide credible data—i.e., they are a critical component in any measurement quality assurance (QA) program, and necessary for developing, testing, and validating nuclear and radioanalytical methods and quantifying radionuclides. A robust supply of CRMs is needed to ensure the quality of analyses performed for nuclear safeguards, forensics, and consequence management activities. Without these CRMs for accurate measurements, policy makers concerned with detecting proliferation and trafficking of nuclear materials, and attribution, retribution, protection of public health and environmental remediation following a nuclear event would have difficulty making informed and responsible decisions based on analytical data that would stand up to scientific, public, and judicial scrutiny.

Currently there is a critical shortage of a number of CRMs required for accurate, precise measurements in the areas of nuclear safeguards, nuclear forensics, and consequence management. In greatest shortage are isotope dilution mass spectroscopy (IDMS) tracer standards and representative radioactive matrices. Uranium-233, 236gNp, 244Pu, and 243Am are the most important IDMS tracers needed. Simulated nuclear debris, particle standards, and actinide and fission product doped environmental matrices are also in critical need due to their non-existence at other than environmental levels.

A concerted government effort is needed to provide an integrated priority list and to ensure adequate funding and resources are made available to the organizations capable of producing CRMs. A scarcity of these CRMs will severely hamper the ability of the U.S. Government to perform accurate, timely, and forensically defensible nuclear and radiochemical analyses of safeguard samples, domestic nuclear event debris, or consequence management assessments. Any significant delays in or reduced ability to perform accurate and defensible radioanalytical measurements could have catastrophic consequences for the nation for a variety of possible incident scenarios. Therefore, the timely availability of these CRMs is a matter of national significance.

A multi-agency workshop was held from 25 to 27 August 2009, at the National Institute of Standards and Technology (NIST), to identify and prioritize the development of CRMs for field and laboratory nuclear-analytical measurement methods to be used to assess the consequences of a domestic or international nuclear event. The workshop concentrated on three areas and identified specific CRM requirements to fulfill these needs:

-

(a)

Post-incident (Improvised Nuclear Device; IND) nuclear forensics;

-

(b)

Safeguard materials characterization; and

-

(c)

Consequence management for an IND or a Radiological Dispersion Device detonation scenario.

Separate breakout sessions for each of the three topics were charged with determining the following requirements for CRMs:

-

Analytes—radionuclides, trace and stable elements, and isotopes

-

Concentrations/uncertainties

-

Matrices

-

Heterogeneity (criteria and evaluation)

-

Sample size

-

Sample preservation and stability

-

Number of units/years of supply

-

Speciation

-

Other proficiency test (PT) issues—number of PTs/year, number of samples/PT, PT grading schemes.

This paper details the discussions held within each breakout group and includes the participant’s consensus on CRM needs in these areas. The workshop identified specific CRM requirements to fulfill these needs.

Post-incident (Improvised Nuclear Device [IND]) nuclear forensics

Legal defensibility

One of complexities of a nuclear forensics study after a nuclear detonation is that collection and analysis of debris is treated as evidence. As such, forensic nuclear-radioanalysis needs to meet “Daubert standard” [1, 2] to provide legally defensibility criteria. The “Daubert standard” asks the following of any technique used to analyze evidence:

-

(1)

Is the underlying reasoning or methodology scientifically valid and properly applied to the facts at issue?

-

(2)

Has the theory or technique been tested?

-

(3)

Has the theory or technique been subjected to peer review and publication?

-

(4)

What is the known or potential rate of error for the theory or technique?

-

(5)

What is the existence and maintenance of standards controlling its operation?

-

(6)

Has it attracted widespread acceptance within a relevant scientific community?

To demonstrate the underlying soundness of a methodology, appropriate reference materials are required to provide an accounting of the measurement accuracy and uncertainty. The post-incident (IND) nuclear forensics breakout discussion clarified and crystallized the needed required reference materials and their prioritization.

The workshop identified specific CRM requirements to fulfill these needs. Isotope dilution mass spectrometry standards, specifically 233U, 236gNp, 244Pu, and 243Am, used for quantitative analysis of the respective elements, are in critically short supply and in urgent need of replenishment and certification. CRMs that are urgently needed for post-detonation debris analysis of actinides and fission fragments, destructive and nondestructive analyses for safeguard measurements, and radioisotopes of interest in environmental matrices were also identified and prioritized.

Initial discussion

Presentations on potential ways to obtain or make surrogate debris were made by Warren Oldham and Simon Jerome (see “Appendix 2” for a list of participants). Based on these presentations, the various requirements were identified, and are summarized thus:

CRM matrices needed |

|---|

(1) Nuclear explosion debris sample—actinides, long-lived fission products, long lived activation products with various soil types/matrix matching |

(2) Simulated fresh nuclear explosion debris—various neutron sources |

(3) Glass doped with various fuels and mixtures of fuels—tailored refractory or synthetic rock |

(4) Isotope dilution standards and tracers |

(5) Calibration standards |

(6) Particles |

Details were developed on each of these matrices to meet forensic analysis needs, and are discussed below.

Aged nuclear explosion debris

Currently, nuclear explosion debris exists on the Nevada Test Site (NTS). Because the age of debris available for collection is at least 45 years old, there is an implied lower limit of half-lives to be 7–10 years and activity levels for nuclides available in this material. “Appendix 1” provides additional information on an aged nuclear explosion debris collection that can provide insight into how this material might be useful as a reference standard. The use of this material is summarized as follows:

Aged nuclear explosion debris sample | |

|---|---|

(1) | Multi-event material, blended and homogenized |

(i) Pu isotopes, U isotopes, Neptunium, Americium, total Pu, total U | |

(ii) 238Pu, 239+240Pu, 242Cm, 241Am | |

(iii) Radio-strontium, radio-Cs, 147Pm, 151Sm, 155Eu | |

(2) | Single-event material, collected “as is” for use in exercises |

(i) Not homogenised, or | |

(ii) Homogenous to 1 g | |

(3) | Classified PT |

(i) End-to-end analysis | |

(ii) Internally homogenized to 1 g | |

100 kg based on available material; Sampled from the Nevada Test Site (NTS); 1,000 units | |

Multi-event material

It is possible to make reference materials from existing debris that can be prepared from multiple surface or near-surface events. Such material can be homogenized and prepared as a material that establishes baseline performance. This CRM can be unrestricted in that the information available from a multi-site homogenized material does not provide specific information about any one event.

This material should contain Pu, U, Np and Am isotopes in quantities such that mass spectrometry can be carried out. Furthermore, it should also be suitable for carrying out α-spectrometry measurements of 238Pu, 239+240Pu, 241Am, and 242Cm, and so the element composition of the material should approach the μg/g level for Pu, U, Np, and Am.

The expected fission products are 90Sr, 137Cs, 147Pm, 151Sm, and 155Eu (with 90Sr, 137Cs being of limited value).

Single-event material

It is possible to make reference materials from existing debris that can be prepared from only a single event. The content of the material, however, may be classified and a resulting CRM may be of limited availability. This can be collected in the same way as the multi-event material but may not be homogenized and provided as (for example) ~1 g pieces. This material allows performance to be tested as from a real event to be tested. Some existing events suitable for such an application were identified in closed discussion.

General comments

In each case, 1,000 units at 100 g each were suggested as a suitable batch and sample size.

Some discussion was had about the legal status of such materials if used for other purposes. If the material meets the “Daubert standard,” [1, 2] then its use can support legally defensible activities and may be used for prosecution; if not, it could still support intelligence gathering activities.

Fresh nuclear explosion debris—doped glass

The production of a matrix containing fresh fission products centered on glass doped with fuels and mixtures of fuels. Much of the discussion focused on the importance and usefulness of this material.

Fresh nuclear explosion debris sample |

|---|

Mixture of ~93 % 235U (with some 236U) and weapons grade 239Pu |

(i) Need samples that provide 1014 fissions after irradiation |

(ii) Urban content of other elements |

The concept of doped glass is similar to the use of Thermal Cals, irradiated enriched U, for comparison exercised between labs but with added matrix complexity in the form of “urban debris,” i.e., steel, sand, or other materials potentially present at ground zero. There are good reasons for and against this concept, and are briefly summarized as:

- Against:

-

The capability to dissolve exploded debris is tested by the old nuclear explosion debris described above. Any synthetic material is unlikely to mimic what may actually be encountered

- For:

-

The dissolution and separation of fresh fission products is not demonstrated by the old nuclear explosion debris described above. Any synthetic material may be radioactively similar to what may actually be encountered and can include “urban impurities” to increase matrix complexity

It was eventually decided that doped glass had merit and debate turned to the practicalities of realizing this material. The fissile material content should be tailored to yield ~1014 fissions in a 1-g sample after suitable irradiation. This was expected to require 1–100 mg/g of fissile material.

The nature of the fissile material was also discussed and the suggested material is 10:1 Oralloy: Weapons grade Pu—nominally 93 % 235U and 239Pu containing <7 % 240Pu.

Finally the glass needs to contain “urban material,” such as Fe and Ca from construction material, which would be straightforward to include—stainless steel can be incorporated as individual elements, if the steel type is specified.

Requirements for fresh nuclear debris samples |

|---|

(1) Analytes—U and Pu isotopes, U and Pu concentration, Major trace elements (metals) |

(2) Concentration—10:1 U:Pu, yielding 1014 fissions; at high flux most representative 1014 fissions after irradiation is ~10 mg 235U/1 g sample (need to specify flux or concentration desired to yield 1014 fissions) |

(3) Matrices—glass (normal impurities) plus urban content (specify—to be decided) |

(4) Homogeneity—at the 1 g level to analyte concentrations |

(5) Sample size/number of samples—To be determined |

(6) Content—93 % 235U with 236U, plus weapon grade 239Pu |

(7) Purpose |

(i) Fresh fission product identification in the presence of urban impurities |

(ii) Realistic test to study dissolution (Ca/Ti/Stainless steel) |

(iii) Study selected activation products (59Fe, 60Co) |

Isotope dilution standards

Prepared individual liquid isotope dilution standards are required for the quantitative measurement of radionuclides and their isotope ratios (and, indeed, other analytes) by mass spectrometry. It was noted that these materials were in short to nonexistent supply for many of the radionuclides. This was not discussed in detail, as this issue was addressed in a 2006 NIST workshop, and the results published in 2008 [3]. Additionally, there is overlap with the standards identified in the Safeguards working group.

Requirements for isotope dilution standards |

|---|

(1) Purpose—Mass spectrometry tracers, activity tracers, neutron deficient lanthanide tracers (to study lanthanide separations) |

(2) Analytes—148Eu, 149Eu, 233U (99.97 %), 236gNp, 244Pu (99.9 %) and 243Am (high purity) |

(3) Concentration—Driven by isotope (solution) and intended use/matrix |

(4) Sample size/number of samples—5 g solution per unit with 1–10 ng per analysis for mass spectrometry (activity concentration to be decided) |

(5) Sample preservation/stability—As long as possible |

(6) Number of units/years of supply— ~10–15 of 5 g liquid samples per year with a 10–20 year supply (subject to stability issues). |

Calibration standards

Generally there is a reasonable supply of radionuclide standards covering a wide range of radionuclides. However, it is critical that the supply continue to be readily available for the medium to long-term future. Similarly to the isotope dilution standards, this was not discussed in greater detail because this issue was addressed in the 2006 NIST workshop, and the results published in 2008 [3].

Requirements for calibration standards |

|---|

(1) Purpose—Detector calibration with low (~1 %) uncertainty; carry out peak deconvolution in gamma-ray spectrometry; enable software validation |

(2) Analytes—2–3 analyte mixture with close line spacing |

(3) Other notes—LANL have all standards readily available internally, but need to ensure continued supply in future. |

(4) Wish list—Geometry: 20 cm3 liquid scintillation vial with up to 5 g solution plus others; mixed γ radionuclide standard with 1 % uncertainty at (k = 2) but 1–3 % may be acceptable; specifically QCY-88 or 88Y (or similar) with 85Sr, 210Pb and 241Am, but at <3 % uncertainty (k = 2) |

Particle standards

It was acknowledged that there will be challenges to develop reference particle standards due to the individuality and general difficulty in preparing such standards. CRMs for particles studies are typically size-distribution element-quantification standards. For nuclear forensic applications the type of particle characterization questions being looked at are properties such as grain size, morphology, speciation, size distribution and elemental concentration to provide information on the overall characteristics of the weapon device. The participants in the session recognized that further effort is needed to definitely define what type of CRMs is needed to validate these studies.

Requirements for particle standards |

|---|

(1) Purpose—quantitative radiography determination; method validation; calibrate EDS/WDS/SEM/other methods (SIMS, etc.); aid in elemental and isotopic concentrations and determinations |

(2) Analytes—McGuire Air Force Base BOMARC plutonium accident particles; to be decided by professional group based on their applications |

(3) Concentration—U, Pu and fission products on particles representative of debris |

(4) Other notes—Existing materials may include fused clay beads with actinides for treaty verification, particle size standards, SIMS actinides—but Radiological Dispersal Device (RDD) type material is missing, e.g., 7Be (air filter), 60Co, 137Cs at <1 μm in size (although these may be useful for IND issues. |

Conclusion

After further extensive discussion, the following priority list (in order, highest priority first) was identified. Priority determined by most important technical need, but also tempered with the reality (cost, technical hurdles, etc.) of making the sample. In some cases, the infrastructure and cost limitations reduced the most technically needed isotopes to a lower priority: Old Nuclear Explosion Debris (multi-site)

-

Relatively easy, as the material exists

-

Most benefit for the lowest cost

-

Addresses current shortfalls in process validation

-

Lacks short term fission products

Old Nuclear Explosion Debris (single site)

-

As for multi-site

-

Address variability in single event

-

Can be collected at the same time as the multi-site material

-

Savings on collection costs available if collected in concert with the multi-site material; processing of the material could be done at a later date

-

Lacks short term fission products

-

Addresses current shortfalls in process validation

Simulated fresh nuclear explosion debris

-

Achievable in the short term

-

Requires some research and development to get the most representative sample

-

Existing mass spectrometry isotope dilution standards

-

Need to be of suitable purity

-

Certified conversion from activity concentrations to mass concentrations required in some cases; conversion is complex and time consuming

-

Possible inventory available from the UK

-

Existing mass spectrometry isotope dilution standards

-

Need to be of suitable purity

-

Certified conversion from activity concentrations to mass concentrations required in some cases; conversion is complex and time consuming

-

Possible inventory available from the UK

-

Mass spectrometry isotope dilution standards that require production

-

Need to define production route (several options available)

-

U.S. production infrastructure insufficient or non-existent in some cases

-

Critical isotopes with very limited availability are 236gNp and 244Pu

-

May be achievable in short term, but will compromise on uncertainty and purity if this is done in the short term

Calibration standards

-

Particles

-

Not enough information to priorities effectively

-

Need expert input

-

Can be collected at the same time as the multi-site material)

-

As for multi-site

-

Address variability in single event

-

Weapons test debris proficiency test

-

Informs end-to-end analysis capabilities

-

Priority is exercise dependent

-

We conclude further work and discussion is needed.

Safeguard materials characterization

Nuclear safeguards

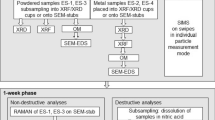

Representatives from the U.S. Department of Energy (DOE) national laboratories, Atomic Weapons Establishment (UK), National Institute of Standards and Technology (NIST), Federal Bureau of Investigation (FBI), and Department of Defense (DOD) attended the “Reference Materials for Safeguards Activities” breakout session. The emphasis on this year’s meeting was international analytical or measurement standards such as reference materials (RMs) needing both destructive and non-destructive analytical analysis (NDA) for bulk nuclear accountancy measurements. Analytical chemistry standard needs associated with key measurements related to environmental safeguards and monitoring, attribution and nonproliferation were also considered. An excellent document on International Target Values (ITV) 2000 for Measurement Uncertainties in Safeguarding Nuclear Materials (Ainger et al. [4]) and the references contained therein, developed by an international committee of experts for uncertainties judging the reliability of analytical techniques applied to fissile materials served as a basis for many of the discussions. Emphasis in discussion leading to recommendation for possible standards took into account commonly safeguarded material types, material form, enrichment levels, burn up and concentration ranges for major and minor analytes. While many of the same international standards of measurement such as CRMs identified in the prior Workshop were reiterated, increased interest in field inspection or screening, forensic (i.e., legal defensibility) analyses and attribution of interdicted special nuclear materials provided the primary, underlying theme.

Currently, available international standards including CRMs produced by national or international standards laboratories serve as the critical quality control materials to achieve traceability, measurement validation, instrument calibration and credible performance evaluation programs. In general, two significant deficiencies identified are more far-reaching than the need for new CRMs: (i) the reevaluation of existing CRMs with more accurate, sensitive, and state-of-the-art (modern) instrumentation; and (ii) the need for intercomparison studies to qualify analytical results [5]. Additionally, uncertainty treatment based on latest ISO [6, 7] guidance document was also recognized as key step in the right direction. It is clear that the production of new CRMs, recertification of CRMs and the qualification of analytical results associated with CRMs will require a concerted effort across the scientific community and those government entities which support scientific progress in analytical measurements. Existing suppliers of special nuclear material reference materials (New Brunswick Laboratory [NBL], European Union [EU] Institute for Reference Materials and Measurement [IRMM] and Commission d’Établissement des Méthodes d’Analyse du CEA [CETMA]), and single isotope supplier such as NIST and commercial vendor catalogs, were examined.

Nondestructive analyses

It was recognized that NDA techniques applied to safeguards accountancy verification measurements as identified in Aigner et al. [4], rely on producing homogeneous, well characterized materials in appropriate geometries which are analyzed internally by on-site DA methods. Analytical NDA techniques applied to nuclear materials are defined by ASTM [8–18] and ANSI standards that include calorimetry, gamma-ray spectrometry, neutron coincidence counting, and passive and active neutron counting. Because of the variation in applications from site to site and current shipping issues, internationally recognized CRMs are difficult to obtain, and performance evaluation studies are hard to perform. Often times, it is hard to establish traceability to internationally recognized certifying agencies because they do not offer the required standards. For example, only three sets of CRMs are available from New Brunswick Laboratory (NBL) for the NDA of contained U materials by gamma spectroscopy (0.2–4.5 % 235U) and neutron counting (20–93 % 235U). Similarly, the European Union (EU) Institute for Reference Materials and Measurement (IRMM) provides a 0.2–4.5 % 235U gamma spectroscopy reference kit. In general these kits consist of uranium oxide (nominally 200 g) contained in a well-defined geometry can, with separate cans for each isotopic assay.

Technology improvements such as the use of smaller portable instrument such as state-of-the-art electrically-cooled high-purity germanium detectors that require, at a minimum, to be able to accurately measure: (i) binary, i.e., yes/no for radioactive constituent; (ii) identity of radioactive constituent; and (iii) isotopic characteristics of radioactive constituent. In addition, to be able to quantitatively estimate the amount of contained Special Nuclear Material (SNM) requires the development and testing using international standards. While radioactive materials can be produced and packaged with specific attenuators and geometries, one of the most difficult tasks in NDA is modeling these properties under non ideal absorption and attenuation conditions. These capabilities are required for quantitative estimation of total nuclear material content and correct isotopic to meet the safeguard verification requirements. Two specific needs were identified for this daunting task: (i) a set of well-characterized, homogeneous standards with different burn ups and enrichment of Pu and U, and of appropriate sample size and geometry attenuation for both calibration and method validation purposes, and a set of appropriate shielding attenuators (of low to high Z, thickness, and density) will provide ideal standards; and (ii) laboratories or sites for testing new or emerging technologies on actual SNM-quantity materials in typical and atypical settings.

Microbeam analyses

While highly-specialized microbeam expertise is represented by a small group of scientists, the implications of these measurements hold high priority in the international and U.S.-domestic environmental nuclear safeguards attribution and nonproliferation communities. The capabilities of modern secondary electron microscopy (SEM) and secondary ion mass spectrometry (SIMS) suffer from lack of matrix matched international standards. Technology advances have quickly outpaced available nuclear CRMs. With the increase in both resolution and detection limits, it has become evident in recent years that there are no existing standards containing nuclear materials, additionally non fissile standards are heterogeneous (with respect to structure, shape, particle size, impurities, isotopic, etc.) than previously assumed. One specific aspiration in the particle analysis community is the achievement of scalable results—i.e., the analysis of an individual particle (or small group of particles) is representative of the native bulk material. This aspiration is difficult to achieve using existing oxide nuclear CRMs because they were typically prepared gravimetrically by adding impurities artificially through blending processes. Therefore, this preparation method is of little use when generating materials certified for trace elements.

For the microbeam analysis community, three areas of concern were identified for micrometer-scale particles: (i) uniform particle size/structure, (ii) uniform isotopic ratios across all particles and (iii) uniform elemental composition. Encompassing all aspects presents a significant challenge to the preparation of a reference material. Particle size, crystal structure, and isotopic ratios typically represent scalable properties down to the micrometer scale. Typically, these properties can be uniform in a particle-based reference material if produced by simple division of a bulk material (e.g., grinding of a high-purity oxide, followed by careful “sifting” techniques). However, scalability begins to breakdown at the micrometer-scale for the distribution of impurities. This becomes evident if we perform a simple approximation of the number of atoms in micrometer-scale (diameter) U-based particles using the bulk density of U3O8, the bulk molecular weight, the volume conversion, and Avogadro’s Constant:

By applying a simple approximation of a 1 micrometer (diameter) spherical particle, the number of atoms would correspond to ~1 × 1010 atoms. Because the concentration of many elemental impurities in highly-purified U-based stocks is typically in the ppm range (especially in oxides), micrometer-scale uniformity presents a significant statistical issue. However, because the number of atoms scales cubically (with respect to the particle diameter) the trace impurity uniformity issue may be overcome relatively quickly at particle sizes above ~10 μm (~1 × 1013 atoms). However, if an impurity is added directly to the starting material, i.e., a molten metal during casting and it is properly homogenized while still liquid and cooled at a controlled rate the distribution of impurity and grain structure can be controlled. This metal can then be oxidized under controlled condition and will serve as ideal standard. At the Institute for Transuranium Elements (ITU), Karlsruhe, mono-dispersed micrometer-sized uranium particles have been produced from reference material which will be another unique method to produce particles needed for this application [19]. With this in mind, particle-based CRMs are desired with specific impurities relevant to environmental safeguards, attribution and non-proliferation activities. Some of international standards which will serve as good starts: thorium oxides or metals, lead compound for isotope ratio and uranium fluoride compounds.

Destructive analyses

A movement in the actinide analytical chemistry to modern multi-elemental techniques with lower detection has again re-iterated the urgent need for international matrix matched standards of Pu, U, Np, etc. These highly precise and accurate measurements are often made on either thermal ionization mass spectrometers (TIMS) or multi-collector inductively coupled plasma mass spectrometers (ICP-MS). Smaller footprint multi-collector ICP atomic emission spectroscopy (AES) has also become the norm in analytical laboratories for trace elemental analyses. Similarly, the amount of U- or Pu-bearing material needed to accurately determine the elemental impurity concentrations has been reduced commensurate with lower detection limits afforded state-of-the-art techniques.

Isotopic standards

Very specific requests were generated in the area of U and Pu isotopic reference materials. For U, the presence of non-anthropogenic isotopes provides clear indications of activities of interest in nuclear safeguards accountancy measurements, environmental safeguards, attribution and non proliferation applications. Thus, the highest priority CRMs identified for U isotopic CRMs included:

-

(i)

Recertification of uncertainties on available U isotopic standards to at least 5–10 times better than international target values for the measurements.

-

(ii)

Reevaluation of current isotopic CRMs to certify the concentration of all isotopes (including 233U) with modern multi-collector or TIMS techniques.

-

(iii)

CRMs with high 235U, but low 236U (<1 ppm) isotopic abundance.

-

(iv)

CRMs free of 239Pu to monitor hydride formation in ICP-MS measurements.

For Pu, a number of CRMs were identified as adequate for measurement control across a wide range of burn-up values from both IRMM and NBL. However, it was requested that smaller quantities be packaged to allow for ease of use in International Atomic Energy Agency’s (IAEA’s) network of analytical laboratories (NWAL)-type environmental laboratory settings. In many cases, the Pu standards must be diluted to significantly low levels in separate laboratories to prevent cross contamination between the CRMs and the samples being analyzed. In addition, the lower concentrations would make it easier to ship materials between sites globally. The highest priority Pu isotopic CRMs included:

-

(i)

Recertification of existing Pu isotopic standard stocks using modern multi-collector or TIMS techniques with all isotopes (including 241Pu).

-

(ii)

100/10/2/2 ratio for 239/240/241/242Pu for multi-collector ICP-MS instrumentation.

-

(iii)

CRM of a mixed-oxide with high burn-up rate.

While multi-collector technology is a prevalent technique, many nuclear facilities rely heavily on alpha spectroscopy for the determination of various isotopes either in bulk or as trace impurities. CRMs listed above should also carry certification across both mass and activity and include minor isotopes and radioactive impurities which may require spectral corrections or cause interferences in alpha spectroscopy.

Elemental assay and IDMS

Elemental assay (g-U/g or g-Pu/g or g-Np/g) characterization is currently accomplished by either titration-based, coulometry, gravimetry, or mass spectrometry-based analytical techniques. The titration techniques include Davies and Gray redox titrimetry for U assay determination and coulometric (e.g., or ceric) titrimetry for Pu assay. These techniques require >100-mg samples but provide highest accuracy for nuclear safeguards accountancy measurements and superior ITV uncertainties [4].

The needs for standards were governed largely by material form (metal, oxide, carbide, etc.) and purity. The currently CRMs generated at NBL, IRMM, and Commission d’Établissement des Méthodes d’Analyse du CEA (CETMA) include metals and oxides (e.g., U3O8, UO2, and Pu02) with different level of purity. However, being able to obtain these CRMs is currently impacted by shipping and other issues. Additional CRMs identified that are needed to cover samples type typically encountered by nuclear safeguards community include:

-

(i)

Relatively pure uranium compounds: uranium trioxide (UO3), triuranium octaoxide (U3O8), uranium tetrafluoride (UF4) and uranium hexafluoride (UF6)

-

(ii)

U metal of low purity (<98 wt% U assay)

-

(iii)

Low-purity metal for assay (<98 wt% Pu assay pure)

-

(iv)

Medium purity (99.9 wt%) or low purity oxide standard

-

(v)

Neptunium oxide of (99.9 wt%) to low purity (<98 wt%)

The uncertainties associated with these standards should at least meet the ITV for nuclear safeguard measurements. International standards for metal scraps, fuel pellets, spent fuel, and mixed oxide (MOX) were considered lower priority as making CRM of these types can be an extremely challenging task. Separate standards for solutions of Pu and U in appropriate media were not considered to be a difficult task.

Recently, the quantities of U and Pu needed to perform titrimetric analyses, combined with the mixed wastes generated by the titration, may have pushed many laboratories to perform assay characterization by isotope dilution mass spectrometry (IDMS). These techniques typically provide higher uncertainties associated with the measurement but require smaller samples and the same sample will also provide isotopic composition. High quality IDMS measurements require high purity, well characterized 233U, 242Pu, 244Pu and 236gNp tracers to quantify U, Np and Pu as well as trace actinides that may be present in such materials. A significant list of highly-purified single-isotope spike materials was identified during the session.

In many cases, isotopic spikes are available from NIST as spectroscopy or counting activity based standards. However, uncertainties associated with half-lives (not the initial concentrations) is making the use of these CRMs for mass spectrometry (g/g) based measurements difficult since the half-life uncertainty contributes substantially to the overall uncertainty of the measurement. For example, as the original solution purchased in the past is used, the uncertainty associated with the 241Am half-life introduces a significant error when it is used to calculate the concentration of the spike solution. As expressed by many during this discussion, the uncertainty introduced into IDMS of fairly short-lived isotopes can range from 10 % to above 50 % of the uncertainty budget for the measurement. It was recommended that a re-certification reevaluation of isotopic half-lives should be undertaken using more precise and accurate instrumentation (Table 1). These tracers are also critical for radiochemical measurements of Pu, U, Am, Th, and Np.

Production of the standard’s is greatly hampered by lack of availability production capabilities for example a reactor followed by mass separators such as a Calutron to be able to produce critical quantities single isotope listed above. Currently there are a few measurement evaluation programs that try and meet the needs of safeguards community.

Bulk impurity nuclear material analyses

Very few CRMs exist for metallic, non-metallic, or radiochemical elemental analyses by DA methods. No CRMs currently exist for Pu, Am or Np in any chemical form (metal or oxide) certified for any level trace impurities. However, in the last several years, the lack of matrix matched CRMs for Pu has been fulfilled by performance evaluation studies sponsored by countries that include the U.S. and France. The following crucial safeguards analytical measurements require impurities international standards: material balance for accountability, correction for interferences for high accuracy elemental assay measurements, accurate material form analysis (e.g., oxygen to metal ratio), purity, and radiochronometry. The impurity measurements are also very important in minimizing the content of burnable poisons such as B and Cd in the production of nuclear fuels. The content of these poisons needs to be known accurately because they impact fuel characteristics. Careful determination of high-Z absorbers in the fuel is also important because of the undesirable analytical bias effects they have on NDA gamma-spectrometry measurements. The concentration ranges of the impurities should meet the dynamic range of instrumentation i.e., there should be at least three concentration ranges: low (1–100 ppm), medium (100–500 ppm) and high (500–1,000s ppm) range of elemental impurities present. The uncertainties associated with these standard’s will depend on the concentration range which may be as high as 1–30 % range for impurities present at ultra-trace levels, but for all concentration ranges mentioned above 1–5 % or better should easily be achievable by using modern ICP-AES, ICP-MS or combustion techniques applied to nuclear safeguards measurements.

Over recent years, significant effort has been placed on a complete cradle-to-grave accountancy of U-bearing materials—i.e., from ore-to-final product. The primary uranium oxide available for impurity analyses (NBL 124-series) was prepared well in the past by gravimetric methods—i.e., oxides of various trace metals were added to a highly-purified uranium oxide (U3O8). This mixture was then ground and blended repeatedly to provide a material that is homogenous on the 0.25–1 g scale, which was the typical subsample used for prior-art analytical techniques. However, many modern inductively-coupled plasma techniques only require 0.05–0.1 g subsamples for analysis, and sample heterogeneity can be problematic at this level. There are also sample dissolution issues associated with these standards. Many candidate CRMs were identified as having importance to safeguards nuclear accountancy attribution, and non proliferation measurement (in order of priority):

-

(i)

Uranium metal standards with critical trace metallic and non metallic impurities ranging in low, medium and high range.

-

(ii)

Matrix matched, higher homogeneity uranium oxide to replace NBL 124-series

-

(iii)

Plutonium metal standards with metallic and non metallic impurities at low, medium and high content range. Similarly, a low fired (650 °C) Pu oxides matching the impurity content in the above concentration range is also needed.

-

(iv)

Neptunium oxide certified for trace elements impurities for mid-range concentration.

-

(v)

Ore concentrate with measurable levels of lanthanide-period elements

-

(vi)

Oxide with complete set of volatile metal-fluoride elements

-

(vii)

Matrix matched standards for Pu and U with certified levels of halogens and H, C, N, O, and S for combustion analyses.

The trace metallic and non metallic impurity components should be reflective of the actual materials encountered in field applications. It is also critical that the impurities not be artificially spiked on the substrate metal but be added directly to the starting material i.e., by adding the trace impurity components to a molten metal during casting, properly homogenized while still a liquid and cooled at a controlled rate the distribution of impurity and grain structure can be controlled. The resulting metal can then be oxidized under controlled condition and will serve as ideal trace element standard with minimal solubility issues for metallic impurity determination and have matrix matching issues critical for techniques involving combustion analyses. Oxalate precipitation is another means to produce Np and Pu oxide standards. Low-fired oxides will generally be the preferred matrix for DA standards. Addition of certain impurities at high concentration e.g., volatile species, such as chloride or fluoride, will have to be limited in these standards. Also, maintaining long term stability of the standards during storage is a major challenge. Controlled large-scale (kilogram quantities) plant wet chemical methods and treatments could be used to produce uranium oxides and fluorides impurity CRMs. It is highly recommended that these international standards not be produced in small quantities using untested table top operations.

Consequence management

Introduction

Sound preparedness is important to mitigate adverse effects resulting from any emergency events. An accidental or intentional radiological or nuclear event could not only cause a catastrophic effect on public safety and health but also have a devastating effect on the Nation’s security and economy. During the initial response phase of the incident, samples taken by the first responders and local health officials will be used to determine the health and safety of the public and those responding to mitigate the incident. An estimated load for laboratory analysis is of the order of 100,000 clinical samples for the Center for Disease Control and Prevention (CDC) and 300,000 environmental samples for Environmental Protection Agency (EPA) resulting from a terrorist attack with a single radiological dispersal device (RDD) or dirty bomb as estimated from the National Planning Scenario #11. The Food and Drug Administration (FDA) laboratory analysis will be requested to test food supplies from adjacent fields as well as stored prior to distribution, and those distributed to the public. In the event of an IND, the damaging effect will be much more overwhelming. The catastrophic nature of human loss, environment contamination, and damages to infrastructure and the economy were estimated in the DHS planning scenario of a 10-kiloton IND event [20].

Efforts should be made for preparedness so that the adverse impacts from a radiological or nuclear event to properly determine the extent of the radiological hazard can be mitigated. The major responsibility of a laboratory in a radiological event is providing timely and high quality radioanalytical results to help in the determination of whether humans, the environment, and foods are contaminated for public health, recovery and cleanup activities, and economic consequence management decision making. One of the critical limiting factors in laboratories’ capabilities to handle surge capacity of samples is CRMs for rapid methods validation and ongoing quality assurance and quality control of sample analyses during response activities. The lack of specific CRMs could cause significant delays in laboratory analysis of samples and could negatively impact the accuracy of laboratory measurement and the data generated for consequence management activities. The consequence management group at the CRM Workshop undertook in-depth discussions to identify and prioritize the needs and main requirements of the CRMs for radiological and nuclear emergency preparedness.

Consequence management group discussion items

Representatives from the Centers for CDC, EPA, FDA, Department of Energy (DOE), Department of Defense (DOD) other U.S. and Canada government agencies, DOE national laboratories, and CRM providers participated in the Workshop to identify CRMs needed during a radiological emergency event. The Consequence Management Group focused on the CRM needs and issues for surge capacity laboratory sample analyses that would be required after a radiological or nuclear national incident. While there were overlaps in CRM needs among different agencies, the discussed items are listed in the order of the subject areas of Clinical, Environmental, and Foods. The priorities of needed CRMs for sample analyses, interlaboratory comparison programs for emergency readiness, action items and follow-up items for each subject area are presented. The following is a summary of the CRM needs by:

-

Categories of analyses (clinical, environmental, and food);

-

Matrices associated with each analysis category, with priority assigned relating to current evaluated needs;

-

Radioisotopes (based on type of plan incident emergency; RDD or IND);

-

Activity and heterogeneity; and

-

Proficiency or performance evaluation program samples to ensure ongoing quality assurance.

Clinical sample analysis needs for CRMs

CRM matrix

The group identified the following matrices for Clinical CRMs:

-

Real urine (Priority 1)

-

Phantoms (upper torso) (Priority 2)

-

Nasal Swabs (Priority 3)

The priority of CRM demand was assigned from 1 to 3; 1 represents the highest priority and 3 denote the lowest priority.

Radioisotopes

The needs for the following isotopes were identified:

Activity requirements

The activity of CRMs for clinical sample analysis was based upon the Annual Limit on Intake (ALI). For urine matrix, the CRM activity should be targeted between 0.5 and 10 ALI with 100 mL volume; for the matrix of phantoms, the CRM activity should be targeted at between 0.5 and 10 ALI for thyroid and lung; the CRM activity for nasal swabs should be targeted at between 0.5 and 10 ALI.

Heterogeneity requirements

The group agreed that the heterogeneity requirement for urine matrix CRM should be 1–2 % at 1 sigma per milliliter; 1–2 % at 1 sigma per sample for phantoms; and 1–2 % at 1 sigma per sample for nasal swab.

Preservative requirements

See Storage Temperature requirements, below.

Storage (temperature) and expiration date requirements

The temperature requirement for CRM storage for the urine matrix is −80 °C, no requirement for phantoms, and −80 °C to ambient temperature for nasal swabs. The expiration date requirement for all matrices is >5 years. Performance evaluation and intercomparison samples could be prepared from real unfrozen urine.

Number of units required for proficiency evaluation programs

One hundred units of CRMs for urine and nasal swab matrices were projected annually; five units of CRMs for phantoms were projected annually.

Isotope ratio requirements

The depleted/enriched U ratio for the matrices of interest is to be determined and will be a subject for the future discussions.

Environmental sample analysis needs for CRMs

CRM matrix

The matrices of interest for environmental sample analyses are identified as following: air filters, soil, drinking water, non-potable water, smears, vegetation, sediment, sludge, asphalt, concrete, wood, clay, steel, and glass. The priority of CRM demand among the matrices is given in Table 2, where 1 represents the highest priority and 3 denote the lowest priority.

Radioisotopes

The needs for the following isotopes were identified:

Activity requirements

The activity of CRMs for environmental sample analysis was based upon a Derived Response Level (DRL). The CRM activity should be targeted at 1.0 DRL for an air-filter matrix and 0.1–1.0 DRL for the other matrices.

Size, density, heterogeneity, and preservative requirements

These are all given in Table 2.

Storage (temperature) and expiration date requirements

There is no temperature requirement for CRM storage for the environmental matrices. The expiration date requirement for all matrices is >5 years.

Number of units required for proficiency evaluation programs

One hundred to two hundred and fifty units of CRMs for air filter, soil, drinking water, non-portable water, smears, vegetations, sediments, and sludge were projected annually. One hundred units of CRMs were projected annually for asphalt, concrete, wood, clay, steel, and glass.

Isotope ratio requirements

The depleted/enriched U ratio for the matrices of interest is to be determined and will be a subject for the future discussions.

Food sample analysis needs for CRMs

CRM matrix

The matrices of interest for environmental sample analyses are identified as following: FDA Market Basket Sample Matrices (FDA MBSM), meat, processed drinking water, vegetation, fruit, dairy, grain, liquids, food ashes, and swipes. The priority of CRM demand among the matrices is given in Table 3, where 1 represents the highest priority and 3 denote the lowest priority.

Radioisotopes

The needs for the following isotopes were identified:

Activity requirements

The activity of CRMs for environmental sample analysis was based upon FDA’s Derived Intervention Level (DIL). The CRM activity should be targeted at the DIL for radioisotopes with given a given DIL. For the isotopes without a given DIL, the guidelines from Operational Guidelines Task Group (OGT) should be referenced for the target levels.

Size, density, heterogeneity, and preservative requirements

These are all given in Table 3.

Storage (temperature) and expiration date requirements

The temperature requirement for CRM storage will be dependent on sample matrix, which is ranged from −20 °C to ambient temperature. The expiration date requirement for all matrices is at least 5 years.

Number of units required for proficiency evaluation programs

Seventy units of CRMs for food matrices were projected annually.

Isotope ratio requirements

The depleted/enriched U ratio for the matrices of interest is to be determined and will be a subject for the future discussions.

Consequence management future work

It was agreed that the group will reconvene in the future to clarify the group isotopes, review and update current CRM listing pertinent to agency needs; obtain cost estimates, identify funding sources/commonalities (bridging assets), and determine field screening versus fixed-lab criteria.

NIST workshop conclusion

As articulated in the three breakout groups, there is a critical shortage of a number of CRMs required for accurate and defensible radiological measurements for in the areas of nuclear safeguards, nuclear forensics, and consequence management, and a need to recertify several of the existing reference materials.

The workshop was very effective in identifying reference materials that are either non-existing or of critical shortage. The current lack of these reference materials sacrifices the pursuit of critical national issues. In greatest shortage are IDMS tracer standards and representative radioactive matrices. Isotope dilution mass spectrometry standards, specifically 233U, 236gNp, 244Pu, and 243Am are the most important tracers needed. Simulated nuclear debris, particle standards, and actinide and fission product doped environmental matrices are also in critical need.

The CRMs identified at this workshop represent a scarcity of fundamental metrology infrastructure that supports nuclear and radiological national strategies, priorities and programs. Developing the CRMs in a timely manner will require considerable effort and resources, and approaches that include interdisciplinary international, commercial and national partnerships.

Workshop follow-up activities

A concerted government effort is needed to provide an integrated priority list and to ensure adequate funding and resources are made available to the organizations capable of producing the CRMs The next step must be to aggressively secure the resources to expeditiously provide the measurement community with the metrology tools needed for high confidence results.

A follow-up workshop is being planned for February 2010 to address particle standards, in situ and field measurements, interagency collaborations that address cross purposes, and engage programmatic leadership to initiate the development of the identified high priority CRMs and reference materials. This work is ongoing with initial efforts focusing on a set of critical isotopes: 60Co, 90Sr, 137Cs, 192Ir, 241Am, and 239Pu.

Projects that National Metrology Institutes have already begun to plan include: weapons debris soil, 229Th mass tracer, high purity 233U and 243Am for mass spectrometry, U- and Pu-doped silica wafers for activation of fresh fission products, 192Ir and mixed gamma reference solution standards, and high neutron energy fission in fused urban material debris.

Highest CRM priorities

This does not imply that this list is complete nor other needs can be neglected.

Nuclear forensics

Multi site, aged nuclear explosion debris

This will be relatively straightforward to produce because the material exists and needs collection and processing. It will provide the quickest and most economic benefit for nuclear forensics, although the main shortcoming is the lack of short-lived fission products, which are important for consequence management.

Single site, aged nuclear explosion debris

Similar comments as for the multi site material apply. Additionally, this material will have a known history and source terms which enhance the relevance for nuclear forensics measurements. However, the measurement of such material will enable the device parameters to be deduced, so any work with such materials will be limited to suitably cleared laboratories.

Simulated fresh nuclear explosion debris

Highly relevant for nuclear forensics and consequence management. This material can be made in a controlled manner and thus the radionuclide content can be deduced (in part) from source data. Such a CRM will be subject to some research (currently in progress at NPL), but is achievable in the short term of 6–12 months.

Existing IDMS standards

It was noted that there is a wide range of material available, but may not be of suitable purity or activity levels. The priority issues here are better decay data—primarily half-lives—which is subject to ongoing work by national measurement institutes (NIST, NPL, LNHB, PTB, IRMM, etc.), but these needs must be communicated to the NMIs. Also see the DDEP website, http://www.nucleide.org/DDEP_WG/DDEPdata.htm, which may be the best data source and the NUDAT website, http://www.nndc.bnl.gov/nudat2/, for nuclides not in DDEP (both sites are updated on a regular basis). There are some suitable materials available from certain NMIs (NIST, NPL, IRMM).

Required IDMS standards

There are significant shortfalls in the supply of IDMS standards, with production route undefined as yet.

It was noted that a large quantity (100s of kg) of high purity 233U (>99.99 %) is held at ORNL, but will be subject to down blending in 2012. If down blending goes ahead without retrieving some of this material and its daughter radionuclides, then this will represent a major and irreplaceable loss material to the nuclear forensics, nuclear safeguards, medical and environmental radioactivity measurement fields. These comments may be applicable to other “legacy” material and it is recommended that an inventory evaluation of such materials is carried out to prevent similar losses.

In addition, infrastructure to identify and develop IDMS standards may be at a nascent stage in some areas; at present, the most critical radionuclides are 233U, 236gNp, 242Pu, 244Pu, and 243Am.

Nuclear safeguards

Materials and requirements detailed here may also have been details in sections “Nuclear safeguards” and “Nondestructive analyses” above. The CRM requirements follow the order of importance to nuclear safeguards measurements these include actinide elemental content followed by isotopics and trace elemental content. For various analytical techniques at a minimum the standards should be able to meet uncertainties recommended in the ITV documents.

Actinide materials for elemental content and trace analysis

Certified RMs covering commonly encountered sample types are pure uranium oxides and fluoride, Pu metal and oxides and neptunium oxide. These are supplemented by standard material types in civil and military nuclear fuel cycle and defense programs, such as U and Pu metals, oxides and other materials with varying levels of impurities (from low to high), with <100 ppm elemental impurities.

Uranium isotopic reference materials

Current isotopic standards require re-evaluation and certification at least 5–10 times better than current international target uncertainties and this to include all relevant isotopes in a particular standard. Furthermore, standards of high purity 235U, containing low (<1 ppm) or no 236U and 239Pu are needed to enhance measurement capabilities.

Plutonium isotopic reference materials

In addition to the comments above, the highest priority Pu isotopic RMs are for re-evaluation and certification at least 5–10 times better than current international target uncertainties and this to include all relevant isotopes in a particular standards and specific ratio 239/240/241/242Pu for both TIMS and multi-collector ICP-MS instrumentation.

Micrometer scale particles

Priority items here are particles with uniform sizes, structure, isotope ratios and elemental composition, subject to subsequent comments.

Other candidate RMs were with high importance to both safeguards and forensic analyses are replacement for NBL-124, ore concentrate, metal fluorides and metals with known light, non-metal content.

Consequence management

Priority 1 matrices

These were identified as (in alphabetical order):

-

Clinical matrices: Urine

-

Environmental matrices: Air Filters, Asphalt, Concrete, Drinking Water, Smears, Soil, Wood

-

Food matrices: Food Ash, Meat, Swipes

Priority 2 matrices

These were identified as (in alphabetical order):

-

Clinical matrices: Body Phantoms

-

Environmental matrices: Clay, Sediment, Steel, Vegetation

-

Food matrices: Dairy Products, Fruit, Grain, Liquids, Processed Drinking Water, Vegetation

Priority 3 matrices

These were identified as (in alphabetical order):

-

Clinical matrices: Nasal Swabs

-

Environmental matrices: Glass, Non-Potable Water, Sludge

-

Food matrices: FDA Market Basket Sample Matrices

Radionuclides

The same radionuclides were identified for all matrices:

Comments

The foregoing will require considerable technical, infrastructural and economic support. It is noted that the provider laboratories are ready and able to deliver these needs.

Abbreviations

- ALI:

-

Annual limit of intake

- ANSI:

-

American National Standards Institute

- ASTM:

-

American Society for Testing and Materials

- BIPM:

-

Bureau Internationale des Poids et Mesures

- CEA:

-

Commissariat à l’Énergie Atomique (France)

- CDC:

-

Center for Disease Control and Prevention

- CETMA:

-

Commission d’Établissement des Méthodes d’Analyse du CEA (France)

- CRM:

-

Certified reference material

- DA:

-

Destructive analysis

- DDEP:

-

Decay data evaluation project

- DIL:

-

Derived intervention level

- DOD:

-

Department of Defense

- DOE:

-

Department of Energy

- DOT:

-

Department of Transportation

- DRL:

-

Derived Response Level

- DTRA:

-

Defense Threat Reduction Agency

- EDS:

-

Energy-dispersive X-ray spectroscopy

- EPA:

-

Environmental Protection Agency

- ENSDF:

-

Evaluated Nuclear Structure Data File

- ESARDA:

-

European Safeguards Research and Development Association

- EC:

-

European Union

- FBI:

-

Federal Bureau of Investigation

- FDA:

-

Food and Drug Administration

- GUM:

-

Guide to Uncertainty in Measurement

- IAEA:

-

International Atomic Energy Agency

- ICP-AES:

-

Inductively coupled plasma atomic emission spectrometry

- ICP-MS:

-

Inductively coupled plasma mass spectrometry

- IDMS:

-

Isotope dilution mass spectrometry

- IEC:

-

International Electrotechnical Commission

- IND:

-

Improvised Nuclear Device

- IRMM:

-

Institute for Reference Materials and Measurement (EC Institution)

- ISO:

-

International Standards Organisation

- ITU:

-

Institute for Transuranium Elements (Germany)

- ITV:

-

International target value

- IUPAC:

-

International Union of Pure and Applied Chemistry

- IUPAP:

-

International Union of Pure and Applied Physics

- LANL:

-

Los Alamos National Laboratory

- LNHB:

-

Laboratoire National du Henri Becquerel (French NMI for Radionuclide Metrology)

- MBSM:

-

Market basket sample matrices

- MIT:

-

Massachusetts Institute of Technology

- MOX:

-

Mixed oxide

- NAREL:

-

National Air and Radiation Environmental Laboratory

- NBL:

-

New Brunswick Laboratory

- NCEH:

-

National Center for Environmental Health (CDC)

- NDA:

-

Non-destructive analysis

- ng:

-

Nanogram

- NIST:

-

National Institute for Standards and Technology

- NMI:

-

National measurement institute (national standards laboratory, e.g., NIST, NPL, PTB, LNHB, etc.)

- NNSA:

-

National Nuclear Security Agency

- NPL:

-

National Physical Laboratory (UK NMI)

- NTS:

-

Nevada Test Site

- NUDAT:

-

ENSDF nuclear data website

- NWAL:

-

Network of Analytical Laboratories

- OGT:

-

Operational Guidelines Task Group

- OIML:

-

Organisation Internationale de Métrologie Légale

- ORNL:

-

Oak Ridge National Laboratory

- ppm:

-

Part per million (i.e., 1 part in 1 × 106)

- PT:

-

Proficiency test

- PTB:

-

Physikalisch-Technische Bundesanstalt (German NMI)

- QA:

-

Quality assurance

- QC:

-

Quality control

- RDD:

-

Radiological Dispersal Device (dirty bomb)

- RM:

-

Reference material

- SEM:

-

Scanning electron microscopy

- SIMS:

-

Secondary ion mass spectrometry

- SNM:

-

Special nuclear material

- TIMS:

-

Thermal ionization mass spectrometry

- TMDE:

-

Test, measurement, and diagnostic equipment

- USANCA:

-

United States Army Nuclear and Combating Weapons of Mass Destruction Agency

- WDS:

-

Wavelength dispersive X-ray spectroscopy

- WEAC:

-

Winchester Analytical and Engineering Center (FDA)

- Z:

-

Atomic number

References

Post-incident [Improvised Nuclear Device (IND)] nuclear forensics

Daubert v. Merrell Dow Pharmaceuticals, Inc. (1993) 509 US 579, 589

Leggitt J, Inn KGW, Goldberg S, Essex R, LaMont S, Chase S (2009) J Radioanal Nucl Chem. doi:10.1007/s10967-009-0293-2

Inn KGW, Kurosaki H, Frechou C, Gilligan C, Jones R, LaMont S, Leggitt J, Li C, McCroan K, Swatski R (2008) Appl Radiat Isot 66:835–840

Safeguards materials characterization

Aigner H, Binner R, Kuhn E, Blohm-Hieber U, Mayer K, Guardini S, Pietri C, Rappinger B, Mitterrand B, Reed J, Mafra-Guidicini O, Deron S (2002) International target values 2000 for measurement uncertainties in safeguarding nuclear materials. ESARDA Bull 31:39–68

Thompson M, Ellison SLR, Wood R (2006) Pure Appl Chem (IUPAC, technical report) 78:145–196

Wellum R, Berglund M (2002) The application of the ‘guide to the expression of uncertainties in measurements’ in safeguards. ESARDA Bull 31:11–17

BIPM, IEC, ISO, IUPAC, IUPAP, OIML (1995) Guide to the expression of uncertainty in measurement. Corrected and reprinted first edition. ISO, Geneva

ASTM C1030-03 Standard Test Method for Determination of Pu Isotopic Composition by γ-Ray Spectrometry

ASTM, C1133-03 Standard Test Method for Nondestructive Assay of Special Nuclear Material in Low Density Scrap and Waste by Segmented Passive γ-Ray Scanning

ASTM, C1207-03 Standard Test Method for Nondestructive Assay of Plutonium in Scrap and Waste by Passive Neutron Coincidence Counting

ASTM, C1221-92(2004) Standard Test Method for Nondestructive Analysis of Special Nuclear Materials in Homogeneous Solutions by γ-Ray Spectrometry

ASTM, C1316-08 Standard Test Method for Nondestructive Assay of Nuclear Material in Scrap and Waste by Passive-Active Neutron Counting Using 252Cf Shuffler

ASTM, C1455-07 Standard Test Method for Nondestructive Assay of Special Nuclear Material Holdup Using γ-Ray Spectroscopic Methods

ASTM, C1458-09e1 Standard Test Method for Nondestructive Assay of Plutonium, Tritium and 241Am by Calorimetric Assay

ASTM, C1493-09 Standard Test Method for Non-Destructive Assay of Nuclear Material in Waste by Passive and Active Neutron Counting Using a Differential Die-Away System

ASTM, C1500-08 Standard Test Method for Nondestructive Assay of Plutonium by Passive Neutron Multiplicity Counting

ASTM, C1514-08 Standard Test Method for Measurement of 235U Fraction Using Enrichment Meter Principle

ASTM, C1592/C1592M-09 Standard Guide for Making Quality Nondestructive Assay Measurements

Erdmann N, Betti M, Stetzer O, Tamborini G et al (2002) Spectrochimica Acta Part B At Spectrosc 55:1565–1575

Consequence management

Homeland Security Planning Scenarios (2012) Scenario 1: nuclear detonation—10-Kiloton Improvised Nuclear Device, http://www.globalsecurity.org/security/ops/hsc-scen-1.htm. Accessed 24 June 2012

Acknowledgments

The authors thank all workshop attendees (“Appendix 2”) for insightful perspective, guidance, and comments.

Author information

Authors and Affiliations

Corresponding author

Appendices

Appendix 1: Option for nuclear debris reference material

A series of low yield weapons-effects experiments were carried out at the Nevada Test Site (NTS) in the early 1960s. These events involved shallow burial or surface bursts that generated discreet local debris fields that have not been subsequently modified or altered over the course of the following nearly 50 years of active NTS operations. These sites represent an historical archive that replicates many aspects of a nuclear terrorist attack or IND event.

Samples collected from these sites represent authentic nuclear debris that could be used as reference materials to exercise and to validate the federal technical response planned in the event of a nuclear emergency. Focused narrowly on the analytical problem, these include:

-

Sample collection and field measurements,

-

Sample logistics and transport, and

-

Laboratory analysis.

Judged as a potential reference material, these samples were originally subjected to the vaporization, melting, and condensation processes that are unique to a nuclear event. The samples contain an accurate composition of nuclear material, fission products, and environmental matrix that were intimately mixed in the fireball and then condensed to glassy debris (Fig. 1). Because of the historic nature of these samples, the short-lived fission products and nuclear activation products have long since decayed beyond detection. The samples do contain the long-lived actinides and long-lived fission products. Of the limited non-destructive assay that has been carried out to date, the samples contain a nominal 10 ppm Pu and on the order of 1014–1015 fissions/g. It should be noted that this relative composition of nuclear material to environmental matrix and fission product to environmental matrix are entirely characteristic of nuclear debris.

Depending on the needs of the analytical and radiochemistry communities, samples could be collected at these sites and prepared as reference materials after grinding and homogenizing the glassy debris. Suitable subsamples could be analyzed by all participating laboratories to generate certified values for Pu and U isotopes, 237gNp, 241Am, and selected long-lived fission products. Classification issues could be addressed by blending multiple events into a CRM.

Appendix 2: Workshop participants

Mohamad | Al-Sheikhly | University of Maryland |

Steve | Barrett | Savillex Corporation |

Joseph | Beckman | USANCA |

Balazs | Bene | University of Maryland/NIST Radioactivity Group |

David | Beutler | Sandia National Laboratories |

Anitta | Bhatt | DOE Idaho |

Debra | Bostick | Oak Ridge National Laboratory |

Stanhope | Crooks | AWE PLC |

Richard | Essex | New Brunswick Laboratory |

Joe | Giaquinto | Oak Ridge National Laboratory |

Stephen | Howard | U.S. Army TMDE Activity |

Kenneth | Inn | NIST |

Mansie | Iyer | DOE |

Simon | Jerome | NIST |

Sonia | Johnson | Health Canada |

Robert | Jones | CDC |

Thomas | Kiess | U.S. Department of Energy/NNSA |

Jerome | La Rosa | NIST |

Ken | Laintz | Los Alamos National Laboratory |

Stephen | Lamont | Los Alamos National Laboratory |

Jeffrey | Leggitt | Federal Bureau of Investigation |

Randolph | Long | Department of Homeland Security |

Pamela | Mackill | U.S. Food and Drug Administration |

Daniel | Mackney | EPA |

Dale | Newbury | NIST |

Katherine | Nielsen | Department of National Defense |

Svetlana | Nour | NIST |

Warren | Oldham | Los Alamos National Laboratory |

John | Ondov | University of Maryland |

Brett | Palmer | DOE/NNSA |

Donivan | Porterfield | Los Alamos National Laboratory |

William | Pramenko | Joint Chiefs of Staff |

Erick | Ramon | Lawrence Livermore National Library |

Lee | Riciputi | Los Alamos National Laboratory |

Gregory | Schaeff | B&W Y12 |

John | Small | NIST |

Donna | Smith | NA-22 (LANL Detailee) |

Nadereh | St-Amant | Health Canada, Radiation Protection Bureau |

Tyler | St. Onge | Science Applications International |

Lav | Tandon | Los Alamos National Laboratory |

Daniel | Velazquez | Defense Threat Reduction Agency |

Michael | Walsh | DTRA (L-3COM) |

Carolyn | Wong | Lawrence Livermove National Laboratory |

Ian | Watson | Dept of Nat’l Defence (DRDC) |

Cong | Wei | U.S. Food And Drug Administration |

Cynthia | Zeissler | NIST |

Rights and permissions

About this article

Cite this article

Inn, K.G.W., Johnson, C.M., Oldham, W. et al. The urgent requirement for new radioanalytical certified reference materials for nuclear safeguards, forensics, and consequence management. J Radioanal Nucl Chem 296, 5–22 (2013). https://doi.org/10.1007/s10967-012-1972-y

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10967-012-1972-y