Abstract

Effect of vacuum annealing and heating–cooling cycle annealing on the soft magnetic properties at room- and high-temperatures for (Fe0.9Co0.1)72.7Al0.8Si13.5B9Cu1Nb3 alloy was investigated by the temperature dependence of initial permeability (μi-T curves). The crystallization behavior and microstructural evolution of alloy with the increase of annealing temperature were studied by means of differential scanning calorimeter (DSC) and X-ray diffraction (XRD). After vacuum annealing at 617 °C for 0.5 h, the µi can reach 30,300 and maintain more than 1000 until 640 °C because of larger crystalline volume fraction (Vcry) of 81.9% and smaller intergranular amorphous layer (\(\Lambda\)) of 0.930 nm, which is more excellent than that of other Fe–Co–Al–Si–B–Cu–Nb alloys annealed at their optimum temperatures. In addition, the crystallized interval temperature (∆Tx) of 158 °C, superior to Fe73.5Si13.5B9Nb3Cu1 and (Fe0.9Co0.1)73.5Si13.5B9Nb3Cu1 alloys ever reported, is conducive to precipitating the bcc α-(Fe,Co,Si) and Fe3(Si,Co,Al) soft magnetic crystalline phases and improving thermostability of alloy.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Magnetism, one of the most basic physical properties, is ubiquitous among various substances. As indispensable functional materials in various fields, a variety of magnetic materials not only meet the development requirements of traditional industries, but also play an increasingly important role in high-tech fields such as power, electronics and communications. The soft magnetic material is one of the most typical magnetic materials, having excellent comprehensive soft magnetic properties including high saturation magnetization (Ms), high permeability (µi), low coercivity (Hc) and low loss (W) etc. [1], which meets the needs of the era of green, energy saving, environmental protection and high efficiency. What's more, typical Fe-based alloys are widely used in communication, computer and other high-tech fields as a result of the high initial permeability at room temperature. However, relatively low Curie temperature of amorphous phase (Tcam) and crystallized interval temperature (ΔTx) limited the application of the alloys at high temperature [2, 3]. Some studies found that the adulteration of moderate Co increased both the ΔTx and the Tcam, which was beneficial to form the single soft magnetic phase and improve the thermostability of the alloys [4,5,6]. And adding moderate Al to FeCo-based alloy obtained larger ΔTx above 210 °C [7, 8] and higher Tcam than that of typical Fe73.5Si13.5B9Cu1Nb3 alloys [3]. Therefore, the nanocrystalline (Fe0.9Co0.1)72.7Al0.8Si13.5B9Cu1Nb3 alloy after vacuum annealing and heating–cooling cycle annealing was studied in this paper.

We mainly analyzed the changes of µi-T curves by XRD patterns, Herzer's Model and magnetic coupling, and further explored the relationship between microstructure and soft magnetic properties in order to find optimal magnetic softness at room and high temperatures.

2 Experimental procedures

First, the smelted spindle was made into a series of amorphous ribbons with the width of 2 mm and thickness of 20 µm by the single-roller melt-spinning technique, some of which were winded into toroidal cores with the outer diameter of 18 mm and inner diameter of 16 mm for cycle annealing and vacuum annealing, some of which were cut up for the thermal analysis of differential scanning calorimeter (DSC) using NETZSCH STA 409 PC/PG from room temperature to 1000 °C at a heating rate of 10 K/min. Next, the µi-T curves of samples after different thermal treatment were measured in a furnace with Ar atmosphere protection in order to observe the temperature dependence of initial permeability by an HP4294A impedance analyzer at H = 0.4A/m and f = 10 kHz. Finally, the characterization of microstructure was obtained by X-ray diffraction (XRD) using D/max-2500/PC with Cu-Kα radiation (λ = 1.54056 Å) to analyze the relations between the microstructure and soft magnetic properties of the alloys after vacuum annealing at 500–660 °C for 0.5 h (Fig. 1).

3 Results and discussion

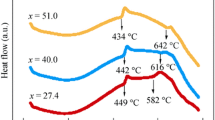

The DSC curves of as-quenched (Fe0.9Co0.1)72.7Al0.8Si13.5B9Cu1Nb3 alloys show two separated exothermic peaks related to the enthalpy change and exothermic phase transformations [9, 10], the endothermic peak is corresponding to the melting of ribbons over the temperature range from 480 to 510 °C [11]. The onset primary crystallization temperature Tx1 corresponds to the formation of crystalline α-Fe(Co,Si) and Fe3(Si,Co,Al) phase shown in Fig. 2b, while the onset temperature of second crystallization Tx2 relates to final crystallization of boride Fe2B [12], the temperature interval ∆Tx (∆Tx = Tx2−Tx1) of 158 °C is superior to that of Fe73.5Si13.5B9Nb3Cu1 [2] and (Fe0.9Co0.1)73.5Si13.5B9Nb3Cu1 alloys [13], which is beneficial to obtain the single crystalline phase. It is well known that the size of particle relates to annealing temperature [14], higher annealing temperature leads to larger average grain size and crystalline volume fraction [15,16,17,18], which is substantiated in Table 1.

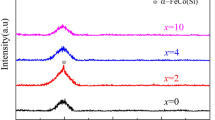

Figure 2 shows the XRD patterns of as-quenched and annealed (Fe0.9Co0.1)72.7Al0.8Si13.5B9Cu1Nb3 alloy. It can be seen that the diffraction peak of as-quenched alloy is one broad scattering peak at around 2θ = 45°, indicating that the as-quenched sample is complete amorphous state [19]. After vacuum annealing at 500–617 °C, the samples show the characteristic (110), (200) and (211) diffraction peaks of bcc α-(Fe,Co,Si) crystalline phase and the characteristic (111), (200), (220), (400) and (422) diffraction peaks of Fe3(Si,Co,Al) crystalline phase, which suggests that the annealed samples are partially crystallized and form the desired two-phase nanocrystalline structure related to the crystallization phase and remaining amorphous phase.

The volume fraction of crystallization phase Vcry can be estimated by XRD spectra as follows [20]:

where Icry and Iam denote the integral intensities of diffraction peaks of crystalline phase and amorphous phase respectively. K is a constant determined by experiment. With the increase of annealing temperature (Ta), the Vcry gradually increases from 77.3% for Ta=500 °C to 81.9% for Ta = 617 °C shown in Table 1. According to the full width at half maximum (FWHM) of the (110) and (220) diffraction peaks, the theoretical Scherrer formula [21,22,23,24,25] is used to calculate the average grain size (D):

where ‘K’, ‘λ’, ‘β’ and ‘θ’ are the Scherrer constant (K is nealy 1) [18, 26], wavelength of Cu-Kα radiation (λ = 1.54056 Å), the full width at half-maximum height (FWHM) and the Bragg diffraction angle, respectively. The results showed that the D gradually increases from 11.5 to 13.5 nm with the increase of Ta shown in Table 1. According to the Vcry and D, the thickness of amorphous layer (Λ) is calculated as follows [27]:

The calculation results show that the Λ decreases from 1.032 nm for Ta = 500 °C to 0.930 nm for Ta = 617 °C, the higher Vcry and the thinner Λ can ensure the penetrating effect of strong exchange coupling between grains [13, 15, 17] and improve the soft magnetic properties of the alloy according to Hernando's model [27].

Therefore, The 617 °C-annealed (Fe0.9Co0.1)72.7Al0.8Si13.5B9Cu1Nb3 alloy with larger Vcry of 81.9% and thiner Λ of 0.930 nm exhibits superior soft magnetic properties, which is verified in Fig. 3b.

Figure 3a shows the µi-T curve of as-quenched (Fe0.9Co0.1)72.7Al0.8Si13.5B9Cu1Nb3 alloy. Amorphous structure with a sharp Hopkinson peak was observed near the Curie temperature of the amorphous phase Tcam due to the faster decrease of magnetic anisotropy than that of the saturation magnetization when the temperature approaches Tcam [28]. The μi abruptly drops to zero just above Tcam due to ferro-paramagnetic transition of the amorphous alloy [13]. The µi rapidly rises from 0 to 2000 above 500 °C because of the precipitation of bcc α-(Fe,Co,Si) and Fe3(Si,Co,Al) crystalline phases and it fleetly declines to zero at about 650 °C due to the precipitation of Fe2B hard magnetic phase, which is consistent with the results of DSC curve.

The µi at room temperature increases greatly with the increase of the annealing temperature from 8400 for Ta = 500 °C to 30,300 for Ta = 617 °C. When Ta is 500 °C and 540 °C, the µi tends to decrease rapidly around Tcam, which can be interpreted by Herzer's model [29]:

where φ, Acr, Aam, K1, Vam, < K > , pμ, μ0 and Js represent the spin rotation angle over the exchange–correlation length, exchange stiffness of crystalline phases, exchange stiffness of amorphous phases, magnetocrystalline anisotropy, amorphous volume fraction, effective magnetic anisotropy, a dimensionless prefactor, vacuum magnetic permeability and average saturation magnetic polarization respectively. In the dual-phase nanostructure, Aam drops to a much smaller value than Acr when the temperature approaches to the Tcam [30], which makes < K > increase and μi decrease rapidly. While the increasing rate of < K > is much slower at higher Vcry, showing the smoother decreasing rate of μi at higher Ta [31] such as annealing at 580 °C and 617 °C.

With further increasing annealing temperature from 625 to 660 °C, the initial permeability at room temperature decreases significantly from 3500 down to nearly zero due to the successive precipitating Fe2B hard magnetic phase from amorphous matrix and the higher magnetocrystalline anisotropy of Fe-borides at room temperature [16]. But the µi of 625 °C-annealed sample gradually increases to 19,300 around 150 °C, and then decreases significantly with temperature further increasing. The µi peak may correspond to the minimum value of magnetocrystalline anisotropy for Fe2B hard magnetic phase [16].

In conclusion, although 625 °C-annealed sample has a small amount of hard magnetic phase, there are few effects on the high-temperature magnetic softness shown in partially enlarged inset of Fig. 3. The reason should be attributed to stronger magnetic coupling between grains for nanocrystalline alloys at higher Ta. What is more, the (Fe0.9Co0.1)72.7Al0.8Si13.5B9Cu1Nb3 alloy has the highest µi of 30,300 and higher µi above 1000 until to 640 °C after optimal vacuum annealing at 617 °C, which is superior to other Fe–Co–Al–Si–B–Cu–Nb alloys in Table 2.

Table 2 shows the initial permeability of different Fe–Co–Al–Si–B–Cu–Nb alloys at 25 °C, 500 °C, 550 °C and 600 °C named as µi25, µi500, µi550 and µi600 to compare their magnetic softness at room- and high-temperatures. The results point out that the room-temperature initial permeability of (Fe0.9Co0.1)72.7Al0.8Si13.5B9Cu1Nb3 alloy is distinctly higher than that of other alloys, and the high-temperature initial permeability at 500–600 °C is clearly superior to others except (Fe0.5Co0.5)72.7Al0.8Si17.5B5Cu1Nb3 alloy at 600 °C. In summary, the (Fe0.9Co0.1)72.7Al0.8Si13.5B9Cu1Nb3 alloy after vacuum annealing at 617 °C has more excellent magnetic softness at room and high temperatures than other Fe–Co–Al–Si–B–Cu–Nb alloys annealed at their optimal temperatures and conditions.

The µi-T curves of (Fe0.9Co0.1)72.7Al0.8Si13.5B9Cu1Nb3 alloy during continuous heating–cooling cycle annealing at 500–660 °C are showed in Fig. 4. The shape of µi-T curves is related to phase structure of the alloys. A sharp Hopkinson peak appears at Tcam for as-quenched alloy shown in enlarged inset of Fig. 4a. The cooling curve of 580 °C and vacuum annealing at same temperature have the same trend, the Hopkinson peak disappears and a higher μi is observed due to the formation of two-phase nanocrystalline structure [33]. In the fifth cycle, the alloy exhibited improved high-temperature magnetic softness during heating curve, the higher µi above 1000 can keep up to 600 °C as a result of stronger magnetic coupling, and a sharp Hopkinson peak appears near 640 °C relating to the Curie temperature of crystalline phase. However, the µi is very low nearly zero shown in cooling curve of 660 °C as a result of precipitating the hard magnetic phase.

4 Conclusion

Effect of vacuum annealing and heating–cooling cycle annealing on microstructure and soft magnetic properties of nanocrystalline (Fe0.9Co0.1)72.7Al0.8Si13.5B9Cu1Nb3 alloy was investigated. With the increase of vacuum annealing temperature from 500 to 617 °C, the Vcry gradually increases from 77.3 to 81.9% and the Λ decreases from 1.032 to 0.930 nm, which is conducive to enhancing the exchange coupling between magnetic particles and improving the soft magnetic properties. So 617 °C-annealed sample shows more excellent magnetic softness at room- and high-temperatures than that of other Fe–Co–Al–Si–B–Cu–Nb alloys ever reported. Furthermore, the variational trends of µi-T curves after cyclic annealing also exhibited that the excellent high-temperature magnetic softness was obtained by annealing around 620 °C.

References

M.E. McHenry, M.A. Willard, D.E. Laughlin, Amorphous and nanocrystalline materials for applications as soft magnets. Prog. Mater. Sci. 44, 291–433 (1999)

T.H. Noh, M.B. Lee, H.J. Kim, I.K. Kang, Relationship between crystallization process and magnetic properties of Fe-(Cu-Nb)-Si-B amorphous alloys. J. Appl. Phys. 67, 5568 (1990)

Y. Jia, Z. Wang, F. Wang, L. Zhang, H. Duan, Effect of Ti on structure and soft magnetic properties of Si-rich Finemet-type nanocrystalline Fe73.5Cu1Nb3-xSi17.5B5Tix alloys. Mater. Res. Bull. 106, 296–300 (2018)

L.-X. Wen, Z. Wang, J. Wang, H. Zhang, High temperature magnetic permeability of Si-rich Finemet-type nanocrystalline (Fe1-xCox)74.5Nb2Si17.5B5Cu1 alloys. J. Magn. Magn. Mater. 379, 265–269 (2015)

L. Xue, W. Yang, H. Liu, H. Men, A. Wang, C. Chang, B. Shen, Effect of Co addition on the magnetic properties and microstructure of FeNbBCu nanocrystalline alloys. J. Magn. Magn. Mater. 419, 198–201 (2016)

Y.-M. Han, Z. Wang, X.-H. Che, X.-G. Chen, W.-R. Li, Y.-L. Li, Influence of Co content on the structure and magnetic permeability of nanocrystalline (Fe1-xCox)73.5Cu1Nb3Si13.5B9 alloys. Mater. Sci. Eng. B 156, 57–61 (2009)

Y. Han, Z. Wang, Y.-C. Xu, Z.-Y. Xie, L.-J. Li, Influence of Al addition on structure and magnetic properties of nanocrystalline Fe65Co15Si5Nb3Cu1B11-xAlx alloys. J. Non-Cryst. Solids 442, 29–33 (2016)

X.-H. Li, Z. Wang, H.-J. Duan, The effect of the minor Al addition on microstructure and soft magnetic properties for (Fe0.5Co0.5)73.5Si13.5Nb3Cu1B9 nanocrystalline alloy. J. Non-Cryst. Solids 517, 114–118 (2019)

M. Yan, H. Tong, S. Tao, J. Liu, Structural and magnetic properties of Fe73.5Cu1Nb3-xTixSi13.5B9 (x ≤ 3) alloys. J. Alloys Compd. 505, 264–267 (2010)

D. Dastan, Effect of preparation methods on the properties of titania nanoparticles: solvothermal versus sol–gel. Appl. Phys. A 123, 699 (2017)

Q. Zhu, Z. Chen, S. Zhang, Q. Li, Y. Jiang, P. Wu, K. Zhang, Crystallization progress and soft magnetic properties of FeGaBNbCu alloys. J. Magn. Magn. Mater. 475, 88–92 (2019)

R. Brzozowski, M. Wasiak, H. Piekarski, P. Sovak, P. Uznanski, M.E. Moneta, Properties of Mn-doped FINEMET. J. Alloys Compd. 470, 5–11 (2009)

L. Zhang, Z. Wang, Y.-R. Jia, Microstructure and soft magnetic properties of (Fe0.9Co0.1)73.5Si13.5B9-xNb3Cu1Gex nanocrystalline alloys. Mater. Sci. Eng. B 231, 1–4 (2018)

D. Dastan, N. Chaure, M. Kartha, Surfactants assisted solvothermal derived titania nanoparticles: synthesis and simulation. J. Mater. Sci.: Mater. Electron. 28, 7784–7796 (2017)

X. Ma, Z. Wang, X. Han, X. Yin, B. Wang, Microstructure and high-temperature soft magnetic properties of nanocrystalline (Fe0.65Co0.35)78.4Si9B9Nb2.6Cu1 alloy. Mater. Sci. Eng. A 448, 216–220 (2007)

Z. Wang, K.Y. He, J. Jin, J. He, L. Zhang, H.W. Zhang, B.G. Shen, Temperature dependence of permeability for Fe–Cu–M–Si–B alloys. J. Mater. Sci. Eng. A 304–306, 1046 (2001)

Y. Han, Z. Wang, Excellent high-temperature magnetic softness in a wide temperature for FeCo-based nanocrystalline alloy. J. Non-Cryst. Solids 434, 92–95 (2016)

Z.-Y. Xie, Z. Wang, Y. Han, F.-F. Han, Influence of Ge on crystallization kinetics, microstructure and high-temperature magnetic properties of Si-rich nanocrystalline FeAlSiBCuNbGe alloy. J. Non-Cryst. Solids 463, 1–5 (2017)

H. Duan, Z. Wang, Z. Xie, Y. Jia, Superior high-temperature magnetic softness for Co and Ge doped nanocrystalline Fe72.7Al0.8Si17.5B5Cu1Nb3 alloys. J. Magn. Magn. Mater. 460, 495–500 (2018)

X.Y. Zhang, F.X. Zhang, J.W. Zhang, W. Yu, M. Zhang, J.H. Zhao, R.P. Liu, Y.F. Xu, W.K. Wang, Influence of pressures on the crystallization process of an amorphous alloy. J. Appl. Phys. 84, 1918 (1998)

D. Dastan, P.U. Londhe, N.B. Chaure, Characterization of TiO2 nanoparticles prepared using different surfactants by sol–gel method. J. Mater. Sci.: Mater. Electron. 25, 3473–3479 (2014)

W.-D. Zhou, D. Dastan, J. Li, X.-T. Yin, Q. Wang, Discriminable sensing response behavior to homogeneous gases based on n-ZnO/p-NiO composites. Nanomaterials 10, 785 (2020)

A. Jafari, K. Tahani, D. Dastan, S. Asgary, Z. Shi, X.-T. Yin, W.-D. Zhou, H. Garmestani, Ş Ţălu, Ion implantation of copper oxide thin films; statistical and experimental results. Surf. Interfaces 18, 100463 (2020)

A. Jafari, M.H. Alam, D. Dastan, S. Ziakhodadadian, Z. Shi, H. Garmestani, A.S. Weidenbach, Ş Ţălu, Statistical, morphological, and corrosion behavior of PECVD derived cobalt oxide thin flms. J. Mater. Sci.: Mater. Electron. 30, 21185–21198 (2019)

X.T. Yin, W.D. Zhou, J. Li, P. Lv, Q. Wang, D. Wang, F.Y. Wu, D. Dastan, H. Garmestani, Z. Shi, Ş Ţălu, Tin dioxide nanoparticles with high sensitivity and selectivity for gas sensors at sub-ppm level of hydrogen gas detection. J. Mater. Sci.: Mater. Electron. 30, 14687–14694 (2019)

V. Uvarov, I. Popov, Metrological characterization of X-ray diffraction methods for determination of crystallite size in nano-scale materials. Mater. Charact. 58, 883–891 (2007)

A. Hernando, I. Navarro, P. Gorria, Iron exchange-field penetration into the amorphous interphase of nanocrystalline materials. Phys. Rev. B 51, 3281 (1995)

Y.Y. Jia, Z. Wang, J. Wang, R.M. Shi, Structure and magnetic properties of Ni5(Fe0.5Co0.5)68.5Si13.5Nb3B9Cu alloy. J. Magn. Magn. Mater. 324, 3981–3985 (2012)

G. Herzer, Grain size dependence of coercivity and permeability in nanocrystalline ferromagnets. IEEE Trans. Magn. 26, 1397–1402 (2002)

Y.R. Jia, Z. Wang, F. Wang, Y. Han, Z.Y. Xie, L.J. Li, L. Zhang, Effect of P substitution for Nb on structure and soft magnetic properties of Si-rich FeCuNbSiB nanocrystalline alloys. Mater. Sci. Eng. B 222, 55–59 (2017)

Y. Han, Z. Wang, L.X. Wen, Y.C. Xu, Excellent magnetic softness at room and high temperatures for Si-rich Fe-based nanocrystalline alloy with a small amount of Al. IEEE Trans. Magn. 51, 2003704 (2015)

X.H. Li, Z. Wang, H.J. Duan, Effect of the partial substitution of FeCo by Ge on the magnetic properties of nanocrystalline (Fe0.8Co0.2)72.7Al0.8Si17.5Nb3Cu1B5 alloy. J. Non-Cryst. Solids 522, 119555 (2019)

L. Li, Z. Wang, Y. Han, Effect of Mo addition on high-temperature soft magnetic properties for air annealed FeCo-based nanocrystalline alloys. Mater. Lett. 185, 235–238 (2016)

Acknowledgements

This work was supported by the National Natural Science Foundation of China (under Grant No. 51271130).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Hao, Qq., Wang, Z., Zhang, Y. et al. Effect of vacuum annealing and heating–cooling cycle annealing on the soft magnetic properties at room- and high-temperatures for nanocrystalline FeCoAlSiBCuNb alloy. J Mater Sci: Mater Electron 31, 21813–21819 (2020). https://doi.org/10.1007/s10854-020-04693-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-020-04693-w